Turning pick-and-place machine

A pick-and-place machine and pick-and-place device technology, which is used in the direction of assembling printed circuits with electrical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

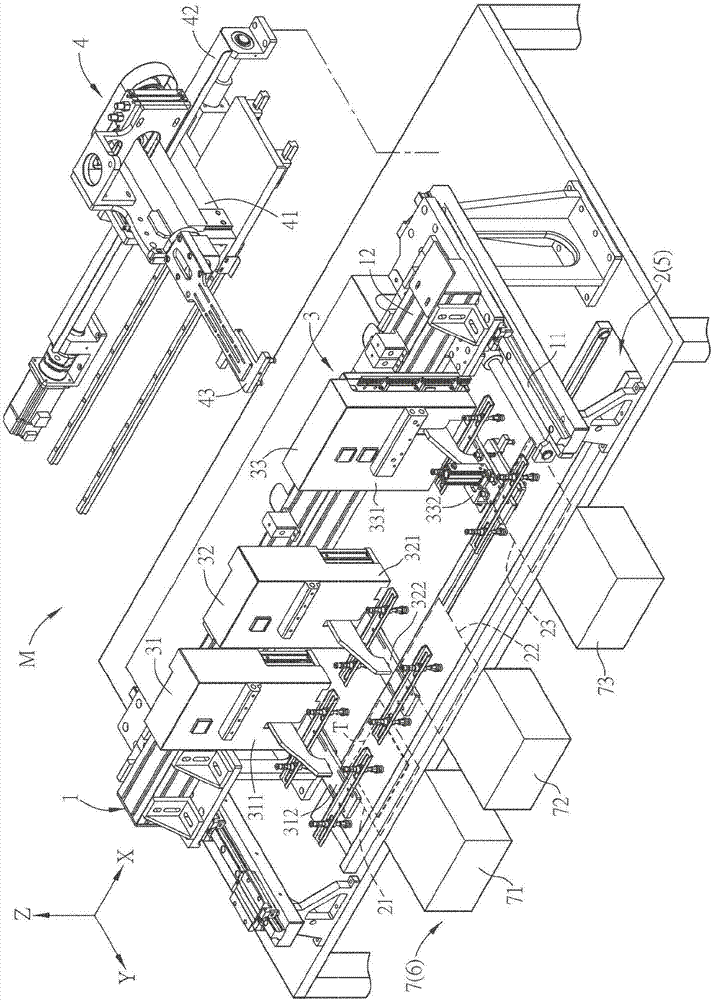

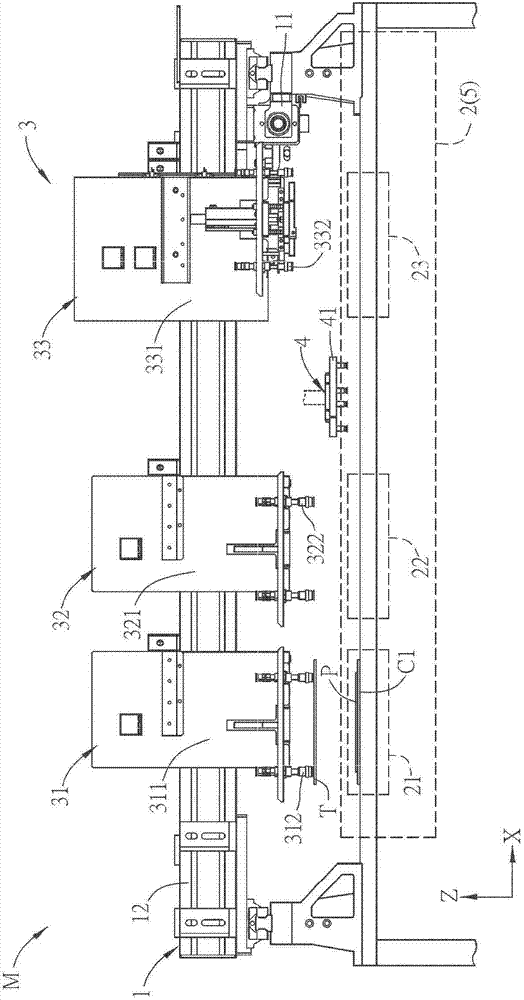

[0065] A turn-over pick-and-place machine according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference symbols.

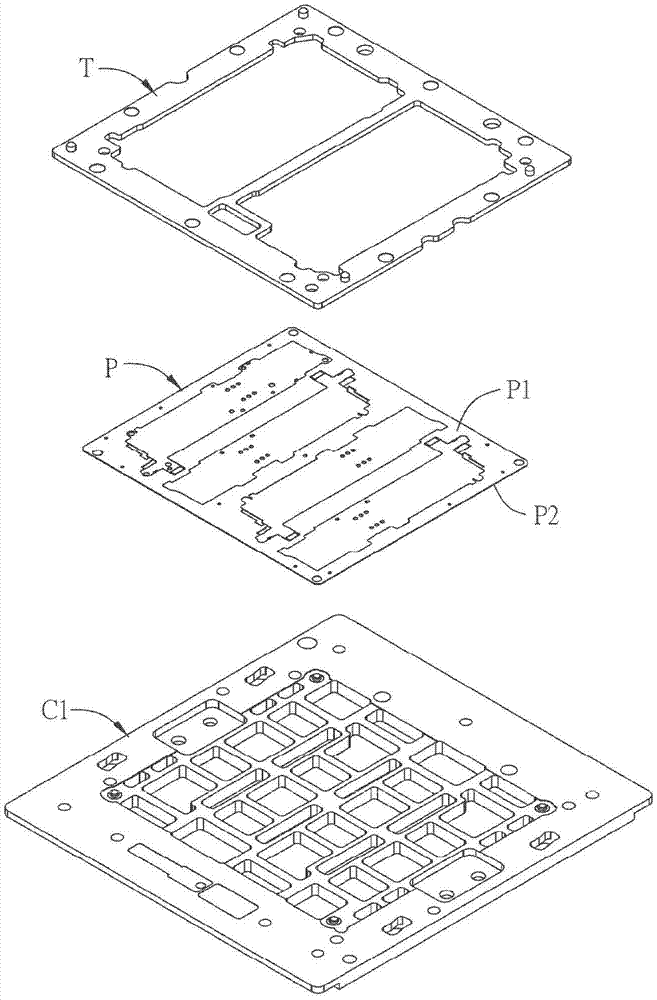

[0066] figure 1 It is a partially exploded schematic diagram of a flipping pick-and-place machine according to an embodiment of the present invention, figure 2 for figure 1 The exploded schematic diagram of the cover plate, workpiece and first carrier shown, please also refer to figure 1 and figure 2 shown. The overturn pick-and-place machine M of this embodiment is used to overturn a workpiece P, and place the overturned workpiece P on a second carrier C2, such as figure 2 As shown, the workpiece P is sandwiched between a cover plate T and a first carrier C1, so the flip pick-and-place machine M must first remove the cover plate T from the workpiece P, so that the workpiece P can be taken out and turned over, and Place the flipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com