Exhaust limiting plate for improving energy efficiency of compressor, and compressor

A technology of limit plate and compressor, applied in the field of compressors, can solve the problems of reducing suction efficiency, reducing exhaust volume, exhaust loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

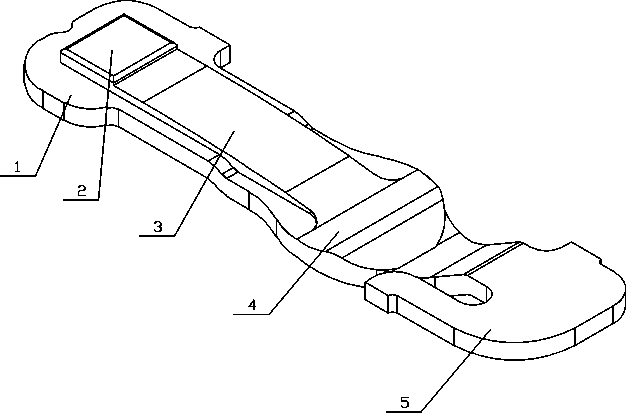

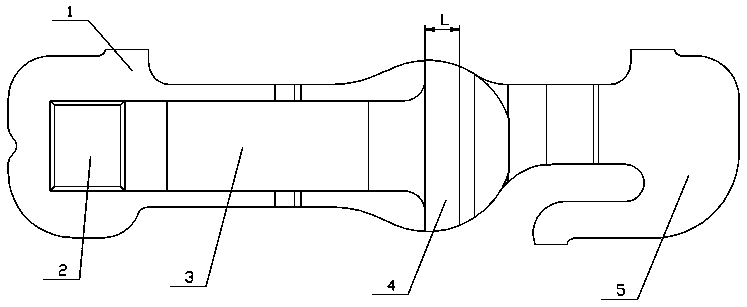

[0017] see Figure 1-6 , this embodiment includes a limiting plate body 1, the periphery of the limiting plate body 1 is matched with the installation groove on the valve plate, and one end of the limiting plate body 1 is provided with a raised portion 2 for pressing the exhaust valve plate 6, the limiting The other end of the plate body 1 is provided with a clamping portion 5 matching the installation groove, and the limiting plate body 1 is provided with a limiting surface 3 from the raised portion 2 to the clamping portion 5, and the exhaust valve plate 6 is limited by the limit surface 3 when it is opened to the maximum angle. The limit surface 3 is provided with a partially concave pit 4 at the end away from the raised part 2. When the exhaust valve plate 6 is opened to the maximum angle First, it is limited by the limiting surface 3, then the tongue of the exhaust valve plate 6 continues to move into the pit 4, and finally rebounds to close.

[0018] The height of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com