A dual-thrust ultra-high pressure boiler feed water pump

A boiler feed pump, ultra-high pressure technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problem of affecting the positioning accuracy of the core package and the pump cylinder parts, affecting the running clearance of the rotor parts, the stop and the sealing groove. Wear and other problems, to achieve the effect of reducing cutting labor cost, good axial compression, and reducing cutting waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

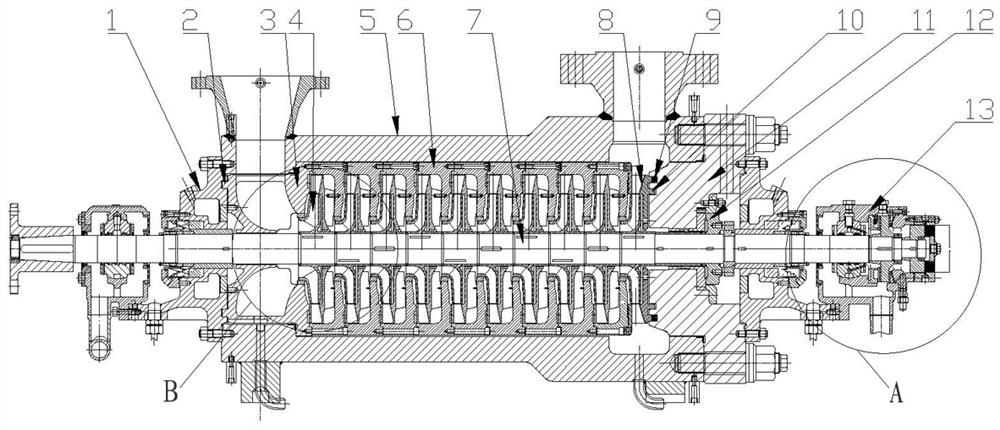

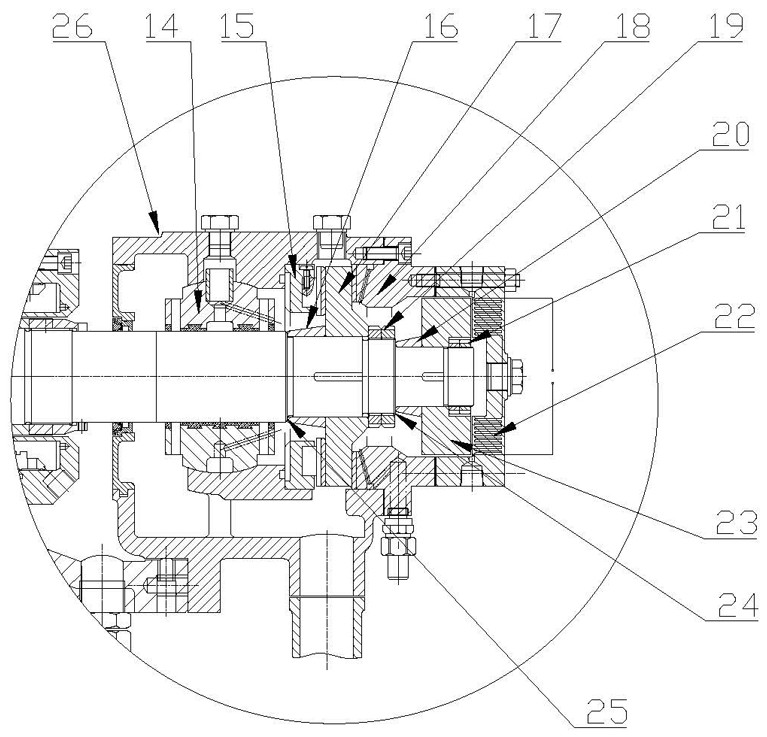

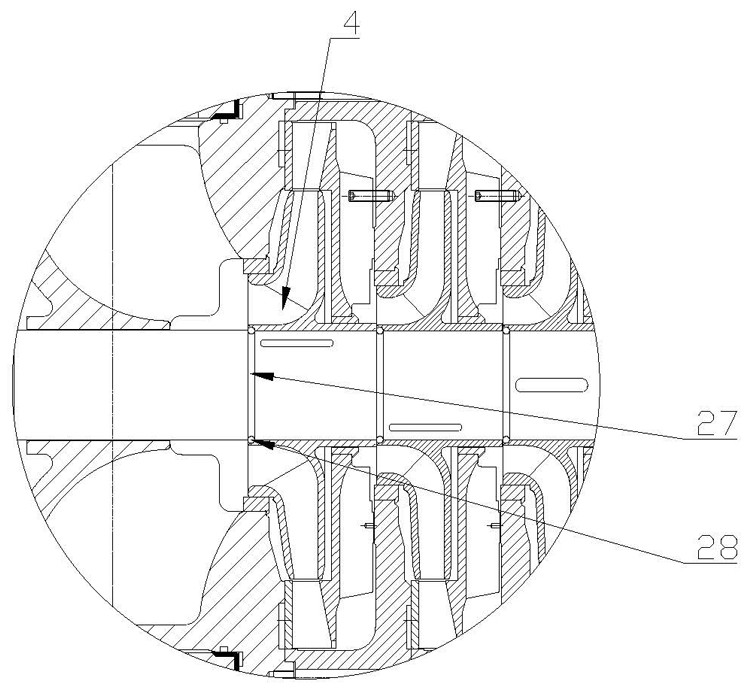

[0021] Such as Figure 1~3 As shown, the present invention comprises a pump body 5, a core pack is arranged in the pump body 5, the left end of the pump body 5 is a suction end, the right end of the pump body 5 is a discharge end, and the right end of the pump body 5 is provided with a tail cap 11, the described The core pack includes a pump shaft 7, and the right end of the pump shaft 7 protrudes from the tail cover 11, and passes through the balance plate assembly 12 to connect with the thrust bearing assembly 13. The thrust bearing assembly 13 includes a housing 26, and the housing 26 is correspondingly The right end of the pump shaft 7 is provided with an end cover 22, and the right end of the pump shaft 7 is fixedly provided with a first thrust bearing disc 23, and the end cover 22 is an electromagnet corresponding to the first thrust bearing disc 23; The second thrust bearing disc 17 is arranged on the left side of the first thrust bearing disc 23, and the thrust bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com