A car front suspension beam

A front suspension and beam technology, applied in vehicle parts, substructure, transportation and packaging, etc., can solve the problems of difficult to control molding accuracy, poor automotive NVH performance, complex structure, etc., to reduce acceleration roar, reduce cutting waste, The effect of enhancing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a specific embodiment of the present invention and in conjunction with the accompanying drawings, further describes the technical solution of the present invention, but the present invention is not limited to this embodiment.

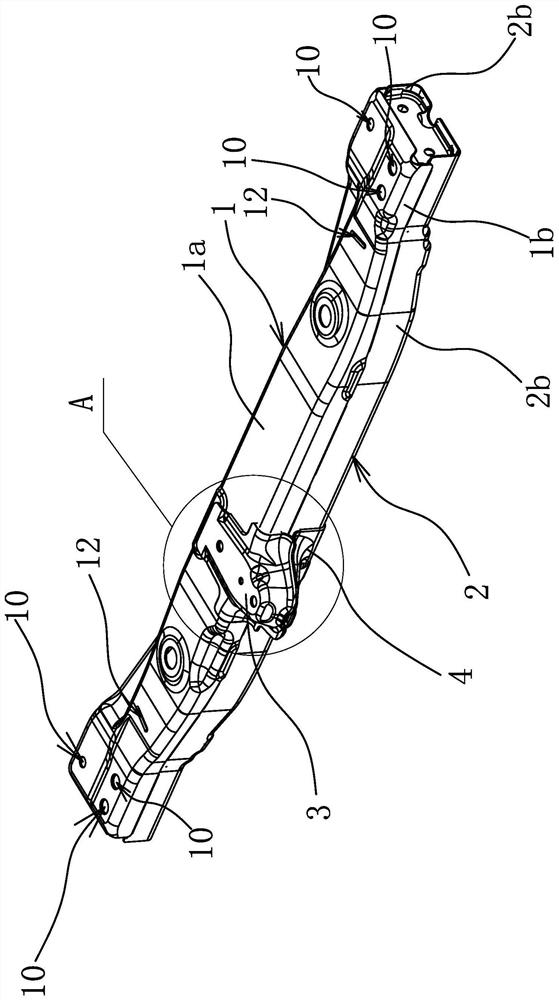

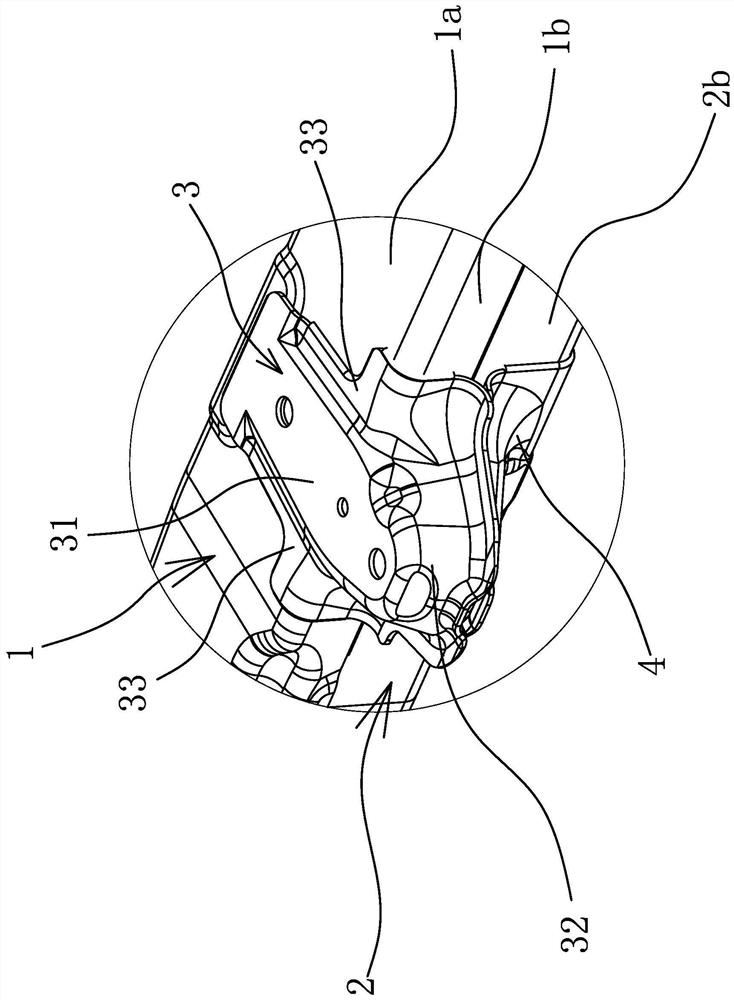

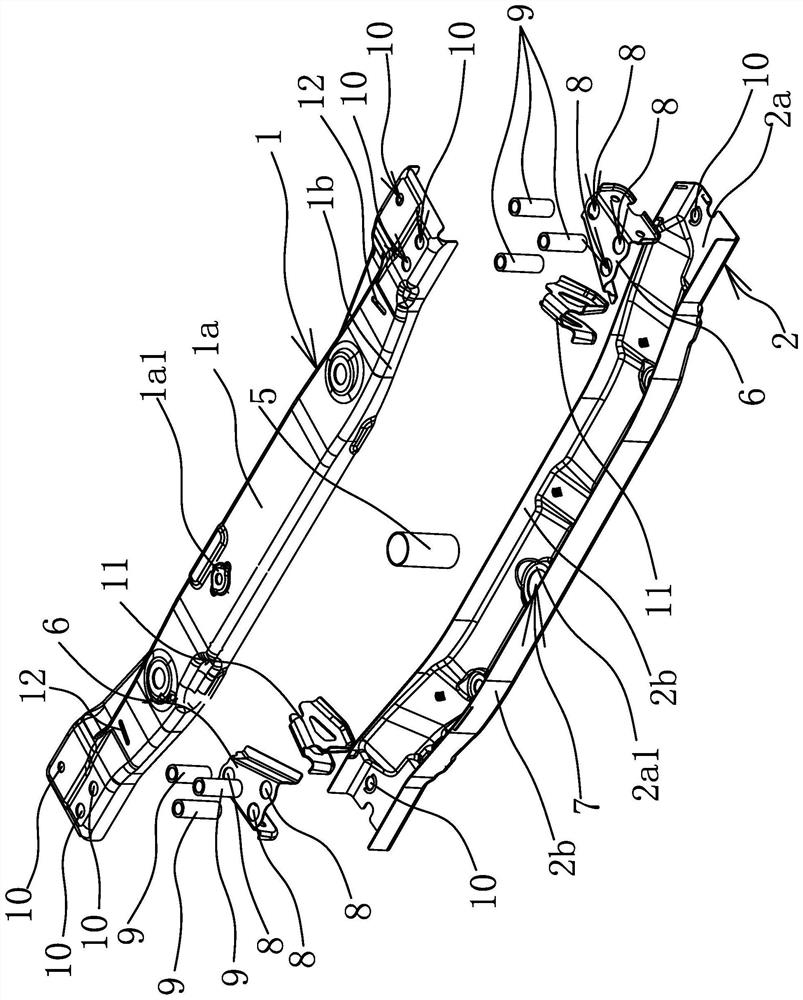

[0028] Such as figure 1 and figure 2 As shown, the front suspension crossbeam of the automobile comprises a crossbeam upper plate 1 and a crossbeam lower plate 2. There is a suspension installation upper plate 3, and the crossbeam lower plate 2 is fixedly connected with a suspension installation lower plate 4 supporting the suspension installation upper plate 3, and the suspension installation upper plate 3 is fixedly connected with the suspension installation lower plate 4.

[0029] Such as figure 2 As shown, the suspension installation upper plate 3 includes a longitudinal top plate 31, the other end of the longitudinal top plate 31 extends to the side of the beam upper plate 1 and has a bent plate body 32 bent downward rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com