Impacting helicoid hydraulic motor and transmission shaft assembly

A technology of screw drilling tools and drive shafts, which is applied to the drilling drive devices, shafts, drill pipes and other directions in the wellbore, can solve the problems of limited application scope, single screw drilling tools, restricting technology development, etc., and achieves widening the application scope. , strong reliability, continuous action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

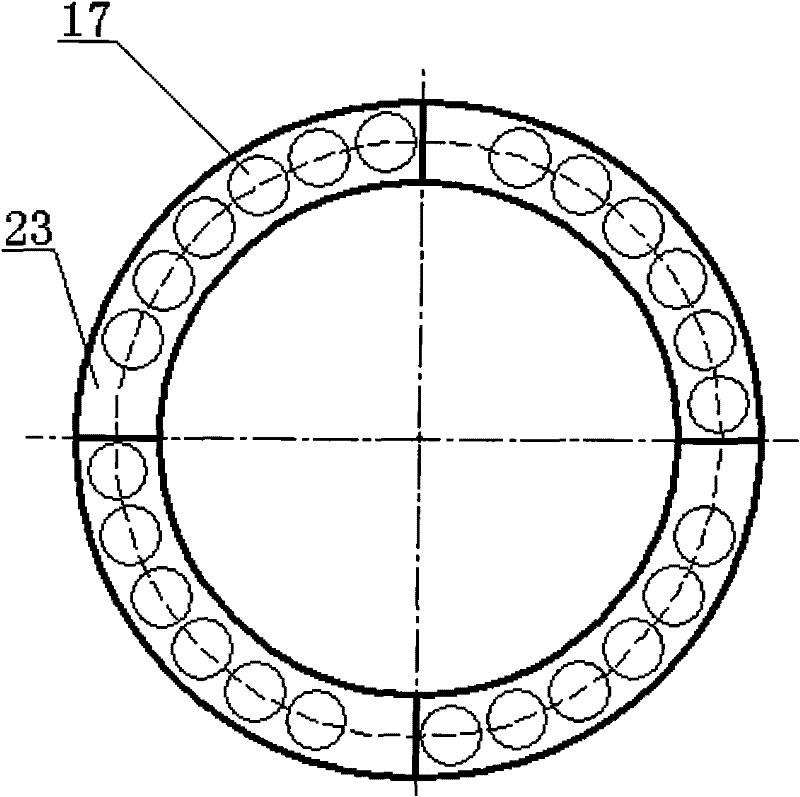

[0032] refer to figure 1 Shown, transmission shaft assembly of the present invention is made up of two major parts:

[0033]One part is the upper body assembly, which is basically similar to the structure of the existing screw drilling tool. It consists of the upper outer body 2, the water connection nipple 1, the upper transmission shaft 5, the upper radial TC bearing 4, the thrust bearing 6 and the back cap 16 compositions. The upper end of the water-passing joint 1 is directly connected with the lower end of the cardan shaft of the screw drilling tool with a male buckle, and the lower end is connected with the upper drive shaft 5 through a screw thread. The water passage hole C communicated with the internal circulation cavity is used for the drilling fluid to flow into the inner cavity of the upper drive shaft 5 . The upper outer body 2 is fitted into the upper radial TC bearing 4 and thrust bearing 6 with slight interference, the upper transmission shaft 5 is inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com