Inchworm type piezoelectric push rod motor and hysteresis characteristic compensation method thereof

A compensation method and piezoelectric push technology, which are applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the inconvenient closed-loop control, the motor body has no stroke detection device, Reduce the positioning accuracy of the inchworm motor, and achieve the effects of easy control, large thrust and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

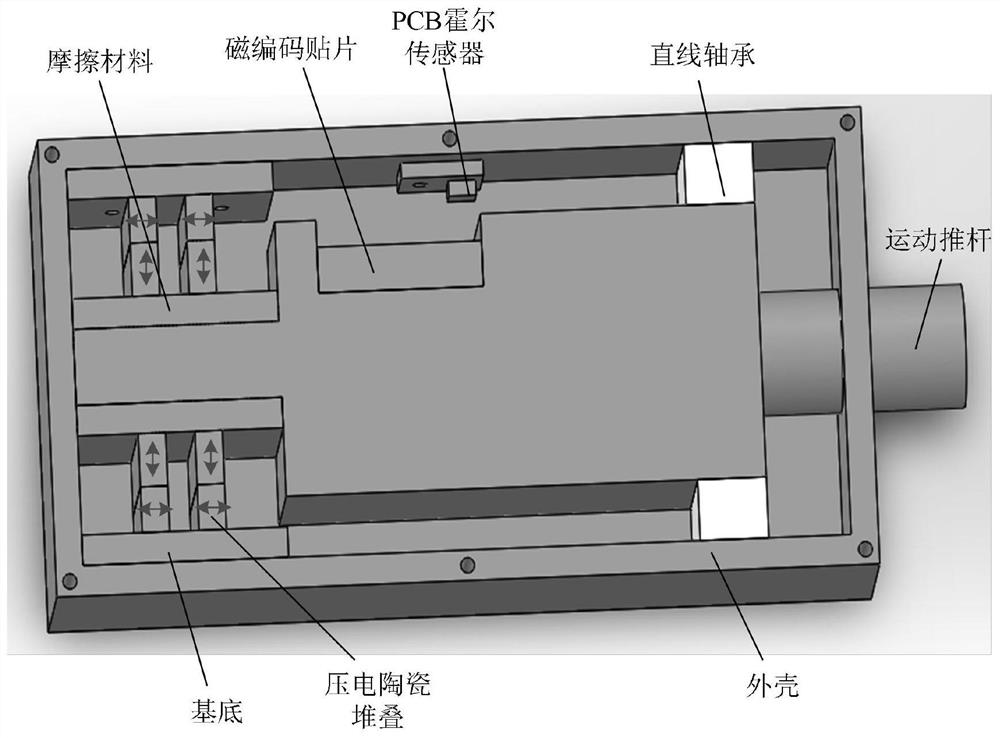

[0053] according to Figure 1 to Figure 4 As shown, the present invention provides a kind of inchworm type piezoelectric push rod motor and its hysteresis characteristic compensation method, such as figure 1 As shown, the drive unit composed of piezoelectric ceramics (including piezoelectric ceramic stacks and ceramic sheets) is fixed inside the housing with bolts, and the motion push rod is installed in the central hole of the housing, drive unit, limit unit and housing end cover . The linear bearing (linear guide rail) is installed between the casing and the moving push rod, and at the same time, a circular hole is opened at the corresponding position of the end cover of the casing, so that the push rod motor can always keep linear motion. Install the magnetic coding piece on the groove on the surface of the moving push rod, and install the PCB Hall sensor on the position where the magnetic coding patch is directly opposite to the shell, so that the stroke of the push rod c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com