Green and environment-friendly explosive simulant material and preparation method therefor

A simulation material, green and environmental protection technology, applied in explosives and other directions, can solve the problems of polluting the environment and difficult to recycle BN, and achieve the effect of uniform filling, accurate simulation and improvement of pouring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of green environment-friendly explosive simulating material, its formula consists of: Al 2 o 3 : 35 parts, PVC: 10 parts, SiO 2 : 23 parts, aldol resin: 32 parts, DES: 0.5 parts, graphite: 0.01 parts, lecithin: 0.06 parts, BX: 0.25 parts.

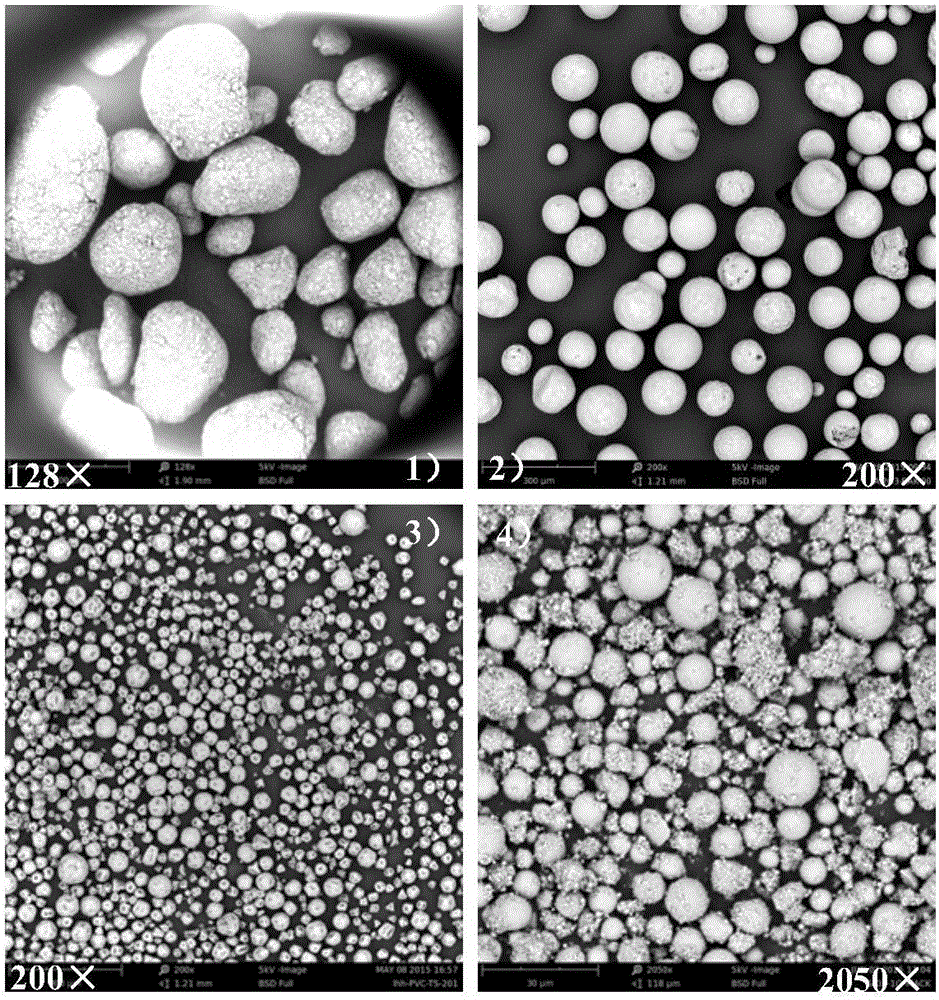

[0035] The particle gradation and particle size distribution of the solid phase filler are: Al 2 o 3 The average particle size is 97.4μm; the average particle size of PVC is 48.1μm; SiO 2 The average particle diameter is 9.4 μm.

[0036] The preparation method of the green environment-friendly explosive simulating material mainly comprises the following steps:

[0037] (1) Batching: quantitatively weigh each component in the formula, and set aside;

[0038] (2) The components of the material are mixed by batch feeding and multi-stage kneading: the first batch: Al 2 o 3 , PVC, SiO 2 , aldol resin, graphite, lecithin and half of the BX are put into the kneader, kneaded at 50℃~70℃ under normal pressure for 15 minutes, th...

Embodiment 2

[0047] A green environmental protection explosive simulation material, its formula is composed of: PTFE: 30 parts, SiO 2 : 30 parts, aldol resin: 40 parts, DES: 0.8 parts, graphite: 0.1 parts, lecithin: 0.06 parts, BX: 2 parts.

[0048] The particle gradation and particle size distribution of the solid phase filler are: the average particle size of PTFE is 567.6 μm; 2 The average particle diameter is 9.4 μm.

[0049] The preparation method is the same as in Example 1.

[0050] The various quality indexes of gained green environment-friendly explosive simulation material are as follows:

[0051] (1) The solid phase content is 60%, the casting rheological properties are excellent, and the molding performance and machining performance of the product after casting and curing are good;

[0052] (2) The measured density of the Φ20mm×20mm grain column ρ=1.662~1.666g / cm 3 , reaching more than 98% of the theoretical density;

[0053] (3) Mechanical properties: compressive strength...

Embodiment 3

[0055] A kind of green environmental protection explosive simulation material, its formula is composed of: PTFE: 16 parts; Al 2 o 3 : 18 parts, PVC: 14 parts, SiO 2 : 20 parts, aldol resin: 32 parts, DES: 0.5 parts, graphite: 0.01 parts, lecithin: 0.06 parts, BX: 0.5 parts.

[0056] The particle gradation and particle size distribution of the solid phase filler are: the average particle size of PTFE is 567.6 μm; 2 o 3 The average particle size is 97.4μm; the average particle size of PVC is 48.1μm; SiO 2 The average particle diameter is 9.4 μm.

[0057] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com