A Method of High-Speed Adjustment of Crystallizer Width in Online Hot State

A crystallizer, high-speed technology, applied in the field of continuous casting, can solve the problems of width adjustment speed limit, hindering productivity, etc., to achieve the effect of eliminating air gap, reducing cutting waste, and shortening adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

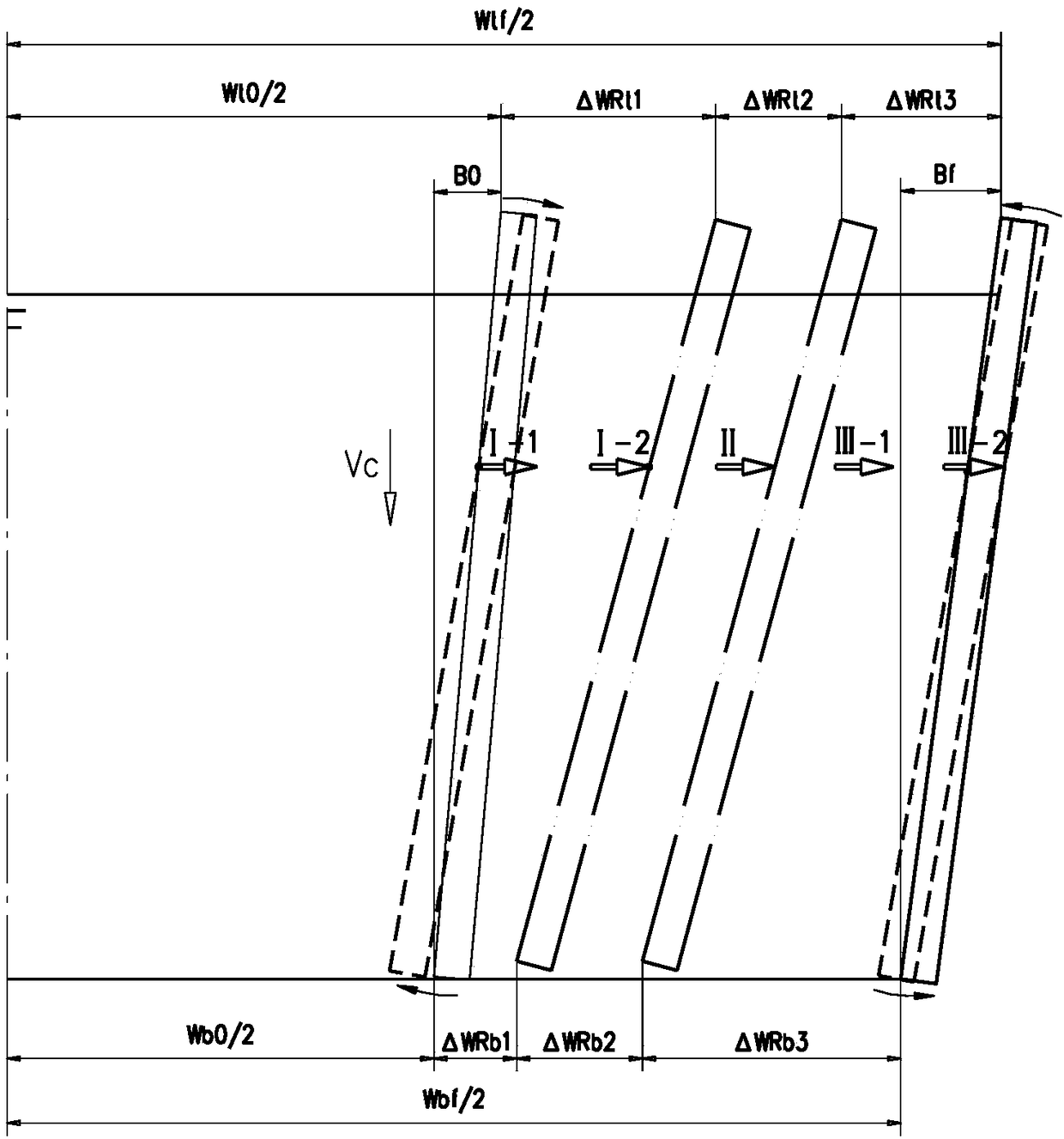

[0042] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] The setting of the mold width should consider the shrinkage caused by the solidification of molten steel and cooling to room temperature, and the setting of the mold thickness should not only consider the shrinkage but also add a light reduction. According to the composition of steel grades and factors such as continuous casting models, this total shrinkage factor X i It is advisable to take 1.008% ~ 1.025%, and ordinary carbon steel can take 1.013%, so the crystallizer real-time lower mouth width W bi It can be calculated by formula (2):

[0044] W bi =W si ×X i (2)

[0045] Where: W si - width of slab in cold state, mm;

[0046] x i - Slab shrinkage factor, %;

[0047] W bi -Theoretical width of the lower opening of the crystallizer, mm;

[0048] When i=0, it represents the current parameters of the crystallizer;

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com