Manufacturing method of cutting piece

A manufacturing method and technology of cutting discs, applied in the field of abrasives, can solve the problems of short service life, low cost, unsatisfactory, etc., and achieve the effects of high cutting efficiency, prolonging service life and reducing cutting waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

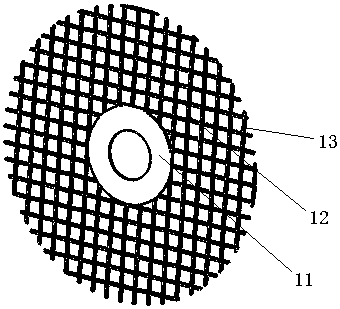

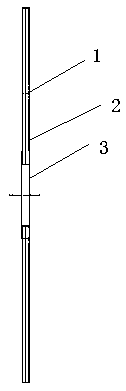

[0014] In order to further illustrate the technical solutions of the present invention, the specific embodiments of the present invention are now described with reference to the accompanying drawings; figure 1 , figure 2 , in this example, a steel wire with a diameter of 0.2 mm is used as the metal wire, and it is woven into a metal mesh with a diameter of 2 mm. The woven metal mesh is cut into a ring with an outer diameter of 150 mm and an inner diameter of 20 mm as the metal mesh 12. Near the inner hole of the metal mesh 12, a phenolic resin is coated with a coating thickness of 0.1 mm, and an annular area with an outer diameter of 40 mm and an inner diameter of 20 mm is used as the coating area 11; the diamond electroplating process commonly used in the industry is used. The surface of the metal mesh 12 is electroplated with diamond particles 13 to ensure that the thickness of the coating is 0.08 mm, and the above constitutes the skeleton 1; since the coating area 11 canno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com