Coal mine ventilation air methane oxidation system

A coal mine and ontology technology, applied in the field of coal mine exhaust air oxidation system, can solve problems such as polluting energy and waste, and achieve the effects of reducing exhaust air loss, short start-up time, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

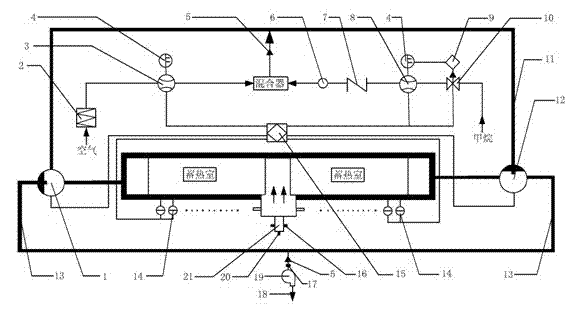

[0026] The detailed structure of the present invention is illustrated in conjunction with examples.

[0027] Such as figure 1 and figure 2 As shown, a coal mine exhaust air oxidation system includes a gas distribution device, a device body, a reversing device, a starting device and a measurement and control device; the gas distribution device includes an air pipeline, a natural gas pipeline and a mixer, and the described The input end of the air pipeline is connected with the air filter 2, and the air filter 2 adopts a BC type plate type primary air filter, and the air pipeline is provided with a vortex flowmeter 3, and the vortex flowmeter The flowmeter 3 adopts a LUGB type intelligent vortex flowmeter, the output ends of the natural gas pipeline and the air pipeline are connected to the mixer, and the air flow is adjusted using a butterfly valve according to the display of the vortex flowmeter 3. The natural gas The pipe is provided with a flashback preventer 6, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com