Full-automatic bucket turnover machine

A fully automatic, barrel-turning technology, which is applied in emptying containers, loading/unloading, bottle filling, etc., can solve problems such as easy to be stained with corrosive materials, large capacity, time-consuming and labor-intensive, etc., to save labor output, easy to operate, Safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

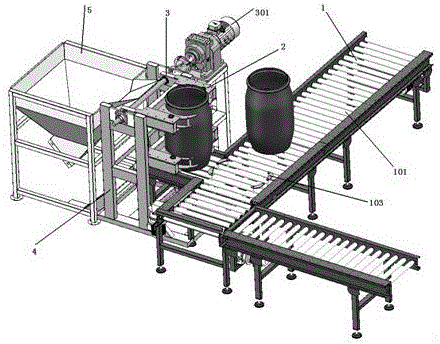

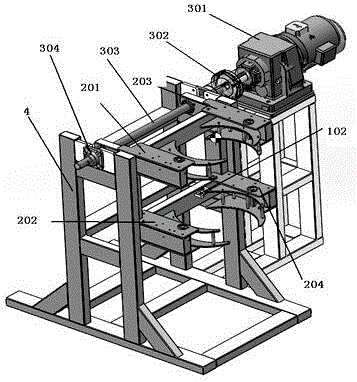

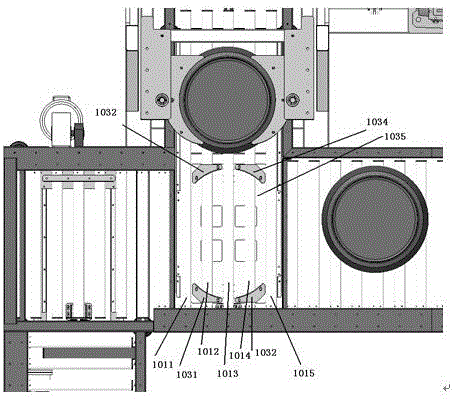

[0021] refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, a fully automatic barrel turning machine mainly includes automatic barrel feeding 1, clamping and releasing device 2, rotating device 3, supporting device 4, receiving device 5 and electric control device, automatic barrel feeding device 1 is connected and clamped Unclamping device 2, the clamping and releasing device 2 is connected to the rotating device 3, the supporting device 4 is equipped with the clamping and releasing device 2 and the rotating device 3, the supporting device 4 is connected to the receiving device 5,

[0022] The automatic barrel feeding device 1 includes a drum line 101, a detection element 102 and a drag translation device 103. The width of the drum line 101 is 150 cm, and the length of the drum at the connection part between the drum line 101 and the clamping and releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com