Application method of bending machine die capable of machining multi-radian circular face

A bending machine and mold technology, applied in the field of bending machines, can solve the problems of low processing precision, narrow adaptability, poor stability, etc., and achieve the effect of high processing precision, good effect and increased buffer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

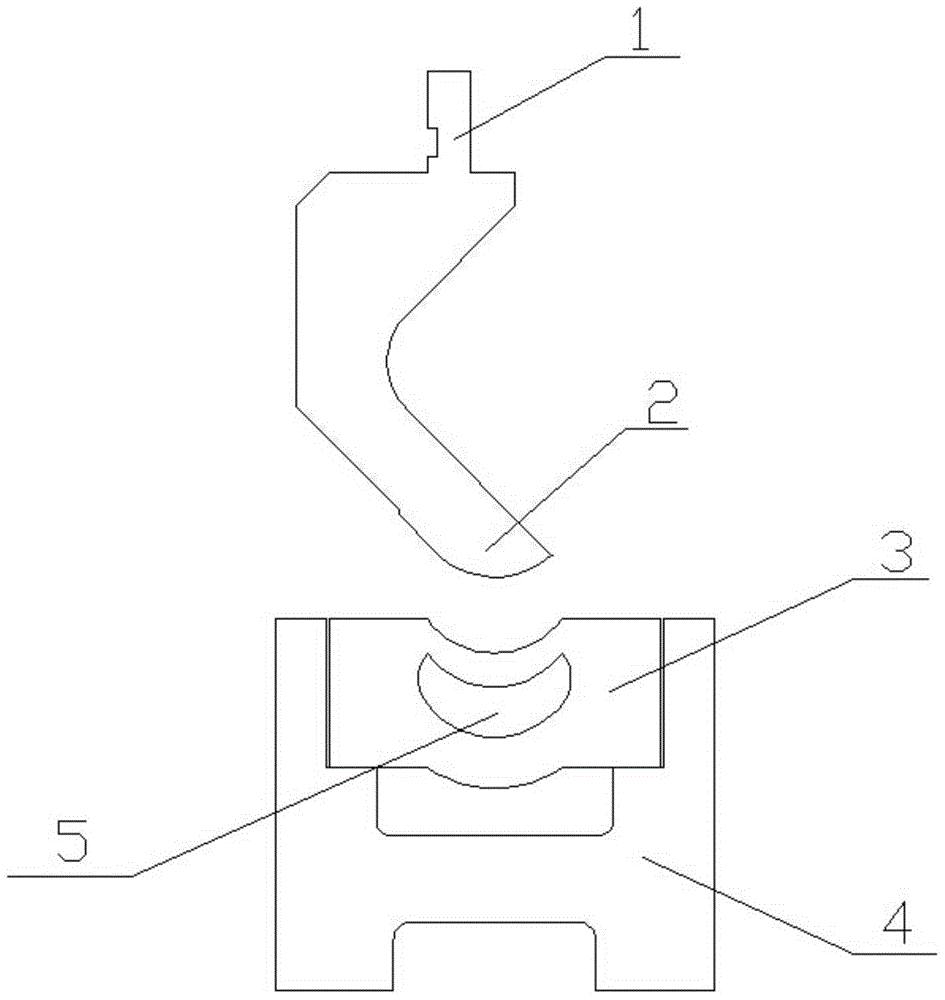

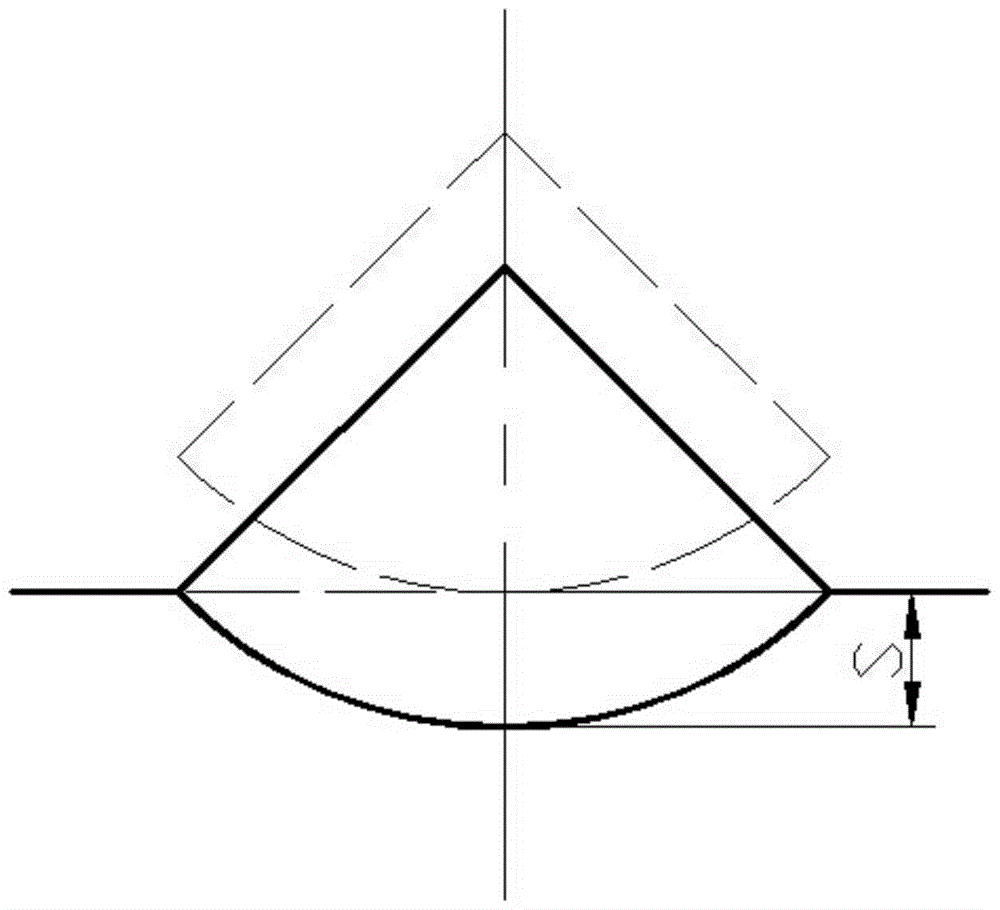

[0043] Such as figure 1 with figure 2As shown, a bending machine mold capable of processing multi-curved circular surfaces includes an upper mold and a lower mold. The upper mold includes an upper mold clamping part 1 and an upper mold cutter head 2; Die base 4; The cross-section of the bottom of the upper die cutter head 2 is arc-shaped, the radius of the arc is 25mm, and the corresponding central angle of the arc is 45 °, and the angle between the upper die cutter head 2 and the vertical direction is 45°; the lower mold base 4 is provided with a first groove, and the bottom of the first groove is provided with a second groove; the lower mold forming body 3 is installed on the first groove, and the upper surface of the lower mold forming body 3 and The upper surface of the lower mold base 4 is at the same height, the upper surface of the lower mold body 3 is provided with an arc-shaped groove, the radius of the arc-shaped groove is 25mm, and the depth is 9mm, and the middle...

Embodiment 2

[0053] A bending machine mold capable of processing multi-arc circular surfaces is the same as the device in Example 1, the difference is that the cross-section of the bottom of the upper mold cutter head 2 is arc-shaped, and the radius of the arc is 50mm; the buffer Cavity 5 is a closed cavity, and the air pressure in the cavity is 1MPa

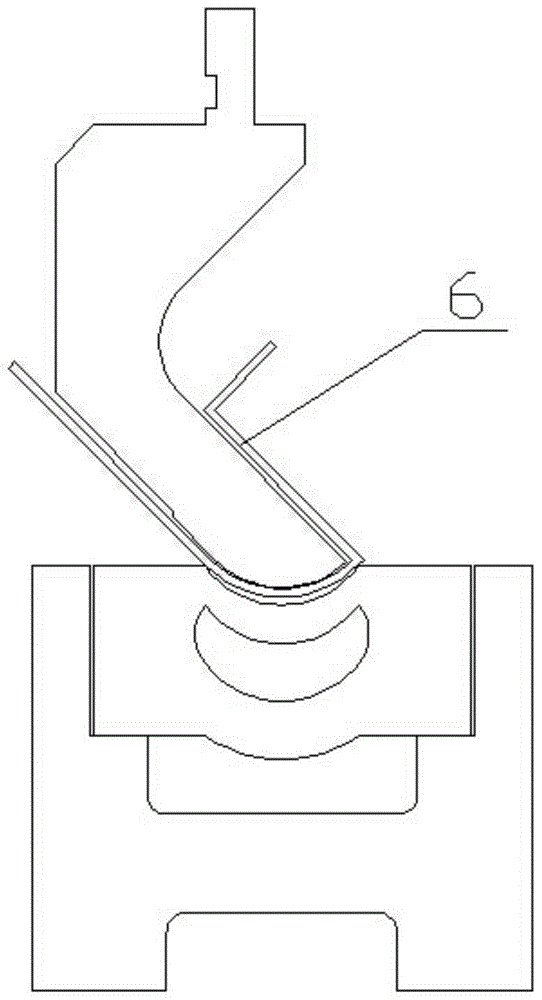

[0054] Such as figure 1 , figure 2 , Figure 4 with Image 6 As shown, a method of using a bending machine mold that can process multi-arc circular surfaces, the steps are:

[0055] (A) First fix the lower mold base 4 on the mold base of the bending machine, and fasten it with bolts;

[0056] (B) placing the lower die forming body 3 on the first groove;

[0057] (C) Select the upper die cutter head 2 with an arc radius of 50 mm, fix the upper die clamping part 1 in the mold clamping device on the slider of the bending machine, and adjust the position of the upper die cutter head 2 so that the bottom Just align with the arc-shaped groo...

Embodiment 3

[0062] A bending machine mold that can process multi-arc circular surfaces is the same as the device in Example 1, the difference is that the cross section of the bottom of the upper die cutter head 2 is arc-shaped, and the radius of the arc is 15mm; The cavity 5 is a closed cavity, and the air pressure in the cavity is 1.2MPa.

[0063] Such as figure 1 , figure 2 , image 3 with Figure 5 As shown, a method of using a bending machine mold that can process multi-arc circular surfaces, the steps are:

[0064] (A) First fix the lower mold base 4 on the mold base of the bending machine, and fasten it with bolts;

[0065] (B) placing the lower die forming body 3 on the first groove;

[0066] (C) Select the upper die cutter head 2 with an arc radius of 15mm, fix the upper die clamping part 1 in the mold clamping device on the slider of the bending machine, and adjust the position of the upper die cutter head 2 so that the bottom Just align with the arc-shaped groove of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com