Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduce exhaust loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

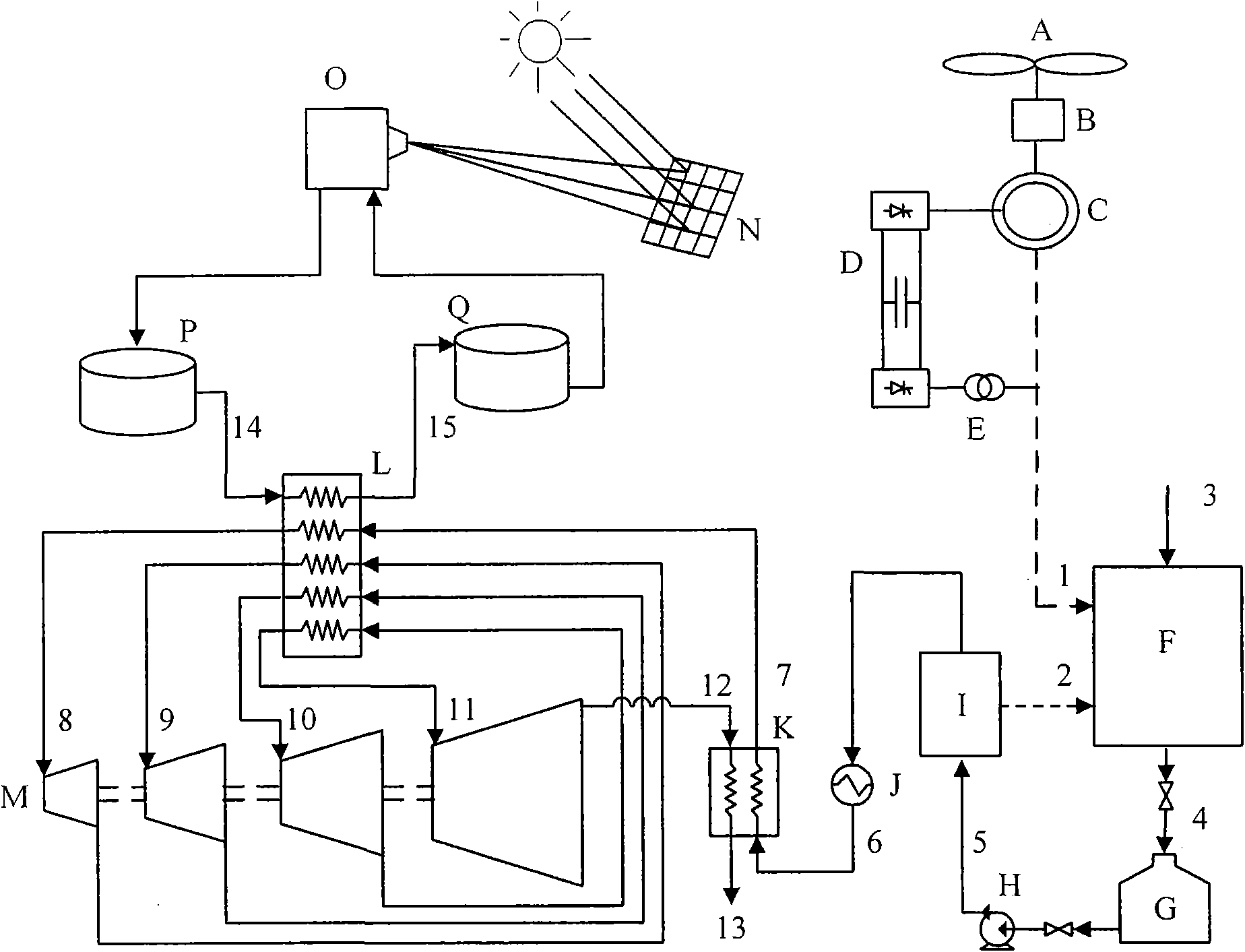

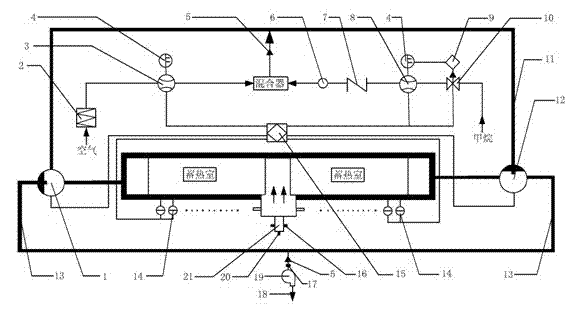

Wind and solar hybrid energy storage and power generation integration system and process

ActiveCN102062052ATo achieve complementary useImprove working abilitySolidificationLiquefactionThermal energyCollector device

The invention discloses a wind and solar hybrid energy storage and power generation integration system and process. The system comprises a wind power generation subsystem, a solar energy storage subsystem, a liquefied air subsystem and a power subsystem. The process comprises the following steps: solar energy is gathered by a thermal collector to obtain heat energy, the heat energy is stored in heat storge medium; wind energy is converted to electric energy, the wind power is used to liquefy air and stored in the liquefied air; and when electricity is required, the liquefied air is pressurized to recycle cold energy for the air liquefying process, then the air is heated by the high temperature heat storge medium which stores solar energy to obtain high temperature and high pressure air, and finally the air is sent to a multistage reheating turbine to expand and do work. The system of the invention recycles the cold energy of the liquefied air to reduce the wasted work for air liquefying; a pump is used to increase the pressure of the working medium, thus reducing the wasted work for compressing the working medium; the turbine utilizes recycled heat for exhaustm, thus effectively utilizing heat energy; solar energy is utilized to heat the working medium at the inlet of the turbine, thus increasing the expansion efficiency of the turbine; and wind energy and solar energy can be utilized for complementation, energy storage and power generation can be integrated and the system of the invention has wide application prospect.

Owner:葛洲坝中科储能技术有限公司

Device and method for collecting storage tank discharged gas

The invention discloses a device and a method for collecting storage tank discharged gas. The device comprises more than one storage tanks A for storing a medium A, and more than one storage tanks B for storing a medium B; breather valves, emergent release valves, pressure transducers and cutting valves are respectively arranged at the tops of the storage tanks; the cutting valves of the storage tanks A are communicated with storage tank A gas phase pipes through storage tank A pipe fire stoppers; the other ends of the storage tank A gas phase pipes are respectively connected with one end of a storage tank A gas phase gathering pipe; the cutting valves of the storage tanks B are communicated with storage tank B gas phase pipes through storage tank B pipe fire stoppers; the other ends of all the storage tank B gas phase pipes are respectively connected with one end of a storage tank B gas phase gathering pipe; the other end of the storage tank A gas phase gathering pipe and the other end of the storage tank B gas phase gathering pipe are respectively connected with one end of a storage tank gas phase gathering pipe main pipe; and the other end of the storage tank gas phase gathering pipe main pipe is connected with a dirty oil collecting system. The device can reduce the loss caused by direct discharge of oil into the atmosphere, and reduces the probability of generating potential safety hazards by feeding a lot of air into the tanks.

Owner:SINOPEC GUANGZHOU ENG +1

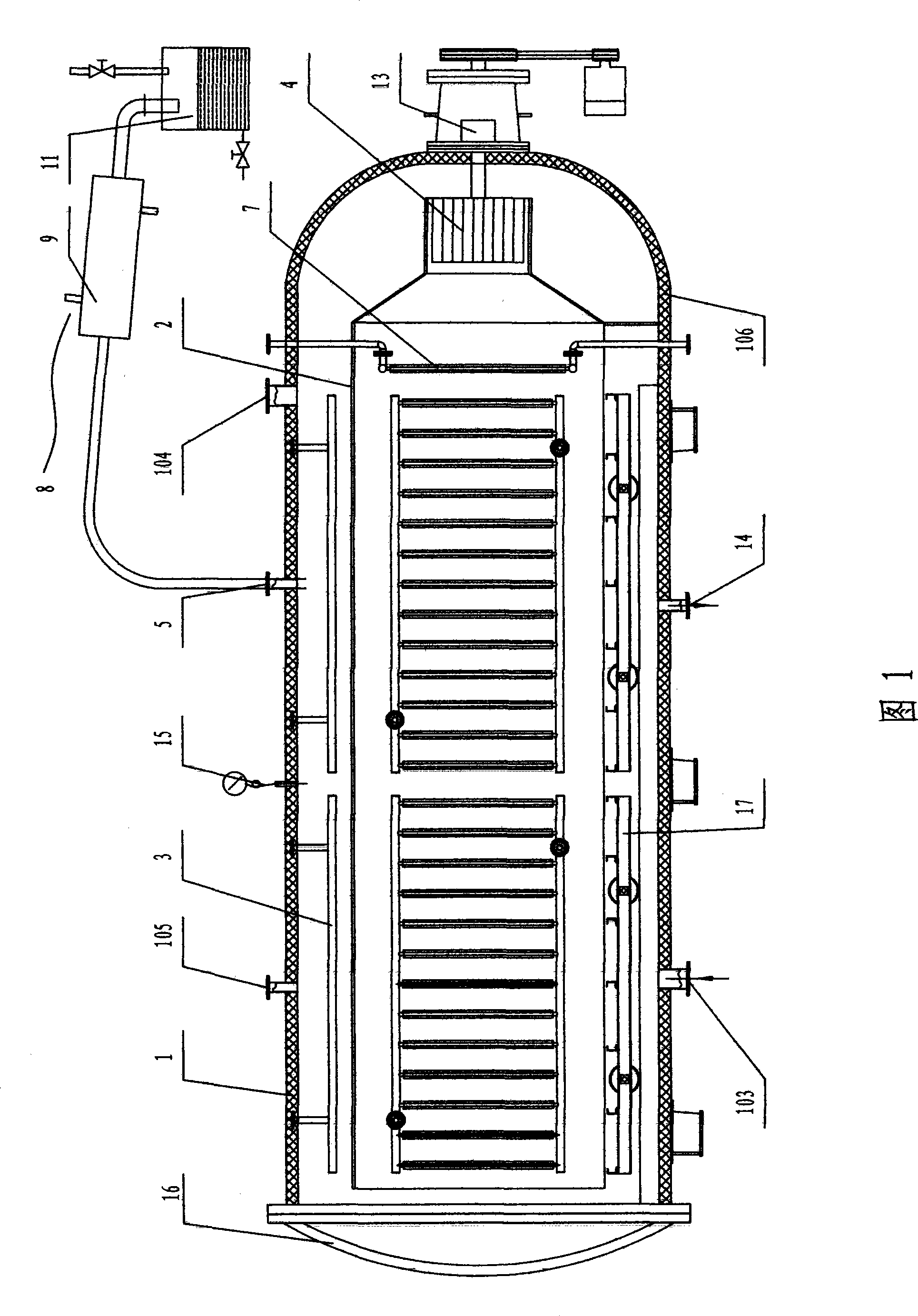

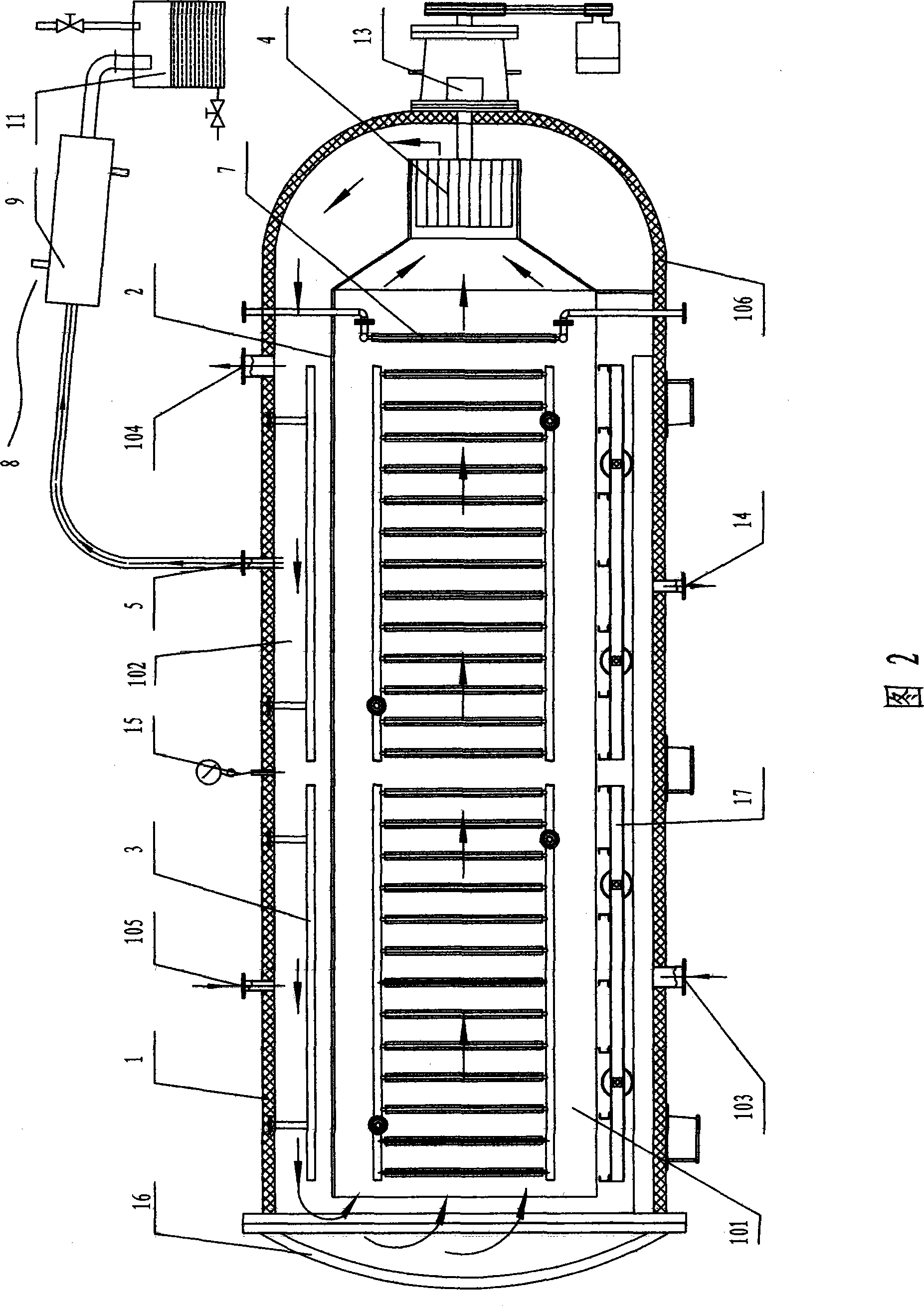

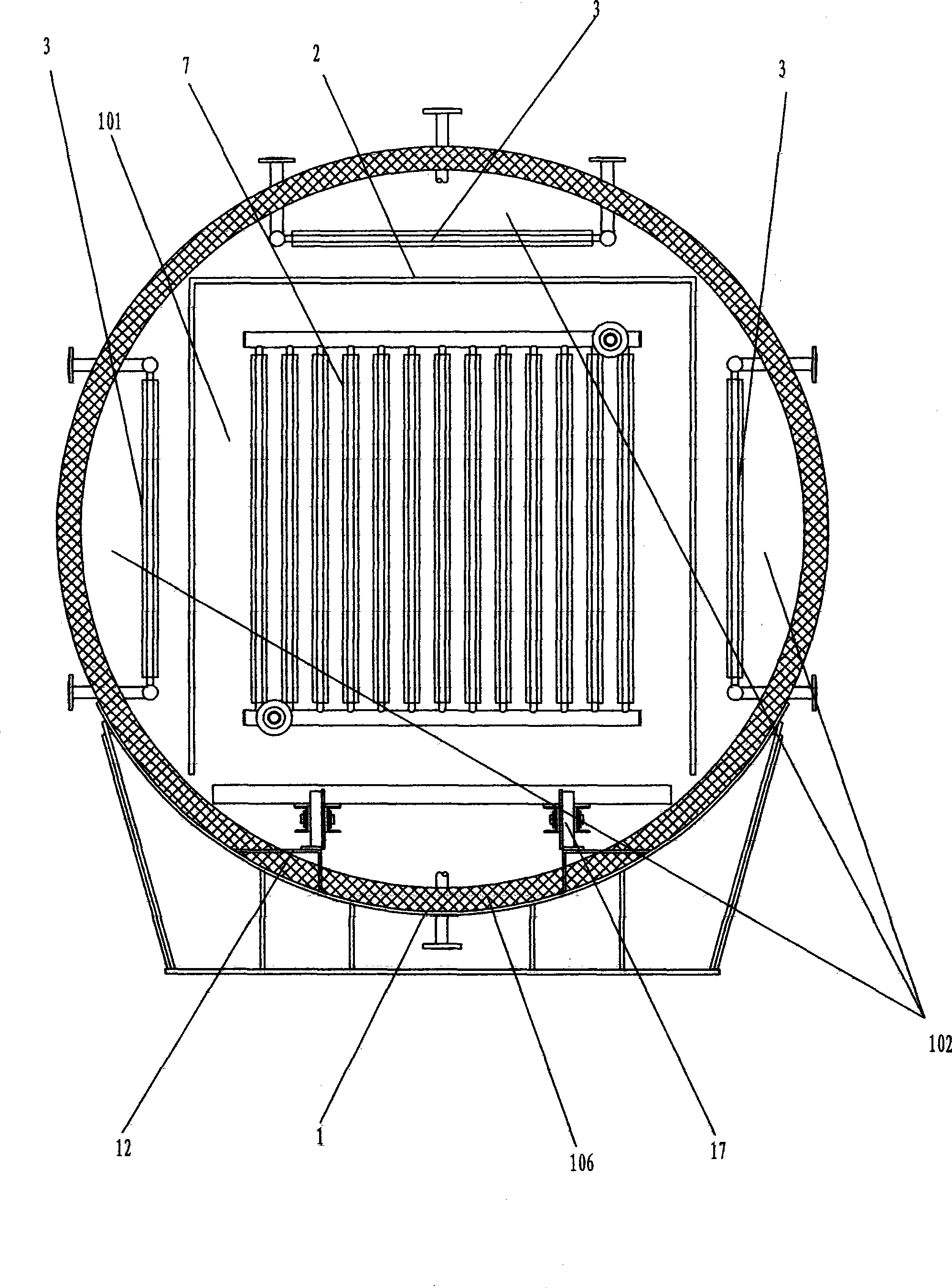

Wood drier

InactiveCN101377377AHigh Equilibrium Moisture ContentDry high qualityDrying solid materials with heatDrying machines with local agitationEngineeringAtmospheric pressure

The invention discloses a timber drying machine. The technical proposal is that the timber drying machine comprises a sealable pressure vessel provided with a door, wherein, the pressure vessel is provided with an internal separator board which divides the pressure vessel into a drying chamber and a heat exchange chamber which are communicated with each other; a heater is arranged in the heat exchange chamber; a circulating fan is arranged between the drying chamber and the heat exchange chamber; the pressure vessel is provided with a safety valve which is communicated with the exterior; the pressure vessel is also provided with a cooling device. The invention overcomes the deficiencies of the prior art that the energy consumption of the prior timber drying devices is high, atmospheric pressure high-temperature drying easily lead to higher level of moisture gradient and thus easy cracking and shrinkage, and the like. The invention provides a timber drying machine, which is used for drying or high temperature heat treatment in high-temperature and atmospheric environment, does not easily lead to higher level of moisture gradient and stress of timber, and ensures the drying quality and efficiency of timber.

Owner:曾令东

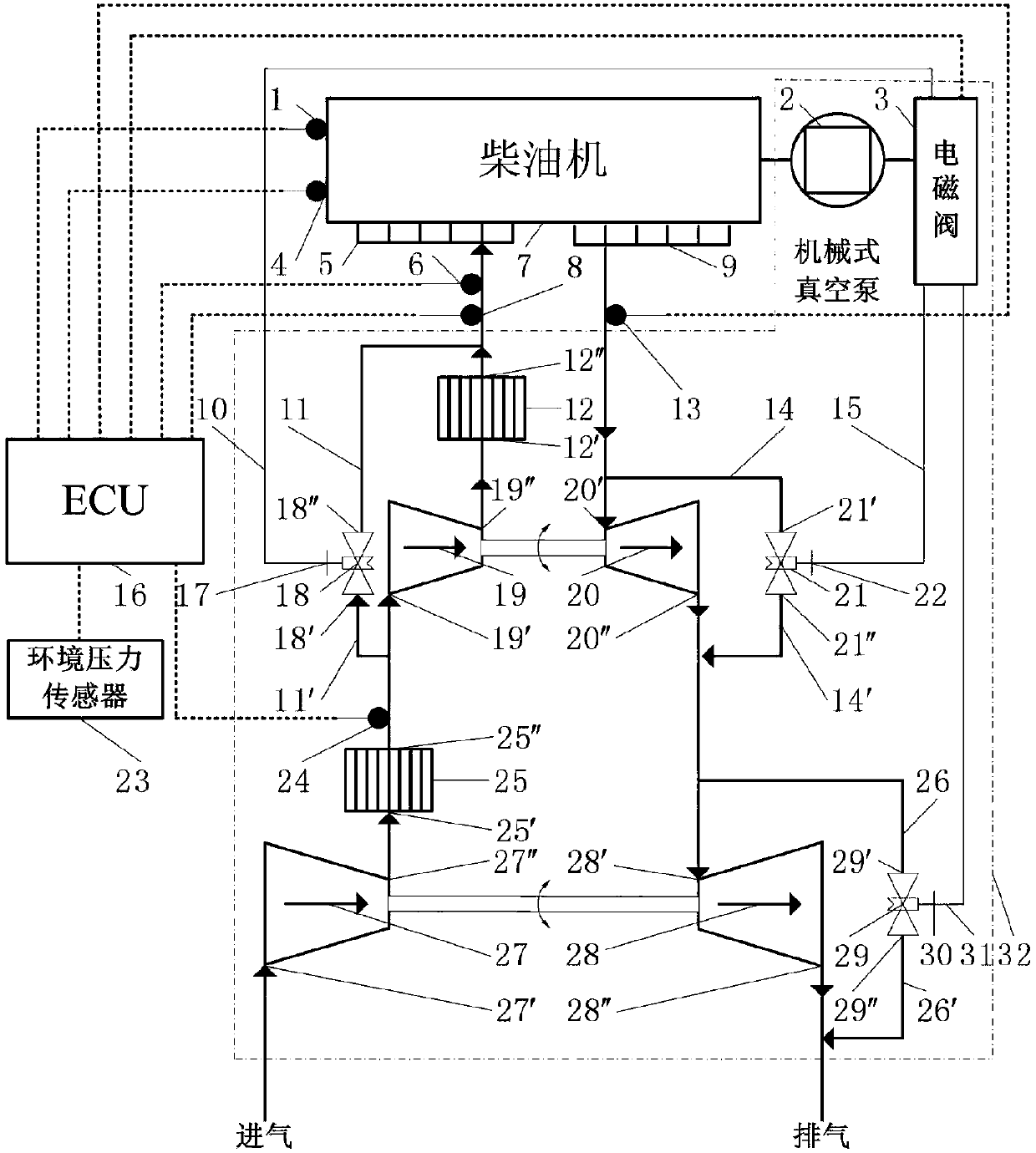

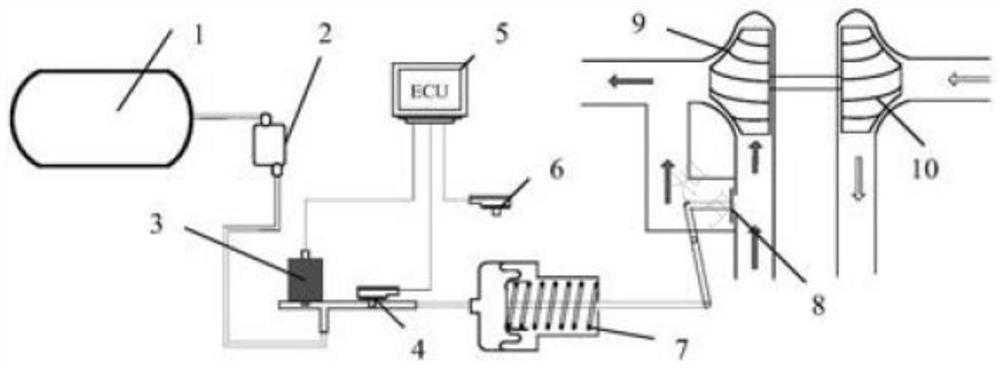

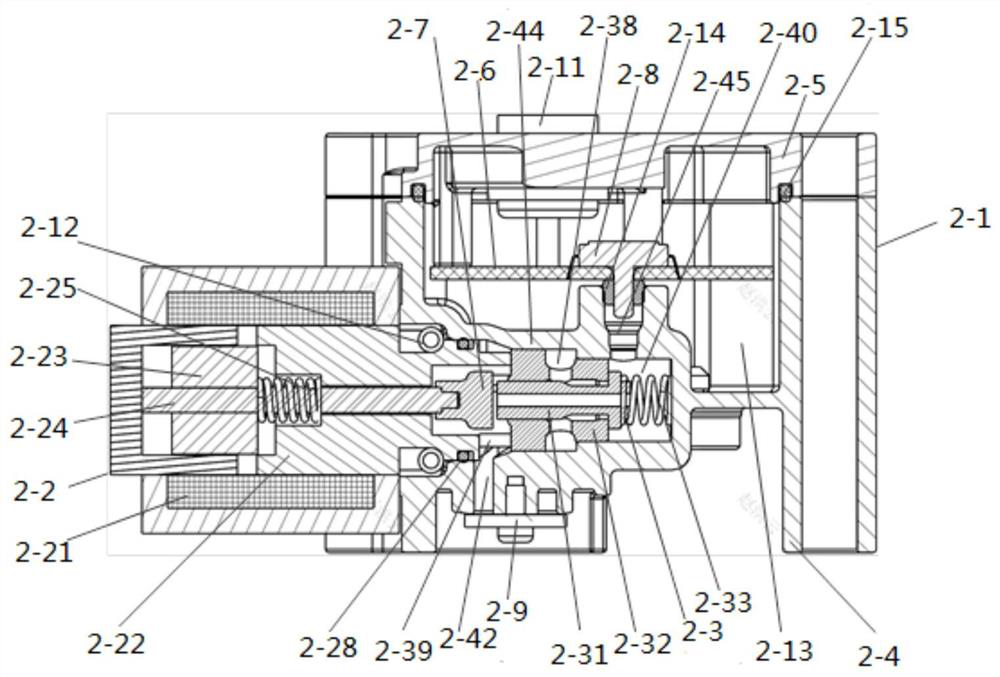

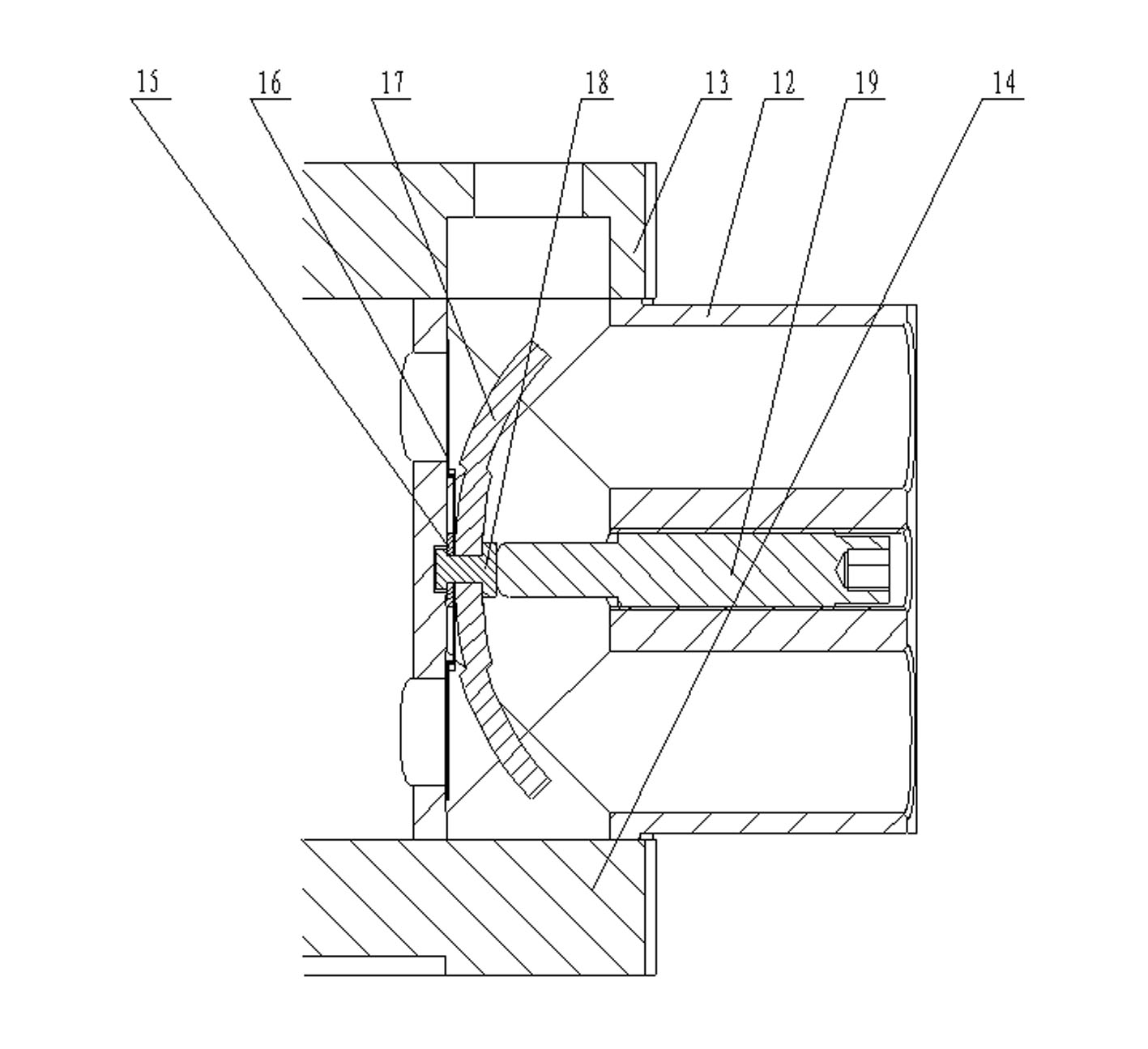

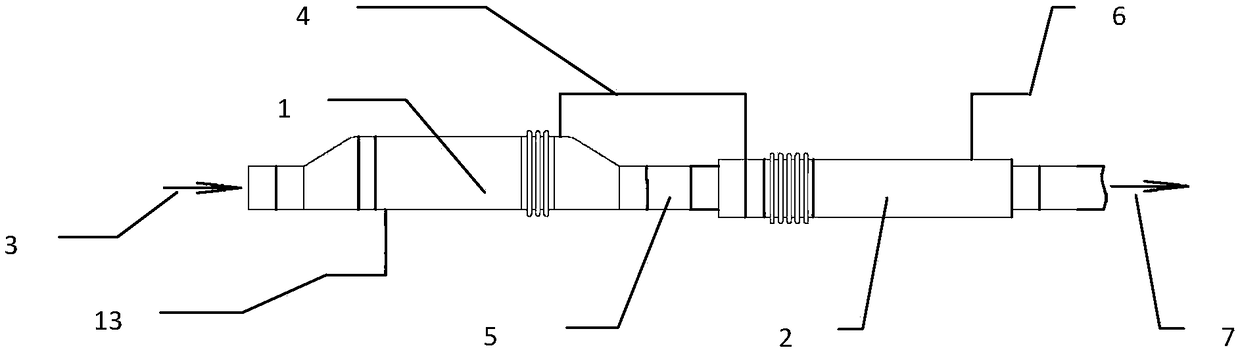

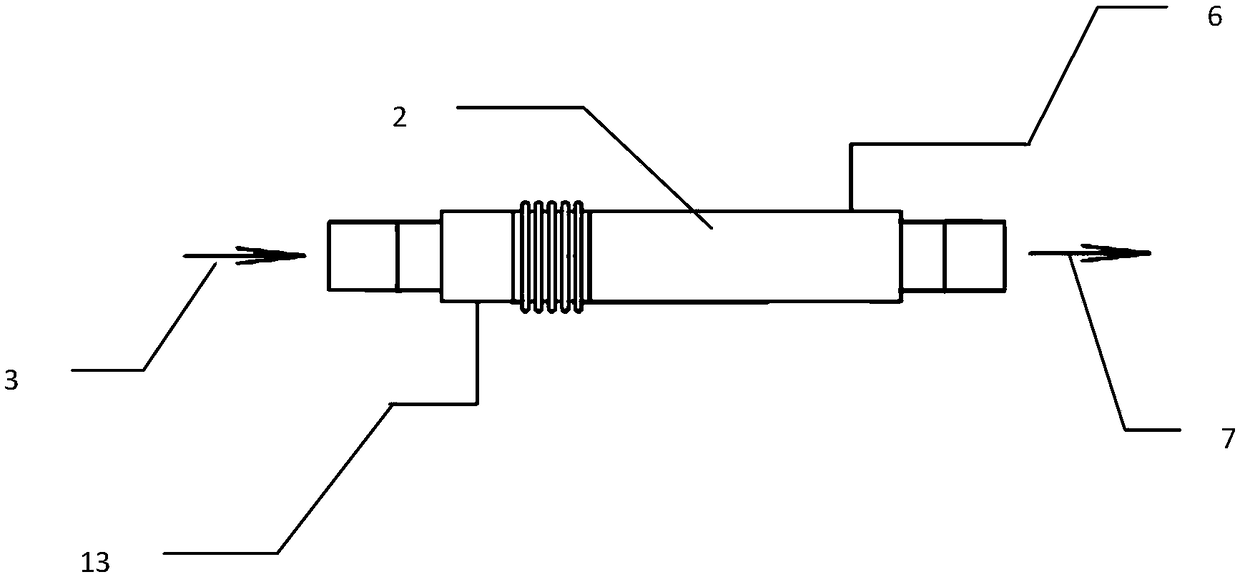

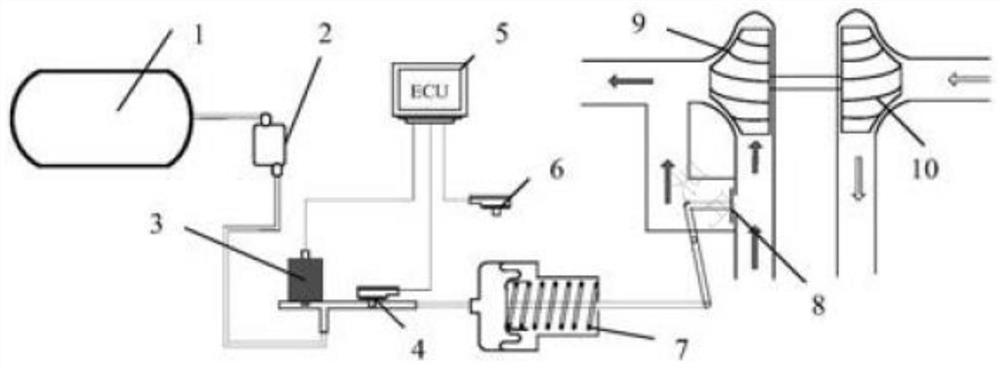

Two-stage electric control pneumatic pressurization system with adjustable turbine bypass valve and variable altitude control method of two-stage electric control pneumatic pressurization system

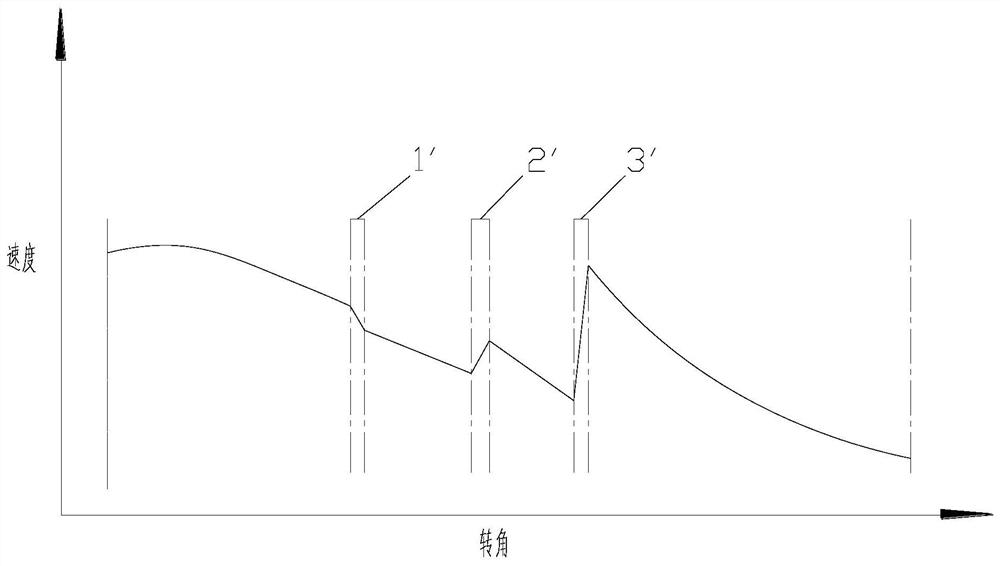

PendingCN110529234AHigh breakaway operating speedReduce exhaust lossElectrical controlInternal combustion piston enginesTurbochargerClosed loop feedback

A two-stage electric control pneumatic supercharging system with an adjustable turbine bypass valve comprises a high pressure-stage turbocharger, a low pressure-stage turbocharger, a high pressure-stage intercooler, a low pressure-stage intercooler and an adjusting device. The high pressure-stage turbocharger and the low-pressure stage turbocharger comprise a high-pressure stage turbocharger and alow-pressure stage turbocharger which are connected in series, the high-pressure stage turbocharger comprises a high-pressure stage bypass valve turbine and a high-pressure stage air compressor, andthe low-pressure stage turbocharger comprises a low-pressure stage bypass valve turbine and a low-pressure stage air compressor; the high-low pressure stage intercooler is composed of a high-pressurestage compressor intercooler and a low-pressure stage compressor intercooler, and the adjusting device comprises a vacuum pump, an electromagnetic valve, a pneumatic actuator, a bypass valve and a connecting pipeline. According to the variable-altitude control method of the system, the variable-altitude full-working-condition supercharging pressure adjustment of the engine can be realized by controlling the opening degree and the opening and closing of each valve, utilizing the calibrated supercharging pressure and the air pressure MAP in a pneumatic actuator and adopting two modes of closed-loop feedback and open-loop feedforward for adjustment according to the working conditions of the engine.

Owner:MILITARY TRANSPORTATION UNIV PLA

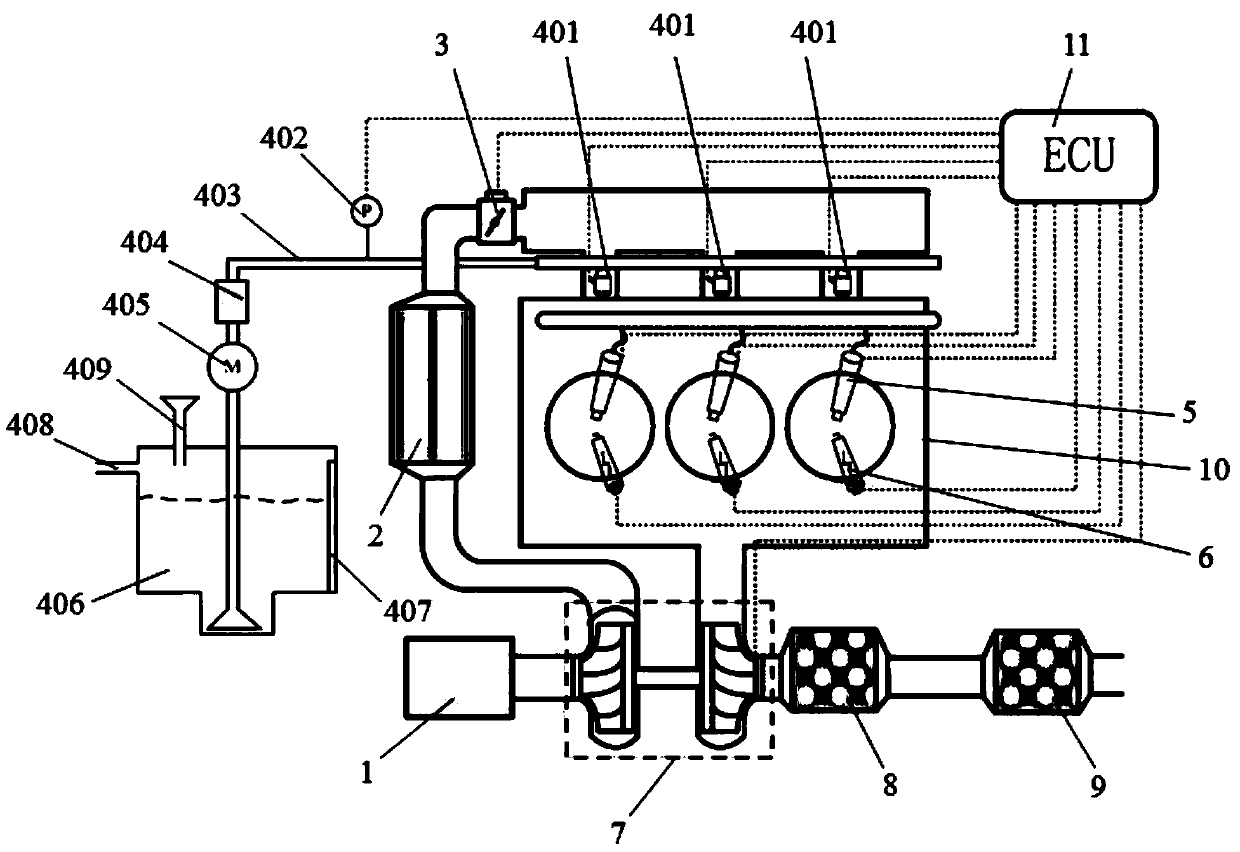

Lean burn engine and automobile

ActiveCN111379634AEfficient and clean combustionLower combustion temperatureElectrical controlNon-fuel substance addition to fuelLean combustionWater pipe

The invention belongs to the technical field of engines, and relates to a lean burn engine and an automobile. The lean burn engine comprises a water spraying system and an electric control unit, wherein the water spraying system comprises air flue water sprayers, pressure sensors and a water supply device; the air flue water sprayers are connected with the water supply device through water pipes;the pressure sensors are used for detecting the pressure values of the water pipes and sending the pressure values to the electric control unit; the air flue water sprayers are arranged on air inlet channels of air cylinders of the engine and spray water to the air inlet channels; the electric control unit is in signal connection with the air flue water sprayers and the pressure sensors; and whenthe engine is in different work conditions, the pressure values of the water pipes change, the pressure sensors send corresponding signals to the electric control unit according to the different pressure values of the water pipes, and the electric control unit controls the air flue water sprayers to adjust the water spraying amount. According to the lean burn engine, the electric control unit controls the air flue water sprayers to adjust the water spraying amount according to different engine work conditions (loads), and efficient clean combustion of the engine is achieved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Coal mine ventilation air methane oxidation system

InactiveCN103933837AReduce exhaust lossReal-time acquisition of monitoring measurement dataMining devicesDispersed particle separationDischarge measurementsProcess engineering

The invention aims to provide a coal mine ventilation air methane oxidation system characterized by stable operation, short system startup time and high heat recovery efficiency. Through matching combination of a gas distribution device, a device body, a reversing device, an actuating device and a measuring and control device, especially the reversing device composed of two three-way valves, the ventilation air methane loss in the pipeline is effectively reduced. The whole system operation, which includes switching of the reversing device, flow measurement and adjustment, pressure and temperature measurement, methane concentration monitoring and feedback, is all carried out under monitoring of the monitoring device. The monitoring and measurement data can be acquired in real time, and a ventilation air methane oxidation operation adjustment scheme can be worked out timely, thus realizing the effects of energy saving and emission reduction. The coal mine ventilation air methane oxidation system provided by the invention has the advantages of stable operation, short system startup time, and high heat recovery efficiency.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

Energy-saving single-screw compressor

InactiveCN101832267ALarge displacementReduce leakageRotary piston pumpsRotary piston liquid enginesGas compressorEngineering

The invention provides a single-screw compressor. The tooth form of a star wheel thereof is a reverse bevel edge with a tooth top wider than a dedendum width. The star wheel tooth of the single-screw compressor of the invention adopts a unique shape and greatly increases the volume of a screw channel under the condition of slightly increasing the length of a meshing pair leakage line, thus reducing the leakage rate of the unit air displacement of the compressor, lowering the air displacement loss of the compressor and improving the efficiency of the compressor. The single-screw compressor of the invention can be widely applied in various industries requiring compressors.

Owner:北京力通高科技发展有限公司

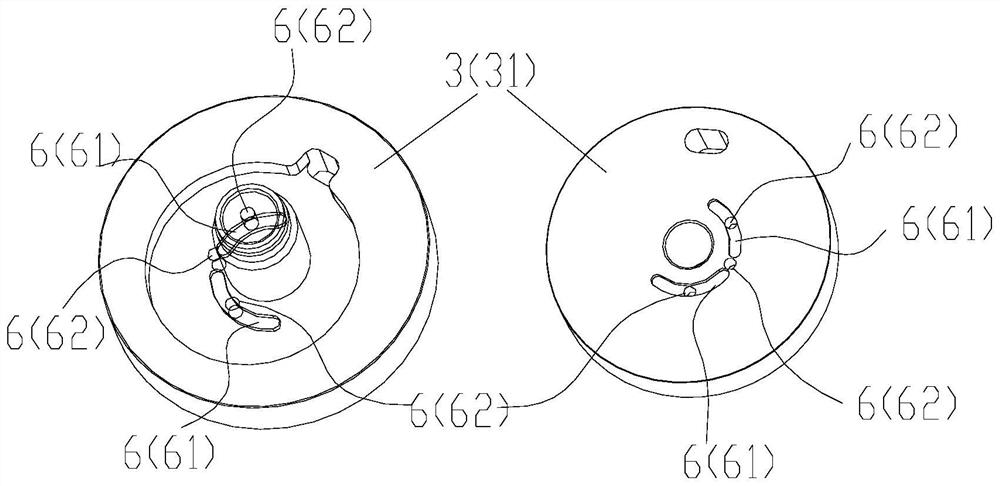

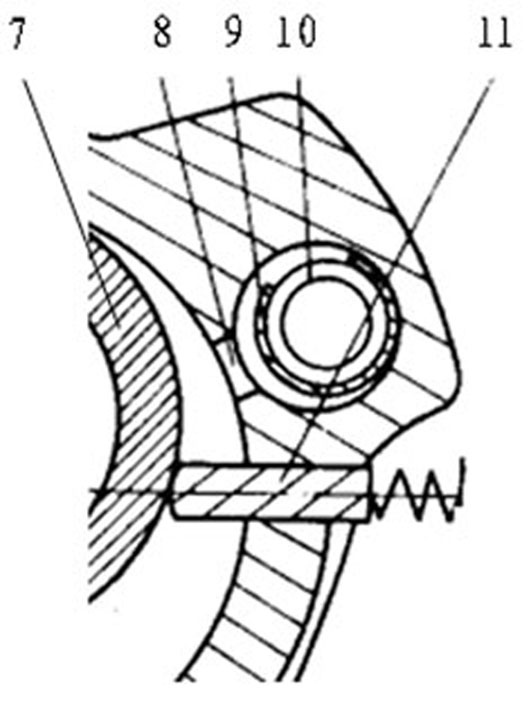

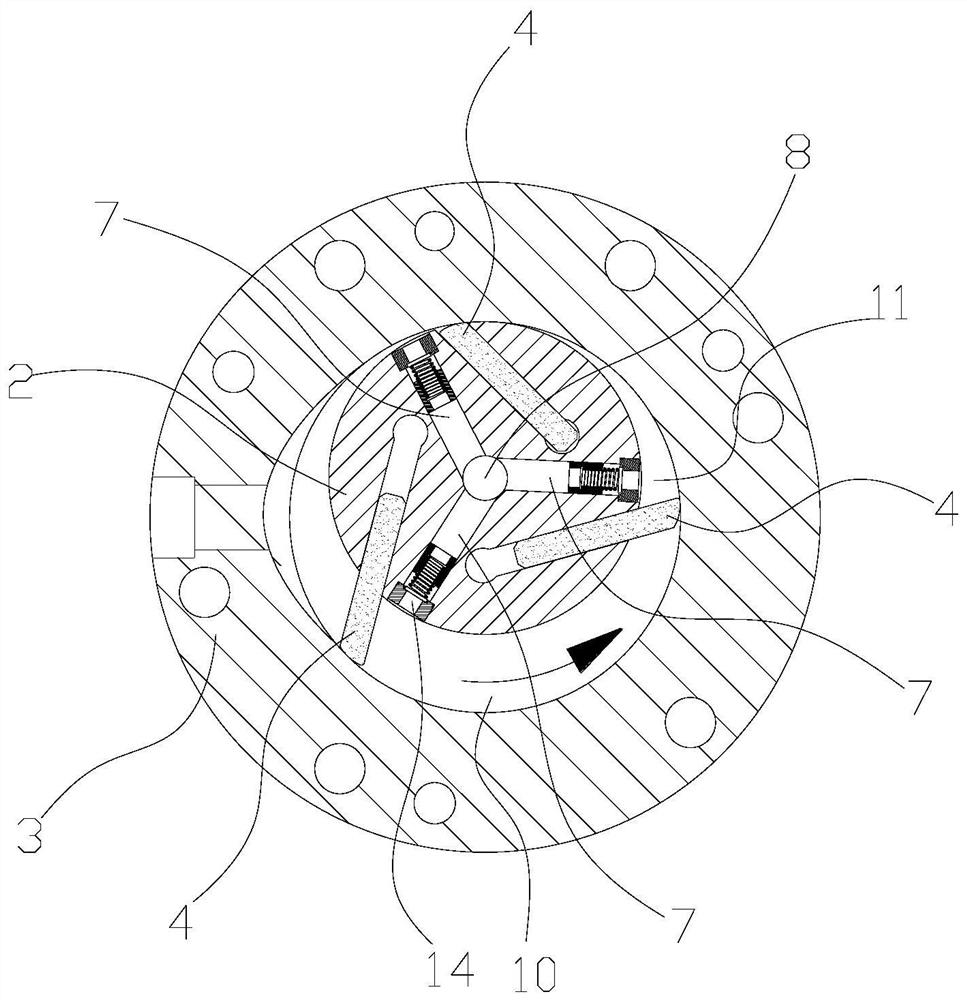

Sliding Vane Type Compressor and Exhaust Structure Thereof

ActiveUS20170342982A1Low production costReduce exhaust lossRotary piston pumpsRotary piston liquid enginesEngineeringFlange

Disclosed are a sliding vane compressor and an exhaust structure thereof. The exhaust structure of the sliding vane compressor includes: an exhaust hole, the exhaust hole being formed in a flange of the sliding vane compressor and being in communication with a compression cavity of a cylinder of the sliding vane compressor; a guide channel, the guide channel being formed on the flange and penetrating through the flange; and an exhaust channel, the exhaust channel being formed on an eccentric circle of the sliding vane compressor, and the exhaust channel being used for communicating the compression cavity with the guide channel using the rotation of the eccentric circle. The sliding vane compressor and the exhaust structure thereof have a small exhaust loss, thereby effectively reducing the power consumption and the production and manufacturing costs of the sliding vane compressor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

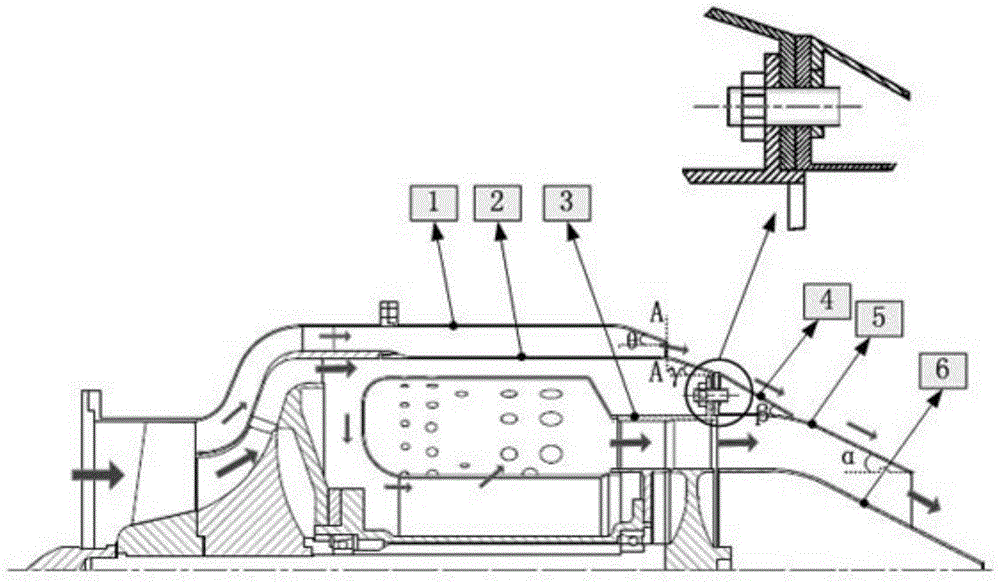

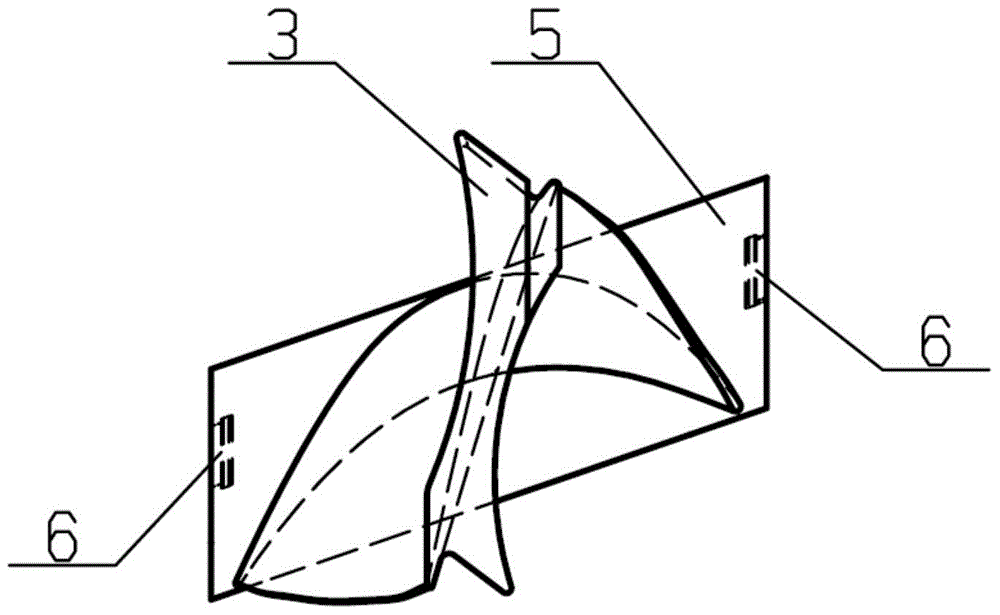

Asymmetrical exhaust structure of lift fan

InactiveCN109606644AReduce exhaust lossGuaranteed nozzle performance and fan aerodynamic performancePropellersVertical landing/take-off aircraftsAirplaneNozzle

The invention belongs to the field of structural designs of aircraft engines, and in particular relates to an asymmetrical exhaust structure of a lift fan. The asymmetrical exhaust structure comprisesan asymmetrical caudal vertebra (4), an adapting cartridge receiver (5) and a sprayer nozzle (6). A fairing adapting section is arranged on the adapting cartridge receiver (5), wherein one end of thefairing adapting section is connected to the asymmetrical caudal vertebra (4) and is coaxial with the lift fan; and the other end of the fairing adapting section is connected to the sprayer nozzle (6) and is coaxial with the sprayer nozzle (6). The middle part of the fairing adapting section is a smooth curved surface section. The lift fan is of an asymmetrical exhaust structure. The adapting cartridge receiver provided with the fairing adapting section is connected to the asymmetrical caudal vertebra and the sprayer nozzle, so that the exhaust loss of the lift fan can be reduced and the sprayer nozzle performance and the fan pneumatic performance are guaranteed.

Owner:AECC SHENYANG ENGINE RES INST

Compressor and air conditioner

InactiveCN111963431AGuaranteed to workGuaranteed reliabilityRotary piston pumpsRotary piston liquid enginesThermodynamicsExhaust valve

The invention provides a compressor and an air conditioner. The compressor comprises a main shaft, an air cylinder, a flange and a slip sheet, wherein the main shaft comprises convex parts, and the convex parts, the air cylinder, the flange and the slip sheet jointly form compression cavities, at least one main shaft exhaust port is formed in the position, corresponding to each compression cavity,of the convex parts, a flange exhaust port is formed in the flange, one ends of the main shaft exhaust ports communicate with the compression cavities, the other ends of the main shaft exhaust portscan communicate with the flange exhaust port in the rotating process of the main shaft so as to exhaust air, an exhaust valve assembly is arranged at the flange exhaust port, and the exhaust valve assembly can automatically exhaust the air according to the pressure in the compression cavities. According to the compressor and the air conditioner, the structural design of the main shaft exhaust ports, the exhaust valve assembly and the flange exhaust port, it is effectively guaranteed that the number and area of the exhaust port in each compression cavity are fixed, the exhaust port area is large, the exhaust speed is reduced, smooth exhaust of the compressor can be achieved, exhaust losses are effectively reduced, the exhaust mode is simple, and the working performance and reliability of the compressor are ensured.

Owner:GREE ELECTRIC APPLIANCES INC

A method and device for collecting heat and storing energy by solar energy double-cavity metal oxide particles

ActiveCN104482663BAvoid tightnessAvoid pollutionExothermal chemical reaction heat productionSolar heat devicesReaction rateAir exchange

The invention relates to a heat collection and energy storage method of solar dual-cavity type metallic oxide particles and a device thereof. Focused sunlight enters into a light suction cavity of a dual-cavity type heat collection reactor to heat a separating plate surface and preheat the metallic oxide particles; the preheated metallic oxide particles enter into a reaction cavity; the metallic oxide particles are heated and reduced along the temperature raising to release oxygen; the released oxygen is output through a gas outlet of the reaction cavity; the reduced metallic oxide particles are output through a particle outlet of the reaction cavity; the reduced metallic oxide particles enter into a restored particle storage box, and then enter into an oxidation heat exchanger to react with the oxygen from the gas outlet of the reaction cavity to release stored chemical energy; the chemical energy is transmitted to a heated working substance; the oxidized metallic oxide particles enter into an oxidized particles storage box and then enter into a light suction cavity particle inlet through a particle conveying device, and air is led in from the environment so as to control the gas flow of the reactor and the reaction rate of the oxidation heat exchanger; the entered air exchanges heat with the residual gas in the oxidation heat exchanger in advance to improve efficiency.

Owner:ZHEJIANG UNIV

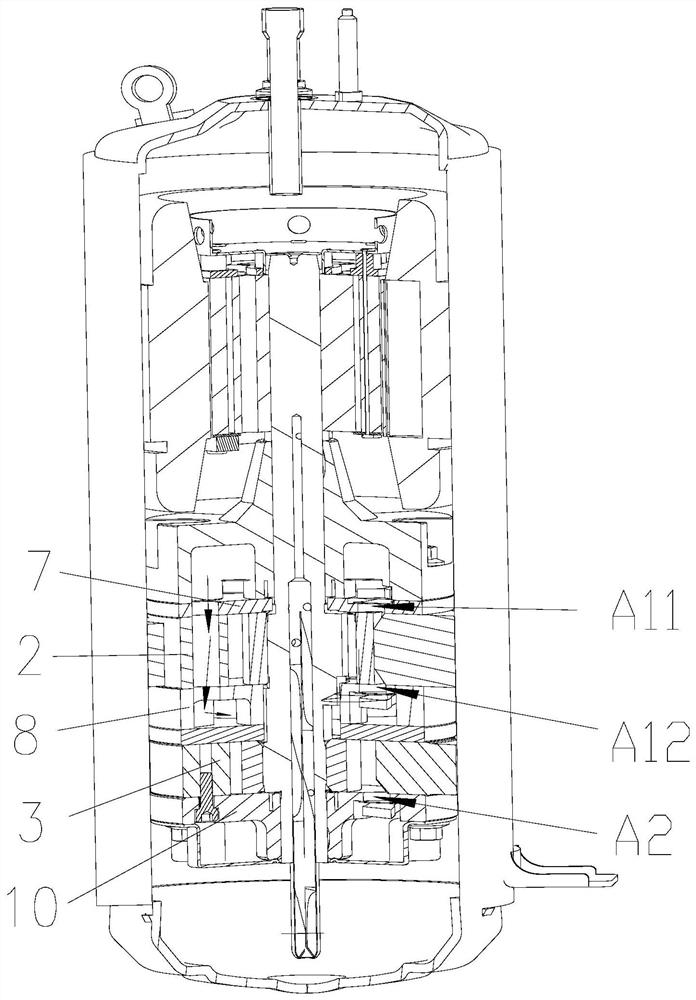

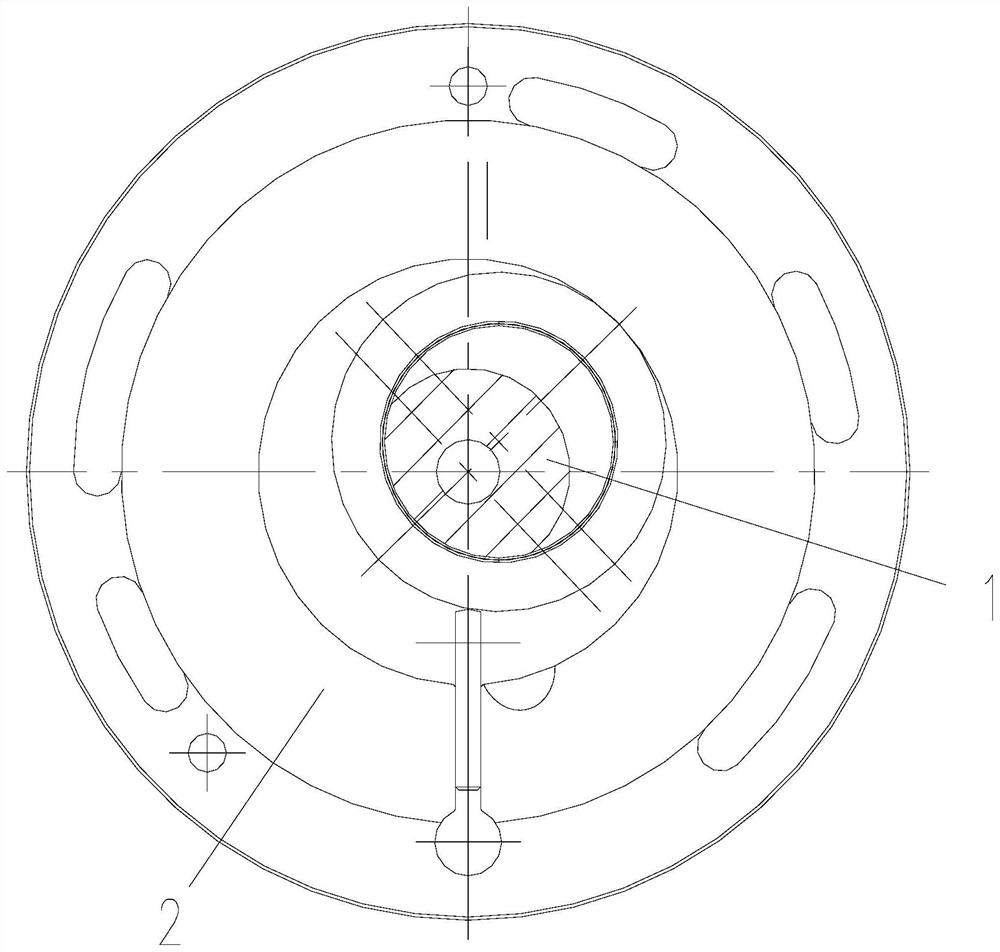

Single-screw compressor

ActiveCN105508243AIncrease the internal pressure ratioWide applicabilityRotary piston pumpsRotary piston liquid enginesGas compressorHelix

Owner:GREE ELECTRIC APPLIANCES INC +1

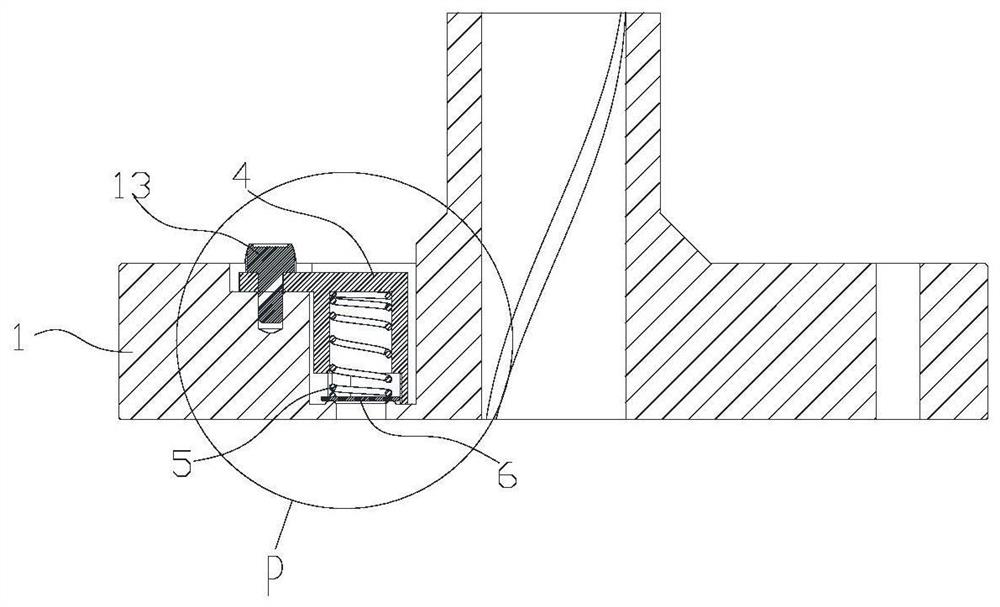

Balance valve control system and control method of asymmetric turbocharger

ActiveCN111779567AAvoid lostEmission reductionElectrical controlInternal combustion piston enginesAutomotive engineeringDiaphragm valve

The invention relates to a balance valve control system and a control method of an asymmetric turbocharger. The control system comprises a balance valve control valve, an engine control unit, a supercharger balance valve control diaphragm valve, a balance valve plate and a supercharger turbine. The control method comprises the steps that of 1, collecting actual supercharging pressure and EGR rateby the engine control unit; 2, comparing with target supercharging pressure and EGR rate, and determining whether adjustment is needed or not; 3, determining the target outlet air pressure of the balance valve control valve; 4, determining a duty ratio, and performing outlet air pressure adjustment; 5, enabling the actual outlet air pressure to be acted on a supercharger balance valve control diaphragm valve; 6, moving a valve element to change the opening degree of the valve plate of the balance valve, thereby causing the change of the output work and the pre-vortex pressure of the supercharger turbine; 7, changing the acting amount of the air compressor on air, and changing the supercharge pressure; and 8, changing the EGR rate of the engine. The control system and control method disclosed by the invention can reduce the pre-vortex pressure and the engine exhaust loss at medium and high rotating speed, and the economic performance and the environment-friendly performance of the engine are improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

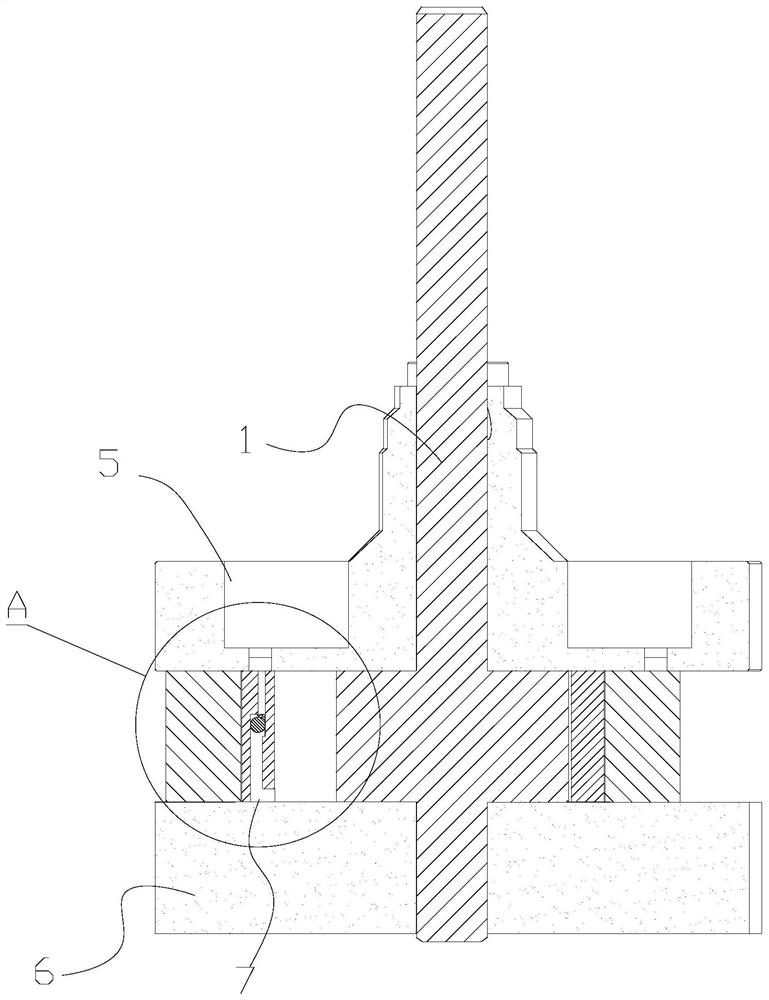

Exhaust limiting plate for improving energy efficiency of compressor, and compressor

PendingCN111425376AImprove energy efficiencyReduce exhaust lossPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveEngineering

The invention relates to the technical field of compressors, in particular to an exhaust limiting plate for improving the energy efficiency of a compressor. The exhaust limiting plate for improving the energy efficiency of the compressor comprises a limiting plate body, wherein the periphery of the limiting plate body is matched with an installation groove in a valve plate; a lug boss for tightlypressing an exhaust valve plate is arranged at one end of the limiting plate body; a clamping part matched with the installation groove is arranged at the other end of the limiting plate body; the limiting plate body is provided with a liming surface in the direction from the lug boss to the clamping part; the exhaust valve plate is limited by the limiting surface when being opened to a maximum angle; a concave pit concaved locally is arranged at one end, far away from the lug boss, of the limiting surface; and the exhaust valve plate is firstly limited by the limiting surface when being opened to the maximum angle, then a tongue part of the exhaust valve plate continuously moves in the foundation pit, and the exhaust valve plate is finally rebounded and closed. According to the exhaust limiting plate for improving the energy efficiency of the compressor provided by the invention, the energy efficiency of the compressor is improved.

Owner:黄石东贝压缩机有限公司

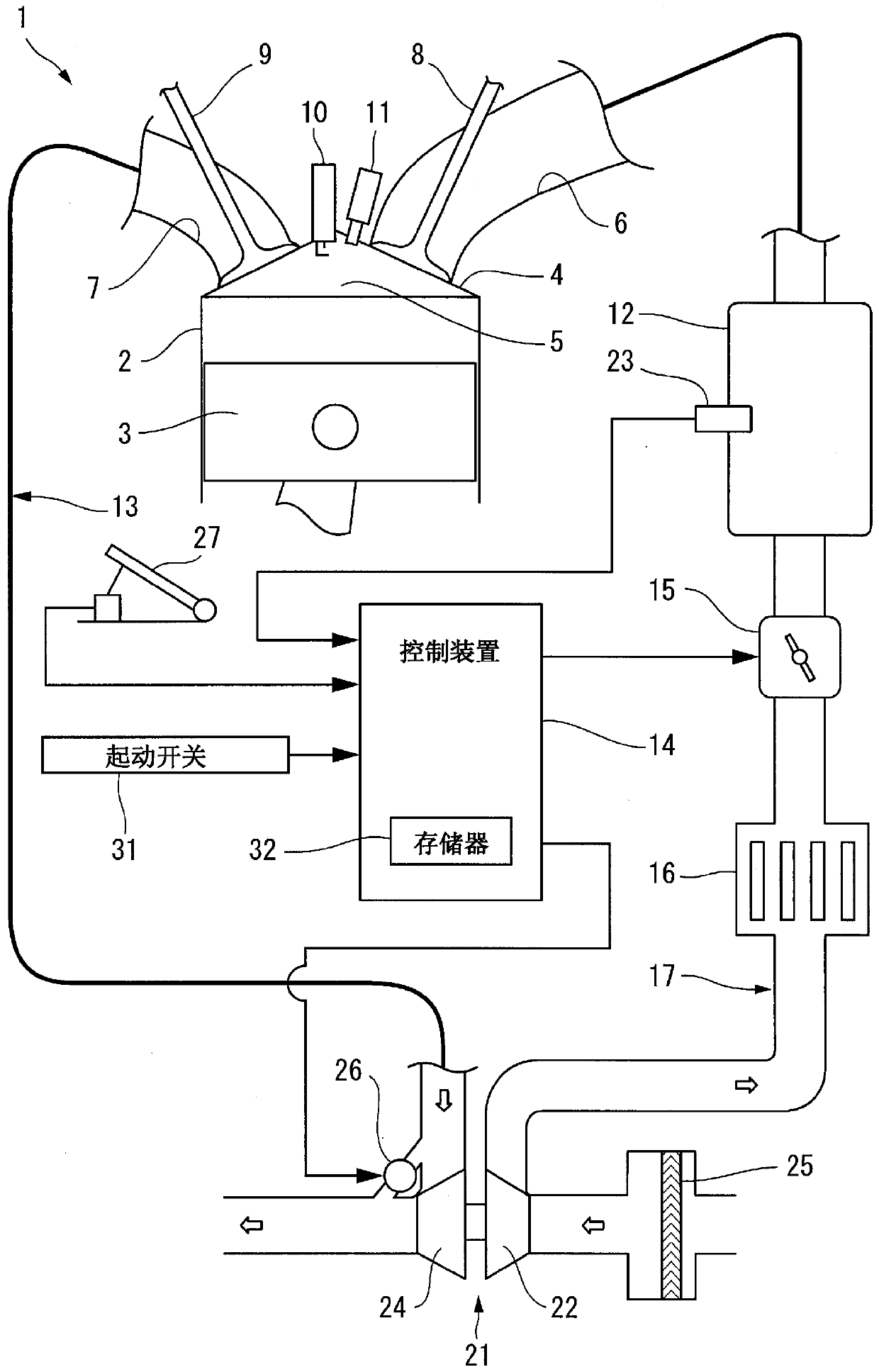

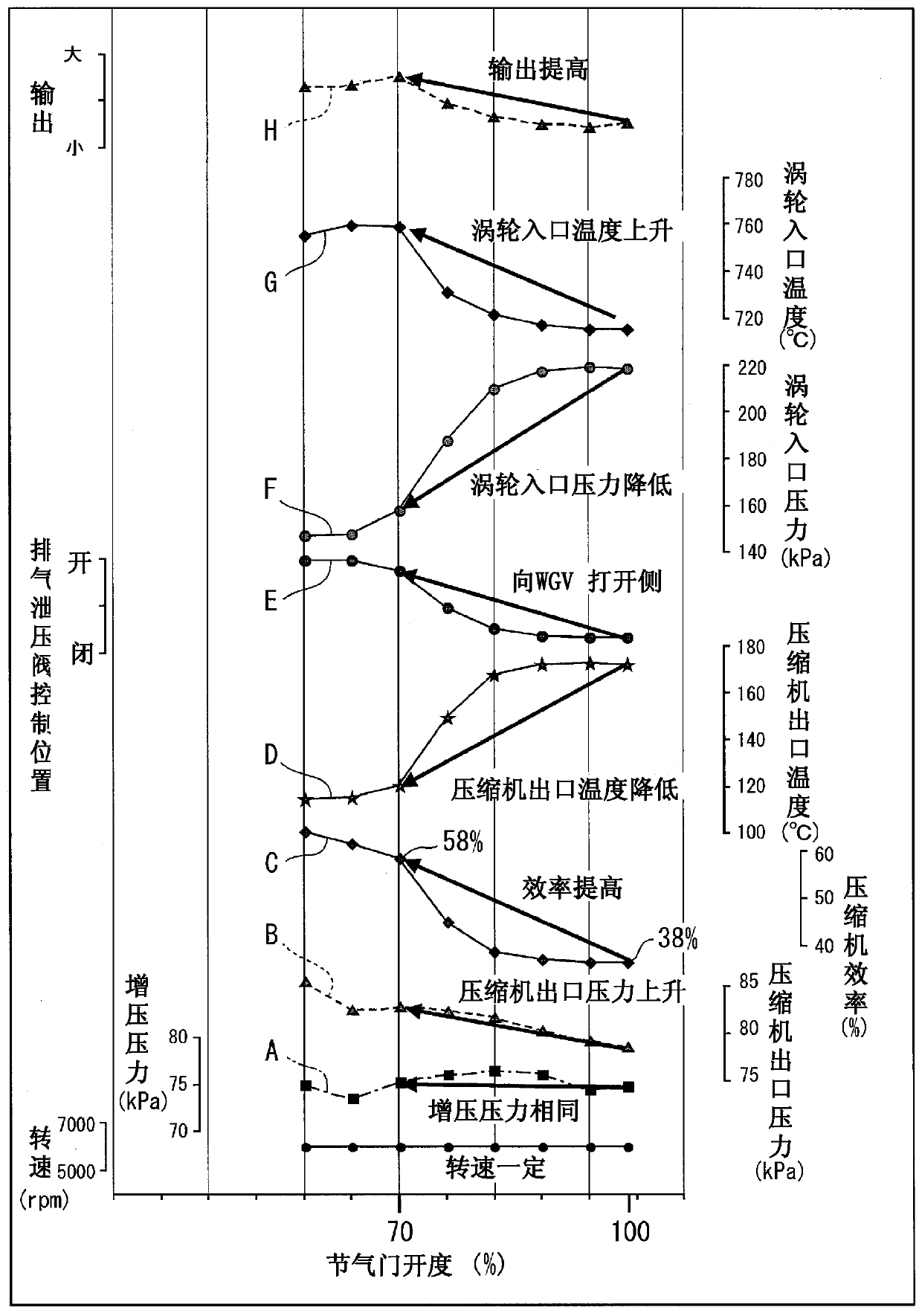

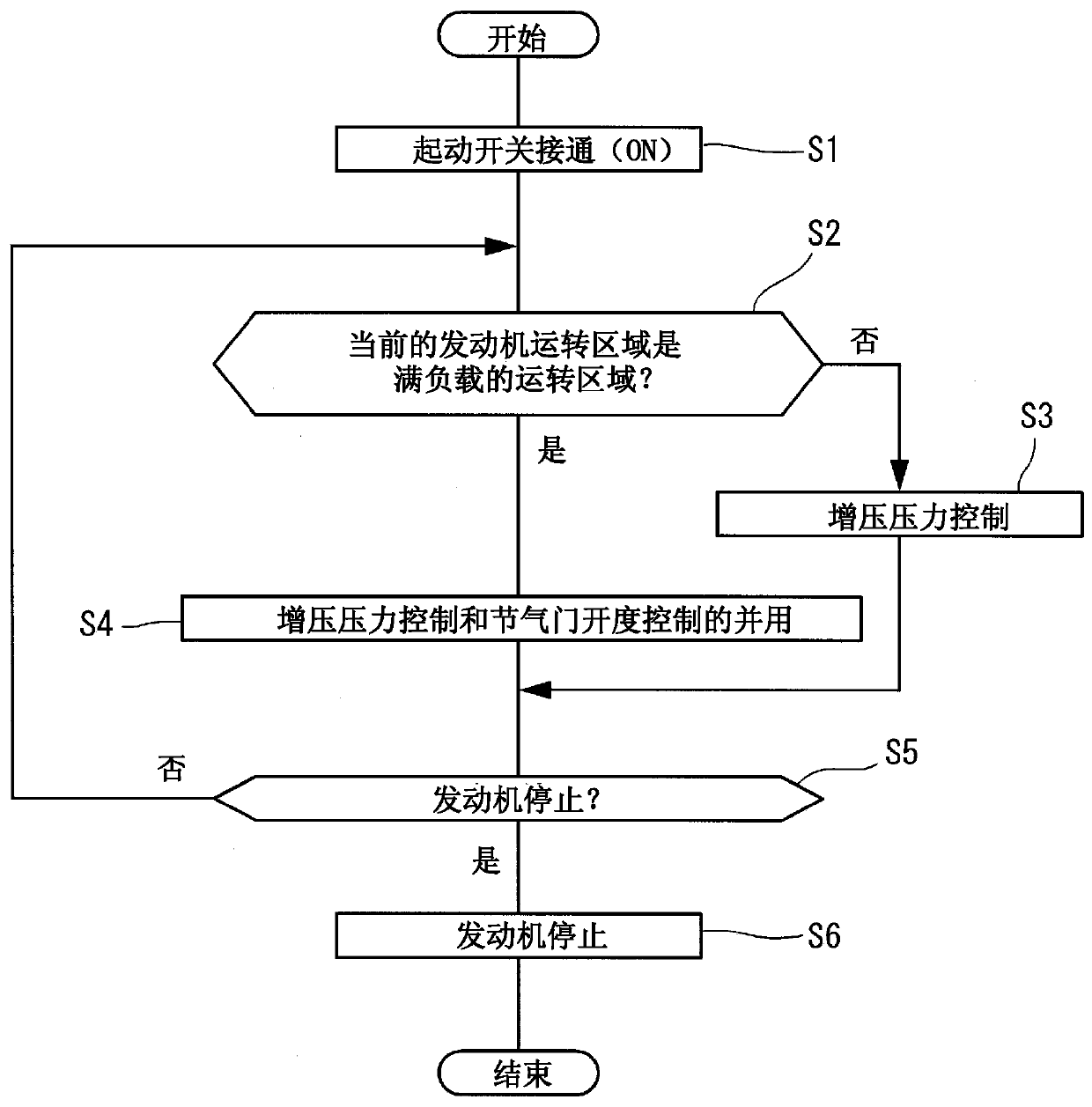

Turbocharger-equipped engine and method for operaing turbocharger-equipped engine

InactiveCN109715917AImprove efficiencyReduce exhaust lossInternal combustion piston enginesEngine controllersCombustion chamberSurge tank

A turbocharger-equipped engine comprises: an intake port (6) and an exhaust port (7), which are connected to a combustion chamber (5); a surge tank (12); and a turbocharger (21) having a turbine (24)located at a position along the length of an exhaust passage (13), the turbocharger (21) also having a compressor (22) rotating with the turbine (24). The turbocharger-equipped engine further comprises: a waste gate valve (26) for regulating the supercharging pressure of the turbocharger (21); a throttle valve (15) provided in an intake passage (17) between the compressor (22) and the surge tank (12); and a control device (14) for controlling the operation of both a control valve and the throttle valve (15). When the engine is operated in a full-load operation range, the control device (14) sets the maximum degree of opening of the throttle valve (15) to the degree of opening closer to the closed side than the degree of opening corresponding to a fully opened throttle position and controlsthe throttle valve (15) so that the compressor efficiency of the compressor (22) will be higher than compressor efficiency corresponding to the fully opened throttle position. The compressor has increased efficiency when the engine is operated in the full-load operation range, and the output of the engine is further increased.

Owner:YAMAHA MOTOR CO LTD

Exhaust device of rolling rotor compressor pump body

ActiveCN102072160AIncrease the cross-sectional areaReduced clearance volumeRotary/oscillating piston pump componentsLiquid fuel engine componentsEngineeringLimiter

The invention discloses an exhaust device of a rolling rotor compressor pump body, mainly comprising an air cylinder provided with a round pore passage, a bent valve plate, a lift limiter with steps, an air cylinder end cover with a stepped exhaust hole, and a gasket, wherein the valve plate, the gasket and the lift limiter are installed in the pore passage of the air cylinder; after the compressor is assembled, the upper end cover of the air cylinder, the lower end cover of the air cylinder and the shell of the compressor seal the pore channel on the air cylinder to form an exhaust space which takes an opened valve plate as an inlet and the stepped exhaust hole on the air cylinder end cover as an outlet. The exhaust device has the advantages of small exhaust loss, low exhaust noise and being easy in processing and assembly.

Owner:NORTHEASTERN UNIV +1

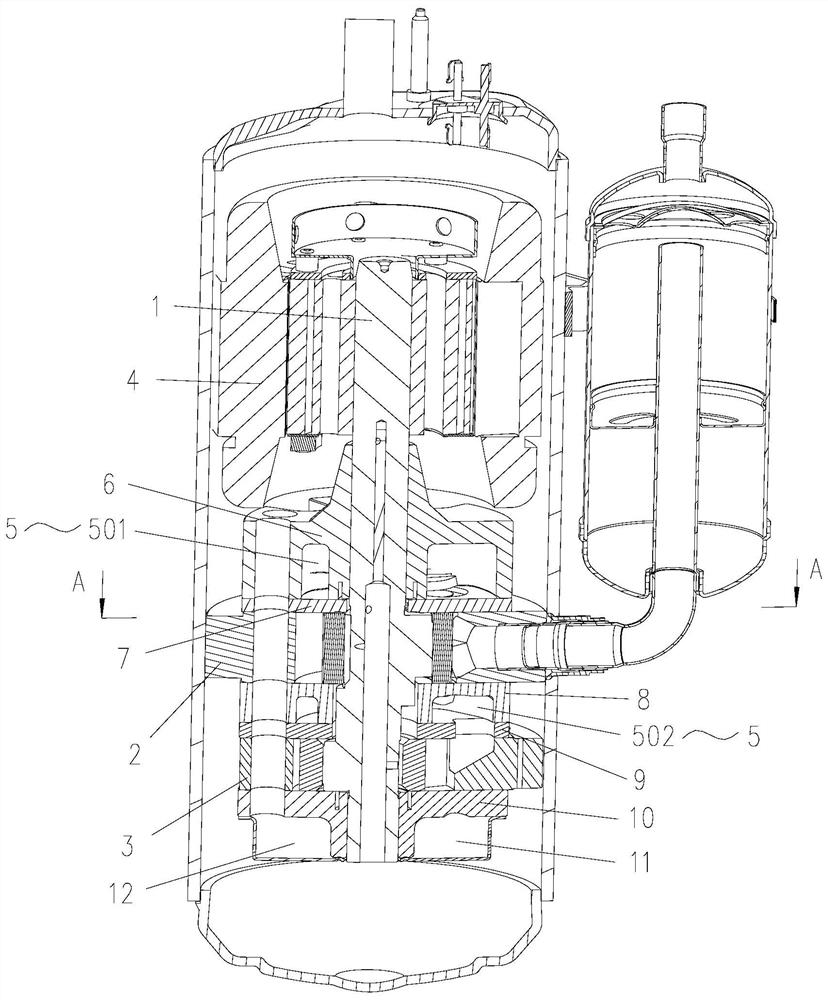

Pump components, compressors and air conditioners

ActiveCN111963434BConsistent exhaust areaReduce the frequency of opening and closingRotary piston pumpsRotary piston liquid enginesExhaust valveEngineering

The application provides a pump body assembly, a compressor and an air conditioner. The pump body assembly includes a main shaft (1), a flange, a cylinder seat (9), a cylinder (3) and slides (4), the main shaft (1) includes a convex part (2), and a plurality of slides (4) along the circumference The flange, cylinder (3), sliding plate (4) and convex part (2) enclose a compression chamber (10), the cylinder (3) only rotates on its own, and the cylinder (3) corresponds to Each compression chamber (10) is provided with a first exhaust channel (7), the flange is provided with a second exhaust channel (8), and the first exhaust channel (7) is provided with a first exhaust channel (7). Passage (7) opens or closes the exhaust valve assembly (11). According to the pump body assembly of the present application, sudden changes in the exhaust speed can be effectively avoided, the frequency of opening and closing of the exhaust valve assembly can be reduced, and the reliability and stability of the operation of the compressor can be ensured.

Owner:GREE ELECTRIC APPLIANCES INC

Valve set structure for reciprocating compressor

ActiveCN100392244CGuaranteed grinding qualitySimple structurePositive displacement pump componentsPositive-displacement liquid enginesExhaust valveEngineering

The invention discloses reciprocating compressor valve block structure. It includes steeliness valve plate, exhaust valve plate, valve plate support, air suction valve plate, valve plate spacercy, cylinder cover, cylinder cover spacercy and elastic plate. The valve plate is plane. The exhaust valve plate and elastic valve plate are fixed on the valve plate. It has the advantages of good technology assurance and low air tight seal underline rate. This can improve clearance volume efficiency and compressor working efficiency.

Owner:JIAXIPERA COMPRESSOR

Lean burn engine and automobile

ActiveCN111379634BEfficient and clean combustionLower combustion temperatureElectrical controlNon-fuel substance addition to fuelSprayerEngineering

The invention belongs to the technical field of engines, and relates to a lean-burn engine and an automobile. The lean-burn engine includes a water spray system and an electronic control unit; the water spray system includes an air passage sprinkler, a pressure sensor and a water supply device, and the air passage sprinkler It is connected to the water supply device through a water pipe, and the pressure sensor is used to detect the pressure value of the water pipe and send it to the electronic control unit. The sprinkler is connected to the pressure sensor signal. When the engine is in different working conditions, the pressure value of the water pipe changes, and the pressure sensor sends corresponding signals to the electronic control unit according to the different pressure values of the water pipe, and the electronic control unit controls the airway sprinkler. Adjust the amount of water spray. In the lean-burn engine of the present application, the electronic control unit controls the airway water injector to adjust the water injection amount according to different engine working conditions (loads), so as to realize efficient and clean combustion of the engine.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

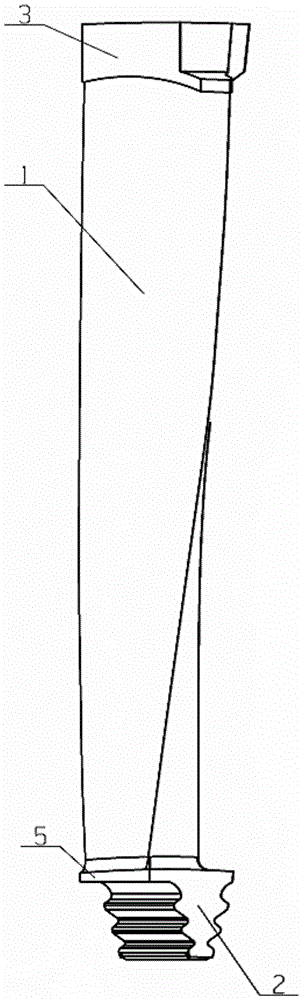

Split exhaust for micro turbofan with rectifier

The invention discloses a miniature turbofan engine separate exhausting device with a rectifier. The miniature turbofan engine separate exhausting device is located in the position of an exhausting outlet of a miniature turbofan engine and comprises an outer case, a turbine guider case, the rectifier, an intermediate case, an inner spray pipe and a center cone which are sequentially connected. The difference value between the shrinkage angle of the rectifier and the shrinkage angle of the inner spray pipe and the difference value between the shrinkage angle of the rectifier and the shrinkage angle of the rear section of the outer case both range from -5 degrees to 5 degrees. By the adoption of the miniature turbofan engine separate exhausting device, friction loss and viscosity loss caused in the exhausting process of the miniature turbofan engine can be greatly reduced; and in addition, the problem that a thread is difficultly machined on high-temperature alloy is solved, connection is convenient, and the structure is simple and feasible.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

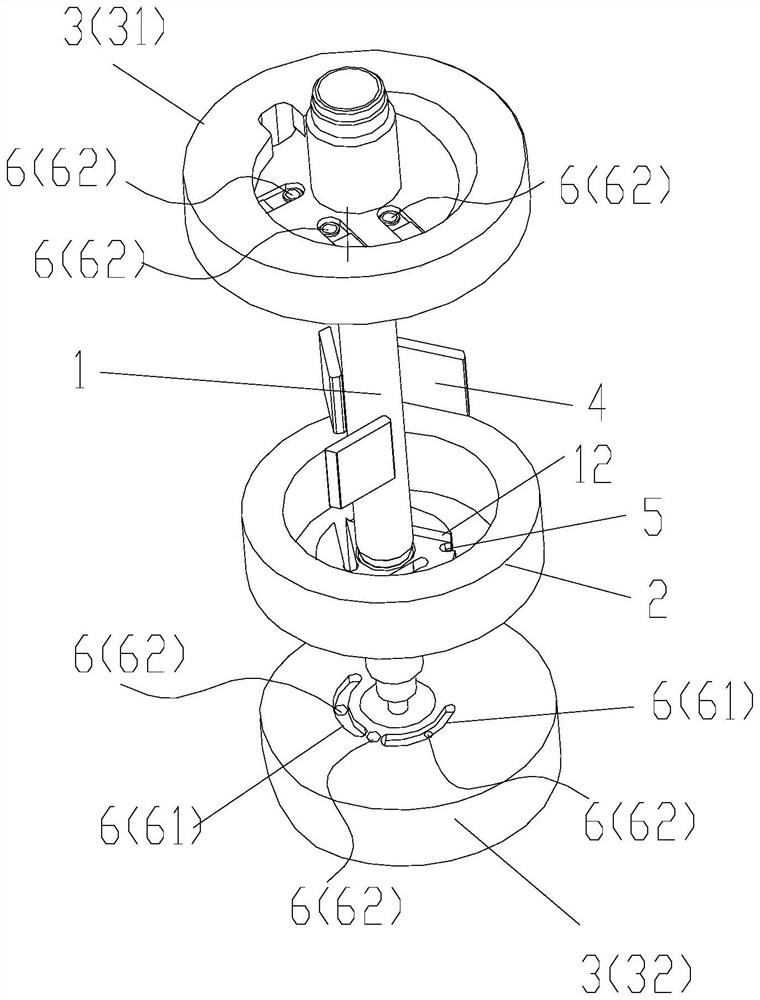

Pump body assembly, compressor and air conditioner

ActiveCN111963428AImprove performanceExhaust chamber area increasedRotary piston pumpsRotary piston liquid enginesExhaust valveEngineering

The invention provides a pump body assembly, a compressor and an air conditioner. The pump body assembly comprises a main shaft, a flange, air cylinders and sliding vanes, the main shaft comprises a convex part, the multiple sliding vanes are arranged on the convex part at intervals in the circumferential direction, compression cavities are defined by the flange, the air cylinders, the sliding vanes and the convex part, at least one radial exhaust channel is formed in the position, corresponding to each compression cavity, of the convex part, an axial exhaust channel is further formed in the main shaft and extends to the exterior of a matching area of the flange and the main shaft in the axial direction of the main shaft and communicates with the space outside the pump body assembly, the radial exhaust channel is internally provided with an exhaust valve assembly, and when the pressure of refrigerants in the compression cavities reaches the preset pressure, the exhaust valve assembly communicates with the compression cavities and the axial exhaust channel. According to the pump body assembly, the area of the exhaust channel can be unlimited, meanwhile, leakage in the compression process of the compressor can be effectively avoided, and the performance of the compressor is ensured.

Owner:GREE ELECTRIC APPLIANCES INC

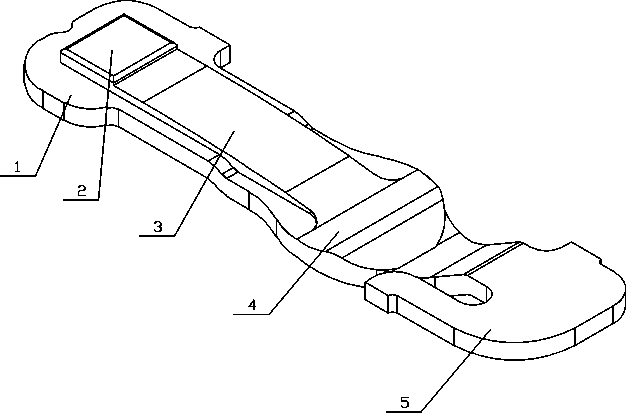

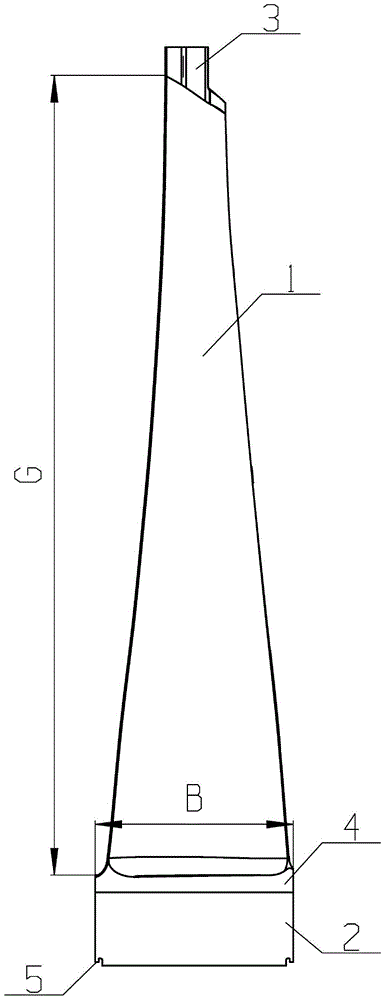

Second-to-last stage moving blades for half-speed large-capacity nuclear power steam turbines

ActiveCN105317466BIncrease the areaImprove rigidityBlade accessoriesMachines/enginesStress concentrationNuclear power

The invention provides a secondary-secondary last-stage moving blade for a half-speed high-capacity nuclear turbine. The secondary-secondary last-stage moving blade comprises shroud rings, a blade work portion, a middle body and a blade root. The height of the blade work portion is 905 mm, the molded line is a variable-section twisted blade, the area of the section of the blade is gradually reduced along with increase of the height of the section of the blade, and relative twisting exists between two adjacent sections. The shroud rings are located at the top of the blade work portion. The blade root is located at the bottom of the blade work portion, and is a laterally-mounted, large-circular-bead and low-stress-concentration longitudinal tree-shaped blade root. The middle body is located between the blade work portion and the blade root, and the width of the middle body is identical to the axial width of the blade root. The shroud rings, the blade work portion, the middle body and the blade root are integrally formed. In a static state, a clearance between the work faces of two adjacent shroud rings is zero. The adjacent shroud rings at work rotating speed are coupled to enable the whole ring of the secondary-secondary last-stage moving blade to be connected into a set. The secondary-secondary last-stage moving blade can be suitable for an AP1000 and future CAP1400 / CAP1700 nuclear power steam turbine generator unit, and the requirement of the half-speed high-capacity nuclear turbine for aerodynamic performance and strength can be met well.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

compressor

ActiveCN112360739BReduce exhaust lossImprove energy efficiency ratioRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsElectric machineryEngineering

The invention provides a compressor, comprising: a crankshaft; a low-pressure cylinder and a high-pressure cylinder, the crankshaft is mounted on the low-pressure cylinder and the high-pressure cylinder, and the low-pressure cylinder is located on the side of the high-pressure cylinder close to the motor of the compressor; The side of the high-pressure cylinder close to the motor has a medium-pressure exhaust port between the low-pressure cylinder and the middle chamber, which is used to communicate with the low-pressure cylinder and the middle chamber, so that the refrigerant flowing out of the low-pressure cylinder flows into the high-pressure cylinder after passing through the middle chamber; among them, The total gas circulation area of the low-pressure cylinder exhausting into the intermediate cavity through the medium-pressure exhaust port is S1, and the total displacement of the low-pressure cylinder exhausting into the intermediate cavity through the medium-pressure exhaust port is V1, 3.5×10 ‑3 ≤S1 / V1≤6.5×10 ‑3 . The compressor of the present invention solves the problem of increased exhaust loss due to the complicated exhaust process of the two-stage compressor placed above the low-pressure cylinder in the prior art.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Boiler burning pulverized coal heating equipment

PendingCN108506957AImprove space utilizationReduce exhaust lossLump/pulverulent fuel preparationPowder mixtureBoiler furnace

The invention relates to boiler burning pulverized coal heating equipment. The boiler burning pulverized coal heating equipment comprises A-type pulverized coal heating equipment and B-type pulverizedcoal heating equipment. The A-type pulverized coal heating equipment and the B-type pulverized coal heating equipment are connected and arranged on a raw pulverized coal pipeline. The other end of the A-type pulverized coal heating equipment is connected with a coal mill, and the other end of the B-type pulverized coal heating equipment is connected with a boiler furnace burner. A transition steam pipeline and a transition pulverized coal pipeline are arranged between the A-type pulverized coal heating equipment and the B-type pulverized coal heating equipment. A dewatering outlet is formed in the A-type pulverized coal heating equipment. A steam turbine steam exhaust pipeline is arranged on the B-type pulverized coal heating equipment. The boiler burning pulverized coal heating equipmentis suitable for heat exchange of a coal mill air and powder mixture, steam turbine exhausted steam and any two gas-solid two-phase media flowing at high speed, different steam parameters can be selected according to actual coal types, and the A-type pulverized coal heating equipment and the B-type pulverized coal heating equipment are matched and combined to be used. The problems that heating equipment is short in wearing life, low in heat exchange efficiency and large in flow resistance, and suffers from accumulative detonation are solved.

Owner:北京蓝爱迪电力技术有限公司

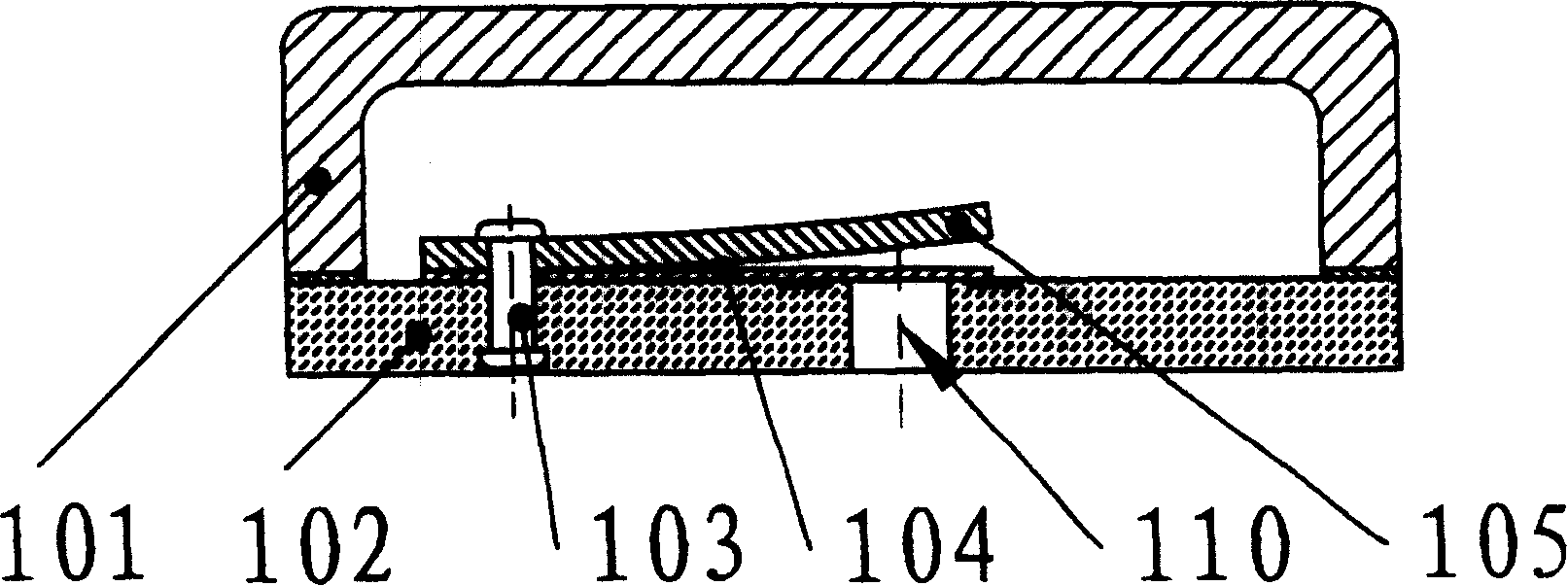

Compressor discharge components and compressors

ActiveCN106837797BReduce exhaust lossImprove efficiencyRotary/oscillating piston pump componentsLiquid fuel engine componentsExhaust valveEngineering

The invention discloses an exhaust assembly of a compressor and the compressor, the exhaust assembly of the compressor includes an exhaust valve seat and an exhaust valve plate, the exhaust valve seat is provided with an exhaust hole, the bottom wall of the exhaust valve seat is provided with a boss and an escrape, the boss surrounds the exhaust hole, the escrape surrounds the boss, the exhaust valve plate is connected with the exhaust valve seat, and is electively attached to the boss, the height of the boss is h0, the depth of the escrape is h1, the radial distance from the side wall of the escrape to the top point of the boss is Delta R, the limitation opening angle is theta, wherein 0<=h1<= Delta R * Tan(theta)+ h0. The exhaust assembly of the compressor can reduce the area of a thinnest region of the exhaust valve seat by defining of multiple-place dimension relationship of the escrape so as to reduce bearing deformation, and meanwhile by limiting of the height of an exhaust channel first step, gas vortex state caused by a refrigerant can be reduced, exhaust losses in the compressor can be reduced, and the efficiency of the compressor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

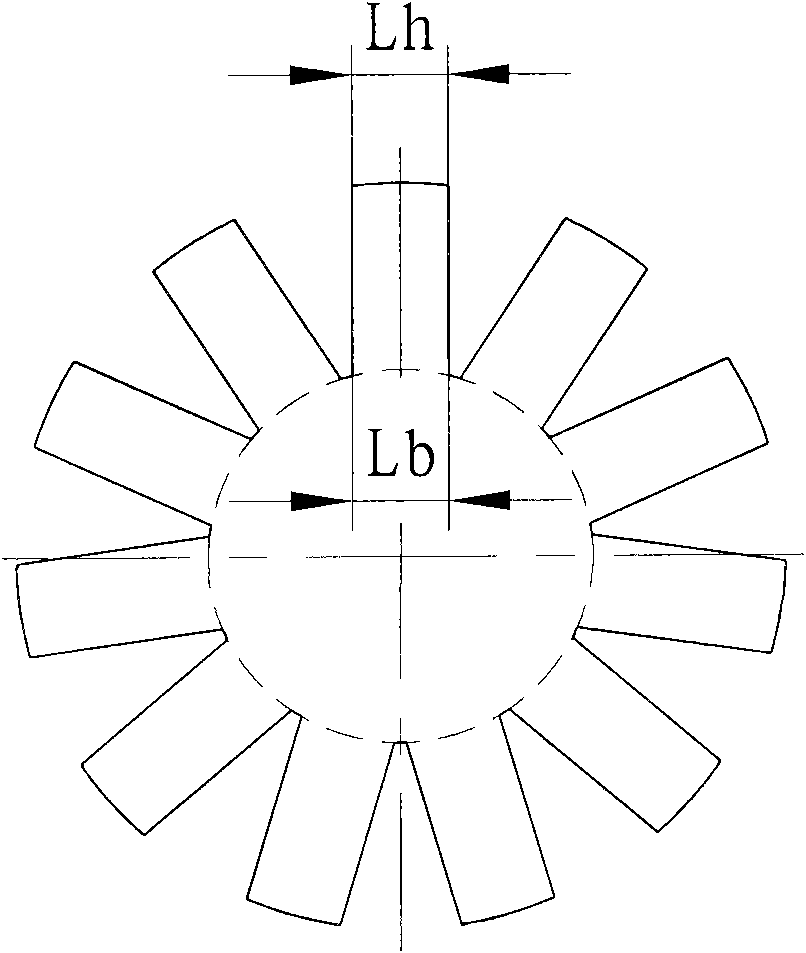

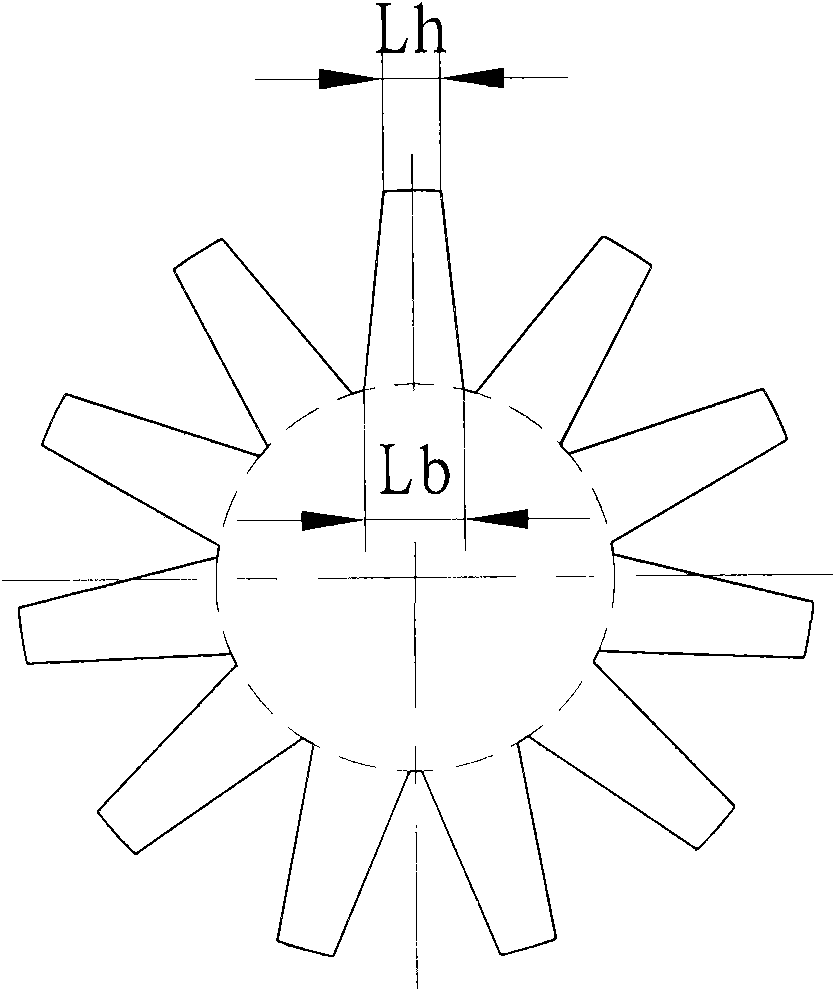

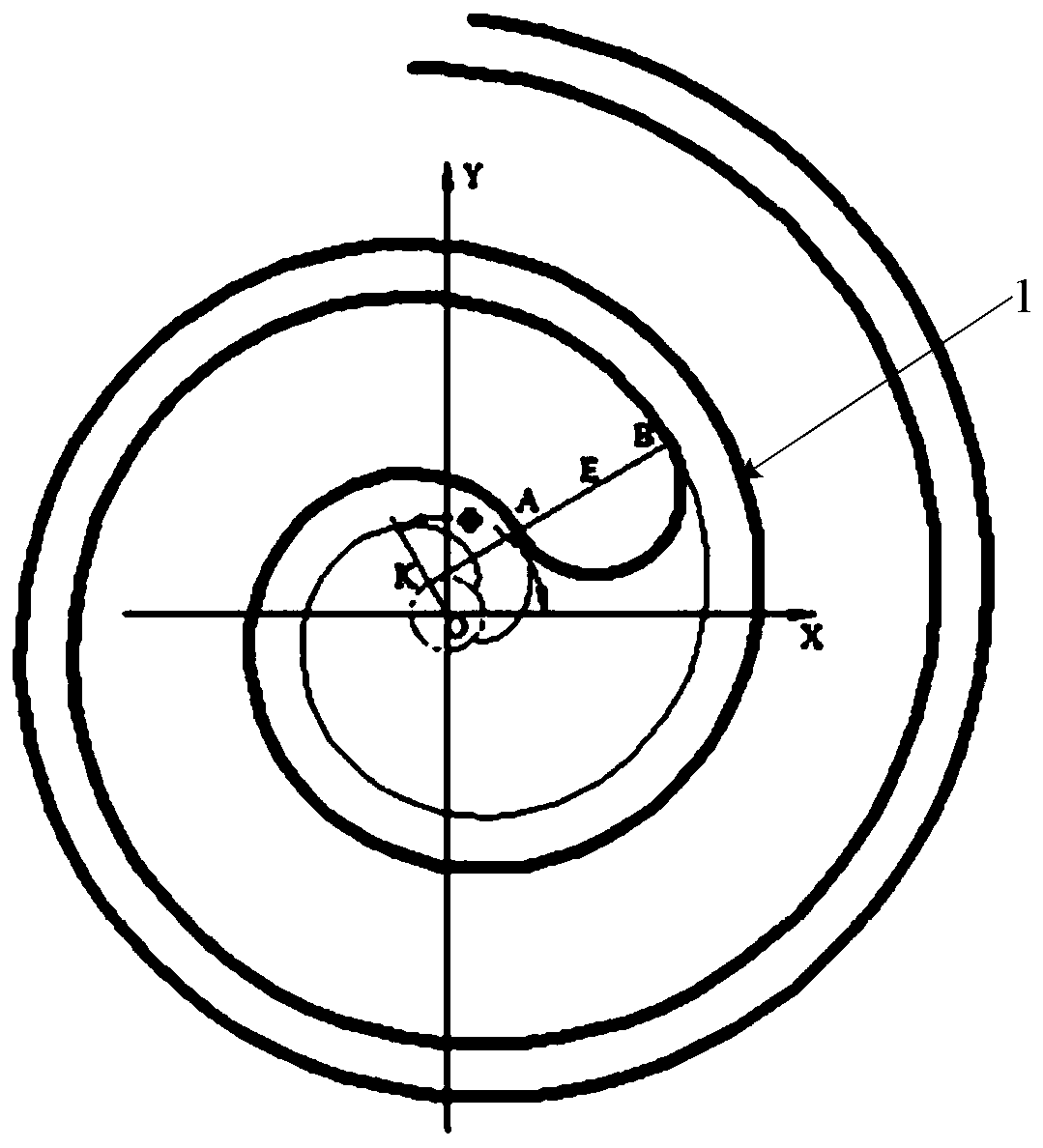

A Displacement Profile Correction Method of Scroll Machine

ActiveCN107178499BIncrease displacementIncrease exhaust volumeRotary piston pumpsRotary piston liquid enginesEngineeringCompression ratio

The invention provides a profile modification method for the displacement of a vortex compressor. The method comprises the steps of profile modification of a dynamic vortex plate and profile modification of a static vortex plate; asymmetric single arcs are adopted for modification; profile modification of the dynamic vortex plate and profile modification of the static vortex plate both adopt the single arcs; the dynamic modification arc and the static modification arc are totally engaged, and thus the gas exhaust volume of the vortex compressor is effectively increased; and under the condition of the same adiabatic compression ratio, the displacement of the vortex compressor is increased, the area of the center of tooth heads of the static vortex plate is increased, it is beneficial for forming an gas exhaust hole with the large area, and the gas exhaust loss can be effectively reduced. According to the profile modification method for the displacement of the vortex compressor, compared with common symmetric double-arc modification, under the condition of the same involute parameter and the modification abduction angle, through asymmetric single arc modification, the volume of an gas exhaust cavity of the vortex compressor can be increased by about 50%; and under the condition of the same adiabatic gas exhaust temperature, namely under the condition of the same adiabatic compression ratio, through asymmetric single arc modification, the displacement of the vortex compressor is increased by about 50%.

Owner:NANCHANG UNIV

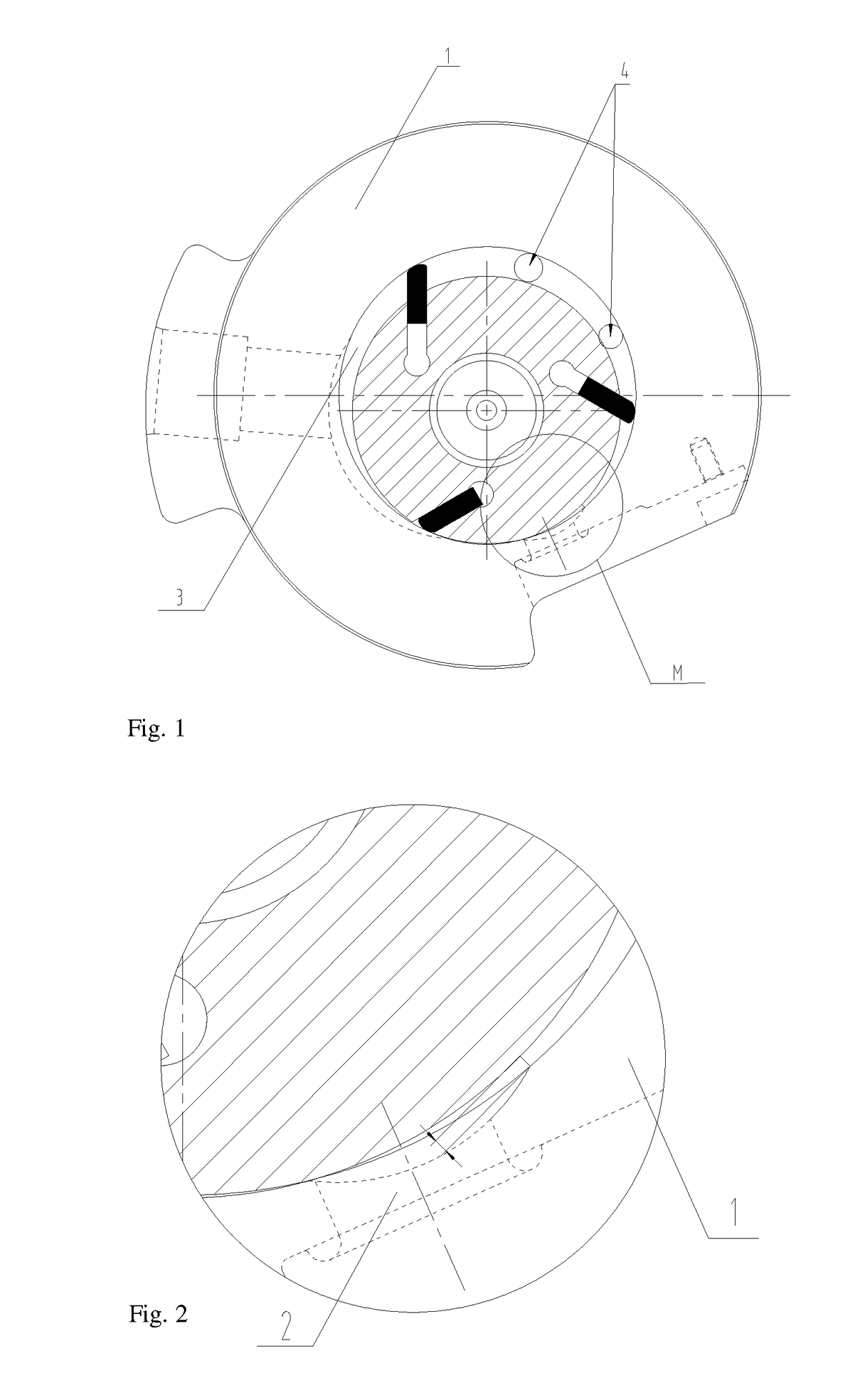

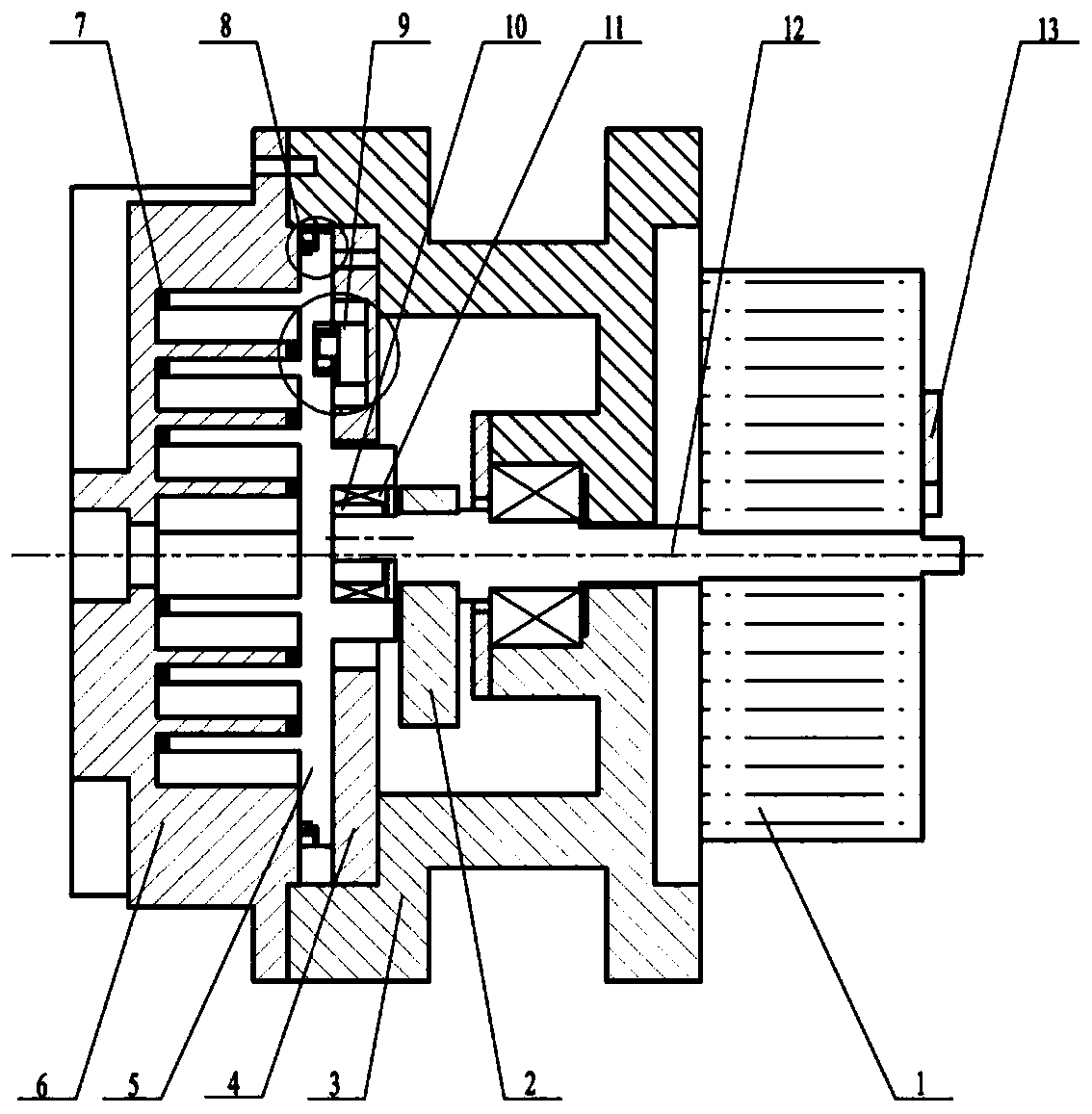

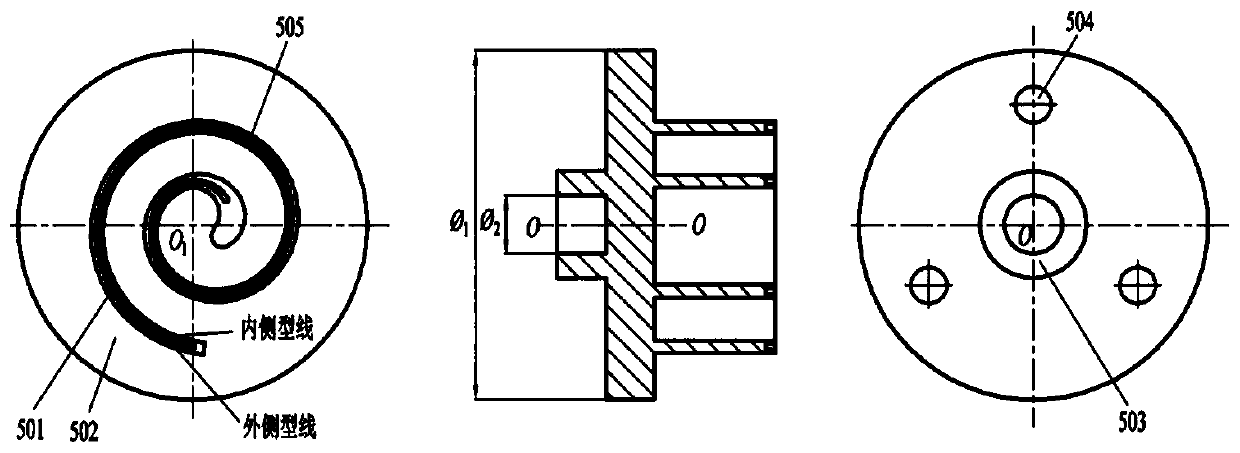

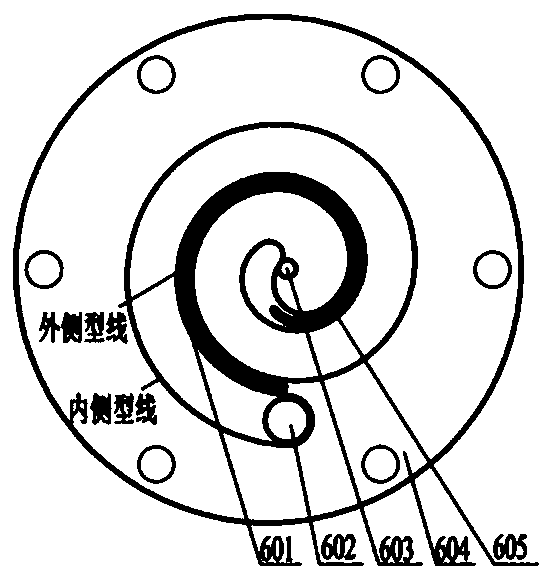

A kind of oil-free lubrication scroll vacuum pump

InactiveCN106989020BGuaranteed self-balancingEliminate design stepsSealing arrangement for pumpsRotary piston pumpsEngineeringVacuum pump

The invention discloses an oil-free lubrication scroll vacuum pump. The pump comprises a movable scroll, a fixed scroll, a crankshaft, a motor, a rotation-prevention mechanism and an axial gap adjusting device; a static-balance-free design structure is adopted in the movable scroll, the movable balance property is improved, the scroll vacuum pump is more compact in whole size, a small-crank rotation prevention mechanism with the radial compliance and a crankshaft with the eccentric structure achieve joint action, the size of the rotation radius is adjusted, and it is ensured that movable scroll revolution and translation are more stable; in order to improve the air suction efficiency of the scroll vacuum pump, the fixed scroll is adopted, wherein the inner side profile and the outer side profile are not symmetric, and the fixed scroll is provided with a single air suction opening; the problems that due to the fixed scroll structure, the volumetric proportion in a work cavity is not equal, the scroll turns over, and the pressure fluctuates are solved through two manners of movable scroll tooth head cutting treatment or the exhaust hole opening range adjustment; meanwhile, an axial gap adjusting device adjusts the gap, caused by the machining error, at the combination position of a movable scroll disc and a fixed scroll disc, and the axial gap leakage is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

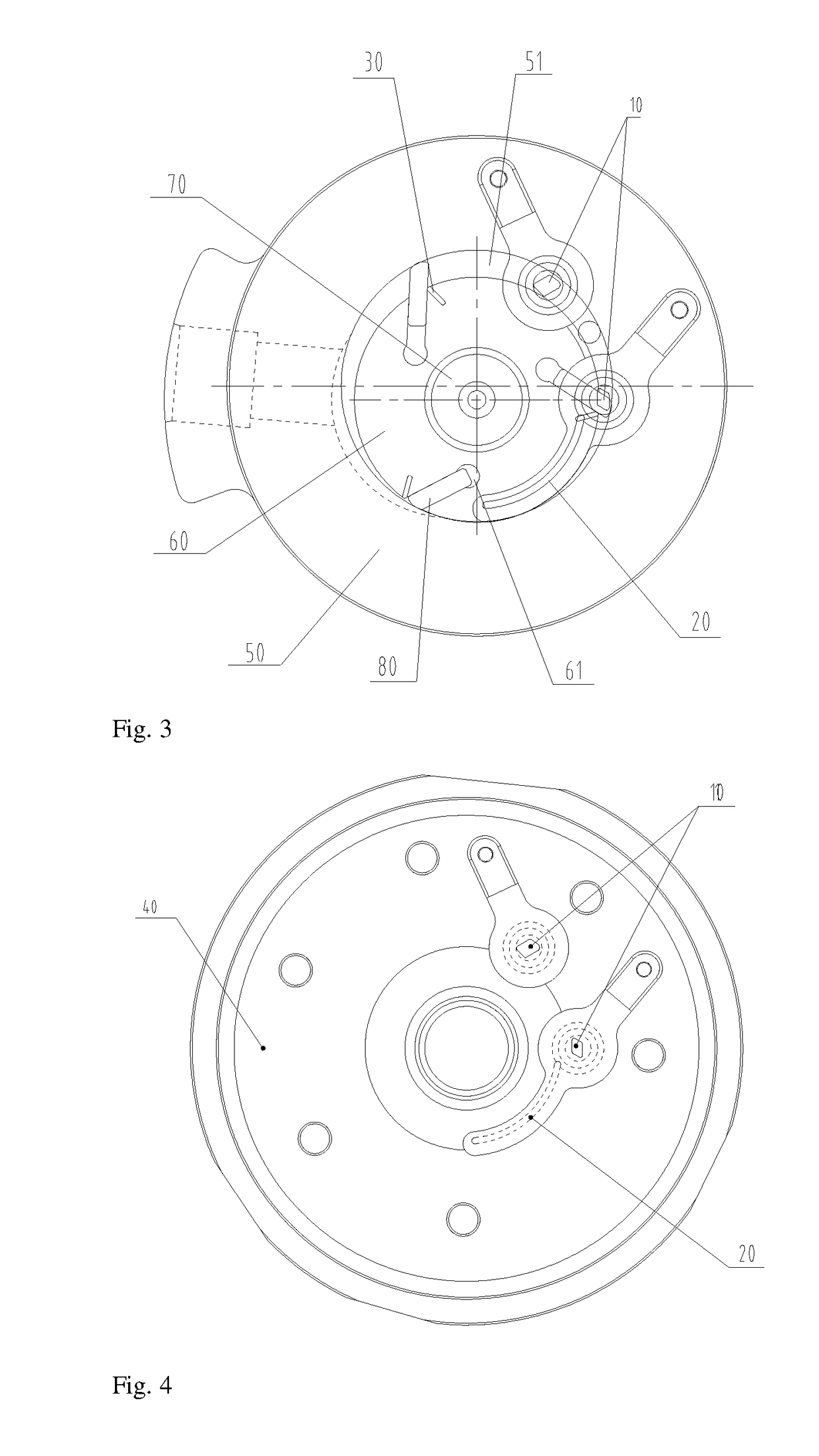

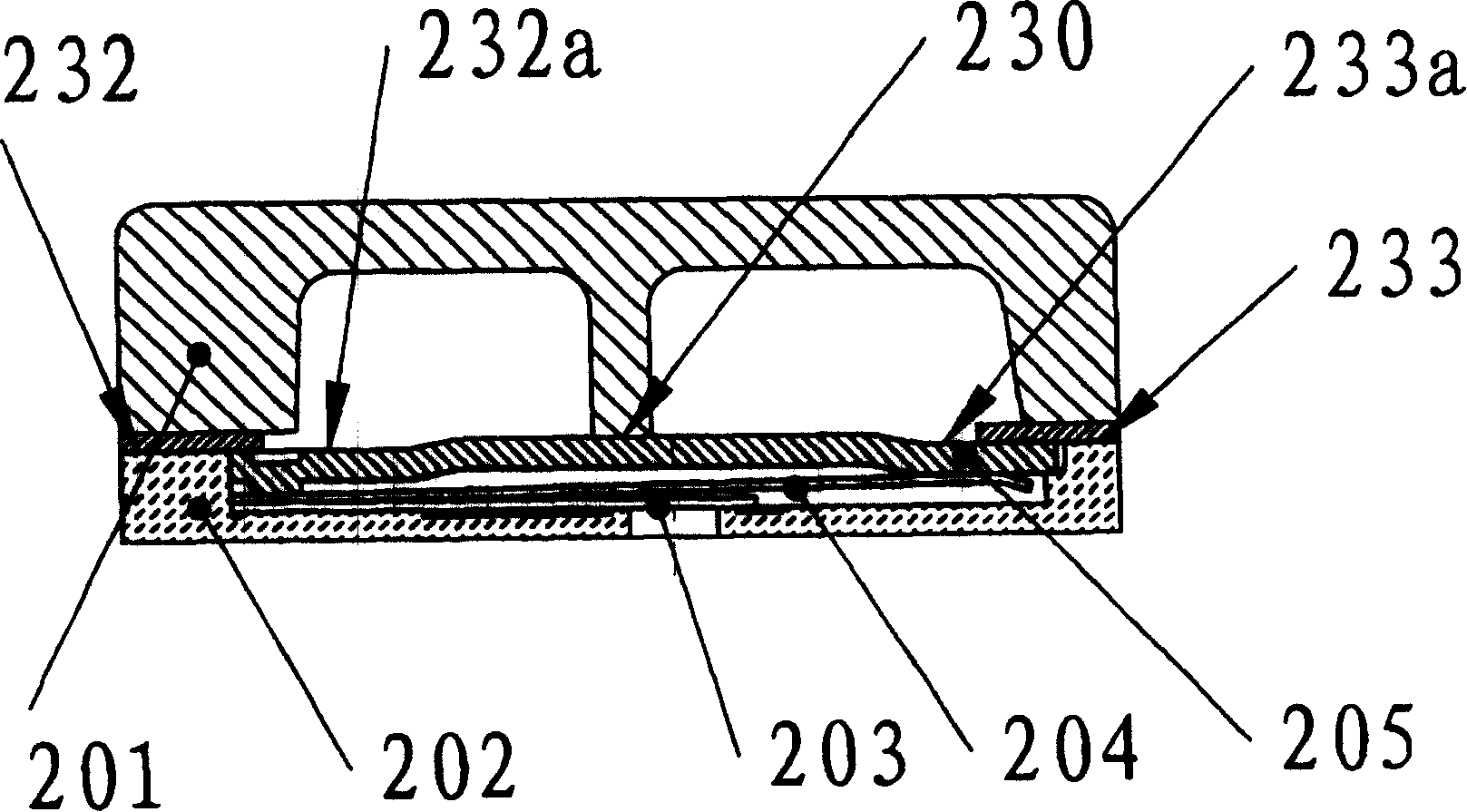

Exhaust valve assembly, compressor and air conditioner

PendingCN113757082AImprove stabilityImprove sealingPositive displacement pump componentsPositive-displacement liquid enginesExhaust valveValve seat

The invention provides an exhaust valve assembly, a compressor and an air conditioner. The exhaust valve assembly comprises a flange (1) and an exhaust valve set, a valve seat (2) is arranged on the flange (1), an exhaust port (3) is formed in the valve seat (2), the exhaust valve set comprises an installation seat (4), an elastic piece (5) and a valve block (6), the installation seat (4) is installed on the flange (1), the valve block (6) is located between the exhaust port (3) and the elastic piece (5), one end of the elastic piece (5) abuts against the valve block (6), and the other end of the elastic piece abuts against the installation seat (4). At least two protruding parts (7) are arranged at the end, facing the exhaust port (3), of the installation seat (4), the protruding parts (7) are arranged in the circumferential direction of the installation seat (4) at intervals, and the valve block (6) moves in a guide space formed by the protruding parts (7). According to the exhaust valve assembly, the area of an airflow circulation channel can be increased, fluid resistance is reduced, exhaust losses are reduced, and the performance of the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

A balance valve control system and control method of an asymmetric turbocharger

ActiveCN111779567BAvoid lostEmission reductionElectrical controlInternal combustion piston enginesTurbochargerControl system

The invention relates to a balance valve control system and control method of an asymmetric turbocharger; the control system includes a balance valve control valve, an engine control unit, a supercharger balance valve control diaphragm valve, a balance valve plate, a booster Control method: 1. The engine control unit collects the actual boost pressure and EGR rate; 2. Compare with the target boost pressure and EGR rate to determine whether adjustment is required; 3. Determine the target outlet air pressure of the balance valve control valve; 4. 1. Determine the duty cycle and adjust the outlet air pressure; 5. The actual outlet air pressure acts on the booster balance valve to control the diaphragm valve; 6. The movement of the valve core changes the opening of the balance valve plate, causing the output power of the turbocharger turbine , the change of the pressure before the vortex; 7. Change the amount of work done by the compressor to the air and change the supercharging pressure; 8. Change the EGR rate of the engine; the present invention reduces the pressure before the vortex and the exhaust loss of the engine at medium and high speeds, and improves the economic performance of the engine and environmental performance.

Owner:FAW JIEFANG AUTOMOTIVE CO

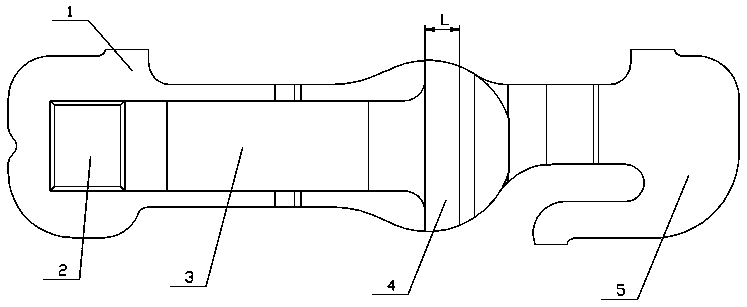

Second-last-stage moving blades for half-speed large-capacity nuclear power steam turbines

ActiveCN105240054BIncrease the areaAvoid stress concentrationBlade accessoriesMachines/enginesStress concentrationEngineering

The invention provides a penultimate-stage moving blade for a half-speed high-capacity nuclear turbine. The penultimate-stage moving blade comprises shrouding strips, a blade working part, an intermediate body and a blade root. The height of the blade working part is 1286 mm. The molded line of the blade working part is a variable cross-section twisted blade. The sectional area of the variable cross-section twisted blade gradually decreases along with increasing of the height of the cross section of the blade. Relative twist exists between every two adjacent cross sections. The shrouding strips are located at the top of the blade working part. The blade root is located at the bottom of the blade working part and is a side-mounted first-tree-shaped blade root with a large round angle and low stress concentration. The intermediate body is located between the blade working part and the blade root. The width of the intermediate body is equal to the axial width of the blade root. The shrouding strips, the blade working part, the intermediate body and the blade root are integrally formed. When the blade is in a static state, a gap between the working faces of the two adjacent shrouding strips is zero. The adjacent shrouding strips are coupled to each other at a working rotation speed, so that the whole circle of the penultimate-stage moving blades are connected into a group. The penultimate-stage moving blade is applicable to AP1000 nuclear turbine power generation units and future CAP1400 / CAP1700 nuclear turbine power generation units and can well meet the requirements for pneumatic performance and strength of half-speed high-capacity nuclear turbines.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com