Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce inventory backlog" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

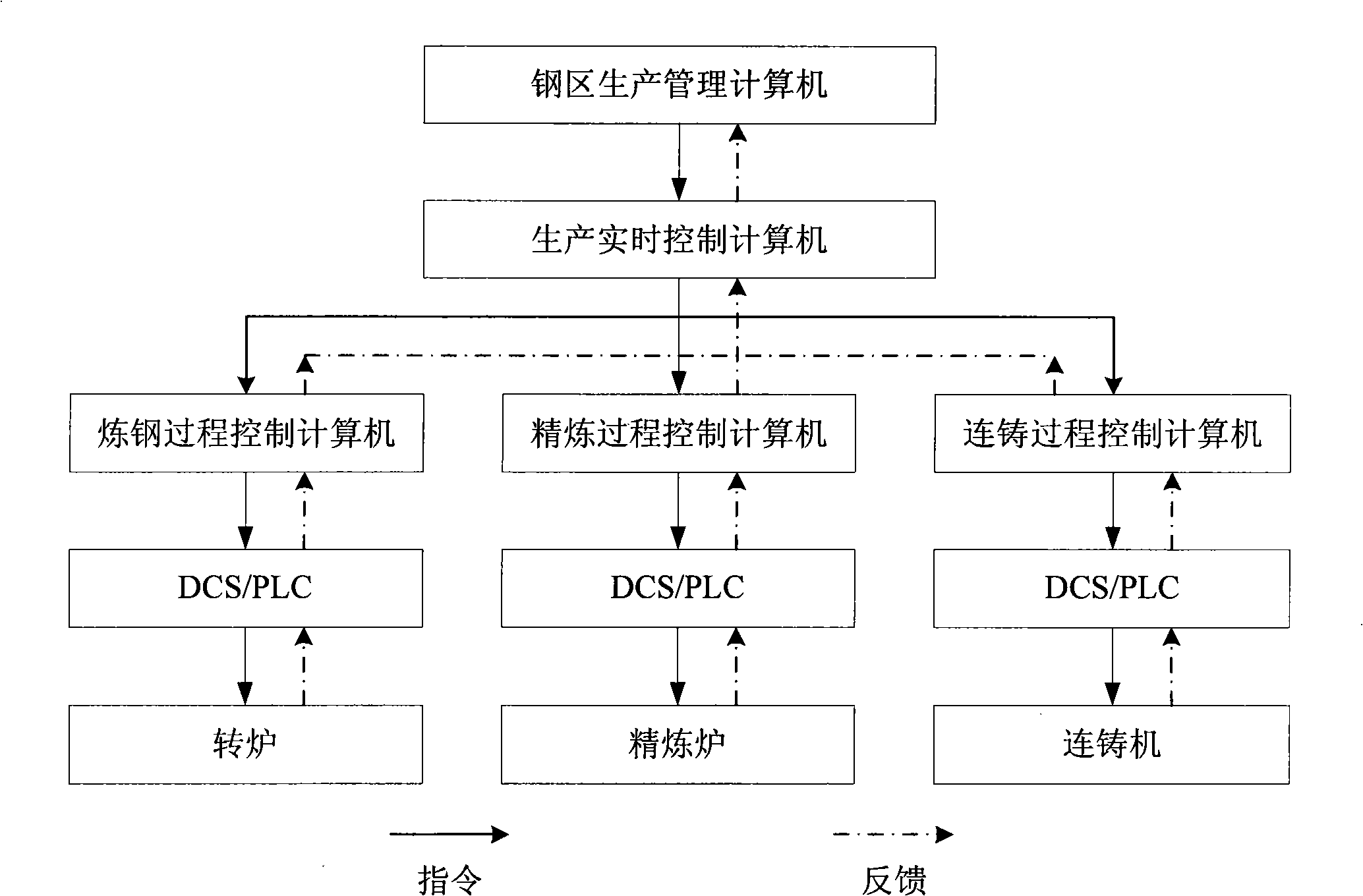

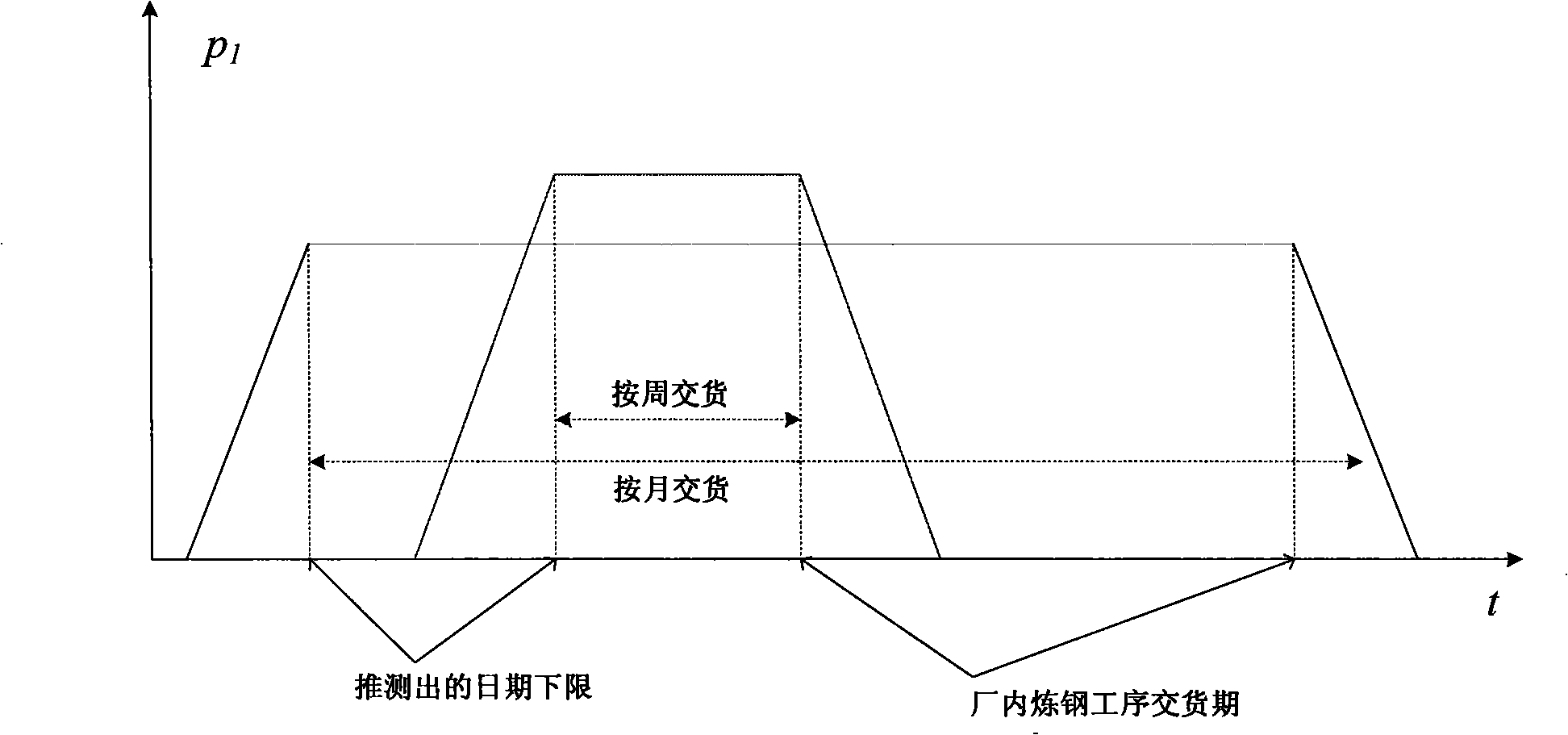

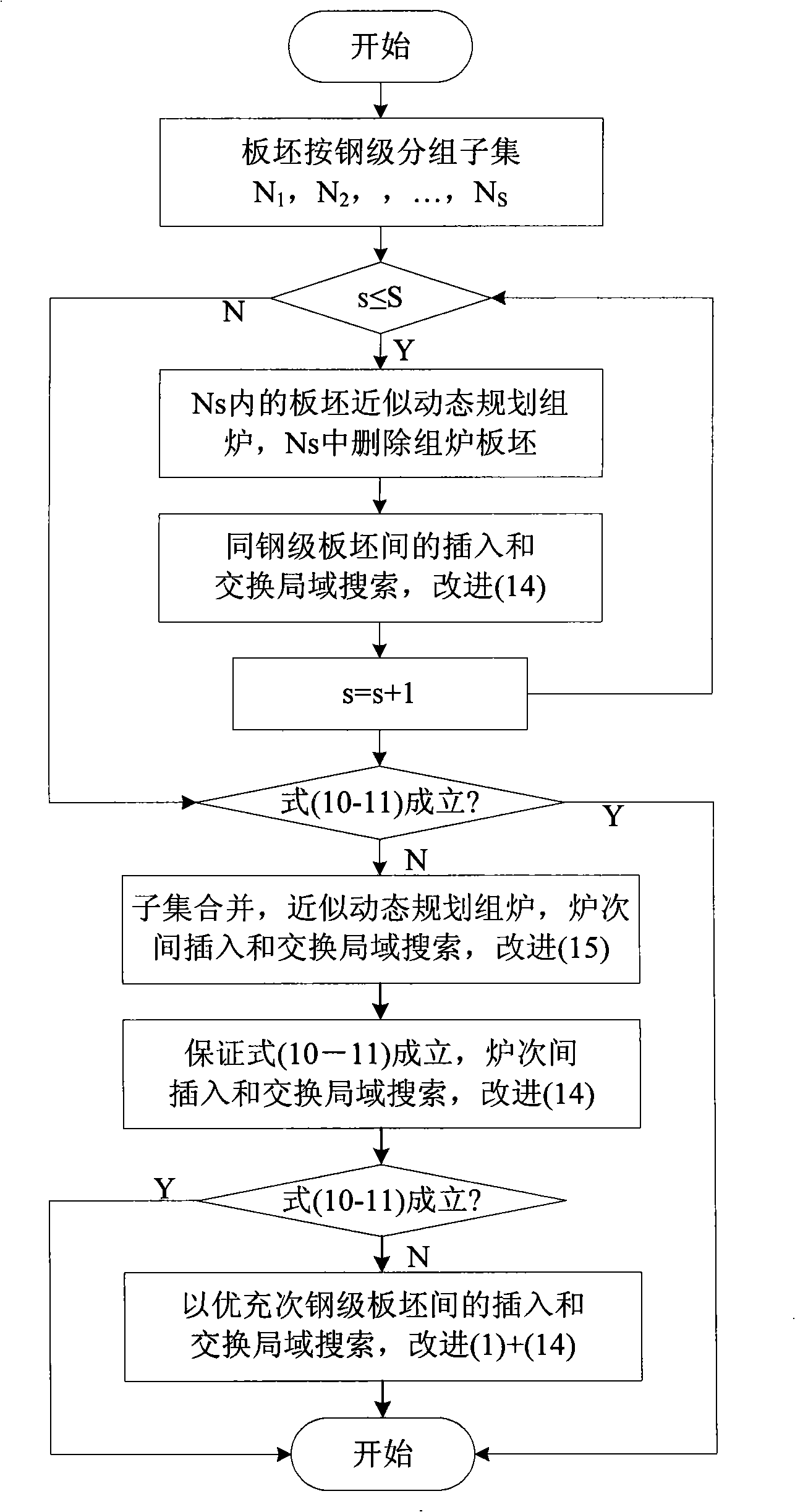

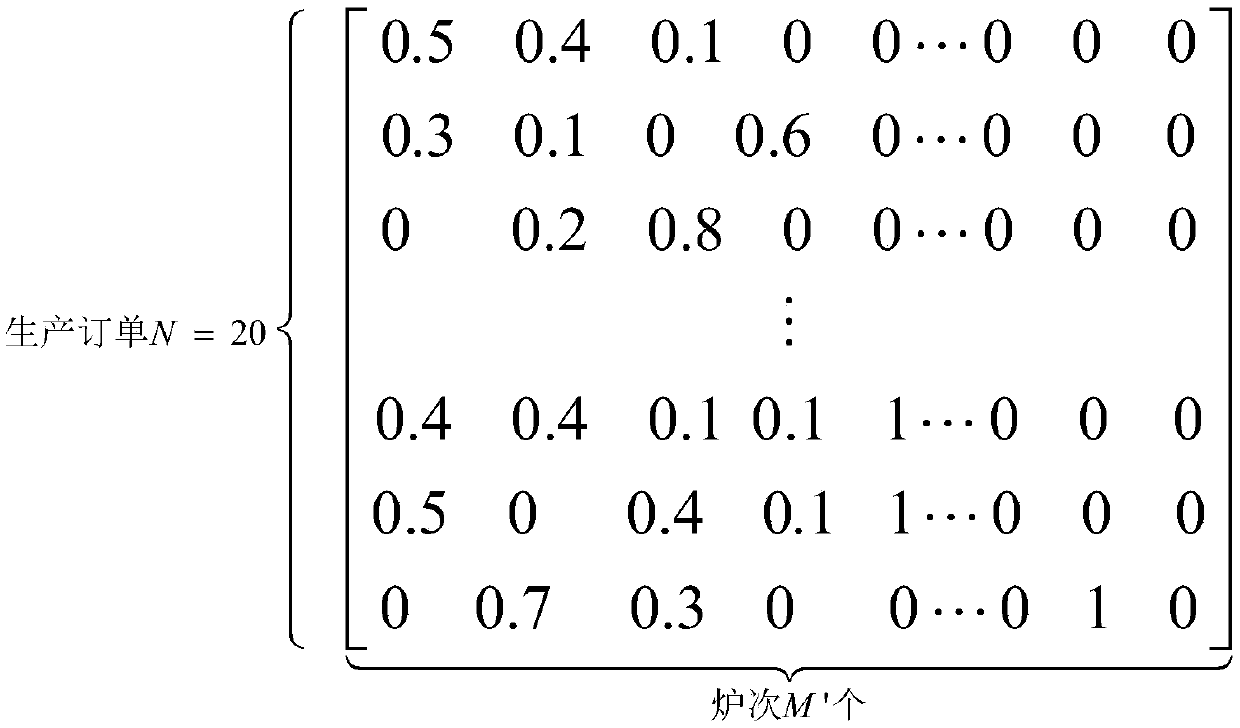

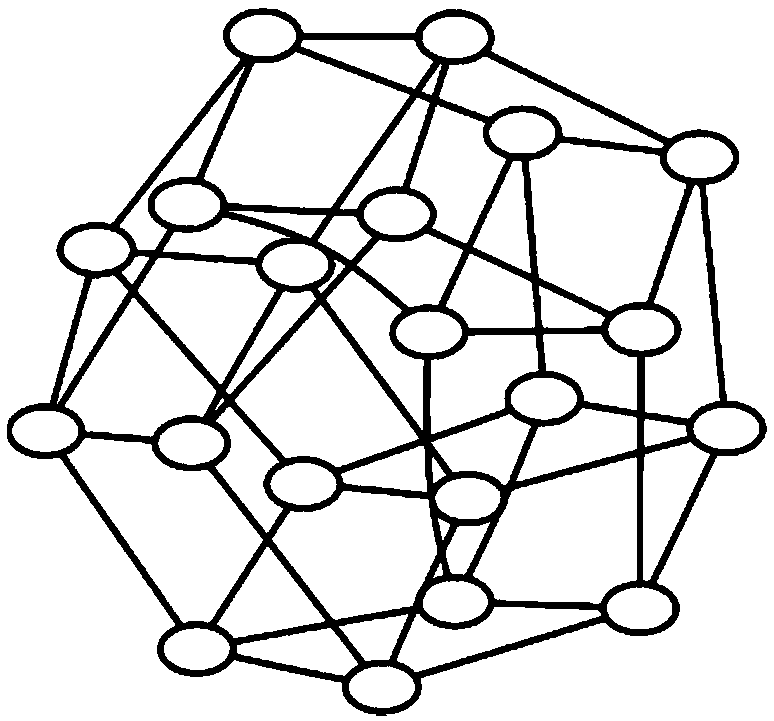

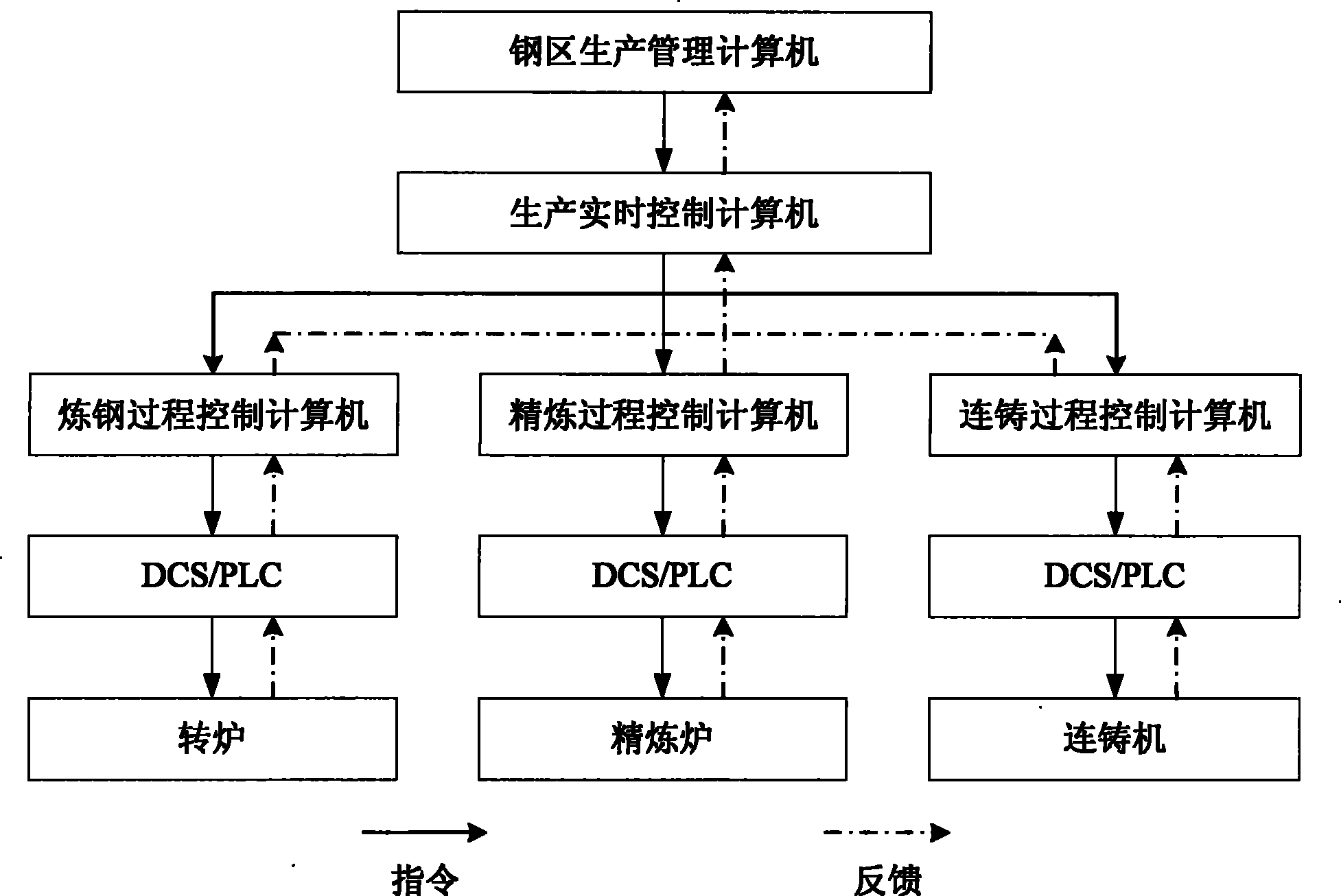

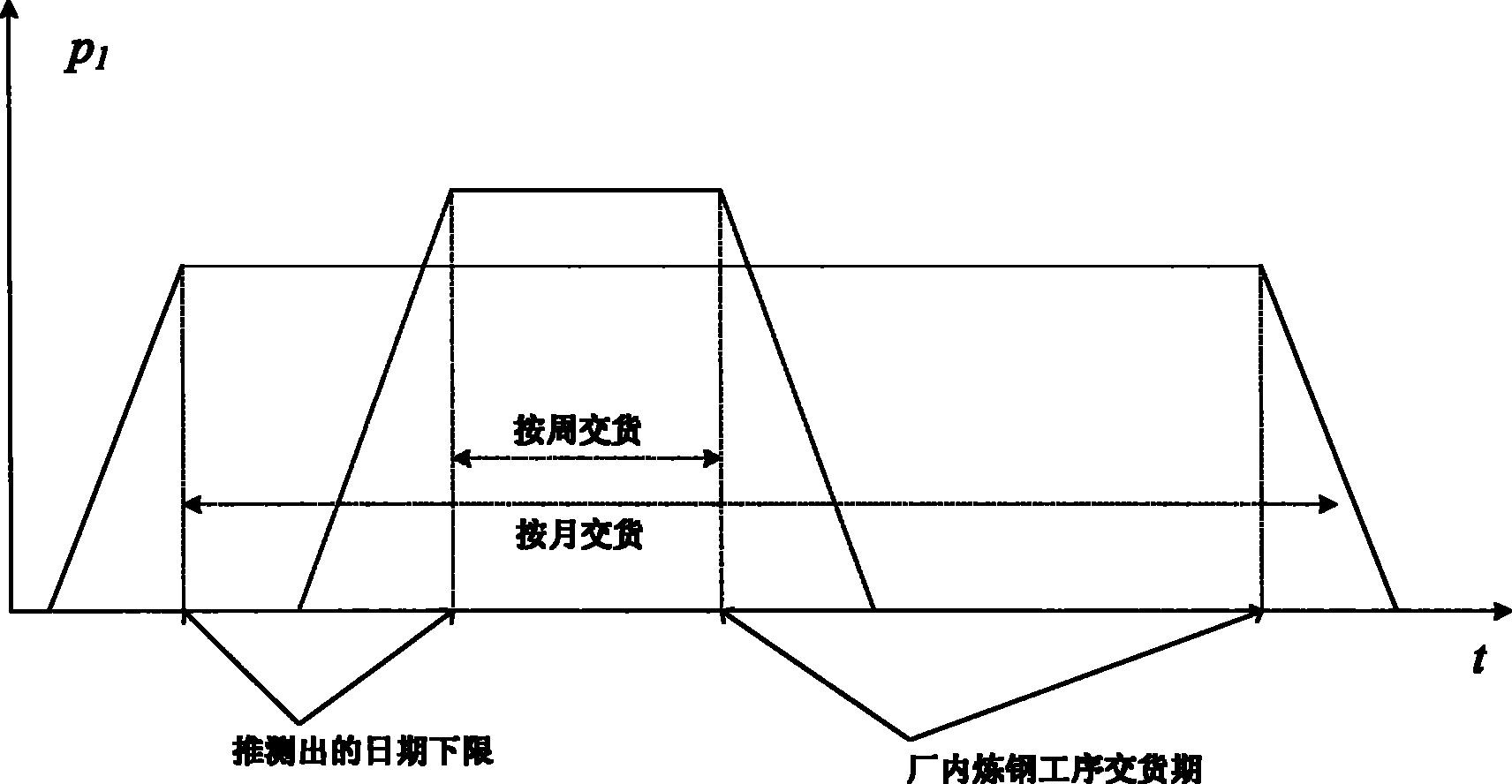

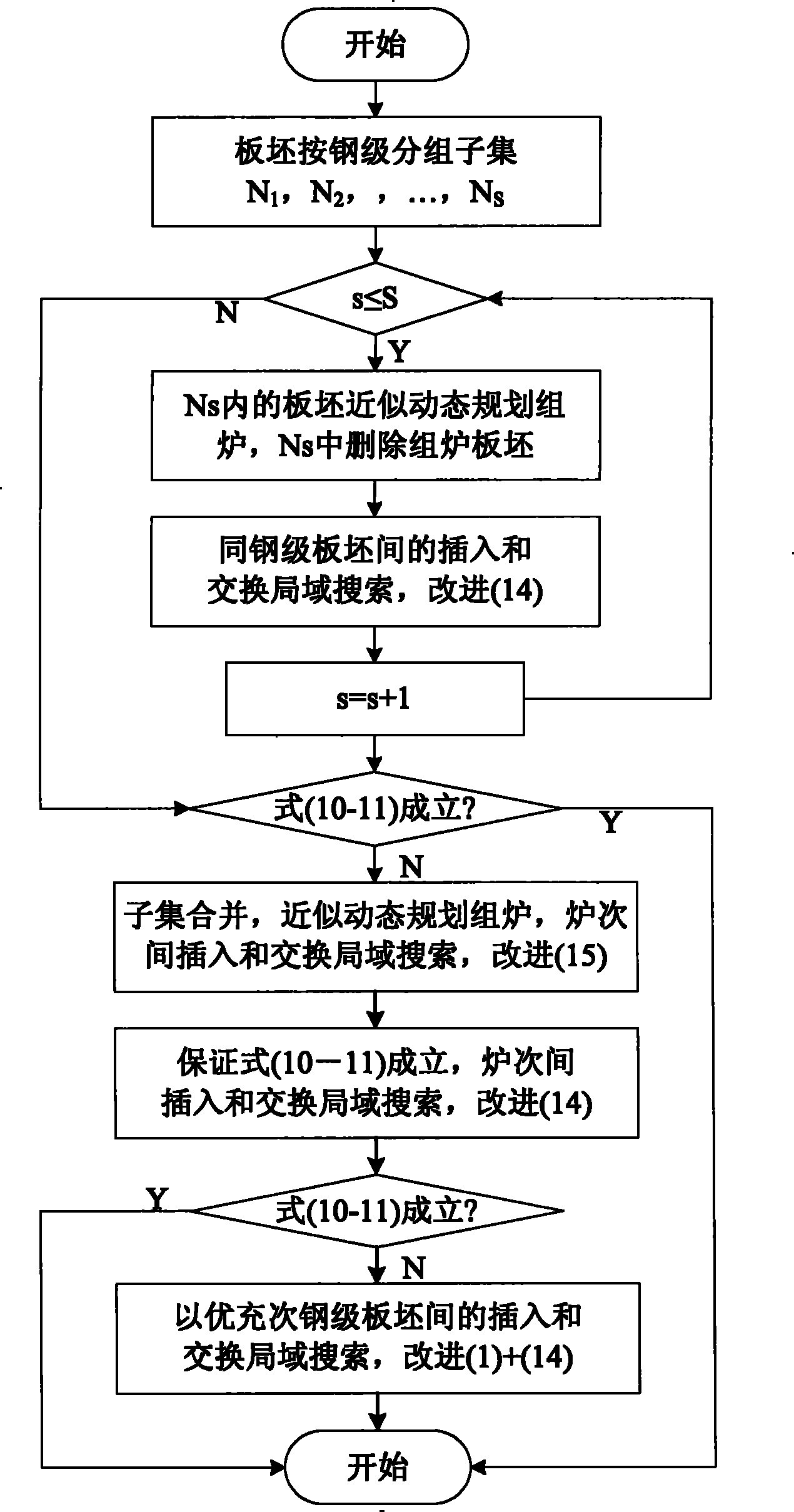

Method and system for automatically making steel-smelting continuous casting furnace sub batch plan

ActiveCN101303588AImprove scienceSolving inefficienciesTotal factory controlProgramme total factory controlSteelmakingOutcome assessment

The invention relates to an automatic planning method of a steelmaking and continuous casting heat batch plan and a system thereof, belonging to the IT field and including the following steps: 1, data collection; 2, construction of model; 3, optimization solution; 4, outcome assessment; 5, human-computer interaction; 6, sending down for executing. All indexes of the heat batch plan result obtained by adopting mathematical model and optimization algorithm of the invention are superior to that of the heat batch plan result obtained by the existing on-site manual planning pattern, in addition, the planning time (about 5 minutes) of the automatic planning method of the invention is far shorter than the planning time (about 2-3 hours) of the manual planning pattern. Therefore, the automatic planning method of the invention improves the scientificity of the traditional manual planning pattern, enhances planning level and quality, solves the problem of low efficiency in the manual planning pattern, and provides a scientific method for planning the on-line heat batch plan on a computer integrated manufacturing system in a steel enterprise.

Owner:NORTHEASTERN UNIV

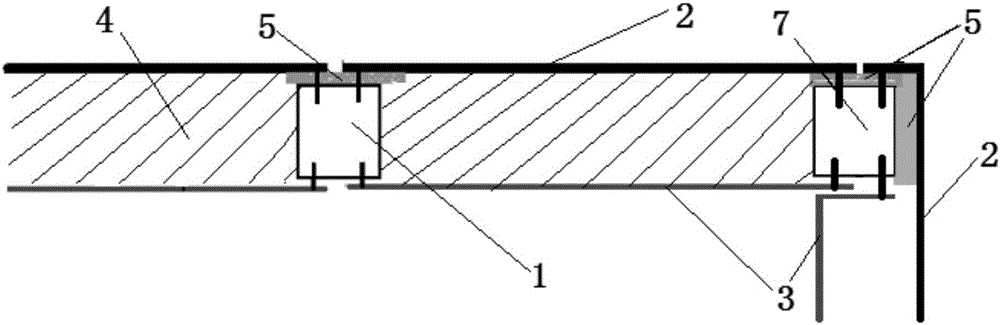

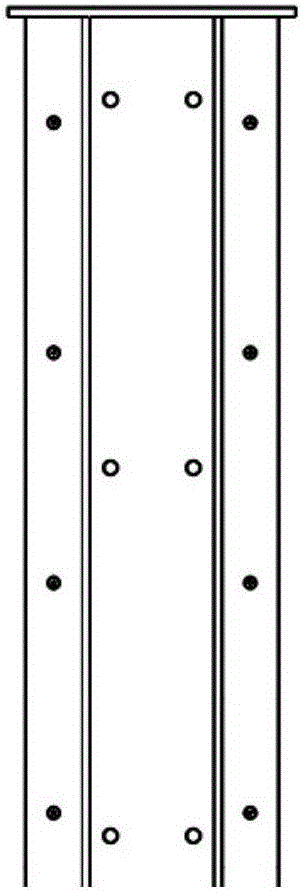

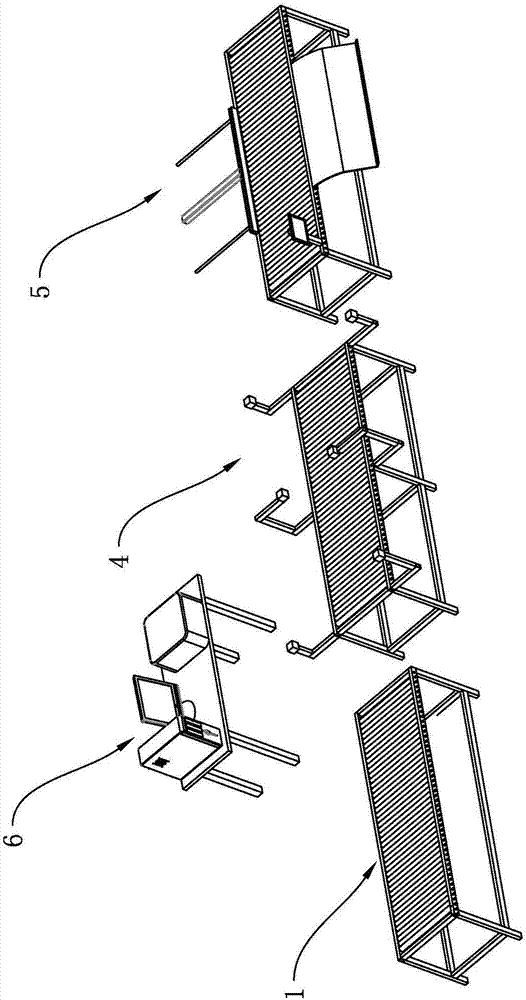

Mobile house

ActiveCN105908836AEasy to transportAvoid transportSpecial buildingHeat proofingEngineeringParallel arrangement

The invention relates to a mobile house. The house is a cabinet body; each side surface of the mobile house consists of a plurality of plate surface modules; each plate surface module comprises an outer sealing plate and an inner sealing plate in parallel arrangement; the two adjacent plate surface modules are fixed through a connecting post or an edge corner upright post; the mobile house also comprises an upper framework and a lower framework; the connecting post or the edge corer posts of the four side surfaces of the mobile house are fixed between the upper framework and the lower framework; the connecting posts positioned at the top surface of the mobile house are fixed on the upper framework; and the connecting posts positioned at the bottom surface of the mobile house are fixed on the lower framework. Compared with the prior art, the mobile house is formed through modular assembly; the dismounting and the moving can be realized through modularization; the mode of breaking up the whole into parts is adopted, so that small parts can be produced by precise metal plate processes; the precision and the anticorrosion performance are greatly improved through being compared with those of a container; and meanwhile, the appearance can be attractive.

Owner:SHANGHAI MOTTON TECH CO LTD

PVC (polyvinyl chloride) floor and production process thereof

InactiveCN102677867AAvoid yellowingReduce inventory backlogLayered productsFlooringPolyvinyl chlorideControl quality

The invention discloses a PVC (polyvinyl chloride) floor which comprises a bottom layer, a middle layer, an ink jet basic layer, an ink jet layer, a UV (ultraviolet) abrasion resistant primer layer and a UV scratch-resistant top coat layer, wherein the bottom layer, the middle layer, the ink jet basic layer, the ink jet layer, the UV abrasion resistant primer layer and the UV scratch-resistant top coat layer are successively distributed from bottom to top. The production process of the PVC floor provided by the invention comprises the steps of: a. pasting the ink jet basic layer on a composite layer formed by the bottom layer and the middle layer; b. printing the ink jet layer on the ink jet basic layer; c. roller-coating the UV abrasion resistant primer layer on the ink jet layer; d. roller-coating the UV scratch-resistant top coat layer when the UV abrasion resistant primer layer is half-dry; and e. embossing or not embossing the UV scratch-resistant top coat layer through a roller or a track. The PVC floor and production process provided by the invention have the following beneficial effects: a colour film needs not pressing and pasting at high temperature, thereby preventing the colour film from getting yellow, reducing the defects of colour film overstock and short colour film effective period in the current production process by using the ink jet layer to replace the colour film and improving the use defect that the PVC floors on the market at present can not resist scrape; and the PVC floor has easily controlled quality, saves manpower and material resources and has high production efficiency and low investment.

Owner:BAROQUE WOOD IND ZHONGSHAN CO LTD

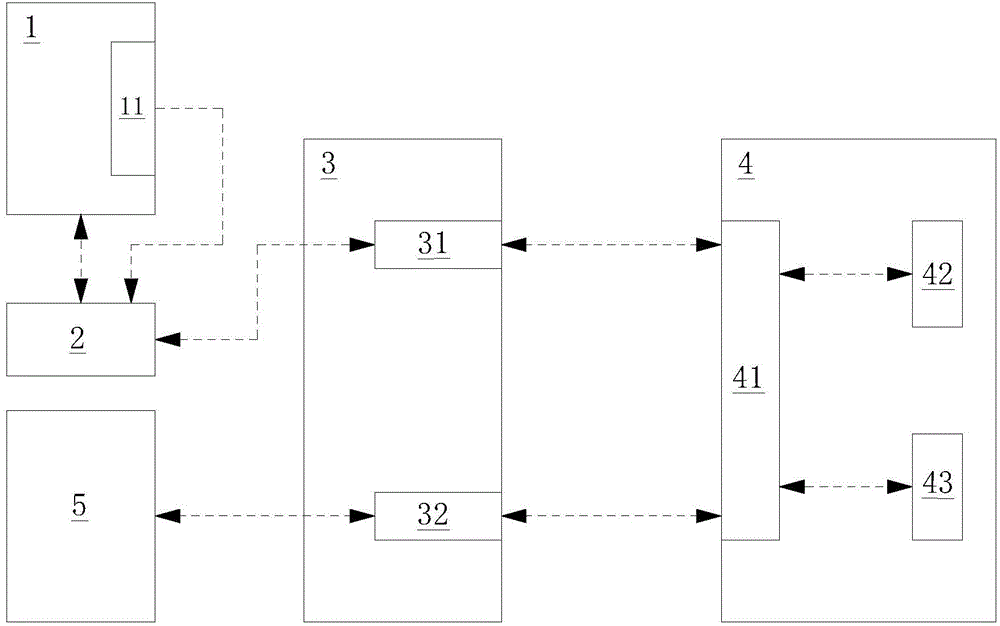

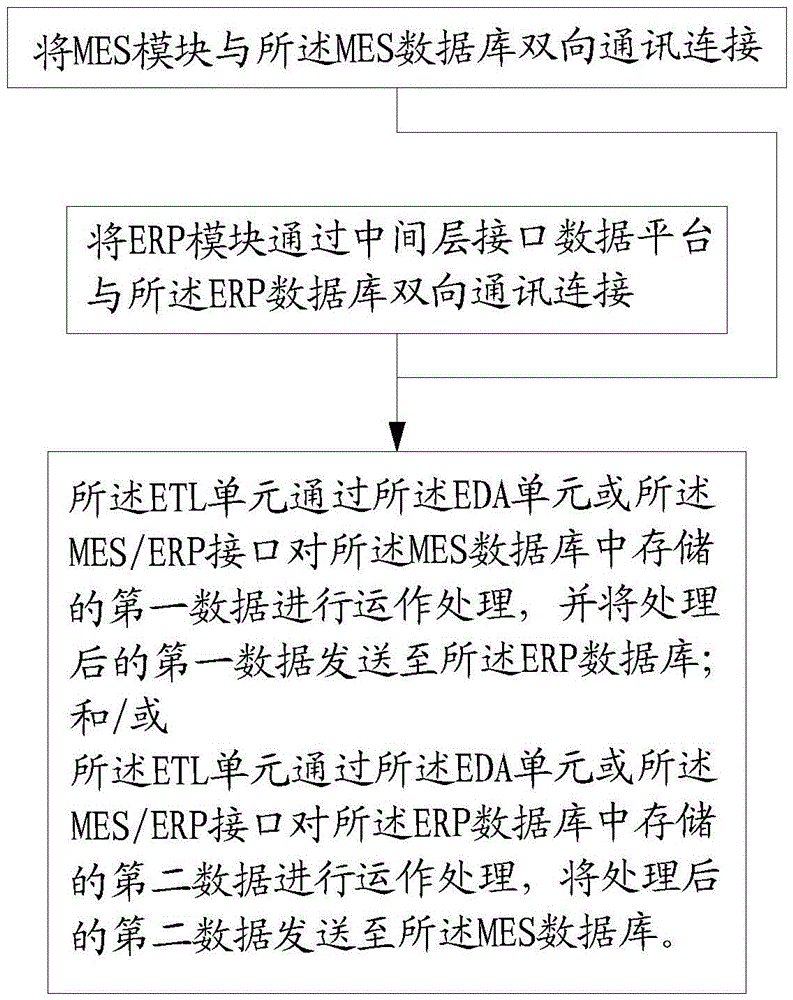

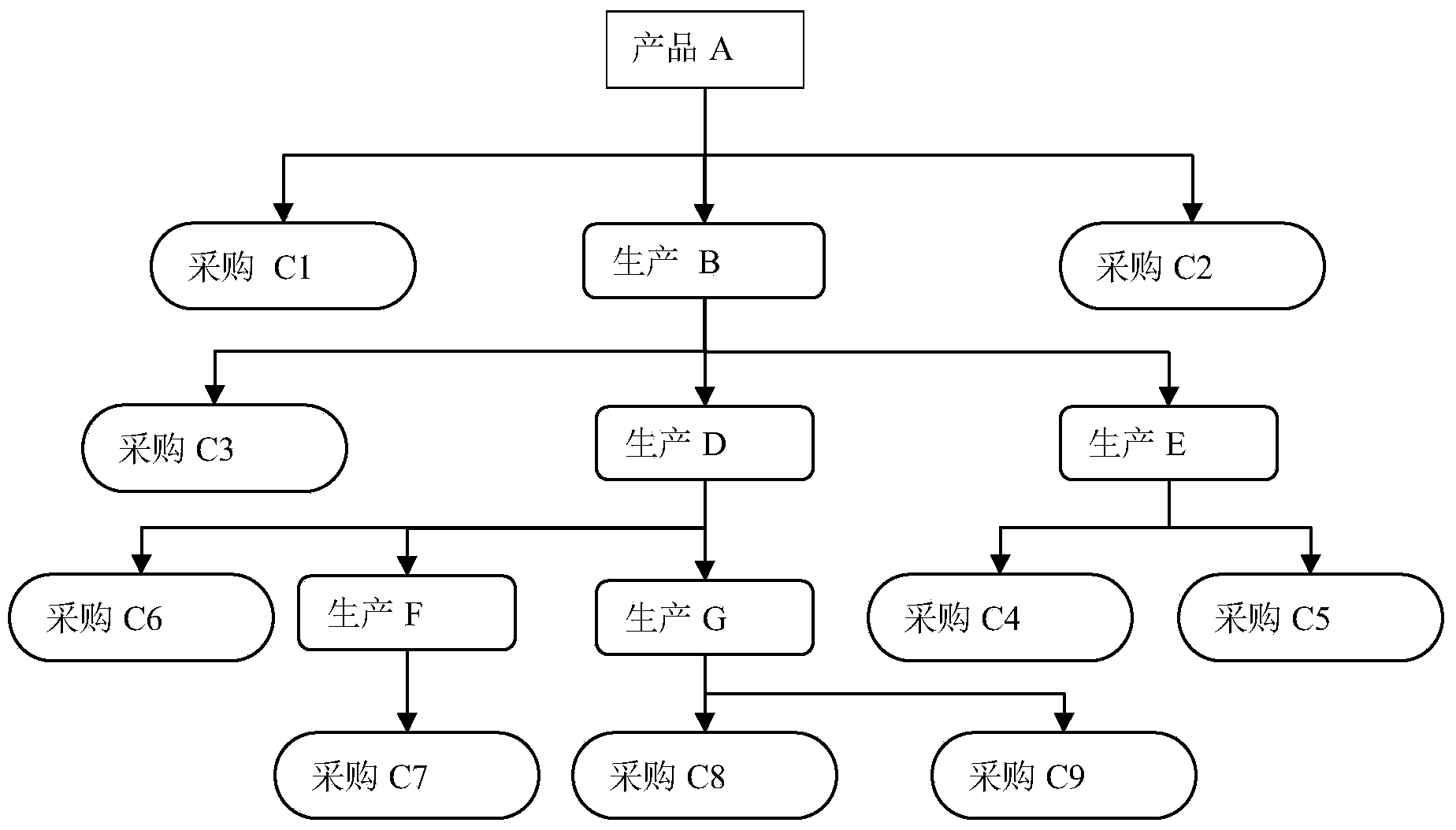

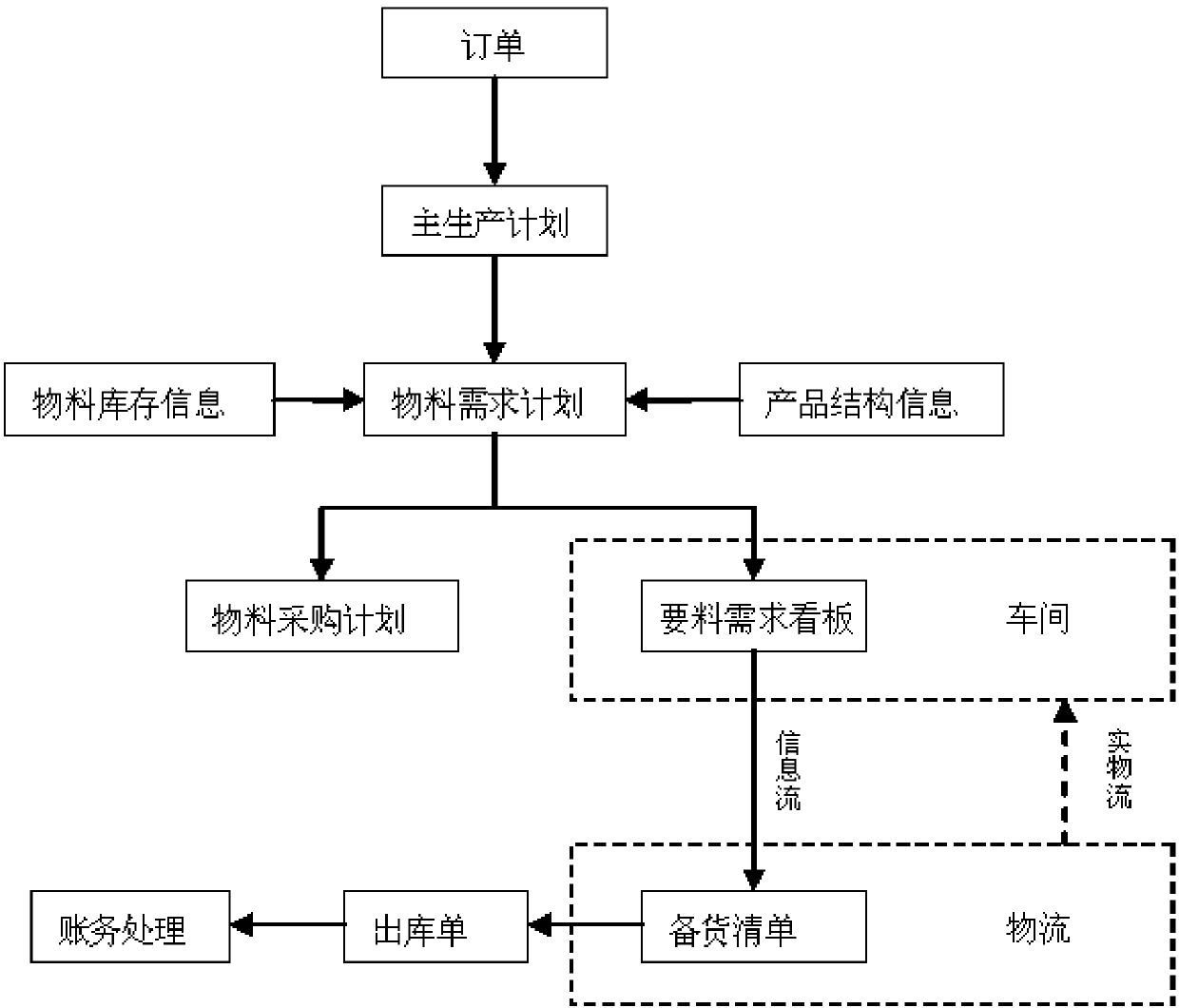

System and method for carrying out data interaction between ERP and MES

InactiveCN106709612AAchieve interactionMiniaturizationResourcesSpecial data processing applicationsProgram planningProduction planning

The invention discloses a system and method for carrying out data interaction between ERP and MES. An ERP module establishes a communication connection with an ERP database in a report module through an intermediate layer interface data platform and carries out data operation exchange operation on an ERP database and an MES database in the report module by using an EDA unit and / or an MES / ERP interface, thus the data interaction between an MES system and an ERP system is realized, and the MES system can timely respond to the order issued by the ERP system so as to reduce receivable risk. Time can be saved and timely delivery is achieved, and inventory backlog is reduced. A raw material purchasing plan, a delivery plan and a production plan can be automatically produced, thus the finished inventory is effectively controlled, and the dynamic inventory miniaturization is realized. At the same time, the MES system also can timely feed production related information to the ERP system so as to effectively manage enterprise self-production service and entrusted external processing service.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

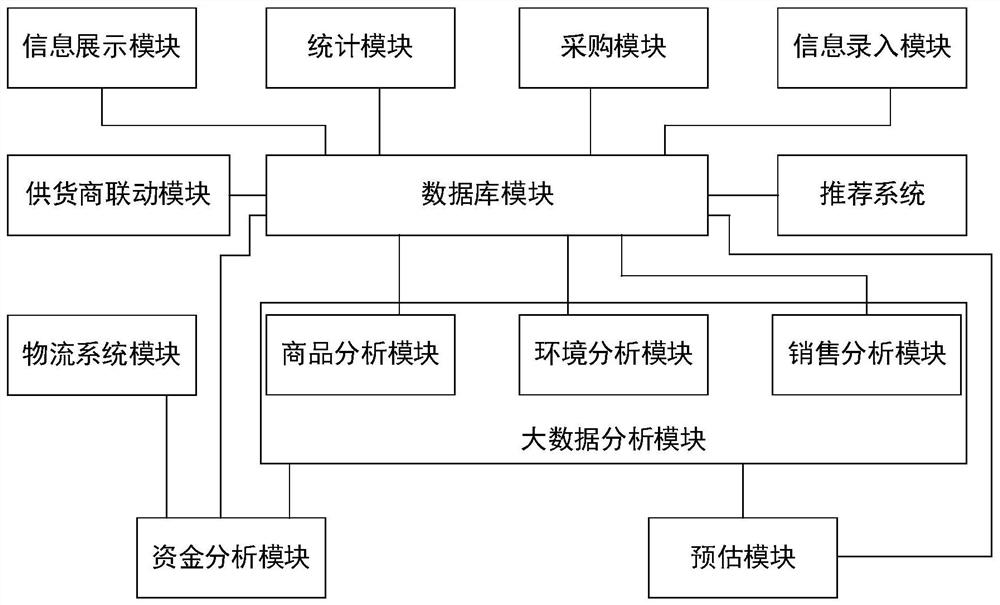

E-commerce platform inventory management system

PendingCN112541723AEasy to predictImprove intelligenceBuying/selling/leasing transactionsLogisticsLogistics managementInformation presentation

The invention relates to the technical field of e-commerce platforms, in particular to an e-commerce platform inventory management system. The system comprises a database module, an information display module, an information input module, a purchasing module and a statistics module, the database module is used for storing all data of an inventory management system, the information display module is used for displaying current commodity inventory information, the information input module is used for inputting commodity information, and the purchasing module is used for increasing the inventoryquantity of purchased commodities, wherein the statistics module is used for calculating the warehouse-out amount and the inventory remaining amount, the system further comprises a supplier linkage module and a logistics system module, the supplier linkage module is used for carrying out network information combination with a supplier and mastering commodity information of the supplier in time through information combination, and the logistics system module is used for tracking and recording logistics information of sold commodities, inventory can be comprehensively managed, the intelligent level of inventory management is improved, and therefore an auxiliary function is well provided for arrangement and management of an e-commerce platform.

Owner:余明华

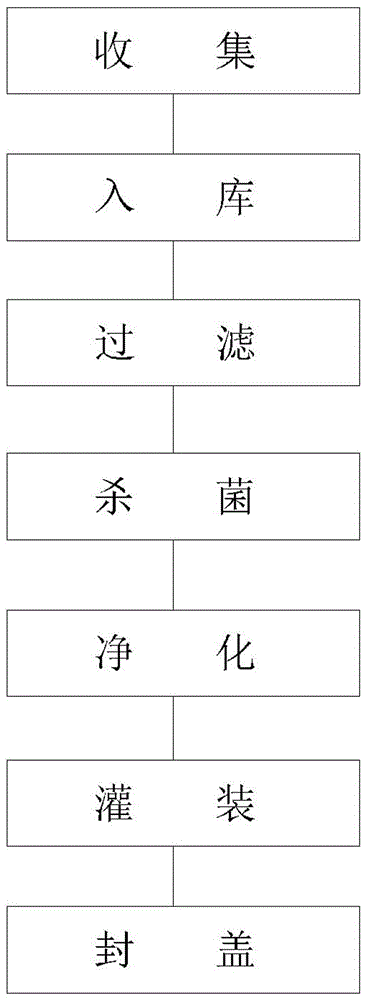

NFC fresh fruit and vegetable juice

The invention relates to NFC fresh fruit and vegetable juice, and belongs to the technical field of agricultural product deep processing. The NFC fresh fruit and vegetable juice comprises fruit juice and vegetable juice and is characterized in that the fruit juice is apple juice or kiwi-fruit juice or banana juice or grape juice or lemon juice or orange juice or the combination of the apple juice, the kiwi-fruit juice, the banana juice, the grape juice, the lemon juice and the orange juice; the vegetable juice is cucumber juice or lettuce juice or celery juice or carrot juice or ginger juice or tomato juice or the combination of the cucumber juice, the lettuce juice, the celery juice, the carrot juice, the ginger juice and the tomato juice, and the fruit juice and the vegetable juice are mixed according to a certain proportion. According to the scheme, the rich taste and comprehensive nutrition of the product are improved.

Owner:德清秋水果汁有限公司

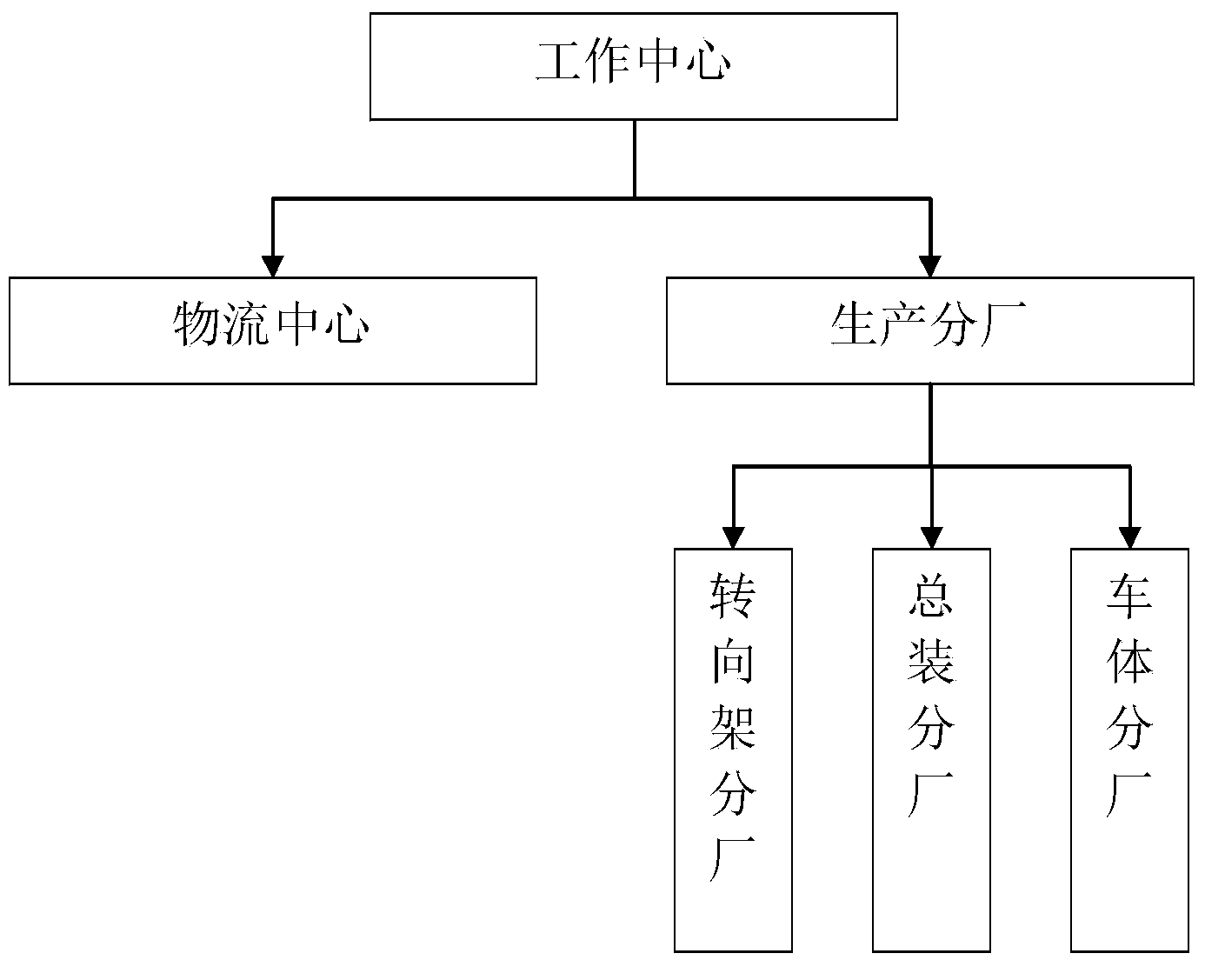

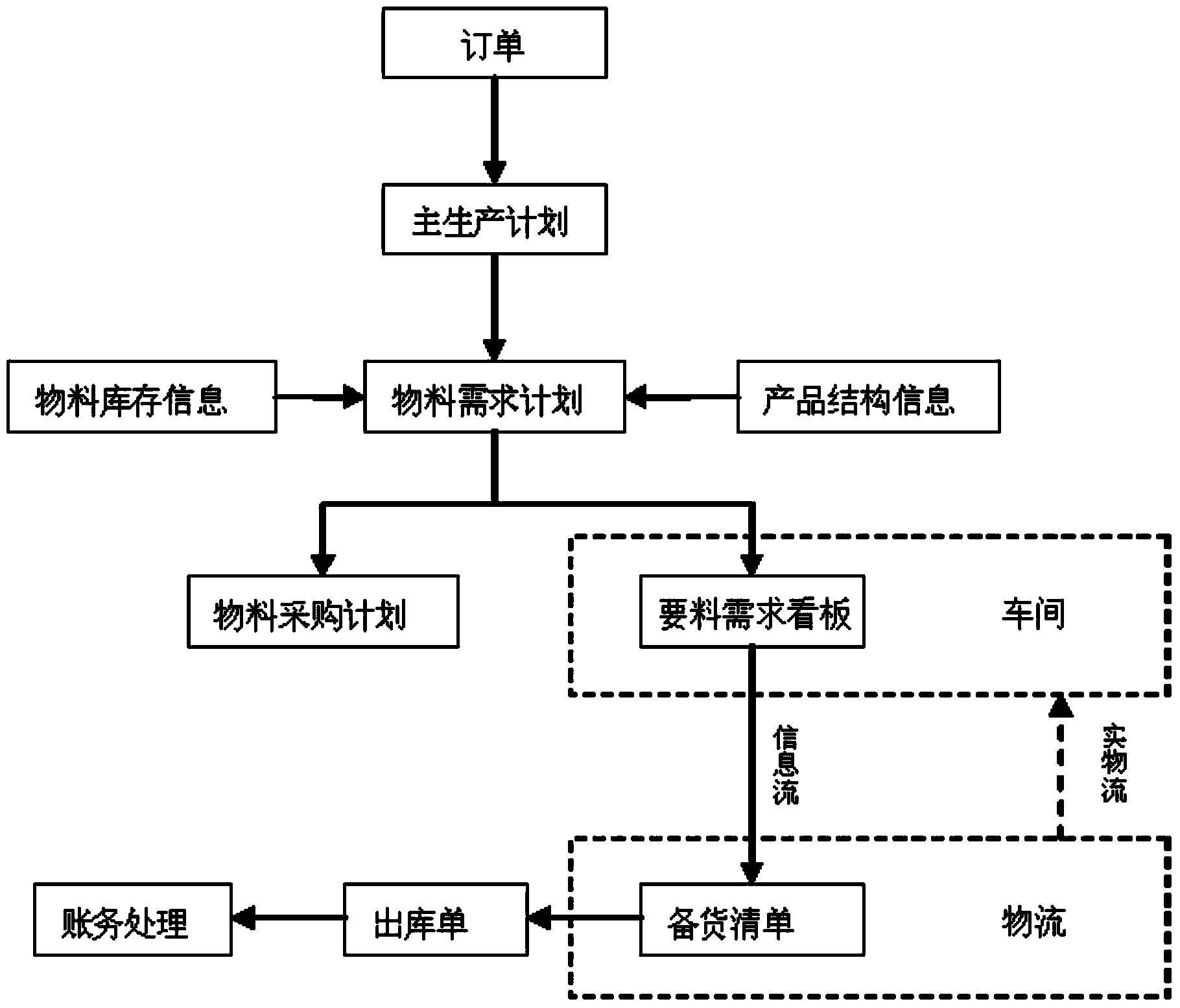

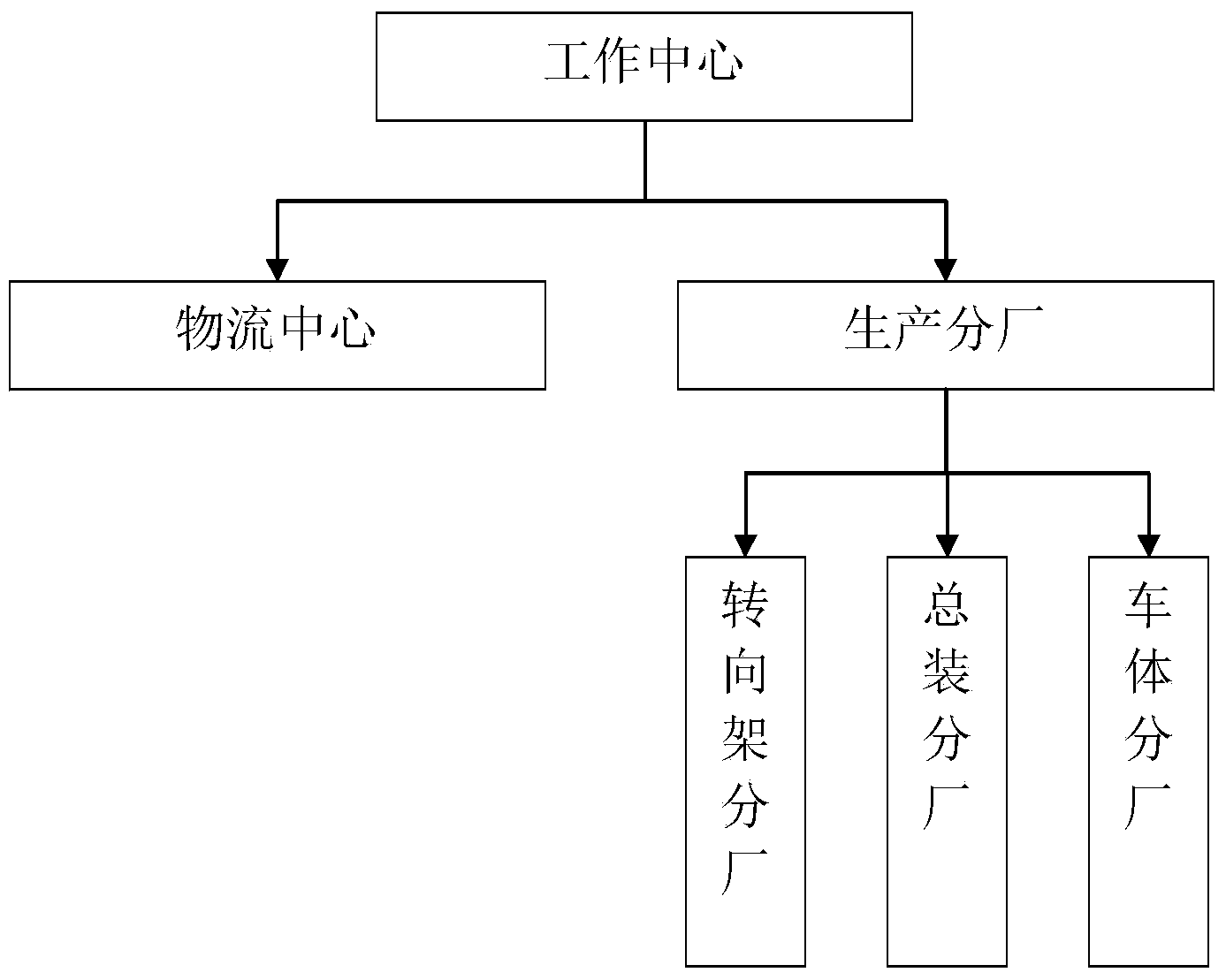

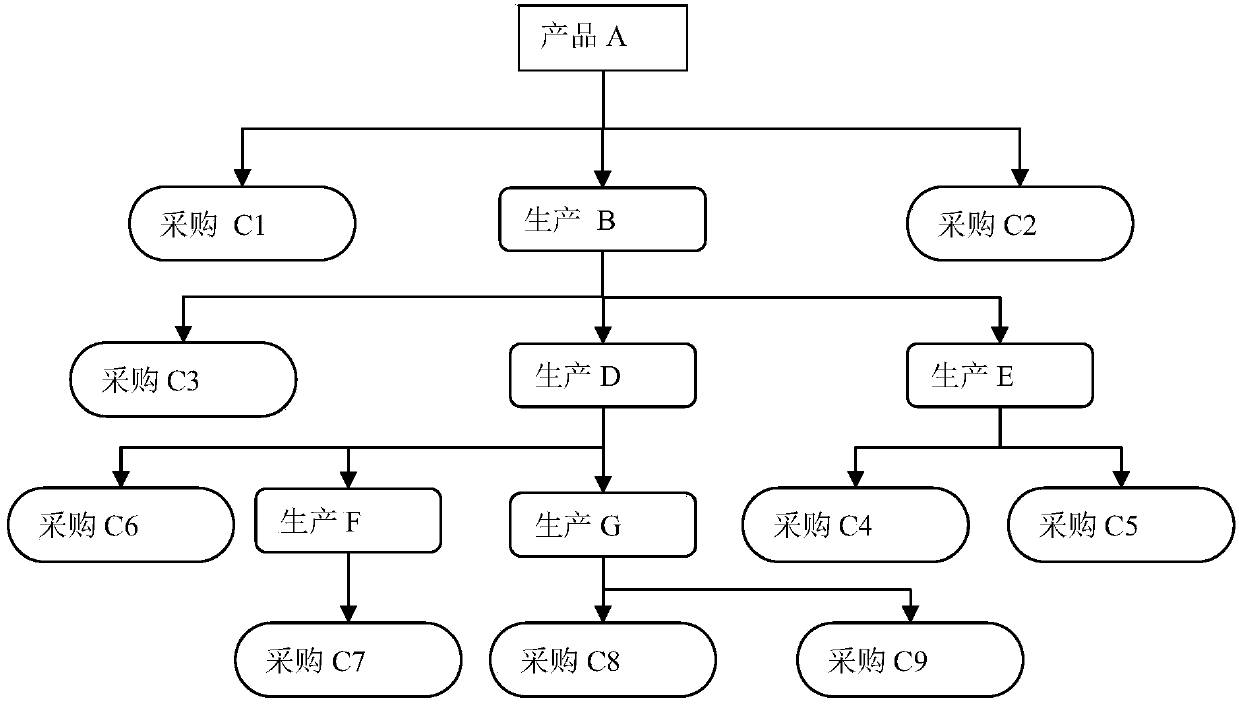

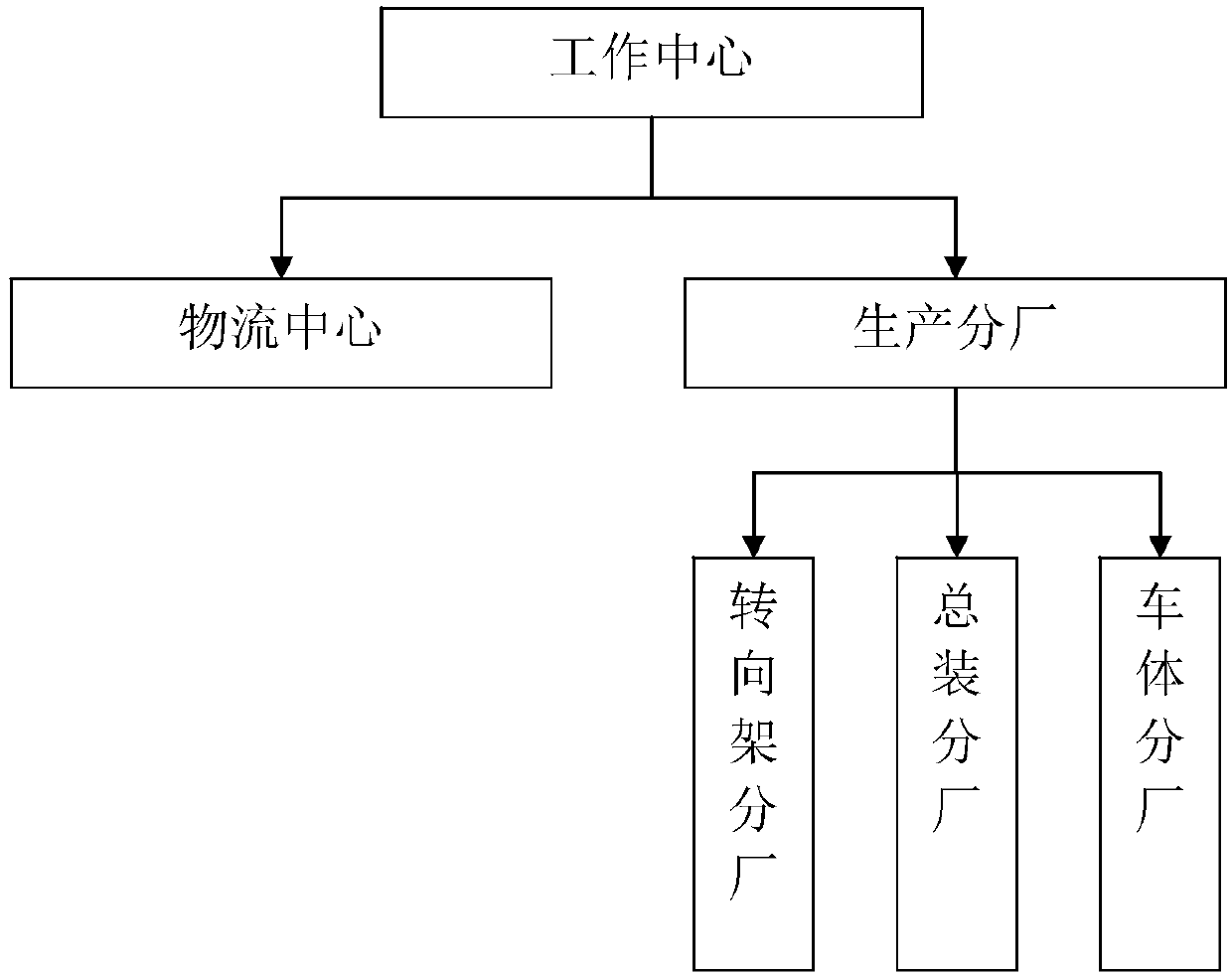

Lean logistics implementation method based on display board

ActiveCN104252671ASolve the contradiction between supply and demandShort delivery timeLogisticsManufacturing computing systemsDisplay boardLogistics management

The invention provides a lean logistics implementation method based on a display board. The lean logistics implementation method comprises the following steps: the display board with material requirements is generated by materials in production orders or three days plans through adopting a parallel processing technology according to the processes and the team and group information. 20 to 30 jobs are defined according to the data volume needing to be calculated, each job is defined with a job name, the job names are circularly distributed for all the order processes according to the defined job quantity, and when a job is operated, only data which is the same as the job name running at present are taken; meanwhile, in order to make the most of server resources, weights are distributed according to the job centers, and the weights are in proportion to the data volume and the total quantity of the job centers; when the generated board details are run, due to larger data volume, data insertion and calculation of the board are executed and computed in background, and therefore, time difference exists with actual business, that is, discrepant data exists. The computational identifications are provided for data of the to-be-generated board with material requirements.

Owner:CRRC QINGDAO SIFANG CO LTD

Template automatic deployment system, method, device and readable storage medium

The invention discloses a template automatic deployment system, method and a device, and a readable storage medium. The template automatic deployment system comprises a deployment platform, purchaser computers, a plurality of manufacturer computers and a storage goods supply area; wherein the deployment platform comprises a database server, an Internet service and function control service device and a template automatic generation server; the purchaser computers are used for sending purchase orders and engineering design drawings to the database server; the plurality of manufacturer computers are used for storing production data of template sub-orders, wherein the production data include categories, number data corresponding to the categories and data which are used for generating identification codes provided for each template unit in template processing; the storage goods supply area is used for generating a plurality of rectangular regions, loading and unloading the templates of sub-orders which are transferred to corresponding rectangular regions by a plurality of manufacturers and providing loading devices and unloading devices in the rectangular regions.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

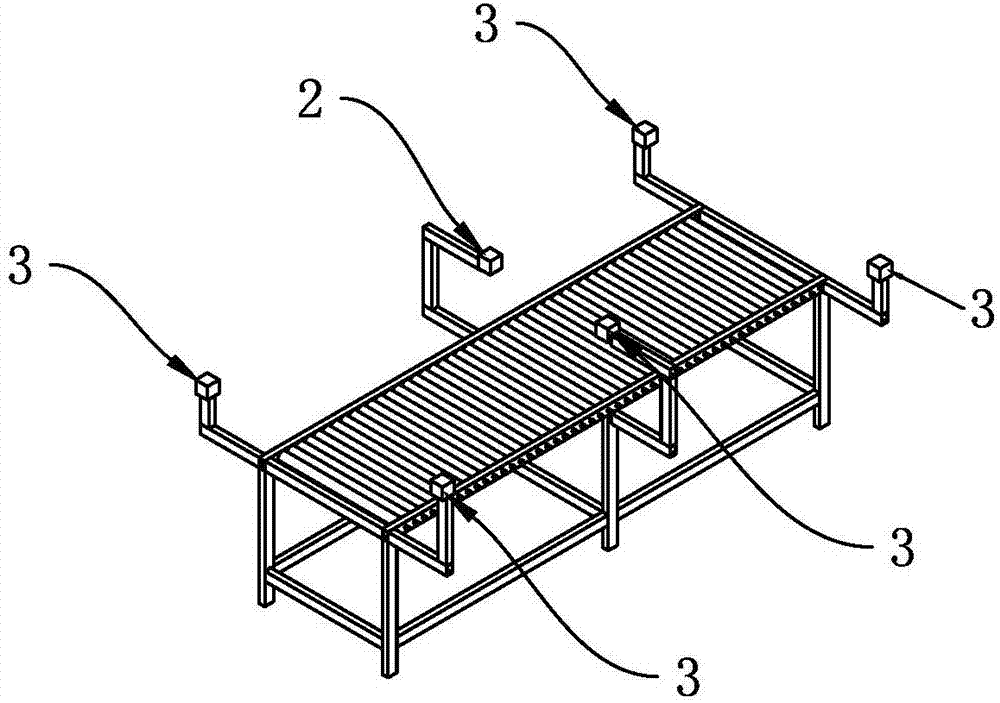

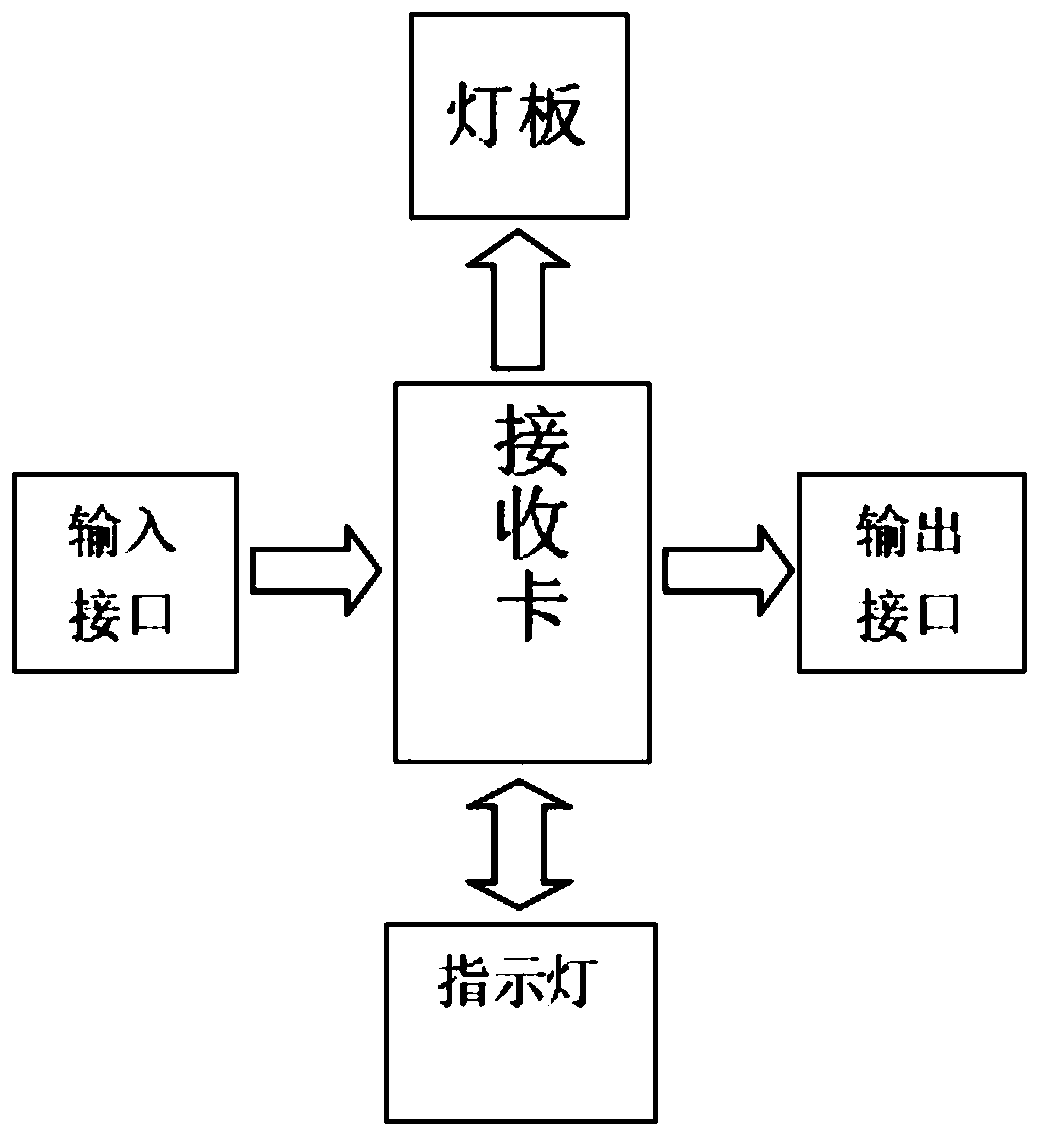

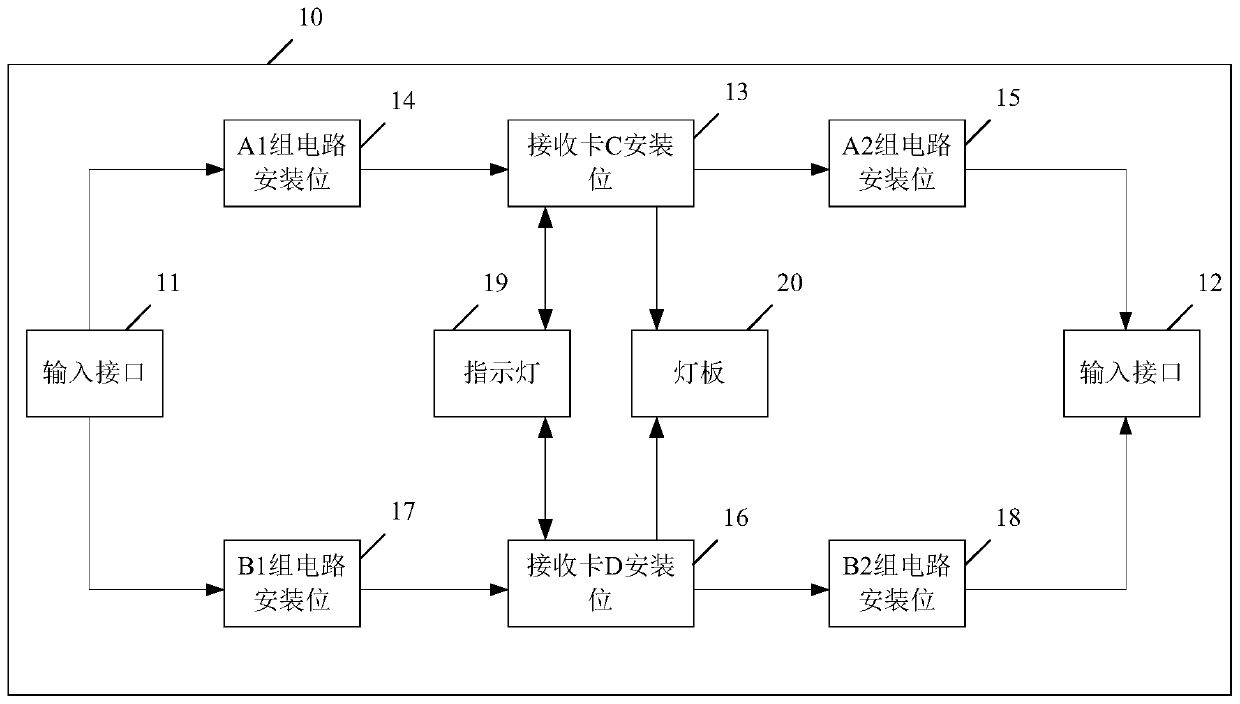

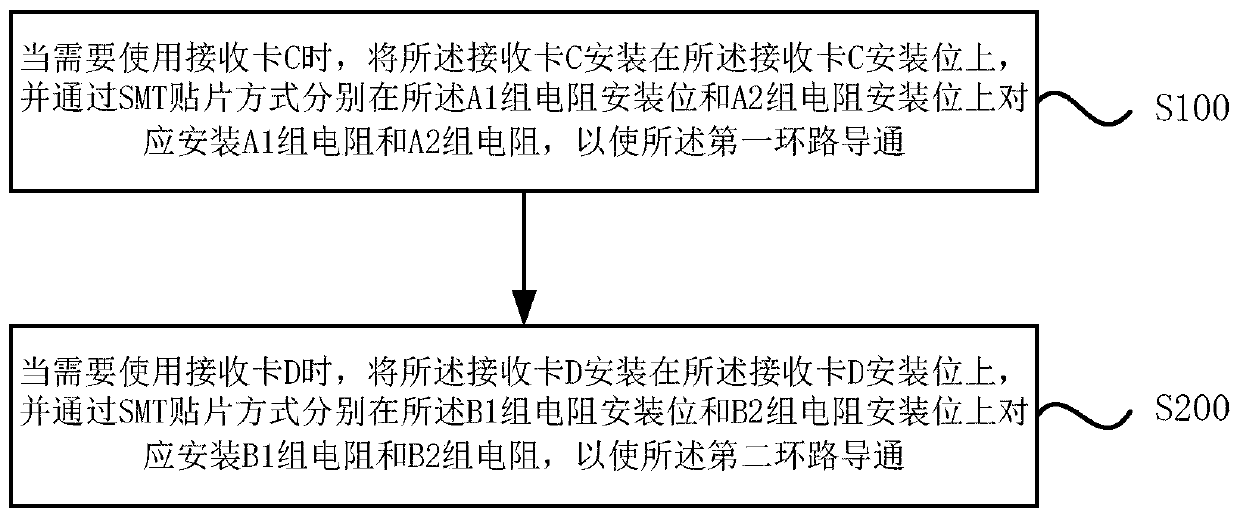

Universal HUB board for LED display screen and card selection method

The invention discloses a universal HUB board for an LED display screen and a card selection method. The HUB board comprises an HUB board body, and the HUB board body is provided with an input interface, an output interface, a receiving card C mounting position, an A1 group of resistor mounting positions, an A2 group of resistor mounting positions, a receiving card D mounting position, a B1 groupof resistor mounting positions, a B2 group of resistor mounting positions, an indicator lamp and a lamp panel. According to the universal HUB board for the LED display screen and the card selection method, on the premise that the display effect is guaranteed, two different types of receiving cards can be selectively installed on the same HUB board, inventory overstocking and resource waste of theHUB board are reduced, and therefore enterprise cost is reduced.

Owner:AET DISPLAY LTD

Method for improving alcoholysis degree of polyvinyl alcohol product

The invention relates to a method for improving the alcoholysis degree of a polyvinyl alcohol (PVA) product. The method is carried out according to the following steps: putting the polyvinyl alcohol product with the alcoholysis degree which is smaller than or equal to 99.8% into methanol and immersing; after the product is swollen, adding an NaOH methanol solution; carrying out a saponification and alcoholysis reaction again; conveying polyvinyl alcohol particles subjected to saponification and alcoholysis into a presser and a dryer in sequence; and pressing and drying to improve the alcoholysis degree of the raw material of the polyvinyl alcohol product. The method provided by the invention can be used for changing the alcoholysis degree of the PVA product so as to change the mark of the PVA product; and furthermore, the stock can be effectively reduced and market requirements are met very well.

Owner:CHINA PETROCHEMICAL CORP +1

Lean logistics system based on spectaculars

ActiveCN104268733ASolve the contradiction between supply and demandShort delivery timeLogisticsLogistics managementParallel processing

The invention provides a lean logistics system based on the spectaculars. According to the system, generation of the material demand spectaculars is achieved through materials in a production order or three-day schedule by means of the parallel processing technique according to working procedure and team information, 20-30 tasks are defined according to the data size to be calculated, a name is assigned to each task, task names are allocated to all the order procedures in a circulating mode according to the defined task number, and only data corresponding to the name of the task operating currently are used during working; meanwhile, to utilize server resources to the maximum, weight allocation is conducted according to the work center, and the weight and work center data size is in direct proportion to the total number; during spectaculars detail generation, due to the large data size, data insertion and calculation of the spectaculars are both conducted through background jobs, and in this way, time difference exists compared with actual business, and it also means that discrepant data exist. According to the system, operation identification is added to the data of the material demand spectaculars to be generated.

Owner:CRRC QINGDAO SIFANG CO LTD

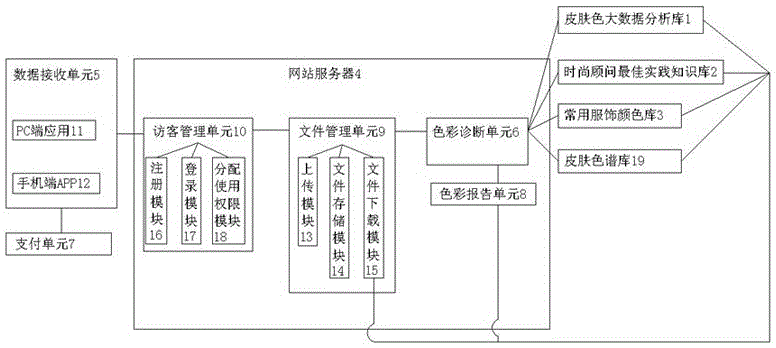

Image processing, big data analysis and knowledge base-based internet personal fashion color diagnosis method

InactiveCN106649700AImprove appreciationImprove matching efficiencyImage analysisAdvertisementsResource utilizationThe Internet

The invention discloses an image processing, big data analysis and knowledge base-based internet personal fashion color diagnosis method. The method involves a skin color big data analysis library, a skin color spectrum library, a fashion consultant optimal practice knowledge base, a common clothing color library, a website server, a data receiving unit and a payment unit, wherein the website server comprises a visitor management unit, a file management unit, a color diagnosis unit and a color reporting unit; the data receiving unit, the visitor management unit, the file management unit, the color diagnosis unit and the color reporting unit are connected in sequence; and the color diagnosis unit is connected with the skin color big data analysis library, the fashion consultant optimal practice knowledge base, the skin color spectrum library and the common clothing color library. According to the method, a customer can know own fashion color and style gene attribute, and find a color matching law most suitable for him, so that the shopping time of the customer is saved, the inventory backlog of an enterprise is reduced, and social resource utilization is optimized.

Owner:杨方

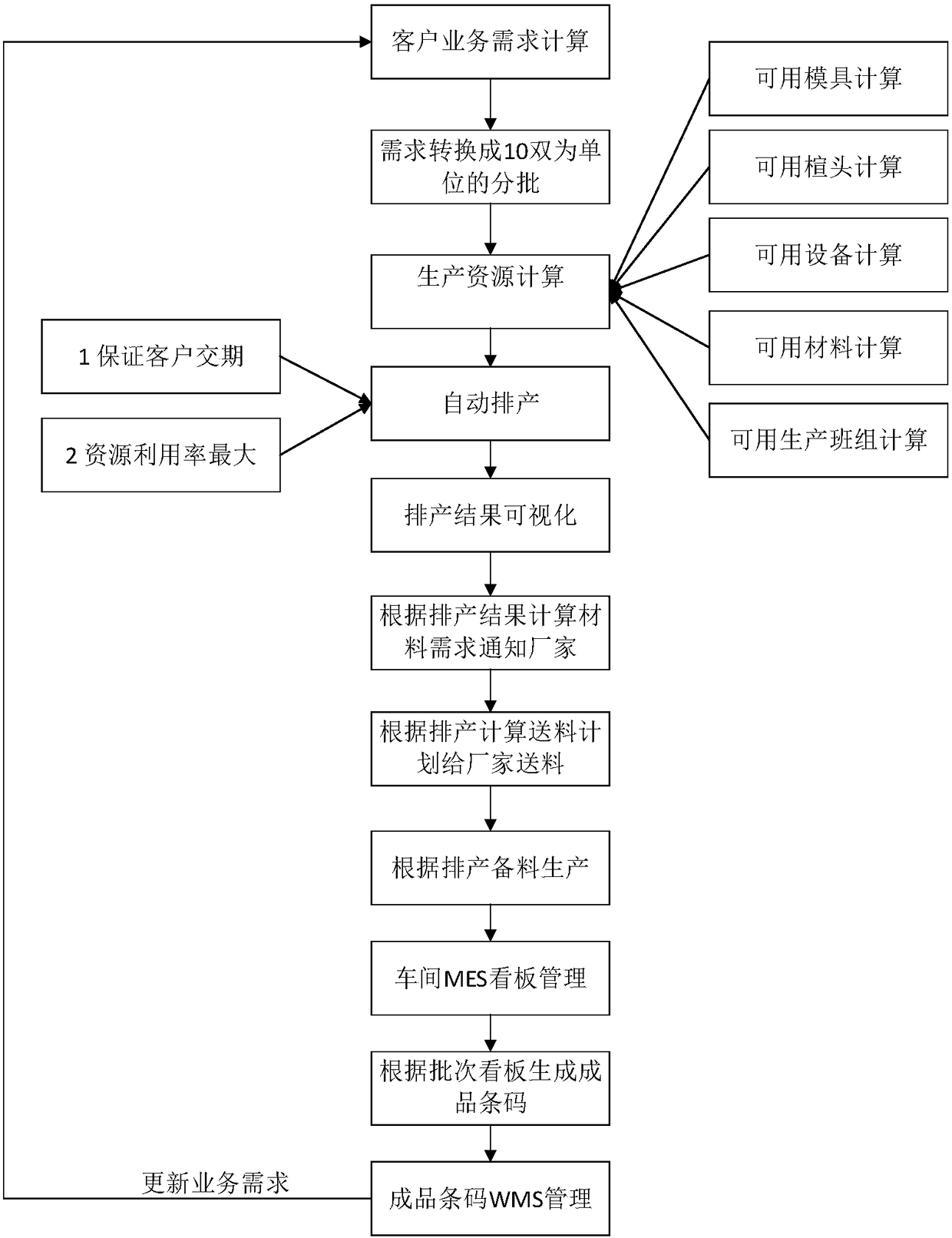

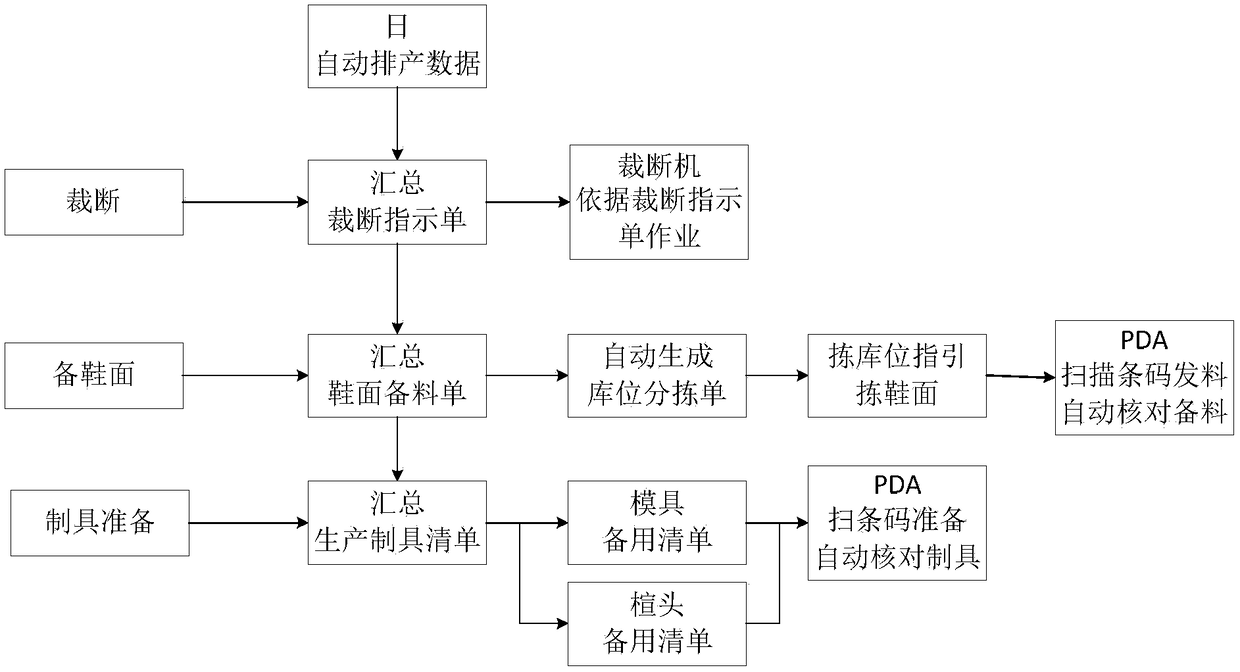

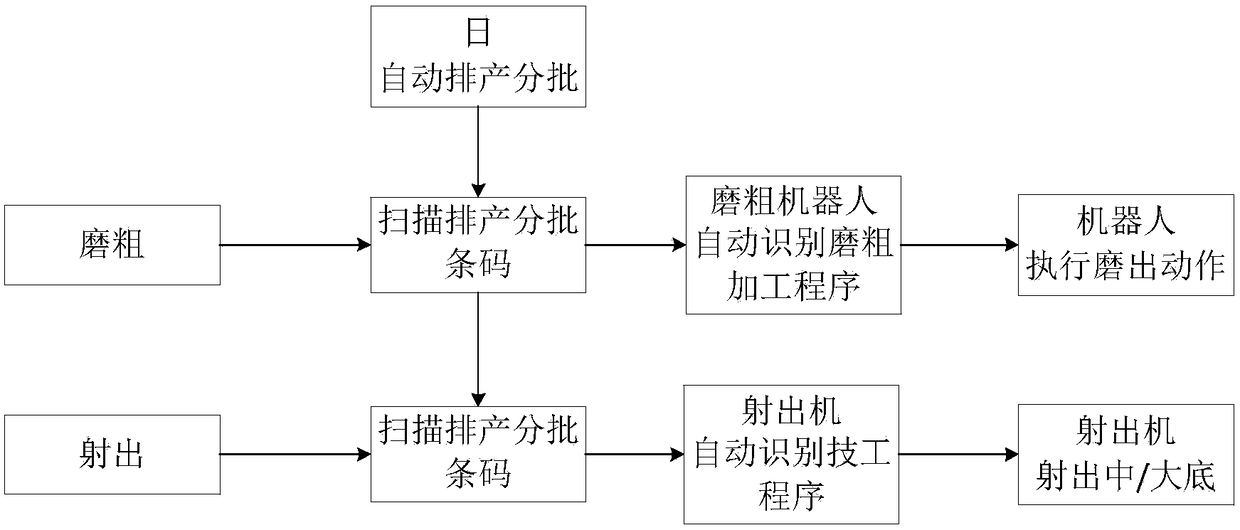

Automatic production scheduling method based on shoes taking 10 pairs as batch

InactiveCN108510190AReduce inventory riskReduce inventory backlogResourcesManufacturing computing systemsResource utilizationComputer science

The invention discloses an automatic production scheduling method based on shoes taking 10 pairs as a batch. The method comprises the steps of automatic production scheduling calculation, previous preparation of production, the production on a machine and discharging. The method disclosed by the invention has the advantages that by dividing orders and taking every 10 pairs of shoes as a productionbatch, automatic production scheduling is realized through big data analysis batch; the resource utilization rate is maximized; the JIT (Just-In-Time) supply of supplier materials is realized; the inventory risk of factories and suppliers is greatly reduced; the efficiency of molds, shoe lasts, personnel and machinery equipment is utilized to the maximum limit; materials are fed as required in the production scheduling to reduce the inventory backlog; and every 10 pairs of shoes is taken as a batch at the production site, so that the production progress is in real time and the generation adjusting is flexible.

Owner:DONGGUAN ZUNRONG SHOES

A Kanban-based Lean Logistics System

ActiveCN104268733BSolve the contradiction between supply and demandShort delivery timeLogisticsLogistics managementOrder form

The present invention provides a lean logistics system based on kanban, which includes: using parallel processing technology to generate a material demand kanban based on materials in production orders or three-day plans according to process and team information. The present invention calculates as needed The data volume defines 20-30 jobs, defines a job name for each job, and all order processes are cyclically assigned job names according to the defined number of jobs. When running a job, only data with the same name as the currently running job is taken; at the same time , in order to maximize the use of server resources, weights are allocated according to work centers. The weights are proportional to the data volume of the work center and the total quantity; when running to generate Kanban details, due to the large amount of data, the data insertion and calculation of the Kanban are done in the background The job execution calculation means that the time difference between the actual business and the actual business also means that there is discrepancy in data. The present invention adds an operation identifier to the data to be generated on the material demand board.

Owner:CRRC QINGDAO SIFANG CO LTD

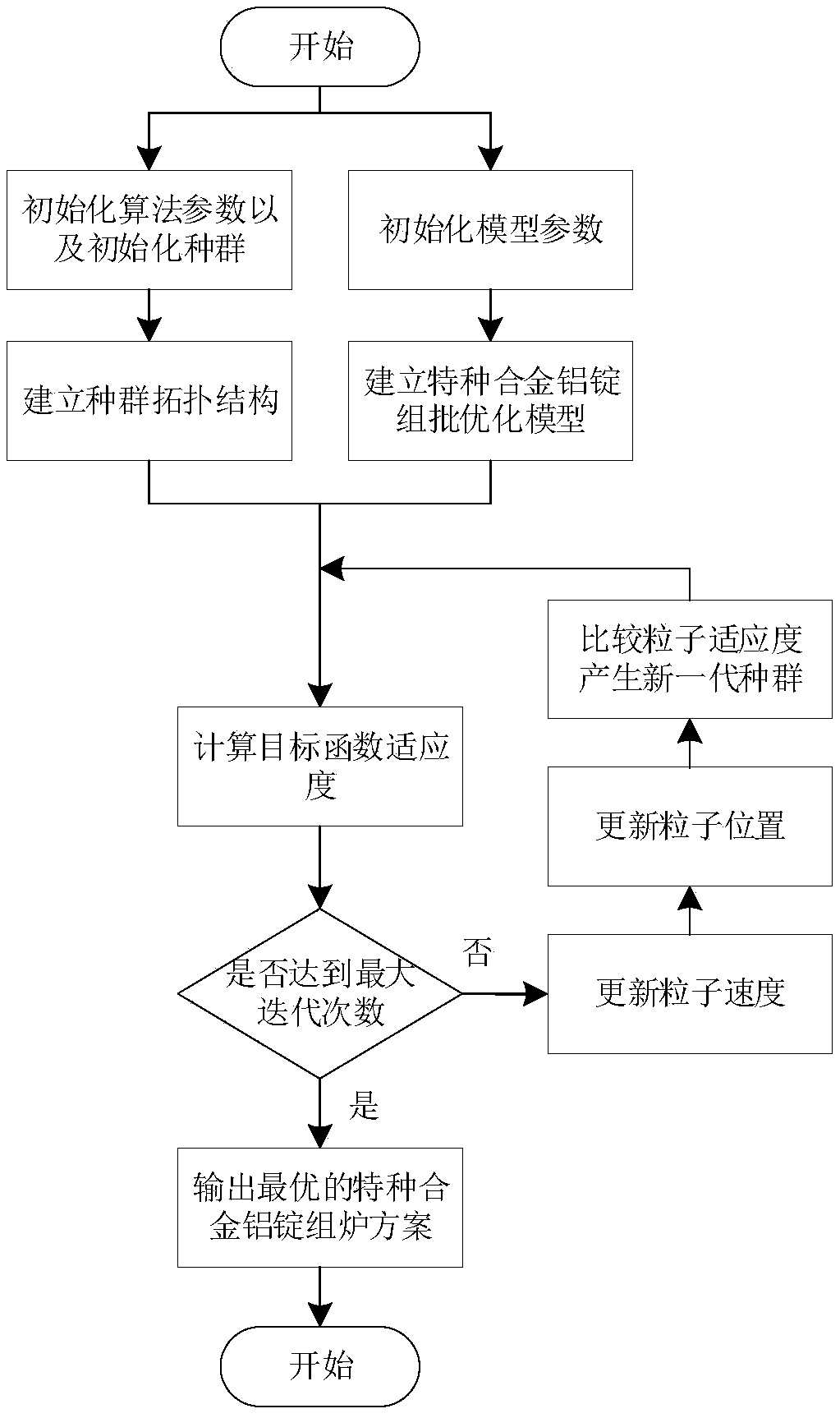

Furnace assembling method for special alloy aluminum ingot production

PendingCN111445050AStrong global search capabilityFast convergenceForecastingManufacturing computing systemsMetallurgyParticle swarm algorithm

The invention relates to a furnace assembling method for special alloy aluminum ingot production. The furnace assembling method comprises the following steps: setting an alloy aluminum ingot furnace assembling scheme as particles; establishing an optimization objective function of an alloy aluminum ingot furnace, and calculating an objective function value by adopting a particle swarm algorithm toserve as the fitness of particles; and optimizing the alloy aluminum ingot furnace assembling scheme through iteration to obtain a final furnace assembling scheme; establishing a furnace assembling model, designing an algorithm with high global search capacity, high convergence rate and high solving precision, achieving automatic calculation of a computer. The furnace assembling efficiency of thespecial alloy aluminum ingots is greatly improved, and the working intensity of planners is reduced; and compared with a manual furnace assembling result, the furnace assembling rate and the metal occupancy ratio are increased, the furnace number is reduced, generation of waste is effectively reduced, inventory overstock is reduced, and consumption reduction and efficiency improvement of enterprises are achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

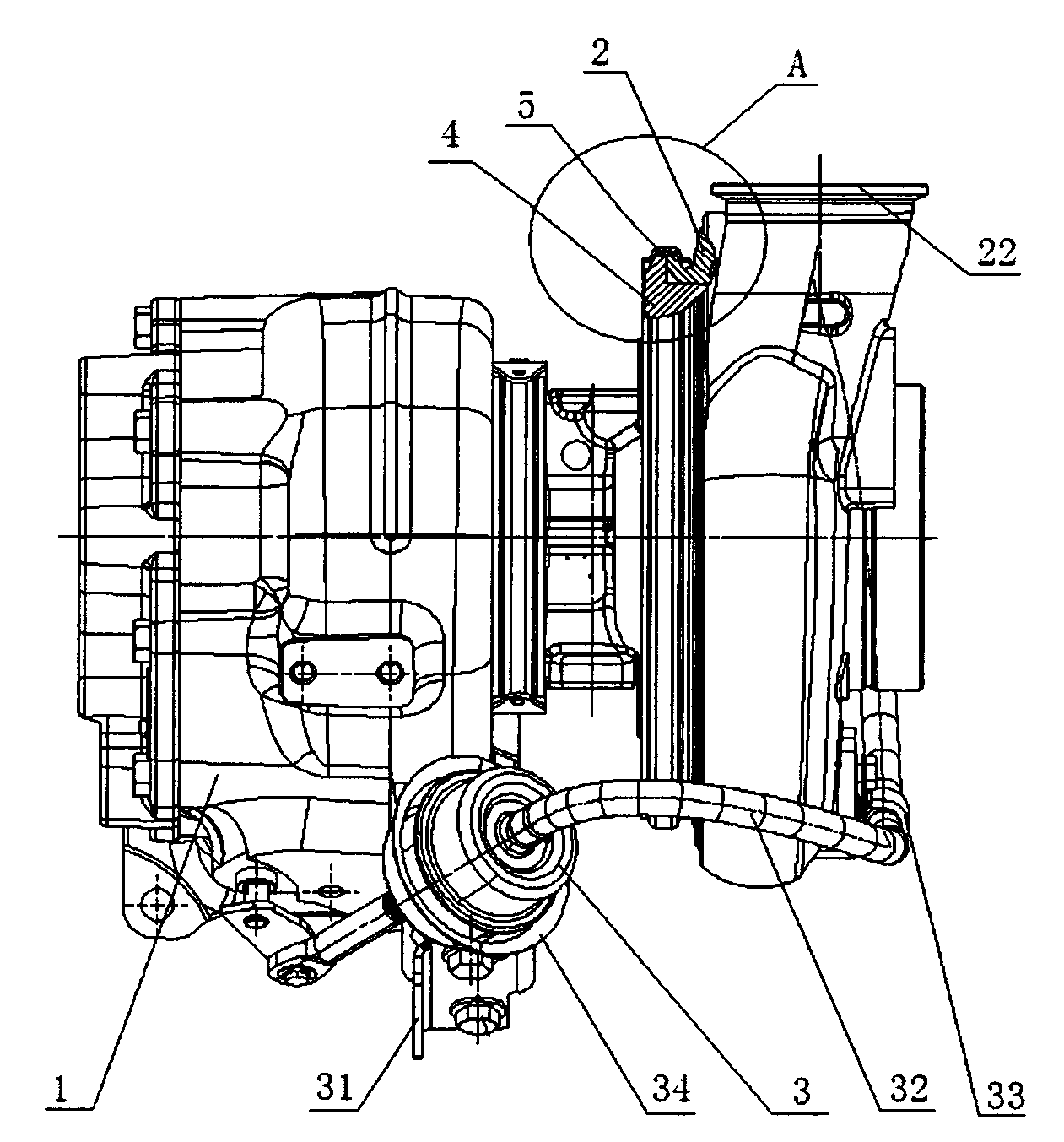

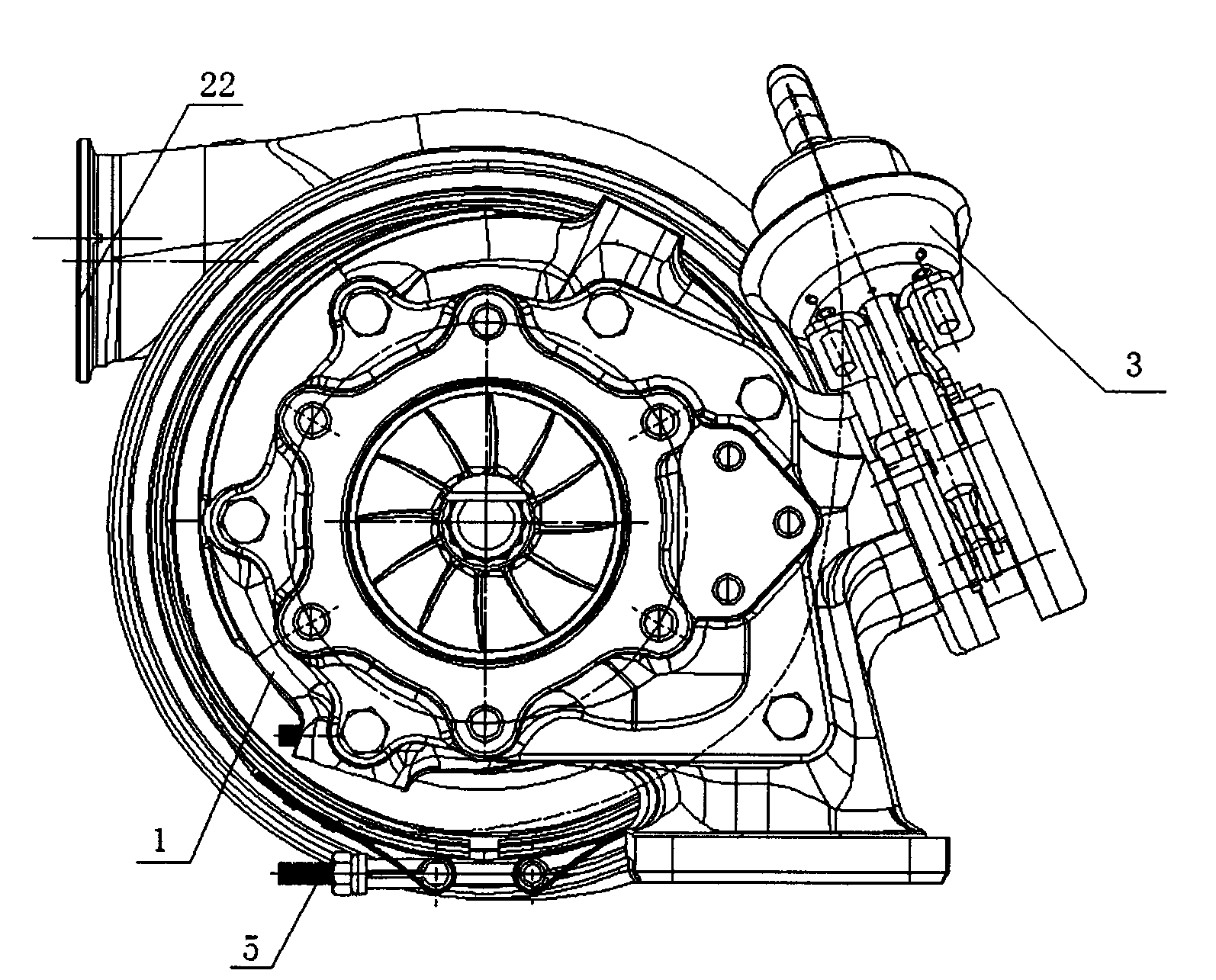

Turbocharger

InactiveCN103807002ASimple structureMeet the supporting requirements of different anglesInternal combustion piston enginesTurbochargerEngineering

The invention discloses a turbocharger which comprises a turbine housing, a gas compressor housing, a bypass valve and a midbody part connecting the turbine housing and the gas compressor housing, wherein the right end of the midbody part is provided with an inclined edge mounting insertion hole stop lug, the left end of the gas compressor housing is provided with an inclined edge mounting flange assembled with the inclined edge mounting insertion hole stop lug in an adapting butting way, and the right end of the midbody part and the left end of the gas compressor housing are mutually locked by tightly pressing the inclined edge mounting insertion hole stop lug and the inclined edge mounting flange via a snap ring with the n-shaped section. The turbocharger is simple and reasonable in structure, the angle between an air outlet of the gas compressor housing and the midbody part can be randomly adjusted according to assembly demands, one type of turbocharger can meet supporting requirements of different engines and different automobile factories on superchargers, the application range of the superchargers is enlarged, the amount of special superchargers is greatly reduced, overstocked superchargers are reduced, and the management is convenient.

Owner:GUANGXI YUCHAI MASCH CO LTD

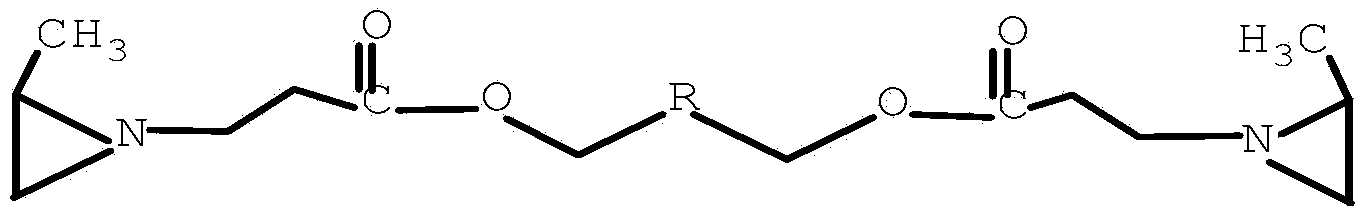

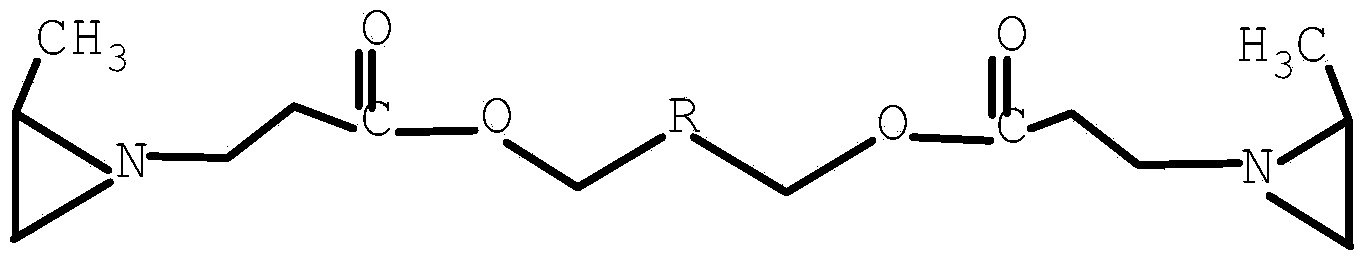

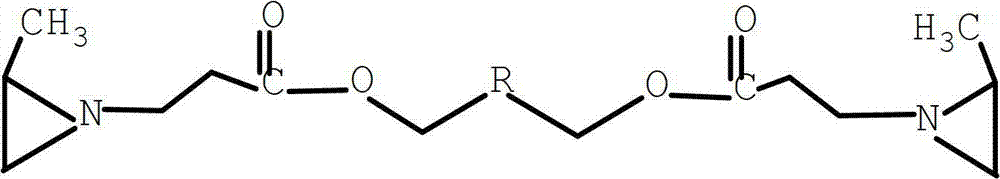

Preparation method for acrylate pressure sensitive adhesive providing good adhesion for low energy surface

ActiveCN102816546BImprove liquidityReduce economic lossNon-macromolecular adhesive additivesFilm/foil adhesivesOrganic baseDiluent

The present invention discloses a preparation method for an acrylate pressure sensitive adhesive providing good adhesion for a low energy surface. The preparation method comprises the following steps: (1) adding an organic base to a pressure sensitive adhesive composition, completely and uniformly stirring, and standing for 10 min to prepare a pressure sensitive adhesive mixture; (2) adding a tackifying resin solution to the prepared pressure sensitive adhesive mixture from the step (1), completely and uniformly stirring, and standing for 10 min; 3) adding an appropriate amount of a curing agent diluent to the prepared pressure sensitive adhesive mixture from the step (2), uniformly stirring, and standing for 20 min; and (4) uniformly coating the prepared pressure sensitive adhesive from the step (3) on a substrate, and carrying out drying curing for 0.5-1 h in a constant temperature oven with a temperature of 60-80 DEG C. The acrylate pressure sensitive adhesive prepared by the method of the present invention can be completely cured within 0.5-1 h, and no post-curing effect is generated, wherein a 180 DEG peel strength is more than or equal to 20 N / 20 mm, a room temperature hold tack is more than or equal to 35 h, and the acrylate pressure sensitive adhesive of the present invention still has fluidity and can be used for the pressure sensitive adhesive product coating step after storing for 8-12 days under conditions of a room temperature, sealing and darkness.

Owner:中新联科环境科技(安徽)有限公司

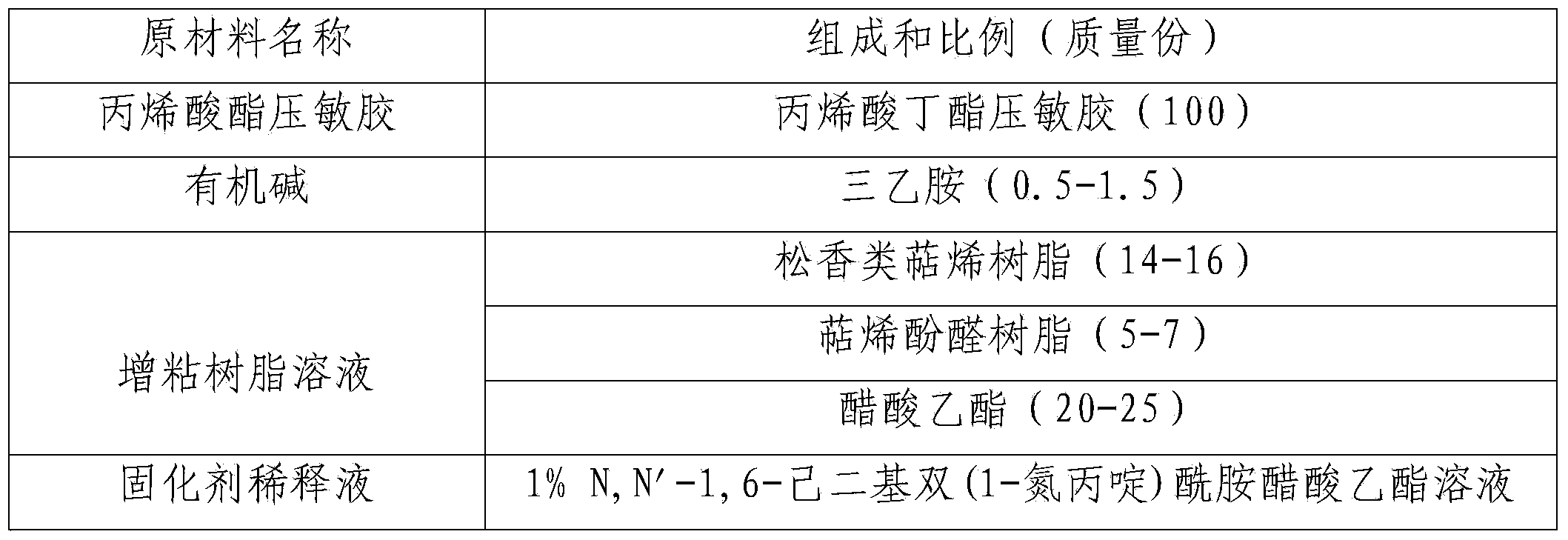

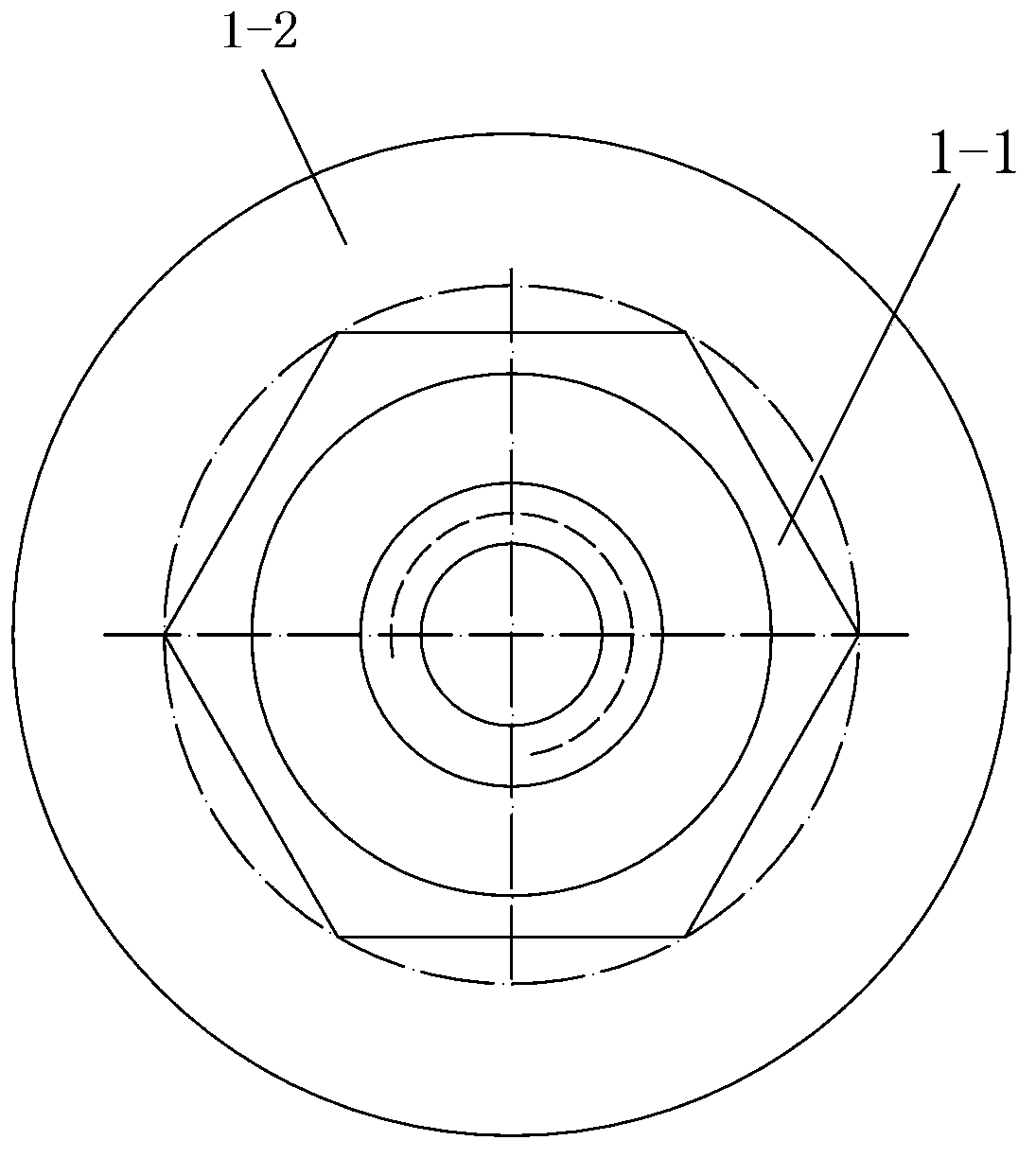

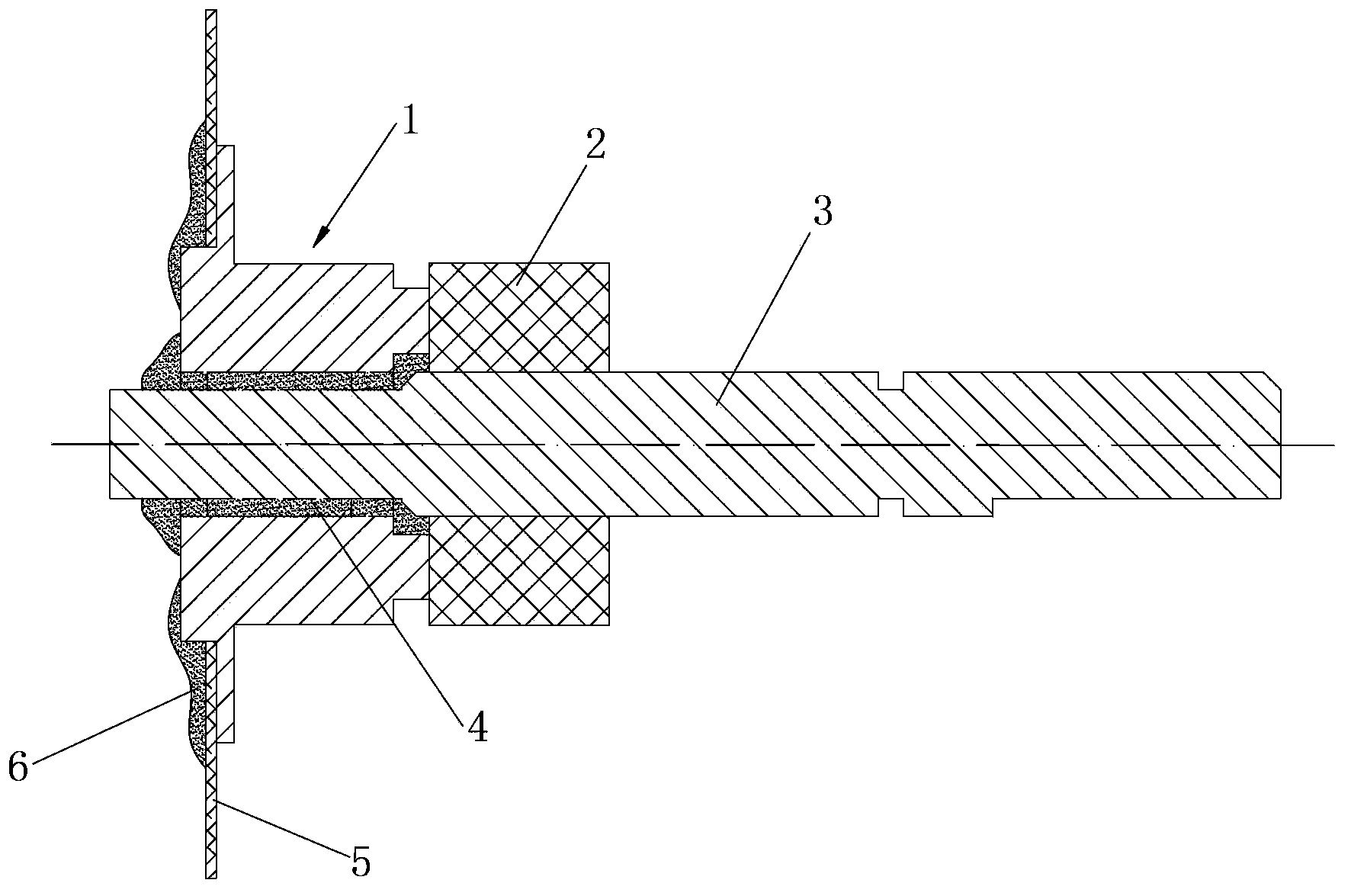

Code disc retaining nut for photoelectric encoder

InactiveCN103790917ASimple structureNovel and reasonable designNutsBoltsEngineeringMechanical engineering

The invention discloses a code disc retaining nut for a photoelectric encoder. The code disc retaining nut for the photoelectric encoder comprises a nut body, wherein the nut body is provided with a threaded hole matched with a solid shaft of the photoelectric encoder in the central axis direction, a code disc is installed at one end of the nut body, and an outer brim for preventing the code disc from shaking is arranged at one end of the nut body. The code disc retaining nut is wide in application range and suitable for all of metals and plastic code discs, the part machining cost is saved, overstocked parts are decreased, assembly, installation and maintenance are facilitated, and part maintenance and replacement are facilitated.

Owner:SHAANXI HONGXING ELECTRONICS COMPONENTS

Method and system for automatically making sub batch plan for steel-smelting continuous casting furnace

ActiveCN101303588BImprove scienceSolving inefficienciesTotal factory controlProgramme total factory controlSteelmakingOutcome assessment

Owner:NORTHEASTERN UNIV LIAONING

Preparation method for acrylate pressure sensitive adhesive providing good adhesion for low energy surface

ActiveCN102816546ASolve the speed problemImprove storage effectNon-macromolecular adhesive additivesFilm/foil adhesivesOrganic baseRoom temperature

The present invention discloses a preparation method for an acrylate pressure sensitive adhesive providing good adhesion for a low energy surface. The preparation method comprises the following steps: (1) adding an organic base to a pressure sensitive adhesive composition, completely and uniformly stirring, and standing for 10 min to prepare a pressure sensitive adhesive mixture; (2) adding a tackifying resin solution to the prepared pressure sensitive adhesive mixture from the step (1), completely and uniformly stirring, and standing for 10 min; 3) adding an appropriate amount of a curing agent diluent to the prepared pressure sensitive adhesive mixture from the step (2), uniformly stirring, and standing for 20 min; and (4) uniformly coating the prepared pressure sensitive adhesive from the step (3) on a substrate, and carrying out drying curing for 0.5-1 h in a constant temperature oven with a temperature of 60-80 DEG C. The acrylate pressure sensitive adhesive prepared by the method of the present invention can be completely cured within 0.5-1 h, and no post-curing effect is generated, wherein a 180 DEG peel strength is more than or equal to 20 N / 20 mm, a room temperature hold tack is more than or equal to 35 h, and the acrylate pressure sensitive adhesive of the present invention still has fluidity and can be used for the pressure sensitive adhesive product coating step after storing for 8-12 days under conditions of a room temperature, sealing and darkness.

Owner:中新联科环境科技(安徽)有限公司

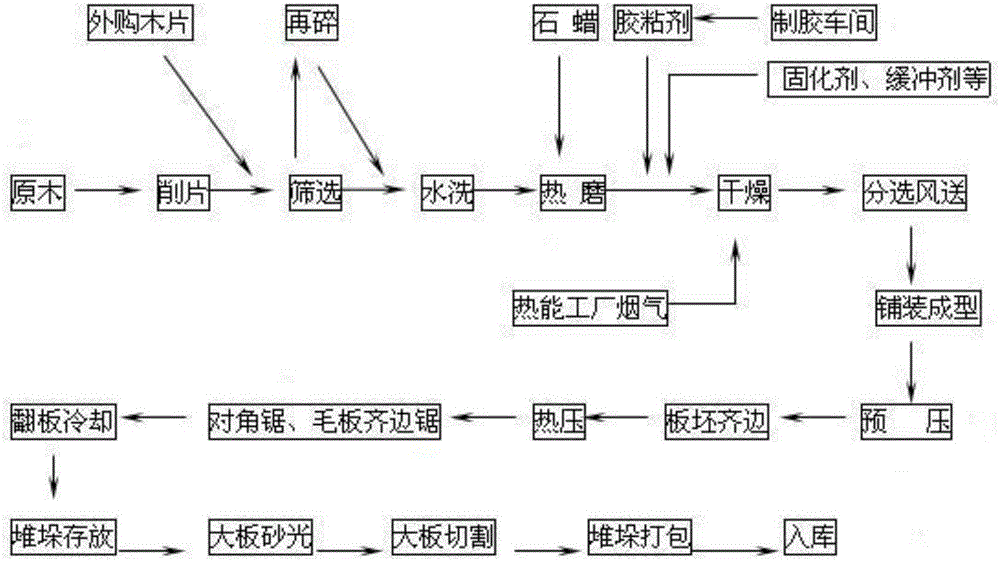

Method for producing mold-pressing door planks through wood scraps

InactiveCN106827157AMeet different individual needsMake full use ofWood working apparatusCycloneAdhesive

The invention discloses a method for producing mold-pressing door planks through wood scraps. The method comprises processes of chipping, screening, washing, heat grinding, drying, matting, pre-press molding, hot pressing, specification sawing after-treatment and the like. Small-sized timber, branches and wood machining residues are chipped and screened; wood chips are washed to remove impurities such as stone, sands and metals and are then boiled in a boiling cylinder; in a defibrator, the wood chips are heat-grinded into fibers at high temperature and high pressure, and before the heat grinding process, paraffin is added into the wood chips, and after the heat grinding process, adhesives, curing agent and buffer agent are added into fibers; the fibers are dried and then separated through cyclone to obtain qualified fibers; the qualified fibers are molded plank blanks; the plank blanks are hot-pressed in a hot press machine into fiber planks. According to the method for producing the mold-pressing door planks through the wood scraps, the obtained fiber planks can meet the personalized requirements of various consumers on furniture and make reasonable use of effective space and are humanized in design; furniture designed from the fiber planks can be assembled and disassembled to reduce inventory overstocking of different furniture.

Owner:刘应福

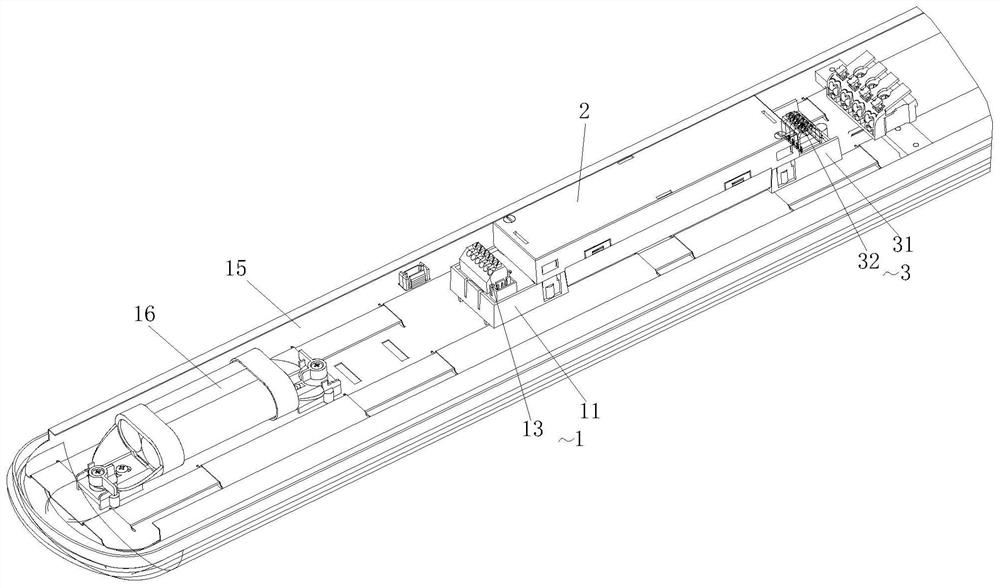

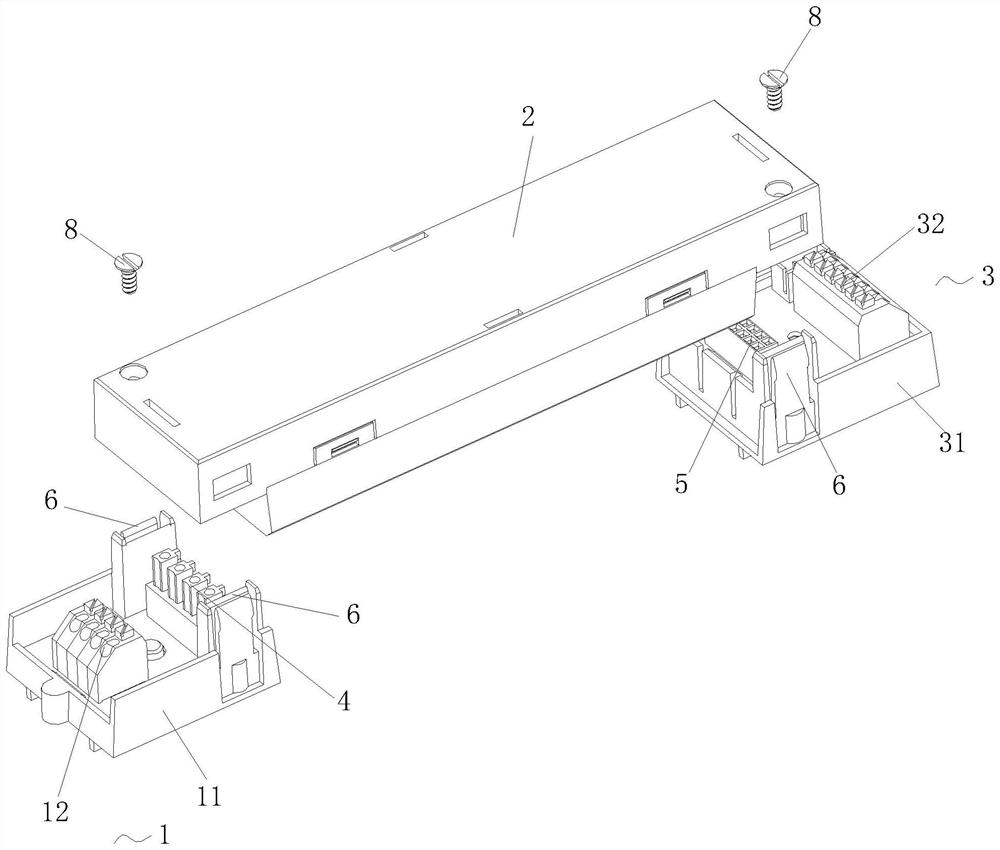

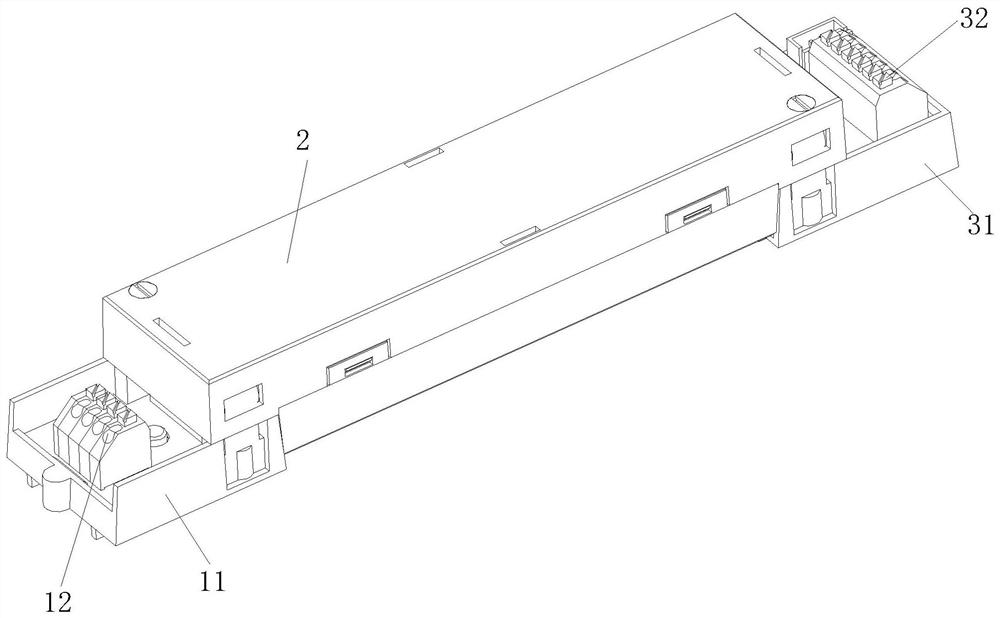

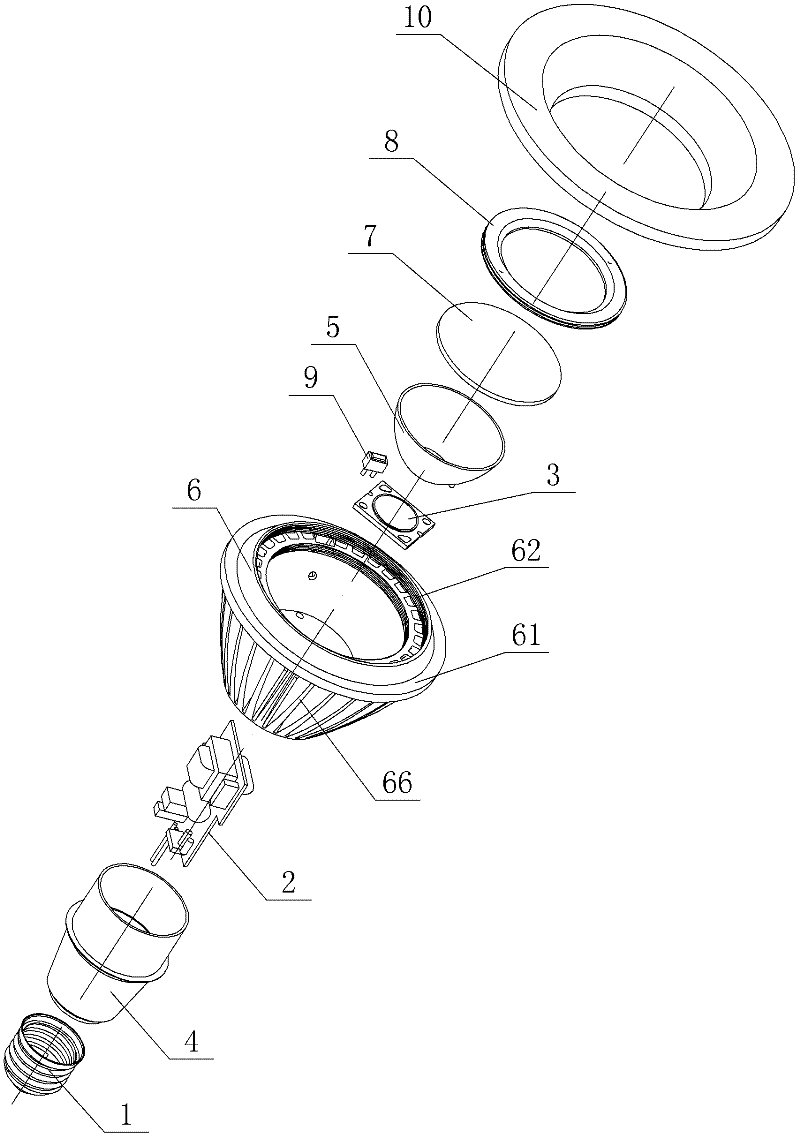

Plugging device of lamp modularized electronic controller and lamp

PendingCN111780071AReduce inventory backlogEasy wiringElectric circuit arrangementsCoupling contact membersElectronic controllerControl engineering

The invention discloses a plugging device of a lamp modularized electronic controller and a lamp. The plugging device comprises at least one electronic plugging fixing part and at least one electroniccontroller comprising an input and output plugging device, and the electronic plugging fixing part is fixedly arranged on the lamp, and the electronic controller is detachably arranged on the electronic plugging fixing part, so that the electronic controller is fixed to the lamp; a wiring device and a plug-in device which are electrically connected are arranged on the electronic plugging fixing part, the wiring device is used for being externally connected with an external power supply and a peripheral electronic device, and the input and output plugging device comprises a plug-in device matched with a plugging terminal on the electronic plugging fixing part; and when the plug-in device of the electronic controller is plugged with the plug-in device of the electronic plugging fixing part,the electronic controller can be electrically connected with the external power supply and the peripheral electronic device. According to the plugging device of the lamp modularized electronic controller and the lamp, the plugging device adopts a modularized plug-in structure to realize required functions, the operation is simple, the plugging device is suitable for different lamps, universalityis achieved, and cost is reduced.

Owner:SUZHOU CYANTRONIC TECH CO LTD

RFID-based conveying device

InactiveCN109230204AReduce accumulationSufficient supplyConveyorsControl devices for conveyorsProcess moduleData acquisition

The invention discloses an RFID-based conveying device which comprises a food conveying belt, a conveying tray for conveying food, an object taking area, a feeding place, and a conveying control system. The conveying control system includes a data acquisition module, a data integration system, a processing module, a central management module, and an external application software module; the data acquisition module includes a converter and a reader; the processing module includes a bill processing module and a food management module; the central management module is used for coordinating, managing and integrating internal and external data flows. The conveying device can be used for enhancing safety of a food supply chain via adoption of RFID technology while inventory control is improved and responsive replenishment is realized.

Owner:广州市康超信息科技有限公司

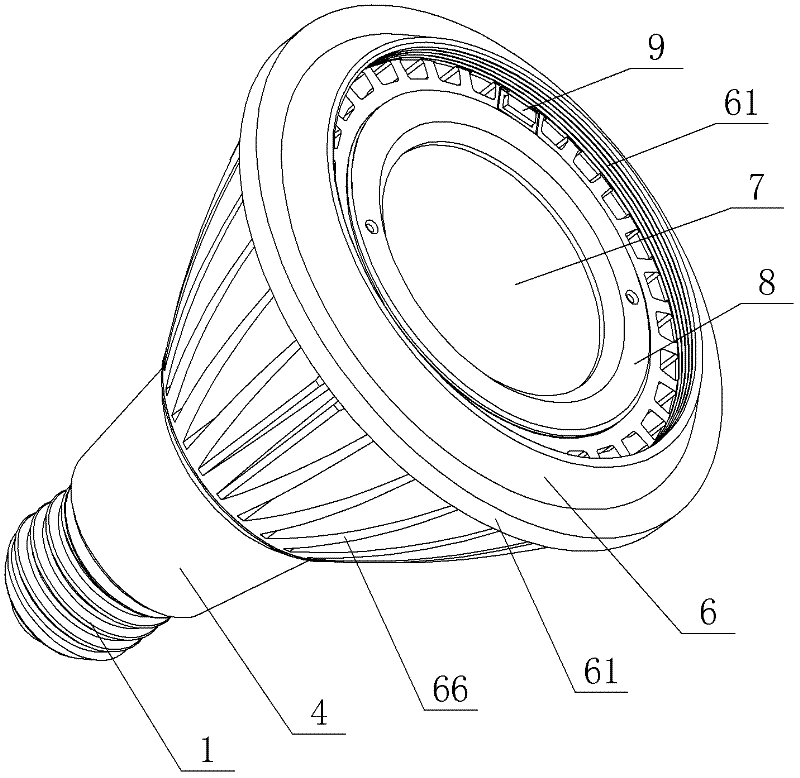

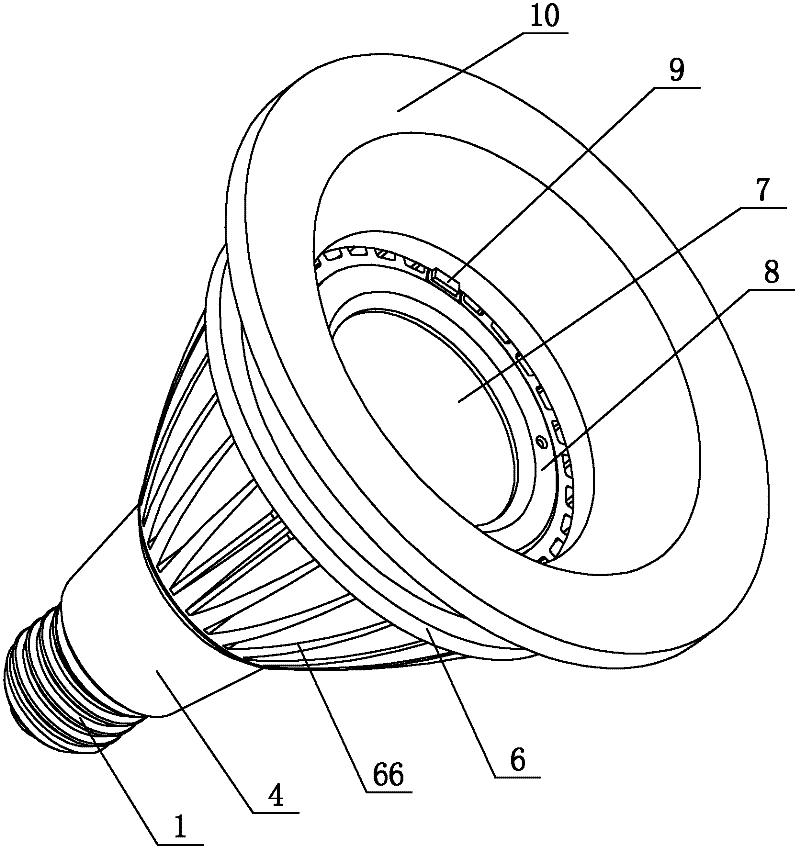

Spotlight conversion device and general spotlight

InactiveCN102506392AEasy to useEasy to convertLighting support devicesElectric circuit arrangementsEffect light

The invention discloses a spotlight conversion device and a general spotlight. The general spotlight comprises a light holder (1), a light body and the spotlight conversion device (10). The spotlight conversion device comprises a large ring (101) at the top, a small ring (103) at the bottom and a variable-diameter portion (102) for connecting the large ring (101) and the small ring (103), wherein the small ring (103) is provided with a connection portion (104) matched with the spotlight. A lighting element is arranged in the light body, a light body connection device is positioned at the top of the light body, and the connection portion (104) and the light body connection device are connected and fixed in matched mode and are detachably connected. After the spotlight conversion device (10) is installed, a small-sized general spotlight is changed into a large-sized spotlight. The spotlight conversion device can be widely applied to the field of spotlights.

Owner:ILLUMINA MFG

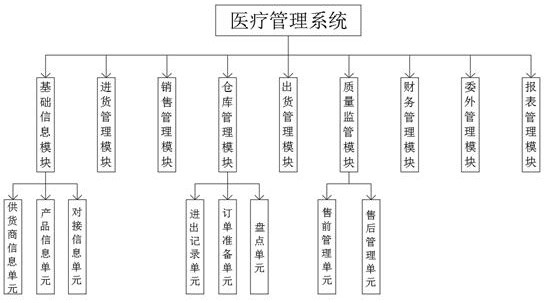

Medical instrument management system for medicine warehouse of medical company

PendingCN113837655AImprove securityScientific and reasonable structureBuying/selling/leasing transactionsResourcesPurchasing managementInventory management

The invention discloses a medical instrument management system for a medicine warehouse of a medical company. The system comprises a basic information module, a purchase management module, a sales management module, an inventory management module, a shipment management module, a quality supervision module, a financial management module, an outsourcing management module, and a report management module. Under normal use and maintenance conditions, faults and service life of products are predicted and analyzed, a product maintenance and recovery processing scheme is formulated, an after-sales management unit analyzes and finds out unpredicted faults, a supplier is helped to improve the products, the maintenance cost is recorded, data is provided for a financial management module, and analysis benefits are helped to reasonably purchase goods. The actual service life of the product is compared with the predicted service life, the product quality is actually known, the product quality information is more comprehensive, purchase management of warehouse medical instruments is facilitated, and sales of medical companies is promoted.

Owner:杭州云呼医疗科技有限公司

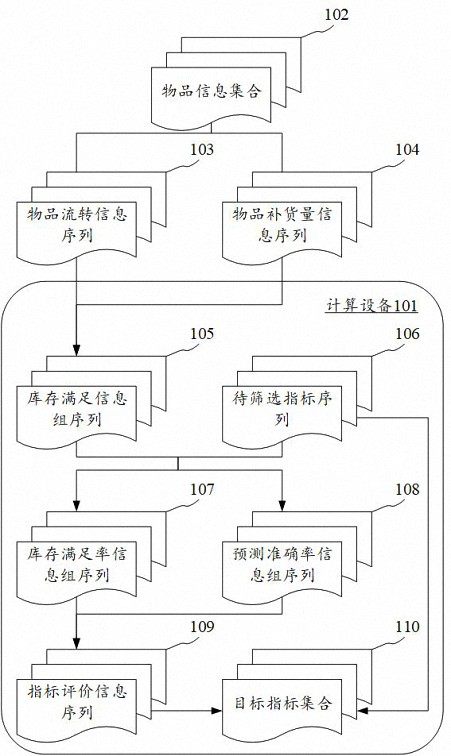

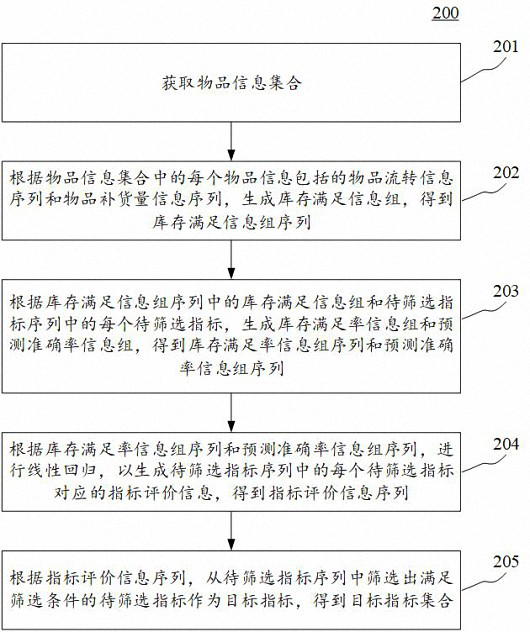

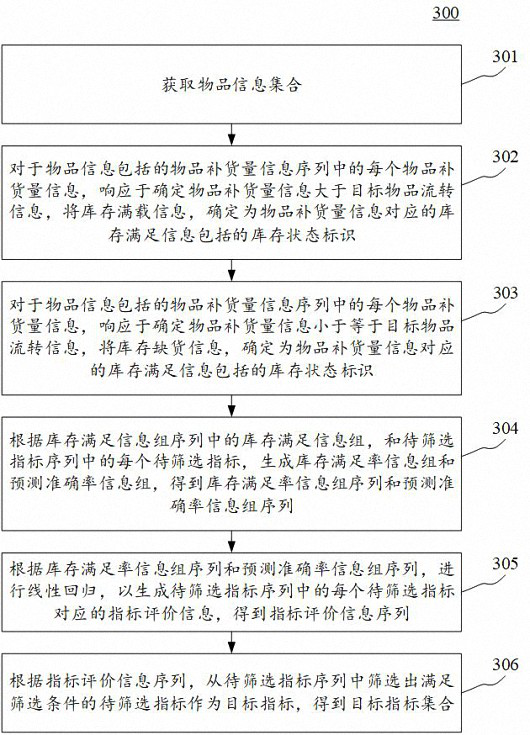

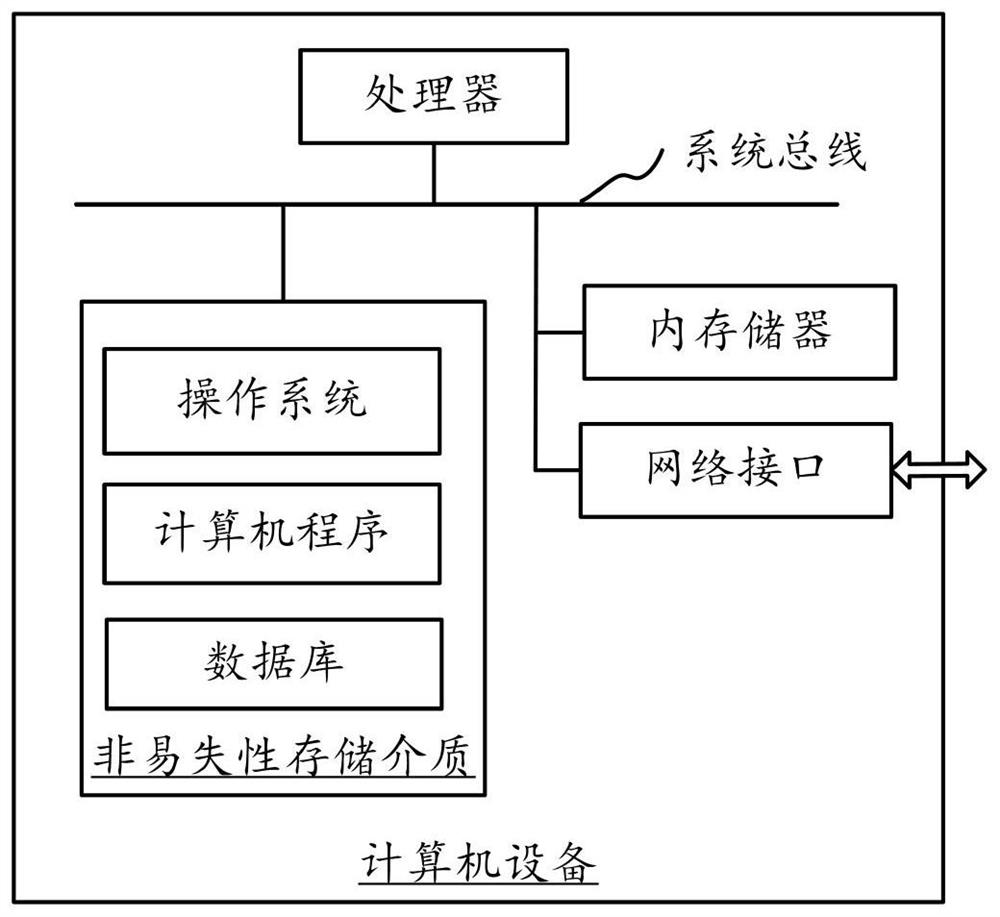

Index determination method and device, electronic equipment and computer readable medium

The embodiment of the invention discloses an index determination method and device, electronic equipment and a computer readable medium. A specific embodiment of the method comprises the following steps: acquiring an article information set; according to an article circulation information sequence and an article replenishment quantity information sequence included in each piece of article information in the article information set, generating an inventory satisfaction information group; according to an inventory satisfaction information group in the inventory satisfaction information group sequence and each to-be-screened index in the to-be-screened index sequence, generating an inventory satisfaction rate information group and a prediction accuracy information group; performing linear regression according to the inventory satisfaction rate information group sequence and the prediction accuracy information group sequence to generate index evaluation information corresponding to each to-be-screened index in the to-be-screened index sequence; and screening out the to-be-screened index meeting the screening condition from the to-be-screened index sequence as a target index. According to the embodiment, the evaluation accuracy of the prediction result is improved, and the occurrence of inventory overstock or inventory shortage is reduced.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

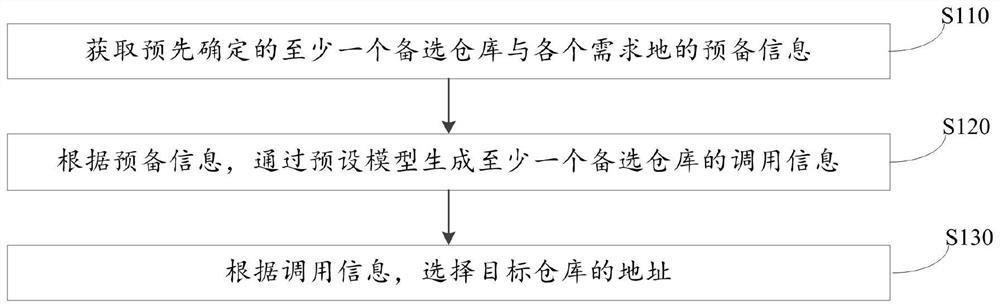

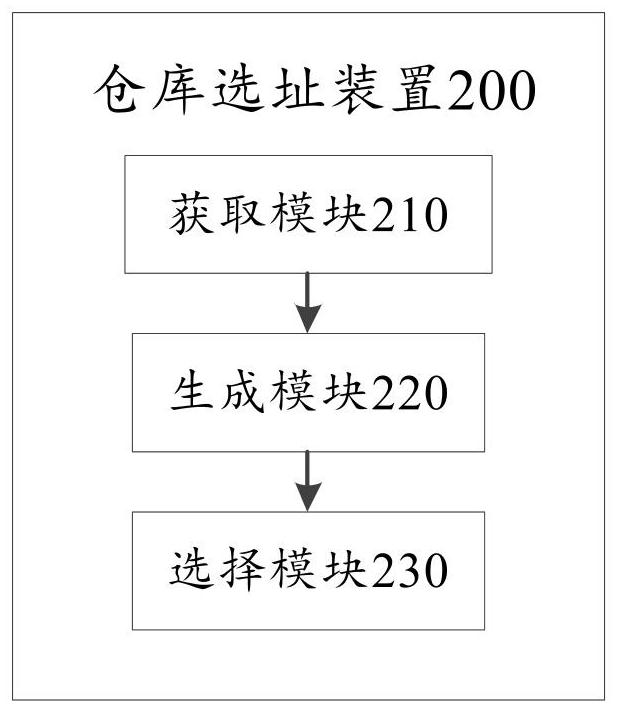

Warehouse site selection method and device

PendingCN114492934AImprove distribution efficiencyEasy to operateForecastingResourcesLogistics managementData mining

The invention relates to a warehouse site selection method and device, and the method comprises the steps: obtaining the preparation information of at least one predetermined alternative warehouse and each demand place, generating the call information of at least one alternative warehouse through a preset model according to the preparation information, and enabling the preset model to comprehensively evaluate the availability of the alternative warehouse through combining the cost and time efficiency, and the address of the target warehouse is selected according to the calling information, so that the address of the calling warehouse can be reasonably selected, the logistics distribution efficiency is improved, the logistics inventory overstock is reduced, and the efficient operation of a logistics system is ensured.

Owner:NANJING SUNING SOFTWARE TECH CO LTD

Preparation method of baking-free magnesium vibration material

The invention discloses a preparation method of a baking-free magnesium vibration material. The vibration material is prepared from 93-96% of magnesite, 3-6% of composite binder, 0.2-0.8% of setting accelerator and 0.2-0.8% of polycarboxylate water reducing agent. The preparation method has the advantages of single raw material, fewer production steps, less material accumulation and lower cost; and besides, the vibration material is free of baking, thereby saving the baking medium and enhancing the turnover utilization ratio of the tundish.

Owner:浙江攀盛冶金材料有限公司

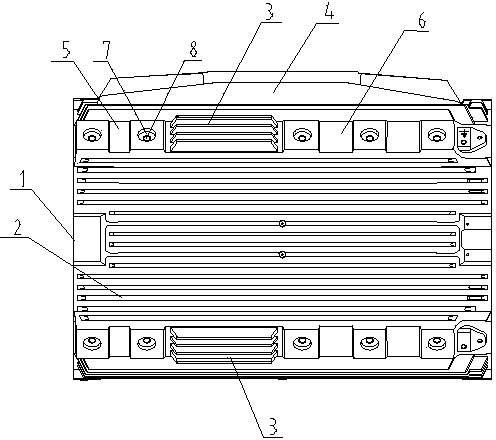

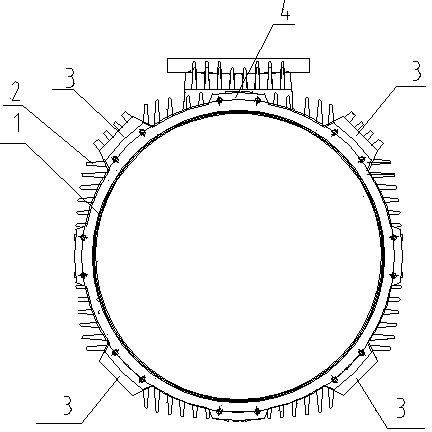

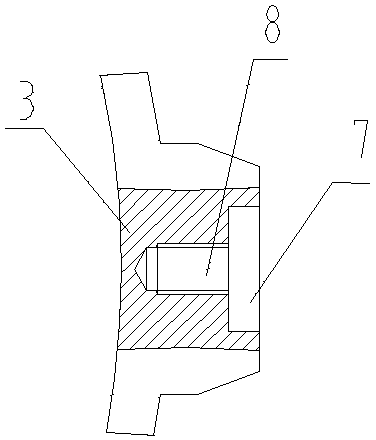

Engine base capable of meeting multiple installing requirements at same time

ActiveCN103683625AReduce inventory backlogReduce manufacturing costSupports/enclosures/casingsEngineeringMechanical engineering

The invention belongs to the technical field of engine manufacturing and provides an engine base capable of meeting multiple installing requirements at the same time to solve the technical problem that machine shell models need to be independently manufactured for engine bases installed in different ways. The engine base comprises a cylindrical engine base body, and heat dissipation ribs are evenly distributed on the engine base body. The engine base is characterized in that four axial reinforced ribs are evenly distributed on the surface of the periphery of the engine base body, a wire outlet hole is formed in the part, between two of the four reinforced ribs, of the engine base body, the reinforced ribs are respectively provided with a front bottom corner installing plane and a back bottom corner installing plane, the front bottom corner installing planes and the back bottom corner installing planes are respectively provided with more than two upper positioning counter bores, and threaded counter bores are formed inside the upper counter bores. The engine base can be used in various engines by arranging the reinforced ribs and movable bottom corners on the surface of the base body, only one engine base model needs to be arranged during the manufacturing process, production cost is effectively reduced, and the overstocked engines can be reduced.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

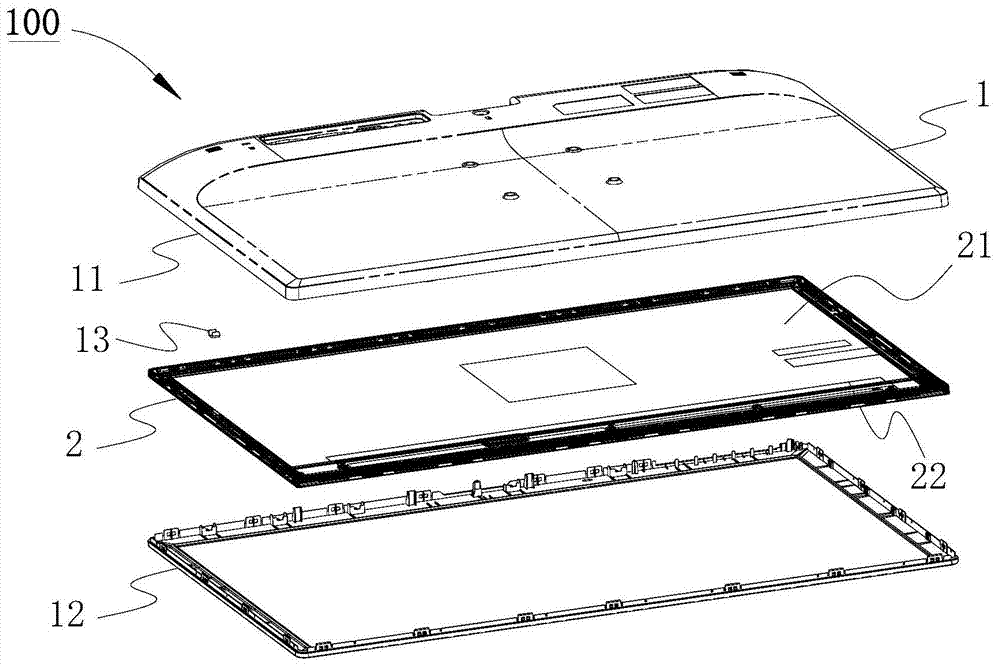

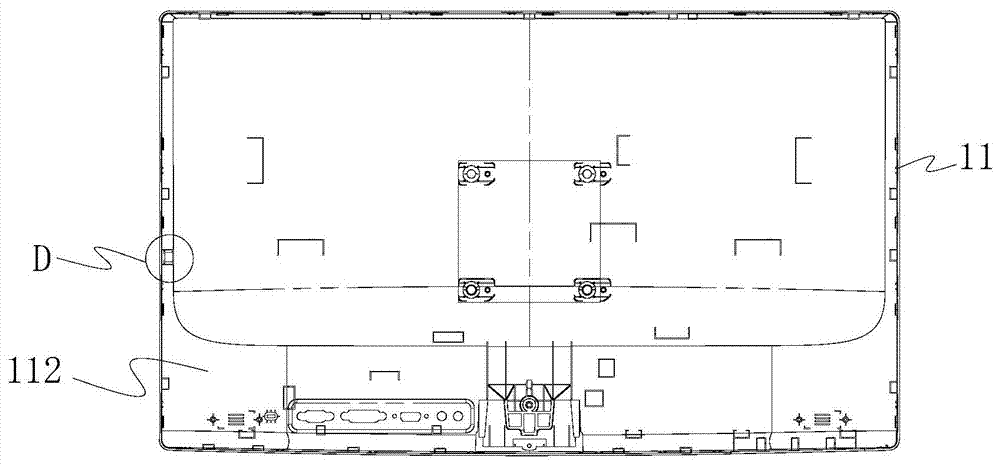

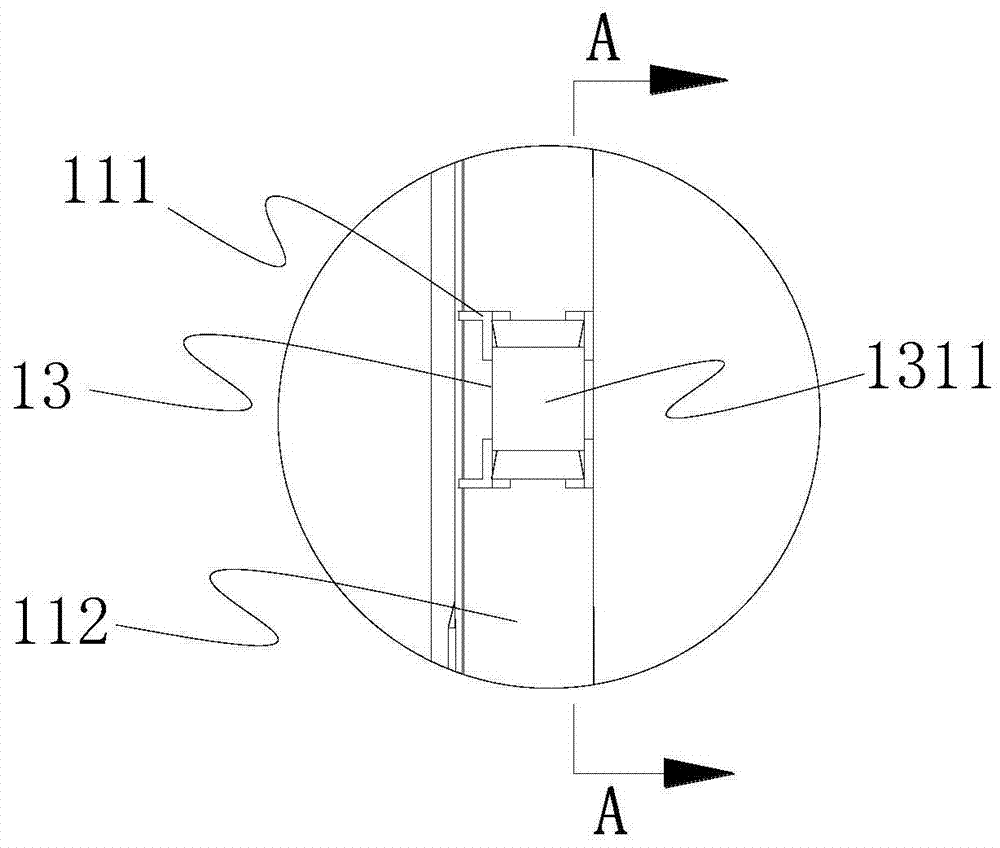

Display device housing and display device

InactiveCN104684288BSolve the generality problemInhibit productionNon-linear opticsElectrical apparatus casings/cabinets/drawersDisplay deviceEngineering

The present invention provides a display device housing and a display device. The display device housing is used to package a display module. The display module has a first thickness. The display device housing includes: a first housing with at least one slide Groove; the movable part has a clamping part and an adjustment part, and the clamping part can slide on the chute along the first direction so that the movable part is separated or fixed on the first housing. When the movable part is fixed on the In the case of the first housing, the clamping part produces elastic deformation to prevent the movable part from falling off the chute, and when the packaging is completed, the adjustment part abuts against the display module; and the second housing is connected with the first housing Body fit and fixed, so that the display module is fixed between the first casing and the second casing; wherein, during the packaging process, when the first thickness changes, the movable part can be adjusted to adapt to the first thickness. In this way, the universality problem of the housing of the display device can be solved by replacing the movable parts.

Owner:QISDA SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com