A steel pipe external circumcision robot

An external ring and robot technology, used in metal sawing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, slowness, and cumbersome cutting process, so as to improve work efficiency, reduce cutting waste, and improve work efficiency. The effect of efficiency and quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

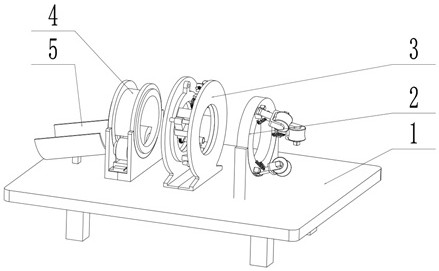

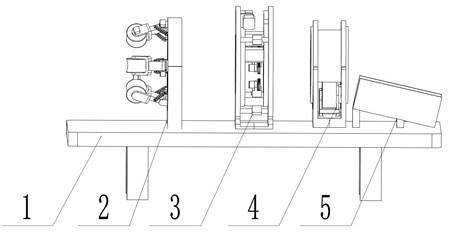

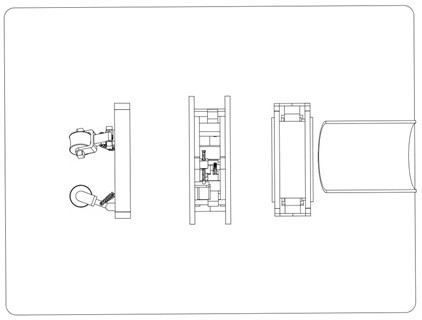

[0023] Example: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 A steel pipe externally ring cutting robot, platform 1 rectangular steel plate work platform, and also is a feeding mechanism 2, a cutting mechanism 3, a rotating mechanism 4, a mounting platform of a transfer passage 5, and a support seat is provided at the lower end of the platform 1. Place the ground to provide support.

[0024] The specific structure of the feed mechanism 2 is like Figure 4 As shown in, the feed mounting plate 201 is a square steel sheet, and the feed mounting plate 201 is provided with a circular arc groove, and the lower end portion and the platform 1 are fixedly mounted vertically by welding technology, and the outer side surface of the feed mounting ring 202 is fixed to the feed mounting plate. In the circular arc groove provided in 201, three feed hingers 203 are provided on the front side surface of the feed mounting ring 202, and each two hinge 203 and the center co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com