Automatic hydraulic drilling machine for coal mine

A hydraulic drilling rig and automatic drilling technology, which is applied to rotary drilling rigs, drilling automatic control systems, drill pipes, etc., can solve the problems of no way to guarantee the personal safety of workers, high labor intensity and low operating efficiency of Caocheng workers, and achieve Improvement of operation productivity, improvement of operation efficiency, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

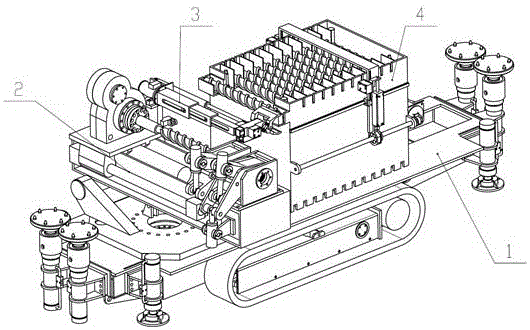

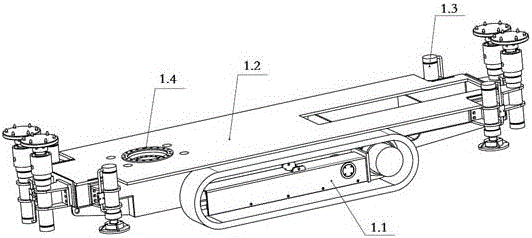

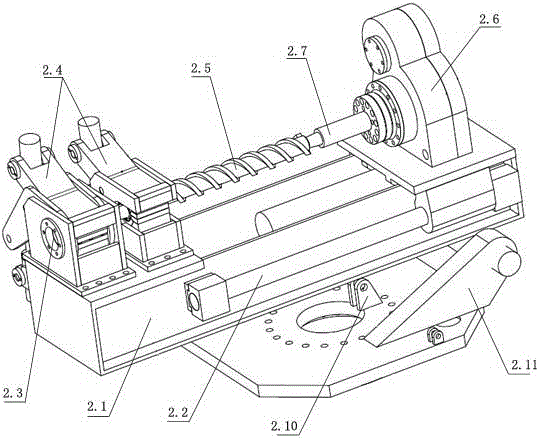

[0021] As shown in the figure, an automatic hydraulic drilling rig for coal mines according to the present invention includes a drilling actuator 2, a manipulator 3, an automatic drill rod box 4, and a crawler walking device 1 for supporting and moving the above three parts, wherein, The manipulator 3 is controlled by the PLC programmable control system to extract the drill pipe from the automatic drill pipe box 4 and place it on the drilling execution device 2, and the drilling operation is completed by the drilling execution device 2. The drilling execution device 2 includes The frame body 2.1 and the slide rails 2.2 arranged on both sides of the frame body 2.1 are provided with two drill pipe fixing parts 2.4 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com