Ceramic part layout structure and common-edge machining method

A technology of ceramic parts and co-edge, applied in the field of typesetting structure and co-edge processing of ceramic parts, can solve the problems of high input cost of materials, waste of resources, and low utilization rate of typesetting, so as to reduce input cost, reduce cutting waste, and avoid resources. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

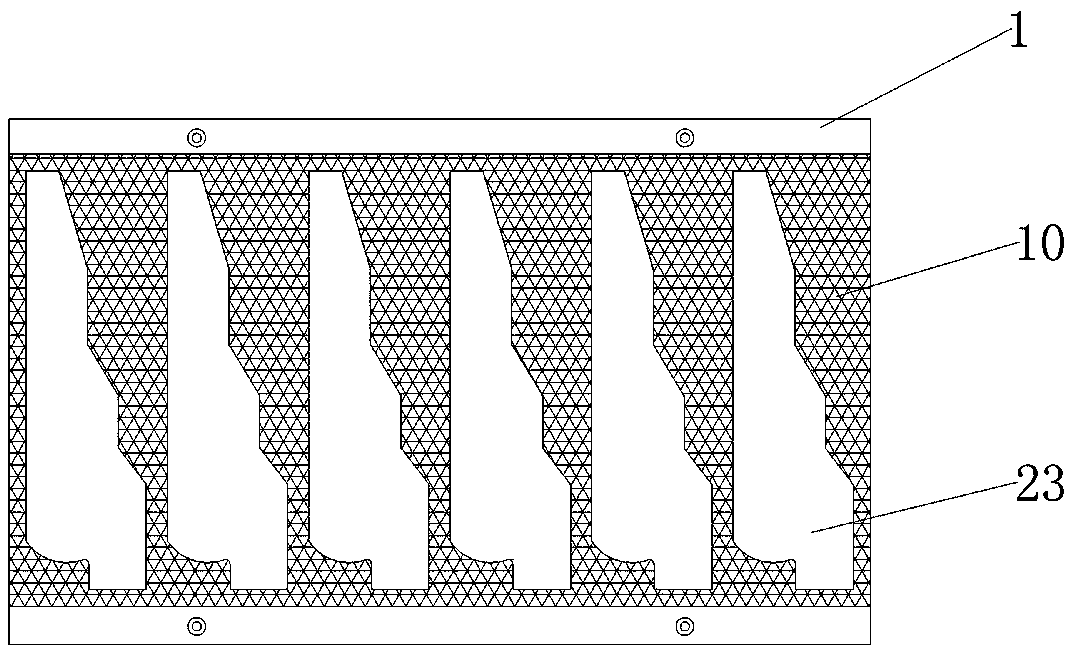

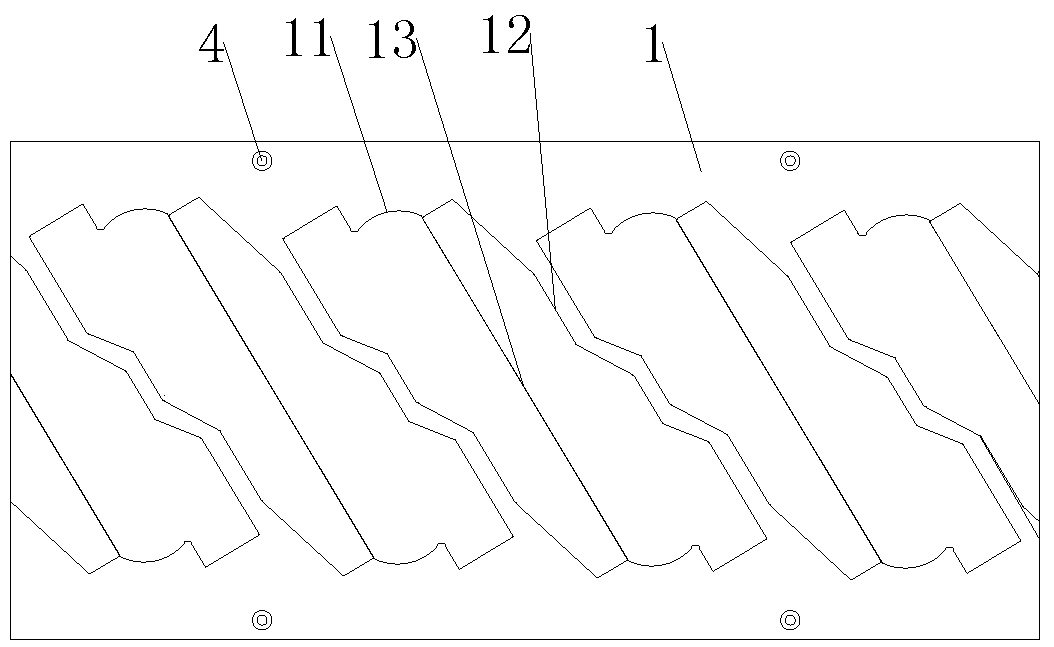

[0029] See figure 2 , image 3 , a typesetting structure of ceramic parts, which includes a material tape 1, a plurality of ceramic part pairs 2 arranged at even intervals are fixed on the material tape 1, the ceramic part pairs 2 are pasted on the material tape 1 by composite glue, and the ceramic part pairs 2 Arranged obliquely on the strip 1, the maximum width L of the gap between two adjacent pairs of ceramic parts is 1.5mm; each pair of ceramic parts 2 includes ceramic part one 21, ceramic part two 22, ceramic part one The straight line side of 21 overlaps with the straight line side of ceramic piece 2 22 as common side 3, and ceramic piece 1 21 and ceramic piece 2 22 are centrally symmetrically arranged with the midpoint of common side 2 as the center,

[0030] The material strips 1 on both sides of the ceramic part 2 are respectively provided with positioning holes 4, and the positioning holes 4 on both sides are arranged symmetrically with the transverse centerline o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com