Accurate sample production method for inclined anchored jointed rock mass, and anchored jointed rock mass

A technology for rock mass and anchor joints, which is applied in the field of accurate sample preparation of inclined anchor joint rock mass and anchor joint rock mass, and can solve problems such as the inability to reserve anchor rod installation holes on three-dimensional structural surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

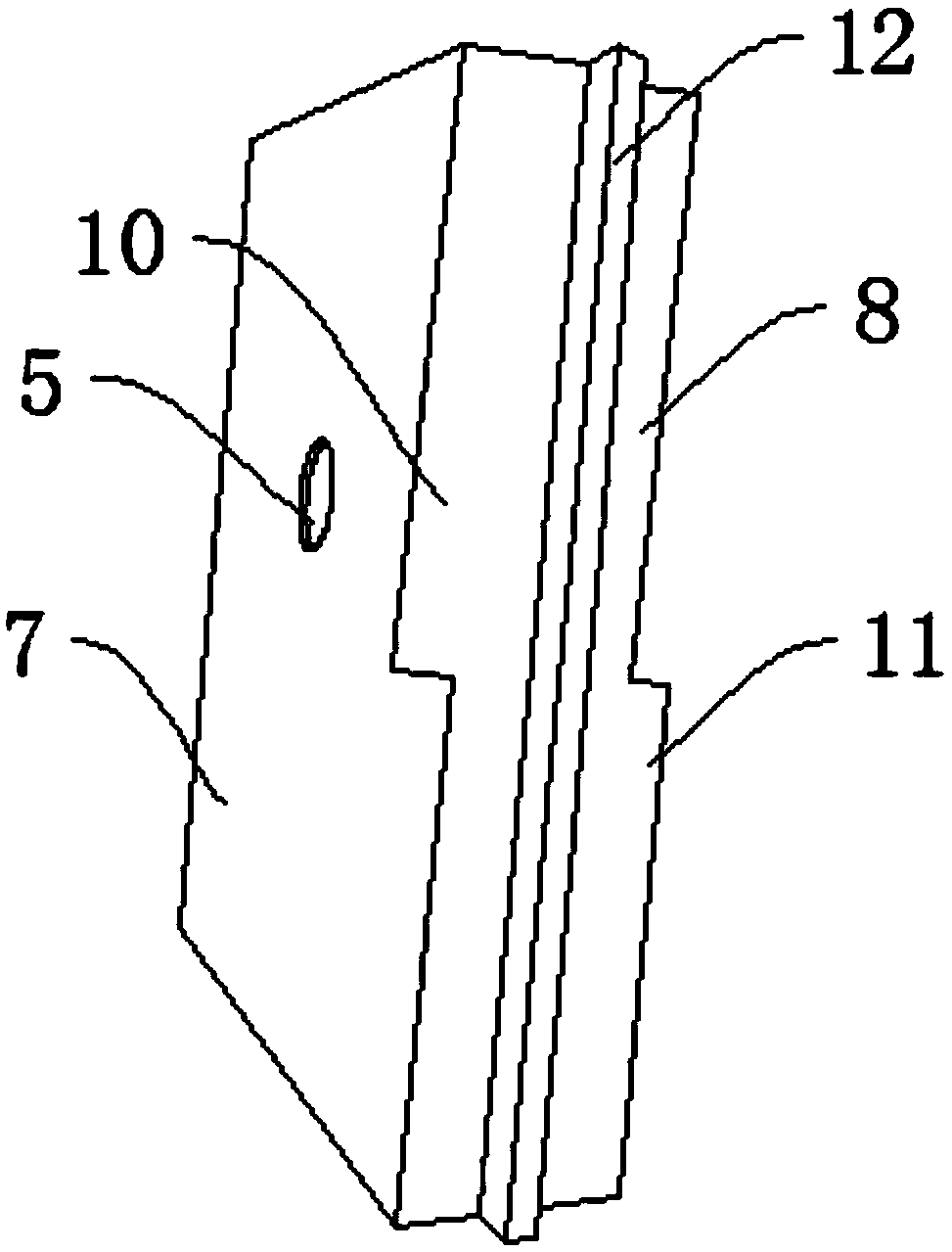

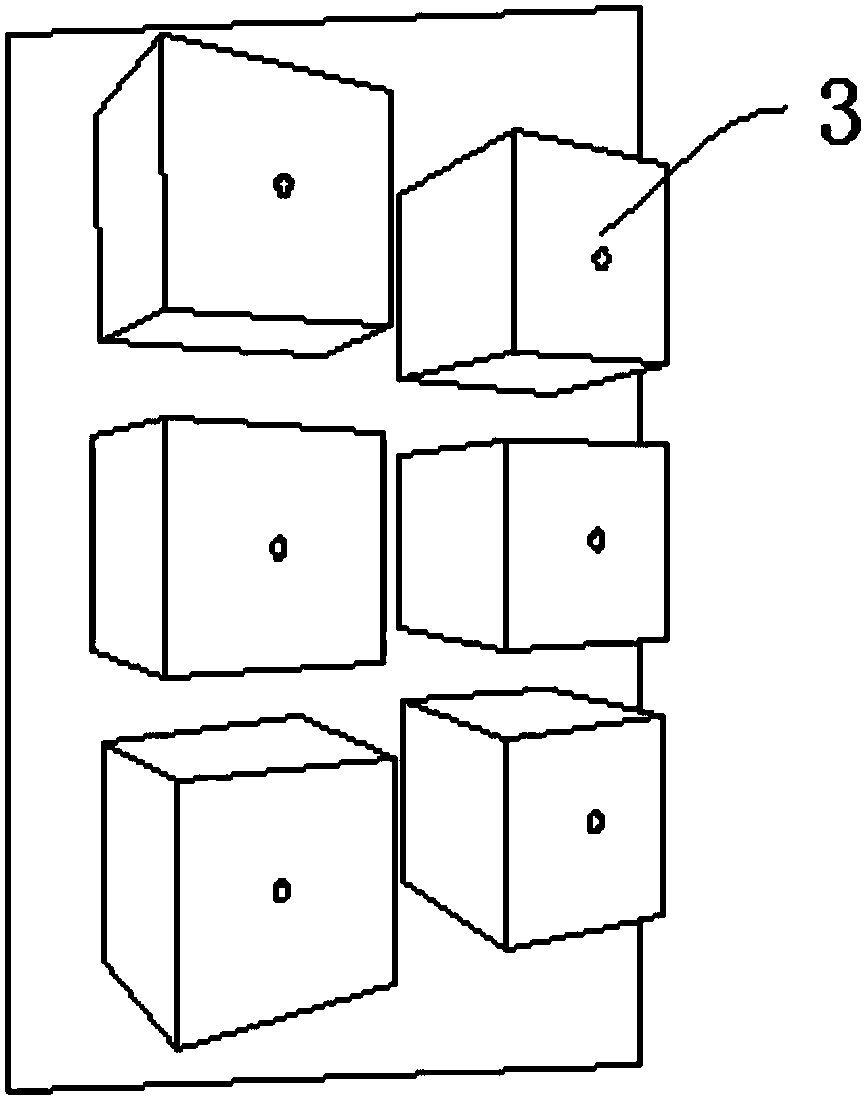

[0060] The first embodiment: a 60-degree inclination angle plus an anchor jointed rock mass sample (single anchor rod 4)

[0061] Gypsum is selected as a similar material, the anchoring agent is cement slurry, and the upper and lower plates of the joint sample are combined to form a cube sample with a length of 100 mm. The anchor rod installation hole 5 passes through the center of the structural surface. The diameter of the anchor rod installation hole 5 is 12 mm. The shear direction of the structural plane is at an angle of 60 degrees.

[0062] (1) Scanning the three-dimensional structural surface, the software reconstructs the three-dimensional structural surface and intercepts blocks within the range of 100*100mm (x*y);

[0063] (2) Stretch 5mm on both sides respectively, and make a cylinder with a diameter of 12mm through the center of the structural surface. The axial direction of the cylinder forms an angle of 60 degrees with the selected shearing direction, and the fir...

no. 2 example

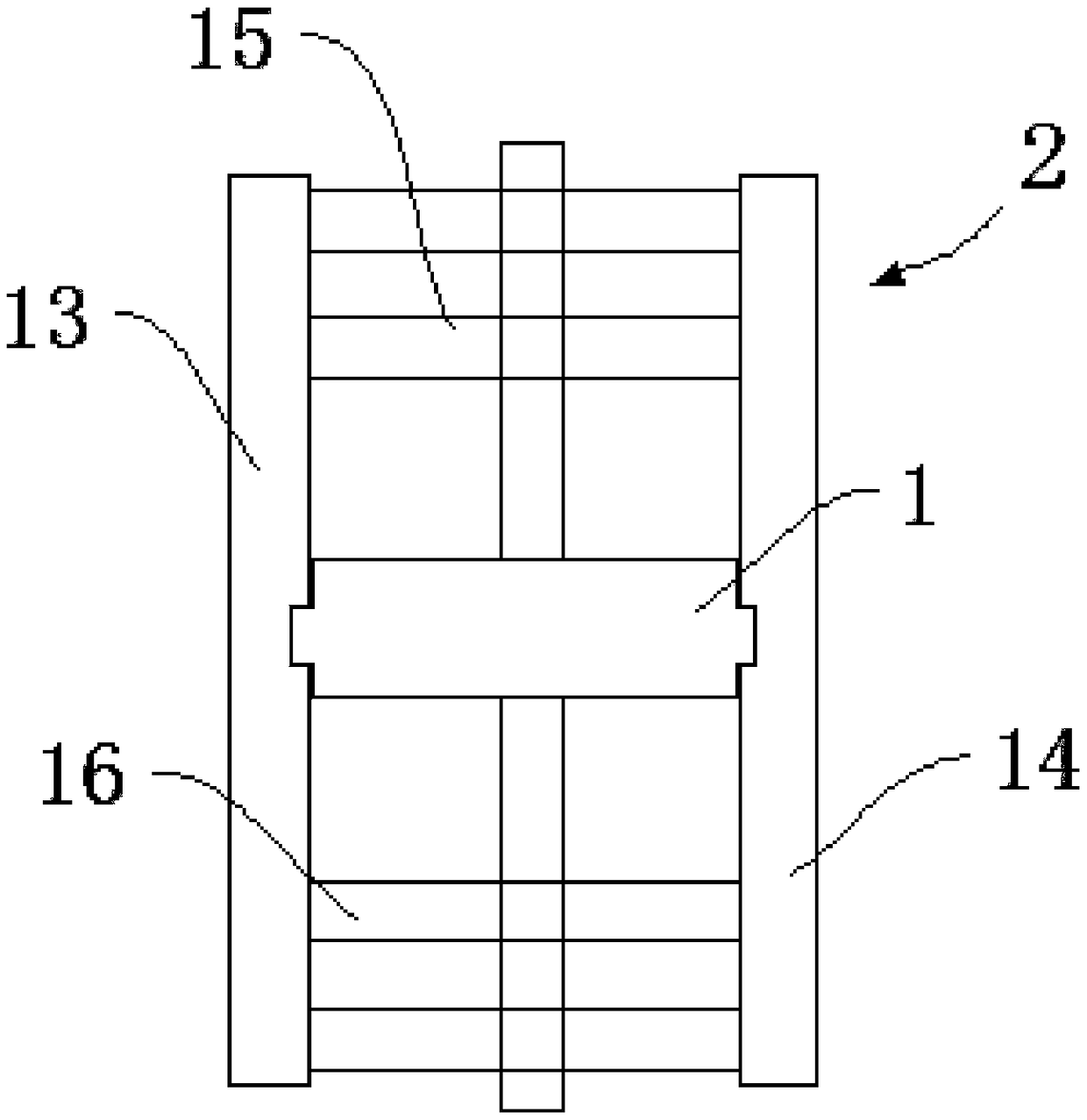

[0068] The second embodiment: 90 degree inclination angle plus anchor jointed rock mass sample (three anchor rods 4)

[0069] Select high-strength cement and river sand as similar materials, and the anchoring agent is cement slurry. The combined size of the upper and lower plates of the joint sample is 300*100*100mm. (150,50) and (250,50), the diameter of the mounting hole is 12mm, and the axis of the mounting hole is at an angle of 30 degrees to the shearing direction of the structural surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com