Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce cutting waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

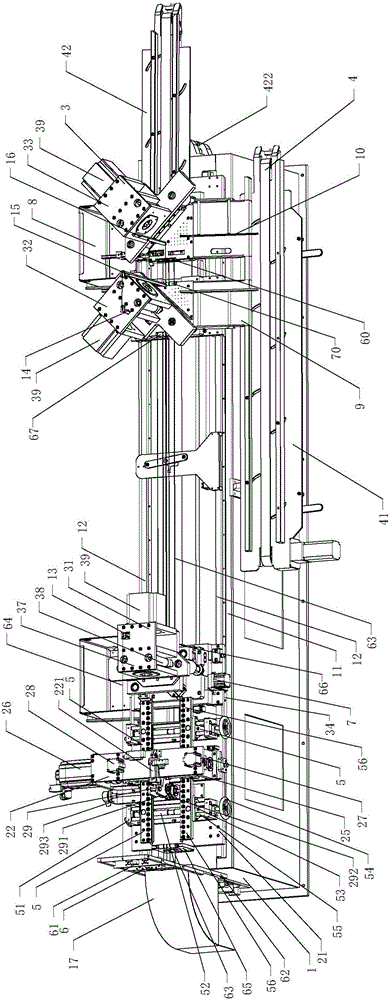

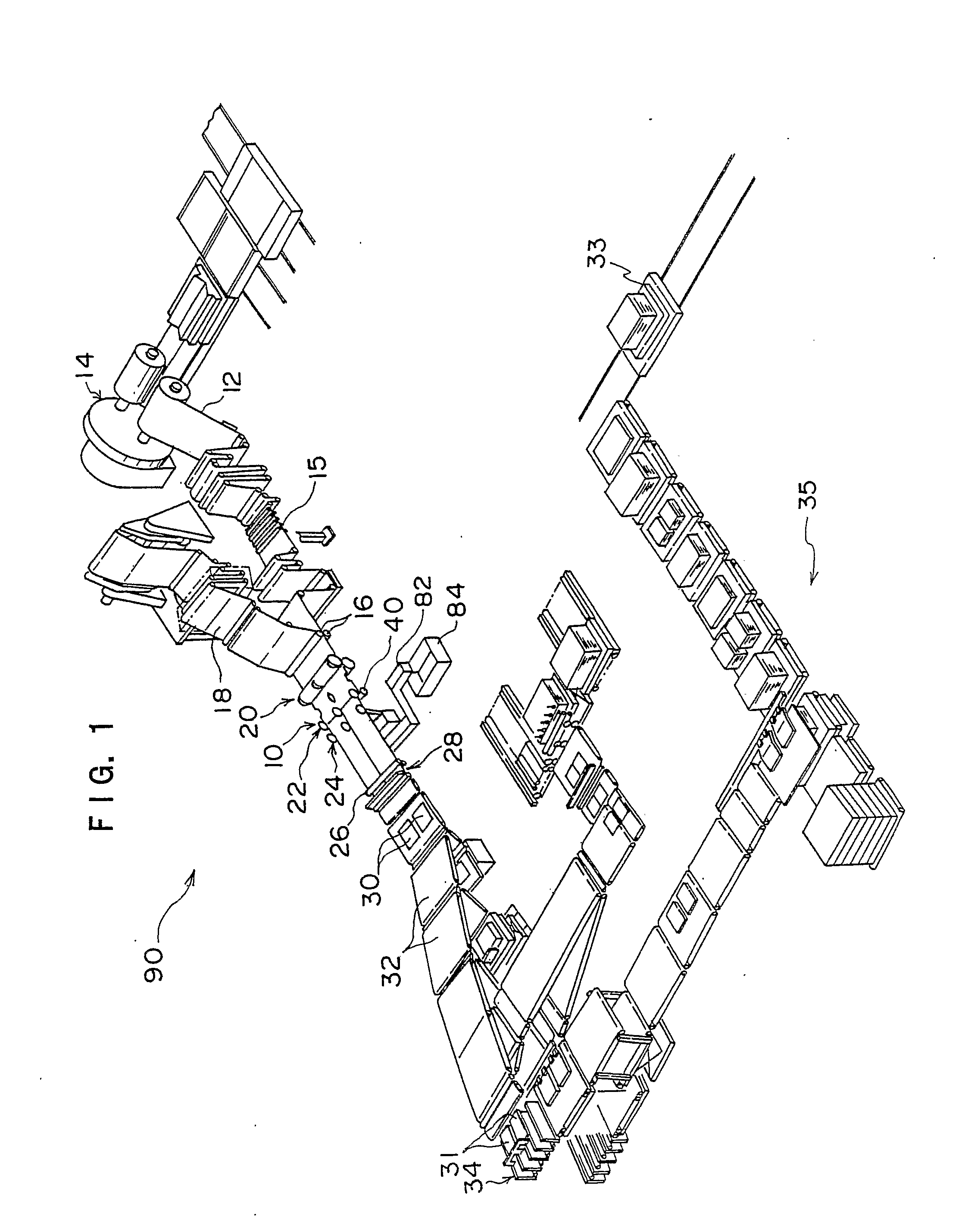

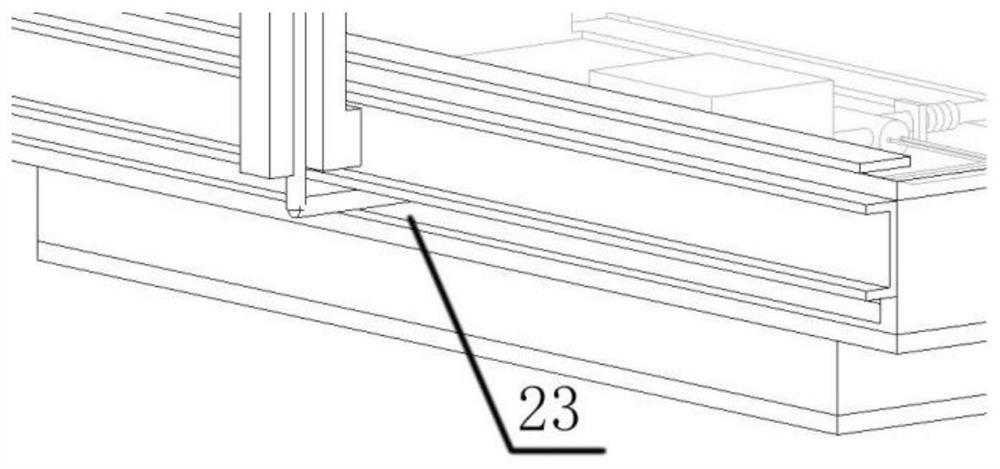

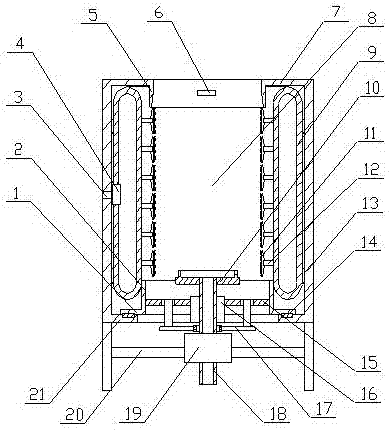

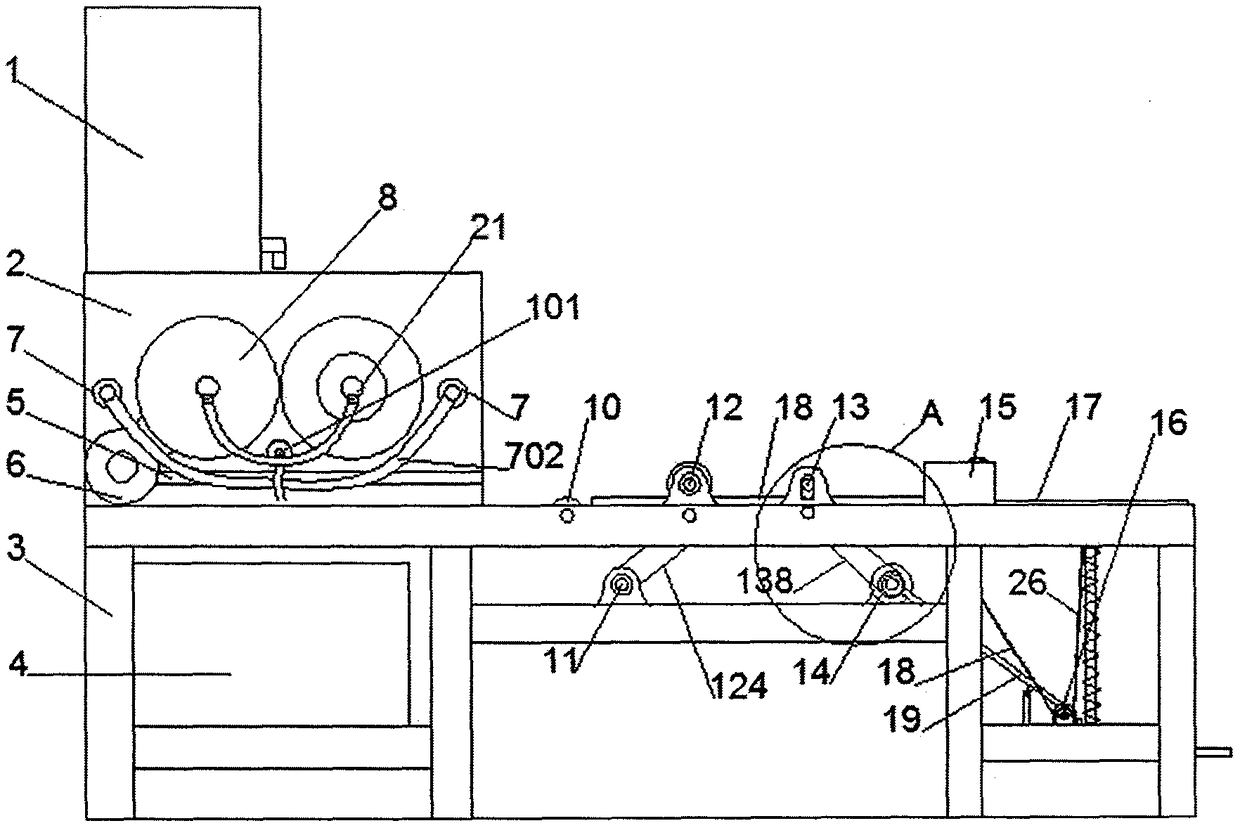

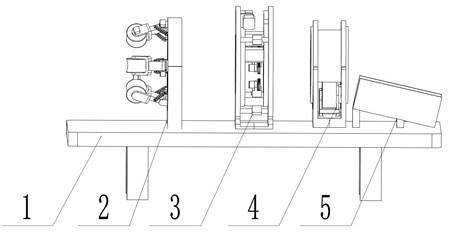

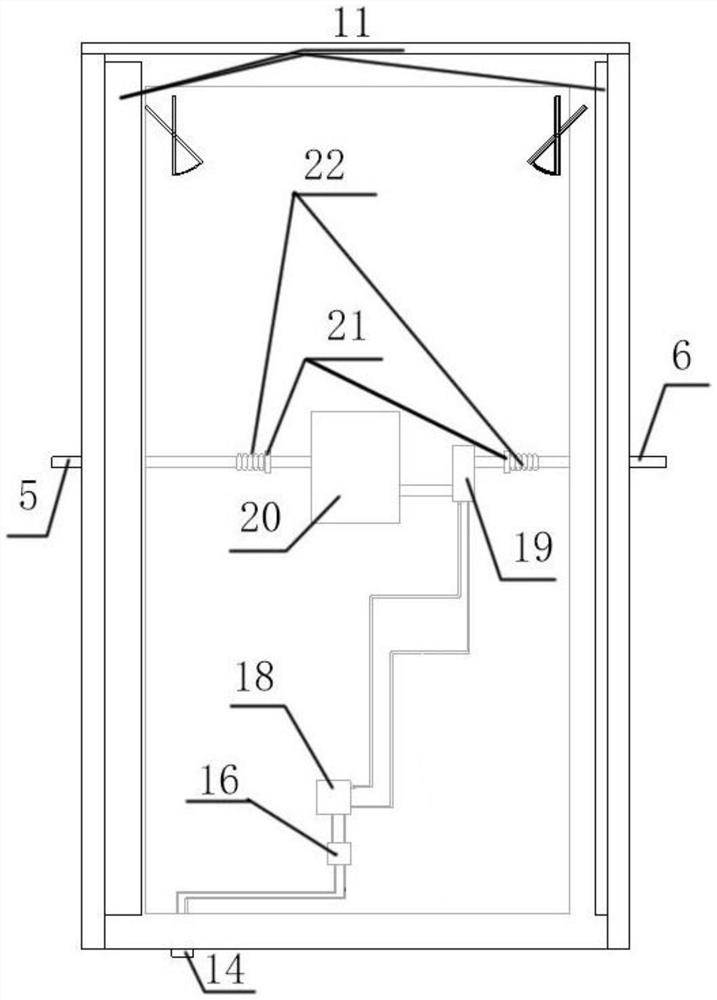

Automatic cutting machine

ActiveCN106735531AReduce impactEnsure measurementShearing machinesShearing machine accessoriesEngineeringMachine tool

The invention discloses an automatic cutting machine. The automatic cutting machine comprises a bottom frame, a feeding mechanism and cutting units. A platform is arranged on the bottom frame. The two sides of the platform are provided with guide rails correspondingly. The feeding mechanism is located on the rear portion of the platform. A large bottom plate at the lower end of the feeding mechanism is in sliding connection with the guide rails. The feeding mechanism comprises a feeding bracket, an upper press roll and a lower press roll. The bottom of the feeding bracket is fixedly connected with the large bottom plate. The upper press roll and the lower press roll are vertically arranged on the feeding bracket. The lower press roll is driven by a first servo motor installed on one side of the feeding bracket. The front side and the rear side of the feeding mechanism are provided with material clamping mechanisms correspondingly. The three cutting units comprise the first cutting unit, the second cutting unit and the third cutting unit and are arranged on the guide rails from back to front in sequence. Through the cutting units of the cutting machine, impact force to a machine tool is decreased, equipment noise is lowered, the cutting precision is high, and the cutting machine is suitable for cutting sheets of various models; and the amount of cutting waste is small, the automation degree is high, and the production efficiency and safety are greatly improved.

Owner:青岛瑞宜利特变压器设备有限公司

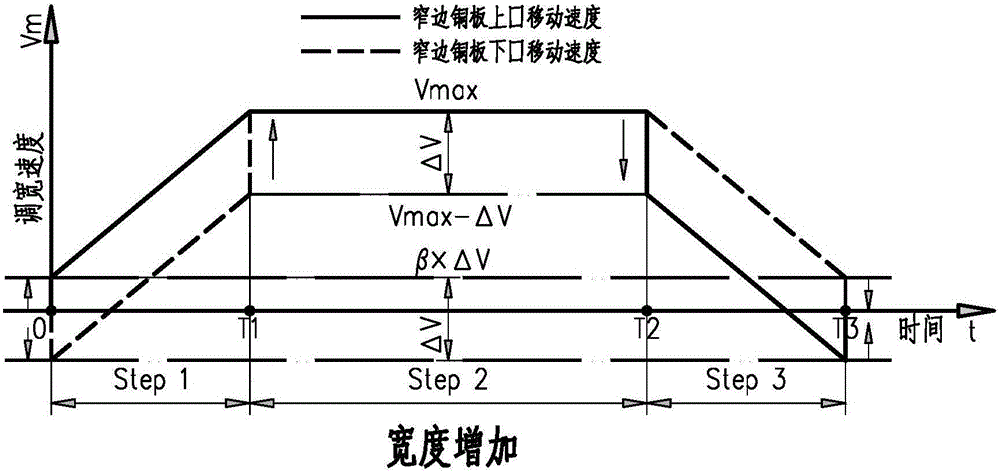

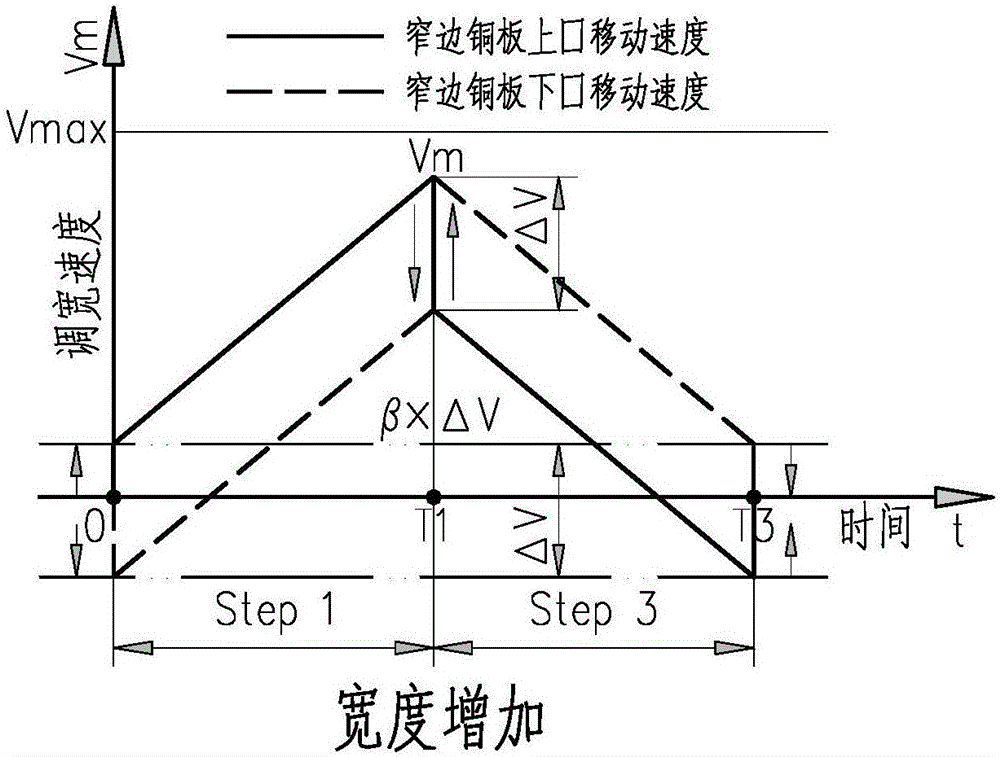

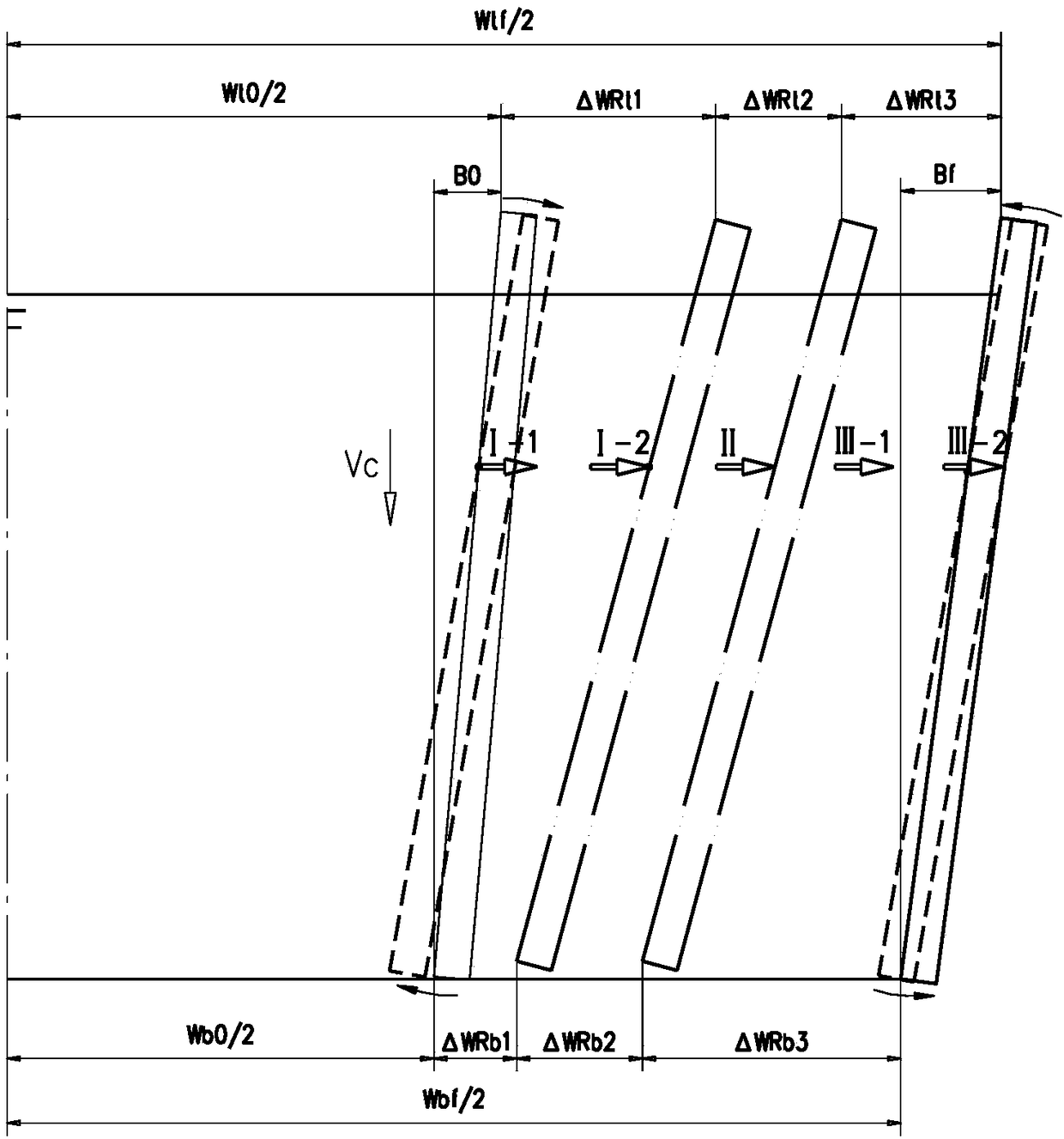

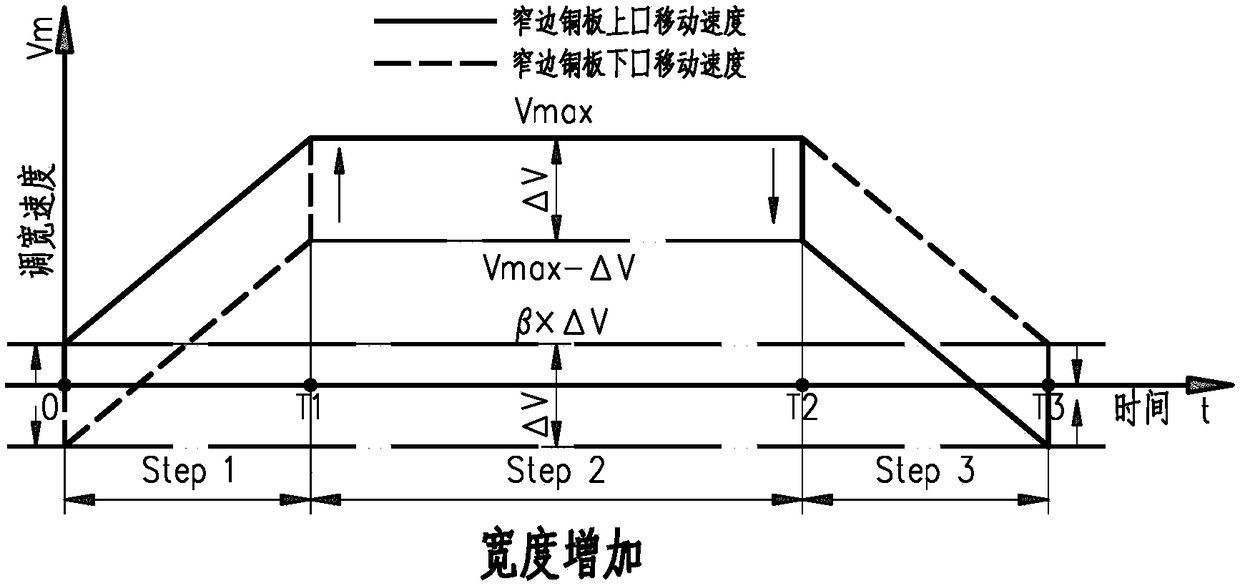

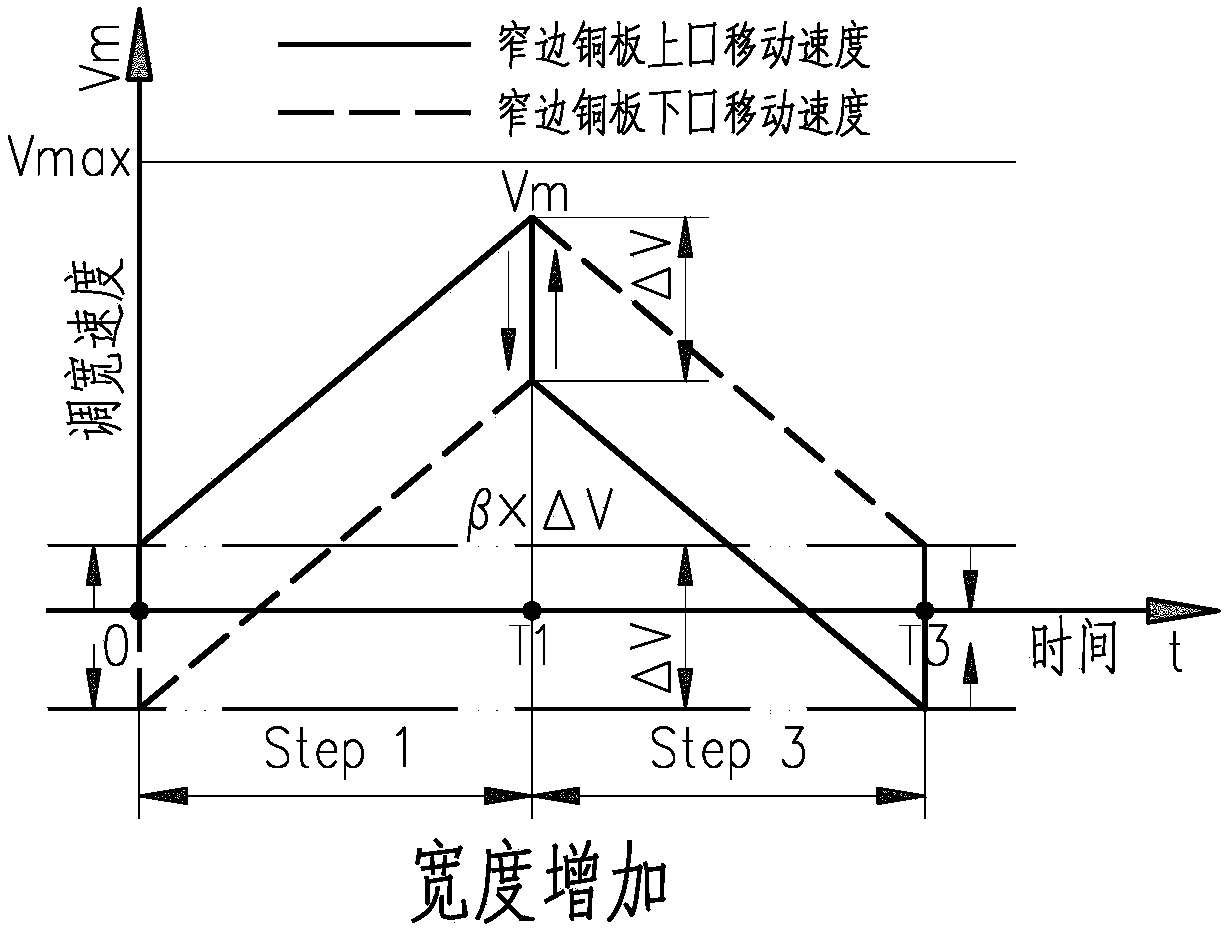

Method for on-line thermal-state high-speed adjustment of crystallizer width

The invention belongs to the technical field of continuous casting and particularly provides a method for on-line thermal-state high-speed adjustment of the crystallizer width. According to the method for on-line thermal-state high-speed adjustment of the crystallizer width, based on the character that the molten steel solidifies and contracts in a crystallizer, a reasonable crystallizer widening or narrowing mechanism is determined, the adjustment limiting speed of crystallizer widening or narrowing is derived, and the best on-line thermal-state high-speed width adjustment parameter of the crystallizer is selected according to actual production needs. By the adoption of the method for on-line thermal-state high-speed adjustment of the crystallizer width, an air gap between a blank shell and a casting blank in the thermal-state widening or narrowing process is eliminated, and the stress borne by the blank shell is low and uniform; and meanwhile, under the condition of not lowering the drawing rate, the speed of widening or narrowing is improved.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Photosensitive planographic printing plate and fabrication process thereof

InactiveUS20090226841A1Avoid quality defectImproved yieldPhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringLight sensitive

Owner:FUJIFILM CORP

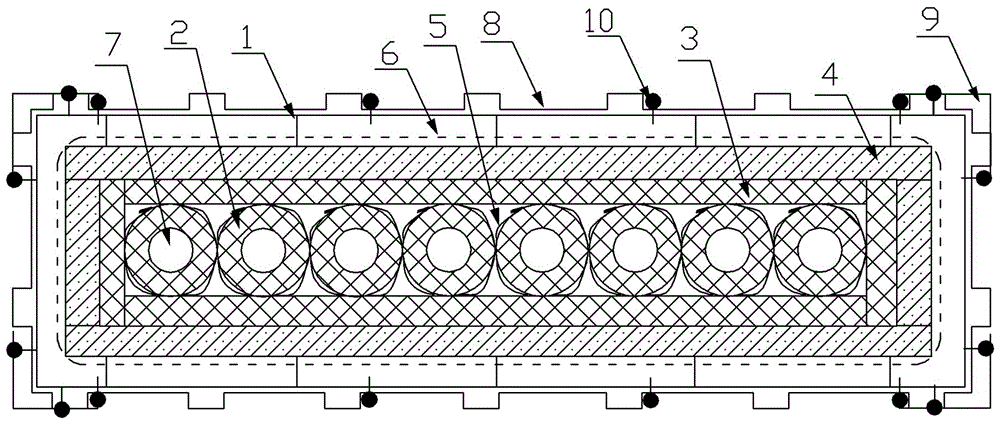

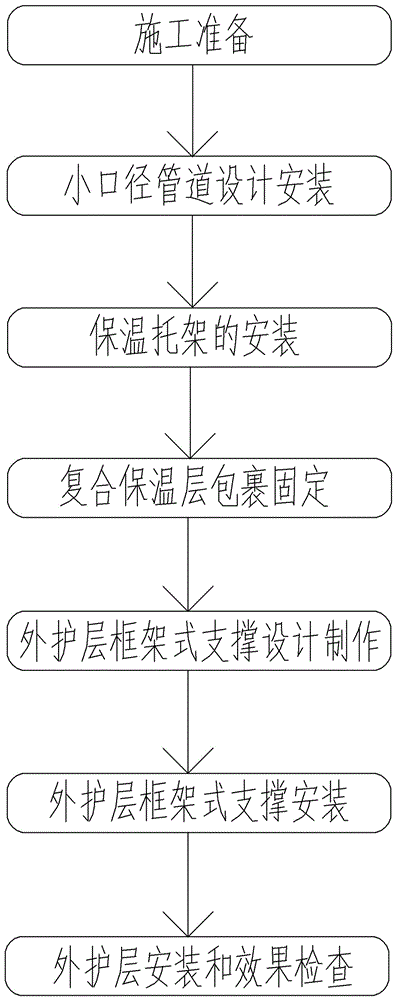

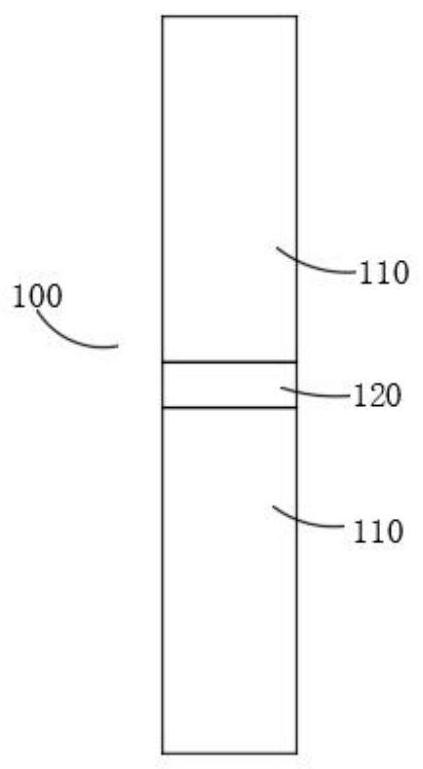

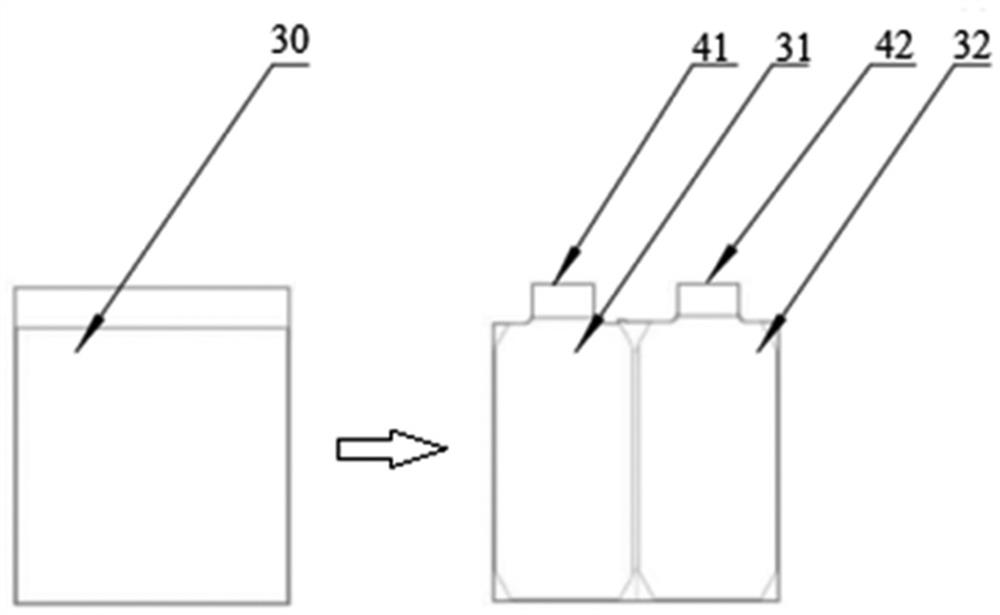

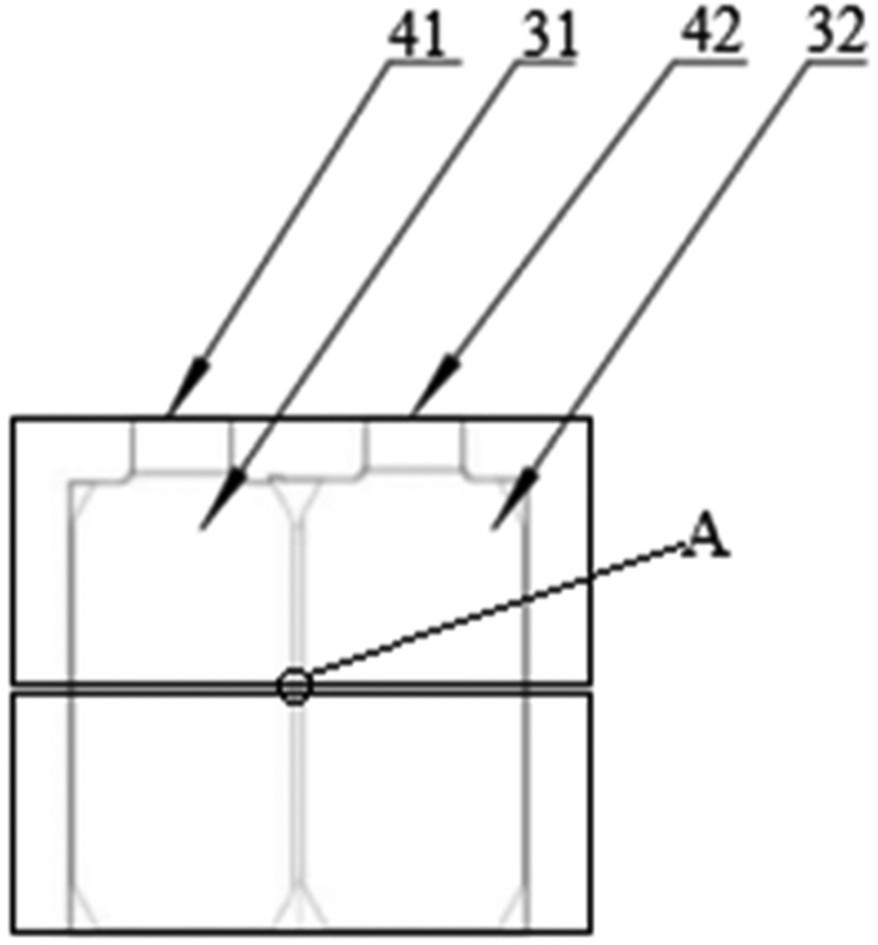

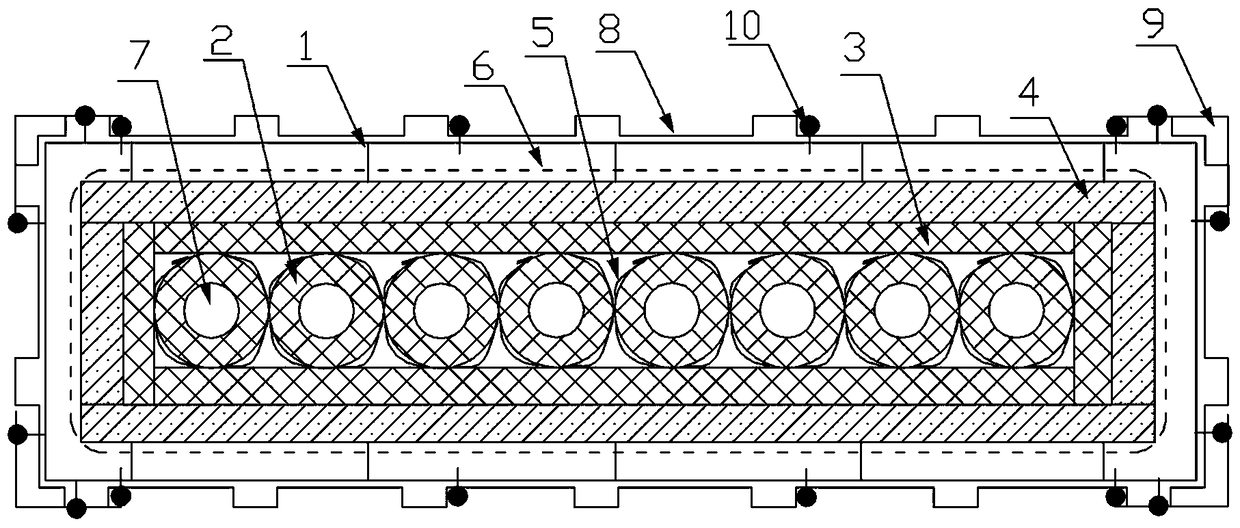

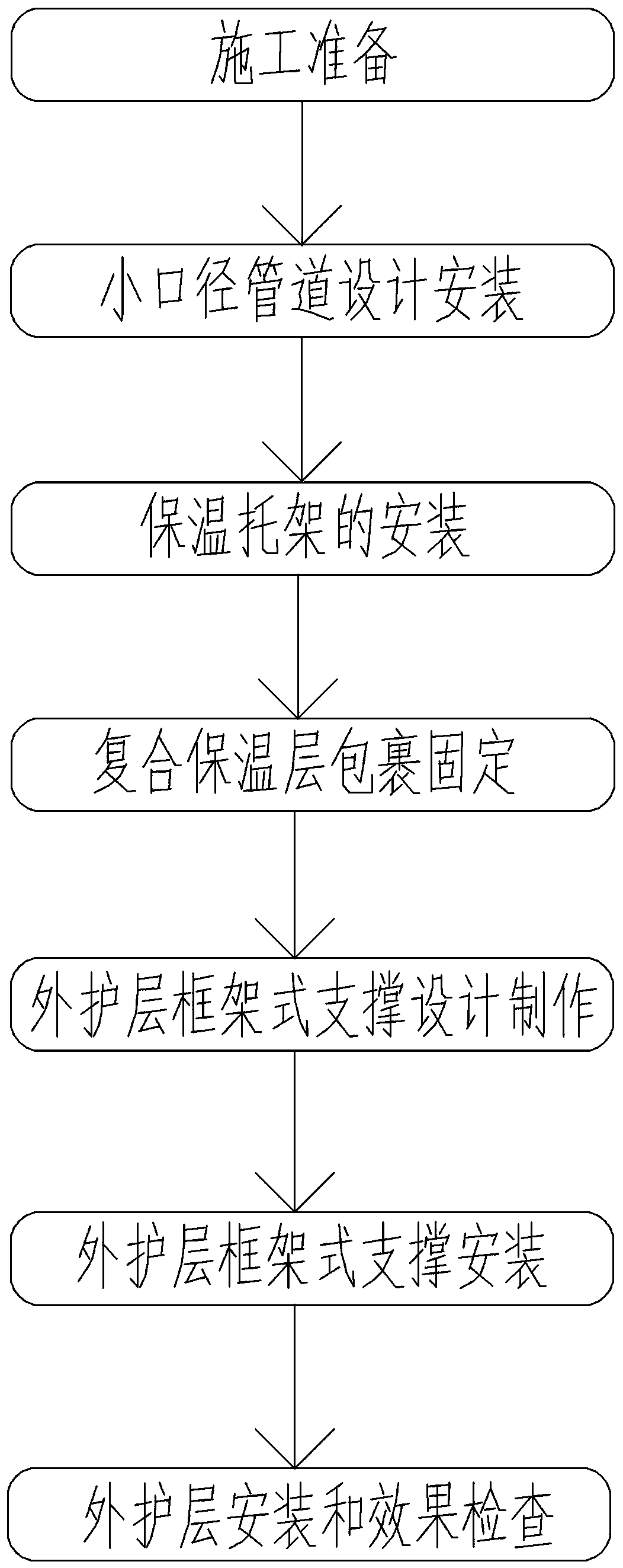

Small-caliber-pipeline intensive type heat preservation device and method

ActiveCN106369226AReduce wasteConstruction loss rate reductionPipe supportsThermal insulationFiberQuality level

The invention discloses a small-caliber-pipeline intensive type heat preservation device and method. The small-caliber-pipeline intensive type heat preservation device comprises a heat preservation layer and an outer protective layer frame type support. The heat preservation layer comprises first aluminum silicate fiber blankets and a composite heat preservation structure. Each first aluminum silicate fiber blanket is wrapped around a single pipeline needing heat preservation. Each first aluminum silicate fiber blanket is externally bundled with a galvanized iron wire. The composite heat preservation structure is wrapped around a row of pipelines wrapped inside the first aluminum silicate fiber blankets. The outer side of the composite heat preservation structure is bundled with iron gauze. The outer layer of the iron gauze is provided with the outer protective layer frame type support. Corrugated plates and corner wrapping plates are arranged on the outer protective layer frame type support and are fixed with self-tapping screws. The corrugated plates are arranged on the outer surface of the outer protective layer frame type support. The corner wrapping plates are arranged at the corners of the outer protective layer frame type support. By the adoption of the small-caliber-pipeline intensive type heat preservation device and method, the construction efficiency and the installation quality level can be improved, and the construction cost can be reduced.

Owner:POWER CHINA HENAN ENG CO LTD

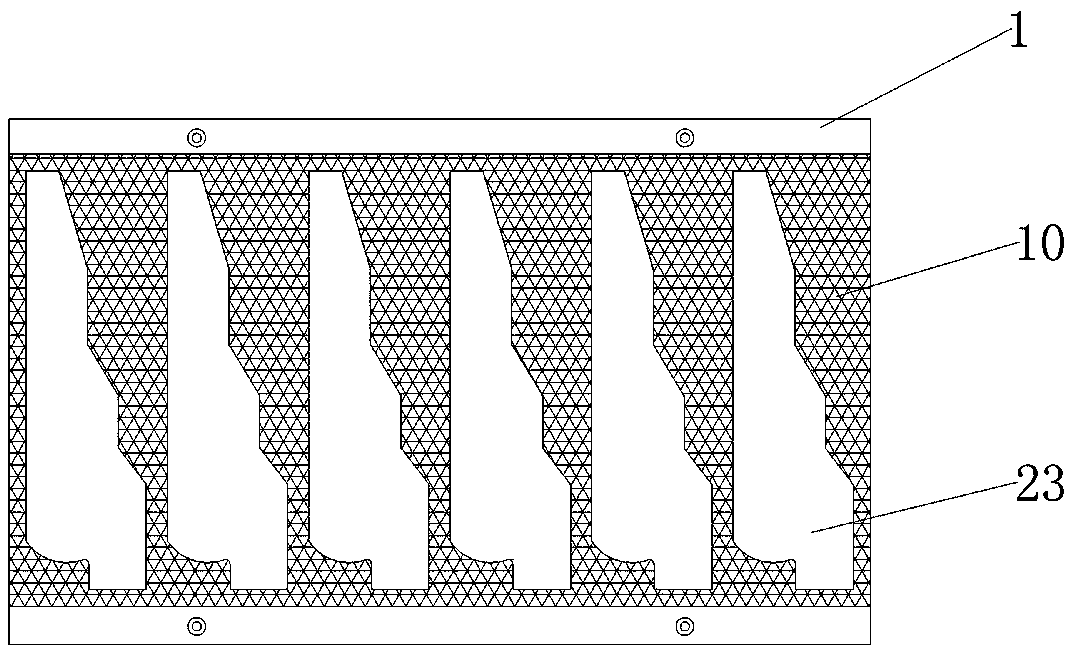

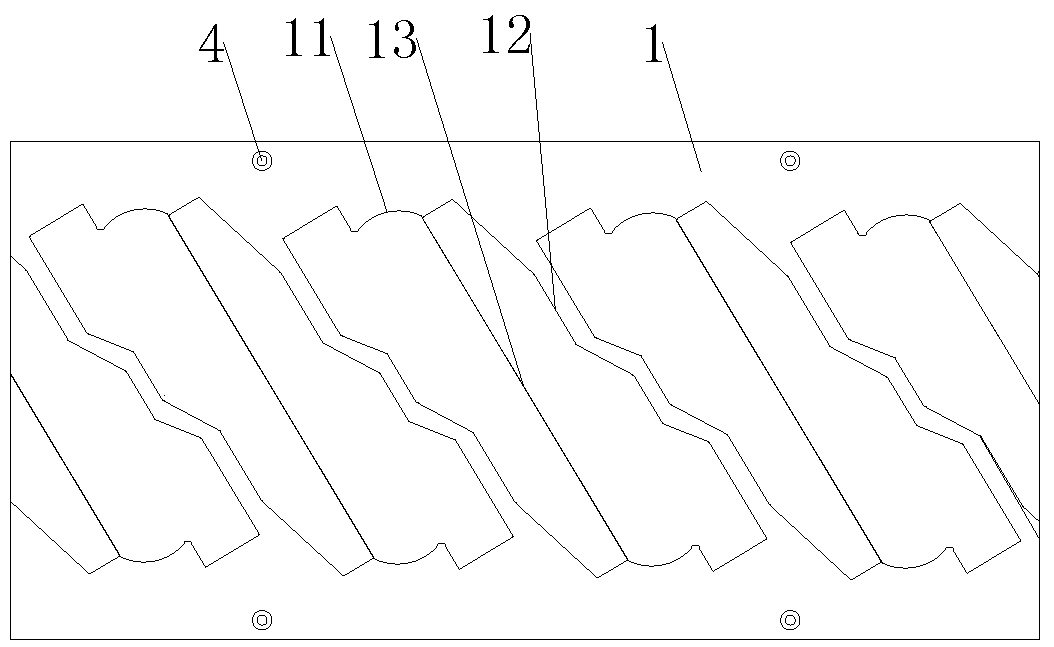

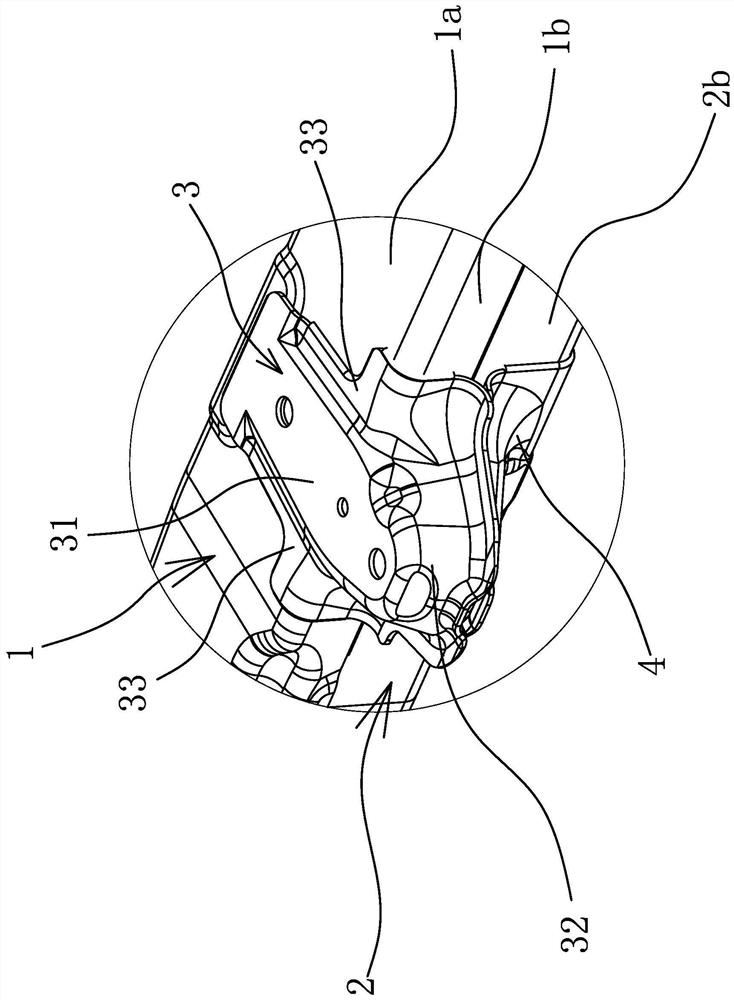

Ceramic part layout structure and common-edge machining method

PendingCN110893651AImprove typography utilizationEfficient use ofWorking accessoriesStone-like material working toolsProcessing costMachining

The invention discloses a ceramic part layout structure and a common-edge machining method, and aims to improve the utilization rate of ceramic raw materials, avoid waste of resources, and greatly reduce the processing cost. The structure comprises a material belt, a plurality of ceramic piece pairs which are uniformly arranged at interval are fixed on the material belt, the ceramic piece pairs are obliquely arranged on the material belt, each ceramic piece pair comprises a first ceramic piece and a second ceramic piece which are arranged by sharing an edge, one side of the first ceramic pieceand one side of the second ceramic piece are overlapped to serve as a common edge, and the first ceramic piece and the second ceramic piece are arranged in a central symmetry mode by taking the midpoint of the common edge as the center.

Owner:无锡积捷光电材料有限公司

Hot-rolled inequilateral channel steel and application thereof

InactiveCN103557428AIncrease stiffnessAvoid deformationElongated constructional elementsLifting devicesMaterial consumptionSteel design

The invention relates to hot-rolled inequilateral channel steel. The hot-rolled inequilateral channel steel comprises a web and wing plates, wherein the wing plates comprise a first wing plate and a second wing plate; two ends of the web are connected with the first wing plate and the second wing plate respectively; the first wing plate and the second wing plate are located on the same side of the web, are parallel to each other and perpendicular to the web; and the height of the first wing plate is larger than that of the second wing plate. According to the hot-rolled inequilateral channel steel, the first wing plate and the second wing plate adopt an inequilateral design, the first wing plate is higher than the second wing plate by 5-30 mm, so that in combination production of a forklift truck gantry and under the same bearing capacity, steel material consumption is reduced, dead weight of a gantry system is reduced wholly, and the manufacturing cost of the gantry is reduced; and meanwhile, due to the inequilateral channel steel design, the inequilateral channel steel is attractive in appearance, not easy to deform and higher in bending resistibility, stable running of the roller is guaranteed, friction period between the roller and section steel is prolonged, and the service life of the channel steel is prolonged.

Owner:LAIWU IRON & STEEL GRP

Automatic cutter for aerated concrete blocks

ActiveCN112873574AMeet cutting needsShorten the timeWorking accessoriesStone-like material working toolsArchitectural engineeringStructural engineering

The invention discloses an automatic cutter for an aerated concrete block. According to the automatic cutter for the aerated concrete block, a second baffle is rotationally arranged on a base to limit the aerated concrete block, the second baffle is rotationally connected with an arc-shaped sliding rail located on the bearing surface, the second baffle locks or unlocks the arc-shaped sliding rail through a telescopic clamping knife, a sliding rod is of a door-shaped structure, the sliding rod is movably connected with a pair of rails to move in a controlled mode in the longitudinal direction of the base, a blade is connected with the sliding rod in a lifting mode through a hydraulic rod, the blade is transversely arranged above the base, a time relay is connected with the hydraulic rod, and the time relay controls the hydraulic rod to drive the blade to automatically cut the aerated concrete block on the basis of a time sequence. The automatic cutter for the aerated concrete block meets the aerated block cutting requirements in different environments, and the problem of a large amount of cutting waste materials caused by inaccurate manual measurement and oblique angle chopping is reduced.

Owner:CHINA CONSTR MUNICIPAL ENG +1

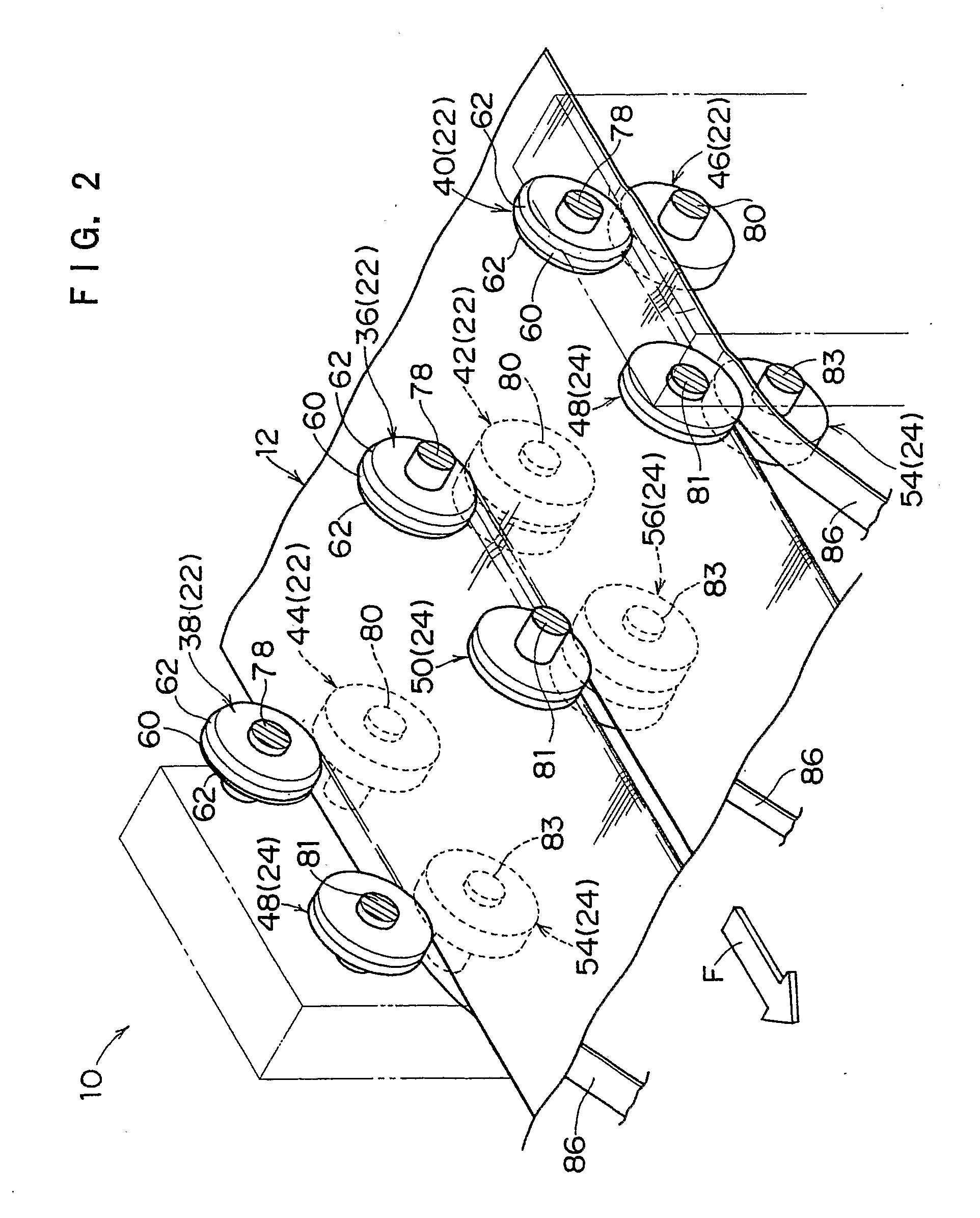

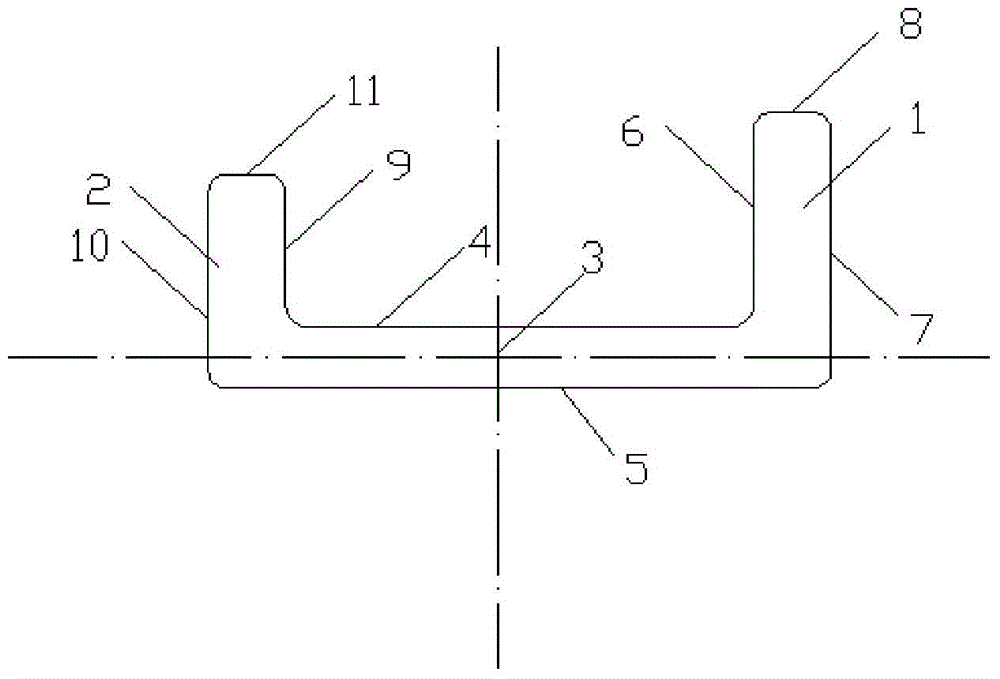

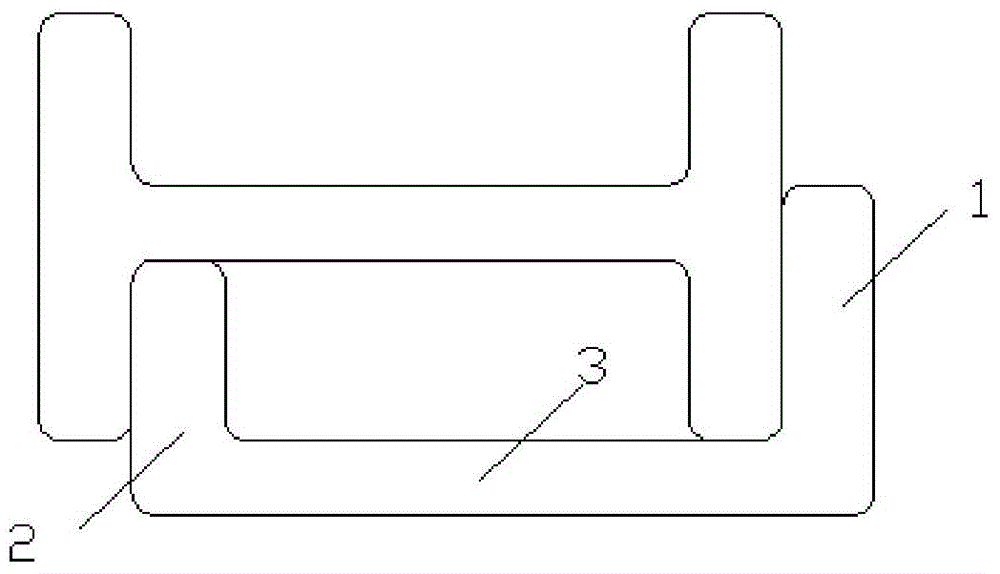

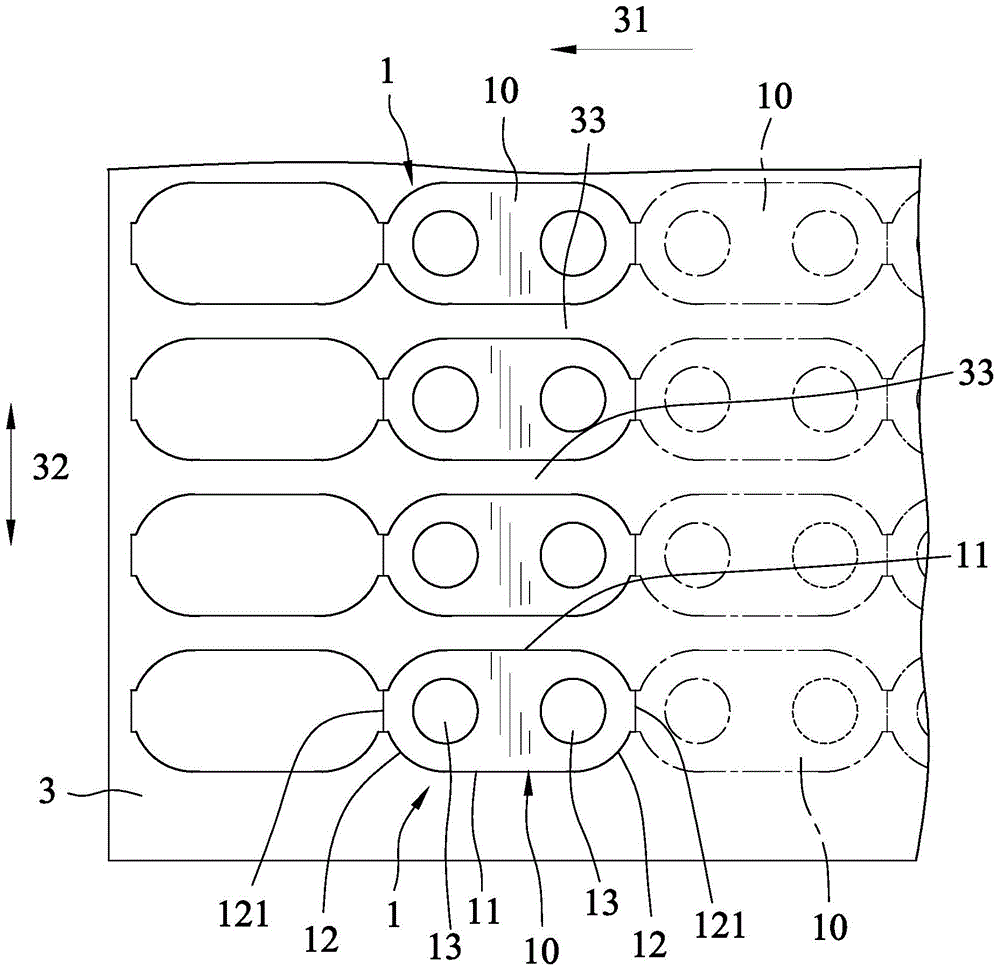

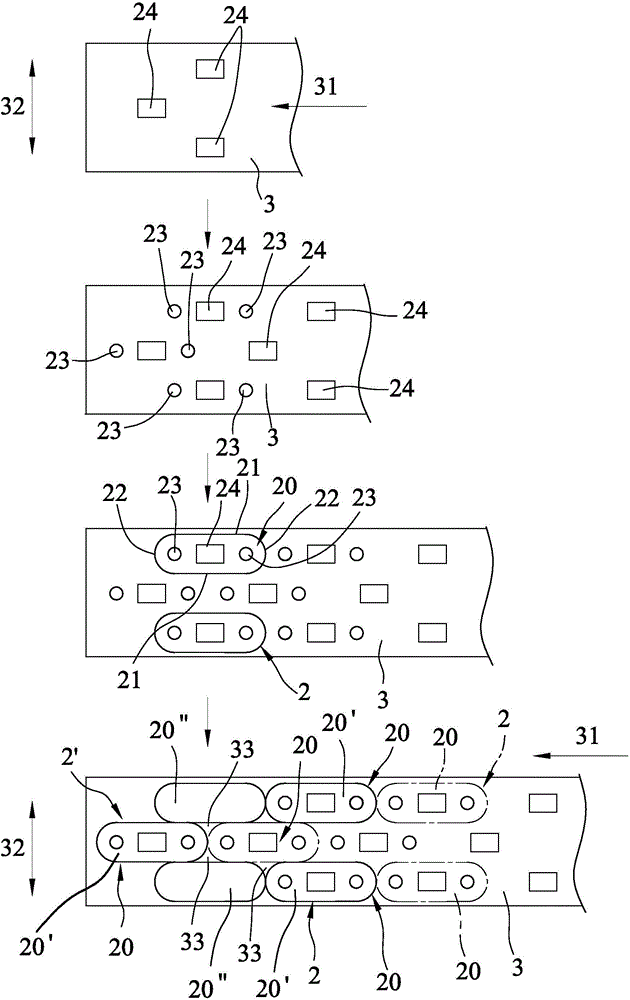

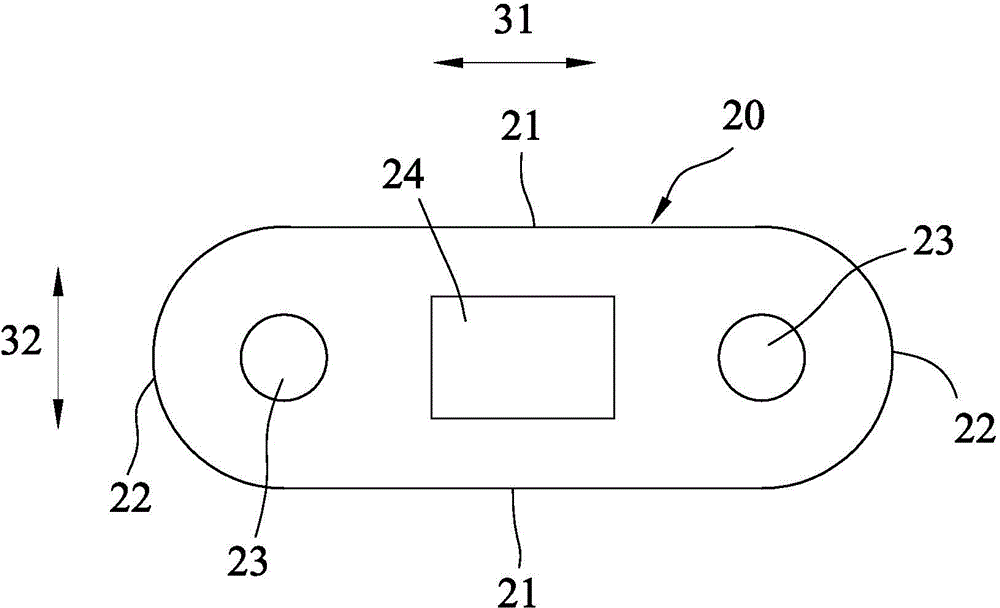

Chain sheet punching method

The invention provides a chain sheet punching method. A plurality of rows of chain sheet units can be punched on a metal plate and strip, each row of the chain sheet units comprise a plurality of chain sheets connected end to end, the metal plate and strip intermittently proceeds in a length direction, and each chain sheet is provided with two straight edges parallel to the length direction, two end edges respectively connected with the straight edges and arranged in tandem at intervals, and two penetration holes respectively close to the end edges. The chain sheet punching method comprises the following steps: a punching step for forming penetration holes of a chain sheet and a blanking step for forming the outline of the chain sheet, wherein in the blanking step, the end edges of the chain sheets in each row of chain sheet units to be cut are connected end to end, and the straight edges of the chain sheets in the chain sheet units which are adjacent left and right are staggered in tandem and partially overlapped. Through the design, the purposes of reducing waste materials and lowering the material cost are achieved.

Owner:YUEMENG ENTERPRISE

Large-sized melon and fruit peeling device for vegetable distribution

The invention discloses a large-sized melon and fruit peeling device for vegetable distribution. The large-sized melon and fruit peeling device is characterized in that by inflating annular airbags, cutting knives on the airbags fit with the surfaces of the melons and fruits to peel the melons and fruits by coordination of suspension. The large-sized melon and fruit peeling device is characterizedin that a main body cylinder is arranged on a fixed frame, gas injection holes are formed in the main body cylinder, multiple sections of discontinuous trapezoidal threads are formed in the inner wall of the main body cylinder, the minor diameter of the threads is smaller than the inner diameter of the main body cylinder, an arc-shaped support plate is arranged on the inner wall of a main body box and positioned at one end, an annular groove is formed in the arc-shaped support plate, a protective cover plate is arranged at the other end of the main body cylinder, a guide sleeve is arranged onan inner ring of the protective cover plate, a plurality of support rollers are arranged at equidistance on the side wall of the guide sleeve, and the support rollers can be telescopically regulatedalong the radial direction of the main body cylinder and can reduce peeling waste of the melons and fruits; and the cutting knives fit with the surfaces of the melons and fruits and can effectively improve the efficiency and effects in peeling the melons and fruits.

Owner:朱家珲

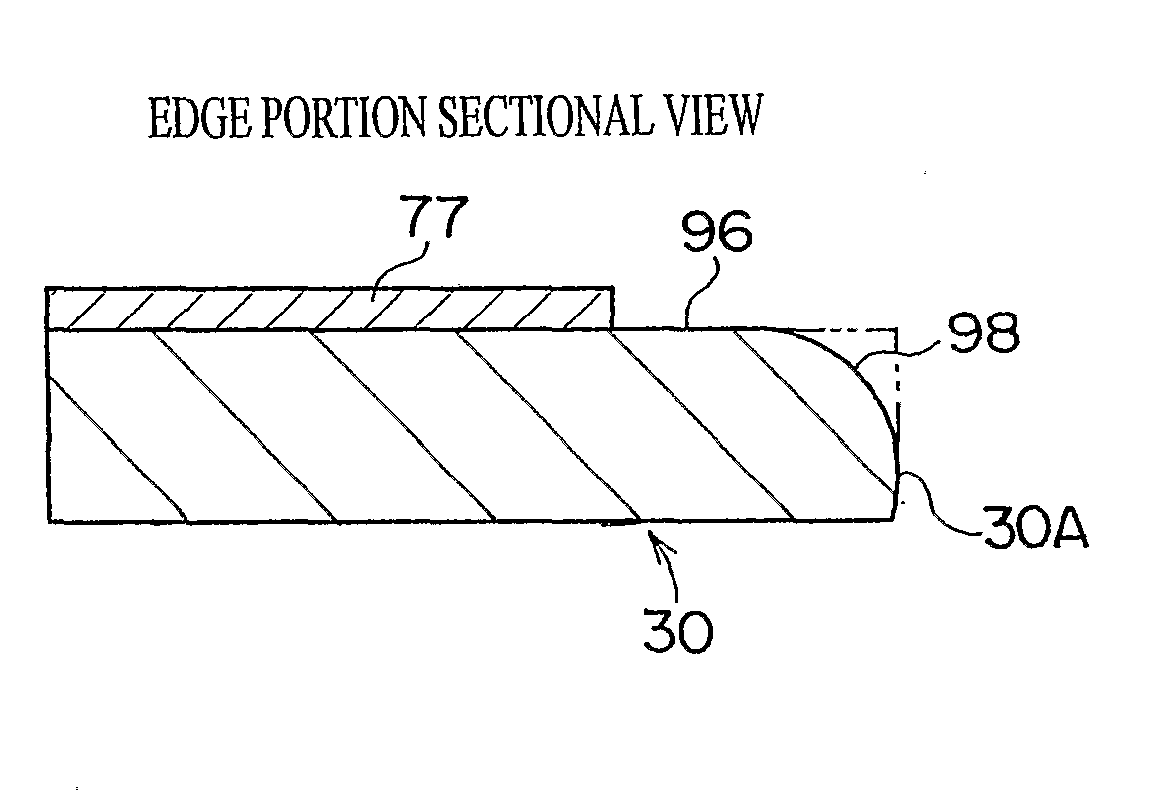

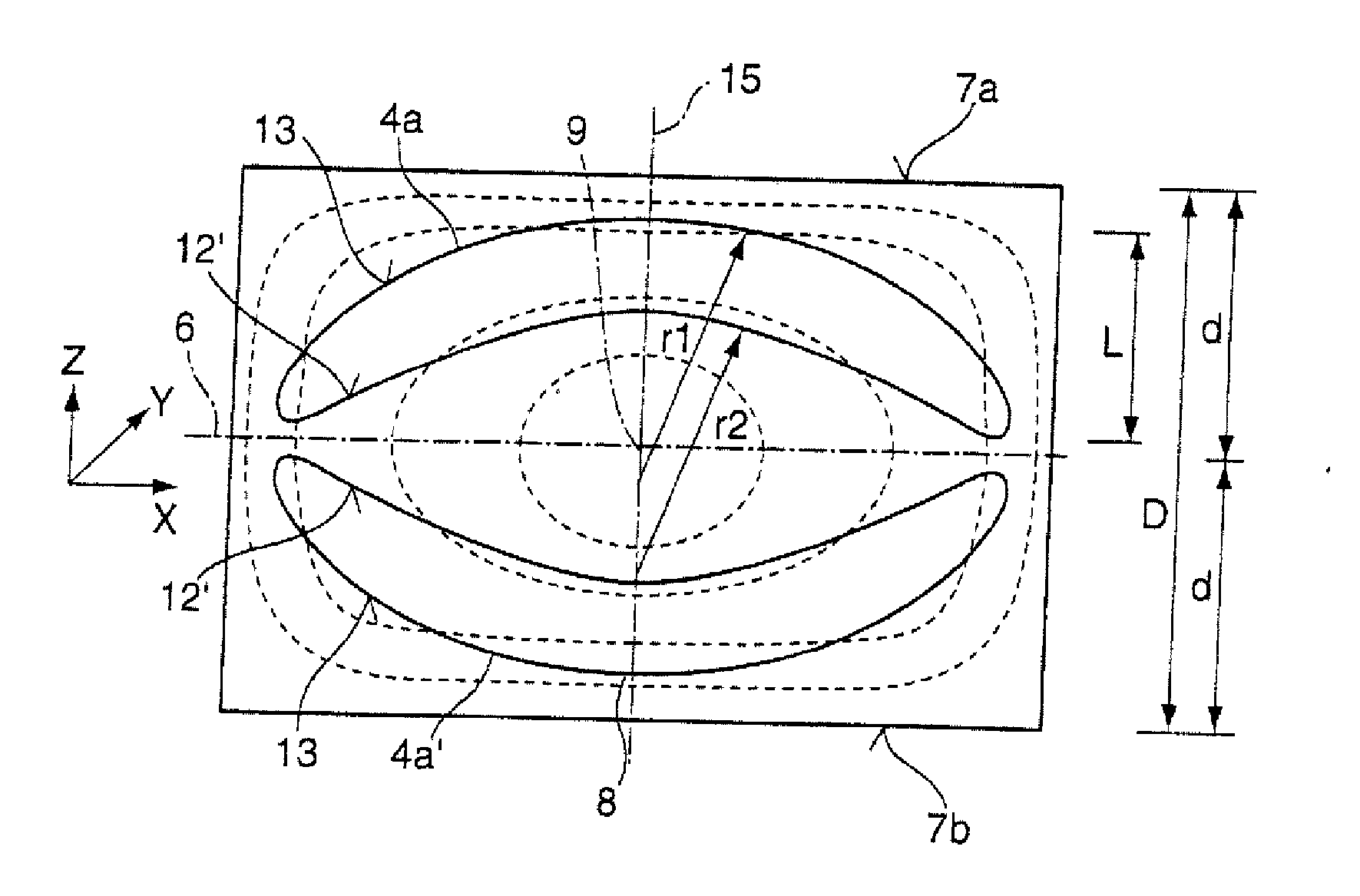

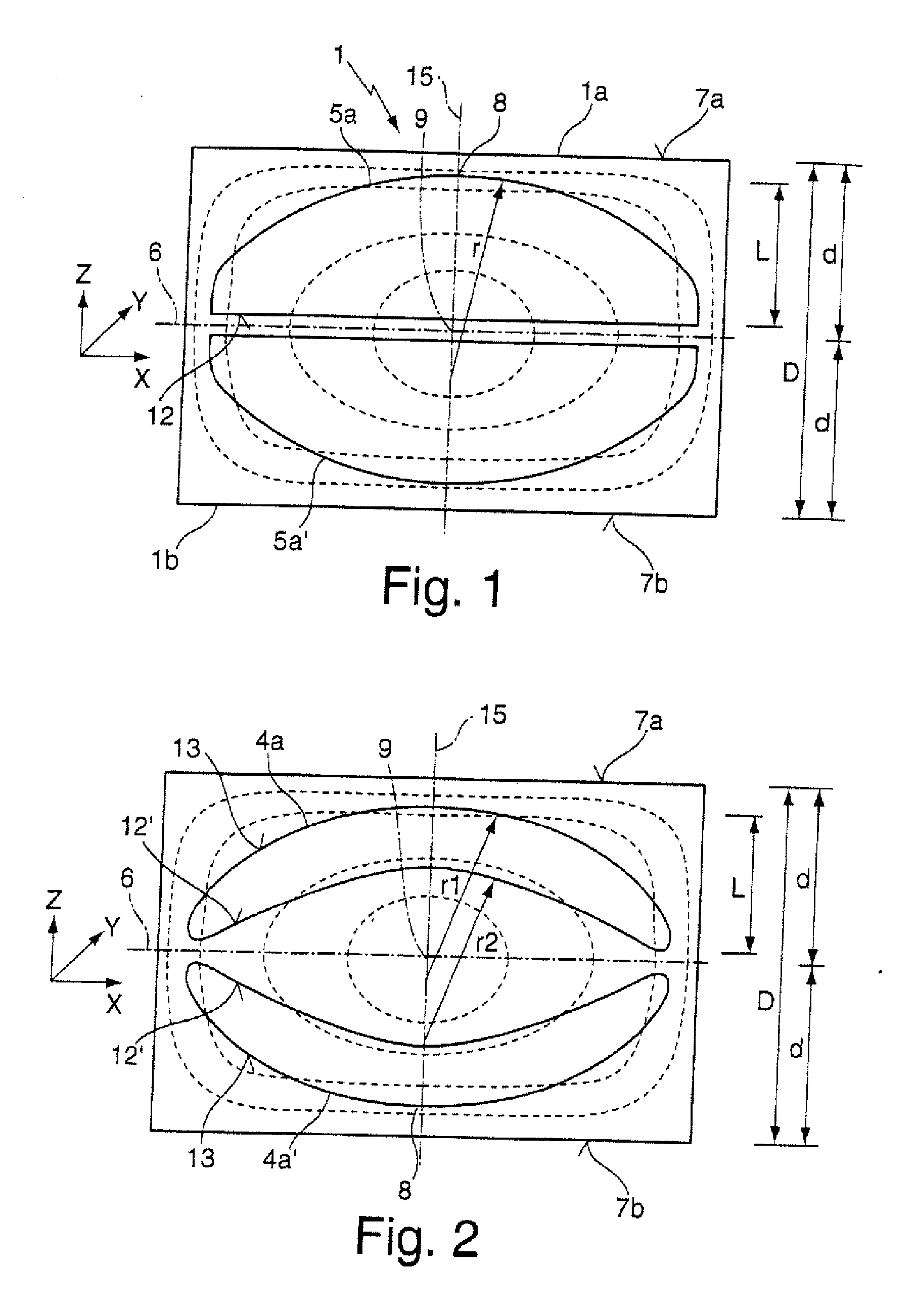

Lens blank and lens elements as well as method for their production

ActiveUS20080018992A1Favorable strain distributionReduce cutting wastePhotomechanical apparatusGlass/slag layered productsMaterials science

Owner:CARL ZEISS SMT GMBH

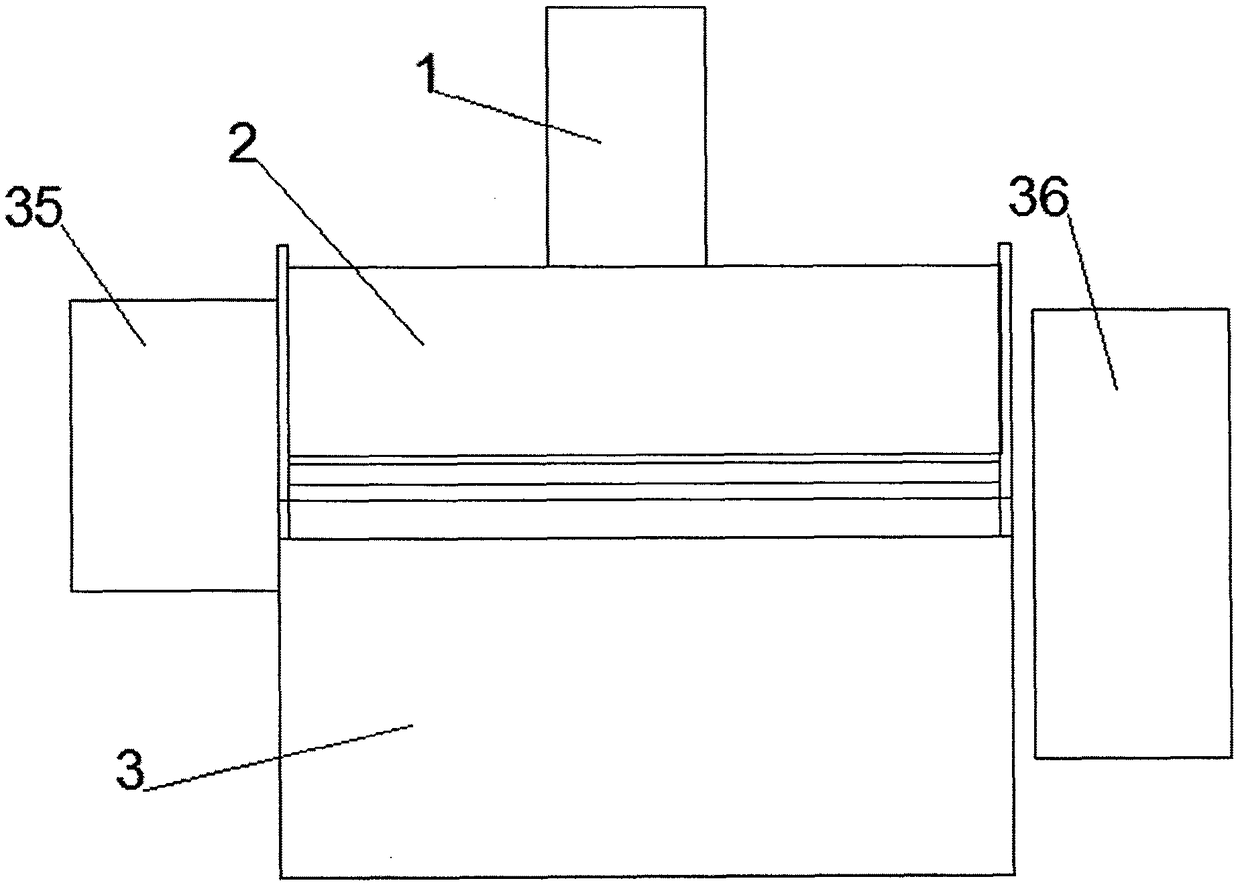

Full-automatic comb foundation machine

PendingCN109454887AFast-settingAvoid affecting productionDomestic articlesMechanical engineeringWaste production

The invention discloses a full-automatic comb foundation machine. The full-automatic comb foundation machine comprises a feeding box, a water collecting tank, a control cabinet and a machine frame. The machine frame is arranged transversely, a roll-in forming device, a width trimming device, a conveying device, a cutting device and a storage device are sequentially arranged on the machine frame from left to right, the feeding box is arranged on the roll-in forming device, the water collecting tank is arranged on the position, under the roll-in forming device, of the machine frame, and the control cabinet is arranged on the front side surface of the roll-in forming device. The full-automatic comb foundation machine has a simple and ingenious structure, the devices cooperate with each otherin a coherent mode, mass mechanized production of comb foundation can be realized, the investment of labor cost can be greatly reduced, the yield of the comb foundation is ensured, higher guarantee ofthe quality of the comb foundation is realized, waste production is reduced, the cost input is saved, the manufacturing cost of the full-automatic comb foundation machine is low, and popularization of the market is facilitated.

Owner:李俊尧

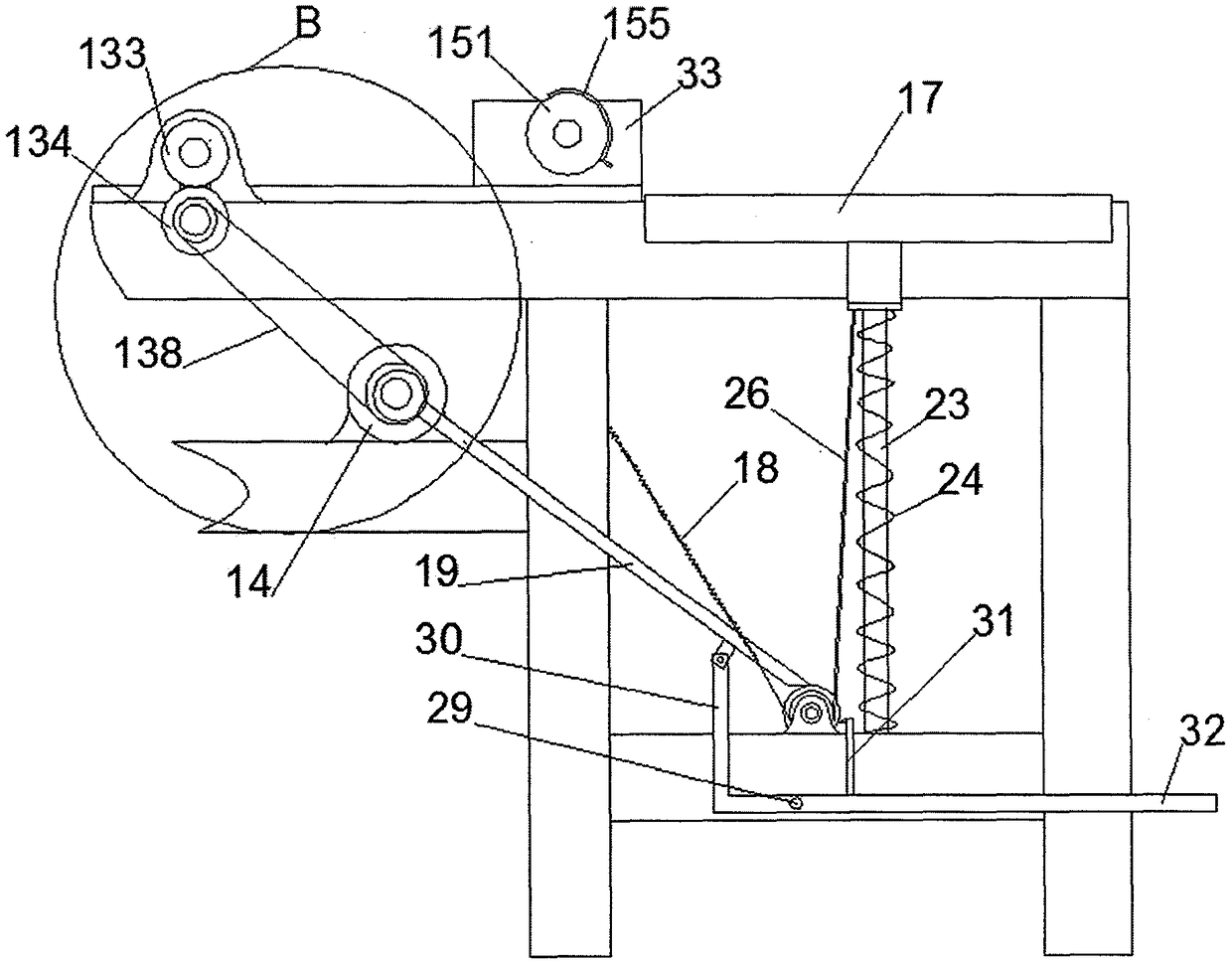

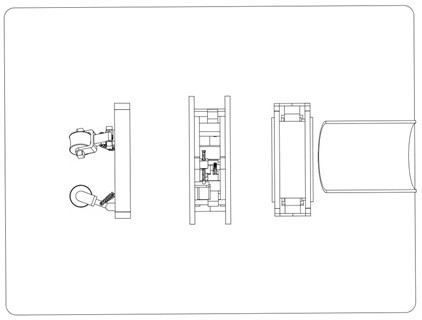

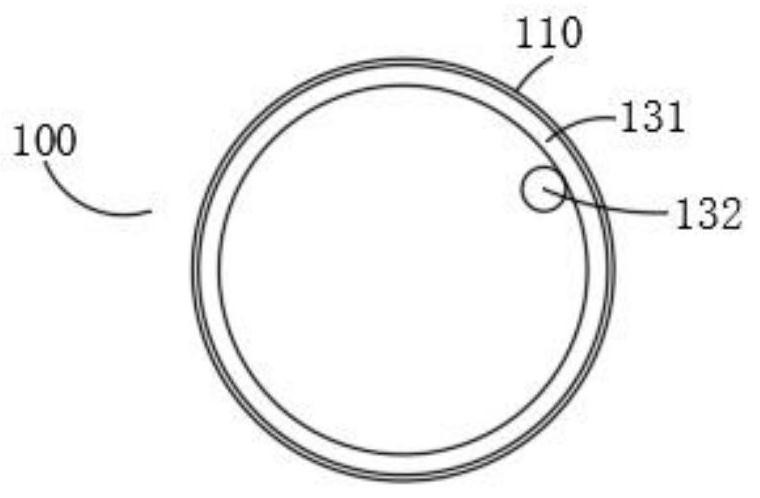

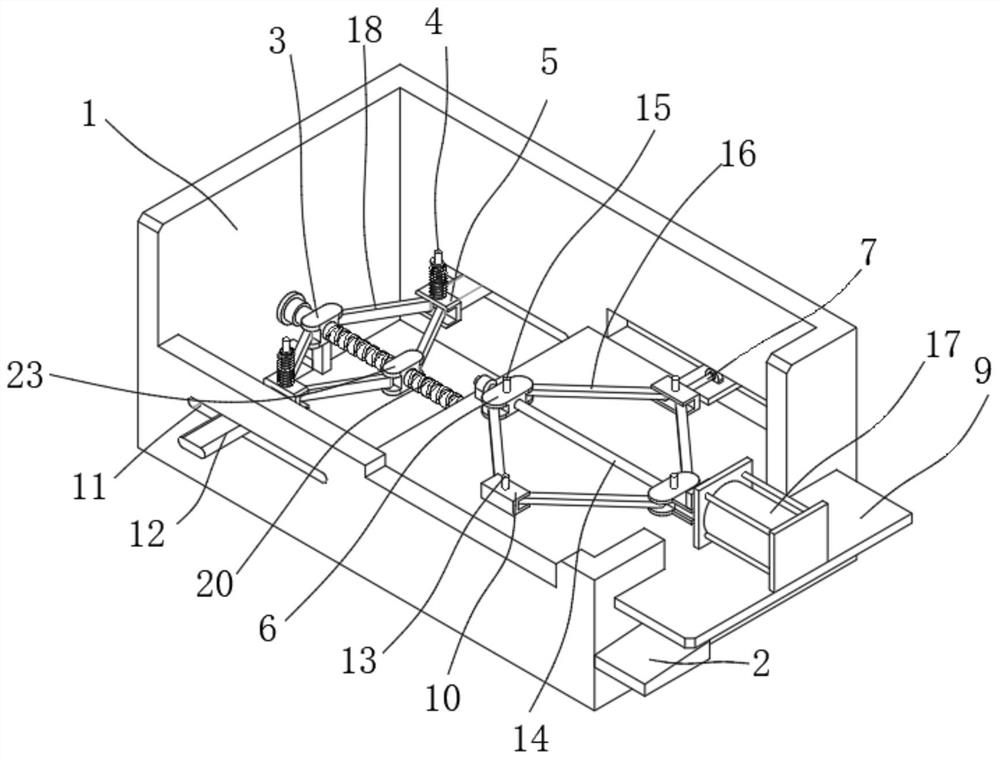

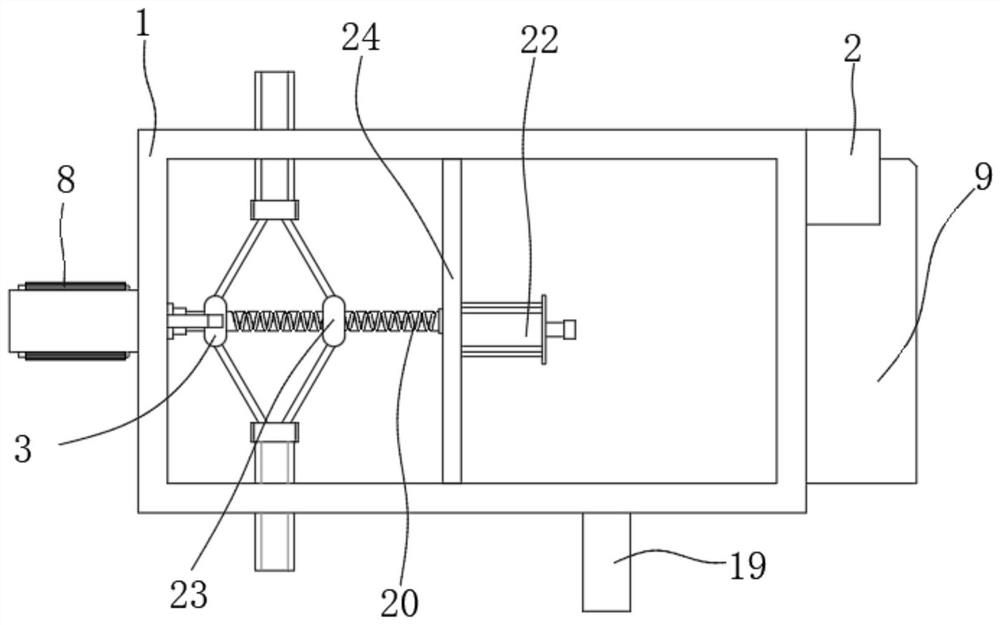

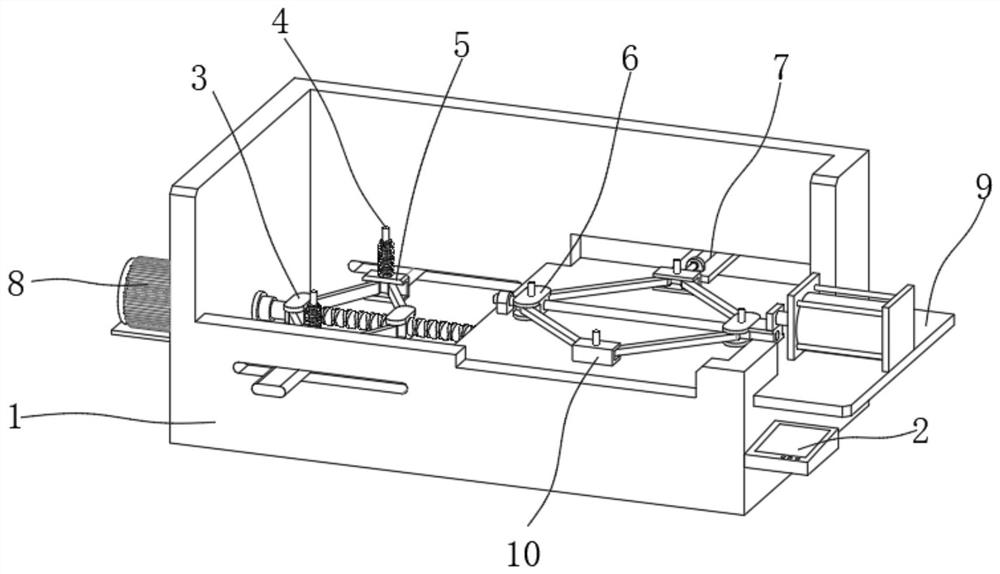

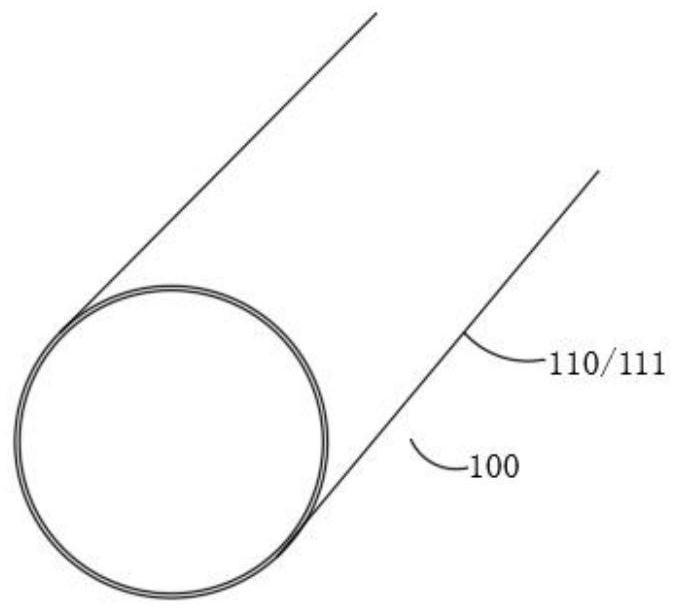

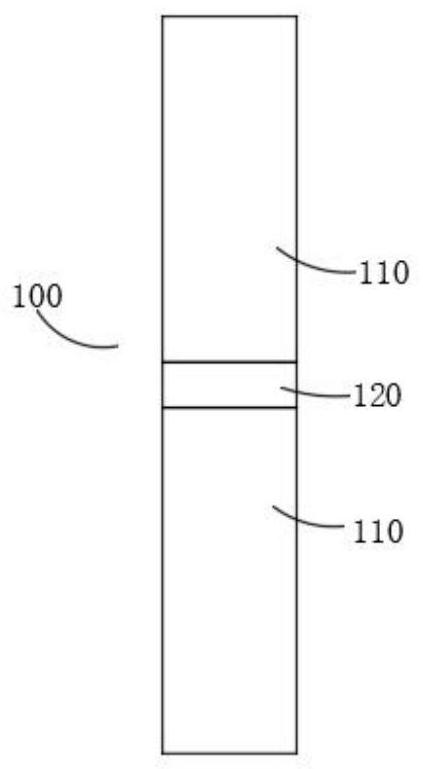

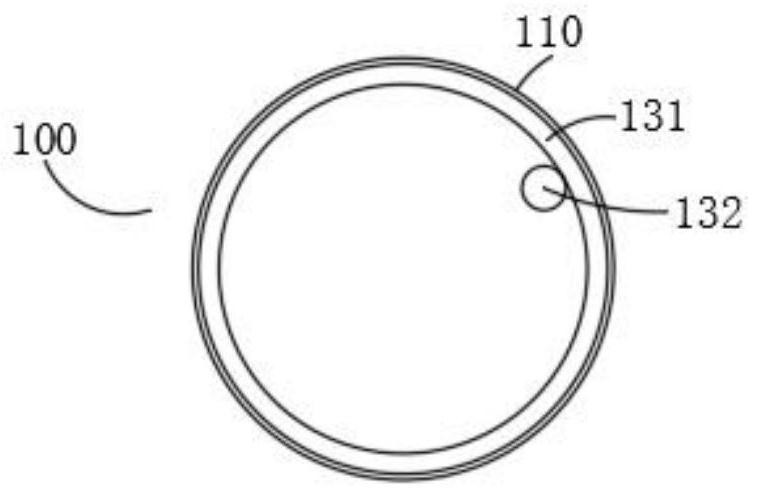

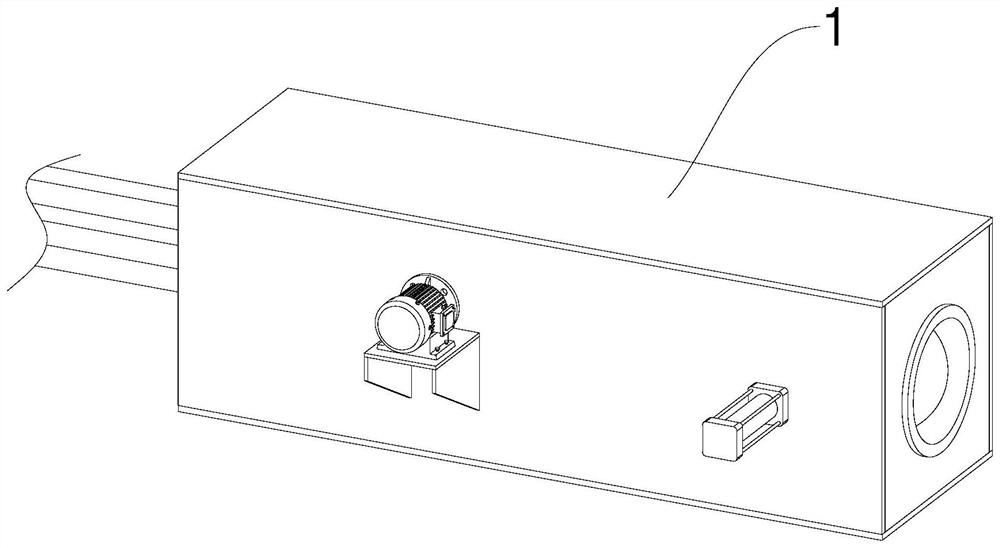

A steel pipe external circumcision robot

ActiveCN111745215BEliminate manual complex operationsImprove work efficiencyMetal sawing devicesClassical mechanicsMechanical engineering

The invention discloses a steel pipe external circular cutting robot, which includes a platform, a feeding mechanism, a cutting mechanism, a rotating mechanism, a transmission channel, a rectangular steel plate working platform on the platform, and an installation platform for the feeding mechanism, the cutting mechanism, the rotating mechanism and the transmission channel; The lower end of the feeding mounting plate is vertically fixed to the platform, and the middle part of the feeding mounting plate is provided with an arc groove, and the outer side of the feeding mounting ring is fixedly installed in the arc groove provided on the feeding mounting plate. The invention actively feeds the steel pipes to be cut through the feeding mechanism, saves complicated manual operations, and improves work efficiency.

Owner:山东鹏耀智佳精密工业有限公司

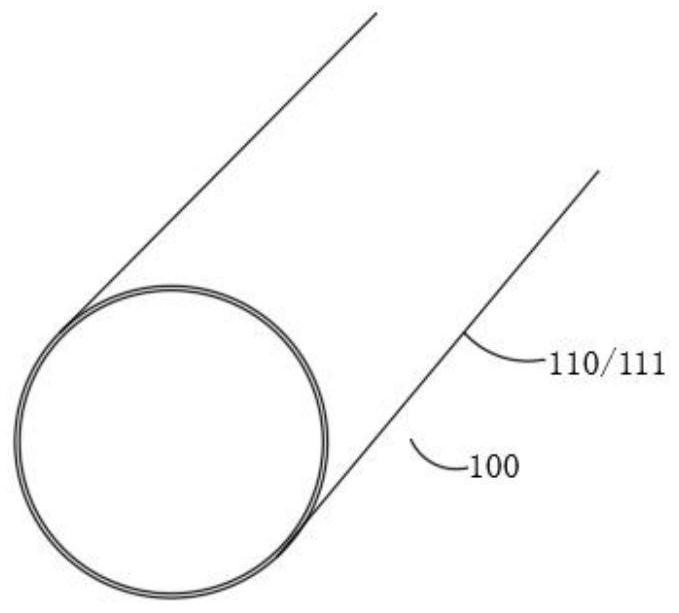

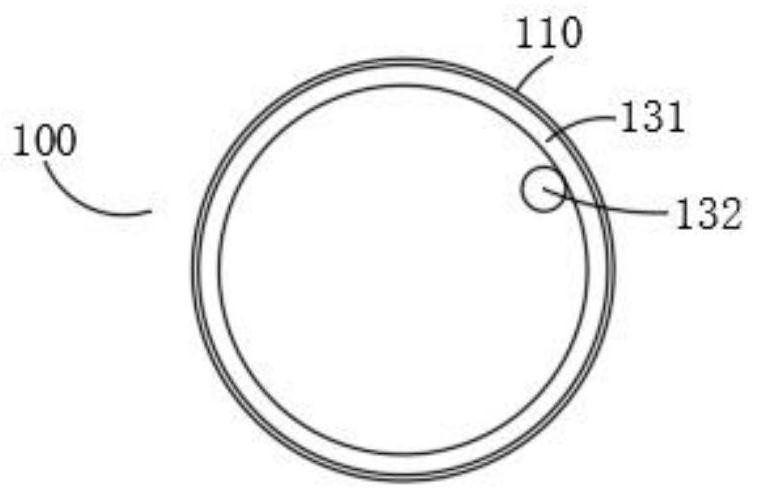

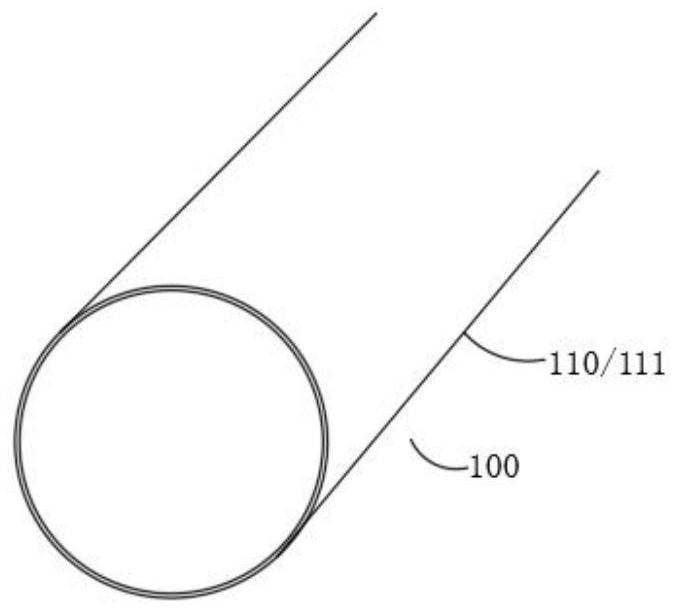

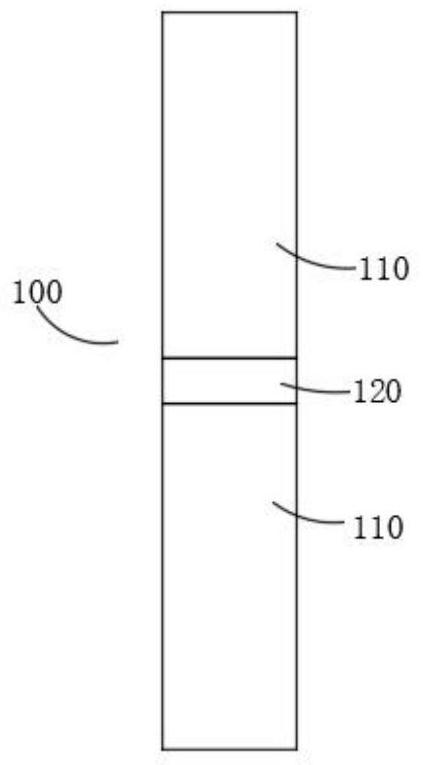

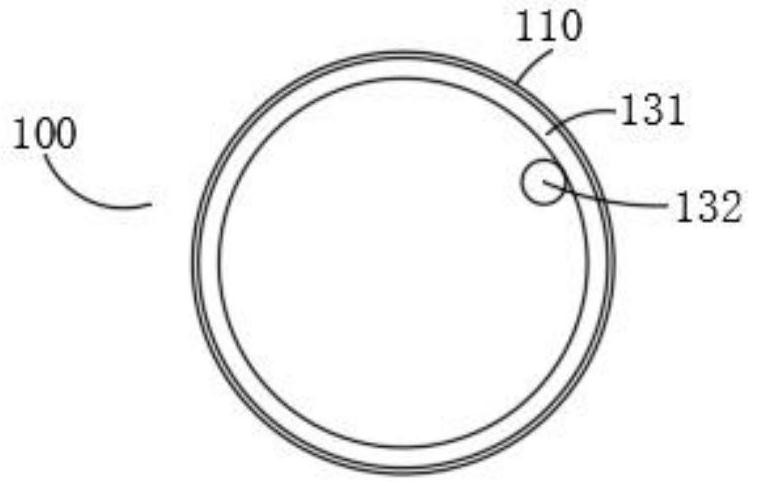

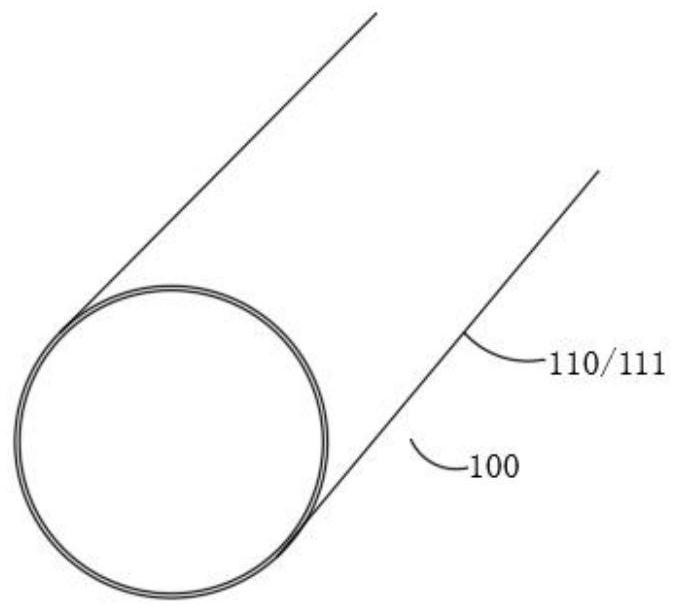

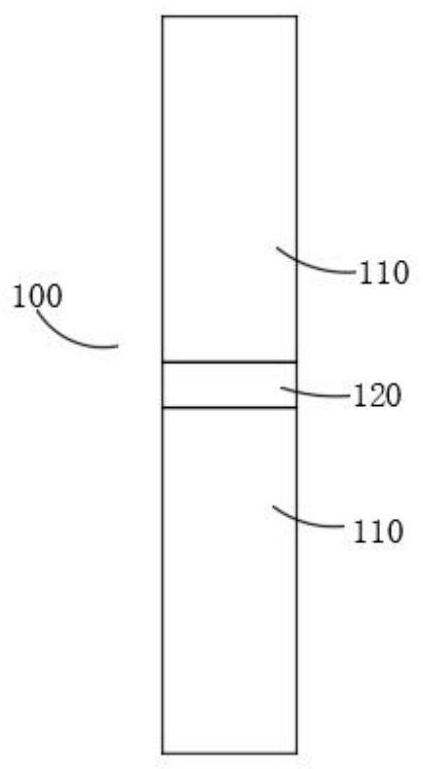

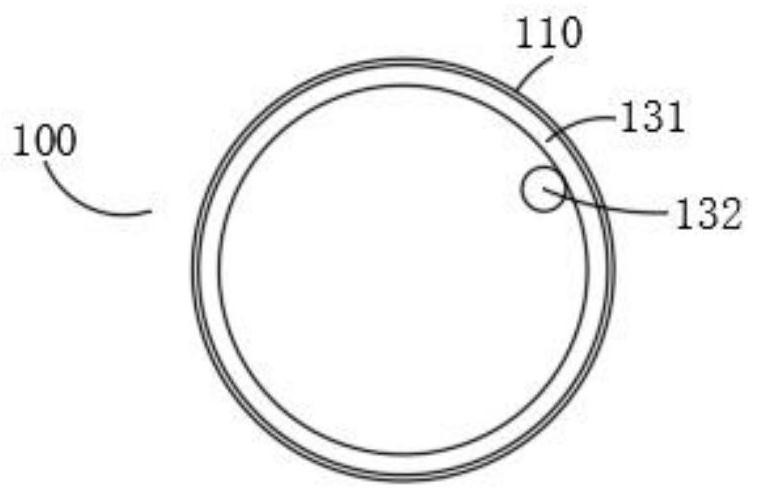

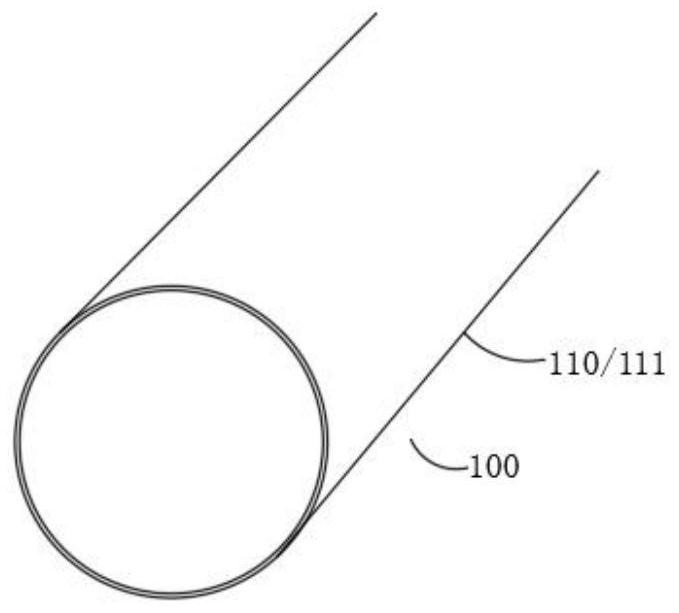

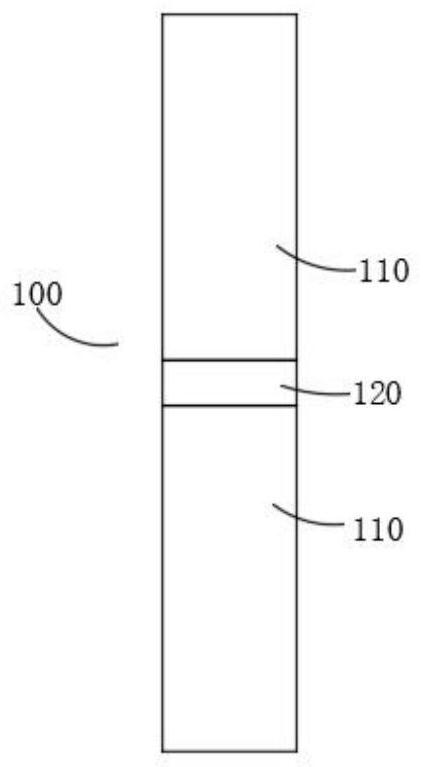

Filter element

PendingCN112237811AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

The invention discloses a filter element. The filter element is placed in a filter to be used for carrying out gas-solid separation filtration and / or liquid-solid separation filtration on an object tobe filtered during use; the filter element comprises at least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or sheet-shaped materials taking the metal as a base body in a rolled mode and carrying out sealing processing on joints; the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm, furtherpreferably 20-60 mm, and further preferably 25-50 mm, and the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm; the lengths of the filter tubes range from 100mm to 5000 mm, preferably range from 100 mm to 3000 mm, further preferably range from 100 mm to 2000 mm, and further preferably range from 200 mm to 1500 mm. A plurality of small-diameter filter tubesare bundled, so the filtering area can be remarkably increased in a limited mounting space; the length of the filter element is reduced, so the blowback effect can be more uniformly distributed in the axial direction of the filter tubes. Therefore, the technical problems that in the prior art, a filter element is small in filtering area and poor in back flushing effectiveness are effectively solved.

Owner:CHENGDU INTERMENT TECH

Packing strap cutting device

PendingCN108406897AImprove Field Work EfficiencyReduce cutting wasteMetal working apparatusEngineeringField working

The invention discloses a packing strap cutting device. The packing strap cutting device comprises a base, a switch blade, a first fixed platform and a second fixed platform. The switch blade is perpendicular to the base and comprises a main knife and an auxiliary knife. The corresponding ends of the main knife and the auxiliary knife are in pin joint, and the auxiliary knife is fixed to the base.The first fixed platform and the second fixed platform are oppositely arranged in the length direction of the base and are both fixedly connected with the base. The first fixed platform is located onthe side, away from the auxiliary knife, of the main knife, and the second fixed platform is located on the side, away from the main knife, of the auxiliary knife and is fixedly connected with the auxiliary knife. The first fixed platform and the second fixed platform are provided with multiple guide rails in the width direction of the base. The guide rails extend in the length direction of the base. Each guide rail is used for limiting movement of a corresponding packing strap in the width direction of the base. According to the packing strap cutting device, the field work efficiency is greatly improved, and cutting waste of the field packing straps is reduced to the maximum degree; and meanwhile, the packing strap cutting device is simple in structure and convenient to carry.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

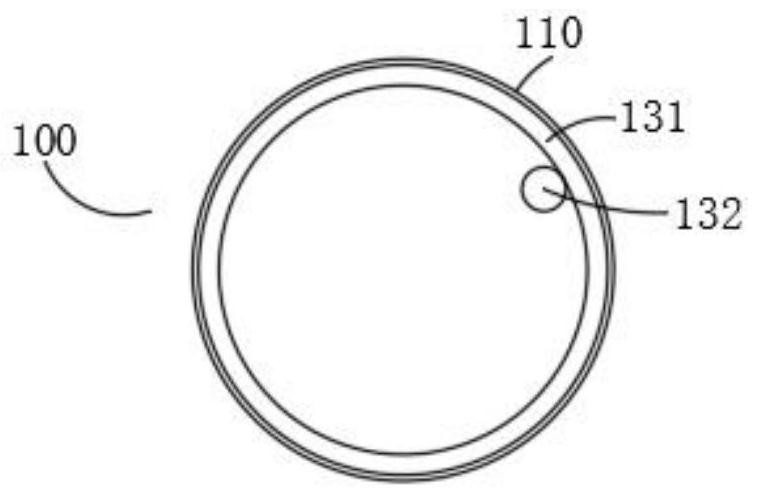

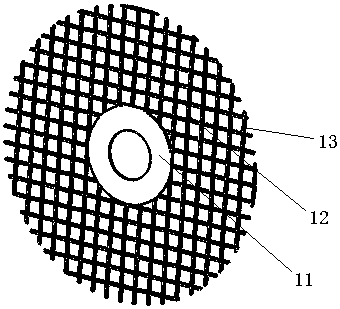

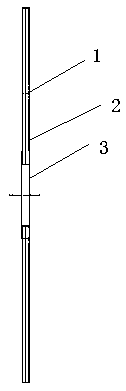

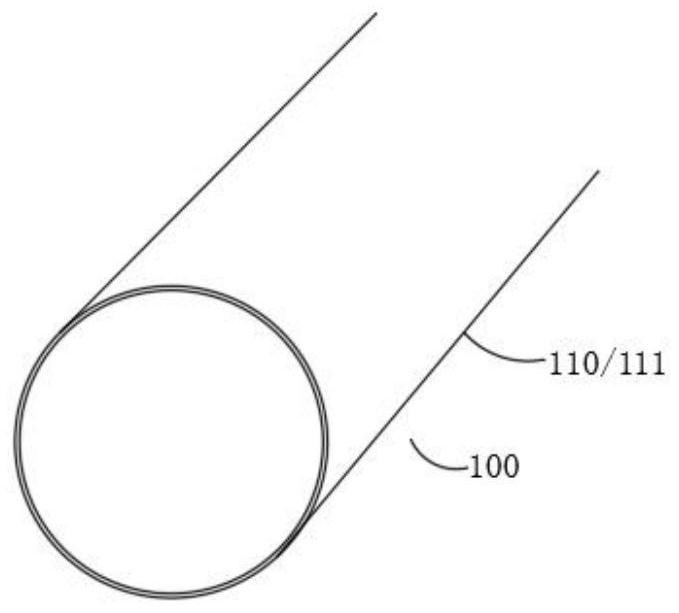

Manufacturing method of cutting piece

ActiveCN109159042AExtended service lifeReduce cutting wasteAbrasion apparatusGrinding devicesAsphaltGypsum

The invention discloses a manufacturing method of a cutting piece, and belongs to the field of abrasive grinding tools. The manufacturing method comprises the following steps that 1, metal wires are woven into a metal net; 2, the metal net is cut into an annular shape; 3, phenolic resin is coated near inner holes of the annular metal net, and the coating thickness is ensured to meet the requirements; 4, the metal net is placed into electroplating equipment for electroplating diamond; and 5, white corundum, anhydrous gypsum, the phenolic resin, asphalt and an additive are crushed and sieved, and then mixed and stirred evenly to form an abrasive mixture. The manufacturing method of the cutting piece has the characteristics that the thinner cutting piece can be manufactured, and the manufactured cutting piece is long in service life and can be used for cutting hard objects.

Owner:河南格锐新材料科技有限公司

Filter

PendingCN112237810AReduce areaSolve the costCombination devicesDispersed particle filtrationProcess engineeringControl theory

The invention discloses a filter. The filter comprises a filter structure, and the filter structure comprises at least two filter elements which are arranged at intervals; the filter element comprisesat least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking the metal as a base body in a rolling manner and performing sealing processing on joints; and the outer diameter of the pipe body formed by rolling is only 20-200 mm. The bundled filter element formed by bundling a plurality of small-diameterfilter tubes is adopted, so that the filtering area can be remarkably increased; for a filter with a large size, the weight of a single filter element can be reduced by adopting a plurality of cluster type filter elements while a high filtering area is ensured, and the installation is simplified; for a filtering structure needing a large number of filter tubes, a plurality of cluster type filterelements are respectively mounted, so that a relatively uniform blowback effect can be ensured. Therefore, compared with the prior art, the filter has the advantages that a larger filter area can be achieved, and the problems of installation and blowback after the filter pipes are bundled are solved.

Owner:CHENGDU INTERMENT TECH

A Method of High-Speed Adjustment of Crystallizer Width in Online Hot State

The invention belongs to the technical field of continuous casting, and in particular provides a method for adjusting the width of a crystallizer in an online hot state at high speed. According to the solidification and shrinkage characteristics of molten steel in the crystallizer, the present invention determines the reasonable mechanism of mold width adjustment or narrowing adjustment, deduces the adjustment limit speed of mold width or narrowing adjustment, and selects the best mold on-line heating according to actual production needs. State high-speed adjustment width parameters. The invention eliminates the air gap between the billet shell and the casting billet during the hot widening or narrowing process, so that the stress on the billet shell is low and uniform, and at the same time, the width or narrowing is improved without reducing the casting speed. speed.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Filter element

PendingCN112237809AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

Owner:CHENGDU INTERMENT TECH

A pole piece laser cutting system and method

ActiveCN114603267BImprove processing efficiencyEasy to cut in bulkCell electrodesLaser beam welding apparatusGalvanometerLight beam

The invention relates to the technical field of pole piece processing, and discloses a pole piece laser cutting system and method. Laser cutting is performed on the to-be-cut sheet in a scanning field of view to form a pole ear, and at the same time, the laser beam emitted by the second laser is also transmitted through the second scanning galvanometer to the to-be-cut sheet in the preset second scanning field of view The laser cutting is performed on the body, and the first scanning galvanometer and the second scanning galvanometer are also used to perform laser cutting on the to-be-cut piece body according to their corresponding preset pole piece division paths, and the to-be-cut piece body is divided into a plurality of pole pieces, A plurality of pole pieces are equipped with pole lugs, wherein the width of the piece to be cut is equal to the sum of the widths of the plurality of pole pieces, which facilitates batch cutting of pole pieces, improves the processing efficiency of pole pieces, and greatly reduces cutting waste. .

Owner:东莞市盛雄激光先进装备股份有限公司

Intensive thermal insulation device and method for small-diameter pipelines

ActiveCN106369226BReduce wasteConstruction loss rate reductionPipe supportsThermal insulationFiberQuality level

The invention discloses a small-caliber-pipeline intensive type heat preservation device and method. The small-caliber-pipeline intensive type heat preservation device comprises a heat preservation layer and an outer protective layer frame type support. The heat preservation layer comprises first aluminum silicate fiber blankets and a composite heat preservation structure. Each first aluminum silicate fiber blanket is wrapped around a single pipeline needing heat preservation. Each first aluminum silicate fiber blanket is externally bundled with a galvanized iron wire. The composite heat preservation structure is wrapped around a row of pipelines wrapped inside the first aluminum silicate fiber blankets. The outer side of the composite heat preservation structure is bundled with iron gauze. The outer layer of the iron gauze is provided with the outer protective layer frame type support. Corrugated plates and corner wrapping plates are arranged on the outer protective layer frame type support and are fixed with self-tapping screws. The corrugated plates are arranged on the outer surface of the outer protective layer frame type support. The corner wrapping plates are arranged at the corners of the outer protective layer frame type support. By the adoption of the small-caliber-pipeline intensive type heat preservation device and method, the construction efficiency and the installation quality level can be improved, and the construction cost can be reduced.

Owner:POWER CHINA HENAN ENG CO LTD

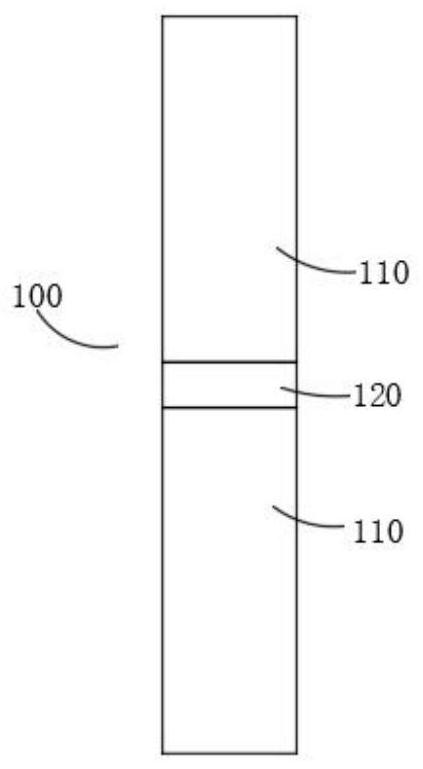

Filter tubes and preparation method thereof

PendingCN112237808AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationMechanical engineering

The invention discloses filter tubes and a preparation method thereof. When in use, the filter tubes are densely distributed in a filter in an array manner and are used for carrying out gas-solid separation filtration and / or liquid-solid separation filtration on a to-be-filtered object, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking metal as a matrix in a rolling manner and carrying out sealing processing on joints; and the outer diameter of the tube bodies formed by rolling is only 20 to 200 mm, preferably 20 to 90 mm, further preferably 20 to 60 mm, and further preferably 25 to 50 mm. The preparation method of the filter tubes comprises the steps: rolling the sheet-shaped material with the thickness of 0.2-2.5 mm into the tube bodies with the outer diameter of 20-200 mm; and when the diameter of the filter tubes is reduced to be 200 mm or less, the strength of the filter tubes can be maintained in a tube shape even if a support bodyis not arranged any more, and self-support can be realized, so that the weight and the cost can be remarkably reduced; therefore, the technical problems of high cost and low strength of a filter element in the prior art are effectively solved.

Owner:CHENGDU INTERMENT TECH

A car front suspension beam

ActiveCN111845939BReduce cutting wasteStructural rulesUnderstructuresSuspension (vehicle)Control theory

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

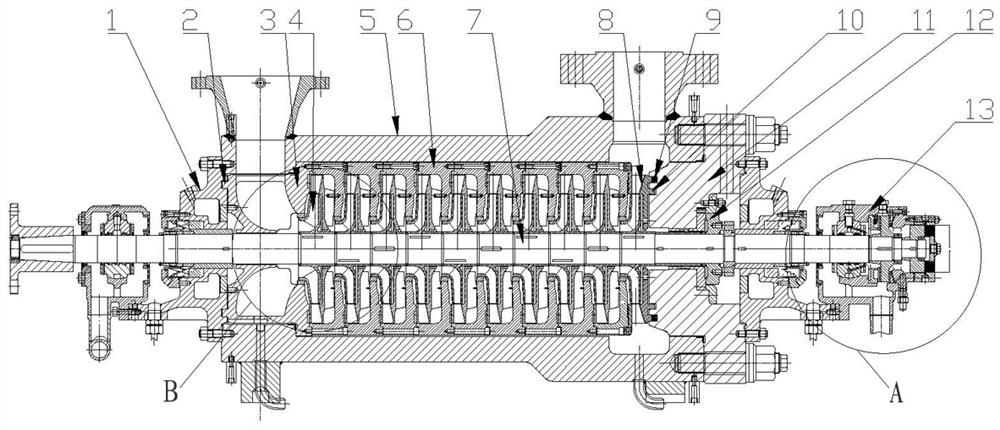

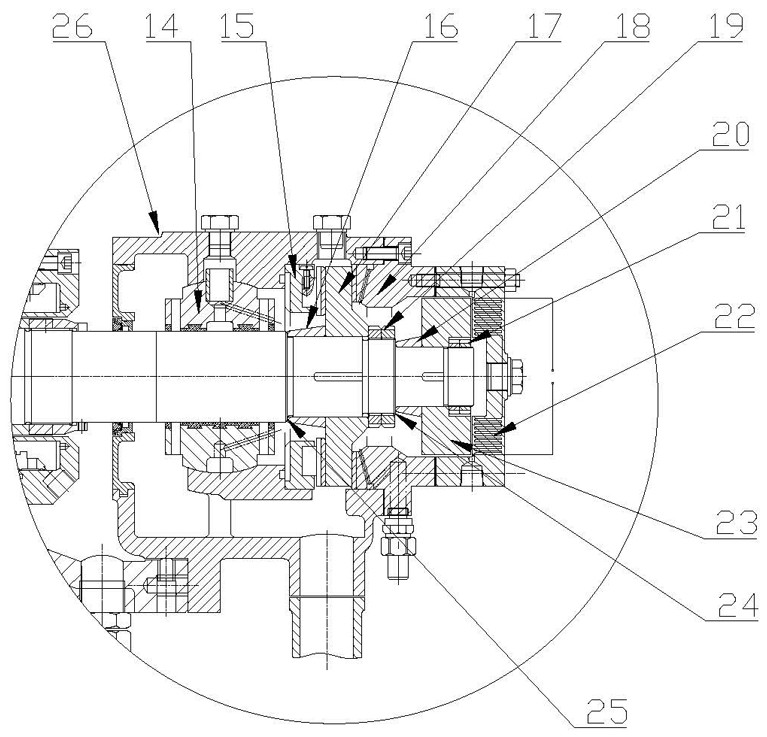

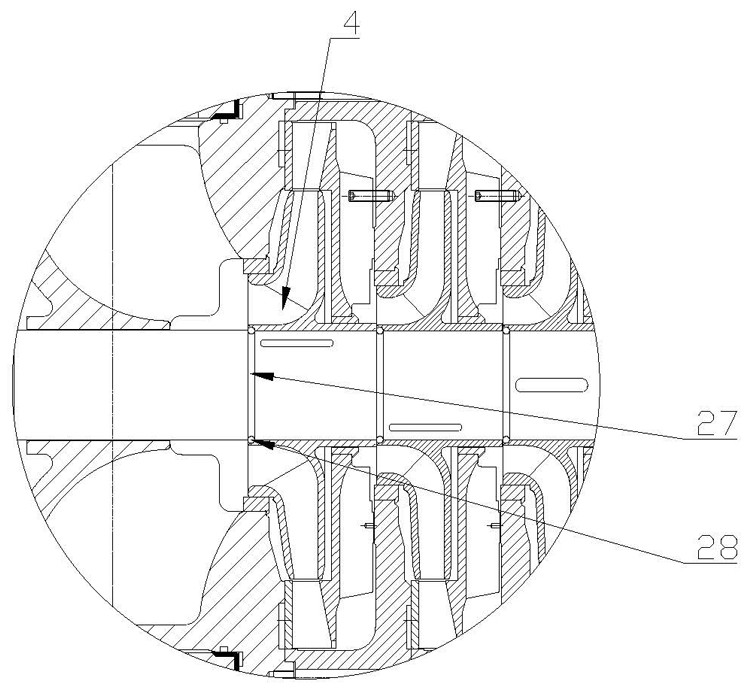

A dual-thrust ultra-high pressure boiler feed water pump

ActiveCN114198314BTake advantage ofLow costPump componentsRadial flow pumpsThermodynamicsBoiler feedwater pump

The invention belongs to the technical field of boiler feedwater pumps, and in particular relates to a double-thrust ultra-high pressure boiler feedwater pump. The feature of the present invention is that: the thrust bearing assembly includes a housing, the housing is provided with an end cover corresponding to the right end of the pump shaft, the right end of the pump shaft is fixedly provided with a first thrust bearing disc, and the end cover is in line with the pump shaft. The electromagnet corresponding to the first thrust bearing disc; the second thrust bearing disc is arranged on the left side of the first thrust bearing disc on the pump shaft, and the thrust bearing is arranged on the right side of the second thrust bearing disc in the casing a seat; a thrust bearing block is arranged on the left side of the second thrust bearing plate in the casing; a sliding bearing matched with the pump shaft is arranged on the left side of the thrust bearing block in the casing. The invention has stable operation, long service life and convenient maintenance.

Owner:SHENYANG QIYUAN INDAL PUMP MFG

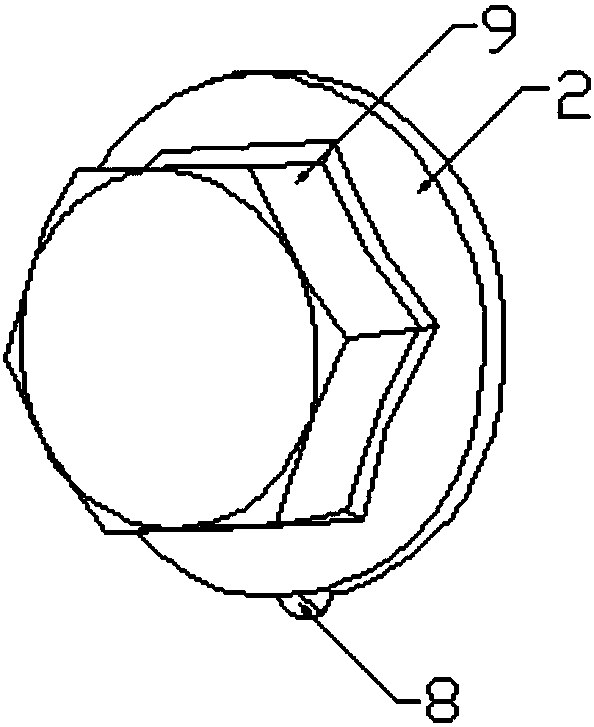

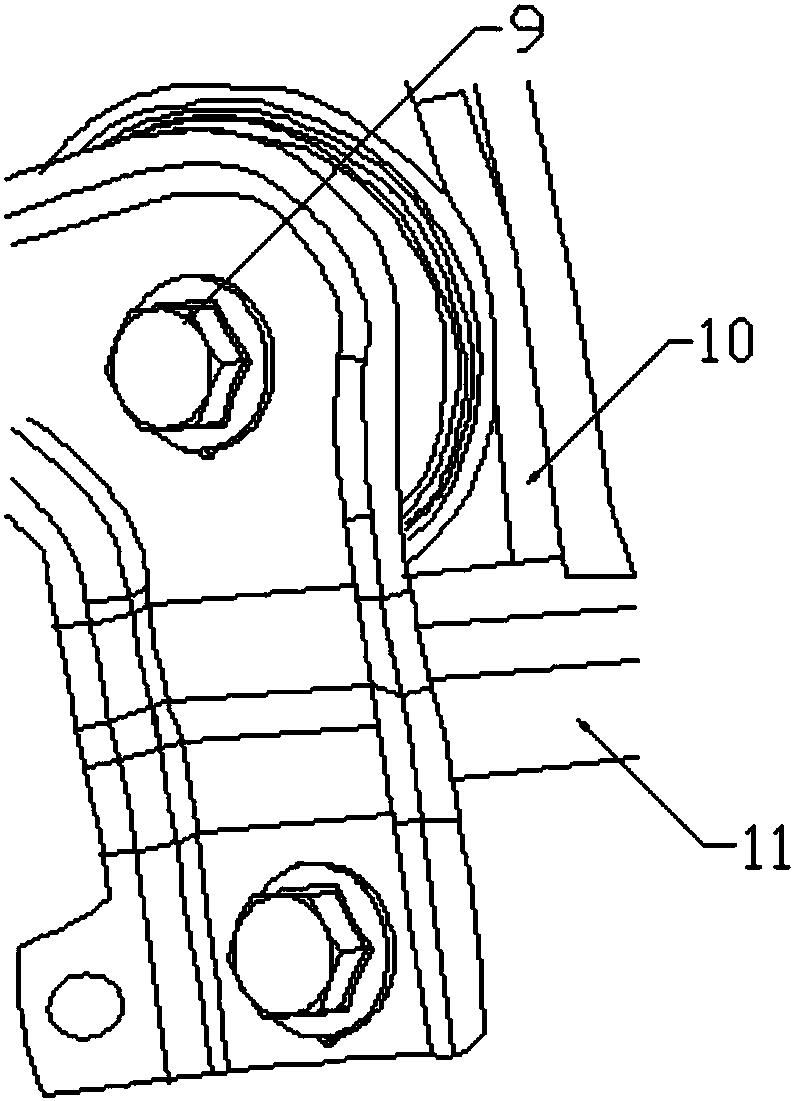

Front sub frame reinforcing support

InactiveCN108382460AReduce cutting wasteReduce development costsUnderstructuresVehicle frameEngineering

The invention discloses a front sub frame reinforcing support. The front sub frame reinforcing support comprises a reinforcing support body; reinforcing support sleeves are welded at the upper ends ofthe two sides of the reinforcing support body and are respectively a first reinforcing support sleeve and a second reinforcing support sleeve; the cross section of the reinforcing support body is ofan Omega shape; a reinforcing support left front mounting hole and a reinforcing support right front mounting hole are formed in the front end of the reinforcing support body; the reinforcing supportleft front mounting hole and the reinforcing support right front mounting hole are of Y-direction waist-shaped holes; X-direction water drain grooves are formed in the reinforcing support left front mounting hole and the reinforcing support right front mounting hole; flexible mounting cover plates are arranged at the upper ends of the reinforcing support left front mounting hole and the reinforcing support right front mounting hole and are respectively a first flexible mounting cover plate and a second flexible mounting cover plate; the lower end surfaces of the flexible mounting cover platesare high-strength plate bodies which are directly connected with a hexagon flange bolt; and the reinforcing support body, the flexible mounting cover plates and a front sub frame assembly are connected with a vehicle body longitudinal beam assembly by sharing a hexagon flange bolt.

Owner:SHANDONG KINGOLD AUTOMOBILE CO LTD

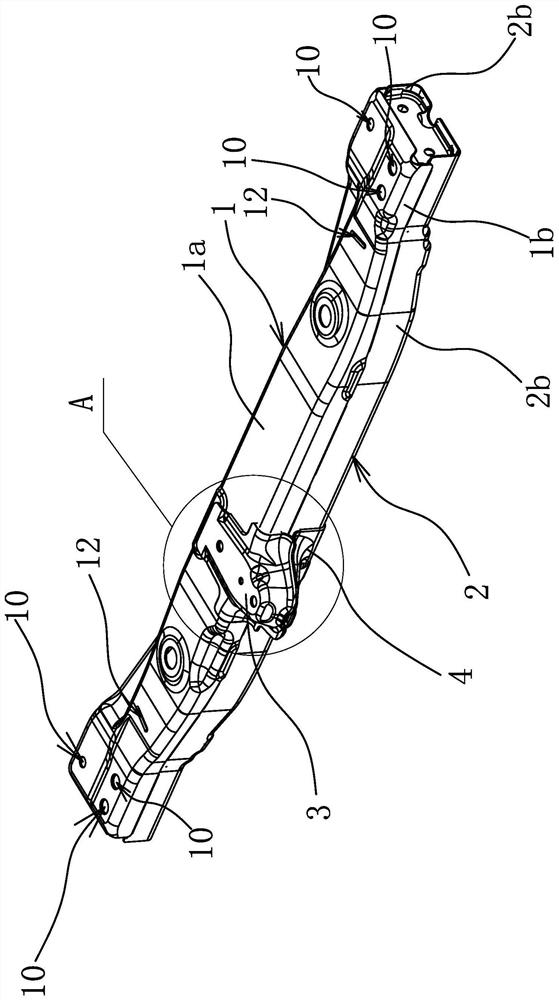

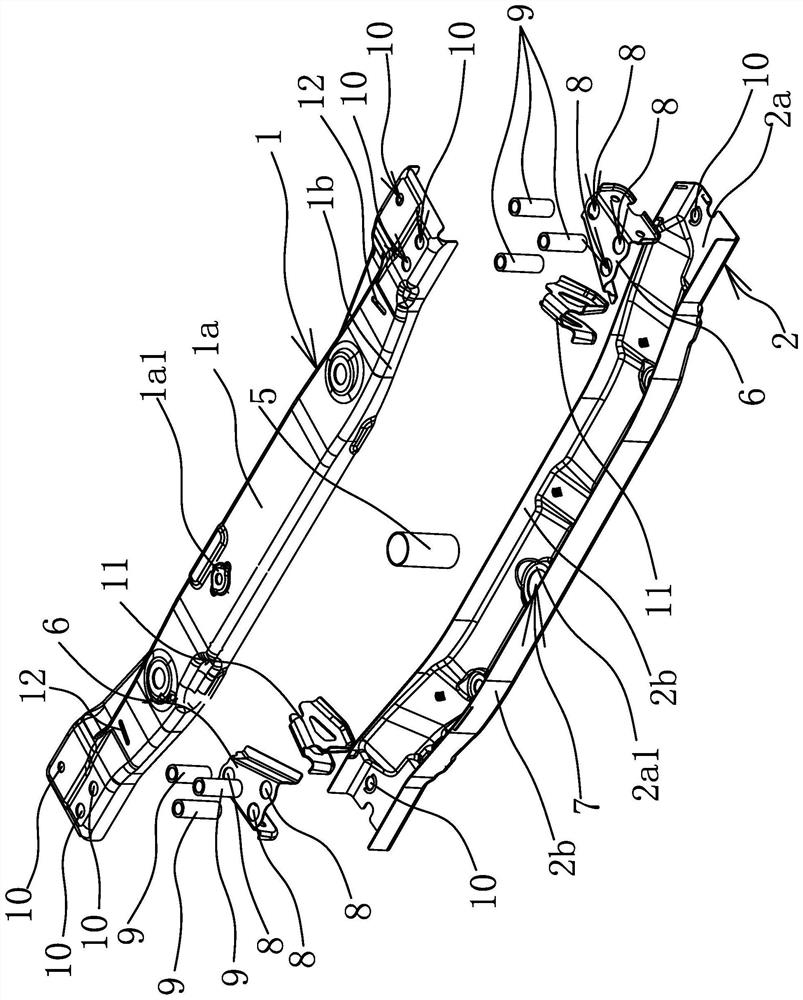

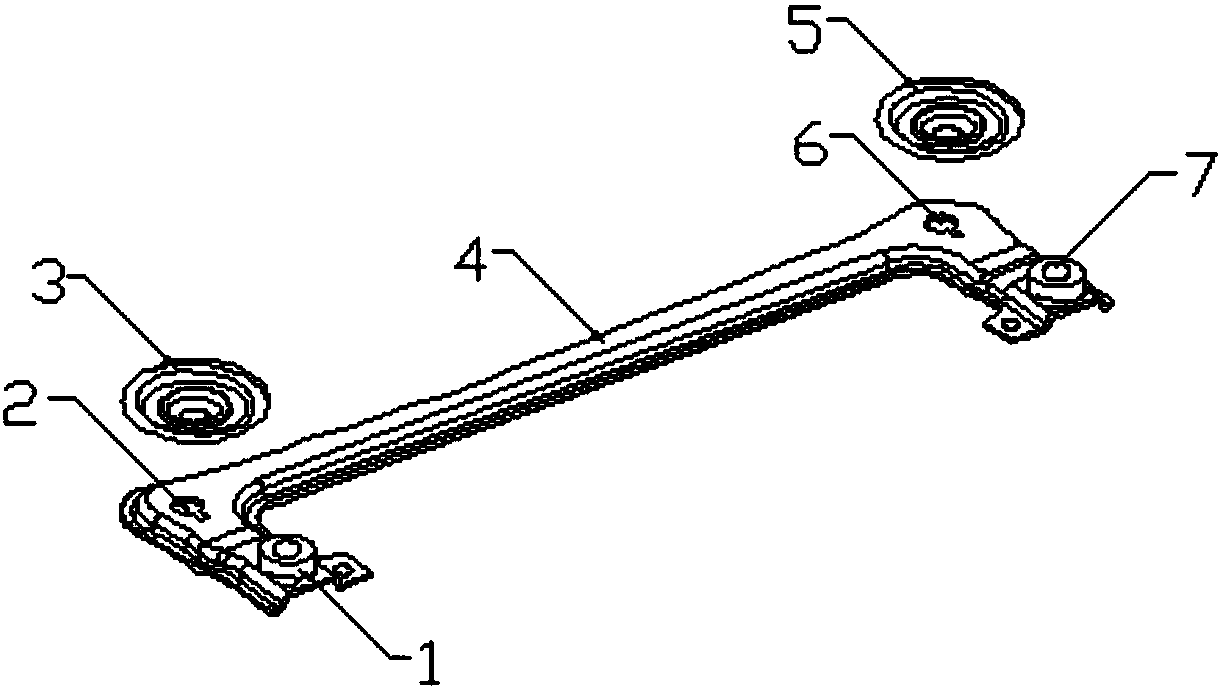

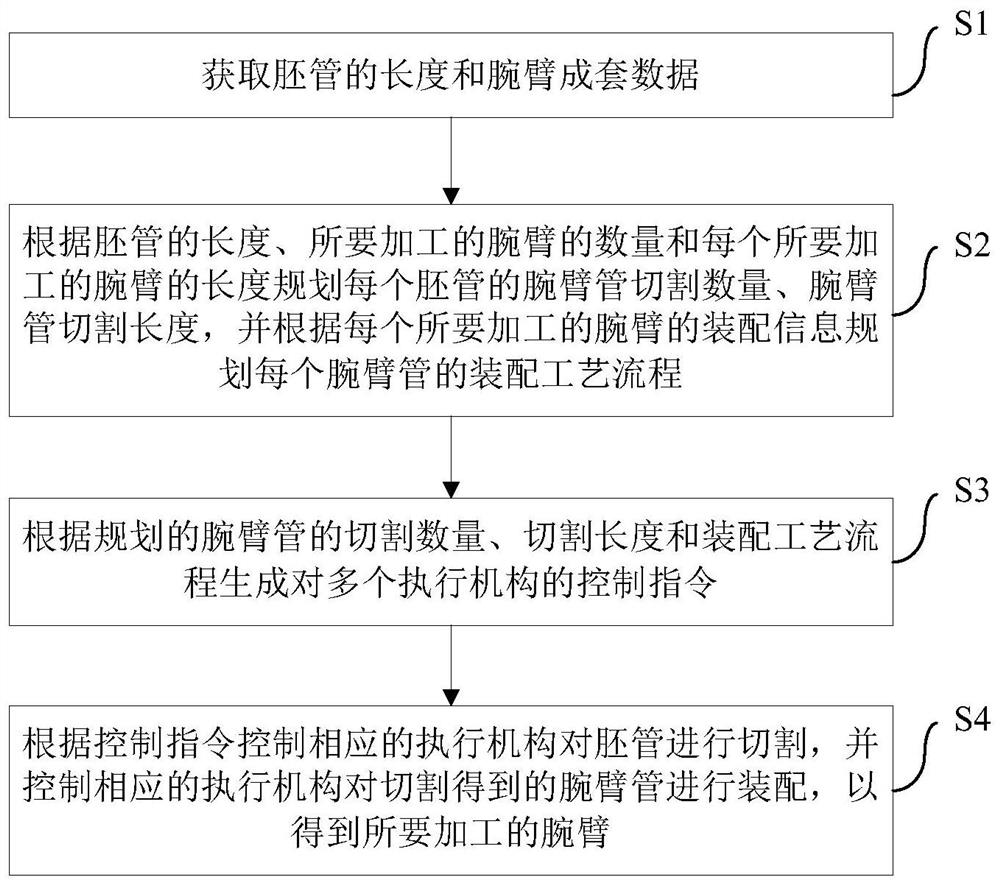

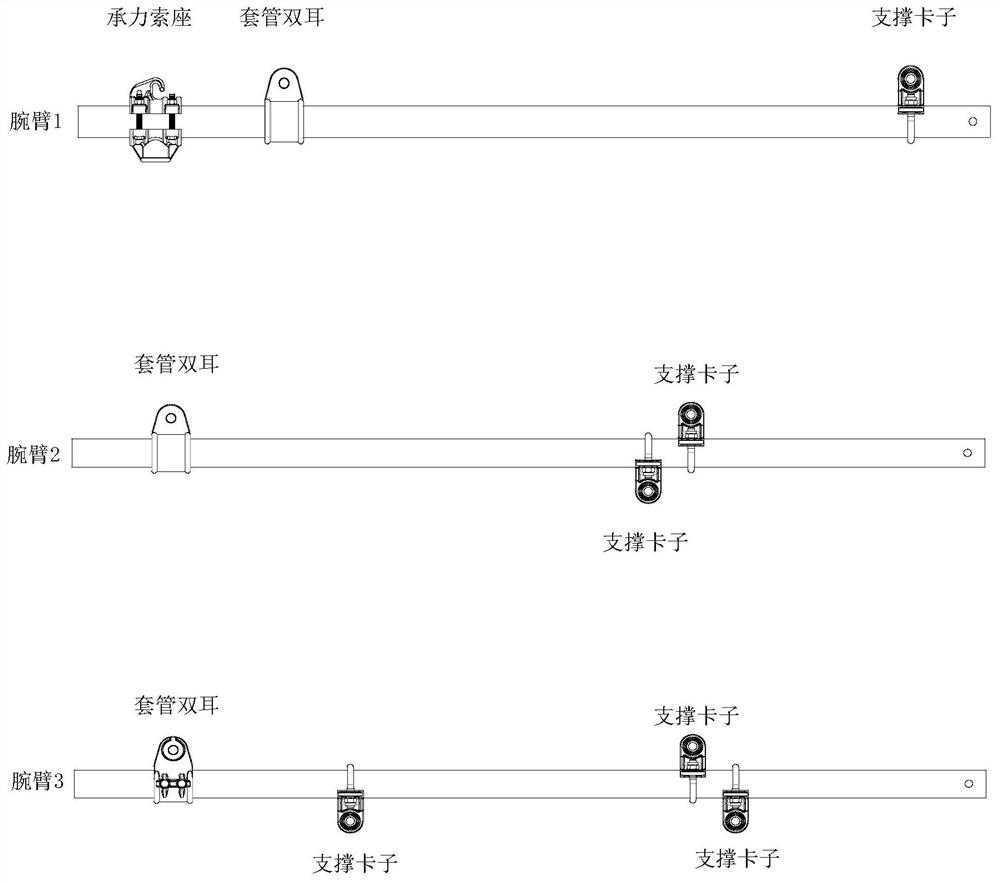

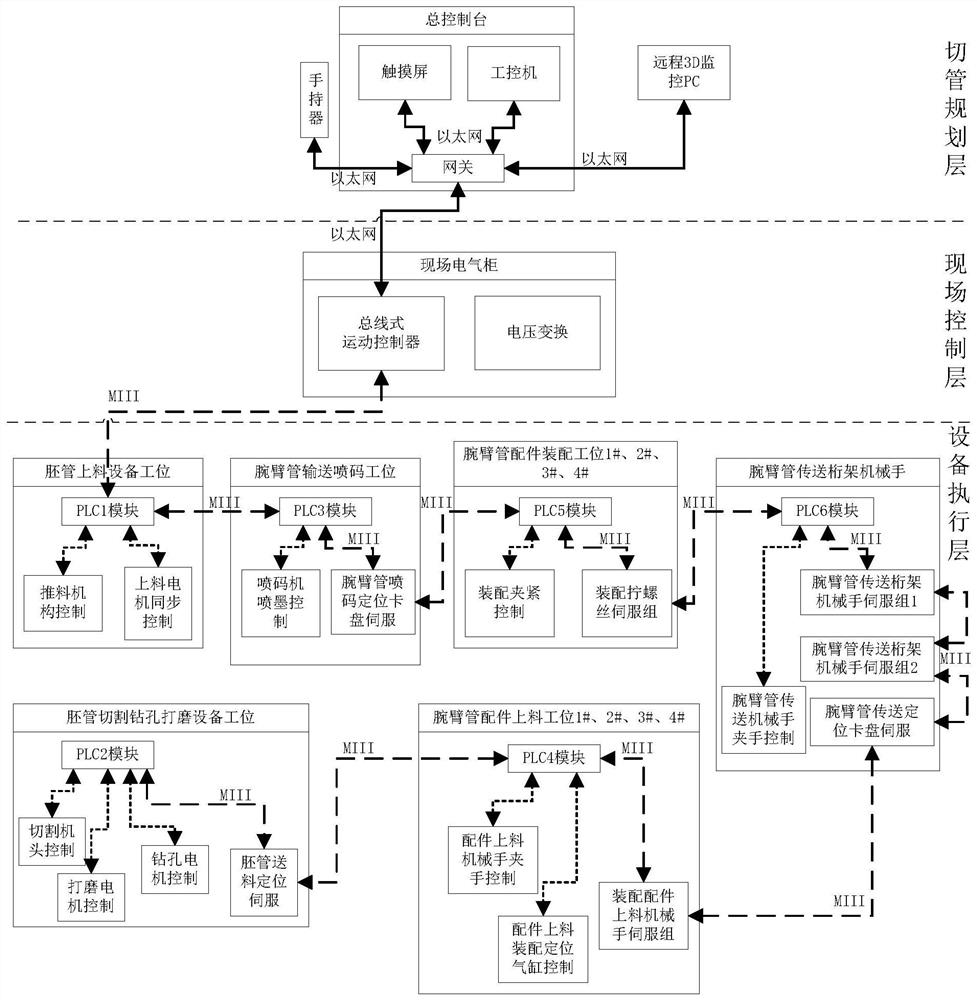

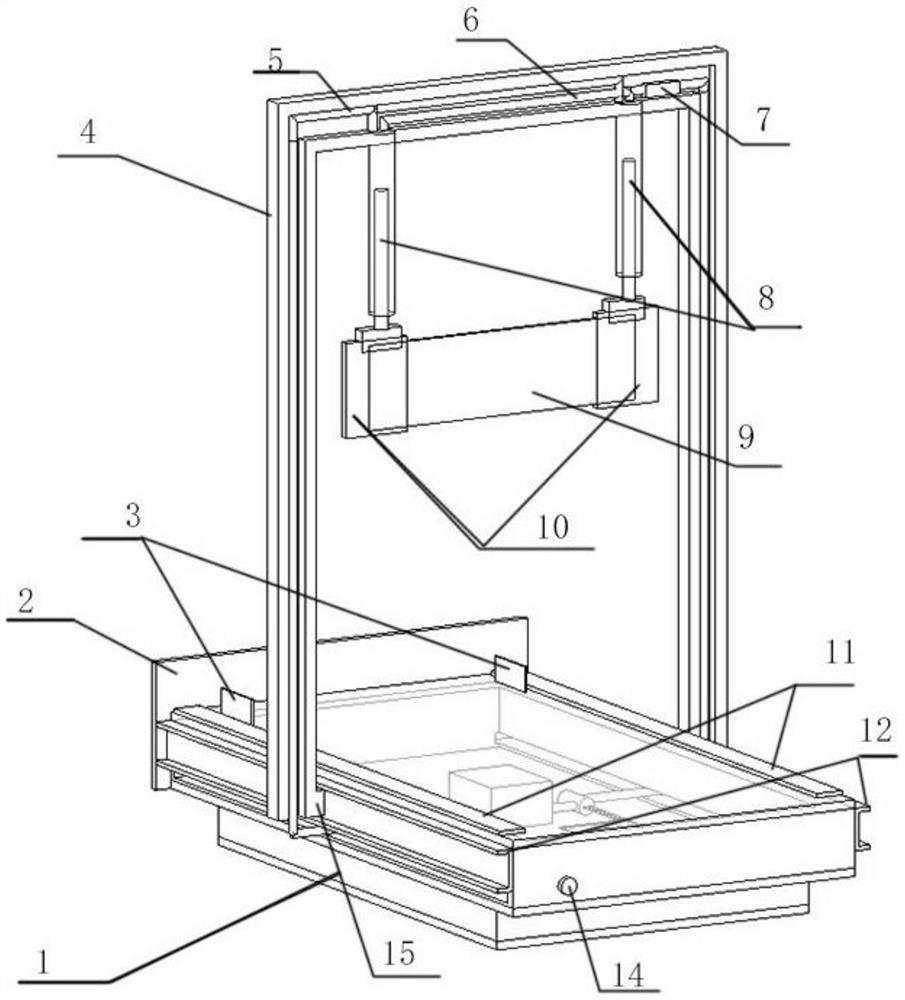

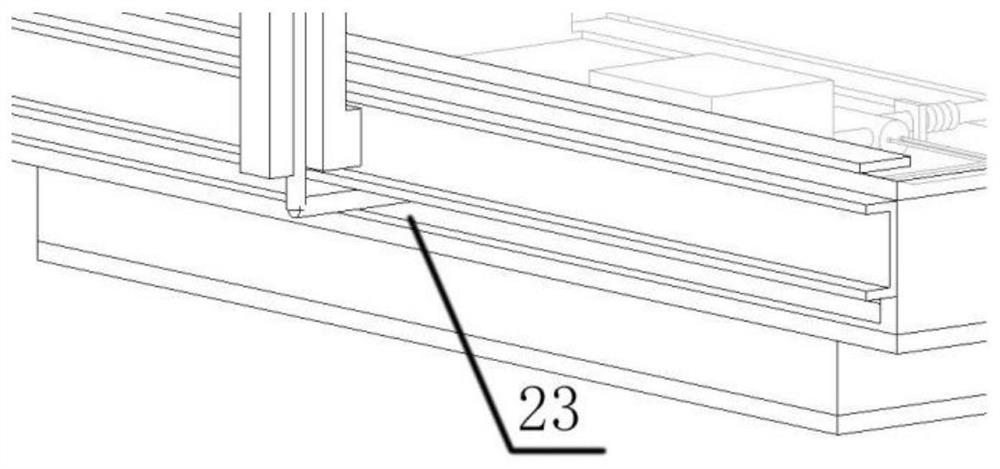

Method and system for machining a wrist arm

ActiveCN109317974BReduce cutting wasteImprove automationOther manufacturing equipments/toolsMetal working apparatusComplete dataEngineering

The invention provides a cantilever machining method and system. The method comprises the steps of acquiring the length of tube blanks and cantilever complete data, wherein the cantilever complete data comprises the number of cantilevers to be machined, the length of each cantilever to be machined and assembly information of each cantilever to be machined, and the assembly information comprises workpieces to be assembled and the position and angle of each workpiece; planning the cantilever tube cutting number and the cantilever tube cutting length of each tube blank, according to the length ofthe tube blanks, the number of the cantilevers to be machined and the length of each cantilever to be machined, and planning the assembly technological process of each cantilever tube according to the assembly information of each cantilever to be machined; generating control instructions to multiple execution mechanisms according to the planned cutting number, the planned cutting length and the planned assembly technological process; and controlling the corresponding execution mechanisms to cut the tube blanks according to the control instructions and controlling the corresponding execution mechanism to assemble the cantilever tubes obtained after cutting to obtain the cantilevers to be machined.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH

A concrete aerated block automatic cutter

ActiveCN112873574BMeet cutting needsShorten the timeWorking accessoriesStone-like material working toolsKnife bladesWaste material

The invention discloses an automatic cutter for concrete aerated blocks. In the automatic cutter for concrete aerated blocks, a second baffle is rotatably arranged on the base to limit the position of the concrete aerated block. The second baffle is rotatably connected and located on the supporting surface. The arc-shaped slide rail, the second baffle locks or unlocks the arc-shaped slide rail through a telescopic knife, the slide bar is a door-shaped structure, and the slide bar is movably connected to a pair of rails to move controllably along the longitudinal direction of the base. The blade is liftably connected to the slide bar via the hydraulic rod, the blade is arranged horizontally above the base, the time relay is connected to the hydraulic rod, and the time relay controls the hydraulic rod to drive the blade to automatically cut the concrete aerated block based on the timing sequence. The concrete aerated block automatic cutter meets the cutting needs of aerated blocks in different environments, and reduces the problem of a large amount of cutting waste caused by inaccurate manual measurement and bevel cutting.

Owner:CHINA CONSTR MUNICIPAL ENG +1

Dust removal method

PendingCN112237805AReduce areaSolve the costCombination devicesDispersed particle filtrationDust controlEngineering

The invention discloses a dust removal method which is characterized in that a dust removal device is adopted, the dust removal device comprises a filter structure, the filter structure comprises a filter element, the filter element comprises filter tubes, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking metal as a matrix in a rolled manner and sealing and processing joints; the outer diameter of the tube bodies is only 20-200 mm, and the distance between every two adjacent filter tubes is 5-100 mm; the filtering wind speed is 0.8-2 m / min, and the temperature of gas to be filtered is less than or equal to 800 DEG C. Due to the adoption of a filtering structure with a larger filtering area, the filtering resistance is smaller, and the filtering wind speed is lower; the tube bodies made of the metal or the sheet-shaped material taking the metal as the matrix is adopted, so the filter element has the filtering resistance obviously smaller than that of a ceramic filter element, and can bear the filtering temperature far higher than that of a non-metal cloth bag. Therefore, compared with the prior art, the dust removal method solves the problems that a non-metal cloth bag is not resistant to high temperature and not high in precision, and the technical problem that the filtering resistance is large due to small filtering area is solved.

Owner:CHENGDU INTERMENT TECH

Numerical control machine tool convenient for PCB positioning

InactiveCN113290608AEasy to useReduce cutting wastePrinted circuit manufactureMetal working apparatusNumerical controlControl engineering

The invention discloses a numerical control machine tool convenient for PCB positioning. The numerical control machine tool comprises a machine tool platform, a controller and a partition plate, wherein a left side positioning unit is arranged on the inner wall of the machine tool platform, and a right side positioning unit is slidably connected between the front inner wall and the rear inner wall of the machine tool platform; the left side positioning unit comprises a fixing seat, and the fixing seat is fixedly connected to the inner wall of the machine tool platform through a mounting block; and a lead screw is rotationally connected between the inner wall of the machine tool platform and the partition plate, the lead screw is rotationally connected with the outer wall of the fixing seat, the portion, penetrating out of the outer wall of the machine tool platform, of the lead screw is provided with a driving mechanism I used for driving the lead screw to rotate, and the portion, between the fixing seat and the partition plate, of the outer wall of the lead screw is in threaded connection with a fourth hinge seat. According to the numerical control machine tool convenient for PCB positioning, through the cooperation of the structures, the numerical control machine tool can position a rectangular diagonal type PCB positioning hole, and can be suitable for non-standard PCBs with special specifications and can realize the positioning of some PCBs with special shapes.

Owner:周有文

Filter element

PendingCN112237807AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

Owner:CHENGDU INTERMENT TECH

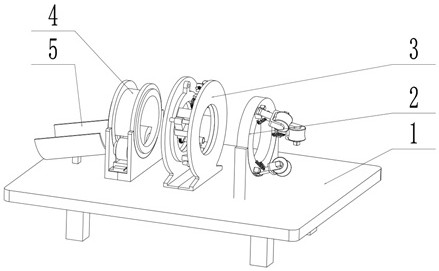

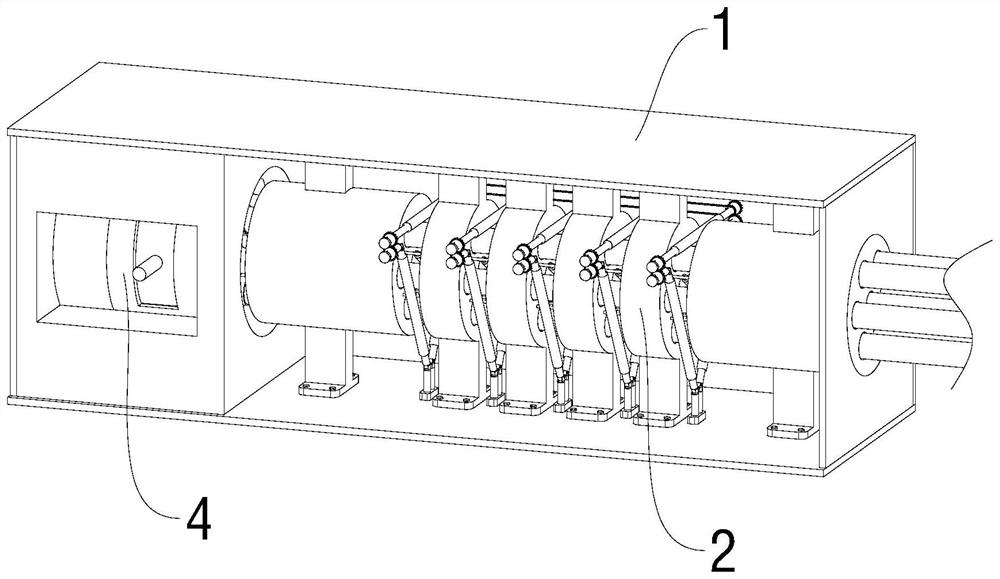

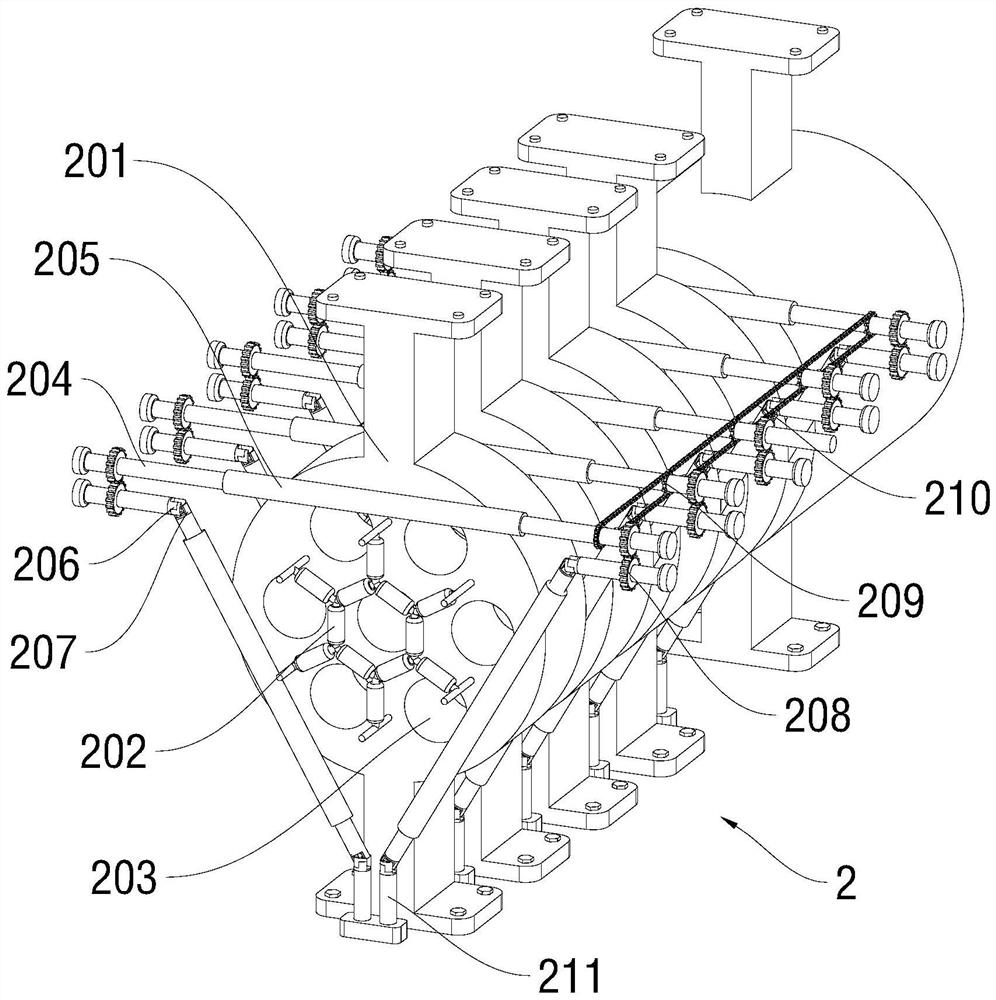

Bridge steel strand integral strand penetrating device

ActiveCN114059774AImprove beam passing efficiencyAvoid beam bendsBuilding material handlingEngineeringStructural engineering

The invention discloses a bridge steel strand integral strand penetrating device and belongs to the technical field of bridge construction. The bridge steel strand integral strand penetrating device comprises a rectangular sealing box body and further comprises a strand pulling conveying mechanism, wherein the strand pulling conveying mechanism is installed in the rectangular sealing box body and used for transmitting a plurality of cables at the same time and locking a strand penetrating head through a steel strand; the strand pulling conveying mechanism is installed in the rectangular sealing box body and is arranged in parallel with the strand pulling conveying mechanism to be in butt joint with the strand pulling conveying mechanism, multiple cables are connected to conduct synchronous strand conveying, the clamping locking mechanism is arranged on the outer side of a steel strand locking strand pulling head, and the steel strand locking strand pulling head is automatically and fixedly connected with the multiple cables. According to the invention, a plurality of steel strands sequentially penetrate from one end of the rectangular sealing box body, are connected and fixed by the steel strand locking and strand pulling head, and then are differently pulled by the strand pulling conveying mechanism, so strand pulling efficiency can be improved, bending can be avoided, the strand pulling length can be better controlled, and the cutting waste can be reduced.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com