Grain dryer

A grain dryer and drying technology, applied in dryers, grain drying, drying of solid materials, etc., can solve the problems of grain mildew, cumbersome labor intensity for farmers, and large floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

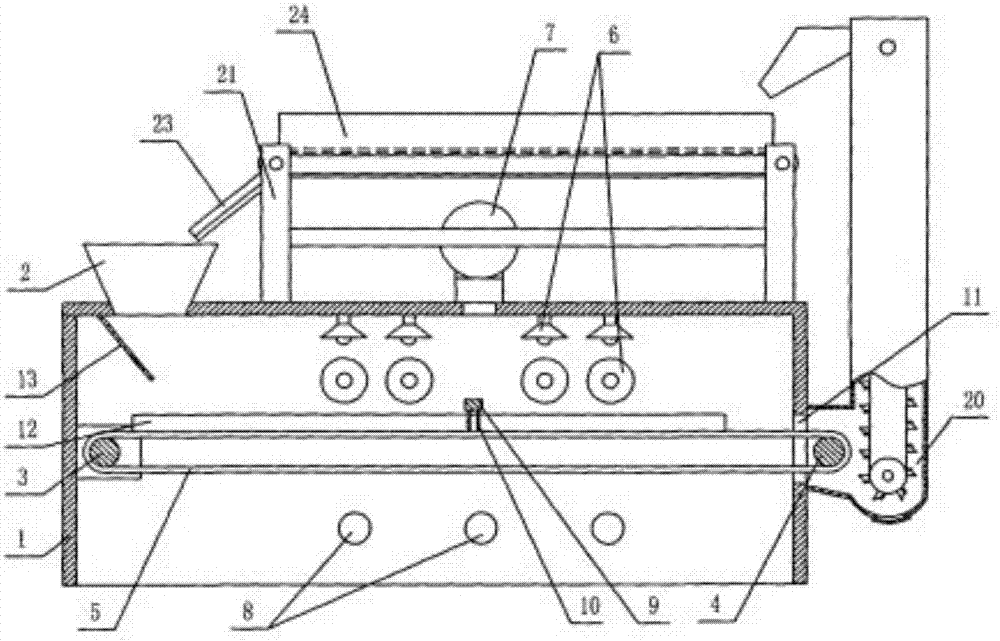

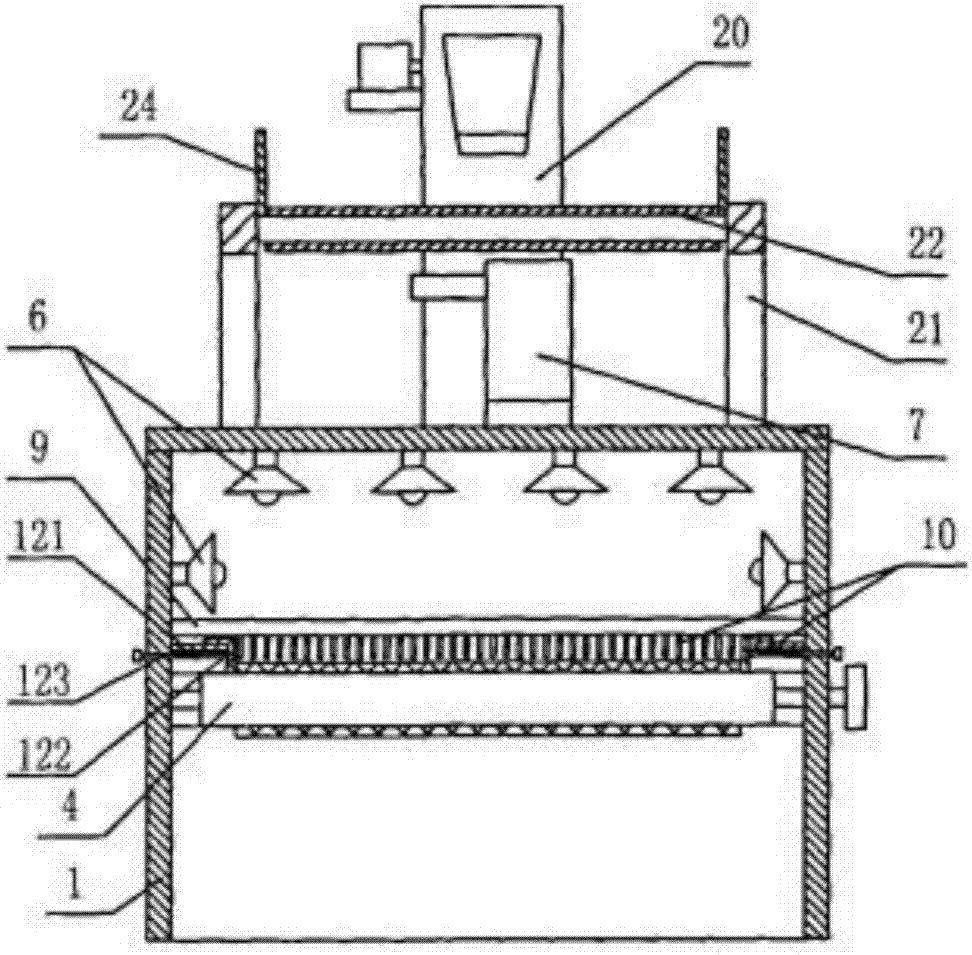

[0025] Such as figure 1 and figure 2 As shown, a grain dryer, which includes a drying machine box 1 and a feed funnel 2 is provided at the front of the top wall of the drying machine box 1. The front and rear of the drying machine box 1 are correspondingly installed with a drive roller 3 driven by a power mechanism and a slave The driving roller 4, the rear wall of the above-mentioned dryer box 1 is also provided with a discharge port 11 corresponding to the rear of the driven roller 4, and the two sides and the dryer box are covered between the driving roller 3 and the driven roller 4. 1. The conveyor mesh belt 5 attached to the inner surface of the side wall, and the outlet where the above-mentioned feeding funnel 2 extends into the dryer box 1 is located above the rear of the conveyor mesh belt 5;

[0026] A plurality of drying lamps 6 are respectively installed on the top wall and the side wall of the middle part of the drying cabinet 1, and the top wall of the drying ca...

Embodiment 2

[0029] combine again figure 1 and figure 2 Shown is a grain dryer, on the basis of the above structure, side baffles 12 are installed on the side wall of the drying machine box 1 to prevent grain from slipping down. The side baffle 12 includes a fixed plate 121 connected to the side wall of the dryer cabinet 1 and a vertical baffle 122 slidably connected to the fixed plate 121. The lower surface of the vertical baffle 122 is attached to the conveyor belt 5. Above, the above-mentioned vertical baffle plate 122 can be composed of a horizontal edge lapped on the fixed plate and a vertical edge extending to the conveying mesh belt 5, and the bottom of the vertical edge can be provided with an anti-slip and wear-resistant rubber strip;

[0030] In addition, on the side wall of the drying machine box 1, there is an adjusting bolt 123 whose inwardly extending end is rotatably connected to the vertical baffle 122 and drives the vertical baffle 122 to slide. The setting of the side b...

Embodiment 3

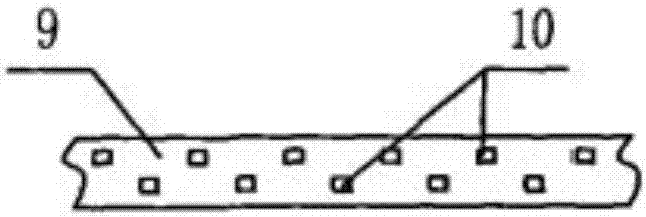

[0032] Such as figure 1 , figure 2 and image 3 As shown, a grain dryer, on the basis of the above structure, a grain turning mechanism is also installed in the drying box 1, wherein the grain turning mechanism includes a The supporting columns 9 are equipped with at least two rows of turning columns 10 before and after, and the turning columns 10 of the front and rear rows are arranged in a laterally staggered manner. In this embodiment, only one supporting column 9 is provided, and multiple drying irradiation The lamps 6 are divided into two groups before and after. The support column 9 is located in the middle of the two groups of drying irradiation lamps 6. The air inlet of the above-mentioned induced draft fan 7 is also located in the middle of the two groups of drying irradiation lamps. According to the requirements of the degree, a plurality of support columns 9 are arranged, and the plurality of support columns 9 are arranged at longitudinal intervals.

[0033] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com