Dust removal method

A dust removal device and dust content technology, applied in the direction of separation methods, chemical instruments and methods, gravity filters, etc., can solve the problems of limited filter area improvement, small-area porous film waste, and low-cost filter area. Achieve the effects of low cost, narrow working surface and high filtration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

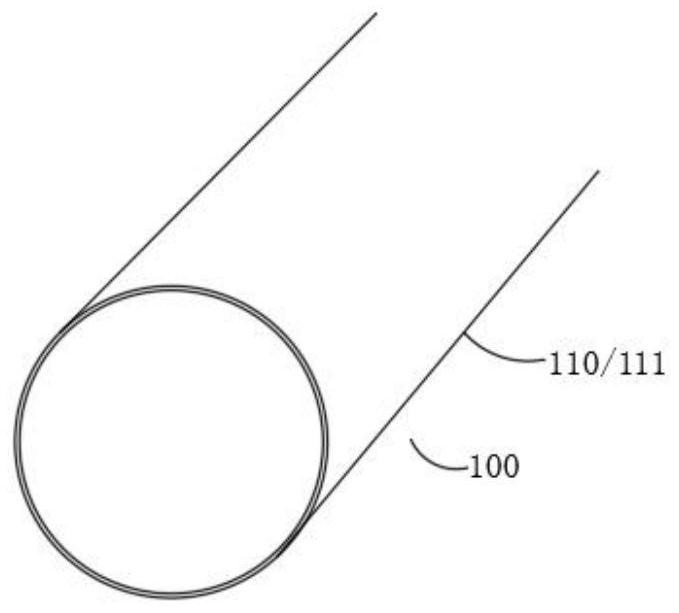

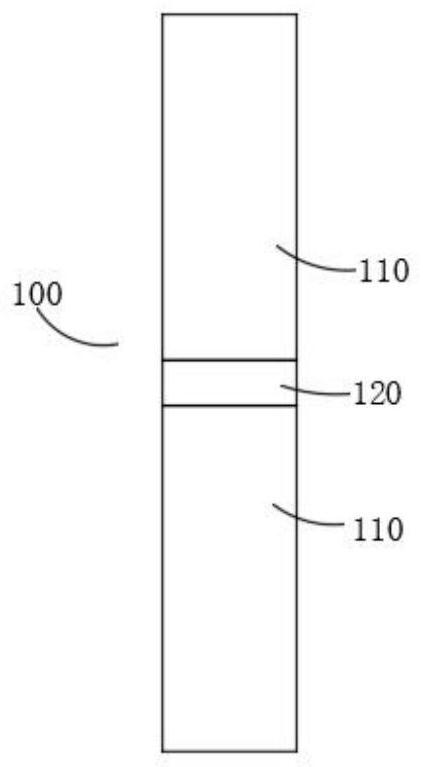

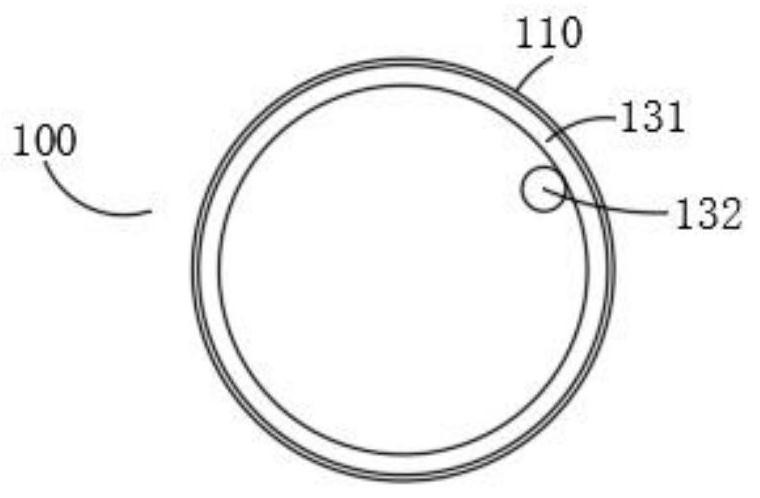

[0134] In addition, the present invention provides a method for preparing the above-mentioned filter tube 100, which includes the steps of: rolling a thin sheet material 111 with a thickness of 0.2-2.5 mm into a tube body 110 with an outer diameter of 20-200 mm, fixing and sealing the seam 112 Welded or glued.

[0135] Figure 4 It is a tube body obtained by rolling in a specific embodiment. Such as Figure 4 As shown, the seam 112 of the tube body 110 is parallel to the central axis of the filter tube 100 , and the tube body 110 is obtained by butting the long side of the rectangular sheet material 111 whose wide side matches the diameter of the tube body 110 .

[0136] Figure 5 It is a tube body obtained by rolling in another specific embodiment. Such as Figure 5 As shown, the seam 112 of the pipe body 110 is in the shape of a helix. The pipe body 110 is prepared by the preparation method published in the Chinese invention patent with the application number 2019102093...

specific Embodiment approach

[0204] Figure 20-21 It is a structural schematic diagram of the first specific embodiment of the pressing mechanism. Such as Figure 20-21 As shown, the pressing mechanism includes: a pressing plate 441, the upper joint 210 and the step 330 are clamped between the pressing plate 441 and the first support structure 420; a pressing assembly, the pressing assembly is connected The pressing plate 441 and the first support structure 420 . in, Figure 20 Push-in installation from top to bottom, Figure 21 Push-in installation from bottom to top.

[0205] Figure 22 It is a structural schematic diagram of the second specific embodiment of the pressing mechanism. Such as Figure 22 As shown, the pressing mechanism includes: a pressing plate 441, the step 330 is clamped between the pressing plate 441 and the first support structure 420; a pressing assembly, the pressing assembly is connected to the pressing assembly. Plate 441 , upper joint 210 and first support structure 420 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com