Automated yellow wine production process

A rice wine and process technology, applied in the field of automatic production technology of rice wine, can solve the problems affecting the quality of wine making, output, insufficient automation of the production process, hidden dangers of food safety, etc., so as to reduce manual labor, improve labor efficiency, and improve quality and safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

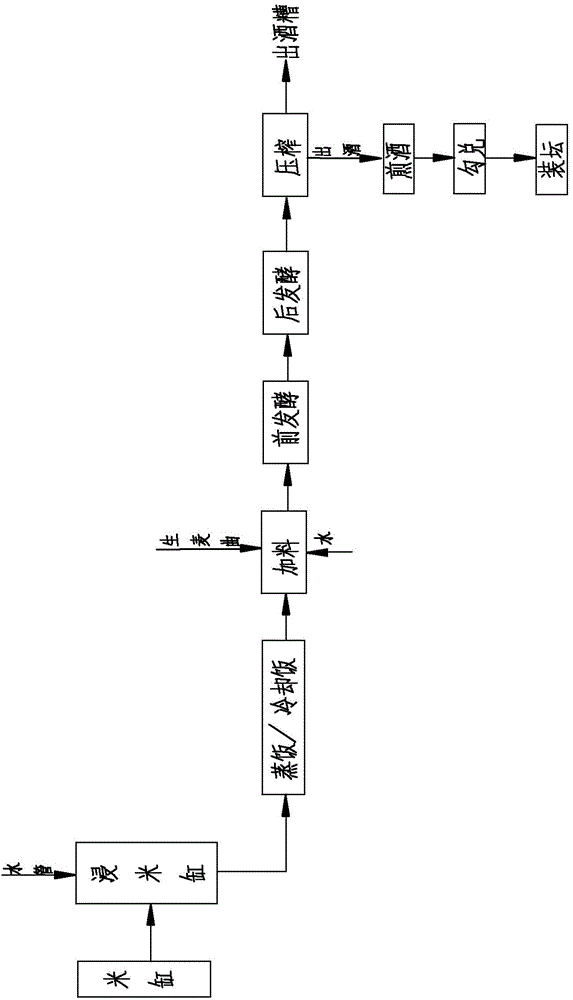

[0054] like Figure 1-Figure 9 Shown, the technique of automatic production yellow rice wine of the present invention may further comprise the steps:

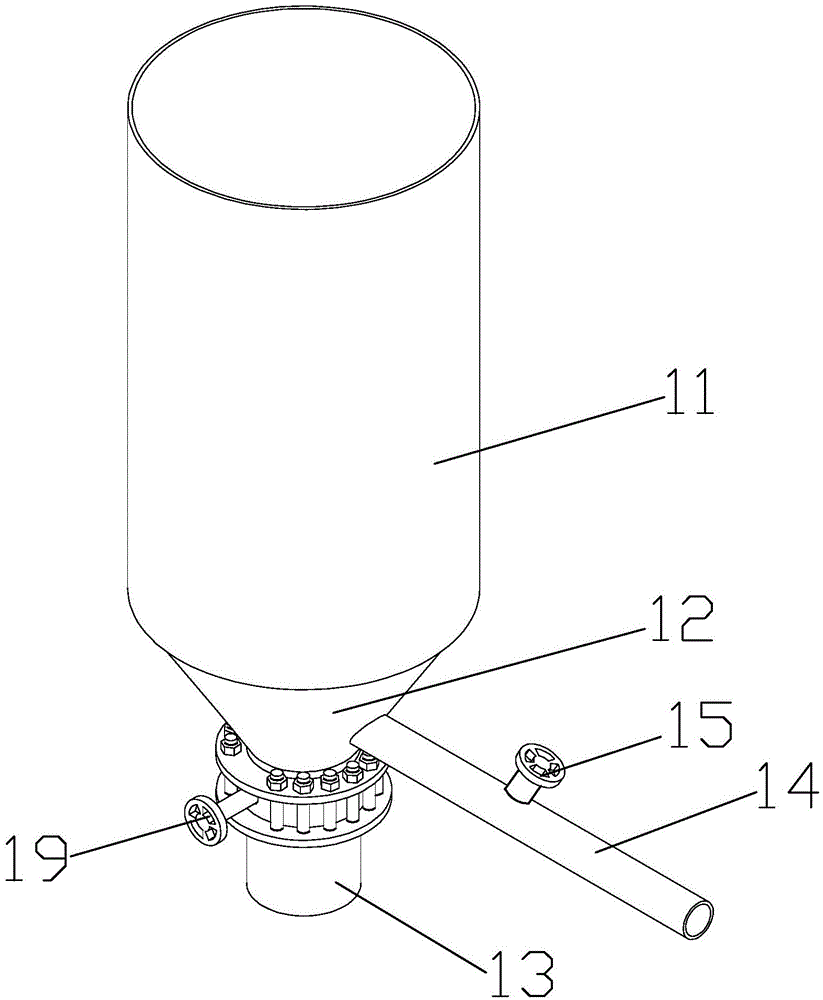

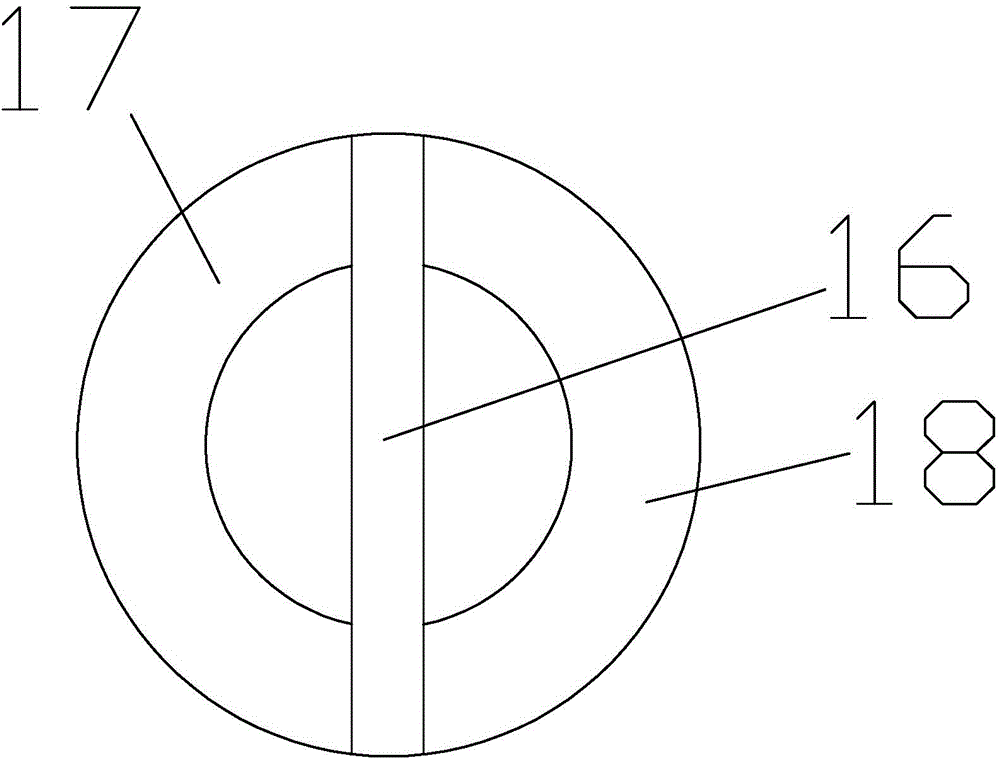

[0055] (1) Rice soaking: rice soaking is carried out in a rice soaking tank, which is connected with a control system (not marked in the drawings of the present invention), and the rice soaking tank includes a cylindrical part 11 connected sequentially from top to bottom, an inverted cone Part 12 and rice outlet 13, the wall of inverted tapered portion 12 is connected with water outlet pipe 14, outlet pipe 14 is connected with water outlet pump 15, and the junction of inverted tapered portion 12 and rice outlet 13 is installed with rice outlet. The convex plate that the entrance of 13 matches, convex plate comprises central axis 16, and left convex plate 17 and right convex plate 18 are installed on central axis 16, and convex plate is connected with rice pump 19, and rice pump 19 and water outlet pump 15 all Connect with the ...

Embodiment 2

[0085] In Example 2, after steaming the rice in step (2), it is cooled to 55°C in the rice cooler;

[0086] In step (7), the rice wine after filtering in step (6) is heat-exchanged according to the automatically set parameters, and the temperature rises to 93°C;

[0087] In step e, the wheat in step d is dragged and transported to the fermentation room for fermentation; fermentation includes the following 6 processes:

[0088] e1. Static period: the temperature of the stationary period is 38°C, the humidity is 95, and the time is 12 hours;

[0089] e2. Breeding period: the temperature of the breeding period is 50°C, the humidity is 95, and the time is 9 hours;

[0090] e3. Exuberant period: the temperature in the exuberant period is 56°C, the humidity is 85, and the time is 18 hours, and the temperature shows an upward trend; or the temperature in the exuberant period is 52°C, the humidity is 85, and the time is 18 hours, and the temperature shows a downward trend;

[0091] ...

Embodiment 3

[0096] In Example 3, after steaming in step (2), the rice is cooled to 50°C in a rice cooler;

[0097] In step (7), the rice wine after filtering in step (6) is heat-exchanged according to the automatically set parameters, and the temperature rises to 92°C;

[0098] In step e, the wheat in step d is dragged and transported to the fermentation room for fermentation; fermentation includes the following 6 processes:

[0099] e1. Static period: the temperature of the stationary period is 32.5°C, the humidity is 95, and the time is 12 hours;

[0100] e2. Breeding period: the temperature of the breeding period is 45°C, the humidity is 95, and the time is 9 hours;

[0101] e3. Exuberant period: the temperature in the exuberant period is 54°C, the humidity is 85, and the time is 18 hours, and the temperature is on the rise; or the temperature in the exuberant period is 53.5°C, the humidity is 85, and the time is 18 hours, the temperature is on the decline;

[0102] e4. Enzyme produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com