Round food forming machine

A molding machine and food technology, applied in the field of devices for processing stuffed foods, can solve the problems of inconvenient disassembly, sticky stuffing, slow handling, etc., and achieve the effect of easy maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

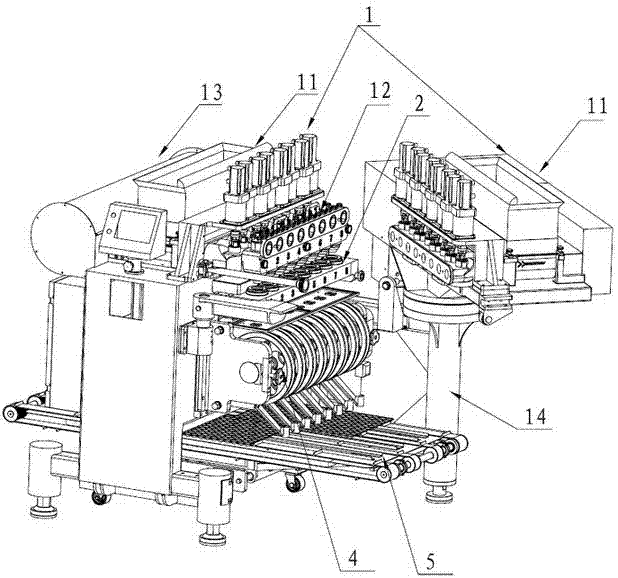

[0071] The round food forming device includes a feeding system 1, a skin filling complex 12, a retracting cutter assembly 2, a retracting and cutting knife lifting assembly 3, a rounding device 4 and a disk assembly 5, the feeding system 1 and the skin filling complex 12 Connected, the skin stuffing complex 12 exits are provided with a retracting cutter assembly 2, the retracting cutter assembly 2 is connected with the retracting cutter lifting assembly 3, and a rounding device 4 is arranged below the exit of the skin stuffing complex 12, and the rounding device 4 exits A tray assembly 5 is arranged at the center; the feeding system 1 is a split feeding system 1, and the split feeding system 1 includes two feeding assemblies 11, and the two feeding assemblies 11 are respectively connected with the skin stuffing complex 12 , and the feeding assembly 11 and the skin-stuffing complex 12 are separable structures, and the feeding assembly 11 can be completely separated from the skin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com