Lean logistics implementation method based on display board

A technology of lean logistics and implementation methods, applied in logistics, instruments, manufacturing computing systems, etc., to solve the contradiction between supply and demand, reduce capital occupation, and maintain the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Kanban composition: Electronic Kanban is composed of header and details (i.e. items). Kanban header is based on order, including demand summary number, process route, sequence, record type, work center, production order number, production order status, etc.; Kanban uses the process as the minimum distribution unit, so the details are based on the process, including specific information such as demand summary number, process route, bench, required materials, factory, inventory location, backflush mark, and material demand time. It meets the requirements of lean production and distribution. In the lean logistics kanban system, the header and details of the kanban are connected through the demand summary number.

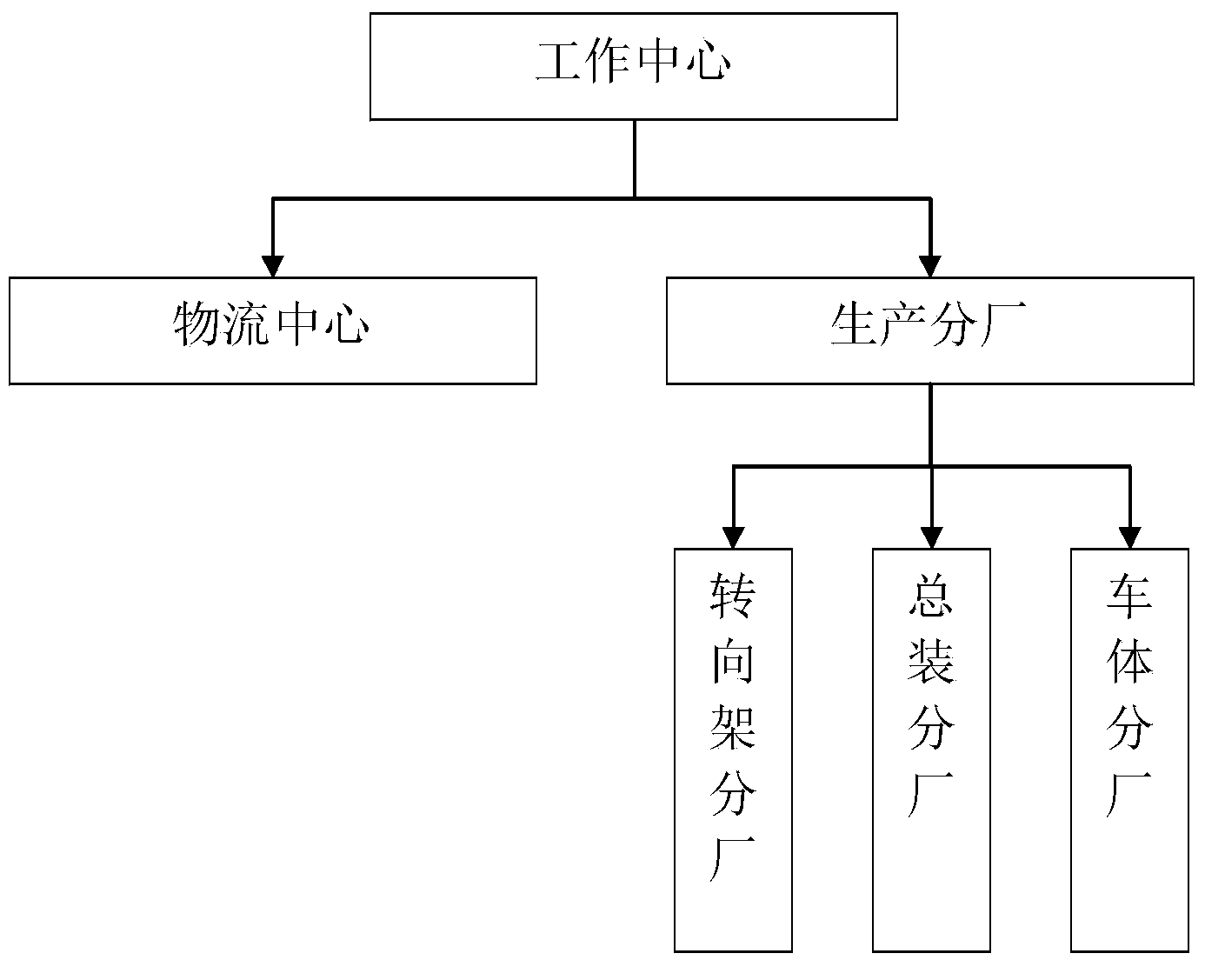

[0075] The work center in the present invention includes a production branch factory and a logistics center.

[0076] 1. Kanban generation:

[0077] 1. The production plan of motor vehicle manufacturing mainly comes from production orders and inspection and revi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com