Garlic full-automatic processing and grinding production system and production technology

A production system and fully automatic technology, applied in food science and other fields, can solve the problems of time-consuming, labor-intensive, low production efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

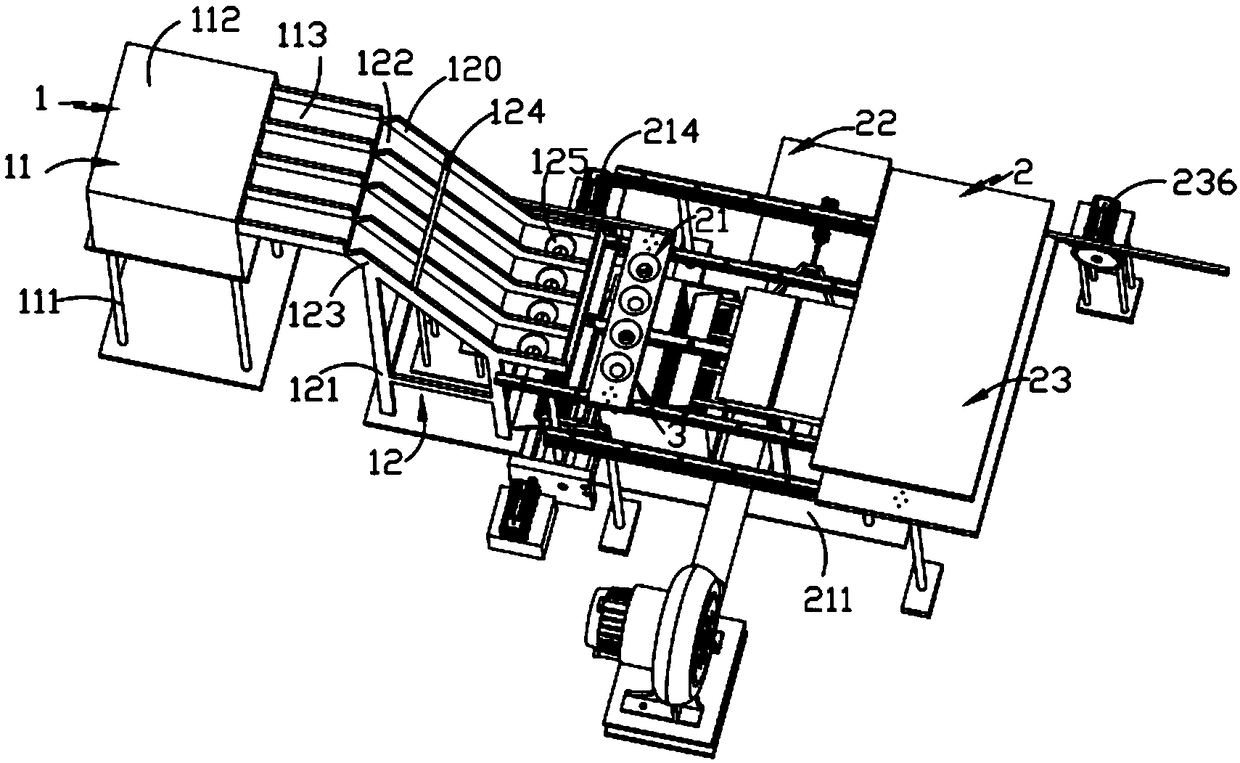

[0112] Such as Figures 1 to 19 Shown, a kind of garlic automatic processing production system comprises:

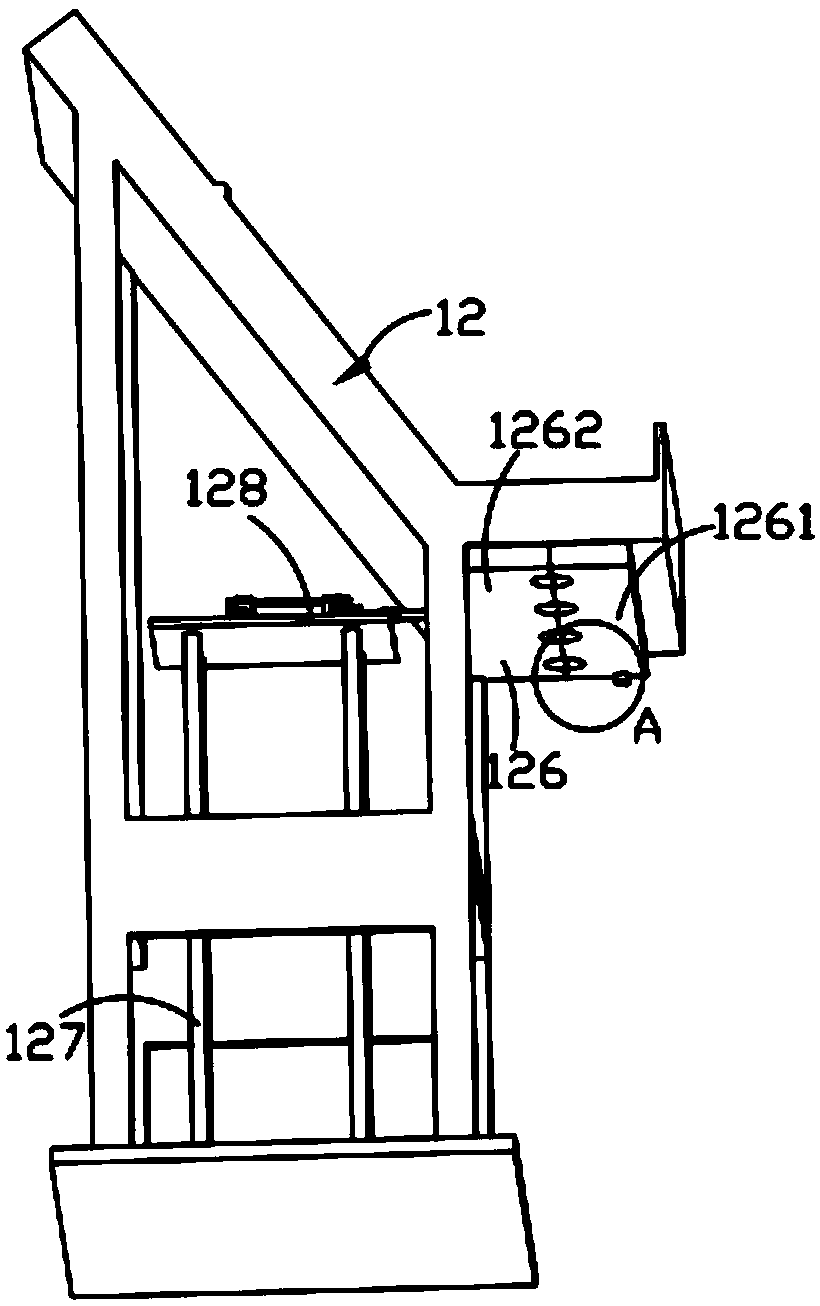

[0113] A feeding mechanism 1, the feeding mechanism 1 includes a sorting assembly 11 and a shunting assembly 12, and the shunting assembly 12 is arranged below the output end of the sorting assembly 11;

[0114] The first processing mechanism 2, the first processing mechanism 2 is arranged on the side of the feeding mechanism 1, and it includes a feeding assembly 21, a shearing assembly 22 and a root removal assembly 23, a...

Embodiment 2

[0188] Referring to Example 1, a technical process for fully automatic processing and production of garlic in Example 2 of the present invention will be described.

[0189] Such as Figure 20 Shown, a kind of garlic automatic processing production technology comprises the following steps:

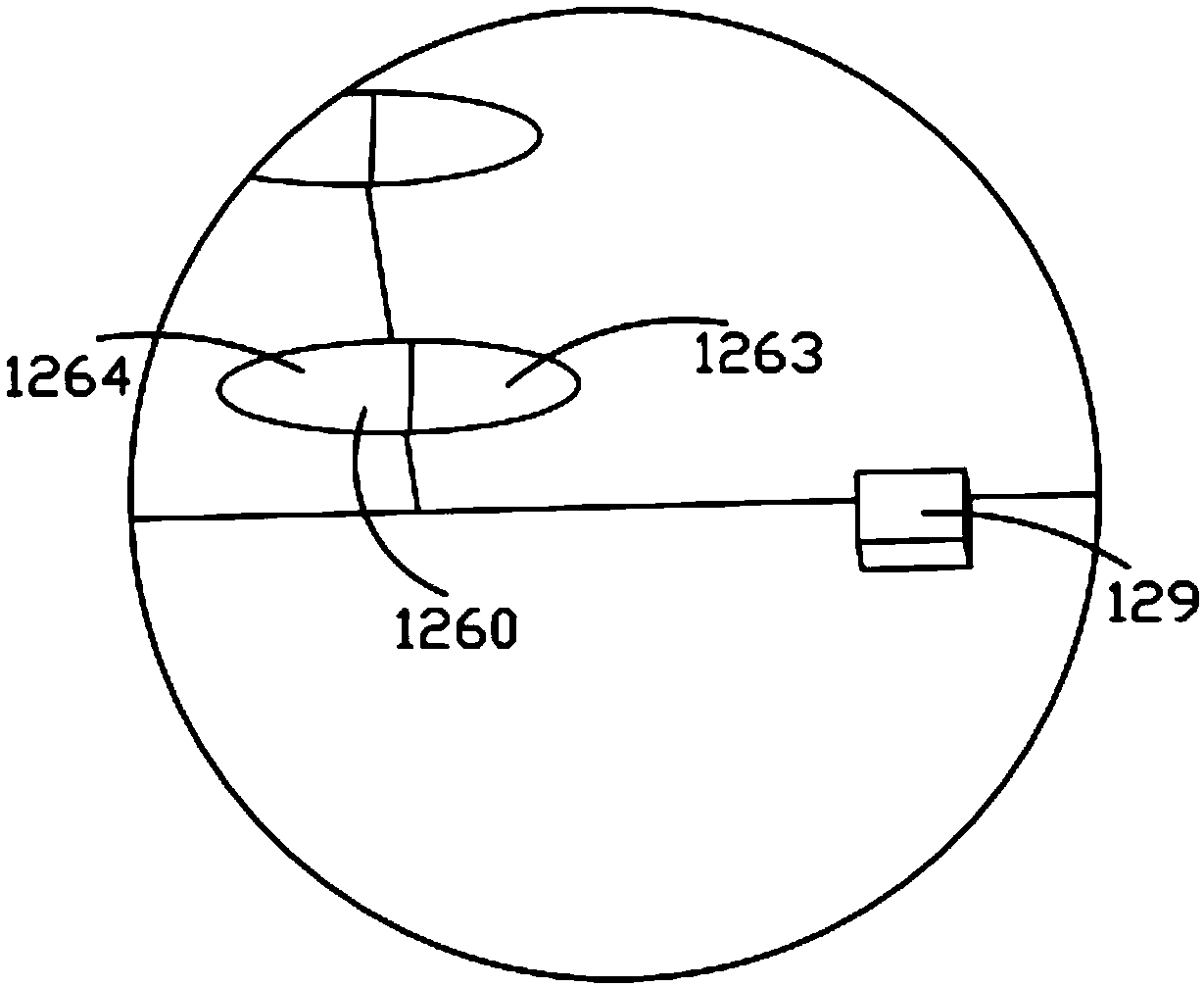

[0190] Step 1) Feeding, the sorting assembly 11 arranges the garlic in a vertically upward state and sends it to the shunt assembly 12. After the garlic passes through the shunt assembly 12, the garlic slides into the garlic retaining groove 1260 with its roots facing upwards and stems and leaves facing downwards;

[0191] Step 2) Feeding, the supporting block 213 is transported by the driving unit a214 to the right below the garlic retaining groove 1260, after the sensor 129 detects that the sensing block 2132 is located directly below, the push cylinder a128 drives the sliding baffle 1262 to slide, and the garlic retaining groove 1260 opens , the garlic falls into the garlic groove 2131;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com