Valve set structure for reciprocating compressor

A compressor and reciprocating technology, applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of reduced reliability of the valve plate, too soft, valve plate vibration, etc., to reach the valve port Grinding quality assurance, easy manufacturing, and the effect of reducing exhaust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

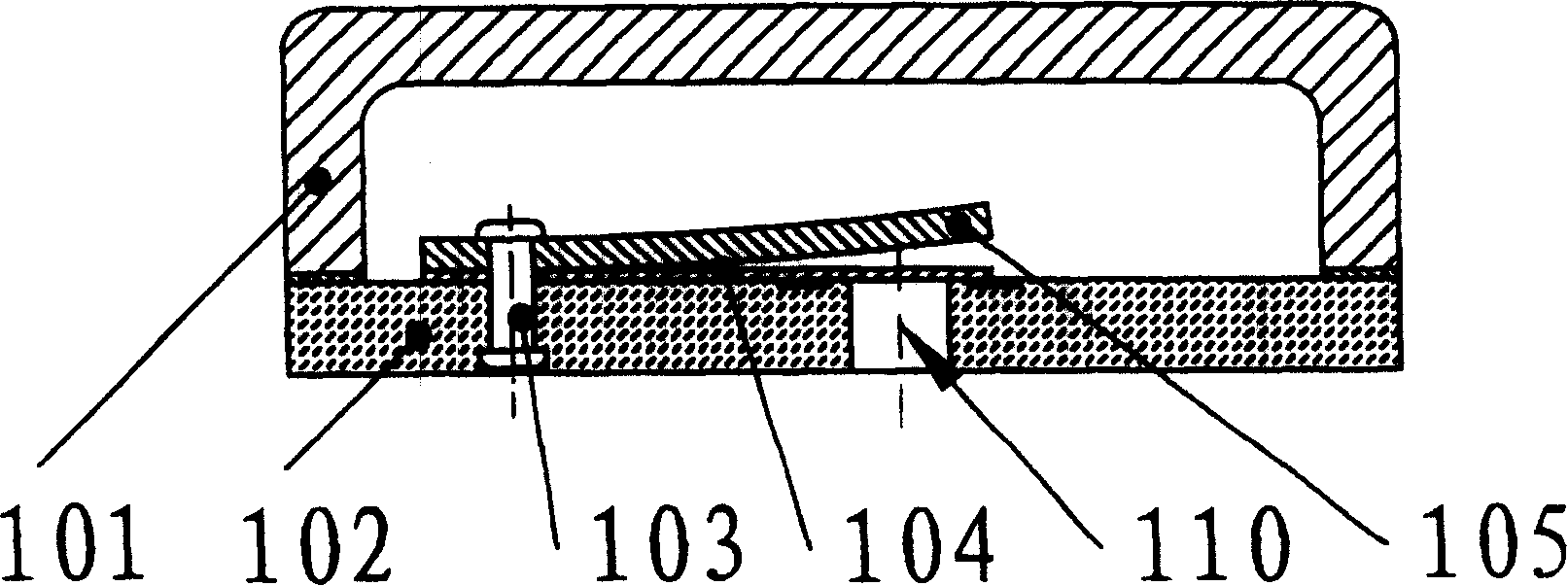

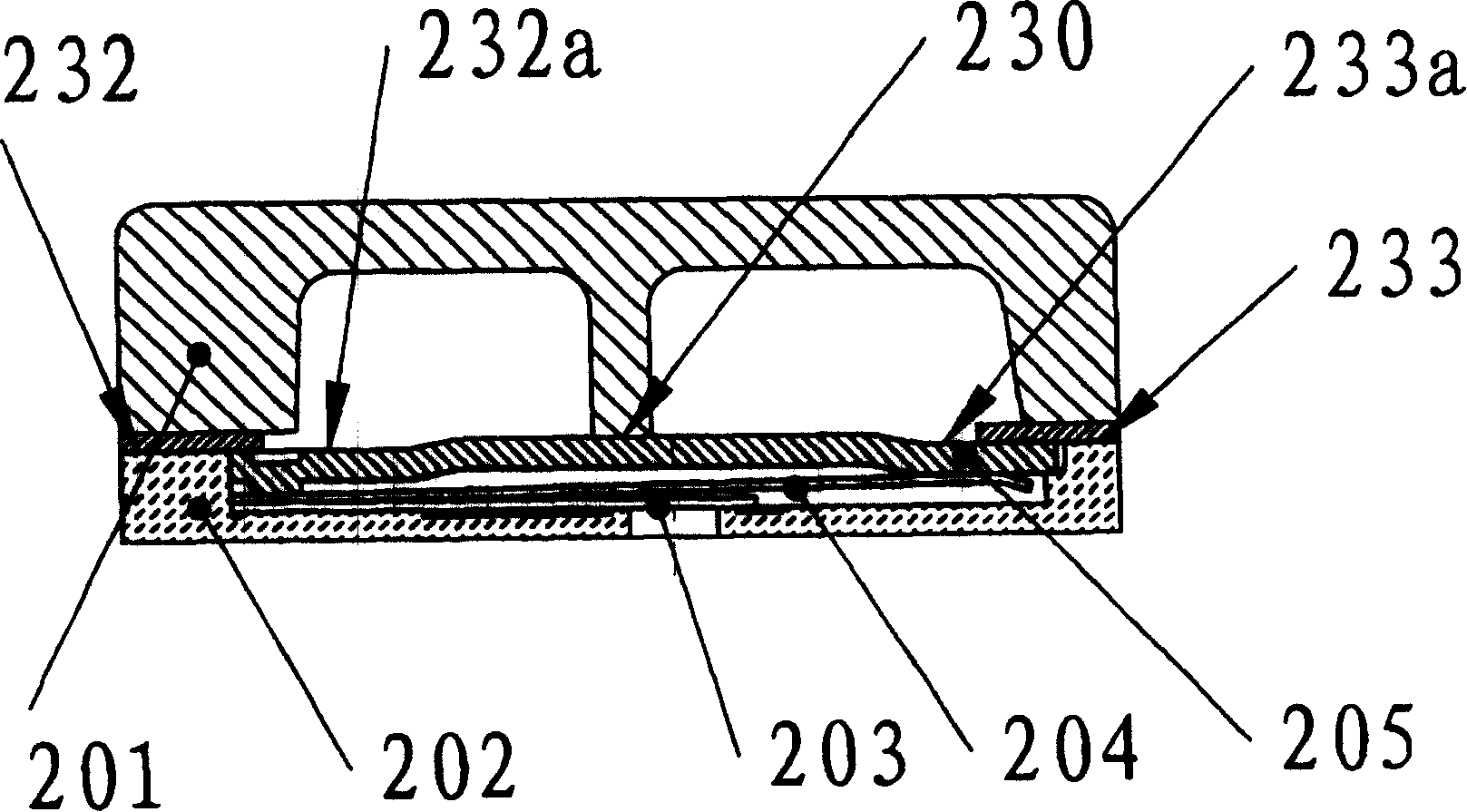

[0018] Such as image 3 As shown, the valve block structure of the reciprocating compressor of the present invention consists of a cylinder head 1, a cylinder head gasket 2, a valve plate support 3, an elastic plate 4, an exhaust valve plate 5 and a thin steel valve plate 6. Since the flat valve plate is still used, the grinding process of the suction and exhaust valve ports can be guaranteed to achieve a high airtight pass rate. At the same time, the valve plate of the present invention is stamped from steel material, and the thickness can reach 1.5 mm or less, so that the compressor can achieve the same clearance volume as the concave valve plate structure or less. Compared with the traditional valve plate, the valve plate 6 of the present invention only adds four mounting holes for valve plate brackets on the valve plate 6, without increasing any process difficulty. When installing the exhaust valve group, the exhaust valve plate 5, the elastic plate 4 and the valve plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com