Automatic production scheduling method based on shoes taking 10 pairs as batch

A technology of batch shoes and automatic arrangement, applied in instruments, manufacturing computing systems, data processing applications, etc., can solve problems such as production process delays, uncontrollable and unfavorable production planning, production tooling and scheduling, and achieve real-time production progress. Reduce inventory backlog and generate flexible adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

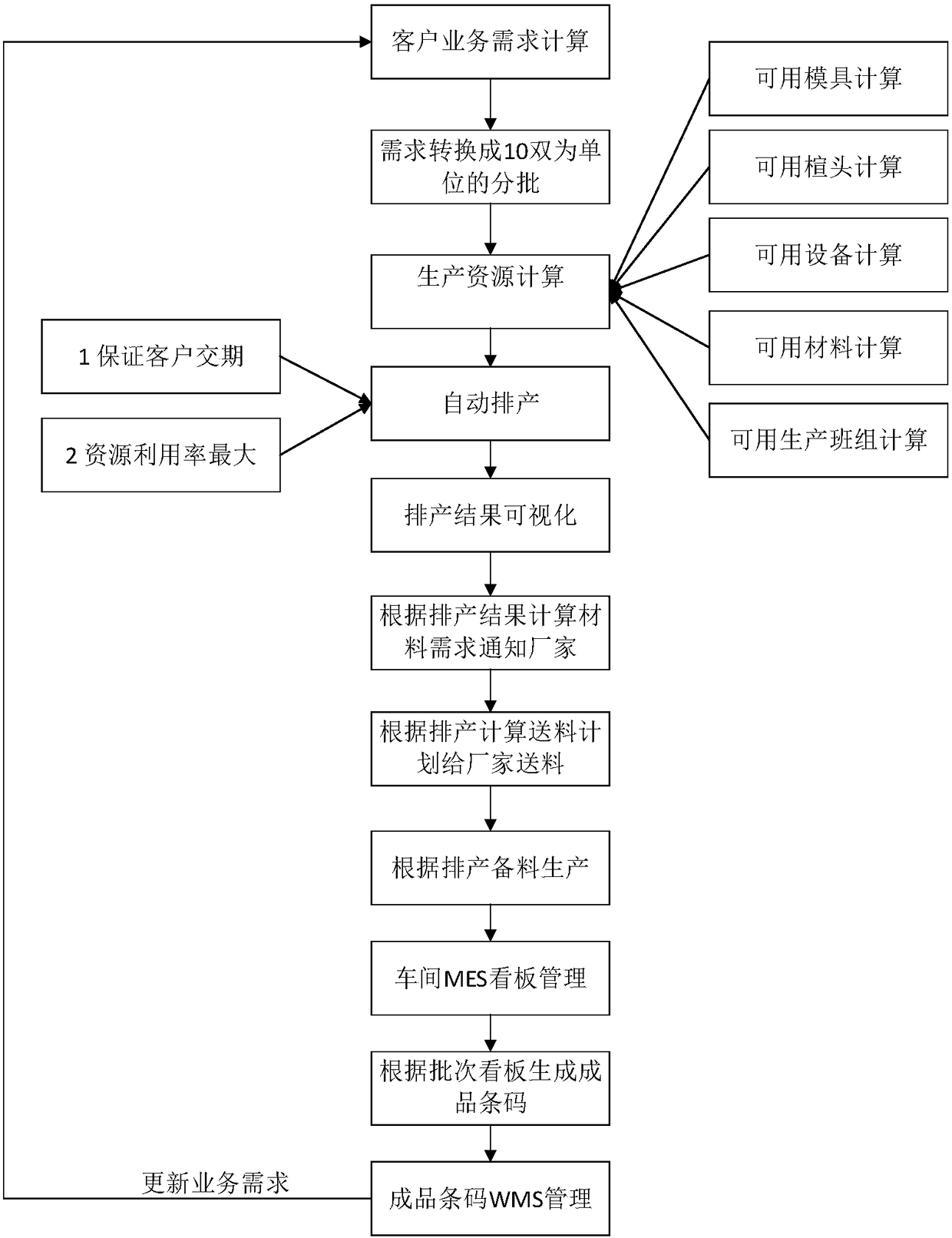

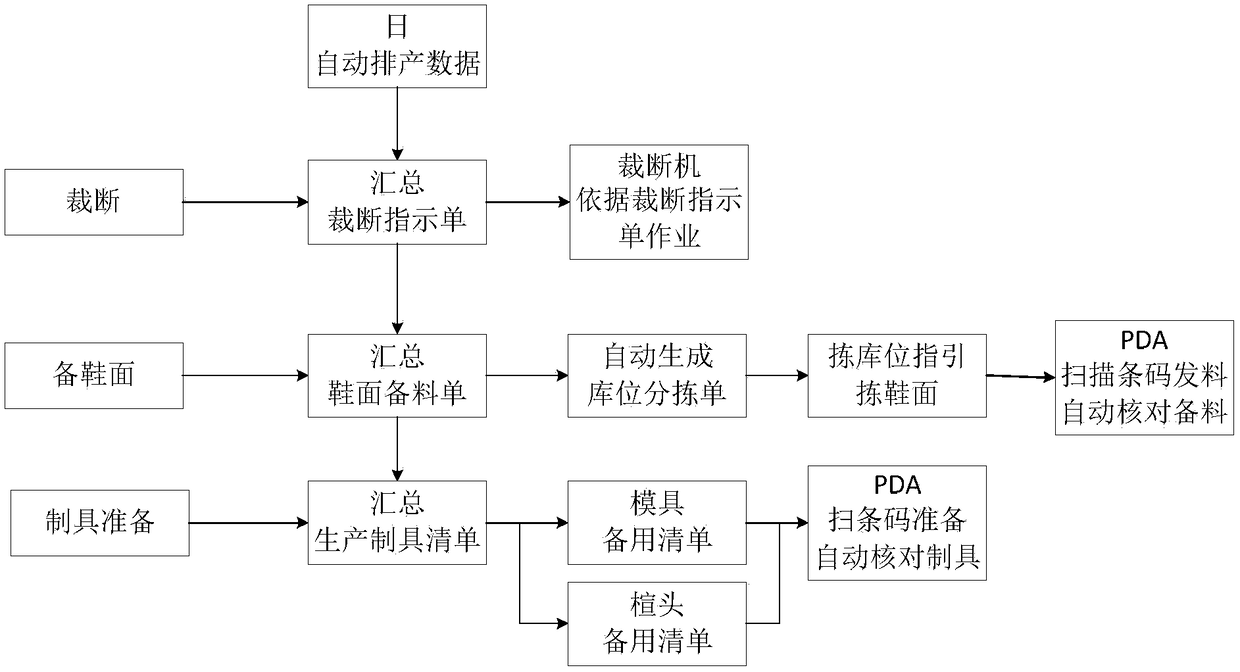

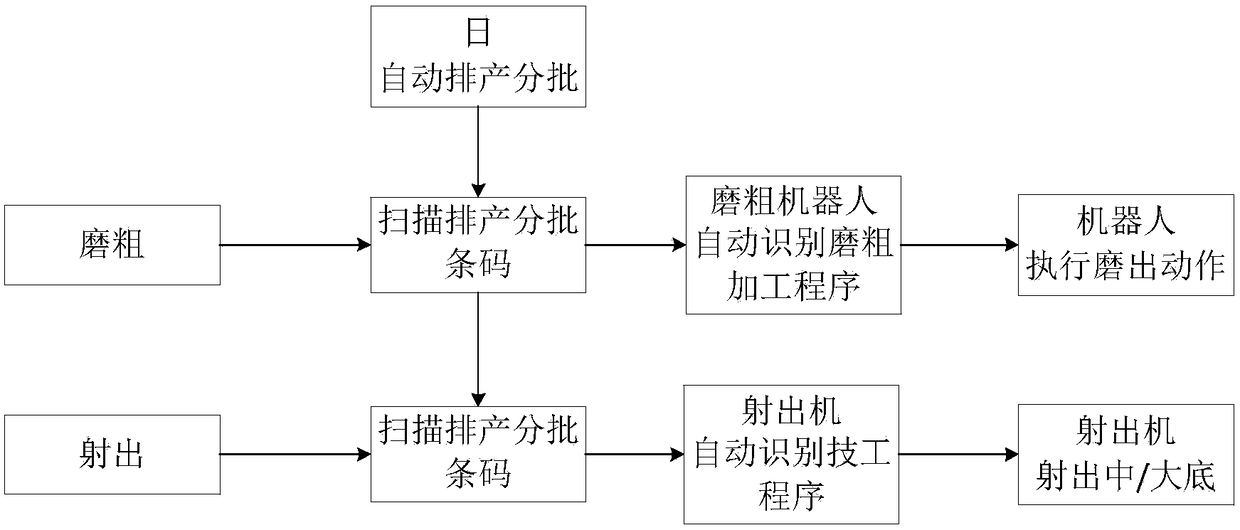

[0028] Combine below figure 1 , figure 2 , image 3 with Figure 4 Shown schematic flow sheet further illustrates the present invention:

[0029] In this embodiment, the automatic production scheduling method based on 10 pairs of unit batches of shoes includes the following process, automatic production scheduling calculation, pre-production preparation, on-machine production and off-line;

[0030] 1. Automatic production scheduling calculation

[0031] 1) Business demand calculation based on big data

[0032] By analyzing historical sales and shipment data, gender, age and size of consumer groups, sales area, sales time and sales quantity indicators, it can automatically estimate the customer's shoe style and size requirements, and automatically adjust the demand according to the actual monthly order status ;

[0033] 2) Automatic scheduling algorithm based on big data

[0034] Automatically arrange the availability of molds and lasts through the use time frequency an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com