Cutting mechanism

A technology of cutting knife and guide rail, applied in metal processing and other directions, can solve the problems of low work efficiency, terminal deformation, affecting the accuracy of cutting position, etc., and achieve the effect of accurate cutting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

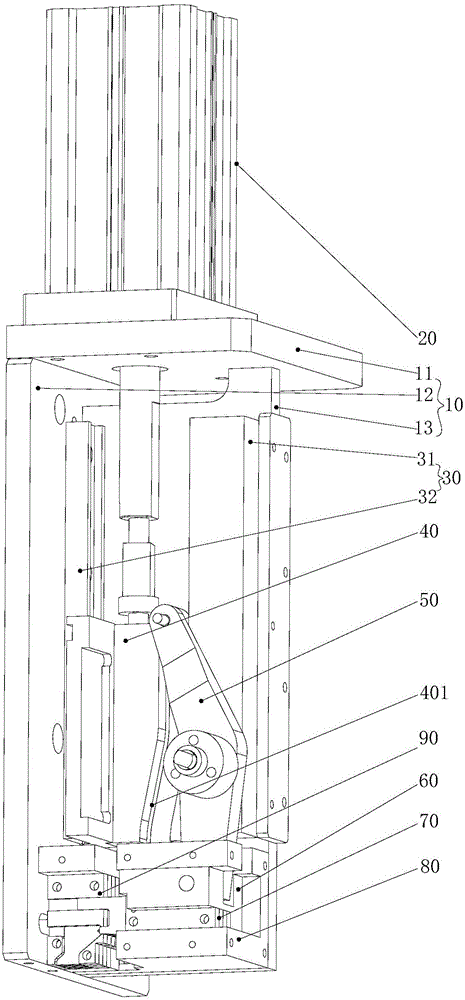

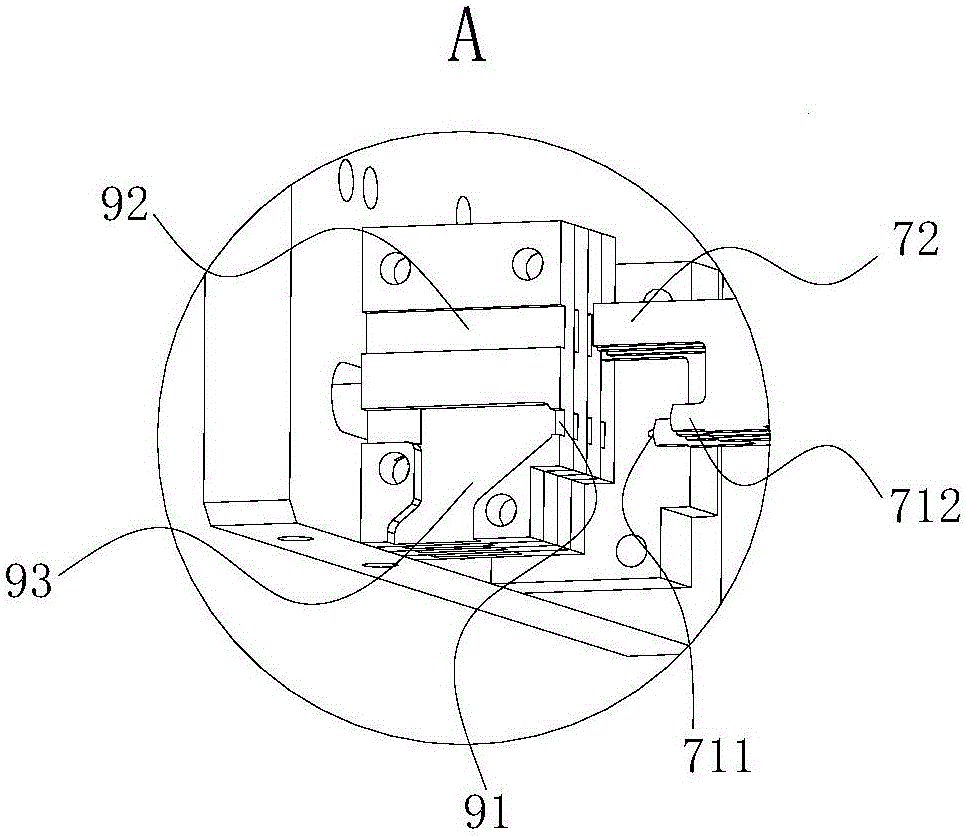

[0034] see Figure 1 ~ Figure 3 , the first embodiment is a preferred embodiment of the present invention, the material cutting mechanism includes a fixed seat 10, a cylinder 20, a guide rail 30, a guide slider 40, a swing rod 50 and a cutter slider 60, a cutter 70, a guide Support 80 and cutter backing plate 90. The fixed seat 10 specifically includes a horizontal plate 11 arranged in the horizontal direction, a vertical plate 12 arranged in the vertical direction, an intermediate vertical plate 13 perpendicular to the horizontal plate 11 and the vertical plate 12, and the vertical plate 12, the horizontal plate 11 and the intermediate vertical plate 13 are two by two. The three-dimensional fixed seats 10 are formed perpendicular to each other. The output shaft of the air cylinder 20 passes through the horizontal plate 11 and is connected with the guide slider 40 . The guide rail 30 includes a first guide rail 31 installed on the middle vertical plate 13 and a second guide ...

no. 2 example

[0041] refer to Figure 4 , The second embodiment is a further improvement of the material cutting mechanism in the first embodiment. This material cutting mechanism has the functions of cutting material and playing terminals at the same time. On the basis of the first embodiment, the material cutting mechanism further includes a knife bar connecting block 210 and a terminal knife 220. The guide slider 40 is composed of a fixedly connected terminal knife guide slider and a swing rod guide slider. The terminal knife guide slide The block is provided with a limit chute 402, the knife bar connecting block 210 is slidably connected with the guide slider 40, the afterbody of the terminal knife 220 is inserted in the knife bar connecting block 210, the head of the terminal knife 220 stretches into the guide bracket 90, and the terminal knife The moving direction of the terminal knife 220 is perpendicular to the moving direction of the cutter 70 , and the terminal knife 220 includes ...

no. 3 example

[0044] refer to Figure 5 and Figure 6 , this embodiment is a further optimization of the material cutting mechanism in the second embodiment. On the basis of the second embodiment, the material cutting mechanism provided in this embodiment also includes a terminal knife box 310, and the terminal knife box 310 is equipped with a cover plate 320, the terminal knife box 310 is set on the outer periphery of the terminal knife 220, the terminal knife 220 is accommodated in the terminal knife box 310, one end of the terminal knife box 310 is in contact with the knife bar connecting block 210, and the other end of the terminal knife box 310 is provided with a terminal Guide groove 311, feed port 312, and cutter hole 313, terminal guide groove and terminal knife are set in cooperation, cutter hole 313 is set in cooperation with cutter 70, and feed port is arranged on the side of terminal knife box, and guide bracket 80 The feeding port 801 is connected. When the terminal is punche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com