Automatic marble pillar machining device and machining method thereof

A technology of automatic processing and Roman columns, applied in the direction of stone processing tools, stone processing equipment, metal processing equipment, etc., can solve the problems of high dependence on the technical experience of the staff, poor product identity, low production efficiency, etc., and achieve simple processing devices Ease of use, reduced labor intensity, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

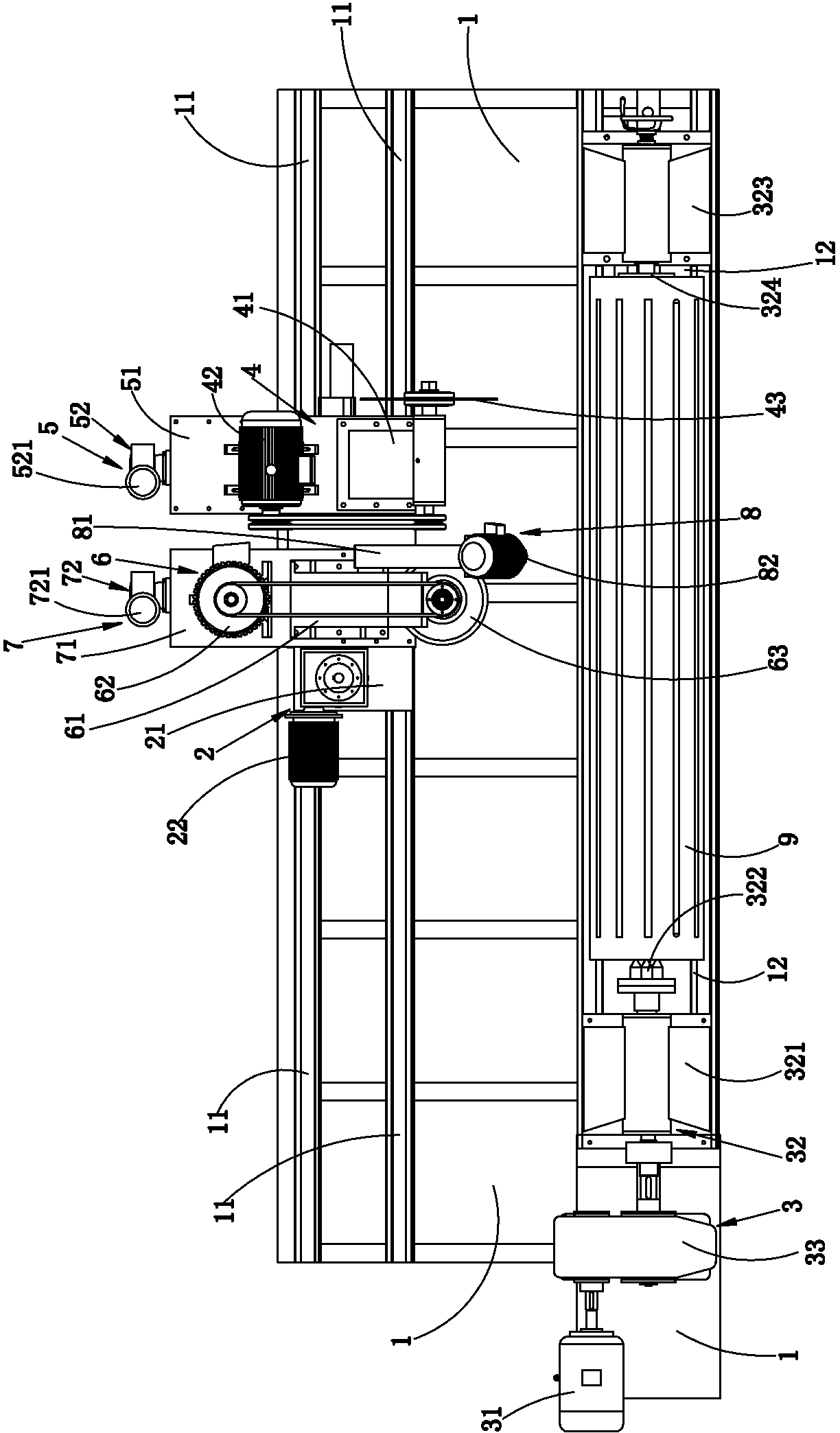

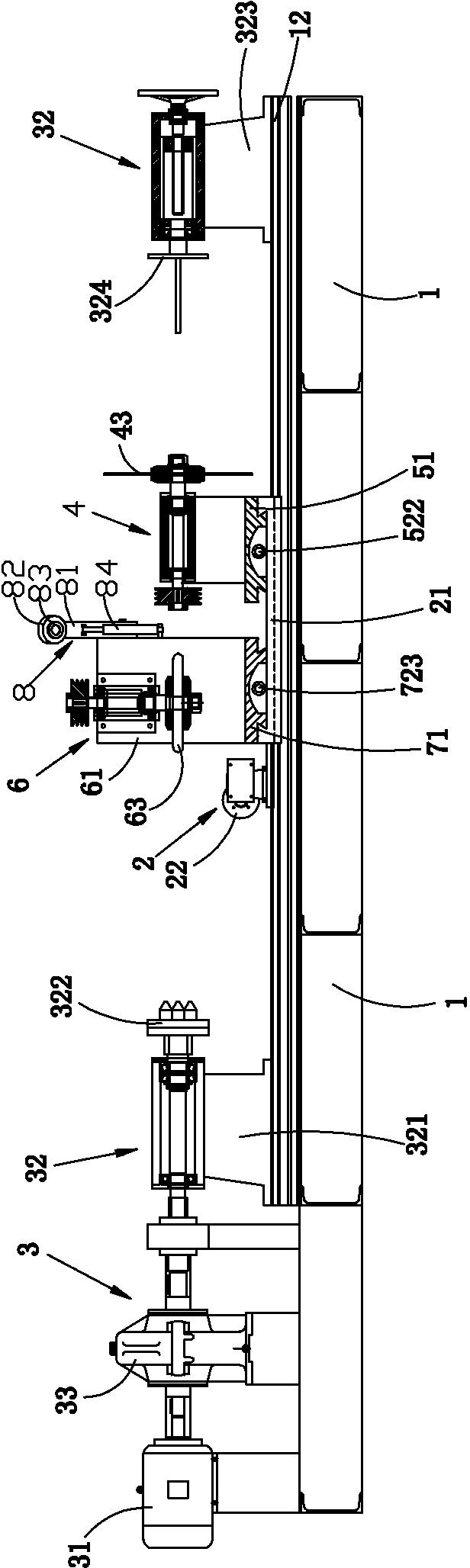

[0026] refer to figure 1 , figure 2 , Roman column automatic processing device, including control device, base 1 and walking mechanism 2 assembled on base 1, rotating mechanism 3, carved column mechanism 4, carved column advancing and retreating mechanism 5, slotting mechanism 6, slotting advancing and retreating mechanism 7 and grinding and polishing mechanism 8. The control device is used to control the actions of each mechanism in sequence.

[0027] Continue to refer to figure 1 , figure 2 , the above-mentioned traveling mechanism 2 includes a moving seat 21 and a traveling motor 22; the base 1 is provided with a traveling guide rail 11, a rack is provided on the traveling guide rail 11, and a gear, a rack and a gear are arranged on the power output shaft of the traveling motor 22 Mesh connection. The traveling motor 22 is fixedly assembled on the movable seat 21, and when the traveling motor 22 rotates forward or reversely, the movable seat 21 promptly travels forwa...

Embodiment approach 2

[0041] The difference between this embodiment and Embodiment 1 lies in the structure of the carved column advancing and retreating power device and the slotted advancing and retreating power device. Assembled on the above-mentioned movable seat, the carved column advancing and retreating air / oil cylinder is used to push and pull the above carved pillar advancing and retreating seat for advancing and retreating action; the slotted advancing and retreating power device of this embodiment includes a slotted advancing and retreating air / oil cylinder, and the slotted advancing and retreating air / oil cylinder is fixed Assembled on the above-mentioned moving seat, the slotted advance and retreat air / oil cylinder is used to push and pull the above-mentioned slotted advance and retreat seat for the forward and backward movement.

[0042] In addition, the present invention also relates to an automatic processing method for curved groove Roman columns. The processing method uses the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com