System and method for carrying out data interaction between ERP and MES

A data interaction and data technology, applied in the field of enterprise informatization, can solve the problems of incompatibility, high risk of receivables, and inability of users to know the operating status of the enterprise in a timely manner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

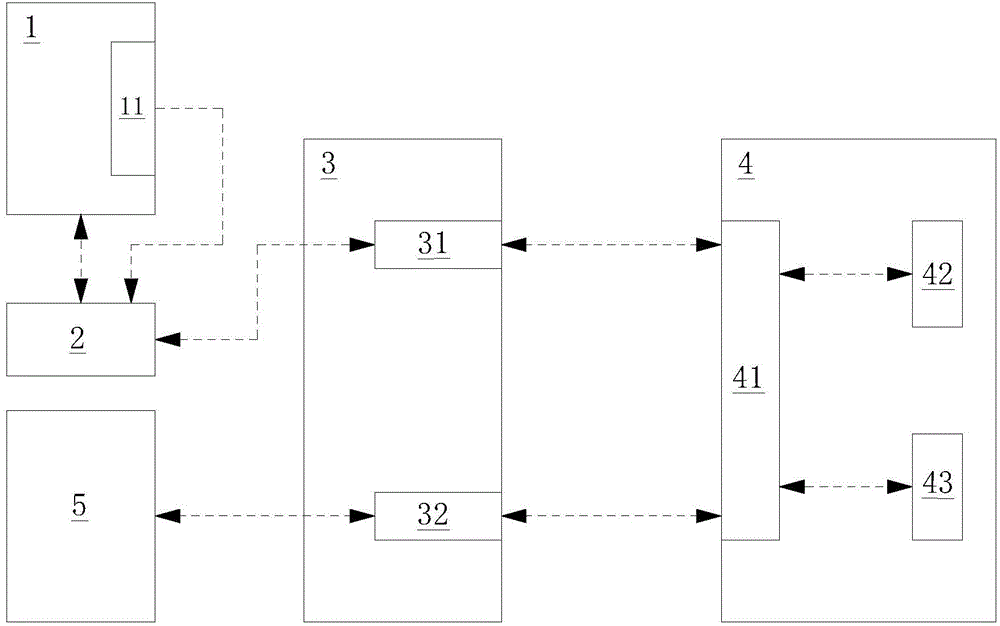

[0057] figure 1 It is a schematic diagram of the module structure of the system for data interaction between ERP and MES in the embodiment of this application.

[0058] like figure 1 As shown, a system for data interaction between ERP and MES in this embodiment can be based on the current ERP system and MES system. The system specifically includes:

[0059] The ERP module (that is, the ERP system) 1 has a middle-level server 11 and is mainly used in the upper-level management of enterprises.

[0060] The middle layer interface data platform 2 can be a data platform developed and generated by using the above-mentioned middle server 11 based on programs such as VB, and the middle layer interface data platform 2 is connected with the above-mentioned ERP module 1 through two-way communication.

[0061] The report module (ie report system) 3 has an ERP database 31 and an MES database 32, and the above-mentioned middle layer interface data platform 2 is connected to the ERP data 3...

Embodiment 2

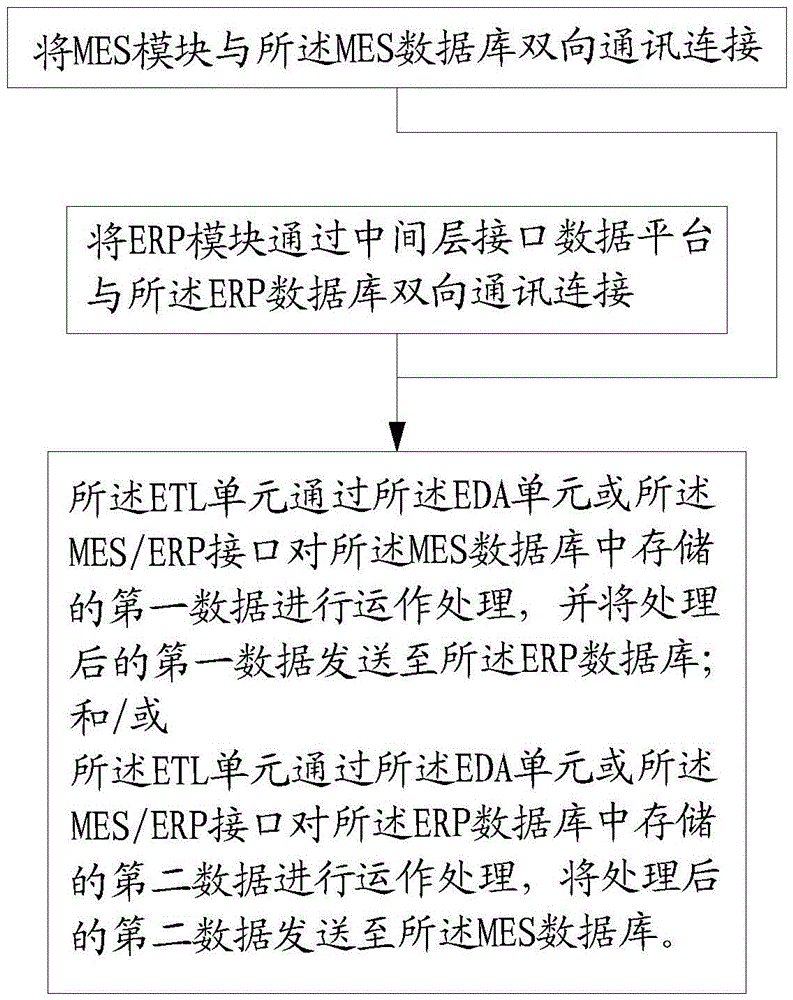

[0071] figure 2 It is a schematic flowchart of a method for data interaction between ERP and MES through a report module and an EDA module in the embodiment of the present application.

[0072] like figure 2 As shown, this application also provides a method for data interaction between ERP and MES through the report module and EDA module, which can be based on the system for data interaction between ERP and MES recorded in Embodiment 1. The methods specifically include:

[0073] First of all, the middle-tier server in the ERP module (that is, the ERP system) can be used to develop and generate the middle-tier interface data platform based on programs such as VB, for the mutual compatibility and communication between the ERP module and the report module (that is, the report system) connect.

[0074] Secondly, establish the communication link between the MES module and the MES database in the report module, and the communication link between the ERP module and the ERP modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com