Automobile part cold stamping device with material taking device

A technology of reclaiming device and auto parts, which is applied in the field of auto parts stamping equipment, can solve the problems of stamping efficiency reduction, trouble, time delay, etc., and achieve the effect of not being easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

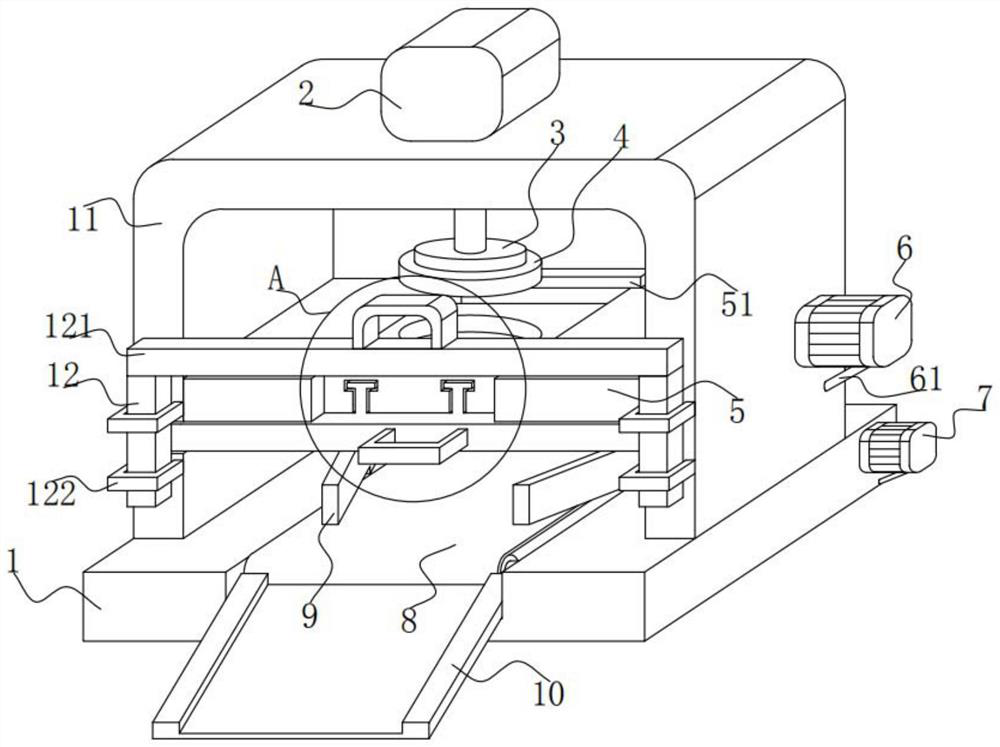

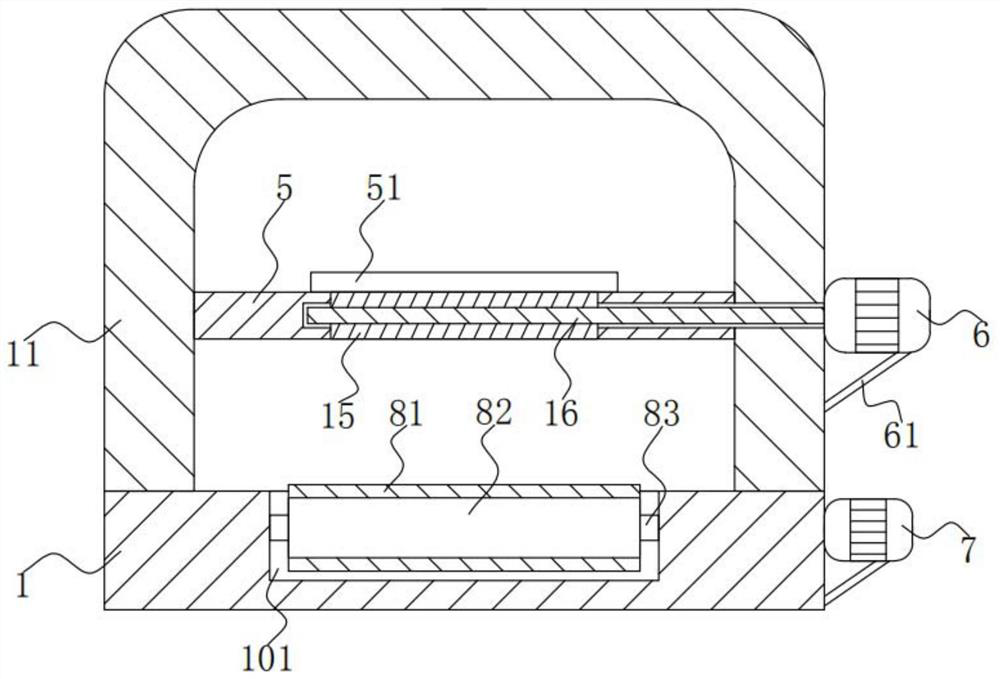

[0028] see Figure 1-5 , the present invention provides the following technical solutions:

[0029]A cold stamping device for auto parts with its own pick-up device, including a base 1, a support frame 11 is fixed on the upper end of the base 1, the support frame 11 is in an inverted "concave" shape, and a punch 2 is fixed on the upper end of the support frame 11 , the lower end of the output shaft of the punch 2 runs through the upper inner wall of the support frame 11 and is fixed with a receiving plate 3, the lower end of the receiving plate 3 is fixed with a stamping plate 4, and the left and right inner walls of the support frame 11 are fixed with a fixed plate 5, two fixed plates 5 is rotatably connected with a rotating rod 16 between the adjacent ends, and the right end of the rotating rod 16 runs through the right end of the fixed plate 5 on the right side and continues to run through the right end of the support frame 11, and the right end of the support frame 11 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com