Split exhaust for micro turbofan with rectifier

A turbofan engine, separate exhaust technology, applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of thrust loss of micro turbofan engine, reduction of external airflow kinetic energy, radial dimension difference, etc. , reduce friction loss, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

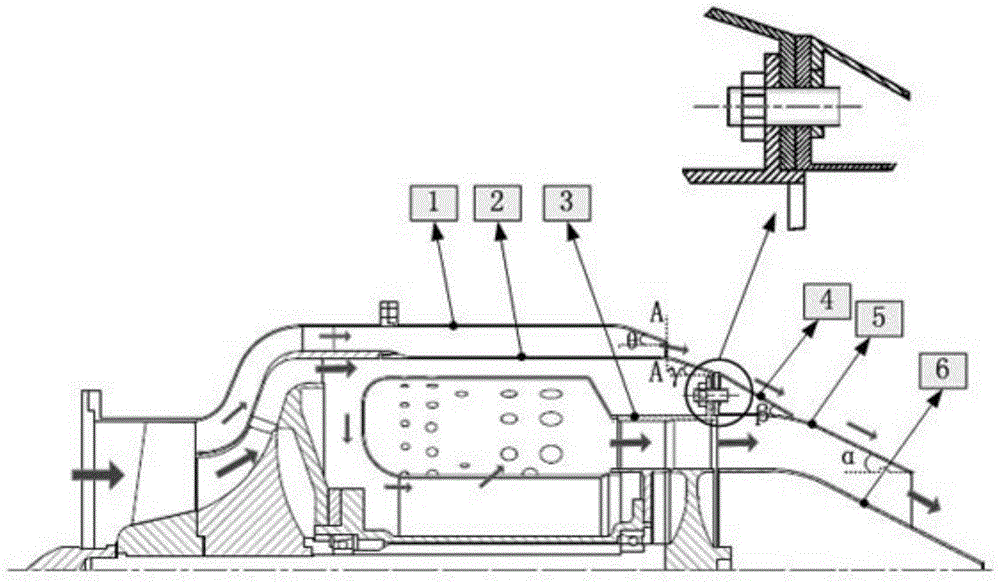

[0027] Such as figure 1 and image 3 As shown, the present invention discloses a separate exhaust device for a micro-turbofan engine with a rectifier, which is located at the exhaust outlet of the turbofan engine and includes an outer casing, an intermediate casing, a turbine guide casing, a rectifier, Inner nozzle and center cone;

[0028] The outer casing, the intermediate casing, the turbine guide casing, the inner nozzle, the rectifier, and the center cone are connected in sequence, wherein the tail of the turbine guide casing is provided with a first flange mounting edge; the intermediate casing The tail of the box is provided with a second flange installation edge; the front end of the internal nozzle is provided with a third flange installation edge;

[0029] Such as figure 2 As shown, the rectifier is in the shape of a conical surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com