Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Continuous action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

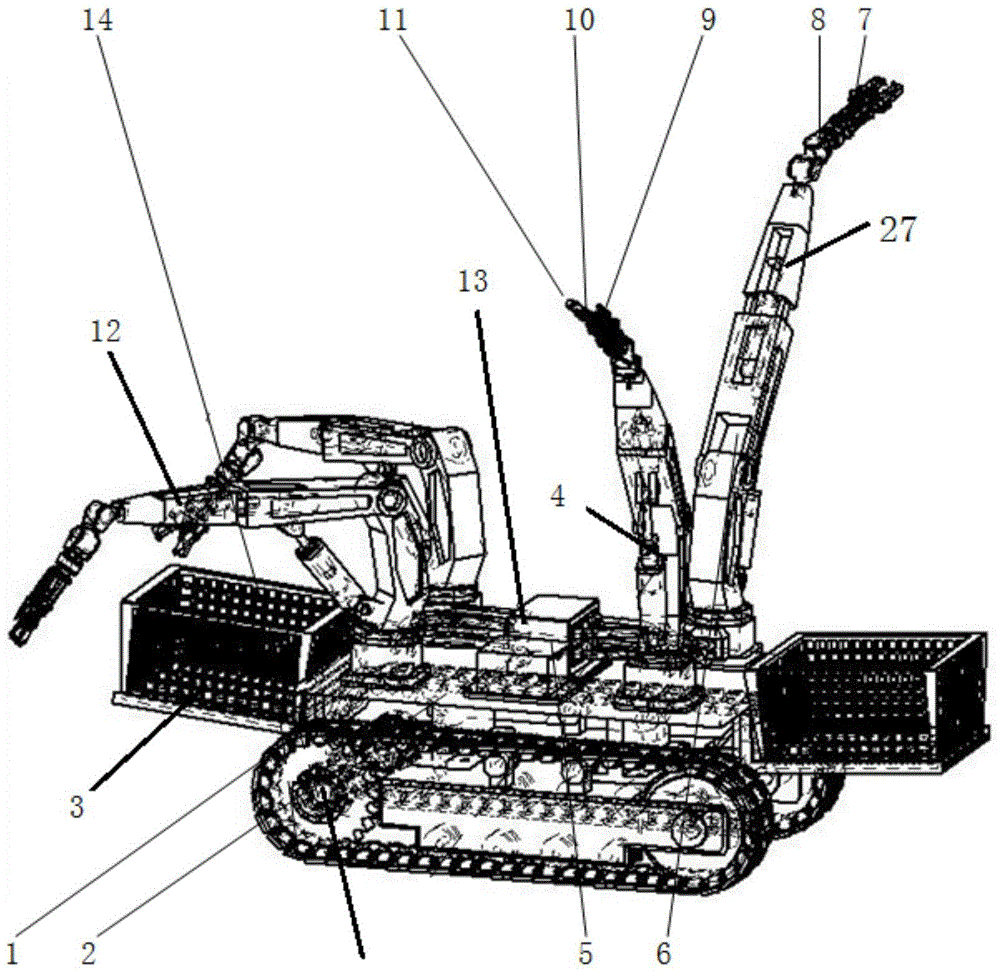

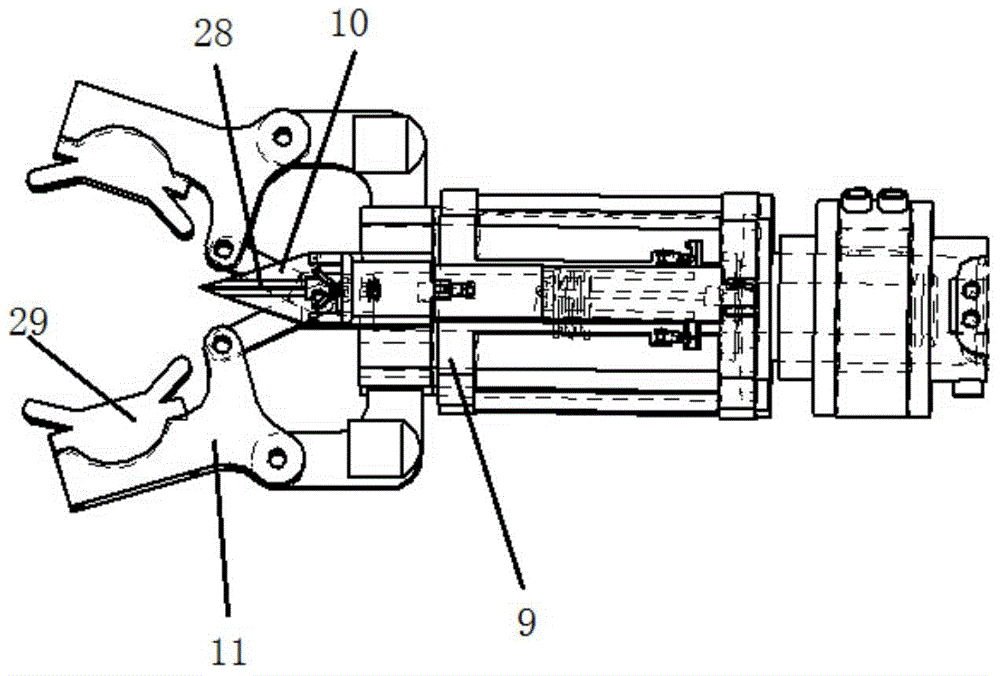

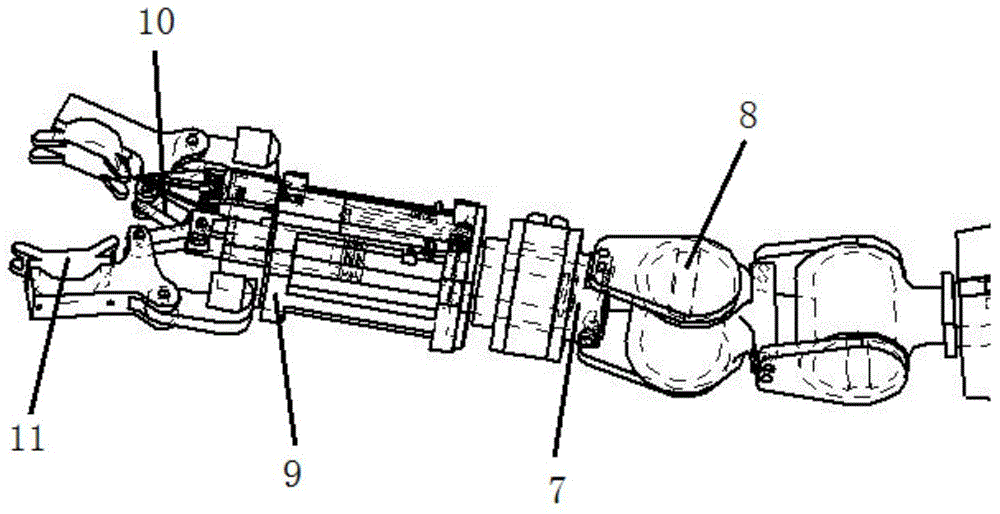

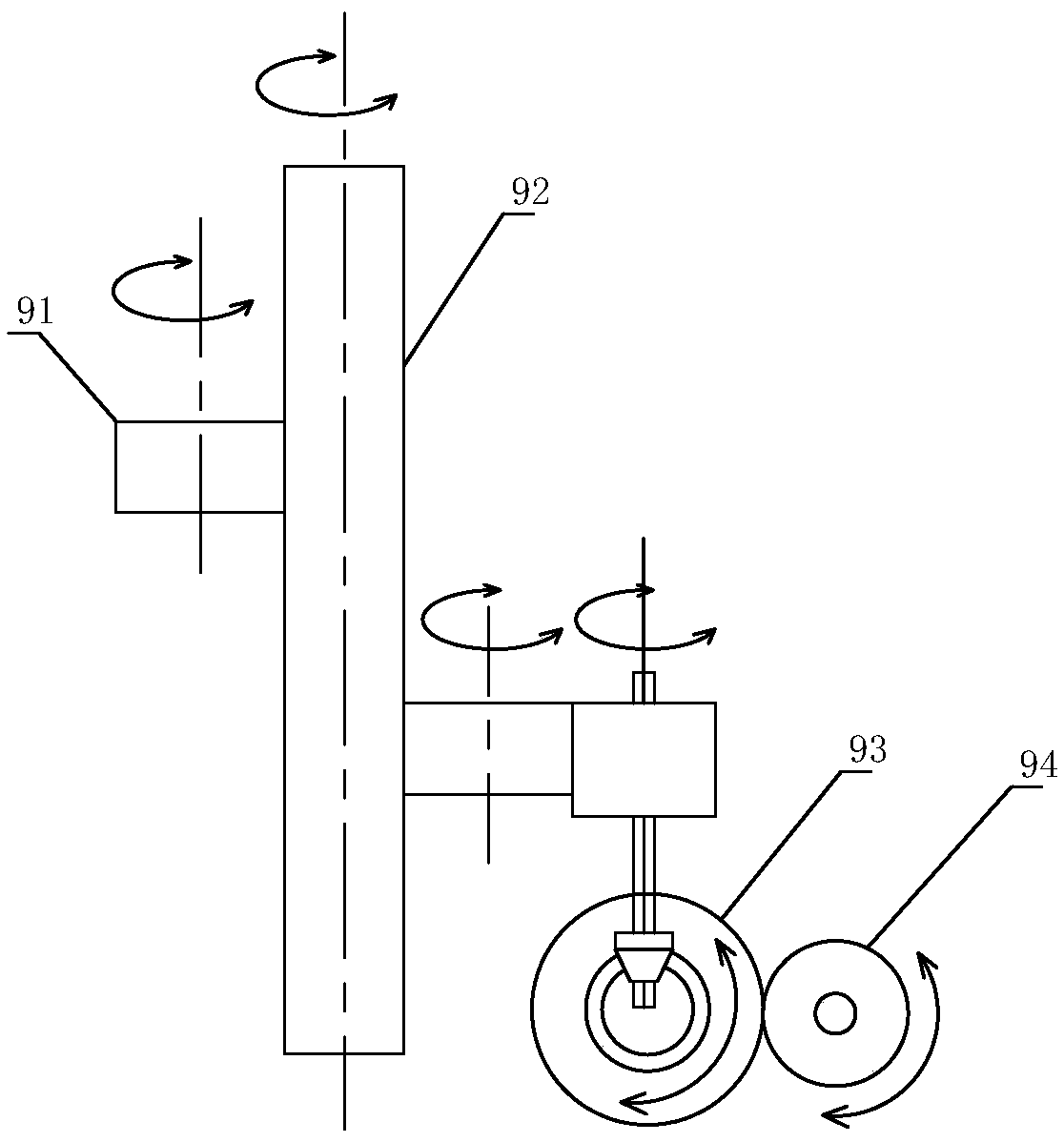

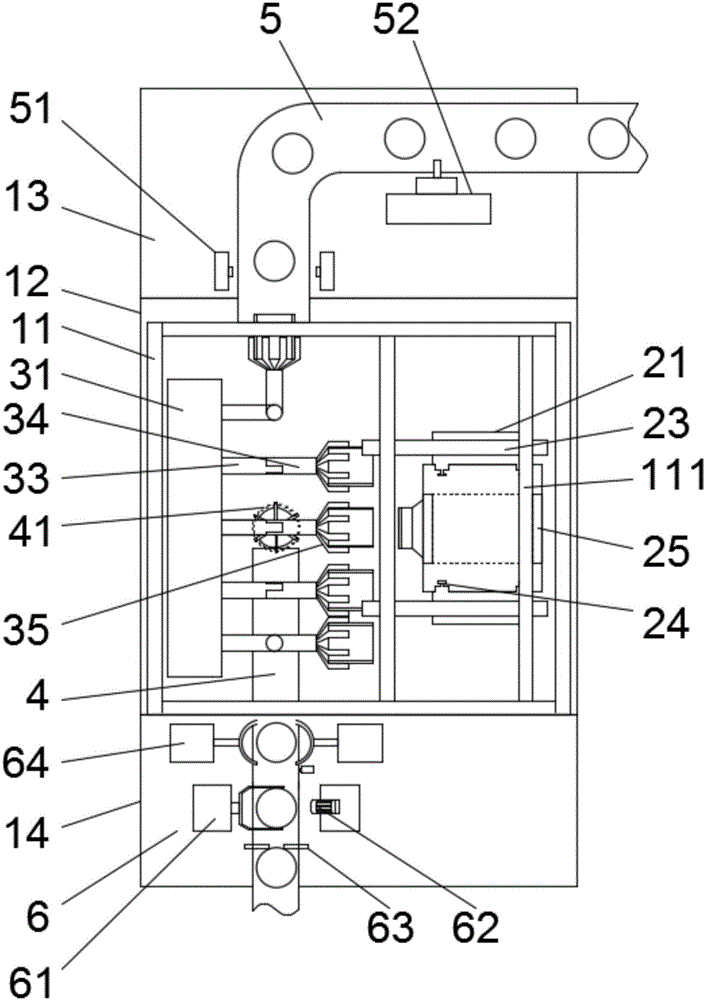

Vegetable and fruit picking robot and control method thereof

InactiveCN105027834ARealize simultaneous movementAccurate identificationPicking devicesRobotic armControl theory

The invention discloses a vegetable and fruit picking robot and a control method thereof. The vegetable and fruit picking robot comprises a walking mechanism. A base is arranged on the walking mechanism. Storage baskets are arranged at the front and rear ends of the base respectively. An execution mechanism, a recognition system, a first driving mechanism, a second driving mechanism and a controller are arranged on the base. The controller is connected with the recognition system, the first driving mechanism and the second driving mechanism through wires. Both fruits on trees and plant fruits at low positions can be picked, and therefore the picking object range is wide; the crawler-type walking mechanism drives a plurality of mechanical arms to work at the same time, and therefore the picking efficiency is high; a small arm is flexible and continuous in movement, the stretching range of the mechanical arms is wide, and therefore the vegetable and fruit picking robot can adapt to various operating environments; the multi-sensor function and the digital imaging technology are adopted, and therefore the fruits can be accurately recognized and positioned; clamping force is controlled through sensor detection, and therefore the fruits are prevented from being damaged.

Owner:平顶山工业职业技术学院

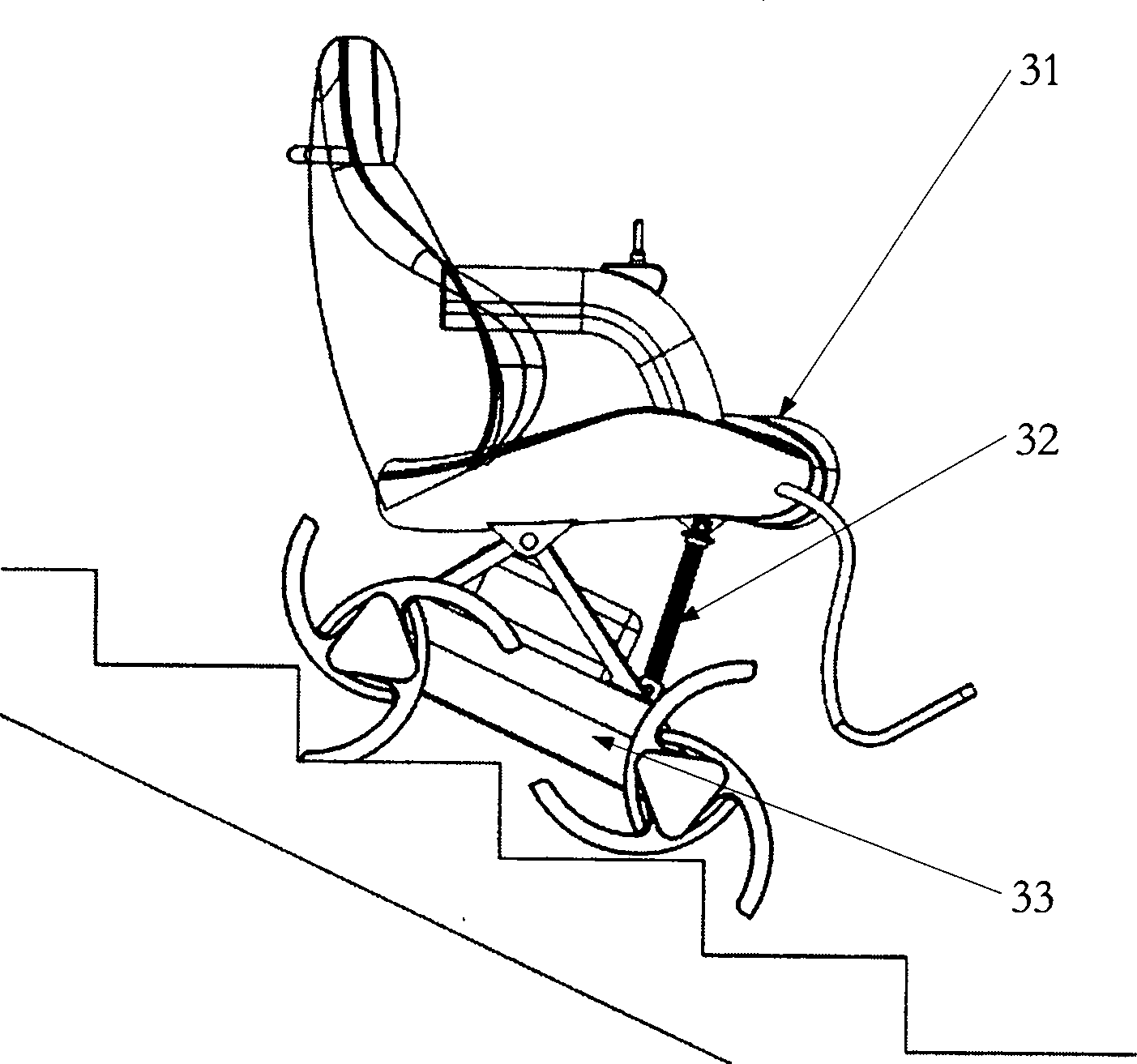

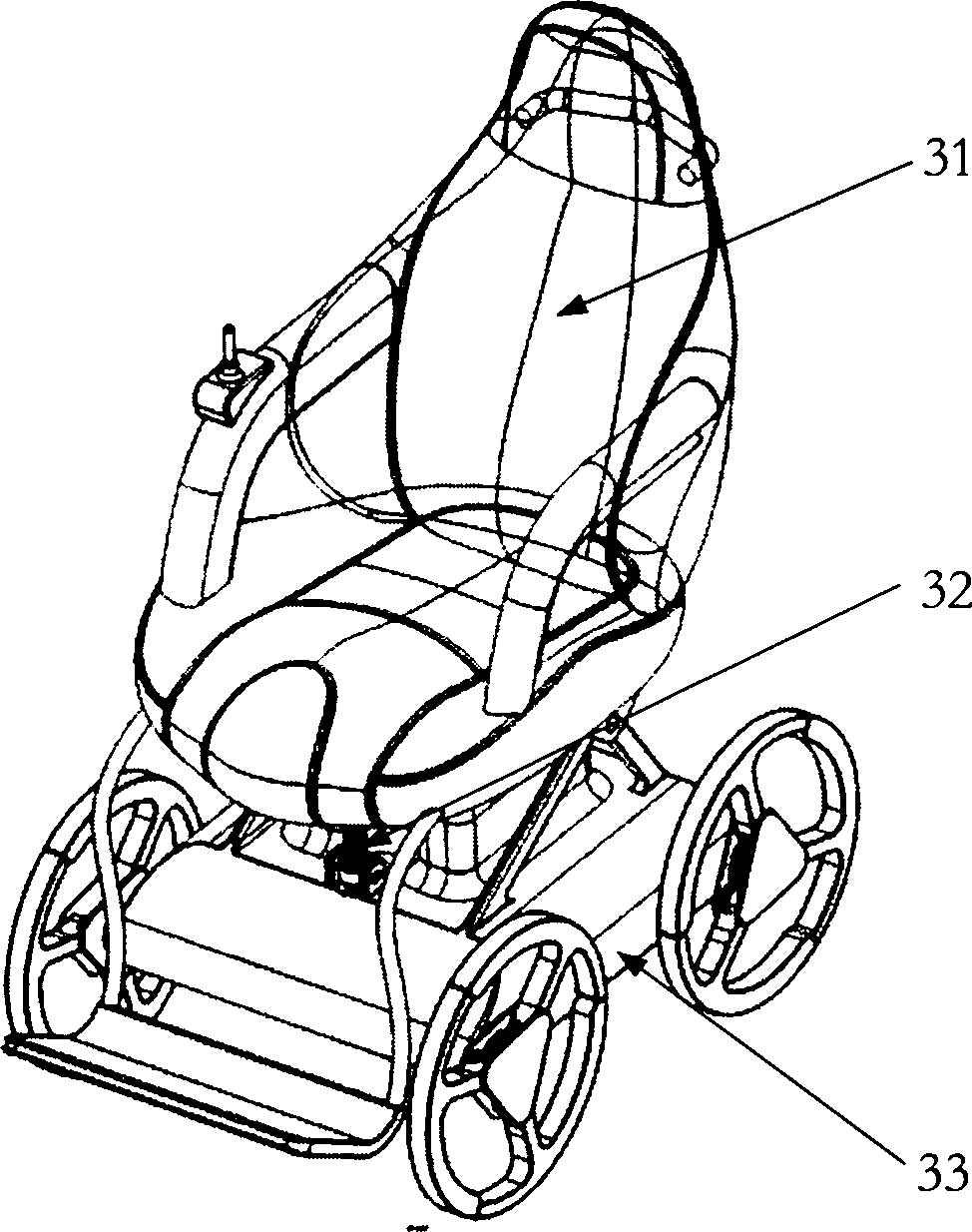

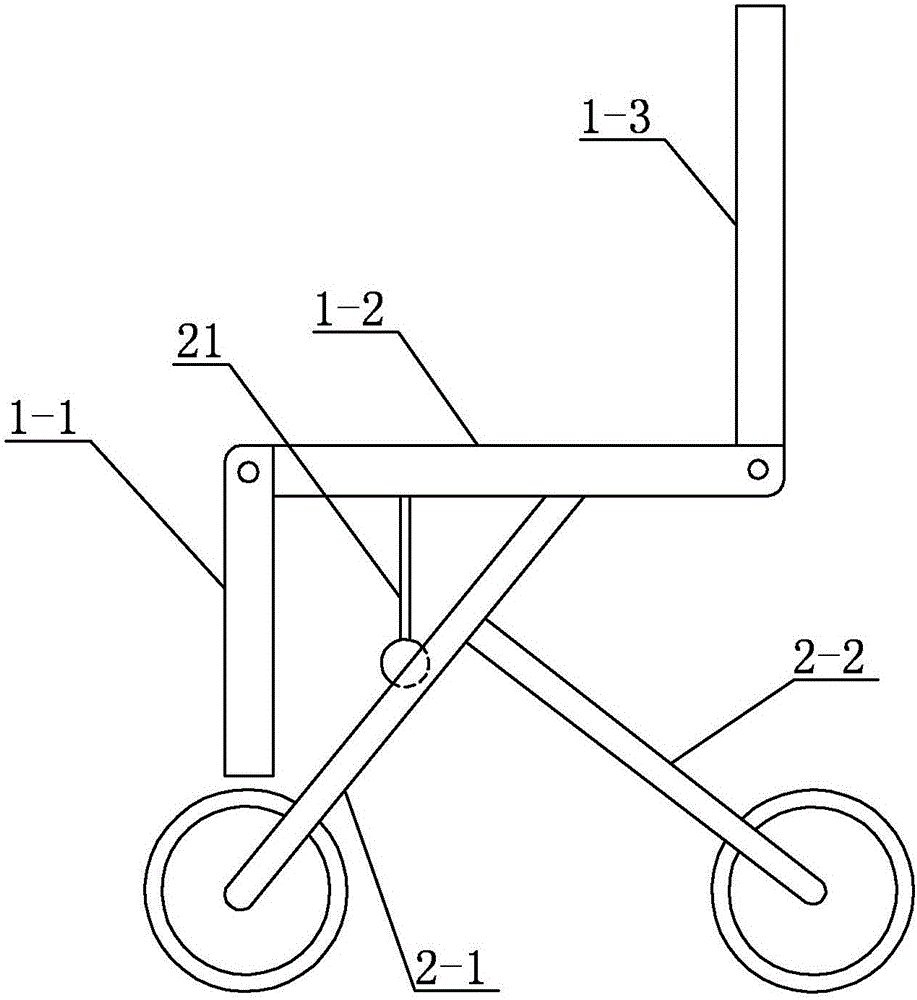

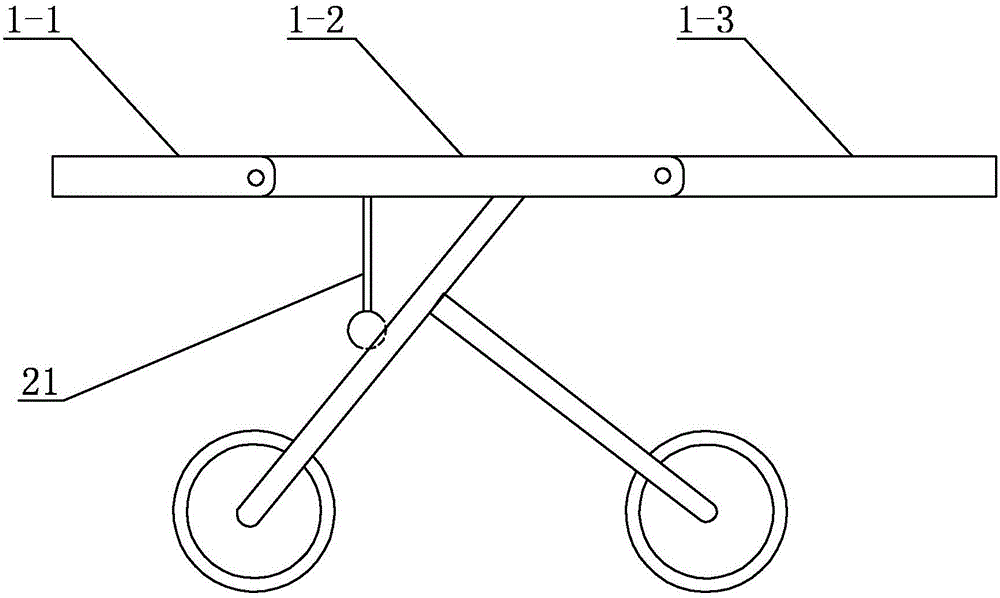

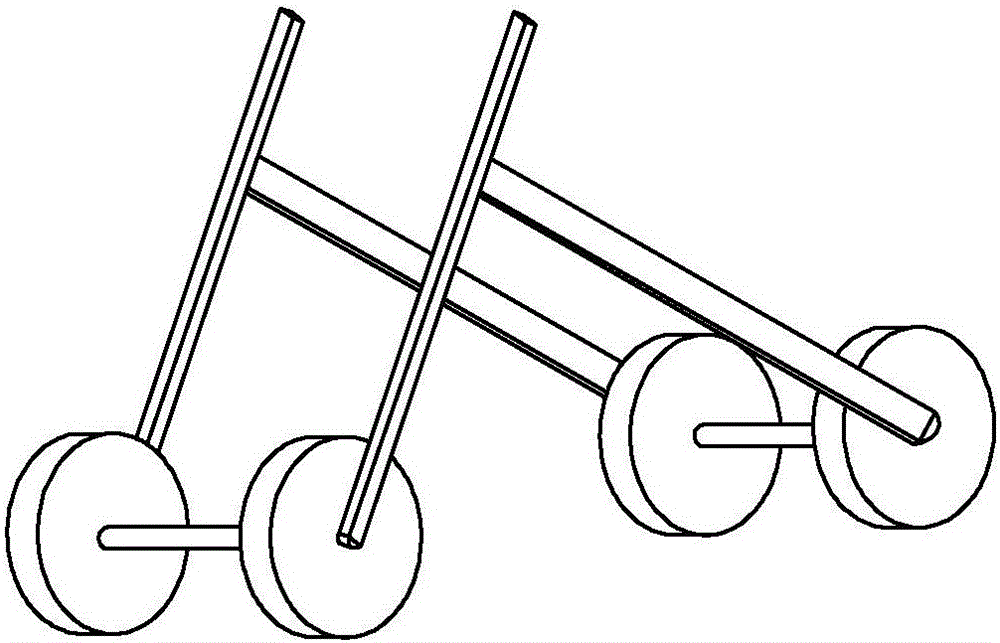

Wheelchair capable of climbing stairs

InactiveCN102860906ASmooth continuous motionImprove bearing capacityWheelchairs/patient conveyanceEffective solutionImpeller

The invention discloses a wheelchair capable of climbing stairs smoothly and running on flats. The wheelchair comprises a chair, a lifting device and a running part, wherein the running part is used for bearing the chair, the balance of the chair is kept under the action of the lifting device, the running part consists of a planetary wheel mechanism and a differential drive system, four working states of the wheelchair can be achieved through the combination of the planetary wheel mechanism and the differential drive system and the four working states comprise running on flats, turning on flats, stair descending and climbing and the shift between stairs and flats. The wheelchair is provided with two sets of drive mechanisms, an electric motor drives a central shaft through a straight-tooth cone gear, a planet carrier is driven through a clutch on the central shaft, and stretching and keeping of an impeller are achieved through transfer and linkage of the clutch and an arrester, i.e., differential and identical speed of the central shaft and the planet carrier. The wheelchair is adapted to prior stairs, runs stably and continuously, is good in bearing capacity and can run on flats. By the aid of the wheelchair, the living trip of the elderly and disabled persons is achieved.

Owner:谢哲

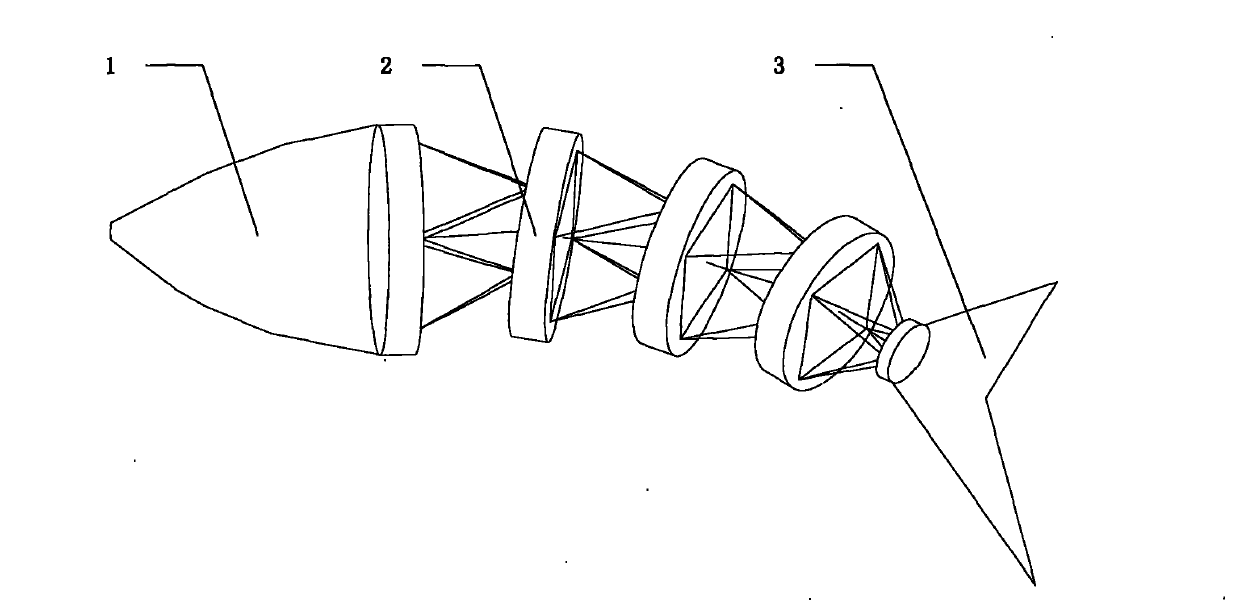

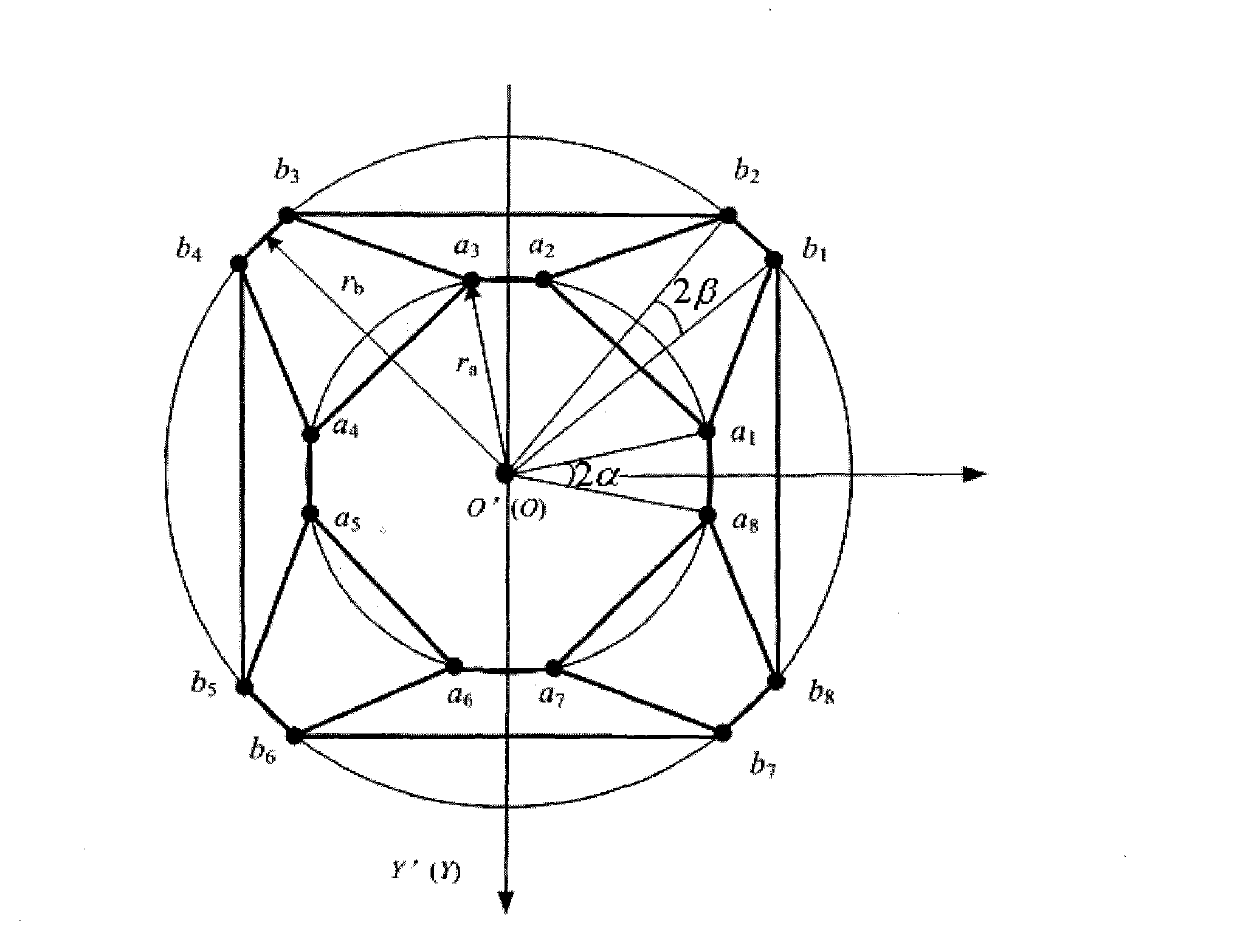

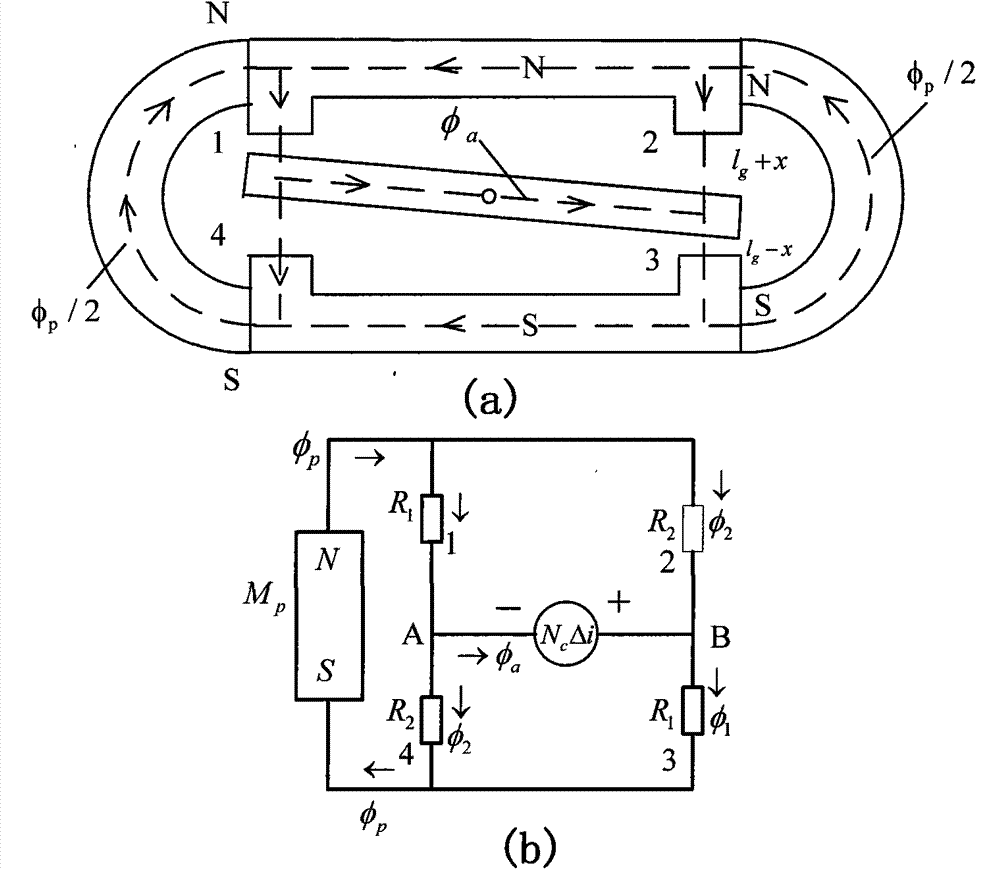

Variable rigidity bionic swinging propulsion unit

InactiveCN102673759ALarge thrustContinuous actionPropulsive elements of non-rotary typeHinge angleAerospace engineering

A variable rigidity bionic swinging propulsion unit comprises a support, more than two joints of swinging devices and a tail fin, wherein each swinging device comprises an upper platform, a lower platform, eighteen flexible hinge points, eight outriggers and a spinal column, a flexible hinge point o' is arranged at the center of the upper platform, a flexible hinge point o is arranged at the center of the lower platform, and the flexible hinge points o' and o are connected together through a spine; and the flexible hinge points are respectively connected with each other through the eight outriggers. The variable rigidity bionic swinging propulsion unit has the advantages that the variable rigidity bionic swinging propulsion unit has the characteristics of large thrust, continuous movement and good flexibility; and the propulsion efficiency is improved, and a variable rigidity energy-saving swimming mechanism for fishes is realized.

Owner:HARBIN INST OF TECH

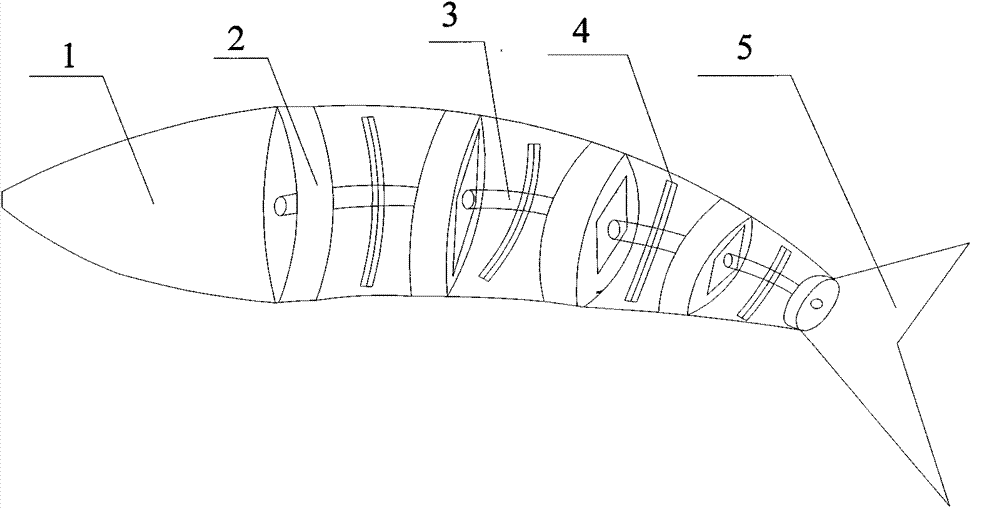

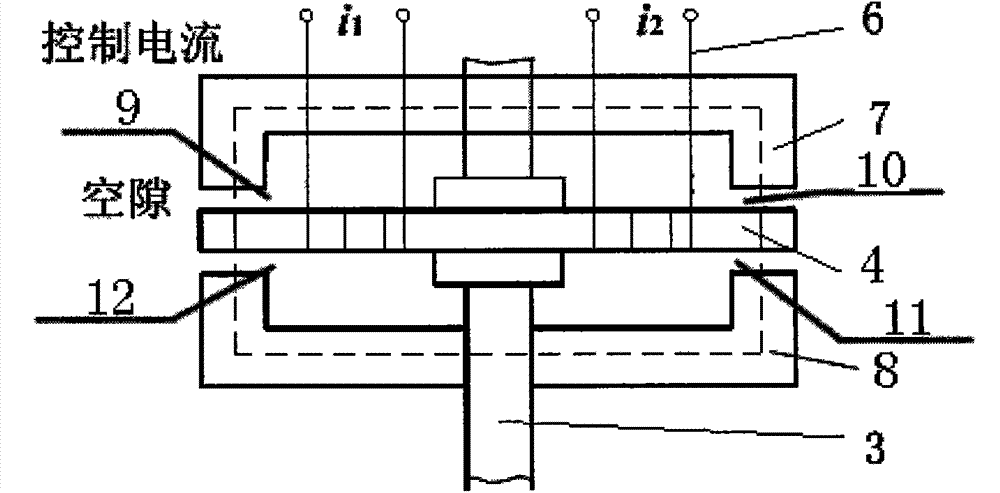

Electromagnetic drive variable-rigidity bionic swing propelling device

InactiveCN103612734ARealize variable stiffness controlLarge thrustAquatic toysPropulsive elements of non-rotary typeEngineeringSingle section

An electromagnetic drive variable-rigidity bionic swing propelling device comprises a support, at least two sections electromagnetic swing units and a tail fin. The whole shape of a fish body is sealed by a fish skin. The first section of electromagnetic swing unit is connected with the head of the head of the fish body. Other sections of electromagnetic swing units are connected with a flexible spine. The last section of electromagnetic swing unit is connected with the tail fin. The electromagnetic swing unit comprises an upper magnetic body, a lower magnetic body, control coils, the flexible spine and an armature. The flexible spine is hollow. A coil for controlling electric currents is embedded into the flexible spine. The upper magnetic body and the lower magnetic body are fixed on the flexible spine respectively. The armature is fixed in the middle of the upper magnetic body and the lower magnetic body. The middle of the armature is fixedly connected with the flexible spine. The control coils are sleeved at two ends of the armature. The flexible spine is driven to bend by the generated electromagnetic torque so as to drive the fish body to swing for propelling. The electromagnetic drive variable-rigidity bionic swing propelling device is small in size, light, continuous in action, easy to implement, low in noise and low in mechanical loss.

Owner:HARBIN INST OF TECH

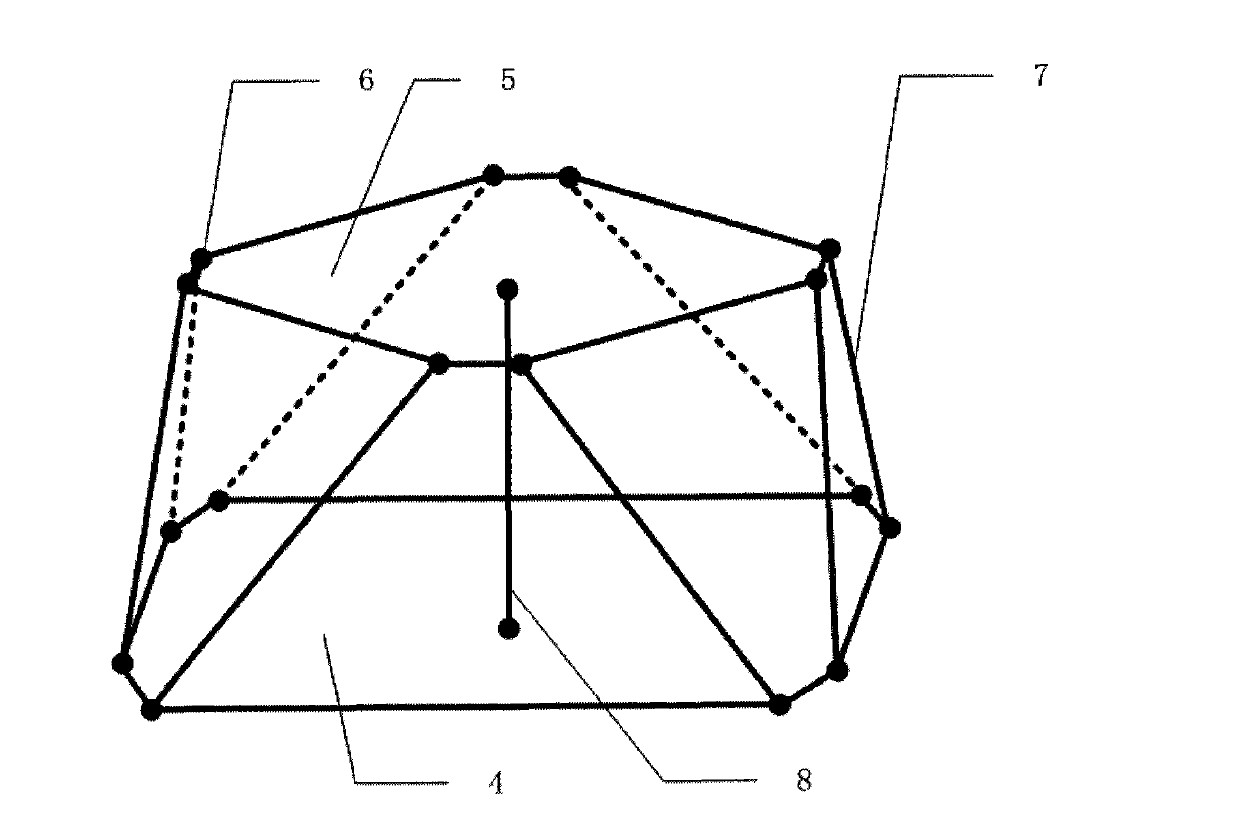

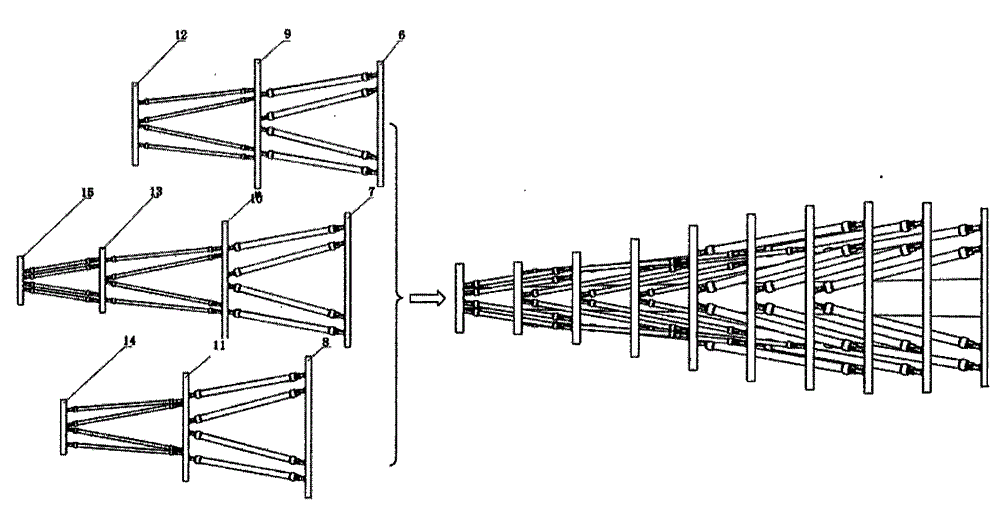

Telescopic type hyper-redundance series-parallel connection variable stiffness swinging and propelling device

ActiveCN104787283AGuaranteed single degree of freedom swingImprove flexibilityPropulsive elements of non-rotary typeVariable stiffnessMechanical engineering

A telescopic type hyper-redundance series-parallel connection variable stiffness swinging and propelling device comprises a head portion, a redundant drive parallel connection mechanism and a tail fin, and the redundant drive parallel connection mechanism comprises a plate spring spine, supporting legs, flexible hinges, a first stage parallel connection mechanism upper platform, a first stage parallel connection mechanism lower platform, a second stage parallel connection mechanism upper platform, a second stage parallel connection mechanism lower platform, a third stage parallel connection mechanism upper platform, a third stage parallel connection mechanism lower platform, a fourth stage parallel connection mechanism upper platform, a fifth stage parallel connection mechanism upper platform, a sixth parallel connection mechanism upper platform and a seventh parallel connection mechanism upper platform; the center of each platform is fixedly connected with the plate spring spine; the eight flexible hinges are uniformly distributed on each platform, and the flexible hinges of the upper platform and the flexible hinges of the corresponding lower platform are connected with the supporting legs; the first stage parallel connection mechanism and the fourth stage parallel connection mechanism form a first set of parallel connection mechanism, the second stage parallel connection mechanism, the fifth stage parallel connection mechanism and the seventh parallel connection mechanism form a second set of parallel connection mechanism, the third parallel connection mechanism and the sixth parallel connection mechanism form a third set of parallel connection mechanism, and the three sets of parallel connection mechanisms are staggered with one another and telescoped. The device has the advantages of being high in thrust, continuous in movement and good in flexibility.

Owner:HARBIN INST OF TECH

Robot wheelchair vehicle

ActiveCN106038104AImprove applicabilityReduce weightWheelchairs/patient conveyanceWheelchairEngineering

The invention discloses a robot wheelchair vehicle, and relates to a wheelchair vehicle. At present, most wheelchairs, which are designed to assist physically disabled patients and people difficult to move in riding instead of walk, are single in function and poor in emergency effect. According to the wheelchair vehicle, a leg moving system is arranged on the lower end face of a seat plate in power; the leg moving system comprises a front leg connecting, a rear leg connecting shaft and two groups of herringbone regulating brackets; a walking wheel assembly is arranged on each front leg rod and a walking wheel assembly is arranged on each rear leg rod; the two walking wheel assemblies on the two front leg rods are connected by virtue of the front leg connecting shaft; the two walking wheel assemblies on the two rear leg rods are connected by virtue of the rear leg connecting shaft; the front leg connecting shaft and the rear leg connecting shaft are rotated by virtue of a power supply; and each pawl can make an action of extending out of a corresponding hub or shrinking into the hub. The robot wheelchair vehicle disclosed by the invention is applicable to medicine and daily lives; in addition, the robot wheelchair vehicle is also provided with image pickup and sensor devices; and the wheelchair, when transformed into a stretcher vehicle, can serve as a rescuing device, a detection vehicle and a scout vehicle; therefore, the wheelchair vehicle achieves multiple purposes.

Owner:鄢俊

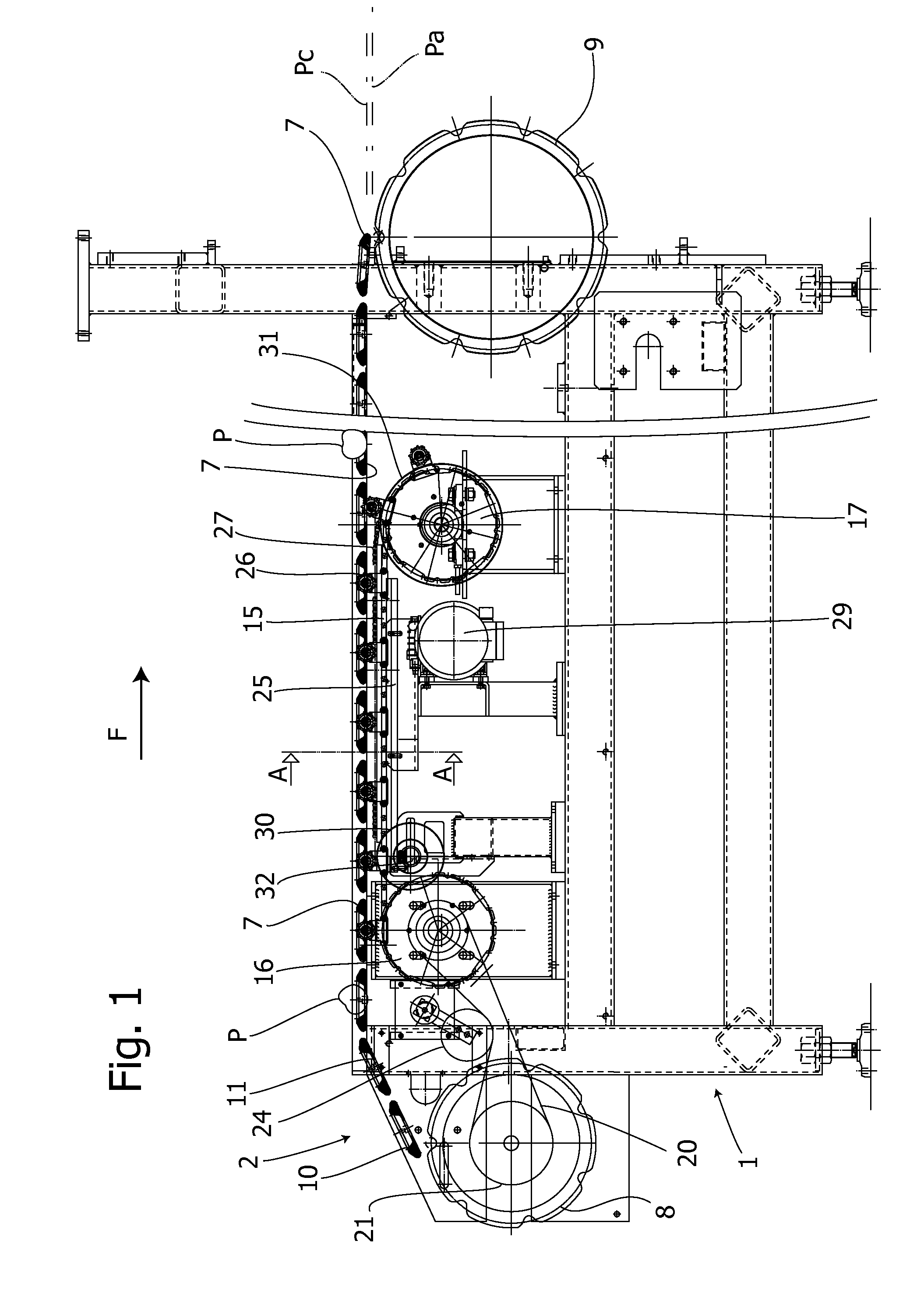

Apparatus for positioning multiple-lane fruit, especially peaches

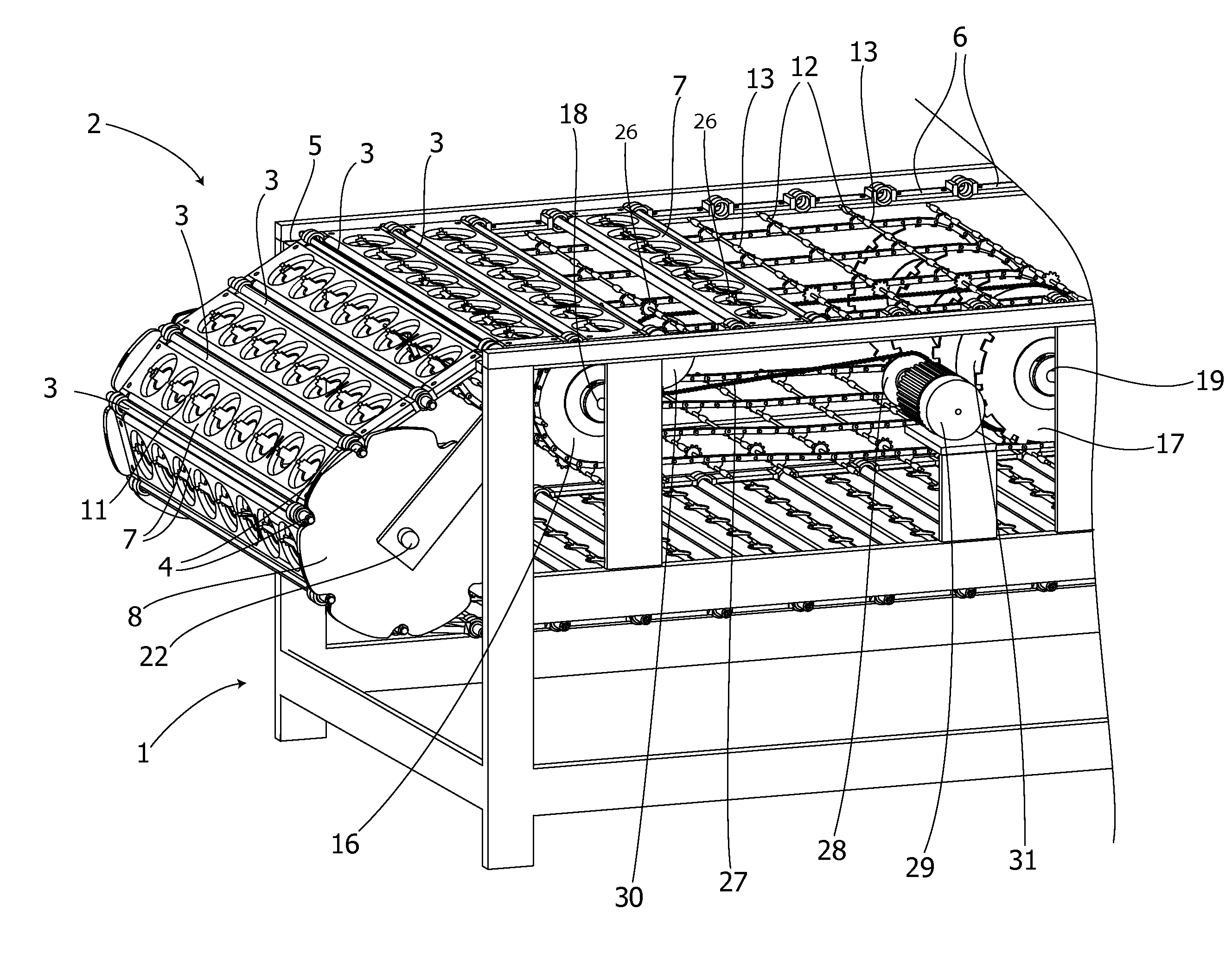

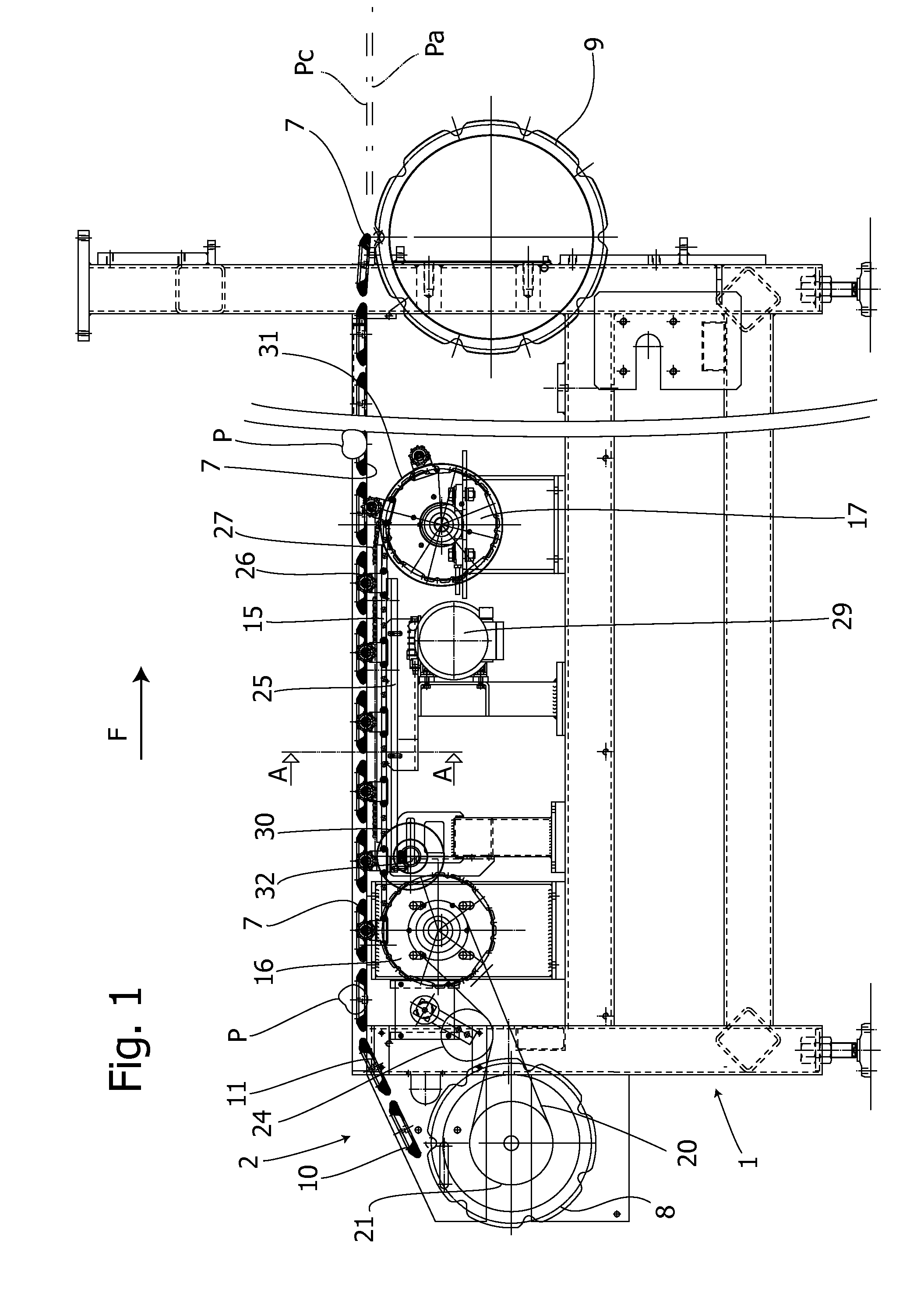

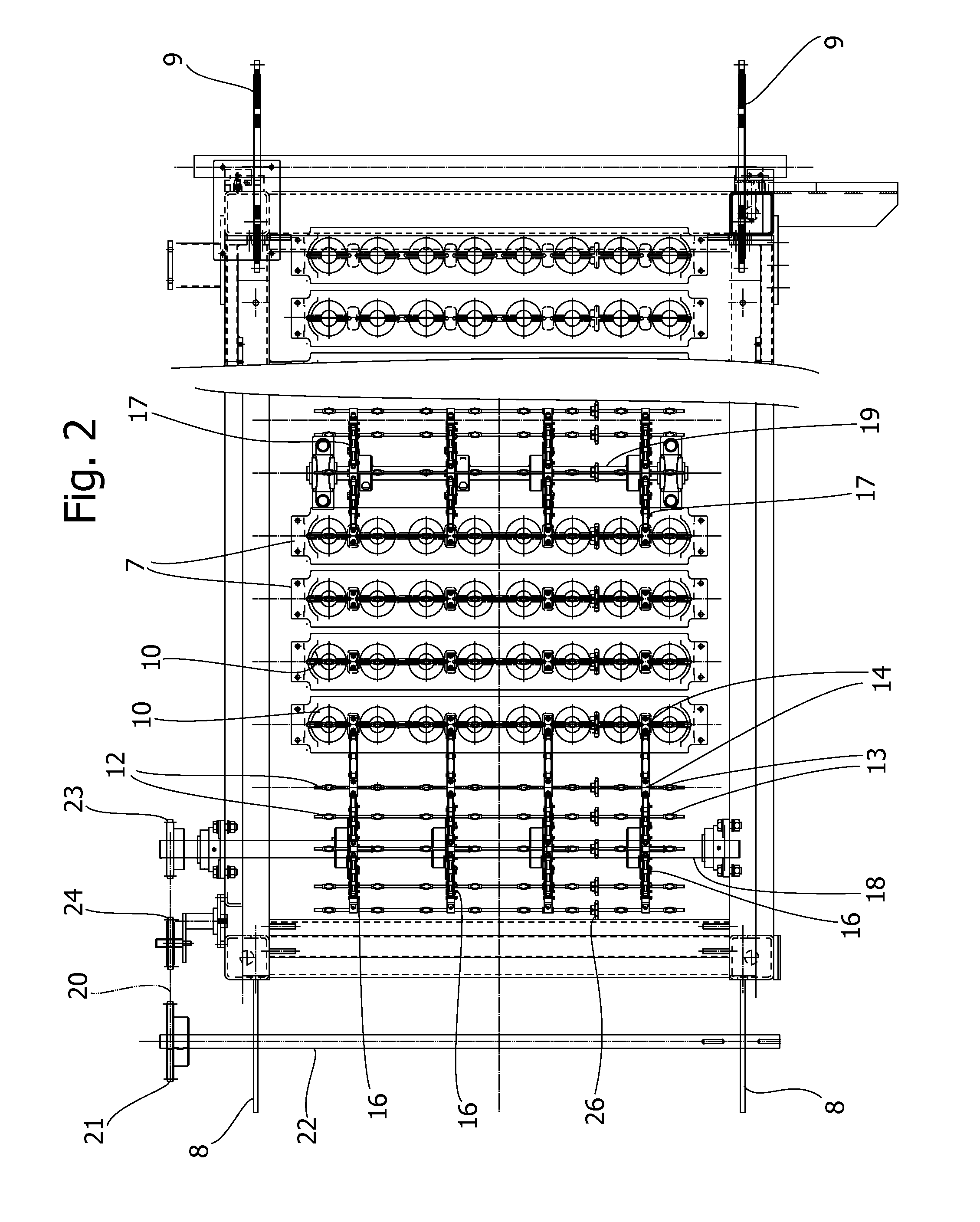

A multiple-lane fruit positioning apparatus, especially suitable for peaches, includes a fruit flight conveyor having fruit holding flights with a number of recesses provided with an opening through which a part of the fruit protrudes. Associated to the fruit flight conveyor is an orientation device including rotating transverse shafts carrying rigidly connected orienting elements. The transverse shafts travel on an operation plane (Pa) that is parallel to a working stroke plane (Pc) of a tape formed by the fruit holding flights in time with a tape of the fruit flight conveyor so that each orienting element, rotating jointly with each transverse shaft by which it is borne, is in the recess opening in contact with the fruit contained therein and moves the fruit until a plane containing the suture line of each fruit is positioned at right angles with the longitudinal direction, and the stalk cavity thereof faces downwardly.

Owner:CRESCENZO BIAGIO

Movement trajectory achieving method of medical bed with patient transfer function

InactiveCN105496689ASmooth motionContinuous actionNursing bedsOptical transfer functionSignal transfer function

The invention discloses a movement trajectory achieving method of a medical bed with a patient transfer function. The method is characterized in that a driving screw rod is controlled to rotate, the driving screw drives a trajectory control wheel to move linearly, the trajectory control wheel works by abutting against a first controller, a second controller, a third controller and the second controller in sequence, continuous rotation, rising, horizontal movement, descending and ascending motions of a first bed board and a second bed board can be achieved, and the motion continuity is improved. An accompanying nurse only needs to fix the position of a wheelchair in advance, then the driving screw rod is operated to rotate, and therefore a patient can be rotated. Operation is stable, the motions are continuous, operation is simple, single-person operation is achieved, the method accords with the human body characteristics, and discomfortableness is avoided; the normal using function of the medical bed is not affected; the medical bed can achieve body muscle activities when the steps 1 and 2 are repeatedly executed, long-term oppression to the body muscles and blood vessels can be reduced, and the risks of unsmooth blood flow and amyotrophy are reduced.

Owner:张合明 +3

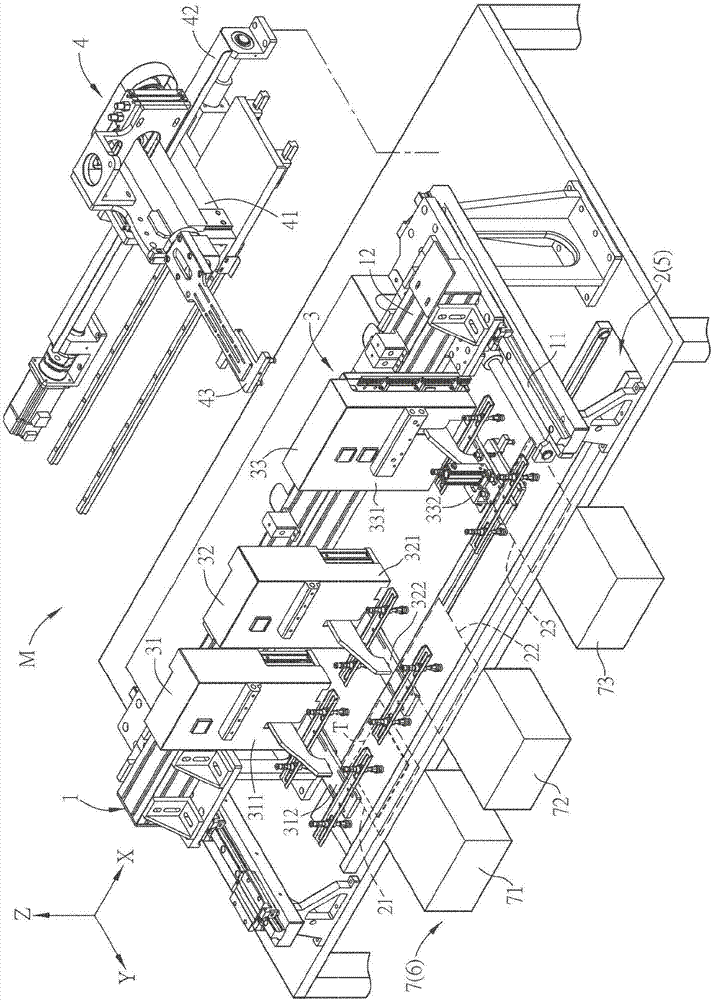

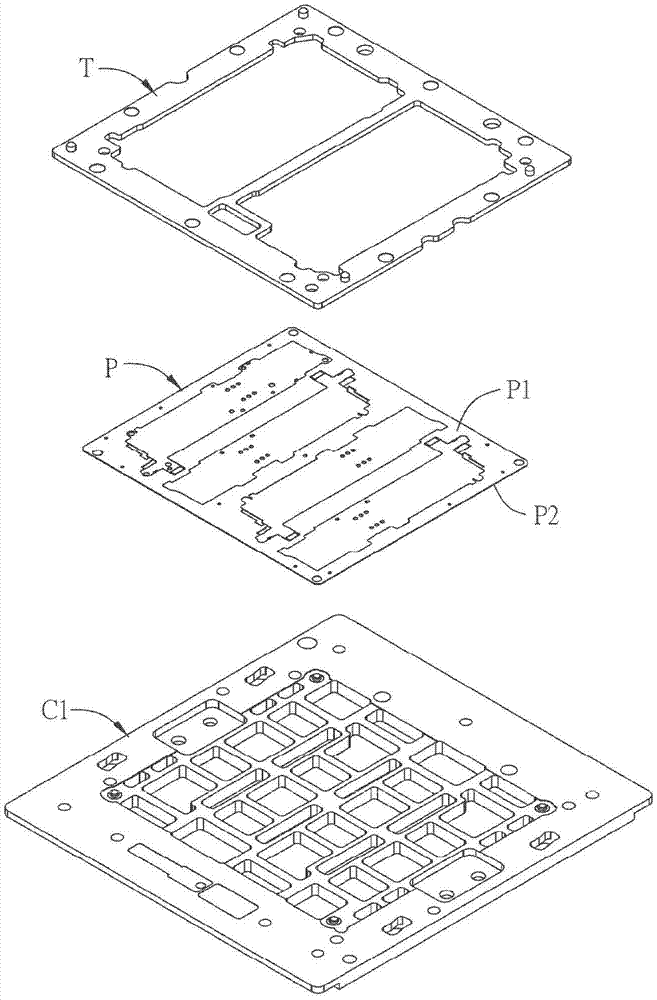

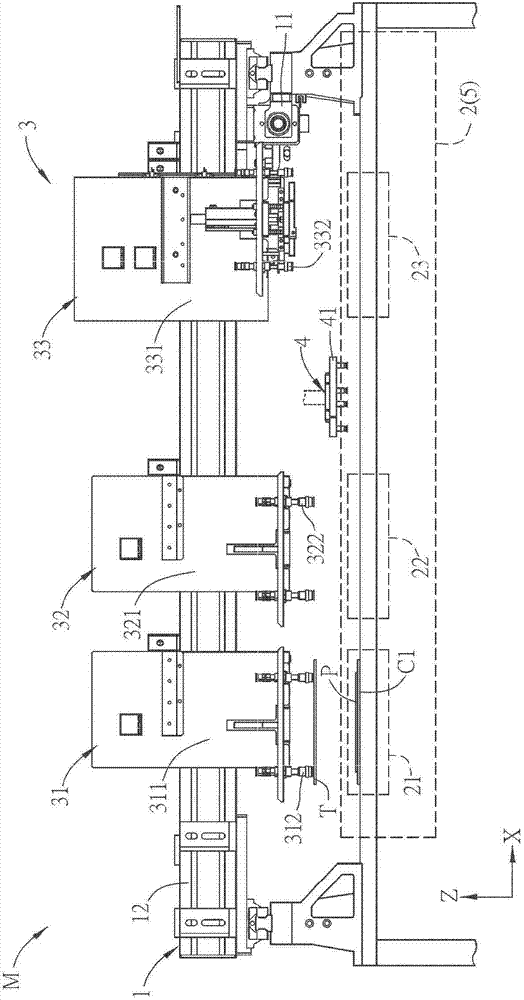

Turning pick-and-place machine

InactiveCN104780713AContinuous actionPrinted circuit assemblingEngineeringElectrical and Electronics engineering

The invention discloses a turning pick-and-place machine comprising a displacement device, a transmission device, a pick-and-place device, and a turning device. The transmission device has a first station, a second station, and a third station. The first station carries a work piece which is clamped between a tablet and a first carrier. The third station carries a second carrier. The pick-and-place device is arranged on the displacement device, and comprises a first pick-and-place module, a second pick-and-place module and a third pick-and-place module. The first pick-and-place module corresponds to the first station to pick the tablet, and the work piece and the first carrier are transmitted to the second carrier. The second pick-and-place module corresponds to the second station to pick the first carrier. The third pick-and-place module corresponds to the third station to put the work piece on the second carrier. The turning device picks the work piece from the second station, turns the work piece, and transmits the work piece to the third pick-and-place module.

Owner:PROTEK SHANGHAI +1

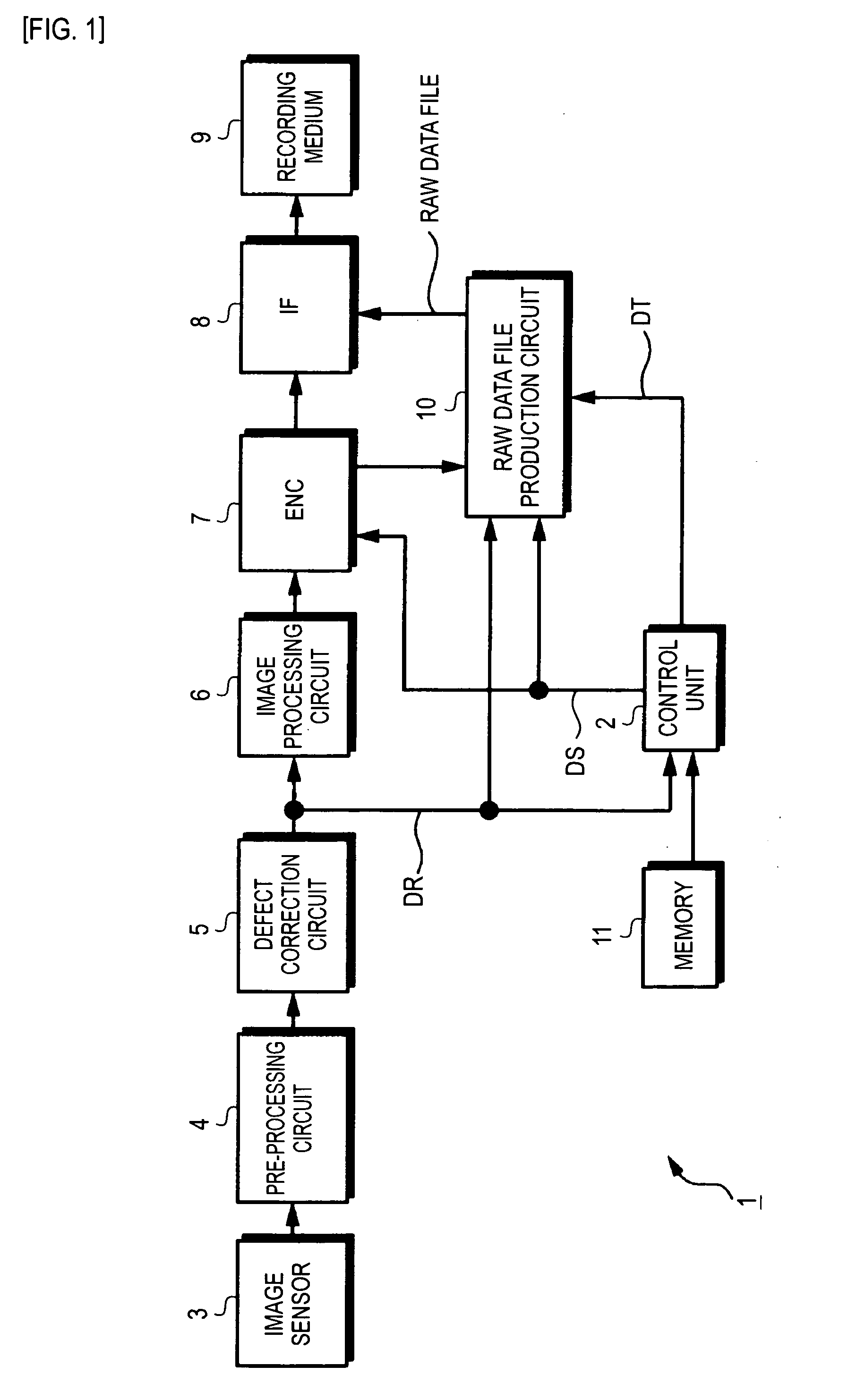

Signal processing method and signal processing system

InactiveUS20100118186A1Little degradationThinning is speededTelevision system detailsGeometric image transformationImage resolutionThumbnail Image

A signal SG41 that has color signals thereof time-sequentially arranged in a color array corresponding to the color array in an image sensor 3 and that has not undergone resolution conversion is subjected to resolution conversion at a conversion rate (for example, ⅓) specified by a phase retention resolution conversion section 42. A de-mosaicing processing section 44 converts a signal SG42, which represents the order of the color array in the image sensor, into RGB signals SG44. A thin-line retention resolution conversion section 45 converts the signals SG44 into signals SG45 at a specified conversion rate (for example, ½). The signals SG45 are compressed by an encoder. In a recording medium 9, YC signals SG48 representing (640×480) pixels, the color signals SG42, a signal SG51 representing (640×480) pixels in the order of a color array and serving as thumbnail image data DT, and imaging information are recorded.

Owner:IMAGE PROCESSING TECH

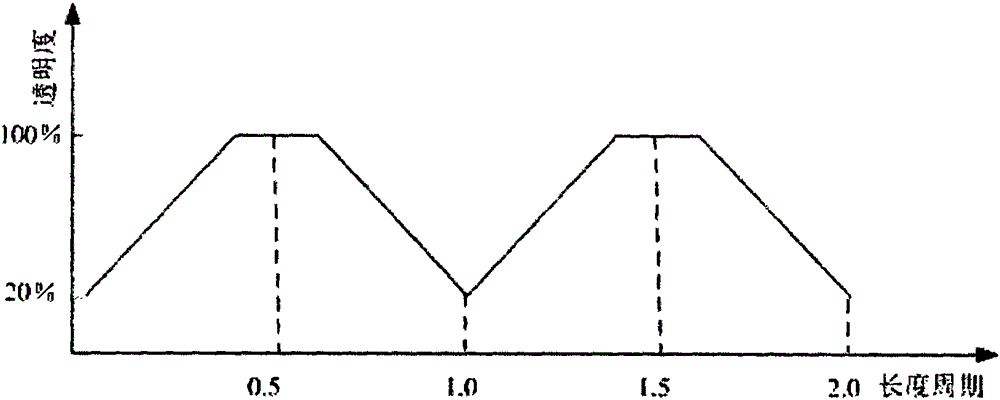

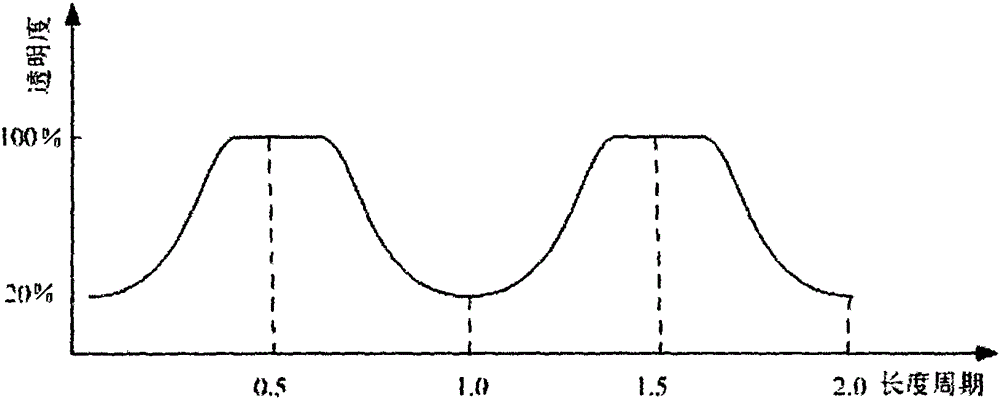

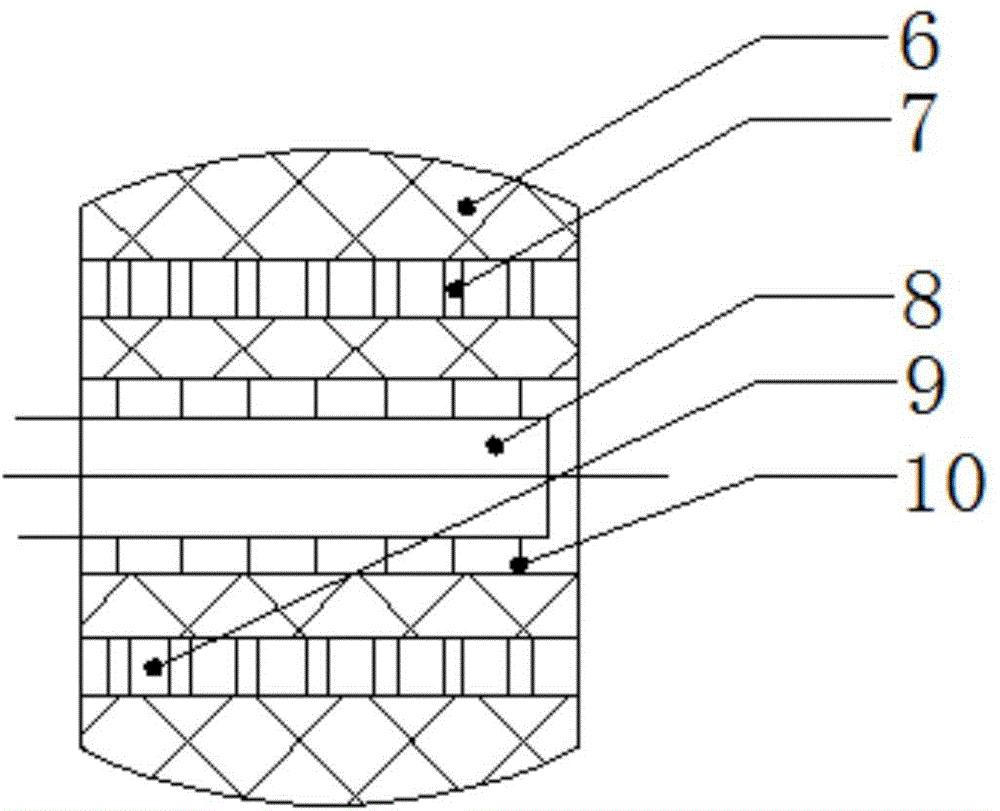

LED screen cover with transparent circular holes formed by multilayer periodical change black nets

The invention belongs to the field of LED display, and in particular relates to an LED screen cover with transparent round holes formed by multi-layer periodically changing black nets. A kind of LED screen cover with transparent circular holes formed by multi-layer periodically changing black nets. The black mesh forms round holes distributed in a dot matrix. There is no black mesh in the round holes, which maintains the transparency of the screen body and is a light-transmitting round hole. The beneficial effect of the present invention is that the shield body reduces the luminous intensity of the pixel unit; and the light transmission in part of the light-transmitting area restrains the mutual crosstalk between pixels, and the part of the light-transmitting area emits light, reducing the periodicity existing in the prior art The black area network structure, strong graininess, glaring local light intensity, and technical shortcomings that are not suitable for close viewing. The beneficial effect is that the PC plastic paper can be hot-compressed or printed or spray-painted, which can satisfy large-scale display on a large screen, has good display effect, low cost, simple technology, and scrub resistance.

Owner:南引明

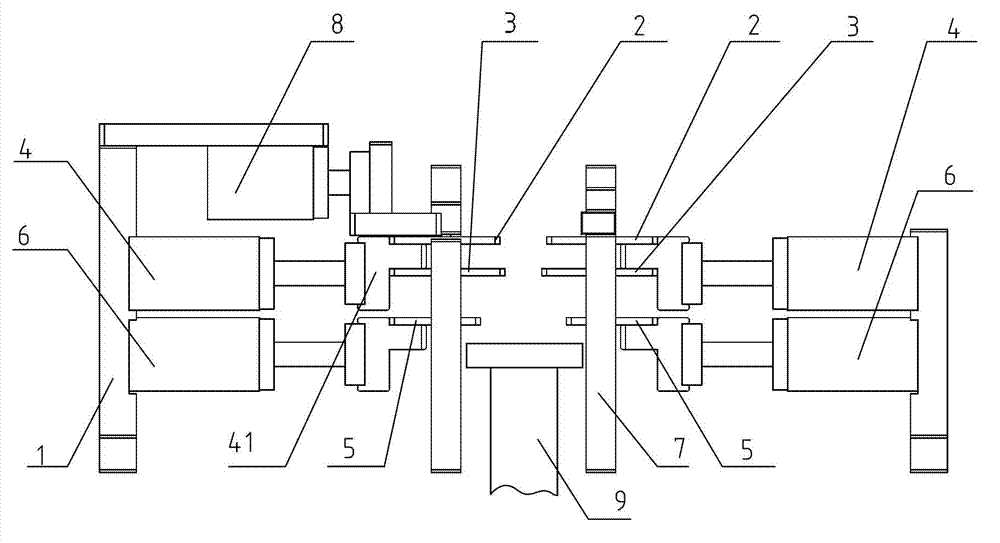

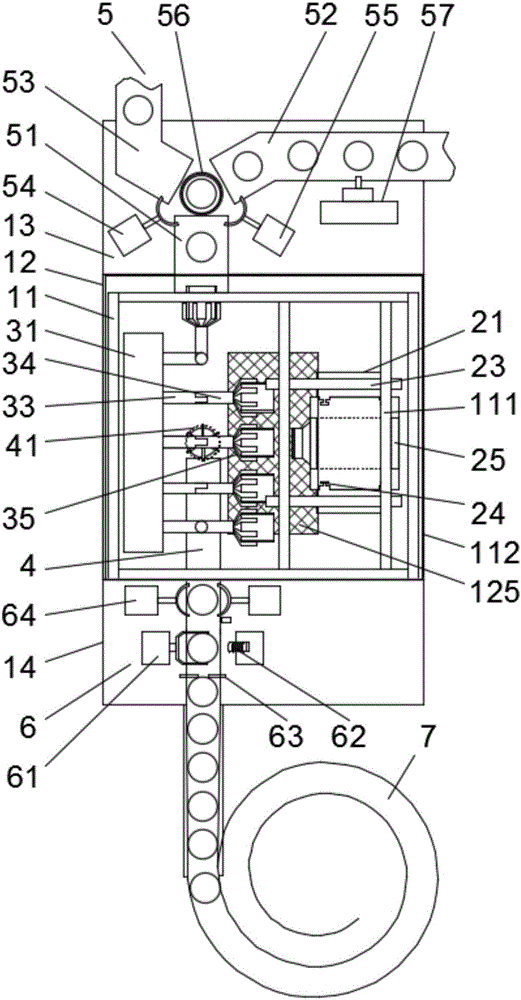

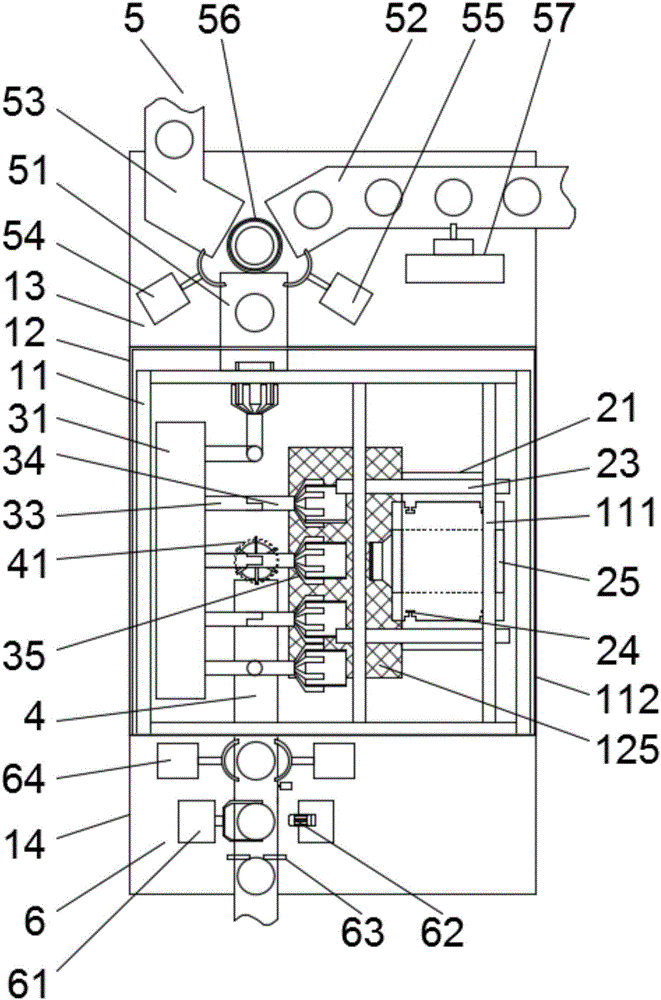

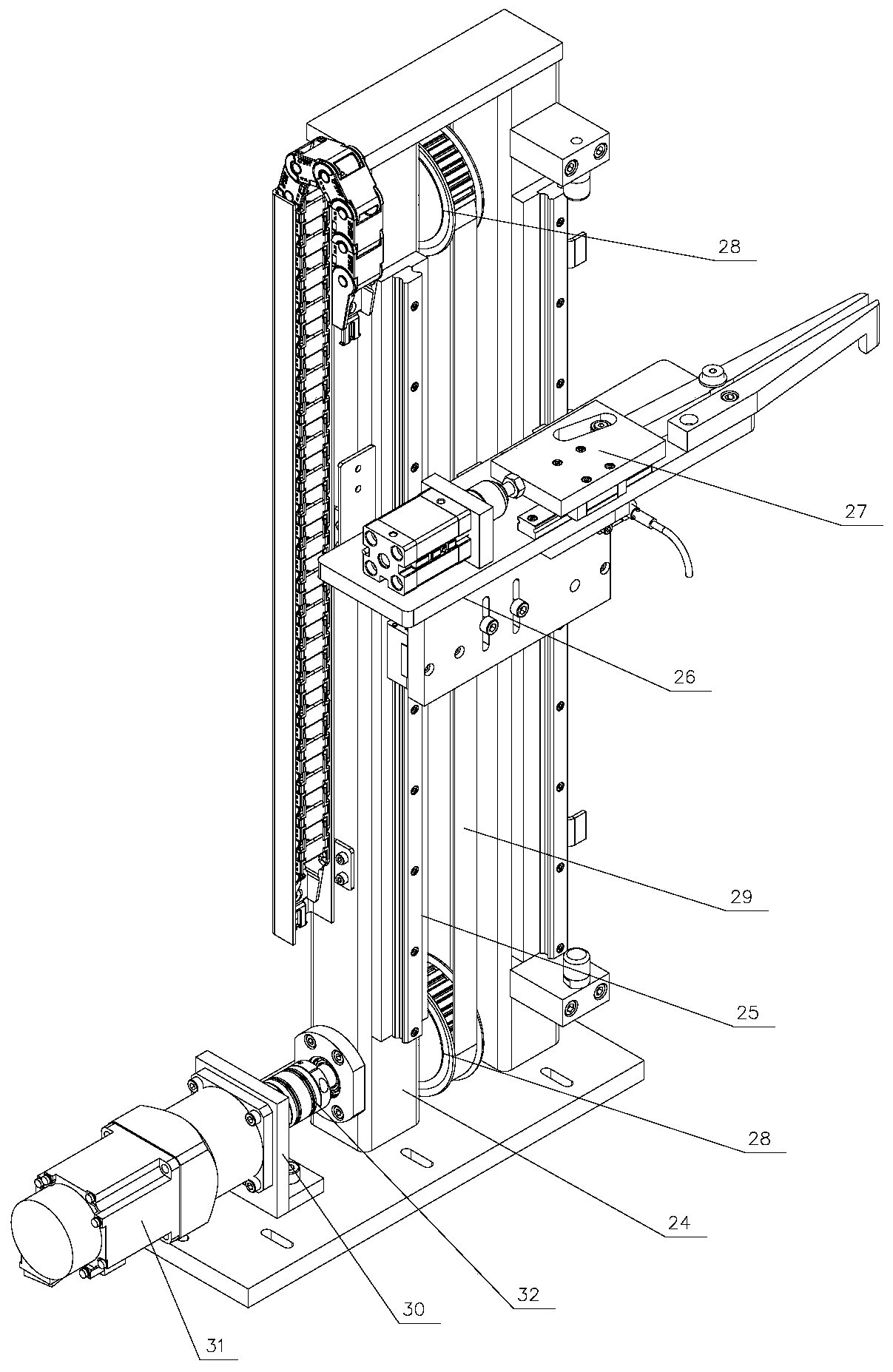

Laminating mechanism of storage battery electrode plate packing machine

ActiveCN103117408AIncrease productivityContinuous actionFinal product manufactureSecondary cells manufactureEngineeringMechanical engineering

The invention provides a laminating mechanism of a storage battery electrode plate packing machine, which relates to production devices of storage batteries, and solves the problems of an existing packing device that the fall between a dropped lifting platform and a supporting plate of a laminating mechanism is relatively large, so that an electrode plate breaks or drops when continuously dropping, and the process can be continuously repeated only after the lifting platform resets. The laminating mechanism comprises a rack which is provided with two opposite side baffles, wherein the side baffles are provided with upper supporting plates and lower supporting plates, which can transversely move; a blanking device is arranged just above the upper supporting plates; the lower supporting plates are connected with packing openings of the electrode plate packing machine; a lifting platform is arranged below the lower supporting plates; and a cushioning supporting plate capable of transversely moving is arranged between the lifting platform and each lower supporting plate. In a resetting process of the lifting platform, the cushioning supporting plate can temporarily collect electrode plates, and the lamination process is continuous without waiting, so that the production efficiency of the electrode plate packing machine is improved.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

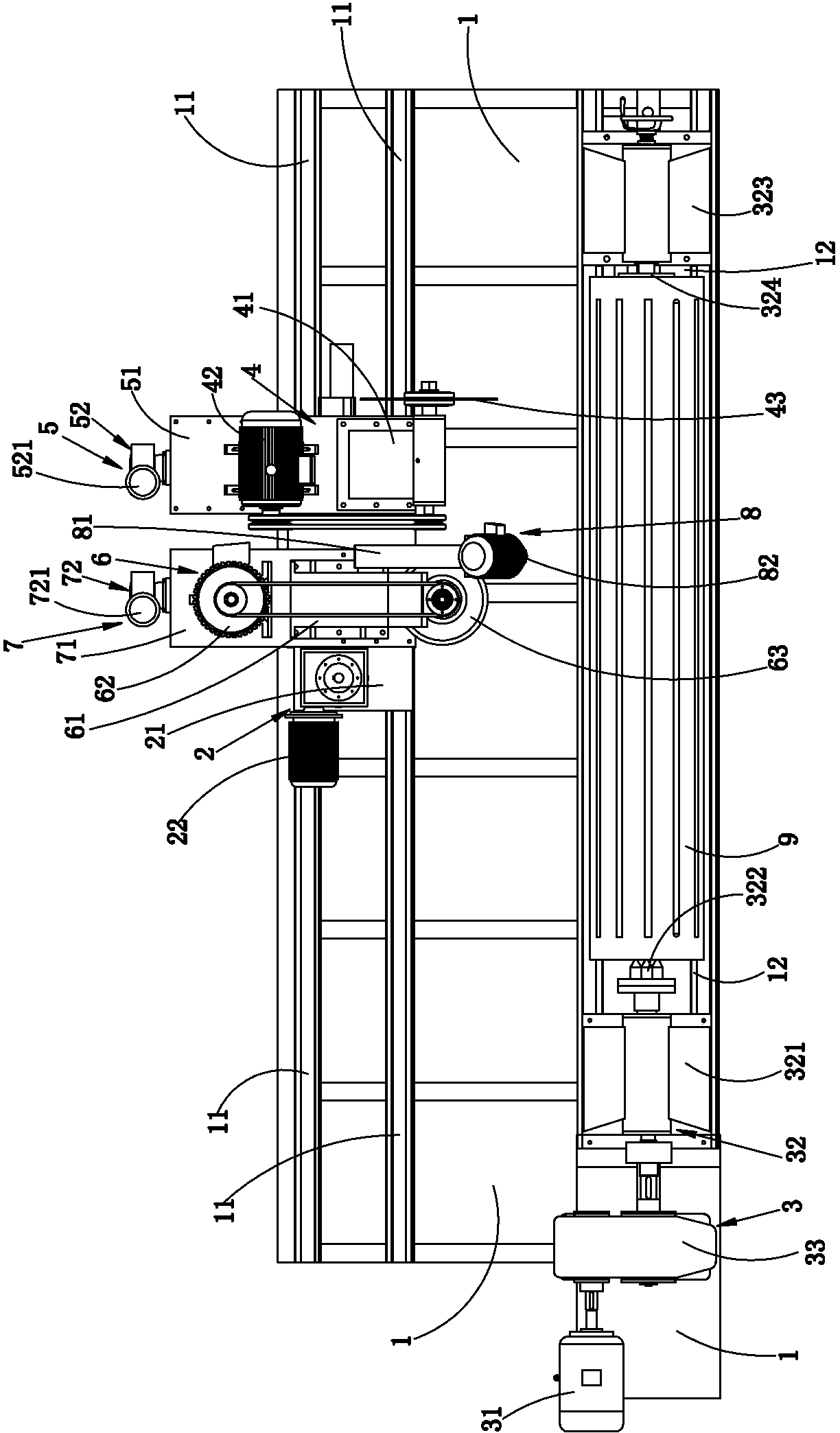

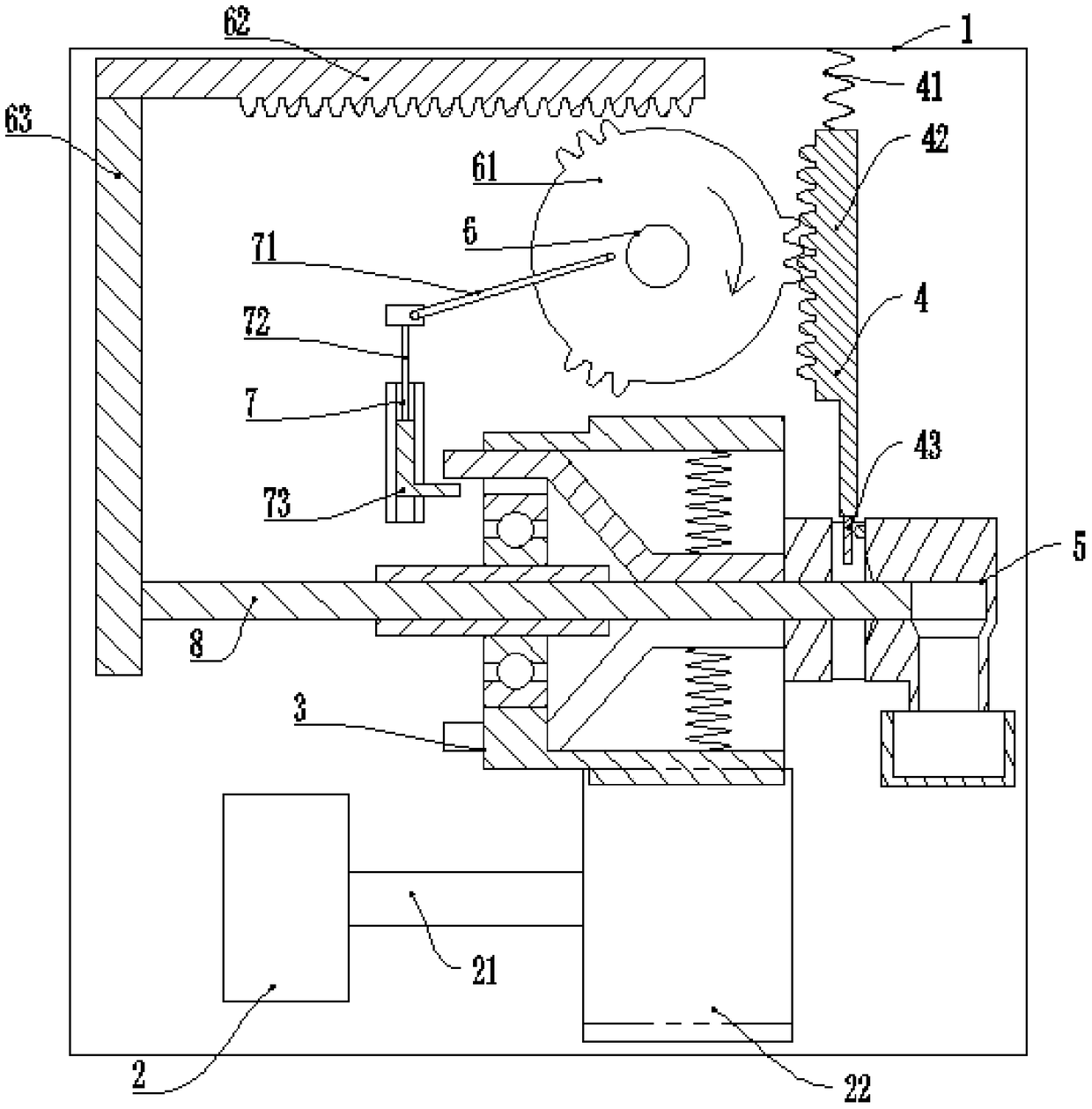

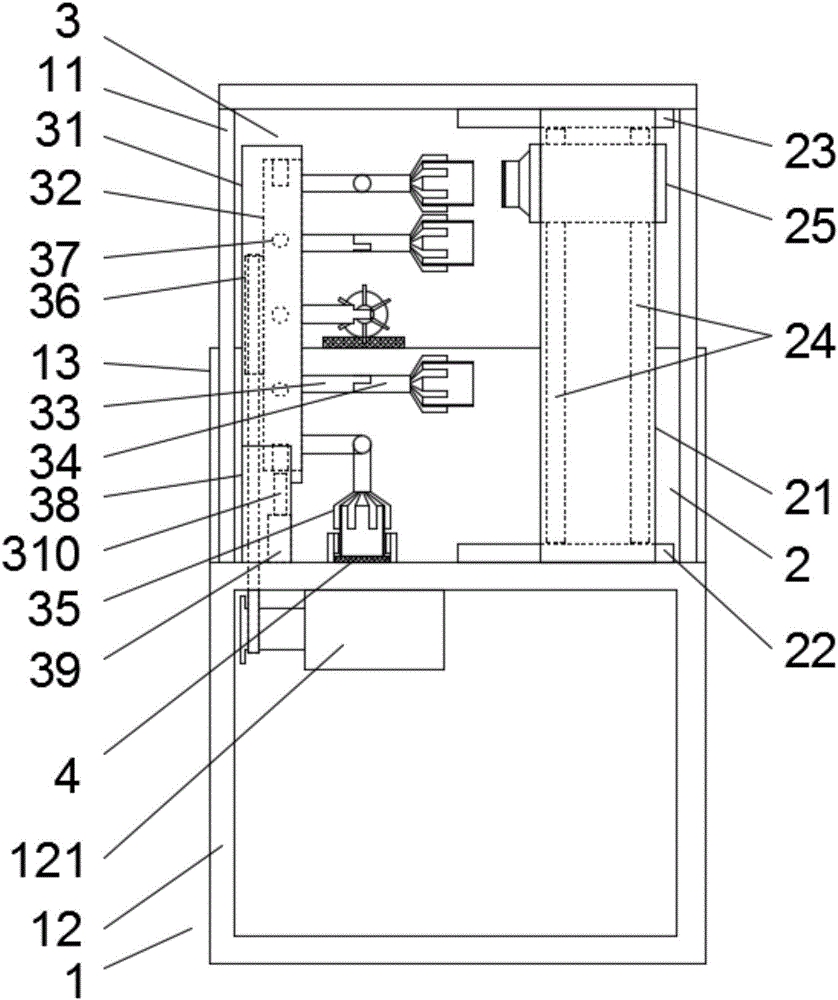

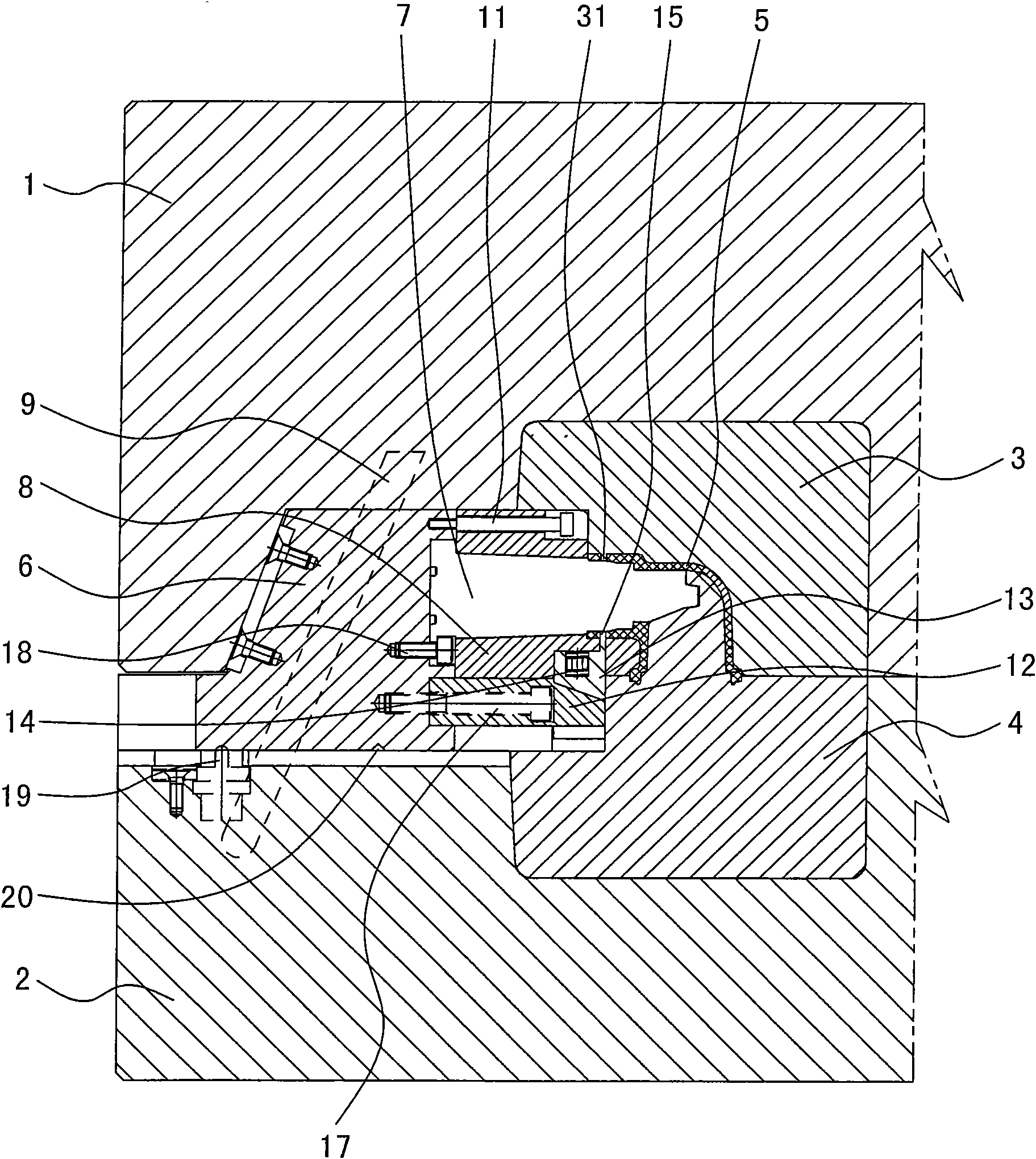

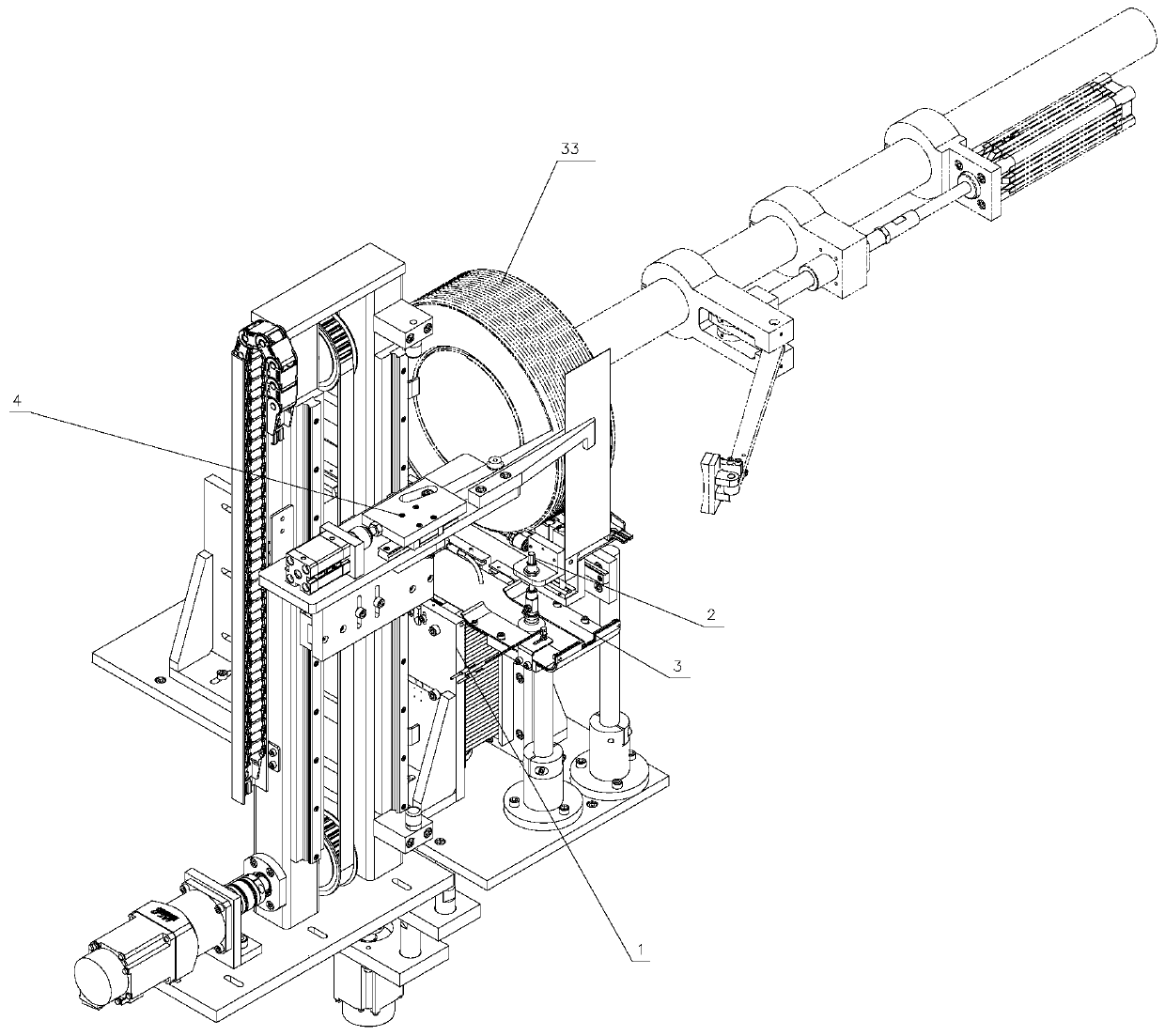

Automatic marble pillar machining device and machining method thereof

ActiveCN104260211AImprove processing efficiencyConsistent shapeRevolution surface grinding machinesStone-like material working toolsEngineeringMachining

The invention relates to an automatic marble pillar machining device and a machining method thereof. The machining device comprises a control device, a base, a travelling mechanism, a rotating mechanism, a pillar carving mechanism, a pillar carving driving and reversing mechanism, a grooving mechanism and a grooving driving and reversing mechanism, wherein the travelling mechanism, the rotating mechanism, the pillar carving mechanism, the pillar carving driving and reversing mechanism, the grooving mechanism and the grooving driving and reversing mechanism are assembled on the base, and the control device is used for controlling the mechanisms to act in sequence. The machining method is characterized in that by the aid of the machining device, under control of the control device, the mechanisms act in sequence, and a stone to be machined and assembled on the rotating mechanism is sequentially carved, grooved and polished to obtain a marble pillar. By the aid of the automatic marble pillar machining device, the stone to be machined can be automatically cut into the polished finished marble pillar, the whole machining process is continuous in action and accurate in plunge-cut position, the machining efficiency of the marble pillar is effectively improved, production cost is effectively reduced, marble pillars with different diameters, lengths, groove numbers and groove line types can be machined, and categories of the marble pillars are rich and varied.

Owner:QUANZHOU MINYAN STONE MACHINERY CO LTD

Apparatus for positioning multiple-lane fruit, especially peaches

ActiveUS20140131174A1Sufficient and effectiveContinuous actionConveyorsFruit stoningEngineeringMechanical engineering

A multiple-lane fruit positioning apparatus, especially suitable for peaches, includes a fruit flight conveyor having fruit holding flights with a number of recesses provided with an opening through which a part of the fruit protrudes. Associated to the fruit flight conveyor is an orientation device including rotating transverse shafts carrying rigidly connected orienting elements. The transverse shafts travel on an operation plane (Pa) that is parallel to a working stroke plane (Pc) of a tape formed by the fruit holding flights in time with a tape of the fruit flight conveyor so that each orienting element, rotating jointly with each transverse shaft by which it is borne, is in the recess opening in contact with the fruit contained therein and moves the fruit until a plane containing the suture line of each fruit is positioned at right angles with the longitudinal direction, and the stalk cavity thereof faces downwardly.

Owner:CRESCENZO BIAGIO

Assembly line type automatic grinding machine

ActiveCN106217204AContinuous actionClamp fasteningGrinding carriagesGrinding feed controlEngineeringAssembly line

The invention relates to an assembly line type automatic grinding machine. The assembly line type automatic grinding machine comprises a rack, wherein the rack comprises a lower rack and a grinding machine upper rack; a grinding device and a rotary disc type clamping device are arranged in the grinding machine upper rack; the lower rack is provided with a rotary disc driving motor; a feeding conveyor belt is arranged on the rack; a discharging platform is further arranged on the rack, and a discharging conveyor belt is arranged on the discharging platform; the bottom end of the feeding conveyor belt is further provided with a feeding CCD detection device; the discharging conveyor belt is provided with a counting sensor, and a laser marking device is arranged at the outlet part of the discharging conveyor belt; the rack is provided with a feeding platform; an adjusting device and a vibrating plate are arranged on the feeding platform; the adjusting device sequentially comprises a feeding baffle, a rotating cylinder and an aligning device in a conveying direction; an azimuth detection device is further arranged near the rotating cylinder; and the right side of the rack is further provided with a sprinkling chamber and a drying chamber. The assembly line type automatic grinding machine continuously acts, automatically carries out clamping and fastening, is short in time consumption, is accurate in locating and ensures workpiece machining quality.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

Slicer

ActiveCN109115571AContinuous actionReduce labor costsPreparing sample for investigationDrive motorEngineering

The invention belongs to the technical field of cable equipment and particularly discloses a slicer which comprises a rack, a drive motor, a clamping mechanism, a cutting mechanism, a feeding mechanism and a material falling seat; the drive motor drives the clamping mechanism to rotate; the feeding mechanism comprises a partial gear, a push plate and a transverse rack which transversely slides; the transverse rack is engaged with the partial gear; the push plate is fixedly connected with the left end of the transverse rack; the material falling seat is provided with a feeding hole and a cutting hole; the cutting hole penetrates through the feeding hole; the clamping mechanism is provided with a clamping disc; a plurality of clamping blocks which are circumferentially and uniformly distributed are connected to the clamping disc; first springs are connected between the corresponding clamping blocks and the clamping disc; the cutting mechanism is sequentially provided with a second spring, a cutter frame and a slicing cutter from top to bottom; the slicing cutter is fixed on the cutter frame; and the cutter frame is provided with a vertical rack which is engaged with the partial gear.The invention provides the slicer which can realize smoothness of notches of slices and uniformity in thickness of the slices and enables the slicing efficiency to be improved and the manpower and equipment costs to be reduced.

Owner:CHONGQING YONGFU WIRE & CABLE CO LTD

Integrated precise adjustment grinder

ActiveCN106166703AContinuous actionClamp fasteningGrinding carriagesGrinding feed controlEngineeringDirection detection

The invention relates to an integrated precise adjustment grinder which comprises a frame. The frame comprises a lower frame and an upper grinder frame, a grinding device and a rotating disk type clamping device are arranged in the upper grinder frame, a rotating disk driving motor is arranged on the lower frame, a feed conveying belt and a discharge platform are arranged on the frame, an L-shaped discharge conveying belt is arranged on the discharge platform, a feed CCD (charge coupled device) detection device is arranged at the tail end of the feed conveying belt, a counting sensor is arranged at an inlet of the discharge conveying belt, a laser labeler is arranged at an outlet of the discharge conveying belt, the frame is provided with a feed platform, an adjustment device and a vibration disk are arranged on the feed platform, the adjustment device sequentially comprises a feed baffle plate, a turnover cylinder and a righting device along the conveying direction, and a direction detection device is arranged near the turnover cylinder. The integrated precise adjustment grinder is continuous in action, firm and automatic in clamping, short in clamping time and precise in positioning, and workpiece machining quality is ensured.

Owner:宿迁海通科技有限公司

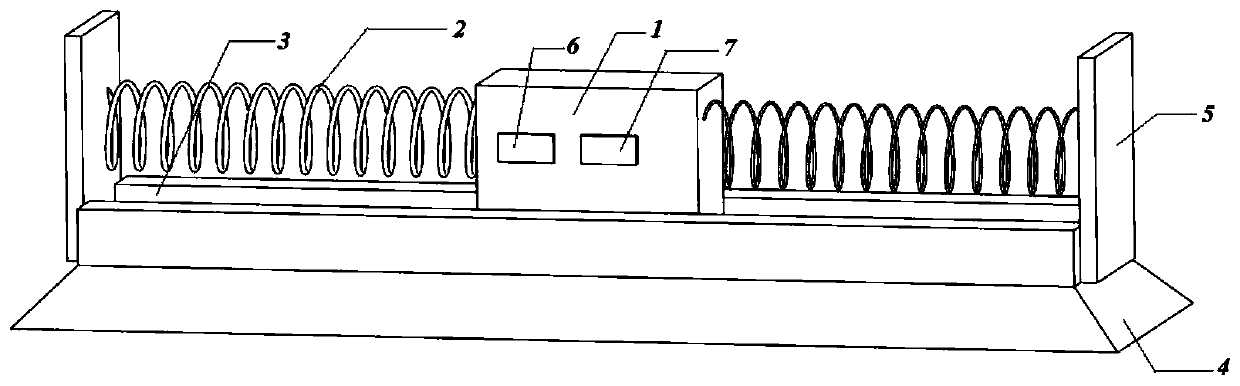

Single mass damper device for hull overall vibration control

PendingCN110422296AStable structureEasy to implementShip vibration reductionMovement controllersAntiresonanceInertia force

The invention relates to the field of mass damper devices, in particular to a single mass damper device for hull overall vibration control. The single mass damper device for hull overall vibration control comprises a single TMD device for controlling horizontal overall vibration of a hull and a single TMD device for controlling vertical overall vibration of the hull. During working, a first TMD mass block in the TMD device for controlling the horizontal overall vibration of the hull is pulled by a first spring to move to and fro between two baffles on a guide rail; a second TMD mass block in the TMD device for controlling the vertical overall vibration of the hull is pulled by a second spring to vertically move on an upright; and therefore, shock is absorbed by using inertia force resistance and antiresonance provided by assistant mass. The single mass damper device for hull overall vibration control is suitable for horizontal and vertical low frequency overall vibration control designof a large-sized surface ship, and has an obvious vibration control effect on the horizontal and vertical bending vibrations of the hull; and the overall response generated by the ship under the action of external load can be reduced, and the overall resistance of the ship to the horizontal and vertical bending vibrations is enhanced.

Owner:HARBIN ENG UNIV

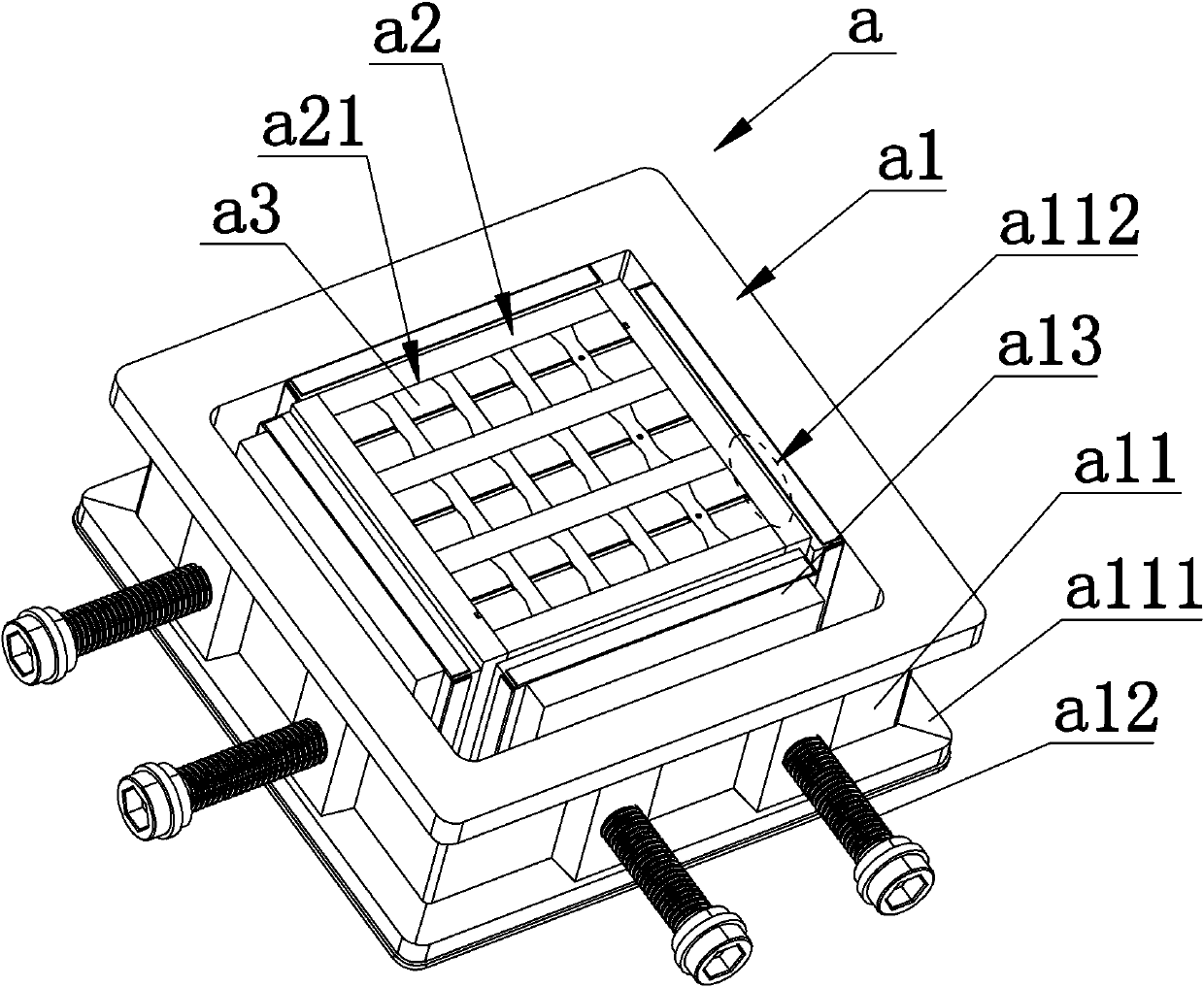

Automatic die dismantling and mounting method suitable for diamond knife head die

The invention discloses an automatic die dismantling and mounting method suitable for a diamond knife head die and relates to the field of mechanical automation. A production line mainly comprises anintermittent rotary table device, a die dismantling device, a screening device, a press cake sorting device, a die main body transferring device and a die main body changing device. According to the automatic die dismantling and mounting method, the intermittent rotary table device, the die dismantling device and the screening device are adopted to automatically dismantle a die frame, a die body,a pressing head and a cold green compact; and the die main body transferring device and / or the die main body changing device is utilized to re-mount the die body or the other die body into the die frame. The automatic die dismantling and mounting method can automatically dismantle the die, separate the cold green compact, and mount the die body to the die frame. The production line has the advantages of being compact in structure, continuous in action, and high in degree of automation.

Owner:福建省泉州万龙石业有限公司

Automatic detection grinding machine capable of adjusting feeding and collecting dust

ActiveCN106217183AGuarantee processing qualityContinuous actionGrinding carriagesGrinding feed controlGlass coverEngineering

The invention relates to an automatic detection grinding machine capable of adjusting feeding and collecting dust. The automatic detection grinding machine capable of adjusting feeding and collecting dust comprises a rack, wherein the rack comprises a lower rack and a grinding machine upper rack; the grinding machine upper rack is provided with a glass cover shell, a grinding device, a rotary disc type clamping device and a dust collector; the lower rack is provided with a rotary disc driving motor; a feeding conveyor belt is arranged on the rack; a discharging platform is arranged on the rack, a Y-shaped discharging conveyor belt is arranged on the discharging platform, a discharging CCD detection device is arranged at the crossed point, and the discharging conveyor belt is provided with a laser marking device; the feeding conveyor belt is provided with a feeding CCD detection device; the rack is provided with a feeding platform; an adjusting device and a vibrating plate are arranged on the feeding platform; the adjusting device sequentially comprises a feeding baffle, a rotating cylinder and an aligning device in a conveying direction; and an azimuth detection device is further arranged near the rotating cylinder. The automatic detection grinding machine capable of adjusting feeding and collecting dust continuously acts, automatically carries out clamping and fastening, is short in time consumption, is accurate in locating and ensures workpiece machining quality.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

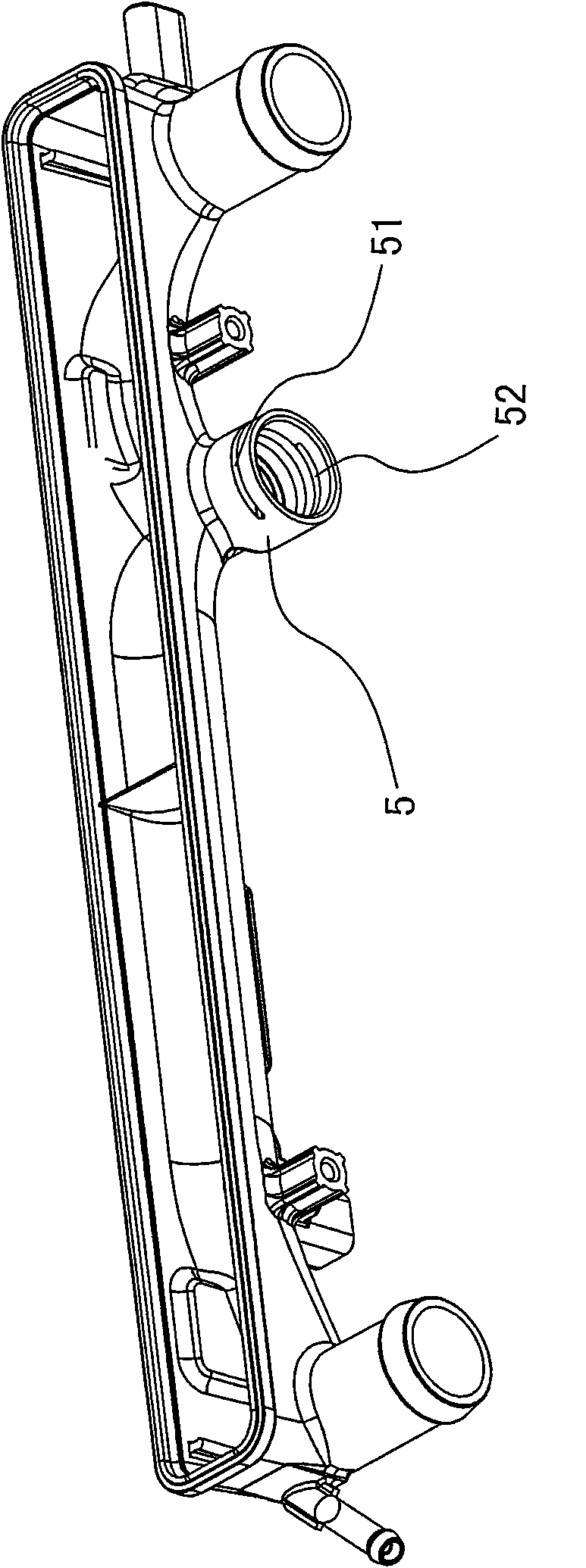

Secondary composite core pulling mechanism for automotive water tank

The invention discloses a secondary composite core pulling mechanism for an automotive water tank, which comprises a mold cavity and a mold core. A mold cavity insert is arranged in the mold cavity. A mold core insert is arranged in the mold core. A die cavity is formed between the mold core insert and the mold cavity insert. A water outlet of the automotive water tank is formed in the die cavity. Nicks are formed on the upper and lower sides of the water outlet respectively. A large sliding block is arranged on one side of the mold core, and is connected with a core and a small sliding block. The core is used for molding the inner wall of the water outlet, and the small sliding block is used for molding the outer wall of the water outlet. An inclined guide pillar is arranged in the mold cavity, and runs through the large sliding block. The secondary composite core pulling mechanism is characterized in that: an upper bump is formed on the mold cavity insert, and is used for molding the upper nick of the water outlet; a distance fixing bolt is arranged in the small sliding block, and is connected with the large sliding block; the lower side of the large sliding block is connected with an inclined cutting block on which a lower insertion block is arranged; a compression spring is arranged in the lower insertion block, and is in contact with the small sliding block; and a lower bump is formed on the lower insertion block, and runs through the small sliding block to form the lower nick of the water outlet.

Owner:ZHEJIANG KAIHUA MOLDS

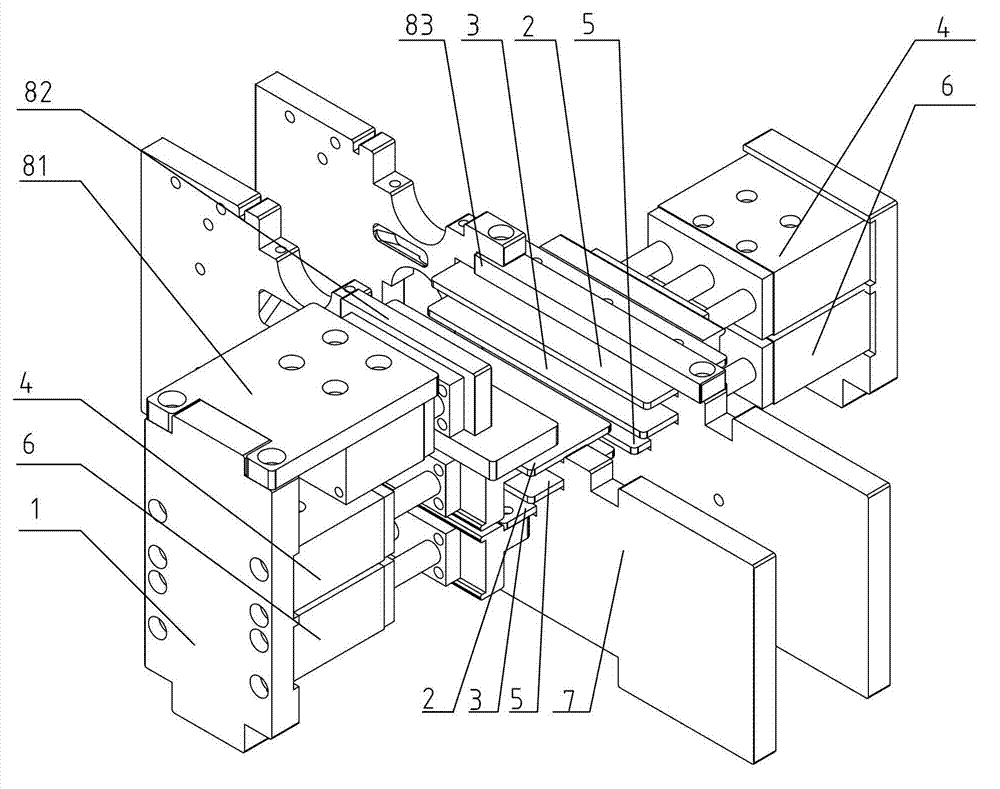

Stripping, bending and forming integrated equipment for electronic component tape

The invention discloses stripping, bending and forming integrated equipment for electronic component tape. The stripping, bending and forming integrated equipment comprises a tape tearing portion for tearing tape on electronic components off and a bending portion for bending pins of the electronic components. The bending portion is located on the material output side of the tape tearing portion. A tape-tearing feeding portion for feeding materials bonded with the tape is arranged on one side of a tape tearing workbench. The lower portion of a tape-tearing execution portion and the lower portion of the tape-tearing feeding portion are provided with a tape-tearing material transfer portion for transferring the materials on the tape-tearing feeding portion to the tape-tearing execution portion. The bending workbench is provided with a bending control portion for controlling the working state of bending equipment and a bending grouped conveying portion for conveying the materials in a grouped manner. By the adoption of the stripping, bending and forming integrated equipment for the electronic component tape, the tape on the electronic components can be torn off from the two sides, meanwhile quantitative conveying of the component materials and the two-time bending and shearing work of the pins can be completed continuously and automatically, the actions are continuous, the efficiency is high, and damage to the components is avoided.

Owner:金动力智能科技(深圳)有限公司

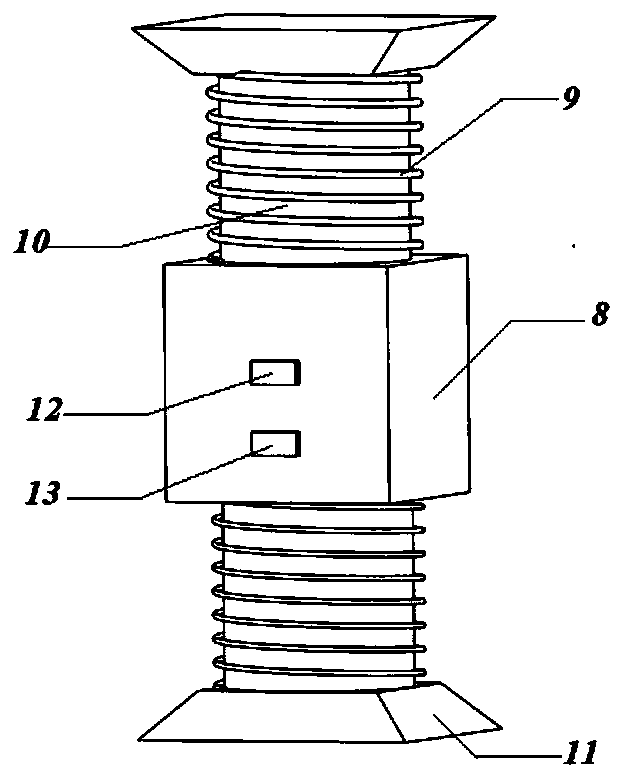

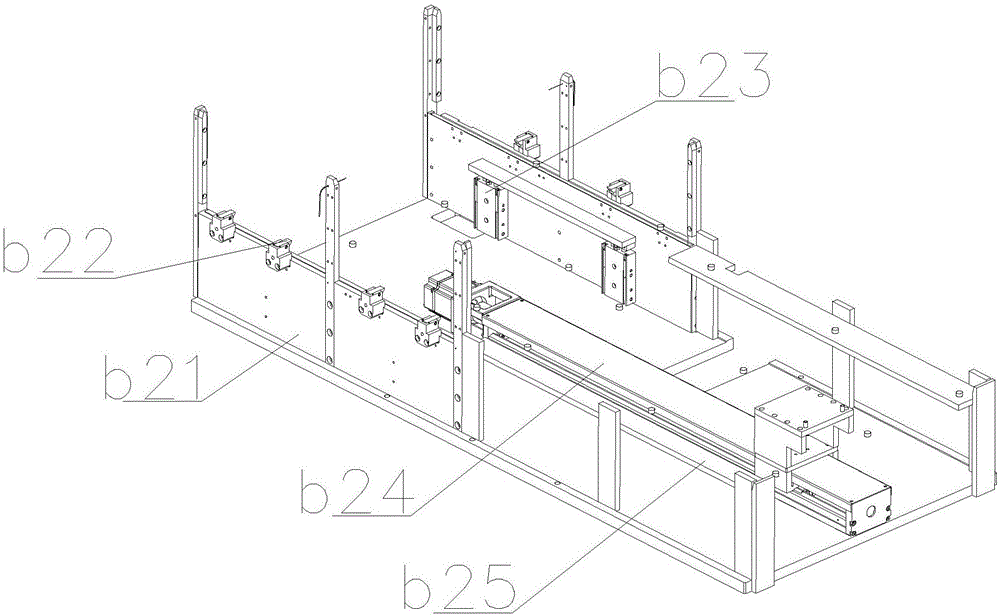

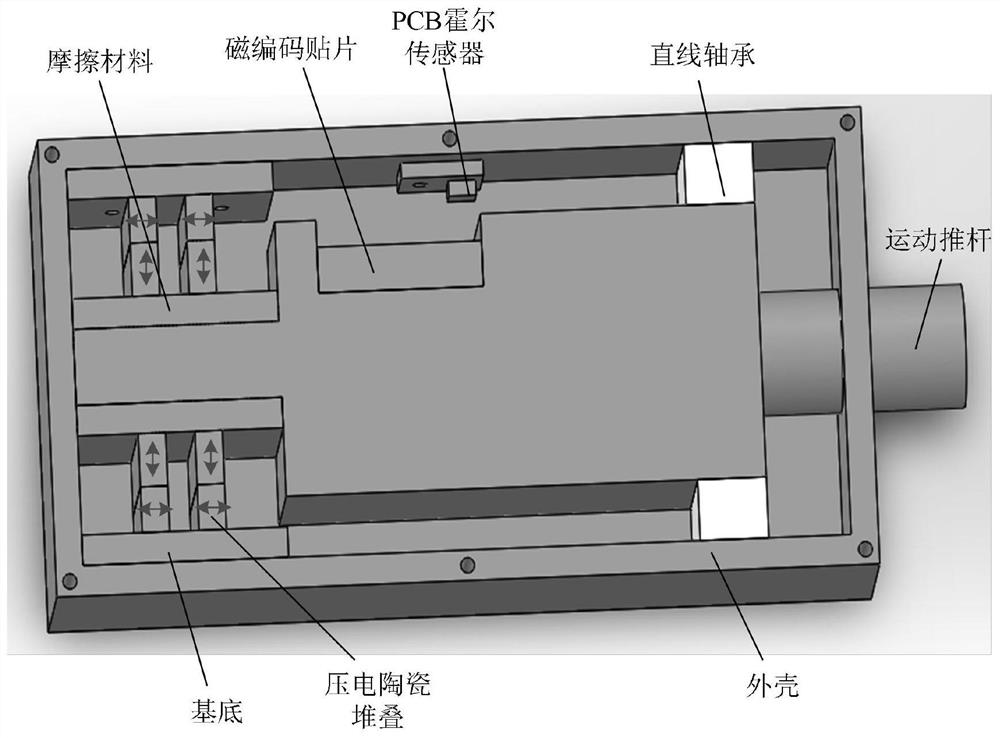

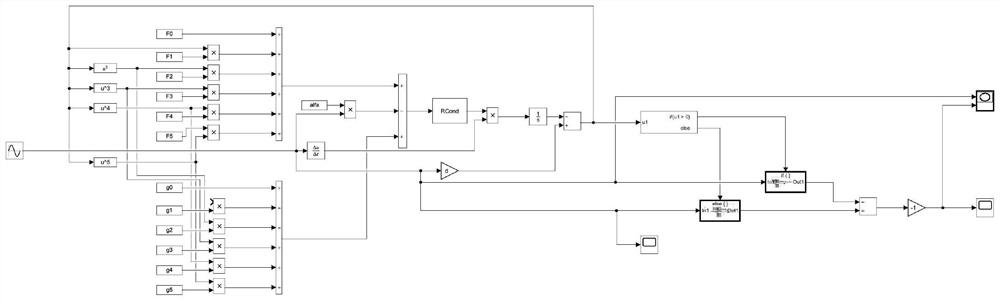

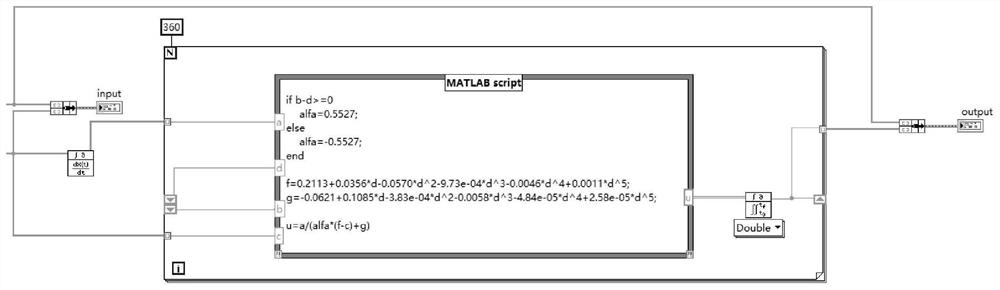

Inchworm type piezoelectric push rod motor and hysteresis characteristic compensation method thereof

ActiveCN113824351AReduce volumeContinuous actionPiezoelectric/electrostriction/magnetostriction machinesBionicsElectric machine

The invention relates to an inchworm type piezoelectric push rod motor and a hysteresis characteristic compensation method thereof. The motor comprises a housing, a moving push rod, a driving unit, a PCB Hall sensor, a magnetic coding paster, a linear bearing and a driving controller. The driving unit comprises a piezoelectric ceramic stack and a ceramic sheet, the driving unit is fixed in the shell by using a bolt, and the moving push rod is mounted in center holes of the shell, the driving unit, the limiting unit and a shell end cover; and the linear bearing is installed between the shell and the moving push rod, and a round hole is formed in the corresponding position of the end cover of the shell, so that the push rod motor can always keep linear motion; and the novel inchworm-type piezoelectric push rod motor is based on the inchworm crawling principle in bionics, electric energy is converted into mechanical energy through the inverse piezoelectric effect, and the novel inchworm-type piezoelectric push rod motor has the advantages of being small in size, continuous in action, large in thrust, high in precision, easy to control and the like. The motor has more advantages in some large-stroke and high-resolution precision positioning fields.

Owner:HARBIN INST OF TECH

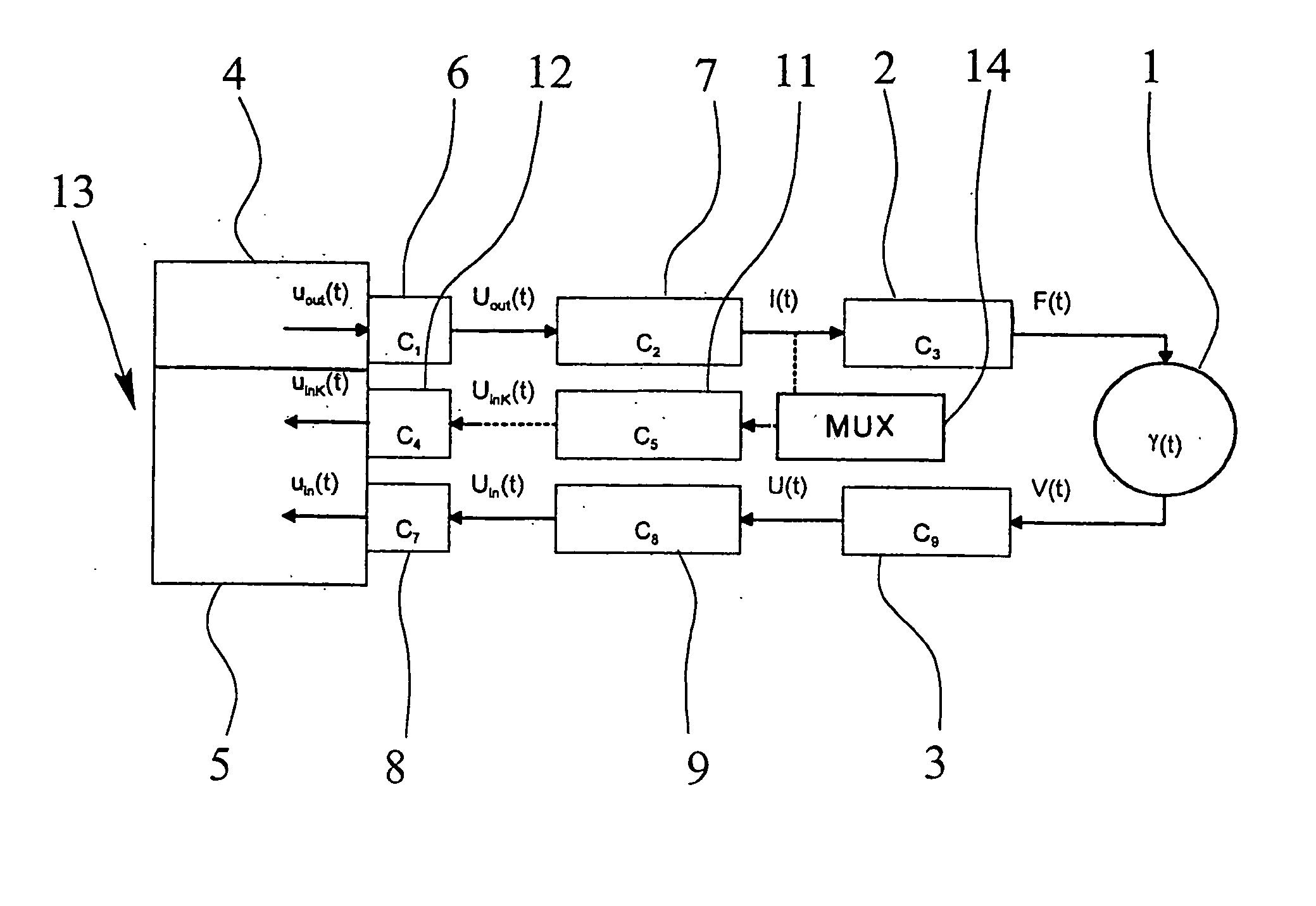

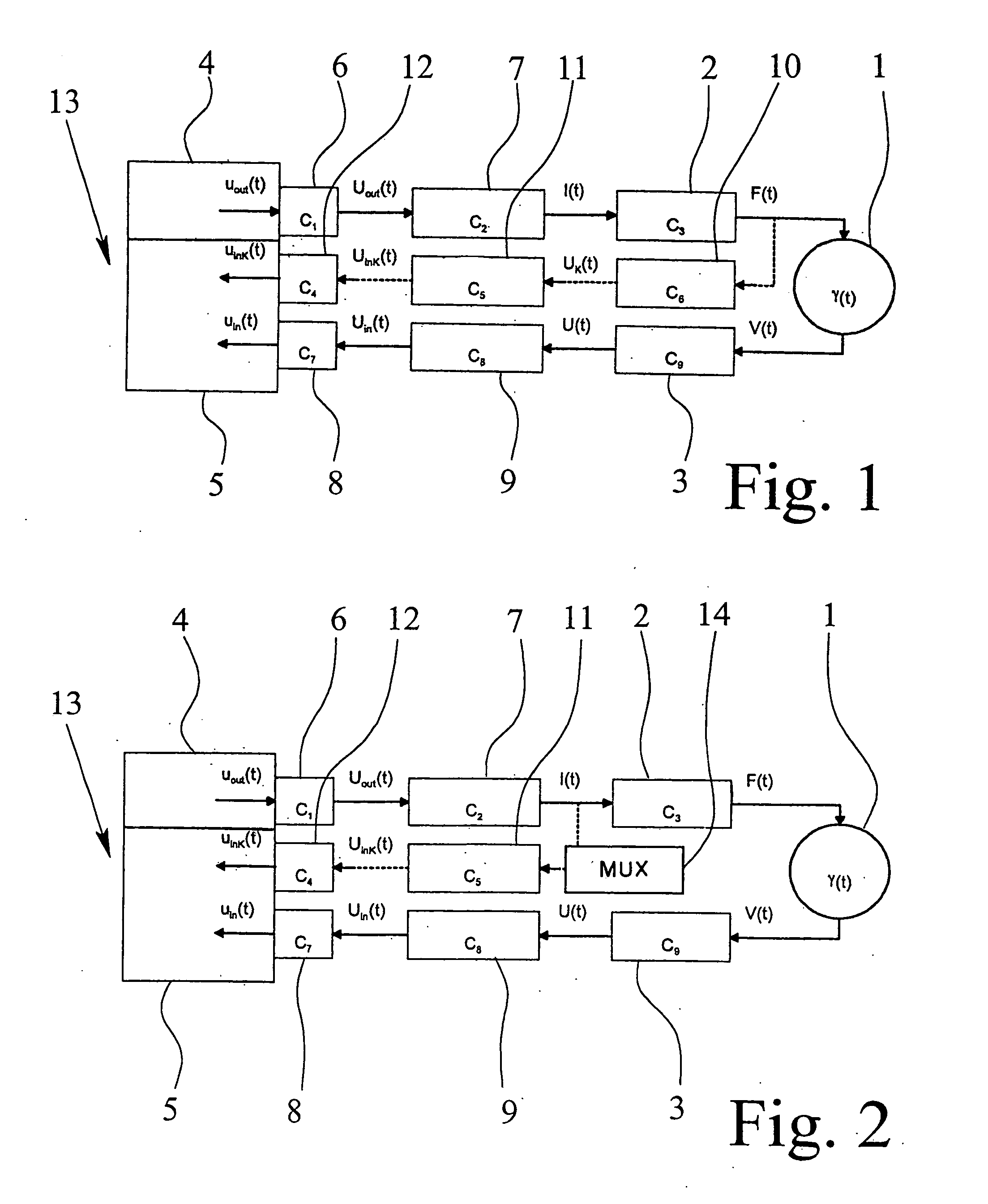

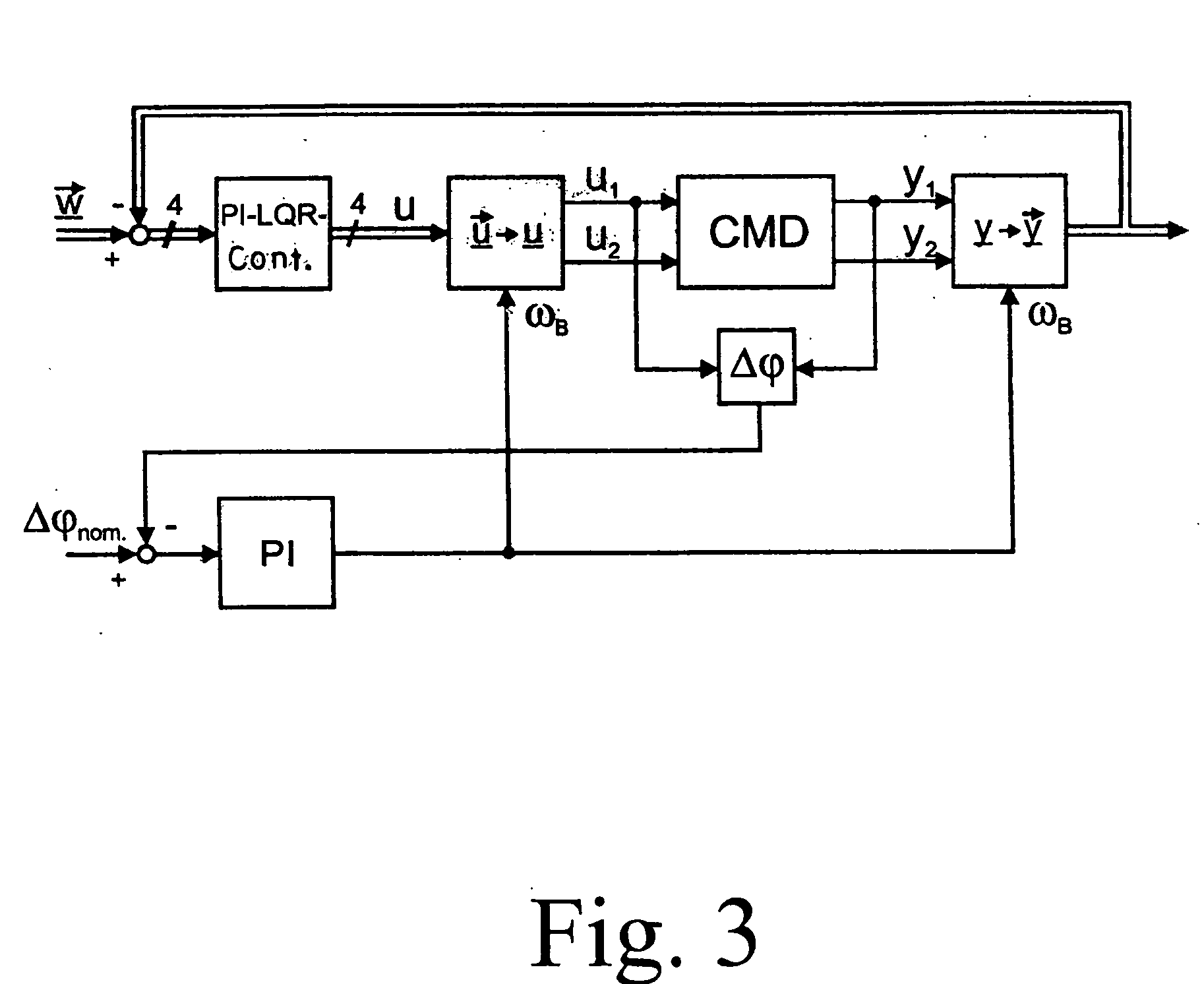

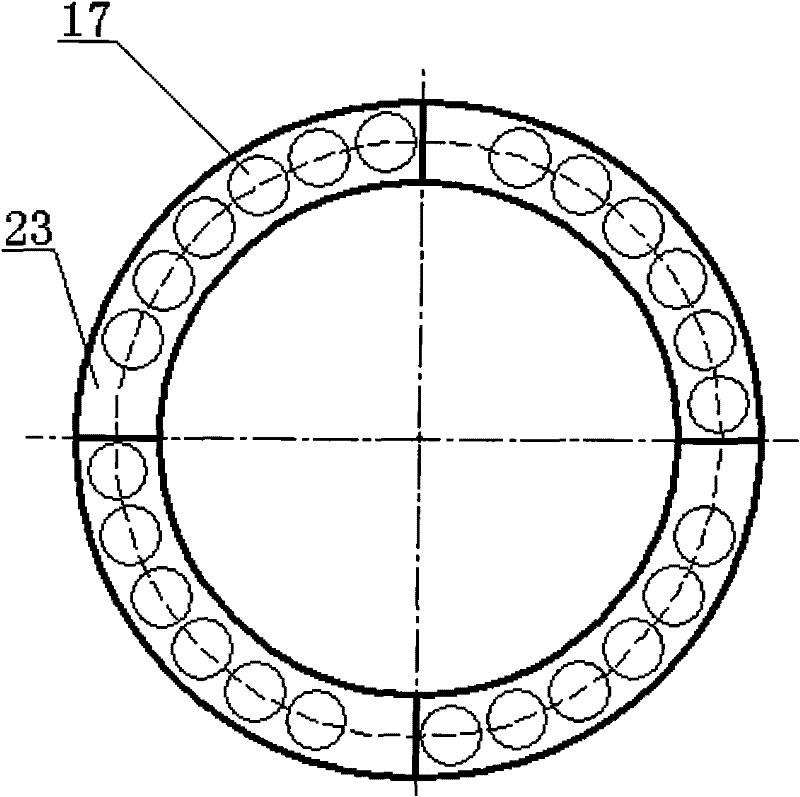

Coriolis mass flowmeter and method for operating a Coriolis mass flowmeter

ActiveUS20050011286A1Easy to correctImprove amplitude accuracyDc level restoring means or bias distort correctionDigital computer detailsControl signalExcitation signal

A Coriolis mass flowmeter incorporates at least one measuring tube, at least one oscillator for the excitation of the measuring tube and at least one oscillation detector for registering the oscillations of the measuring tube, with an activator serving to energize the oscillator, at least one evaluation unit serving to analyze the oscillations registered by the oscillation detector, an excitation signal path including excitation signal-path devices provided between the activator and the oscillator for transmitting an excitation signal, and a measuring signal path with measuring signal-path devices provided between the oscillation detector and the evaluation unit for transmitting the measuring signal. A control signal path with at least one control signal path device is provided, the control signal path directly connecting the excitation signal path to the evaluation unit, whereby the excitation signal that passed through at least one excitation signal path device is fed as a control signal, via the control signal path, to the evaluation unit, with the control signal path device in the control signal path corresponding to a measuring signal path device. This permits the correction of the measuring signal, received via the measuring signal path, with the aid of the control signal received by the evaluation unit via the control signal path, the result being improved measuring accuracy. A method of operating such a flowmeter is also disclosed.

Owner:KRONE GMBH

Impacting helicoid hydraulic motor and transmission shaft assembly

InactiveCN101581196BStrong reliabilityContinuous actionDrilling rodsShaftsHydraulic motorDrive shaft

The invention discloses an impacting helicoid hydraulic motor and transmission shaft assembly, which comprises transmission shafts and external bodies, wherein bidirectional limiting bearings are arranged between the external bodies and the transmission shafts. The impacting helicoid hydraulic motor and transmission shaft assembly is characterized in that: the transmission shafts consist of an upper transmission shaft and a lower transmission shaft; the external bodies corresponding to the transmission shafts also consist of an upper external body and a lower external body; an annular rigid impact socket and an upper vibration starting seat which are connected into a whole are movably arranged in an annular cavity between a lower external body and the lower transmission shaft; the lower end of the annular rigid impact socket is provided with an impact seat fixedly connected with the lower transmission shaft; and vibration starting devices are arranged between the upper vibration starting seat and the lower transmission shaft as well as between the annular rigid impact socket and the lower transmission shaft. While retaining the functions of a helicoid hydraulic motor, the impactinghelicoid hydraulic motor and transmission shaft assembly has the functions of a hydraulic impactor which is long in service life and controllable in frequency and impact force. The impacting helicoidhydraulic motor and transmission shaft assembly can greatly improve rock breaking efficiency of a drill bit and the drilling speed of a drilling machine and reduce the drilling construction cost during drilling construction of various wells.

Owner:李鹏飞

Adjustable sorting detecting grinding machine

ActiveCN106181682AContinuous actionClamp fasteningGrinding carriagesGrinding drivesGlass coverDrive motor

The invention relates to an adjustable sorting detecting grinding machine. The adjustable sorting detecting grinding machine comprises a frame, wherein the frame comprises a lower frame and a grinding machine upper frame; a glass cover shell, a grinding device, a rotating plate type clamping device and a dust removal device are arranged on the grinding machine upper frame; a rotating plate driving motor is arranged on the lower frame; the frame is provided with a feeding conveying belt and a discharging platform; the discharging platform is provided with a Y-shaped discharging conveying belt; a discharging CCD detector is arranged at a junction; the discharging conveying belt is provided with a laser marking device; the feeding conveying belt is provided with a feeding CCD detecting device; the frame is provided with a feeding platform; an adjusting device is arranged on the feeding platform; the adjusting device successively comprises a feeding baffle, an overturning cylinder and a correction device in the conveying direction; and a direction detecting device is further arranged nearby the overturning cylinder. The adjustable sorting detecting grinding machine is continuous in action and clamps fixedly, automatic clamping can be implemented, consumed time is short, positioning is accurate, and machining quality of workpieces is guaranteed.

Owner:宿迁海通科技有限公司

Signal processing method and signal processing system

InactiveUS8269850B2Improve user friendlinessImprove processing speedTelevision system detailsGeometric image transformationImage resolutionThumbnail Image

A signal SG41 that has color signals thereof time-sequentially arranged in a color array corresponding to the color array in an image sensor 3 and that has not undergone resolution conversion is subjected to resolution conversion at a conversion rate (for example, ⅓) specified by a phase retention resolution conversion section 42. A de-mosaicing processing section 44 converts a signal SG42, which represents the order of the color array in the image sensor, into RGB signals SG44. A thin-line retention resolution conversion section 45 converts the signals SG44 into signals SG45 at a specified conversion rate (for example, ½). The signals SG45 are compressed by an encoder. In a recording medium 9, YC signals SG48 representing (640×480) pixels, the color signals SG42, a signal SG51 representing (640×480) pixels in the order of a color array and serving as thumbnail image data DT, and imaging information are recorded.

Owner:IMAGE PROCESSING TECH

Dual-detection integrated grinding machine

ActiveCN106217237AGuarantee processing qualityContinuous actionGrinding carriagesGrinding feed controlEngineeringGrinding wheel

The invention relates to a dual-detection integrated grinding machine. The dual-detection integrated grinding machine comprises a rack, wherein the rack comprises a lower rack and a grinding machine upper rack; a grinding device and a turntable type clamping device are arranged in the grinding machine upper rack; the grinding device comprises a fixed frame, a lower X-axial sliding rail, an upper X-axial sliding rail, Y-axial sliding rails and a grinding wheel device; the turntable type clamping device comprises a turntable shell, a clamping turntable, fixed arms, bent arms, clamping claws, a transmission gear, a turntable supporting frame and a locating cylinder; the lower rack is provided with a turntable driving motor; a material entering conveying belt is arranged on the rack; a material discharging platform is further arranged on the rack; a Y-shaped material discharging conveying belt is arranged on the material discharging platform, and a material discharging CCD detection device is arranged at the position of an intersection; a laser labeling device is arranged at the tail end of the material discharging conveying belt; and a material entering CCD detection device is further arranged at the tail end of the material entering conveying belt. The dual-detection integrated grinding machine operates continuously, clamps workpieces firmly, realizes automatic clamping, is short in operation time and accurate in location, and guarantees the machining quality of the workpieces.

Owner:MAANSHAN YASHIDA INTELLIGENT TECH CO LTD

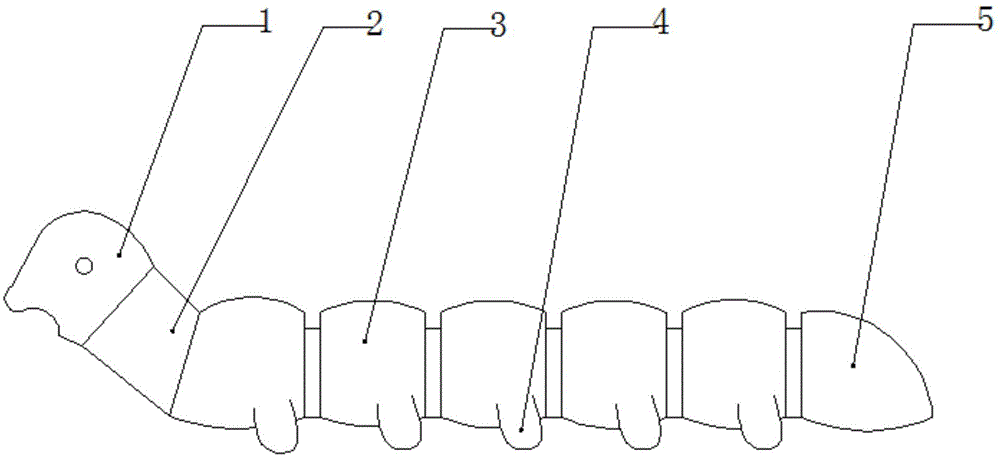

Software robot

The invention relates to a software robot which can be applied to non-structural operation environments of pipeline maintenance, ruins searching and rescuing, military reconnaissance and the like. The software robot mainly comprises a matrix, differential magnetic rigid units or differential magnetic polymer composite materials, a control power source and a control circuit, the matrix comprises a head, a neck, a trunk, feet and a tail, the differential magnetic rigid units or the differential magnetic polymer composite materials are of a small laminated structure, four or more channels are circumferentially arranged in the trunk, the differential magnetic rigid units or the differential magnetic polymer composite materials are axially embedded in the channels, and integral bending and wriggling are achieved by controlling stroke of the differential magnetic rigid units or the differential magnetic polymer composite materials in the channels. According to the software robot, the built-in power source is used, the whole circuit is wrapped in the matrix so that the circuit is prevented from being eroded and destroyed by environments, forming processability and elasticity are good, and actions of the robot are flexible and continuous.

Owner:BEIJING UNIV OF CHEM TECH

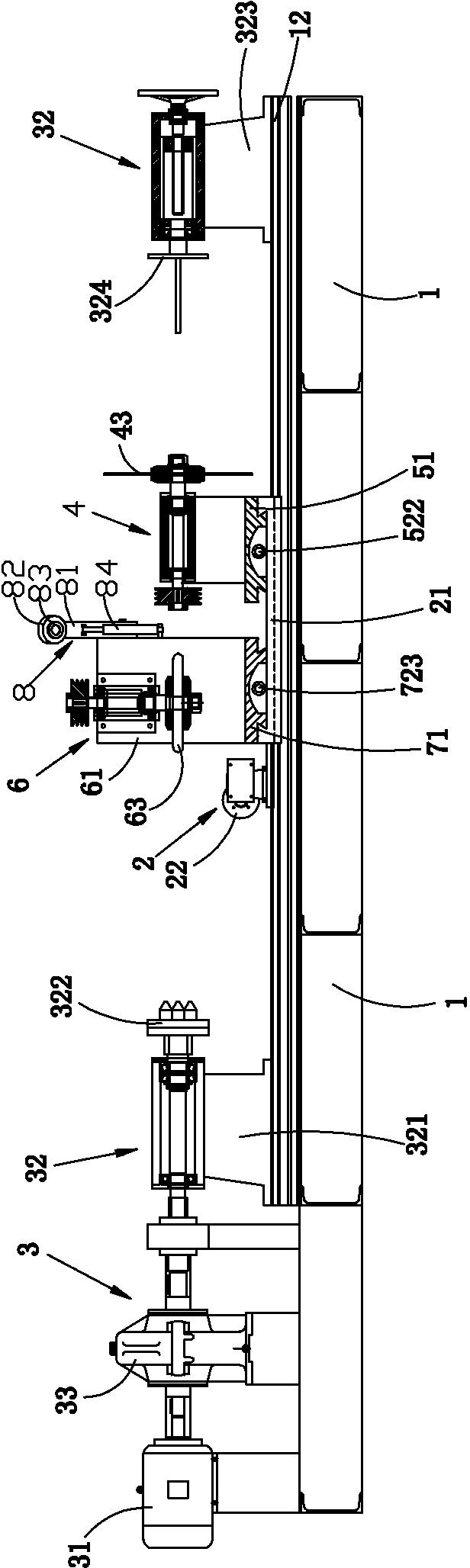

Automatic electric coil label placement device

PendingCN109896092AContinuous actionEnsure accuracy and consistencyLabelling machinesElectric machineryEngineering

The invention belongs to the technical field of electric machinery, and particularly relates to an automatic electric coil label placement device. The automatic electric coil label placement device iscomposed of a label storage box, a movable label sucking head, a label separating and guiding groove and a lifting label clamping assembly. Labels are horizontally put in the label storage box, the label sucking head downwards extends to suck the horizontally put labels and forwards moves, the labels pass through the guiding groove and are changed to be vertically arranged along the guiding groove, a pneumatic label clamping head clamps the labels to upwards move, the labels are put on the side face of a coil, and the label placement task is automatically completed. According to the automaticelectric coil label device, sucking to placement of the labels is automatically completed, movement is continuous and reliable, the automatic electric coil label device can take the place of manual work, the accuracy and the consistency of the put labels can be effectively guaranteed, the labor intensity of manpower can be greatly reduced, and the production efficiency is improved. The automaticelectric coil label device is compact in design and safe and reasonable in transmission and can completely meet requirements of the production process.

Owner:WUXI HENGTAI CABLE MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com