Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "Accurate cutting position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

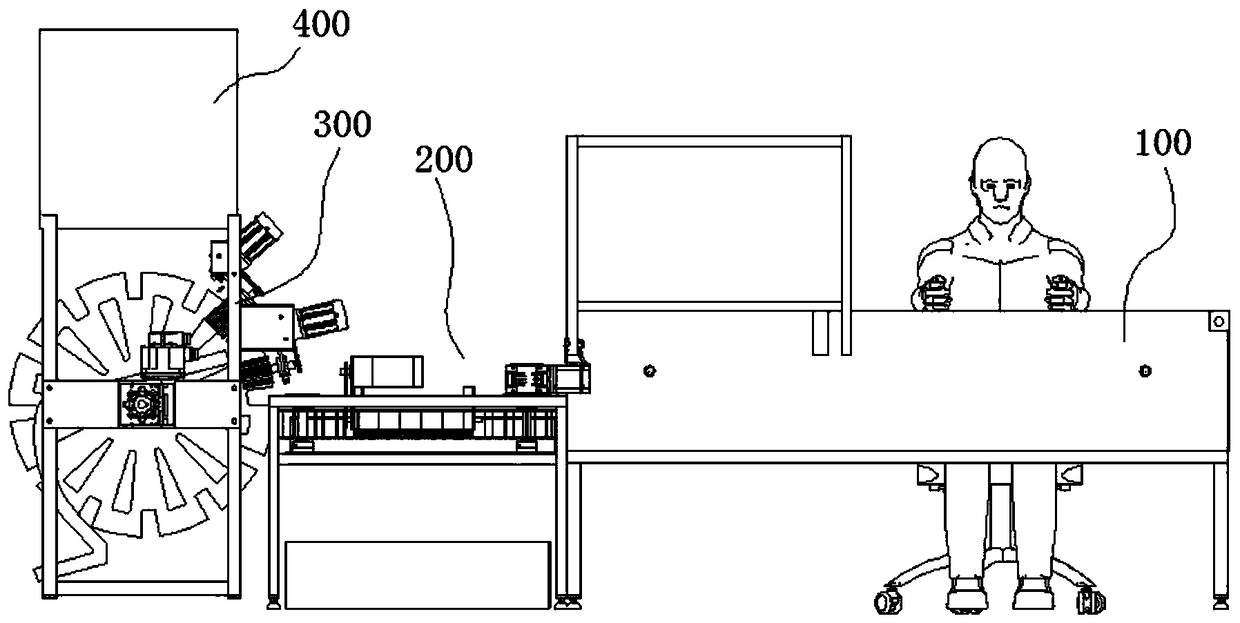

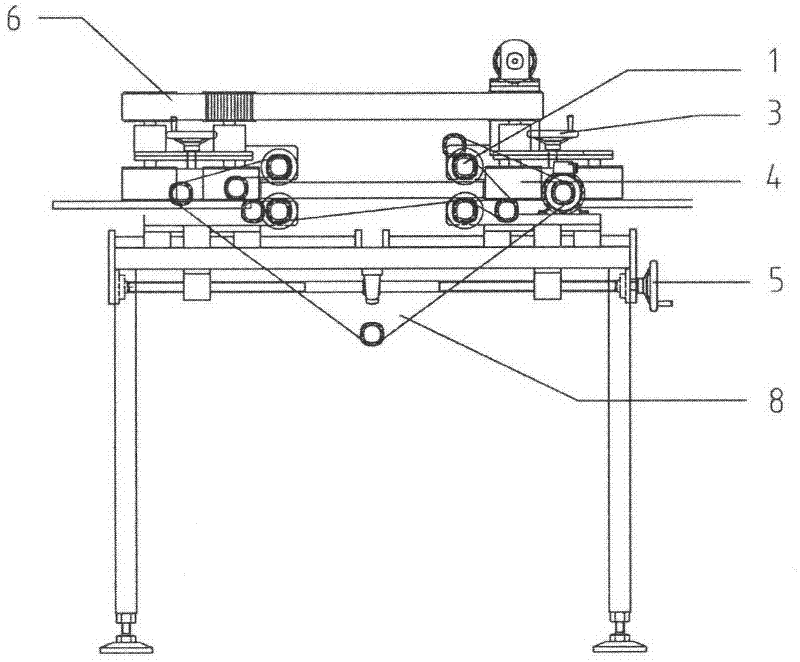

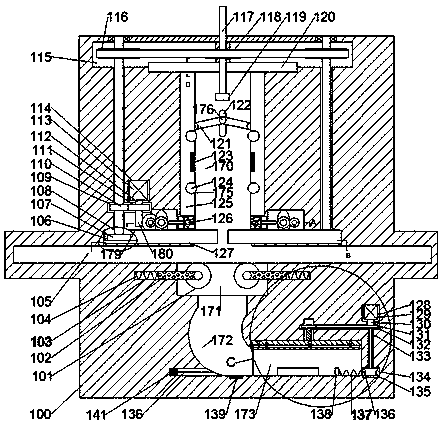

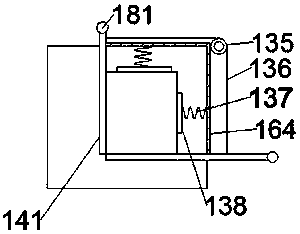

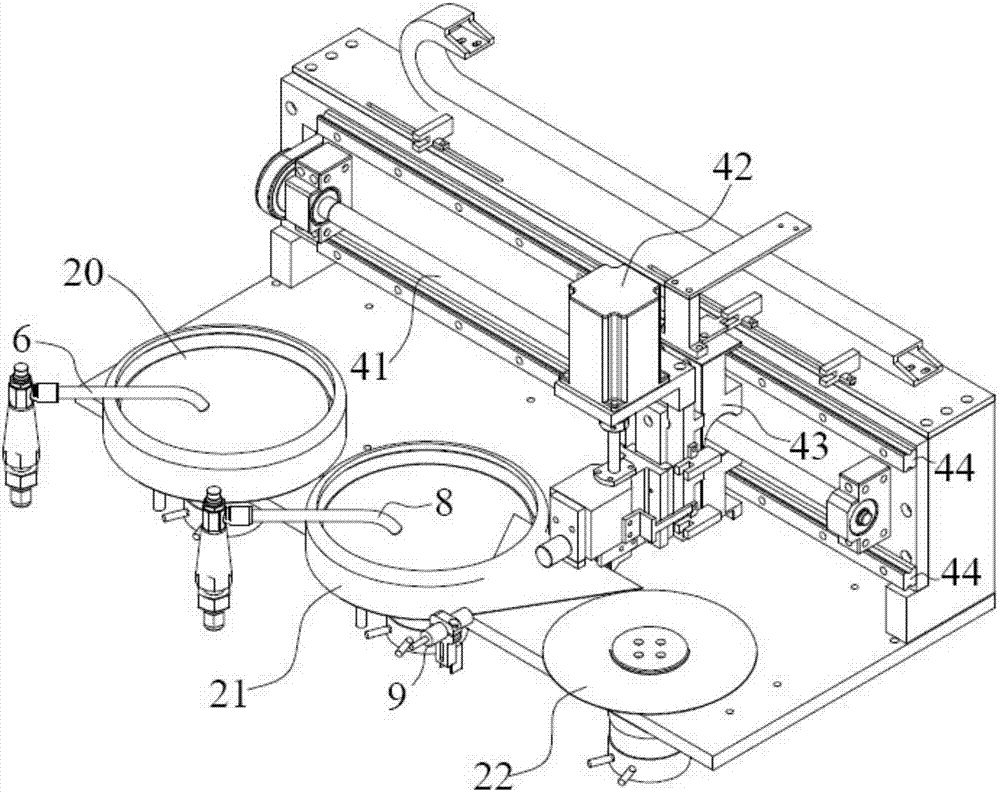

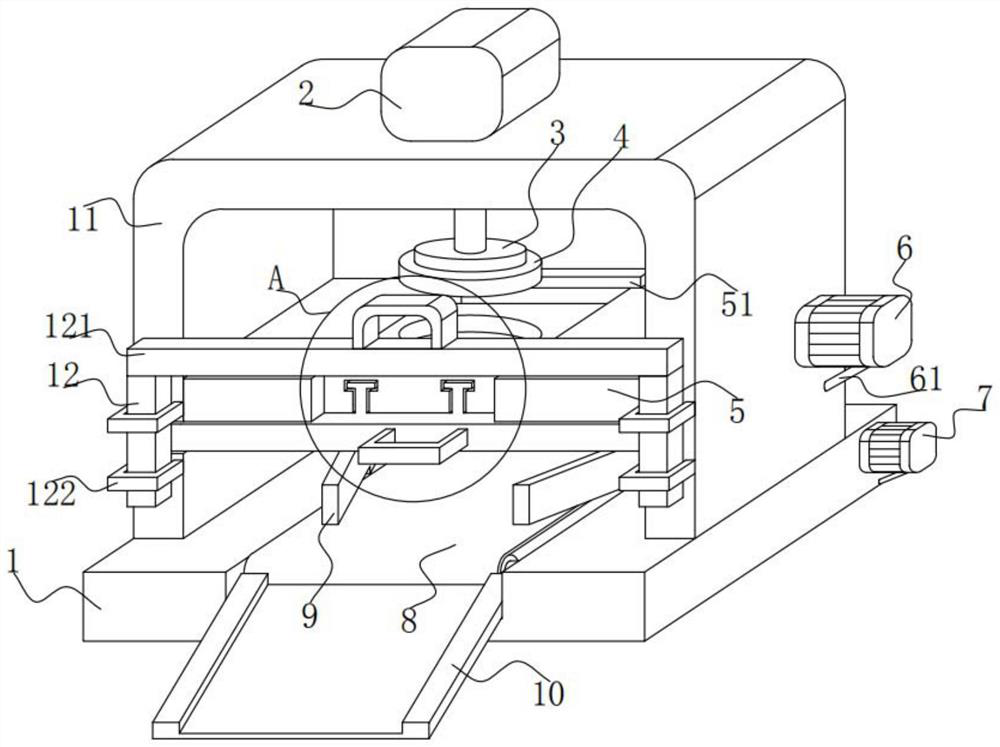

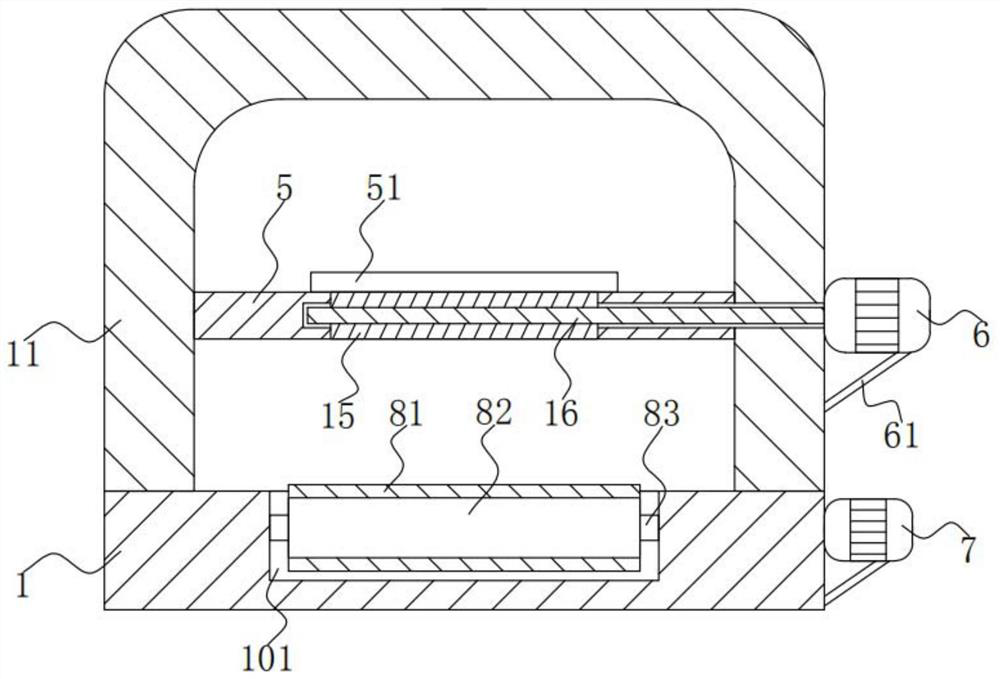

Molding method for food with round shape

ActiveCN102228305AEasy to disassembleEasy to installFood coatingFood shapingEngineeringIndependent feeding

The invention relates to the field of processing filling food, in particular to a molding method for food with round shape, comprising the following steps that: A, charging: skin and stuffing are added in feeding assemblies of a split type feeding system of a molding machine for food with round shape; B, compositing: the skin and stuffing of the feeding assembly are allowed to enter a skin-stuffing complex; C, cutting off: the skin and stuffing output by the skin-stuffing complex are cut off by a cutting assembly which is connected with a cutting lift assembly, the cutting assembly is driven by the cutting lift assembly to realize the cutting function and moving up and down simultaneously; D: ball-kneading: the cutting-off skin and stuffing are put into a ball-kneading device for kneading into balls; and E, discharging on the plate: the products obtained by ball-kneading are transferred to a discharging plate assembly from the ball-kneading device. According to the invention, the two independent feeding assemblies and the skin-stuffing complex have the advantages of simple disassembling and installation, when cleaning or maintaining the parts, only at least one feeding assembly needs be disassembled from the skin-stuffing complex to carry out the cleaning and the maintenance. Because the disassembling is realized by simple rotation, the present disassembling mode is simplified with saving the disassembling time and improving the work efficiency.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

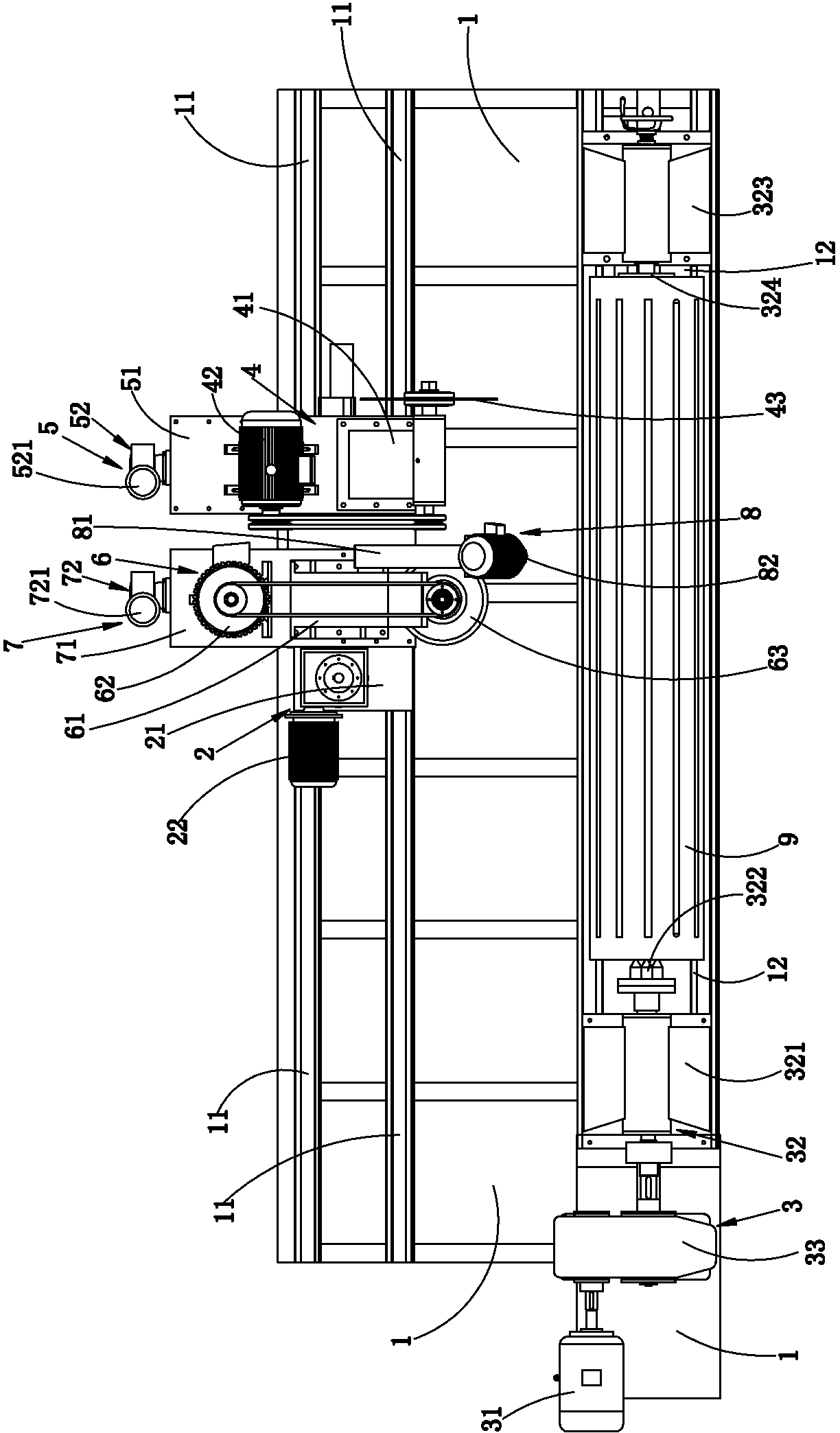

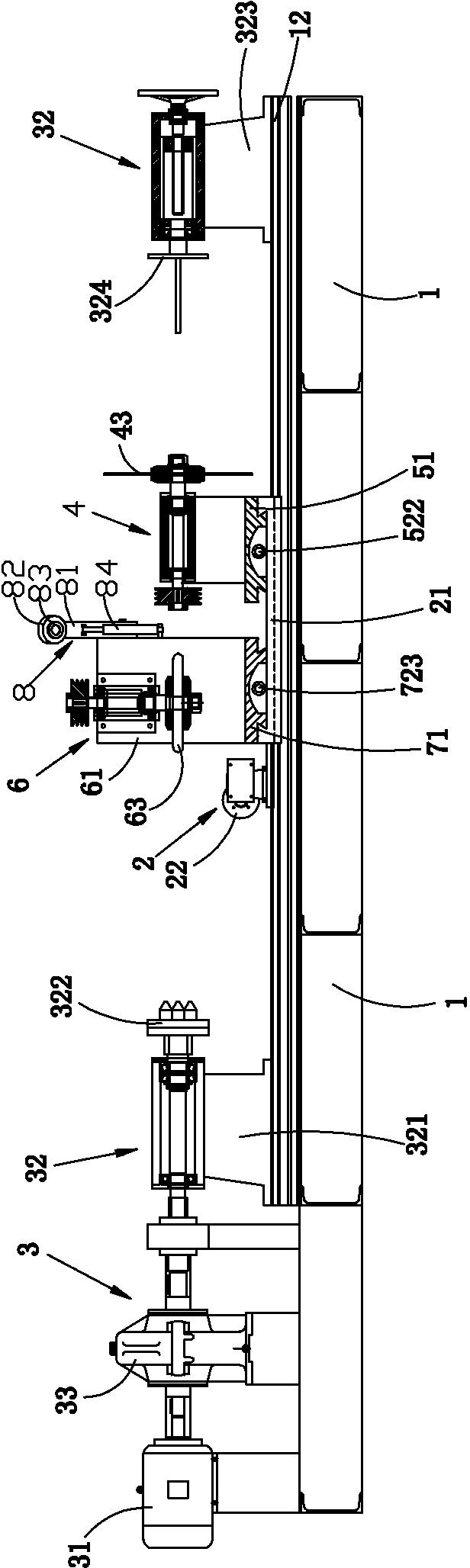

Automatic cutting machine

ActiveCN106735531AReduce impactEnsure measurementShearing machinesShearing machine accessoriesEngineeringMachine tool

The invention discloses an automatic cutting machine. The automatic cutting machine comprises a bottom frame, a feeding mechanism and cutting units. A platform is arranged on the bottom frame. The two sides of the platform are provided with guide rails correspondingly. The feeding mechanism is located on the rear portion of the platform. A large bottom plate at the lower end of the feeding mechanism is in sliding connection with the guide rails. The feeding mechanism comprises a feeding bracket, an upper press roll and a lower press roll. The bottom of the feeding bracket is fixedly connected with the large bottom plate. The upper press roll and the lower press roll are vertically arranged on the feeding bracket. The lower press roll is driven by a first servo motor installed on one side of the feeding bracket. The front side and the rear side of the feeding mechanism are provided with material clamping mechanisms correspondingly. The three cutting units comprise the first cutting unit, the second cutting unit and the third cutting unit and are arranged on the guide rails from back to front in sequence. Through the cutting units of the cutting machine, impact force to a machine tool is decreased, equipment noise is lowered, the cutting precision is high, and the cutting machine is suitable for cutting sheets of various models; and the amount of cutting waste is small, the automation degree is high, and the production efficiency and safety are greatly improved.

Owner:青岛瑞宜利特变压器设备有限公司

Automatic duck gizzard cutting, washing, and grinding production device

The invention discloses an automatic duck gizzard cutting, washing, and grinding production device, which comprises an electrical control system, a gizzard cutting mechanism, a washing mechanism, anda gizzard grinding mechanism. The gizzard cutting mechanism, the washing mechanism, and the gizzard grinding mechanism are sequentially connected and all connected to the electrical control system. Under the control of the electrical control system, the gizzard cutting mechanism, the washing mechanism, and the gizzard grinding mechanism automatically cut and wash duck gizzards and remove yellow peels of duck gizzards through grinding. Only two persons are needed to place the duck gizzards. For each production line, six persons are reduced, and the human cost is largely reduced.

Owner:南京深农智能装备有限公司

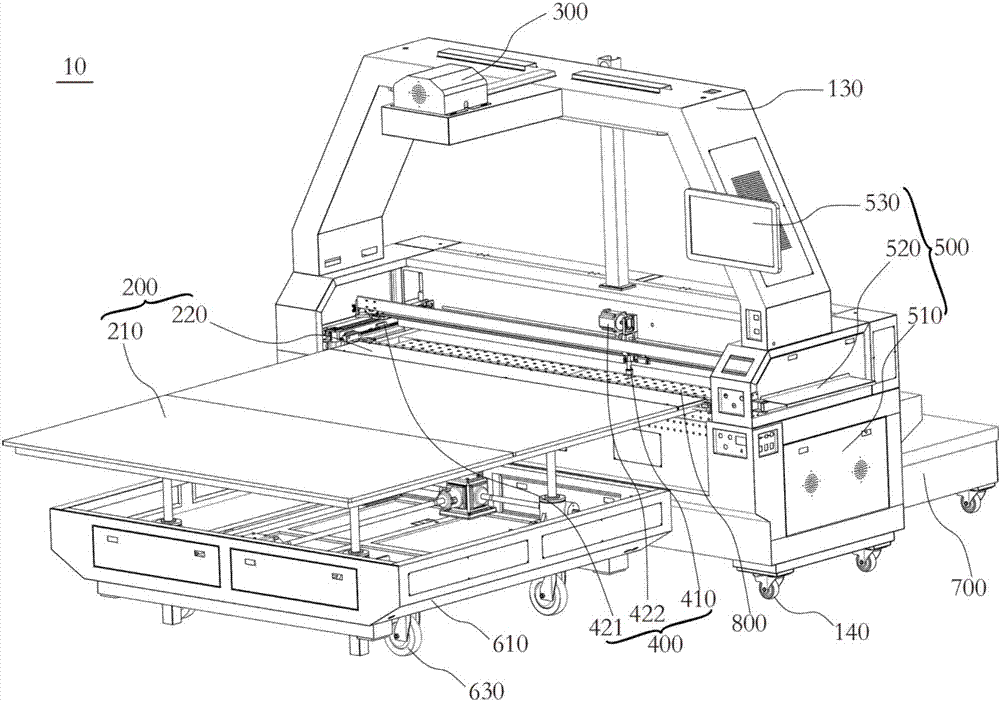

Automatic recognizing cutting mechanism

ActiveCN106903444AExquisite designReasonable structureLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses an automatic recognizing cutting mechanism. The automatic recognizing cutting mechanism comprises a machine table, a support part, an image acquiring part, a processing part and a cutting part. The machine table has a working platform; the support part has a support plate, a shielding plate and a shielding drive part; the shielding drive part is arranged on the machine table and connected to the shielding plate, the shielding plate is attached to the support plate in an initial state, after cloth is cut, the shielding plate is driven by the shielding drive part to be turned over so as to be drawn out from a position below the cloth and to press the end part of the cut cloth; the image acquiring part is arranged on the machine table to acquire an image of the cloth, the processing part is connected to the image acquiring part to determine the position of a cutting line on the cloth by the image of the cloth; and the cutting part is used for cutting the cloth along the position of the cutting line on the cloth. The automatic recognizing cutting mechanism can quickly and automatically recognize stripes and can automatically and precisely cut according to a radian curve of the stripe lines and is high in cutting efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Corrugated pipe cut-off machine

ActiveCN104552397AThe principle is simpleAvoid scratchesMetal working apparatusPipe fittingEngineering

The invention relates to pipe fitting cutting equipment, in particular to a corrugated pipe cut-off machine. The corrugated pipe cut-off machine comprises a base and a conveying mechanism, a wave crest and wave hollow detection mechanism and a cutting mechanism which are sequentially arranged on the base; the conveying mechanism and the cutting mechanism are mutually connected; the wave crest and wave hollow detection mechanism which is arranged at a discharging end of the conveying mechanism is used for feeding back wave crest position information; the wave crest and wave hollow detection mechanism comprises a photoelectric detection sensor and an adjusting plate which is fixed on the photoelectric detection sensor and can vertically move. The corrugated pipe cut-off machine cuts off at the wave crest position of the corrugated pipe, the cutting efficiency is high, and the cutting speed is rapid.

Owner:SUZHOU HUISIFU AUTOMATION TECH

Full automatic edge bar assembly equipment for square vehicular air conditioner filter

The invention provides a set of full automatic edge bar assembly equipment for a square vehicular air conditioner filter. The full automatic edge bar assembly equipment is characterized in that partition wheel device and an edge pressing adjustment mechanism are arranged on a main rack moving platform device, totally four partition wheels are distributed at the upper part, the lower part, the left part and the right part of the main body of the filter, the partition wheels on each diagonal line are same and both rotate outwards, screw threads of two groups of the partition wheels are opposite in direction and are trapezoidal threads, and screw pitch is the distance between adjacent edgefolds. The equipment comprises an edge pressing synchronous mechanism, an open / close adjustment mechanism and a pressing height adjustment mechanism which are installed on a countertop as a whole; the open / close adjustment is implemented by a screw mechanism and two guide shafts, wherein the two guide shafts are arranged below the countertop; and the lifting adjustment is implemented by the pressing height adjustment mechanism. The full automatic edge bar assembly equipment for a square vehicular air conditioner filter has the advantages of high automation degree, high edge adhering speed and low cost and can improve the yield of qualified finished products greatly.

Owner:彭松

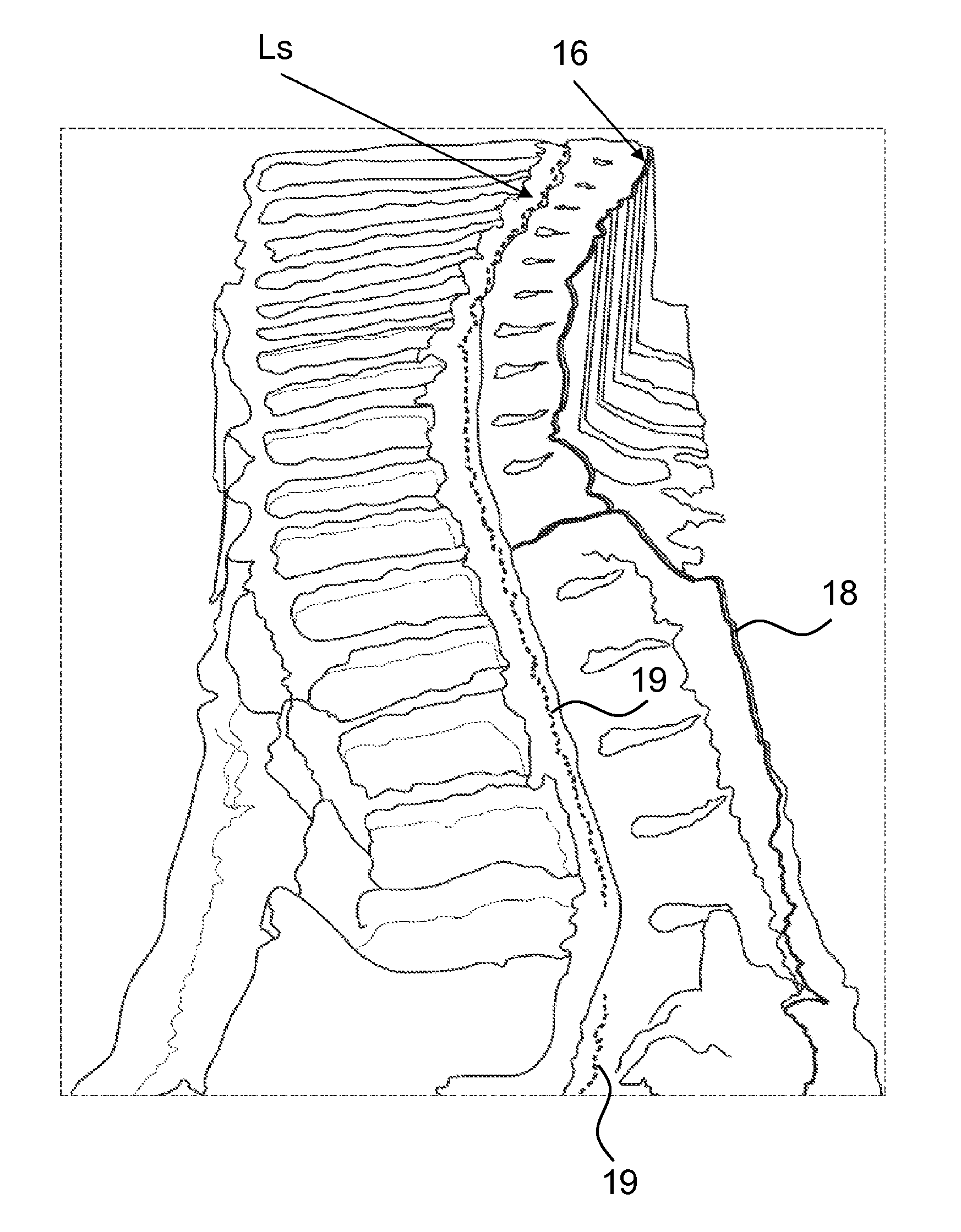

Separation of the spinal column from a carcass middle part

ActiveUS8915773B2Quantity minimizationAccurate cutting positionMeat processing plantsPoultry processingSpinal columnEngineering

Owner:HUMBOLDT

Device and method for cutting lone stone in front of tunnel by utilizing laser

ActiveCN109226979AAccurate cutting positionGuaranteed high efficiencyArtificial islandsUnderwater structuresTelescopic cylinderTunnel construction

The invention belongs to the technical field of tunnel construction, and particularly relates to a device and method for cutting a lone stone in front of a tunnel by utilizing laser. The method comprises the following steps: 1, firstly, moving the device to an appointed position through a fixing seat; 2, adjusting the height of a bearing plate through a telescopic cylinder according to the use environmental condition, and then turning on a first servo motor to adjust the angle of a mounting block; 3, turning on a second servo motor to drive a screw to rotate, and adjusting the distance betweenthe two sliding blocks to adjust the distance between the two lasers; 4, finally turning on the lasers to cut the lone stone. According to the invention, through the arrangement of the lasers and theplurality of adjusting mechanisms, the device can quickly cut the lone stone, so that the high efficiency and safety of tunnel construction are ensured.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Fully-automatic positioning and sectioning type waste tobacco rod recycling machine

ActiveCN104983068AQuality improvementCutting position is accurateCigarette manufactureStructural engineeringFully automated

The invention provides a fully-automatic positioning and sectioning type waste tobacco rod recycling machine. The machine comprises an automatic feeding device, a waste tobacco rod sorting device, a tobacco rod sectioning device and a vibration screening device. The waste tobacco rod sorting device further comprises a plurality of cylindrical guide rails, a conveying belt and a tobacco rod rolling device. The parallel cylindrical guide rails obliquely arranged on a rack are arranged below the tail end of an arc-shaped guide groove of the automatic feeding device. The conveying belt is arranged below the cylindrical guide rails and parallel to the cylindrical guide rails. The distance between the conveying belt and the cylindrical guide rails ranges from 0.5 mm to 5 mm. The tobacco rod rolling belt is arranged on the upper portions of the cylindrical guide rails. The tobacco rod sectioning device is arranged below the cylindrical guide rails and comprises a cutter roller perpendicular to the cylindrical guide rails. The vibration screening device is arranged below the cylindrical guide rails. The fully-automatic positioning and sectioning type waste tobacco rod recycling machine has the advantages that waste tobacco rods are limited through the cylindrical guide rails, the sectioning position is precise, the tobacco rods are not overly smashed, the cigarette paper is complete after the tobacco rods are sectioned, the tobacco rods are screened clearly and easily, the recycled tobacco rods are high in quality, the sectioning depth of the waste tobacco rods is adjustable, and the recycling machine is high in automation degree.

Owner:CHANGDE RUIHUA MFG

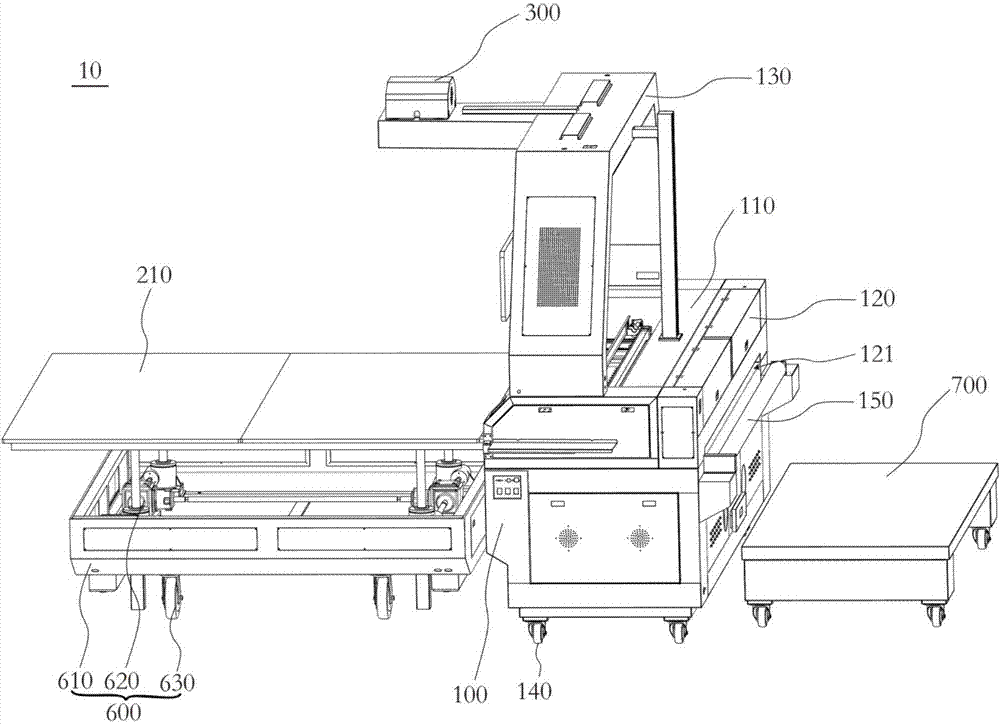

High-precision digital light processing three-dimensional printer and printing method thereof

InactiveCN106799836AHigh precisionAccurate cutting positionAdditive manufacturing apparatus3D object support structuresEngineeringLight source

The invention relates to a high-precision digital light processing three-dimensional printer and a printing method thereof. The high-precision digital light processing three-dimensional printer comprises a frame, a photosensitive resin groove and a printing platform for bearing a printing object; the photosensitive resin groove is formed in the frame and contains liquid photosensitive resin; the printing platform can move in the photosensitive resin groove; a first illuminant is arranged below the photosensitive resin groove; a controller is electrically connected with the printing platform, and comprises a processor and a calibration module; and data of fine adjustment distances is set in the calibration module. Through the fine adjustment distances set in the calibration module, the movement height to be compensated is calculated, and the precision of moving the printing platform upwards by a spacing distance is improved.

Owner:荆门米丰信息科技有限公司

Automatic marble pillar machining device and machining method thereof

ActiveCN104260211AImprove processing efficiencyConsistent shapeRevolution surface grinding machinesStone-like material working toolsEngineeringMachining

The invention relates to an automatic marble pillar machining device and a machining method thereof. The machining device comprises a control device, a base, a travelling mechanism, a rotating mechanism, a pillar carving mechanism, a pillar carving driving and reversing mechanism, a grooving mechanism and a grooving driving and reversing mechanism, wherein the travelling mechanism, the rotating mechanism, the pillar carving mechanism, the pillar carving driving and reversing mechanism, the grooving mechanism and the grooving driving and reversing mechanism are assembled on the base, and the control device is used for controlling the mechanisms to act in sequence. The machining method is characterized in that by the aid of the machining device, under control of the control device, the mechanisms act in sequence, and a stone to be machined and assembled on the rotating mechanism is sequentially carved, grooved and polished to obtain a marble pillar. By the aid of the automatic marble pillar machining device, the stone to be machined can be automatically cut into the polished finished marble pillar, the whole machining process is continuous in action and accurate in plunge-cut position, the machining efficiency of the marble pillar is effectively improved, production cost is effectively reduced, marble pillars with different diameters, lengths, groove numbers and groove line types can be machined, and categories of the marble pillars are rich and varied.

Owner:QUANZHOU MINYAN STONE MACHINERY CO LTD

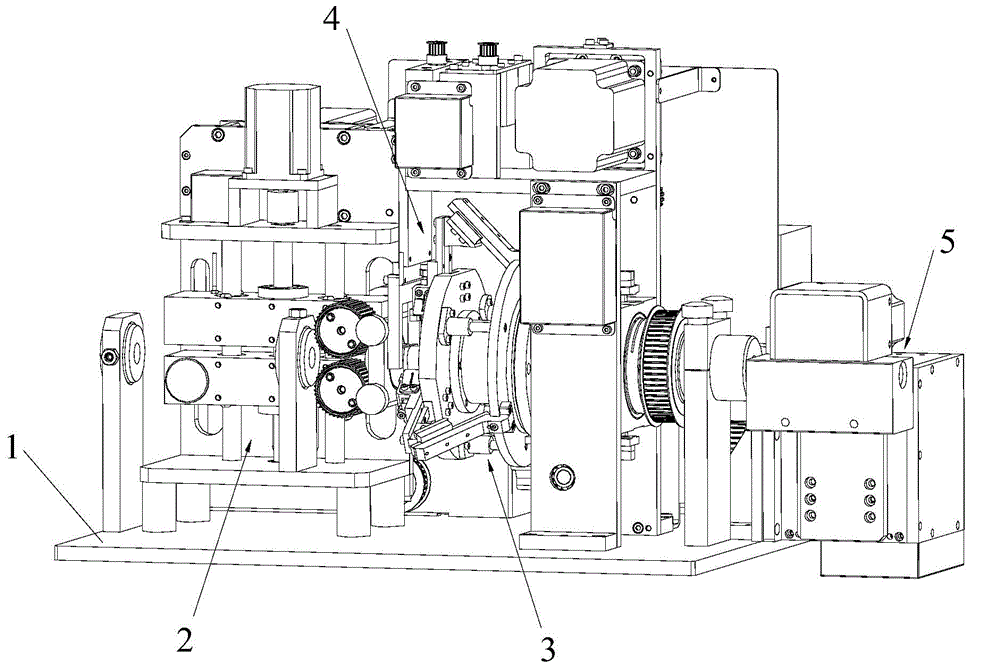

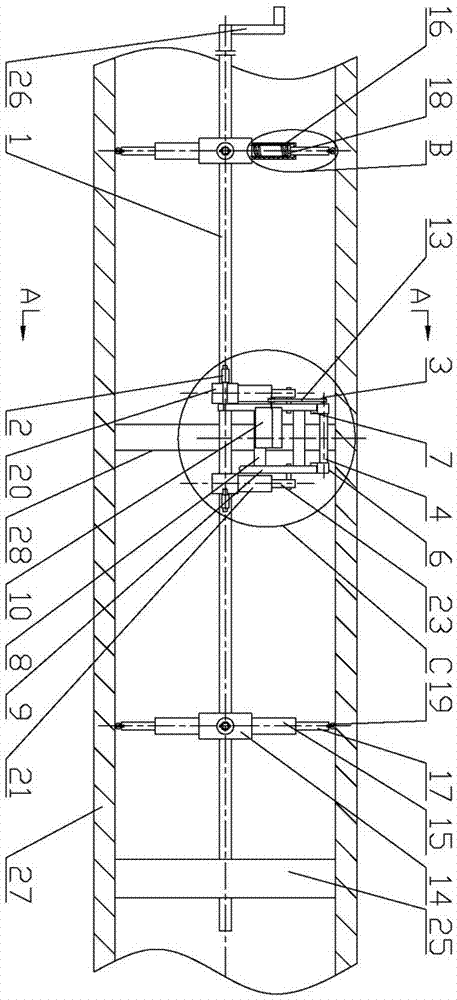

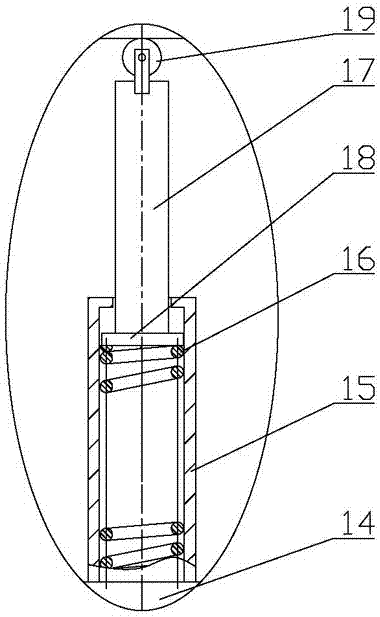

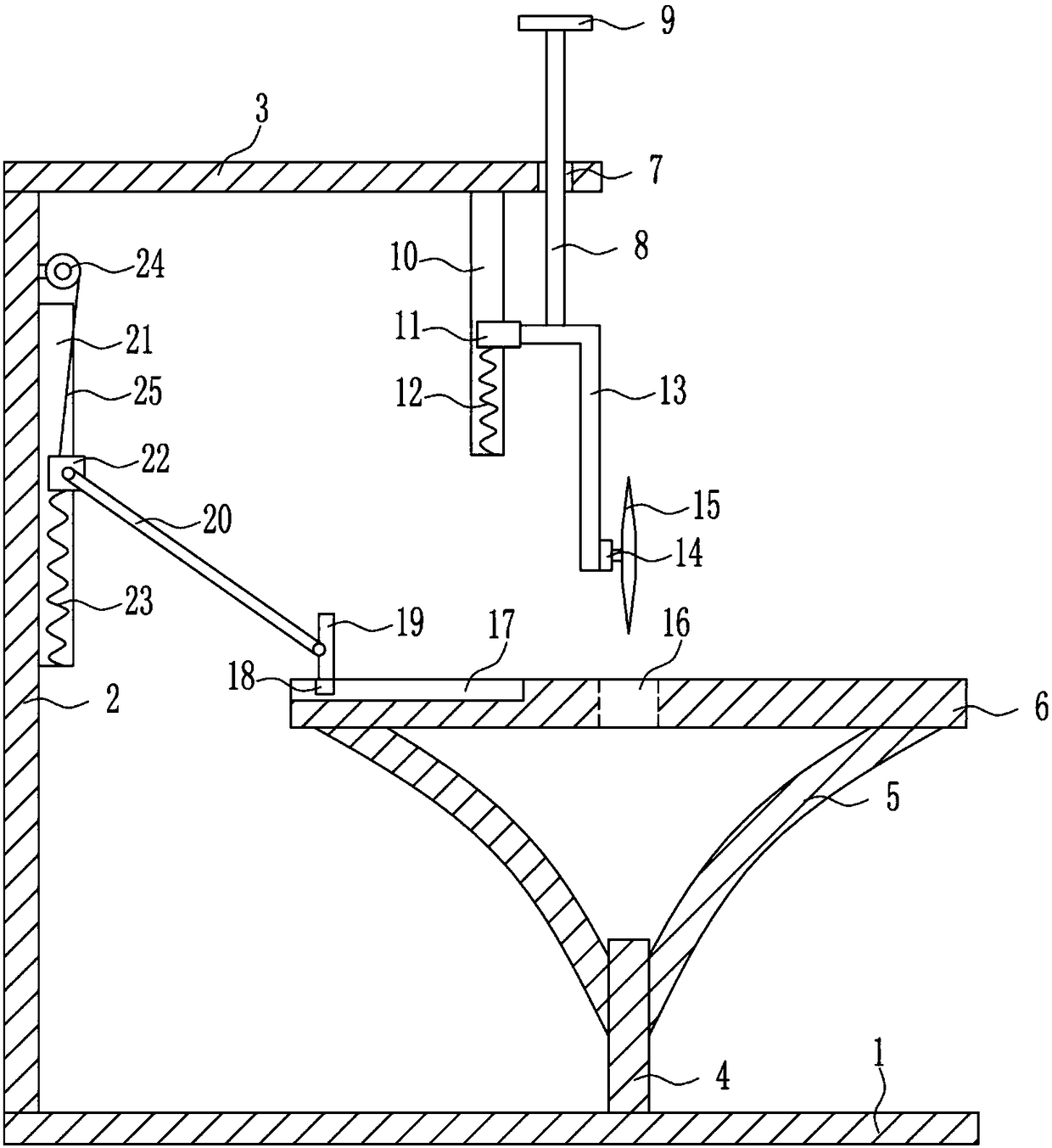

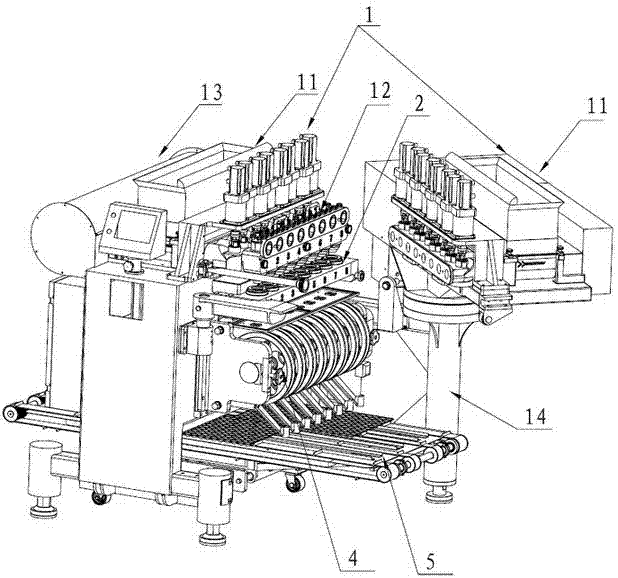

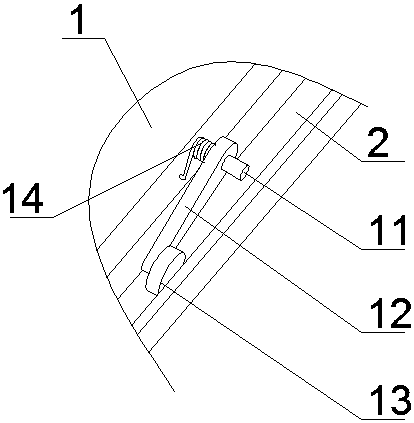

Hose embossing cutting-off machine

The invention discloses a hose embossing cutting-off machine. The hose embossing cutting-off machine comprises a worktable (1) which is horizontally and sequentially provided with a feeding device (4), an embossing device (2) and a cutting-off device (3), wherein electric control parts on the feeding device (4), the embossing device (2) and the cutting-off device (3) are all electrically connected with a same main controller; the embossing device (2) comprises an upper mould (201) and a lower mould (202), which are matched with each other and are used for embossing and molding a hose; the hose is located between the upper mould (201) and the lower mould (202); the two ends of the upper mould (201) and the lower mould (202), which extend along the direction of the hose, are respectively provided with embossing parts (205) which are matched with each other and are used for pressing two adjacent sections of threads; and the cutting-off device (3) comprises a cutting wheel capable of cutting off the hose from the two adjacent sections of threads. The hose embossing cutting-off machine disclosed by the invention is high in hose machining efficiency; and meanwhile, the labor cost is low.

Owner:NINGBO AUTO CABLE CONTROLS

Optical line testing device using wavelength tunable laser to measure cutting position of optical line

ActiveUS10274398B2Increased resolution and dynamic rangeMinimizing nonlinear effectReflectometers dealing with polarizationElectromagnetic transmittersTunable laserPhysics

An optical line testing device for measuring at least a cutting position of an optical line according to the present invention includes: a first wavelength tunable laser source configured to generate a first optical signal in which a plurality of wavelengths appear alternately and periodically; a second wavelength tunable laser source configured to generate a second optical signal which is identical to the first optical signal but has an adjustable delay time; and an interferometer configured to cause interference between a reflected optical signal, corresponding to the first optical signal, which is returning after having been emitted to the optical line, and the second optical signal to output an interference signal.

Owner:SOLID

Manufacturing method for power distribution module of new energy automobile

InactiveCN110289441AUneven sizeEasy to useAssembling battery machinesFinal product manufactureNew energyEngineering

The invention discloses a manufacturing method for a power distribution module of a new energy automobile. The module comprises a robot body, and a power distribution module discharging space with a forward opening is formed in the machine body. A centering clamping device is symmetrically arranged on the left end wall and the right end wall of the discharging space of the power distribution module; a gluing device is arranged on the outer side of the centering clamping device; a locking device is arranged on the lower end wall of the discharging space of the power distribution module in a bilateral symmetry manner; a cutting space is formed in the lower side of the interior of the machine body; a cutting device is arranged on the upper side of the cutting space; a driving space is formed in the upper side of the cutting device; and a driving motor is fixedly arranged on the upper end wall in the driving space. The module further comprises an auxiliary cutting device driven by the same driving motor, the module enables binding to be firmer in an adhesive binding mode, the manual cutting is not needed, the labor intensity is reduced, binding efficiency is improved through one step from the binding process to the forming process, and the auxiliary cutting device enables the cutting position to be more accurate.

Owner:义乌纹挺新能源科技有限公司

Automatic butchering and head cutting machine for poultry

ActiveCN103651718AGood separation effectConsistent positionPoultry/fish slaughtering/stunningPoultry processingCircular discReducer

The invention relates to equipment for carrying out butchering and head cutting on poultry, in particular to an automatic butchering and head cutting machine for poultry. The automatic butchering and head cutting machine mainly aims to solve the problem that the butchering and head cutting are manually carried out on the poultry with knives. The automatic butchering and head cutting machine comprises a machine body, a disc blade is arranged on a main motor shaft in the machine body, and a blade protection cover is arranged on a main motor. A transverse adjusting mechanism and a longitudinal adjusting mechanism of an upper adjusting mechanism and a lower adjusting mechanism are respectively provided with an adjusting handle, a threaded adjusting rod, a movable adjusting tube, a nut, a fixed tube and a blocking sheet, the fixed tube of the transverse adjusting mechanism is fixed to the machine body through a fixing supporting tube, the outer end of the movable adjusting tube of the transverse adjusting mechanism is connected with the fixed tube of the longitudinal adjusting mechanism, and the movable adjusting tube of the longitudinal adjusting mechanism is connected with an upper guide head guide rail. The movable adjusting tube of the lower adjusting mechanism is fixed to the machine body, and the fixed tube of the lower adjusting mechanism is connected with a lower guide head guide rail through a lower guide head guide rail fixing tube. A poultry head drive plate motor, a speed reducer, a poultry head drive plate, a stirring rod, a carcass blocking spring plate, a spring baffle, a screw rod and a spring are further arranged. The automatic butchering and head cutting machine has the advantage of being high in butchering and head cutting speed.

Owner:李传芳

Automatic cutting, grinding and polishing machine for PCB

PendingCN107378707AAccurate cutting positionImprove processing efficiencyGrinding feed controlGrinding machinesEngineeringMechanical engineering

The invention provides an automatic cutting, grinding and polishing machine for a PCB. The automatic cutting, grinding and polishing machine comprises a machine body, a working region, a clamping jaw, an action executing unit and a control panel, wherein the machine body is provided with a horizontal plane and a vertical plane which is perpendicular to the horizontal plane and is positioned at one side of the horizontal plane; the working region is arranged on the horizontal plane, and comprises a polishing disc, a grinding disc, a cutting disc and a laser aligning device; the action executing unit is arranged on the vertical plane, and the clamping jaw is connected with the action executing unit and is driven by the action executing unit to move in the vertical plane; and the control panel is arranged on the machine body and is positioned at one side of the working region. The automatic cutting, grinding and polishing machine for the PCB provided by the invention can realize advanced determining as well as automatic continuous cutting, grinding and polishing treatment of the PCB, is accurate in cutting position, is high in processing efficiency, is good in continuity, and sufficiently meets the needs, on product structure checking, of a laboratory of the PCB.

Owner:昆山寰升电子有限公司

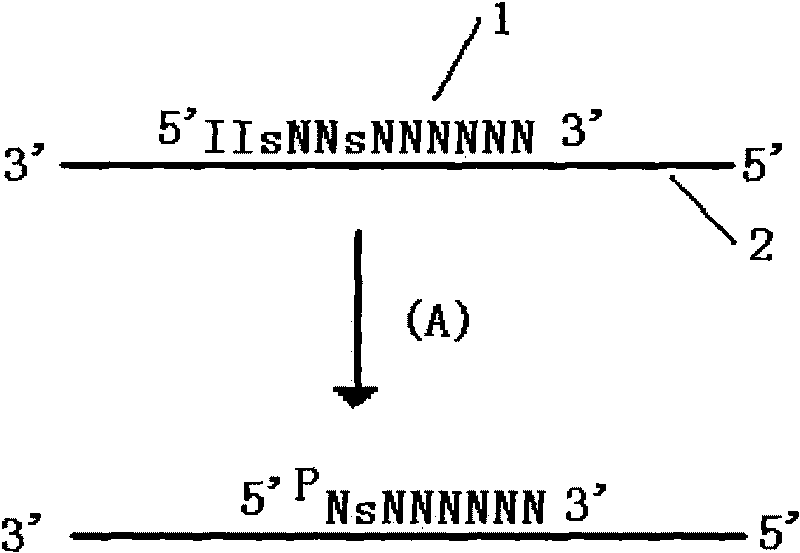

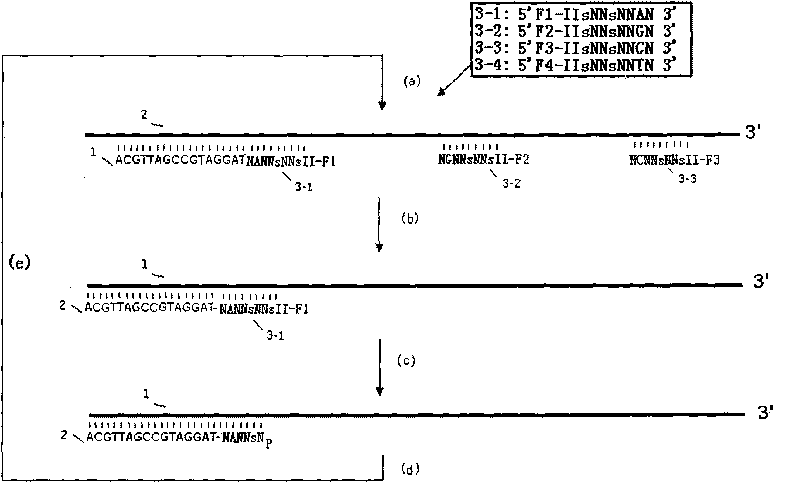

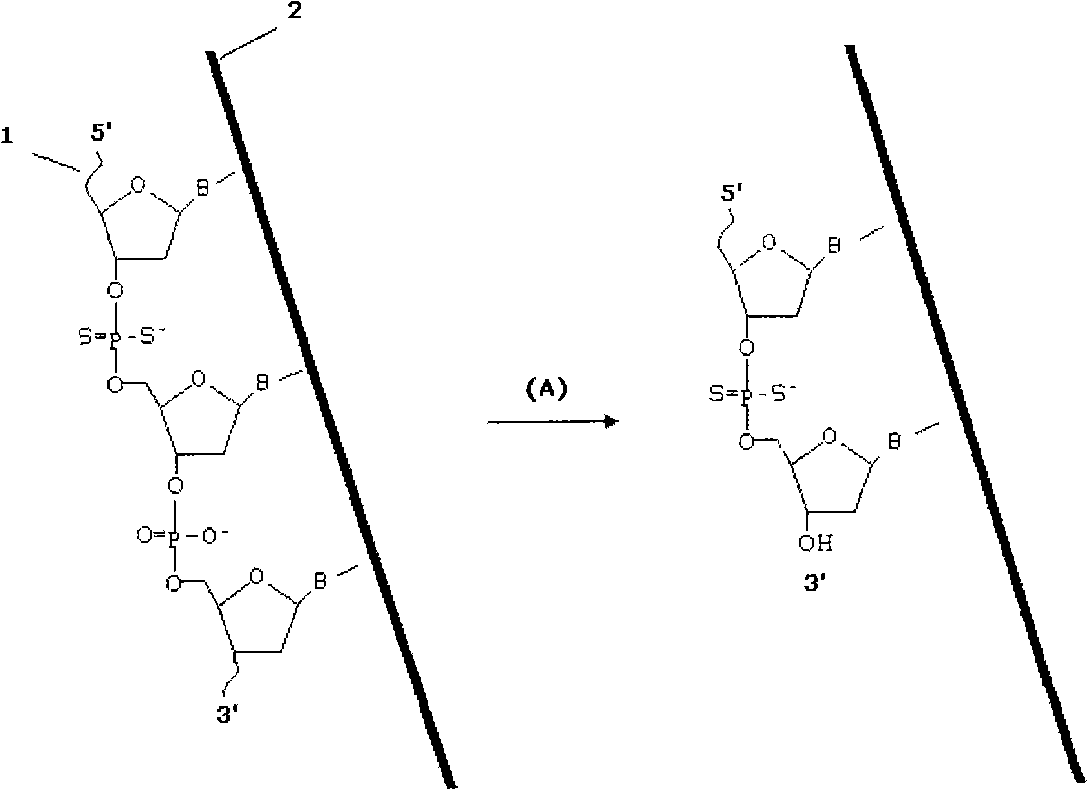

Method for improving specificity in cutting position of endonuclease V

InactiveCN101693918AAccurate and reliableAccurate cutting positionMicrobiological testing/measurementDNA fragmentationA-DNA

The method provides a method for improving the specificity in a cutting position of endonuclease V and relates to a high-throughput method for analyzing DNA sequences, in particular to a high-speed low-cost and high-throughput method for DNA sequencing. Recognition-site deoxyinosine dI containing the endonuclease V and DNA segments of single-chain oligonucleotide at a site where oxygen on one or more phosphodiester bonds in a DNA chain is sulfo-modified are introduced into a DNA probe, and the distance between the recognition site of the endonuclease V and the sulfo-modified site is two or more basic groups. The method can be used for analyzing unknown DNA, namely sequence information of a template DNA to be analyzed. Re-hybridized high-throughput primers are obtained by synthesis and purification by a very mature solid-phase DNA method, and therefore, the method does not have wrongly extended accumulative effect and can maintain the amount of DNA templates and sequencing primers. The determination of the sequence is correct and reliable, having no limitations on sequenced length.

Owner:SOUTHEAST UNIV

Cutting device of annular protruding flanging at welding line inside polyethylene pipe

The invention relates to the technical field of welding tools, and provides a cutting device of annular protruding flanging at a welding line inside a polyethylene pipe. The cutting device comprises a center rod, elastic centering supports, a fixing base, a connecting base, a cutting assembly and an elastic supporting base; the at least two elastic centering supports are distributed on the outer side of the center rod at intervals in the left-right direction, the fixing base and the elastic supporting base are arranged between two elastic centering supports, one end of the fixing base and the center rod are fixed together, the other end of the fixing base and one end of the connecting base are hinged together, and the other end of the connecting base is fixedly provided with the cutting assembly capable of conducting lossless operation on the annular protruding flanging at the welding line inside the polyethylene pipe. By means of the cutting device, lossless operation on the annular protruding flanging at the welding line inside the polyethylene pipe can be achieved through the elastic centering supports, the cutting assembly and the elastic supporting base, the cutting position of the cutting device is accurate, the pipe is not prone to being damaged, and smooth implementation of repairing engineering construction of the HDPE pipe penetrating a steel pipe.

Owner:克拉玛依市博瑞科技发展有限公司

Cutting machine for window frames of aluminum alloy doors and windows

InactiveCN105499687AReduce manufacturing costAccurate cutting positionShearing machinesShearing machine accessoriesEngineeringAlloy

The invention belongs to the technical field of manufacturing of aluminum alloy doors and windows and particularly relates to a cutting machine for window frames of the aluminum alloy doors and windows. The cutting machine comprises a workbench, a supporting frame, an air cylinder and a motor, wherein the supporting frame is fixed on the workbench, the air cylinder is fixed above the supporting frame, guiding rails are arranged between the supporting frame and the workbench, a sliding block is mounted on one side of the motor and slidingly matched with the guiding rails, a piston rod of the air cylinder is fixedly connected with the upper side of the motor, a cutting wheel is arranged on and in keyed connection with an output shaft of the motor, and limiting blocks are arranged in positions, corresponding to the cutting wheel, of the workbench. With the adoption of the cutting machine, the to-be-cut window frames can be arranged between the left limiting block and the right limiting block which are adjusted in advance, the air cylinder is started and drives the motor to move downwards along the guiding rails, cutting of the window frames is completed, cut positions are accurate, persons are far away from the cutting wheel in the process, the personal safety is guaranteed, the working efficiency is greatly improved, and the production cost of an enterprise is saved.

Owner:天津畅兴建筑装饰工程有限公司

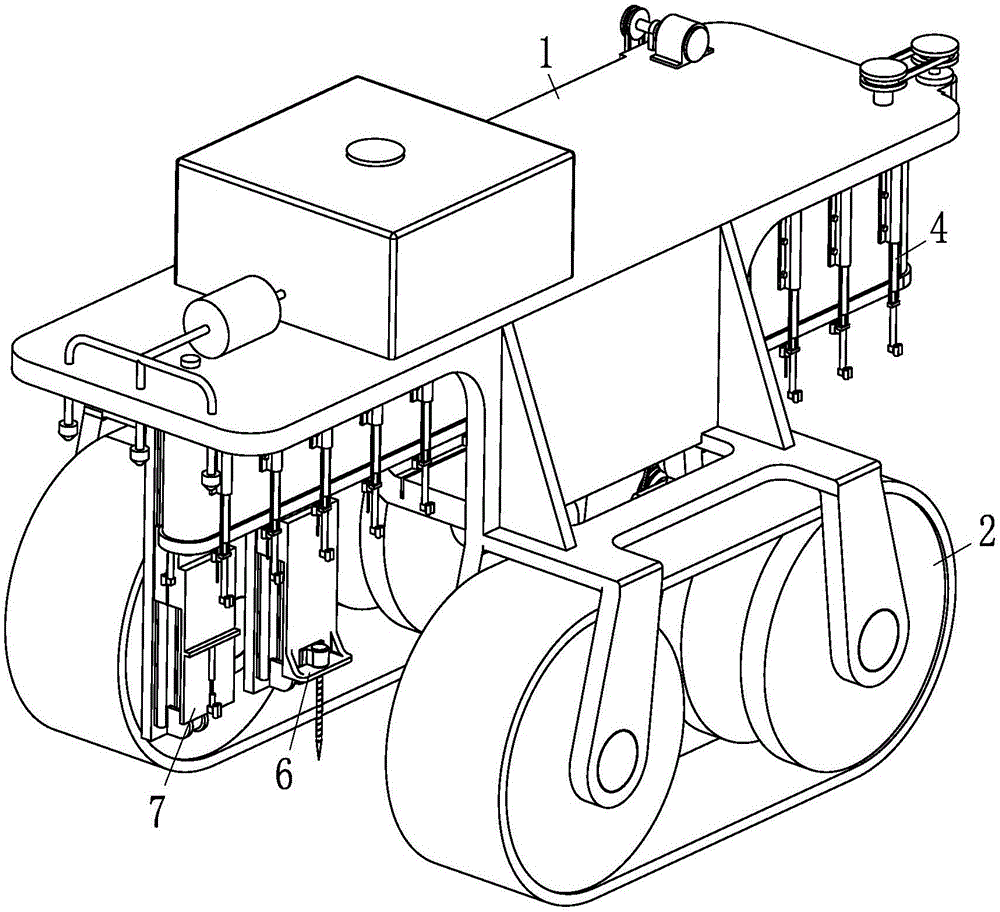

Mobile intelligent jasmine cutting machine

InactiveCN106258125ARealize automatic cuttingFor precise cuttingPlantingAgricultural engineeringSeedling

The invention relates to the field of agricultural machinery, in particular to a mobile intelligent jasmine cutting machine. The mobile intelligent jasmine cutting machine comprises a machine body, a walking device, a stem shearing device, a stem delivery device, a drilling device, a stem cutting device and cameras; the walking device is located on the lower portion of the machine body, the stem shearing device is located on the left side of the upper end of the machine body, the stem delivery device penetrates through the upper end of the machine body, the drilling device is located on the rear portion of the machine body, and the stem cutting device is located behind the drilling device; the cameras are installed at the front end of the lower end face of the top plate and a rotating disc of the stem shearing device respectively. According to the mobile intelligent jasmine cutting machine, automatic shearing, delivering, automatic drilling and seedling cutting on jasmines can be integrally operated in the whole process, and the practicability is high.

Owner:射阳县方圆机械厂

Application of oligonucleotide probe containing dithio nucleotide on detecting DNA sequences

InactiveCN101550448AAccurate and reliableEasy to cutMicrobiological testing/measurementNucleotideHigh flux

The invention aims at providing an application of oligonucleotide probe containing dithio nucleotide on detecting DNA sequences, namely a nucleotide sequence detecting probe (namely containing dithio) without an enantiomorph structure which uses the degradation of excision enzyme II on the phosphodiester bonds between normal basic groups and the function of not being cut of the excision enzyme on the phosphodiester bonds modified by dithio to remove markers in the sequence detecting reaction and build a new hybridization-enzyme connection-enzyme cutting high flux sequence detecting technology. The nucleotide sequence detecting probe provides a new method for analyzing a genome DNA sequence, builds a quick, accurate and cheap genome sequence detecting technology, and has the advantages of accurate and reliable detecting and easy realization.

Owner:SOUTHEAST UNIV

Urban pipeline valve installing construction technology

The invention provides an urban pipeline valve installing construction technology and belongs to the technical field of auxiliary pipeline installing equipment. The method comprises the steps that a valve and a force transmission connector are assembled to manufacture a valve set, the cutting size of a pipeline is calculated according to the size of the valve set, a measuring tool is manufactured according to the cutting size and utilized for determining the cutting position of the pipeline, the pipeline is cut according to the cutting position, and the valve set is installed on the pipeline through a flange plate. According to the method, the construction technology is simple, the construction period is short, the installing precision of the valve is high, and use is safe and reliable.

Owner:CHINA AEROSPACE CONSTR GROUP +1

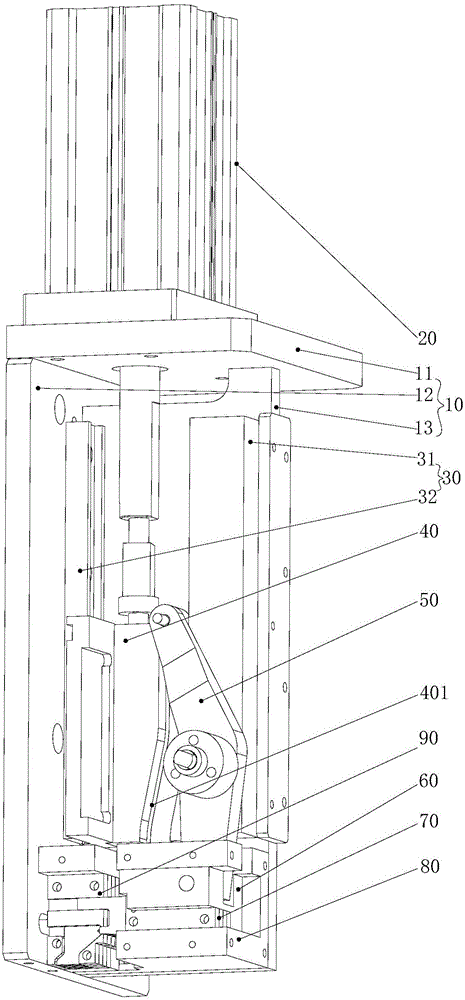

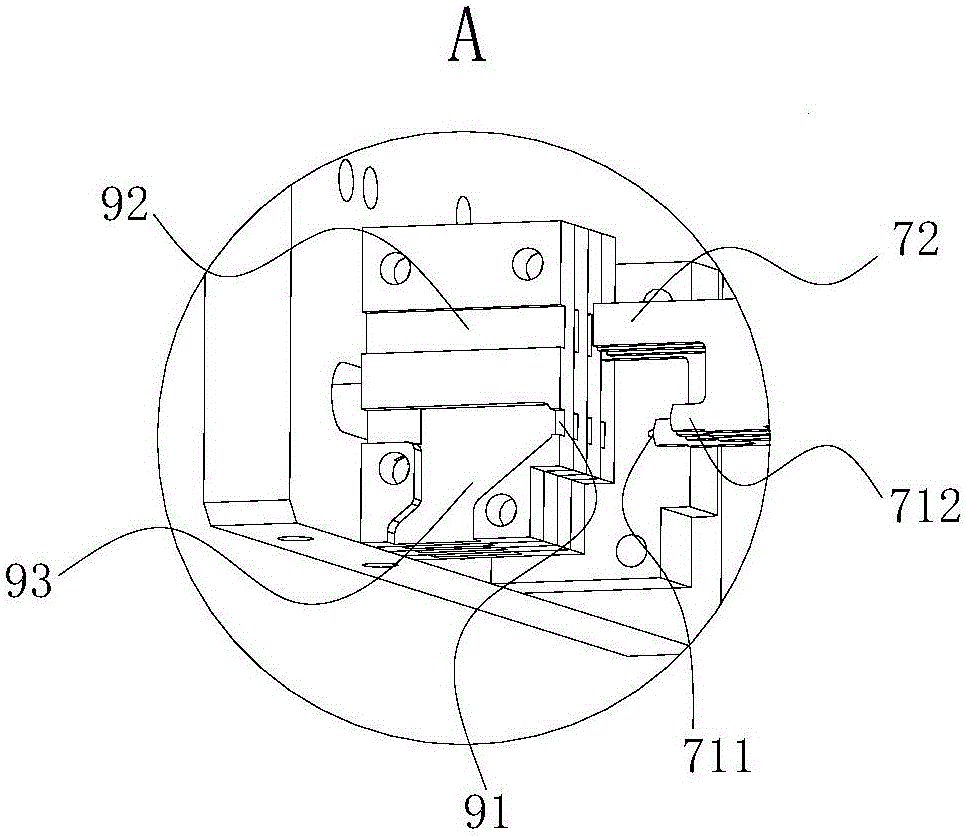

Cutting mechanism

ActiveCN105034038APrecise cutting positionAccurate cutting positionMetal working apparatusReciprocating motionEngineering

The invention discloses a cutting mechanism which is provided with a fixing seat, guide rails and a guiding slide block, wherein the fixing seat, the guide rails and the guiding slide block can guarantee the precision of a cutting action. A cylinder is used for driving the guiding slide block to slide along the guide rails. A curved guiding groove is formed in the guiding slide block. One end of a swing rod is connected with the guiding slide block in a sliding mode, and the other end of the swing rod is connected with a cutter slide block. The middle of the swing rod is connected with the first guide rail through an eccentric shaft and a needle bearing. The cutter slide block moves in a reciprocating mode in the slide block guiding groove to drive a cutter to cut materials continuously, and a cutter groove is matched with the cutter. According to the cutting mechanism, the automatic cutting process is achieved, and the cutting mechanism has the advantages that the cutting position is precise, and burrs are avoided. The cutting mechanism can be further improved to have terminal cutting and crimping functions.

Owner:SANHE IND AUTOMATION EQUIP CO LTD SHUNDE DISTRICT FOSHAN CITY

Cutting device for metal pipeline production

ActiveCN114378584AAccurate cutting positionImprove cutting effectOther manufacturing equipments/toolsPositioning apparatusSlide plateMaterials science

The cutting device for metal pipeline production comprises a cutting box, a cutting assembly is arranged at the bottom end in the cutting box, the cutting assembly comprises a cutting table, two fixing plates are fixed to the two sides of the cutting table correspondingly, two cutting air cylinders are fixed to the two sides of the bottom end in the cutting box correspondingly, and first sliding plates are fixed to the output ends of the cutting air cylinders; grinding boxes are arranged on the two sides of the cutting box correspondingly, grinding assemblies are arranged at the bottom ends of the interiors of the grinding boxes, straightening boxes are arranged on the sides, away from each other, of the two grinding boxes correspondingly, clamping bases are arranged on the sides, away from each other, of the two straightening boxes correspondingly, and two clamping mechanisms are arranged above the clamping bases correspondingly; the problems that in the prior art, after a metal pipeline is cut, follow-up grinding, straightening and other treatment on the pipeline are lacked, so that the cut position of the pipeline is prone to being scratched by personnel, and the production quality of the metal pipeline is reduced are solved; and meanwhile, after the metal pipeline is clamped, rotation of the pipeline cannot be achieved, and the problem that the cutting efficiency is low is solved.

Owner:ANHUI LONGTAI ELECTRIC TECH

Ceramic tile cutting device for bathroom decoration

InactiveCN108582501AFor precise cuttingAvoid offsetWorking accessoriesBuilding constructionsHuman healthMaterials science

The invention relates to the field of bathrooms, in particular to a ceramic tile cutting device for bathroom decoration. According to the ceramic tile cutting device for bathroom decoration, the cutting efficiency is high, dust generated during cutting can be treated, and operation is easy. The ceramic tile cutting device for bathroom decoration comprises a bottom plate, a left side plate, a top plate, a supporting rod, arc-shaped plates, a storing plate, a guiding rod, a pressing plate, a first sliding rail, a first sliding block, a first spring, a first connecting rod and the like. The leftside plate is arranged on the left side of the top of the bottom plate; the top plate is arranged at the top of the left side plate; the supporting rod is arranged on the right side of the top of thebottom plate; the arc-shaped plates are arranged on the left side and the right side of the top of the supporting rod correspondingly; the top ends of the arc-shaped plates are connected with the storing plate; and a linear groove is formed in the middle of the storing plate. The left side of a ceramic tile is fixed through a baffle, thus the cutting position is more accurate, a sawing disc downwards moves while conducting cutting, the cutting speed is high, an air suction hood and a hose can suck air with the dust into a box to be treated, and thus human health is not affected.

Owner:闵忠武

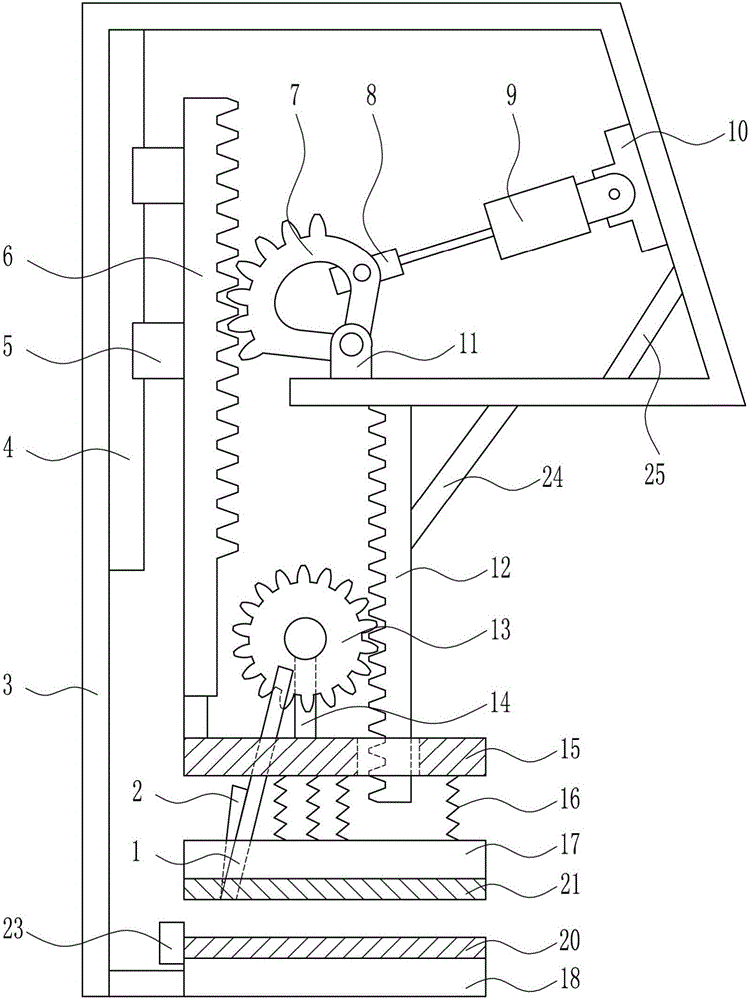

High-precision cutting device for fruit cartons

The invention relates to a cutting device, in particular to a high-precision cutting device for fruit cartons. The high-precision cutting device for the fruit cartons aims at achieving the technical purpose that cutting precision is high. To achieve the technical purpose, the high-precision cutting device for the fruit cartons comprises an oscillating rod, a cutter, a lifting frame, a sliding rail, sliding blocks, a second rack, a sector-shaped gear, a connecting block, an air cylinder, a first oscillating seat, a second oscillating seat, a first rack, a first gear, a support bar, a cutting table, springs, a pressing plate and a containing table. The second oscillating seat is arranged on the left side of the bottom in the lifting frame. The sector-shaped gear is arranged on the rear side of the second oscillating seat. The first oscillating seat is arranged on the right side in the lifting frame. According to the cutting device, through the linkage feature, the air cylinder drives the oscillating rod to rotate to drive the cutter to rotate so as to cut the cartons, the cartons are pressed through the pressing plate so that the cartons can be prevented from moving when cut, and the cutting orientation is more precise.

Owner:武汉雅佳荣纸制品有限公司

Automobile part cold stamping device with material taking device

PendingCN112139333ANot easy to shakeNot easy to slide outShaping toolsMetal-working feeding devicesStampingMotor vehicle part

The invention provides an automobile part cold stamping device with a material taking device, and belongs to the technical field of automobile part stamping equipment.The automobile part cold stampingdevice with the material taking device comprises a base, wherein a supporting frame is fixed to the upper end of the base, the supporting frame is in an inverted-U shape, a stamping device is fixed to the upper end of the supporting frame, the lower end of an output shaft of the stamping device penetrates through the upper inner wall of the supporting frame and is fixedly provided with a bearingplate, a stamping plate is fixed to the lower end of the bearing plate, fixing plates are fixed to the left inner wall and the right inner wall of the supporting frame, a rotating rod is rotatably connected between the ends, close to each other, of the two fixing plates, and the right end of the rotating rod penetrates through the right end of the fixing plate located on the right side and penetrates through the right end of the supporting frame continuously, and a servo motor is fixed to the right end of the supporting frame. According to the device, after an automobile part is stamped, it isunnecessary to take out the part manually from a stamping die 15, so that it is convenient to collect the stamped and formed automobile part and the part is collected conveniently and rapidly, and therefore, the automobile part stamping efficiency is improved greatly.

Owner:HEFEI CHANGQING MACHINERY

Method for realizing degradation of stacked IC defective products through cutting break line of package body

ActiveCN106158741AAvoid wastingReduce wasteSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a method for realizing the degradation of stacked IC defective products through cutting the break line of a package body. the method comprises the steps of packaging an outline drawing, an internal weld line drawing, an IC, a die, a metal line, a blade and a scribing machine, wherein the IC is of a multi-layer structure; figuring out a problematic layer die among the internal multi-layer structure of the IC through testing; determining the feeding position of the blade and setting parameters; putting a to-be-cut IC onto the cutting disc of the scribing machine with the vacuum adsorption function by means of the scribing machine for cutting wafers in order to meet the requirements on the cutting precision; cutting to obtain IC particles; cleaning and drying particles in the scribing machine, and testing rest dies after the cleaning and drying process, wherein the ICs of rest dies without problems are adopted as degraded products. According to the technical scheme of the invention, scrapped ICs are degraded and used based on the physical damage isolation method. Therefore, the income is increased, and waste is reduced.

Owner:TEKISM

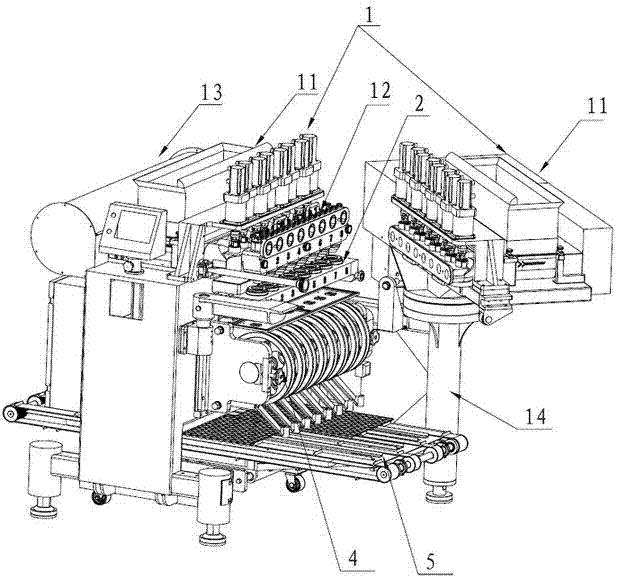

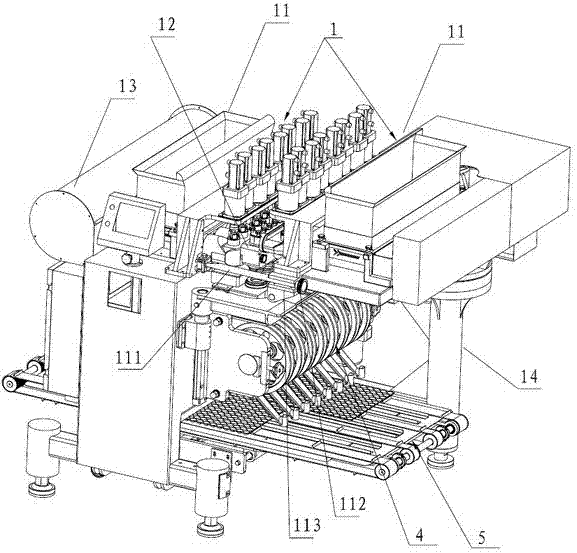

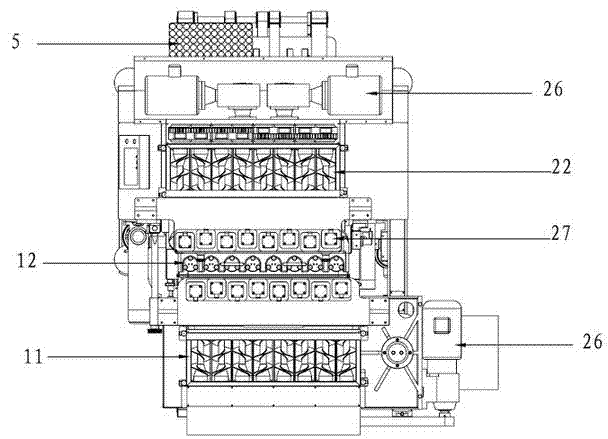

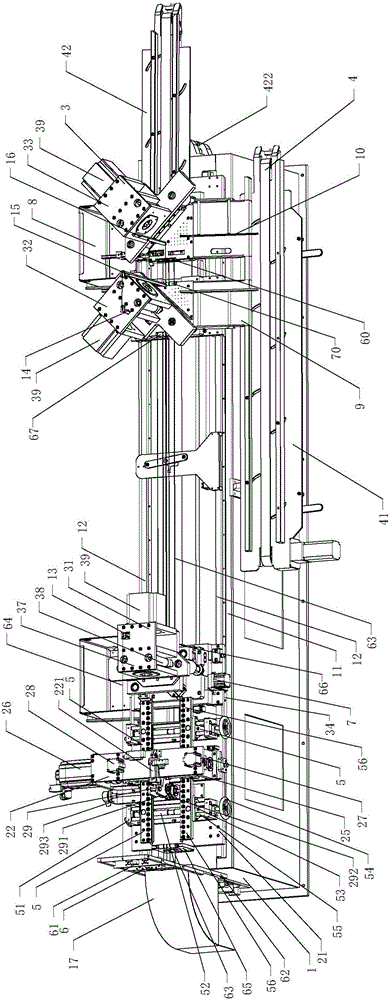

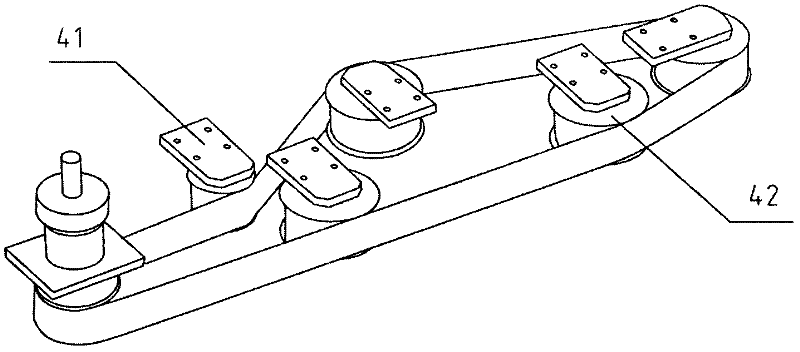

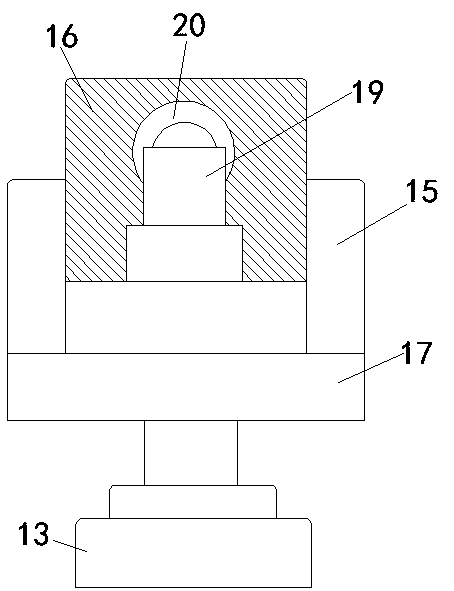

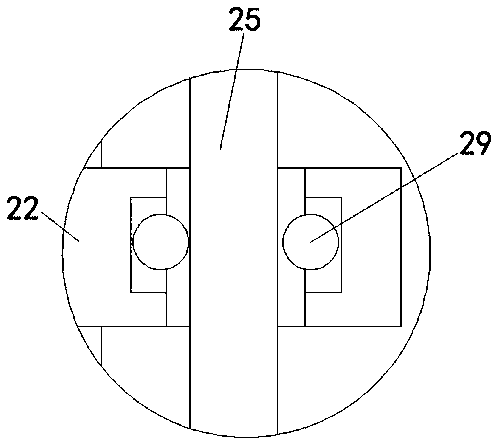

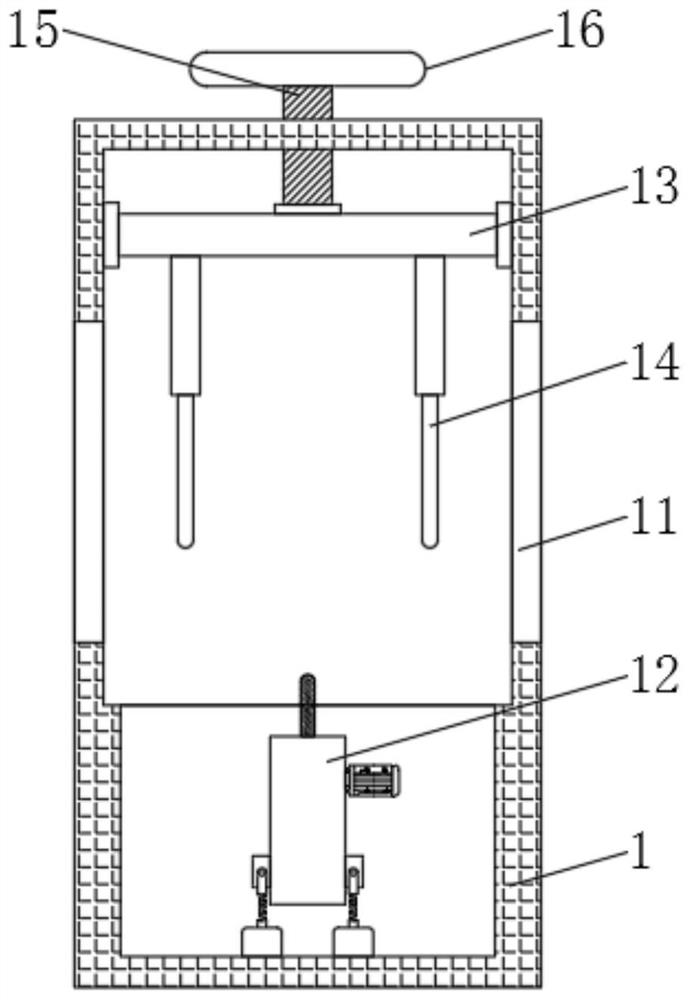

Round food forming machine

The invention relates to a device for processing stuffing foods, and particularly relates to a round food forming machine. The round food forming machine comprises a feed system, a wrapper-stuffing compounder, a retracting / cutting tool assembly, a retracting / cutting tool lifting assembly, a rounding device and rows of trays, wherein the feed system is a split one which comprises two independent feed assemblies and the wrapper-stuffing compounder; and the feed assemblies can move relative to the wrapper-stuffing compounder, thus forming the split structure. The round food forming machine has the advantages that the two independent feed assemblies and the wrapper-stuffing compounder are convenient to disassemble and install; when the components need to be cleaned or maintained, the cleaningor maintenance operation of each component can be performed by simply disassembling at least one feed assembly from the wrapper-stuffing compounder; and the disassembling mode is realized by simple rotation, thereby simplifying the existing disassembling mode, saving the disassembling time and improving the working efficiency.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

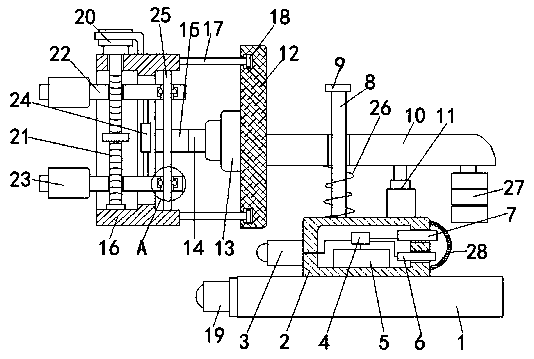

Automatic feeding vehicle for cutting machine

InactiveCN107856106ALifting and moving smoothlyReduce clearanceMetal working apparatusEngineeringScroll wheel

The invention discloses an automatic feeding vehicle for a cutting machine, comprising a support plate, two rails, a support and a cylinder, wherein the two rails are arranged in parallel; one ends ofthe rails are connected through the support, and the other ends of the rails can be placed on a working table-board of the cutting machine; the support plate is placed between the rails; the width ofthe support plate is smaller than the opening distance between the rails; the two sides of the support plate are symmetrically provided with shafts, each side being provided with two shafts; the shafts are movably connected with rocking arms; the other ends of the rocking arms are connected with rolling wheels which can roll on the rails; torsional springs are arranged between the support plate and the rocking arms; the cylinder is arranged on the support; the top of a telescopic rod of the cylinder is connected with a push rod; the two ends of the push rod are provided with connecting rings;the support plate is also provided with two positioning rods which are perpendicular to the support plate and are movably connected with the connecting rings. When a pressing plate of the feeding vehicle performs pressing, the support plate makes contact with the working table-board, the pressure is uniformly distributed, so that the working table-board is not easy to damage, and the rails and the rolling wheels of the feeding vehicles are not pressure-bearing parts, so as to be prevented from being easily damaged and do not need to be frequently replaced.

Owner:HONGCHENG SCI & TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com