Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce cleaning pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

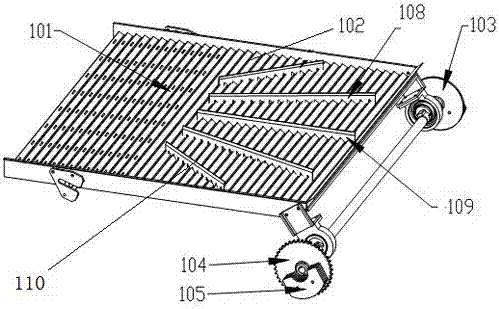

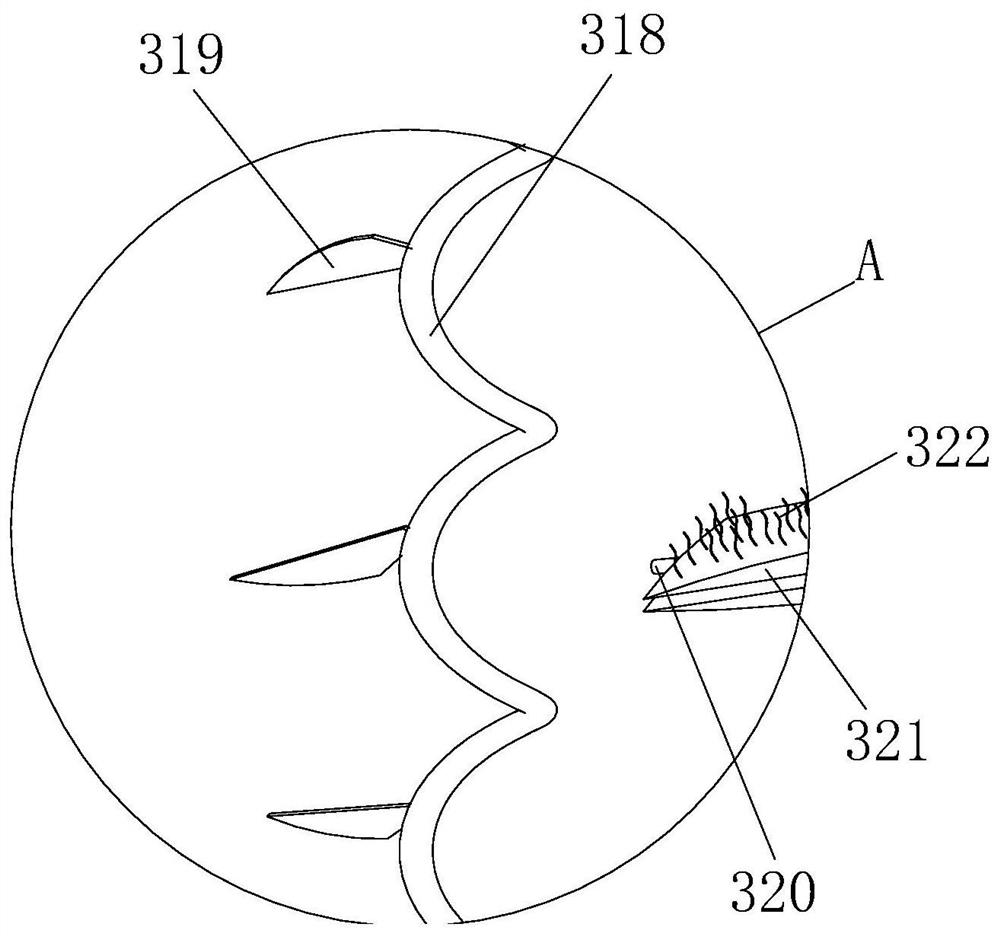

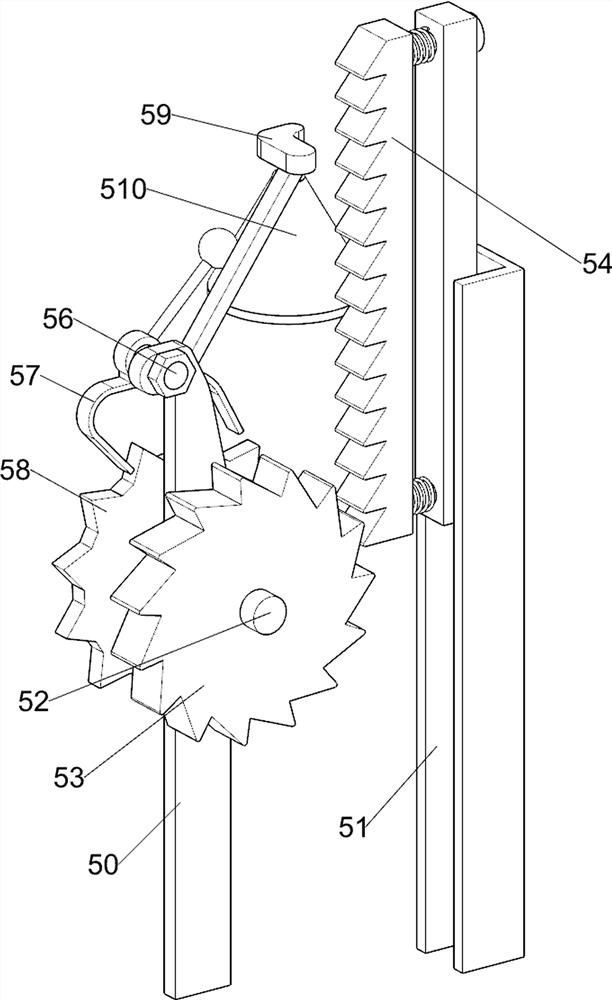

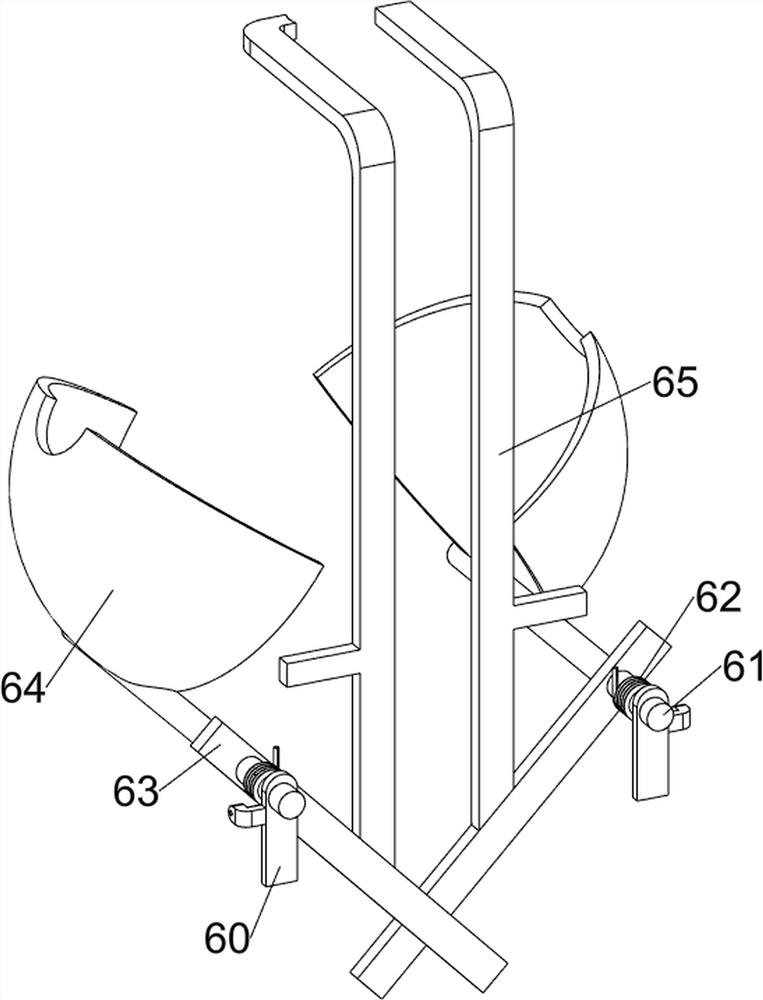

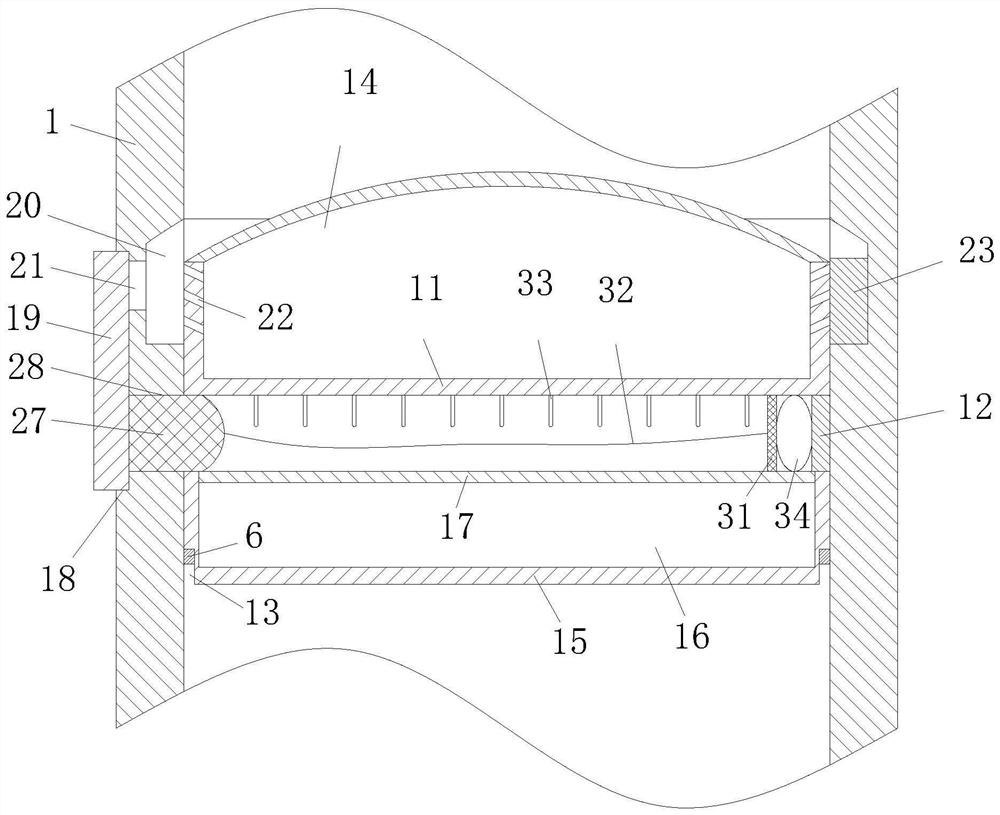

Grain selection system having function of distributing materials uniformly and pre-selecting

The invention relates to a grain selection system having the functions of distributing materials uniformly and pre-selecting. The system includes a material vibrating plate, a selection sieve and a fan. The material vibrating plate is composed of a vibrating plate surface, a vibrating plate guide strip, a vibrating plate weight counterweight wheel, a vibrating plate chain wheel and a vibrating plate counterweight sheet. When grain is selected, the grain is distributed uniformly in the radial direction of the selection mechanism, pre-selection can be conducted on materials, a part of the grain can pass through the sieve in advance, the selection pressure of a rear-portion selection mechanism is thus reduced, and the selection efficiency is largely improved. By additional installing sheet-like adjustable counter weights on power input parts of the material vibrating plates and the selection sieves, the inertia force of the selection mechanism can be reduced by adjusting the counter weights, and the effect of reducing vibration and noise is thus achieved.

Owner:JIANGSU UNIV

Purification method for cisatracurium besylate

InactiveCN104892508ASimplify cumbersome operationsReduce consumptionOrganic chemistryCisatracurium BesylatePurification methods

The invention discloses an industrial purification and preparation method for cisatracurium besylate. According to the preparation method, the refining operation process is simplified, and firstly, under the circumstance of not changing a base, high-purity cisatracurium besylate is obtained in a non-column chromatography preparation mode. By adopting the preparation method disclosed by the invention, the production cycle is shortened greatly, productivity is improved, the yield reaches 40% or above, the content of cisatracurium besylate in a product is not less than 98%, the total content of impurities is less than or equal to 2%, the content of mono-quaternaries is less than or equal to 0.5%, the content of other single maximum impurity is less than or equal to 0.5%, and the content of all isomers is less than or equal to 0.1%.

Owner:TIANJIN ZHONGRUI PHARMA

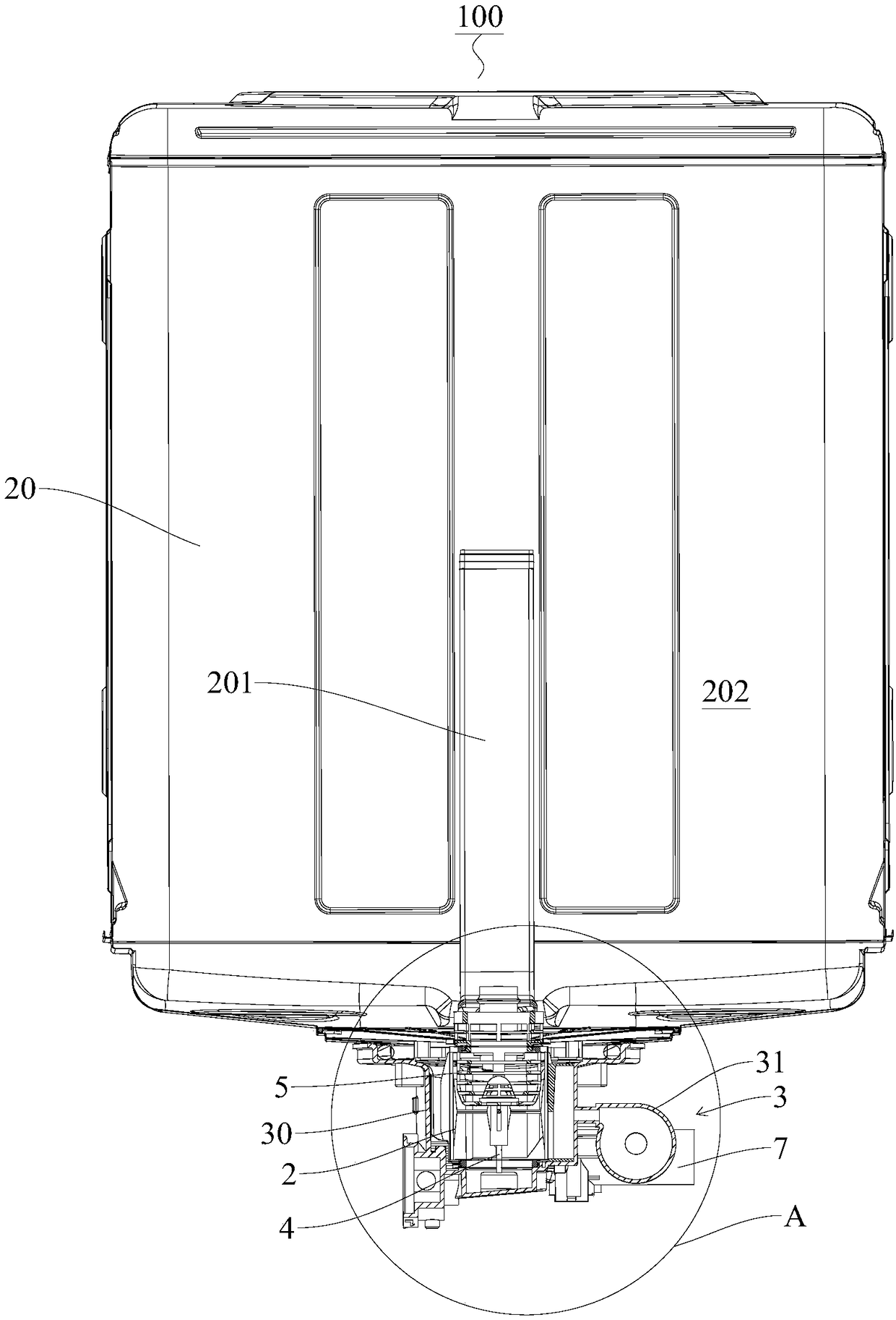

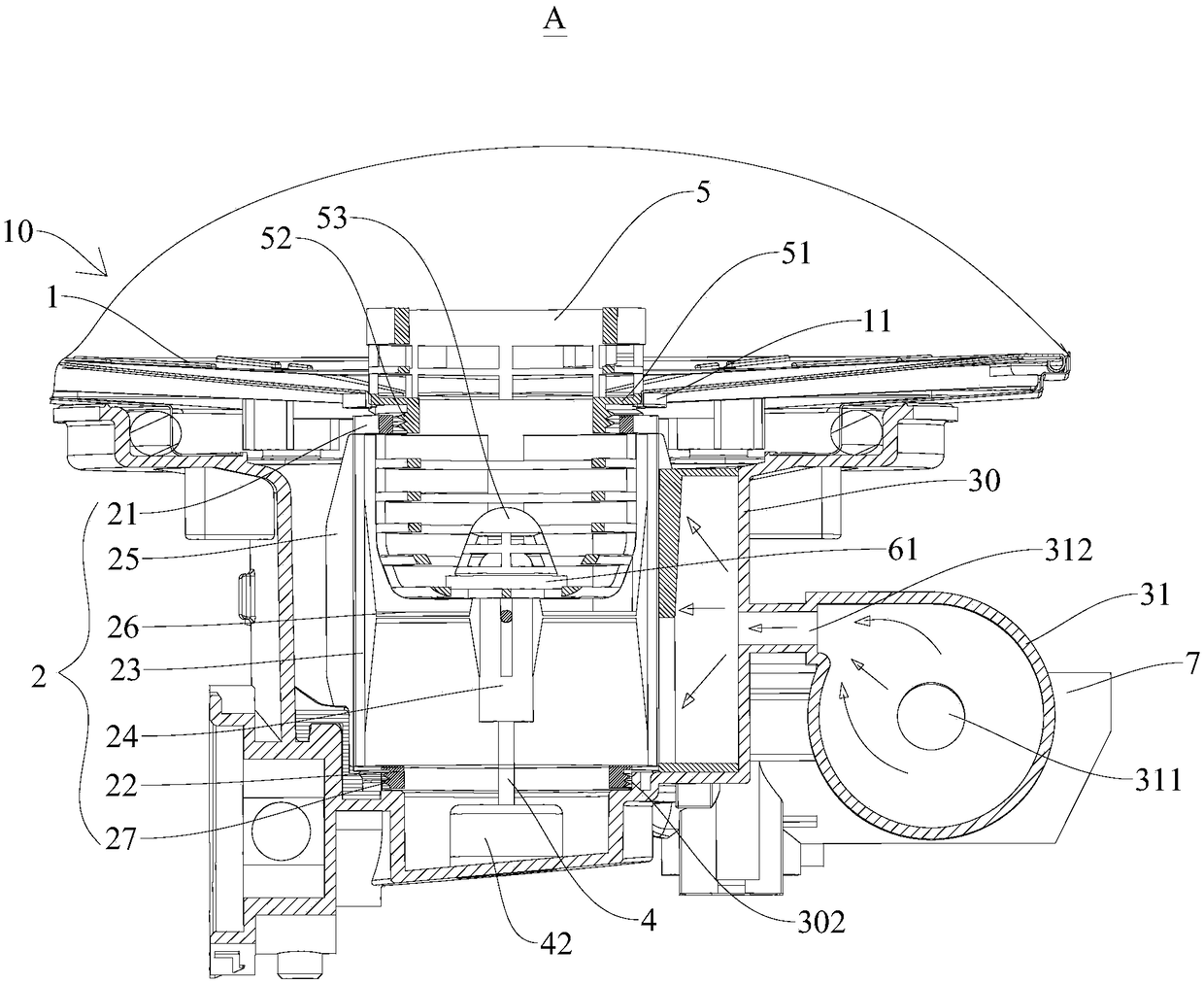

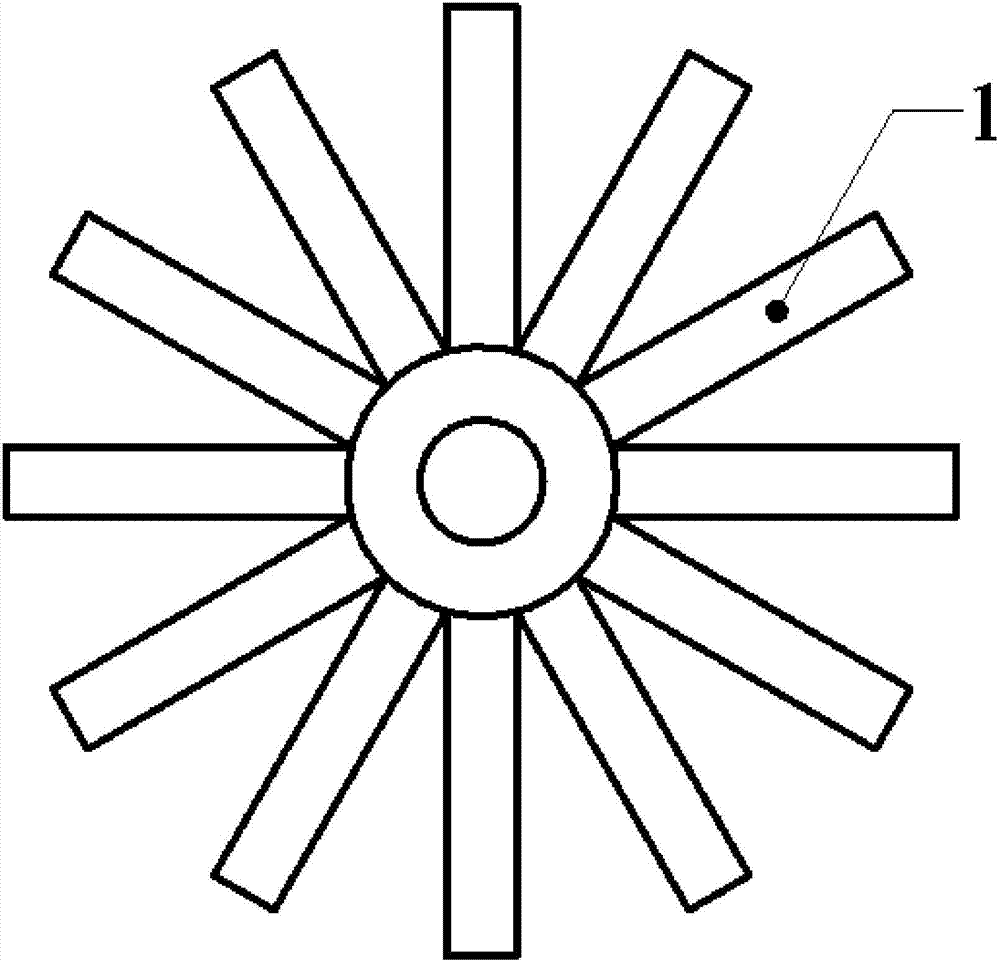

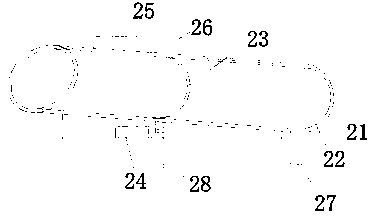

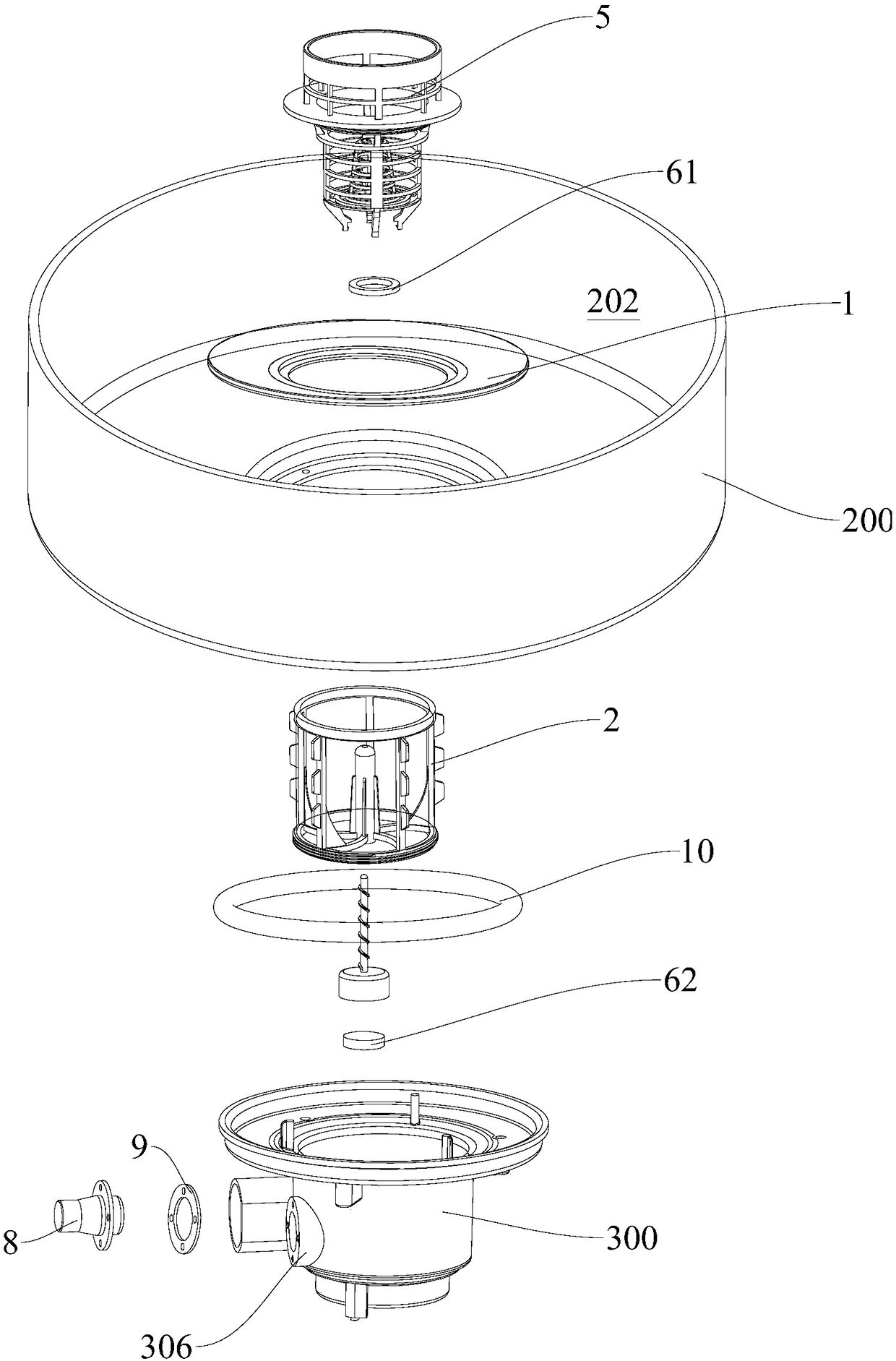

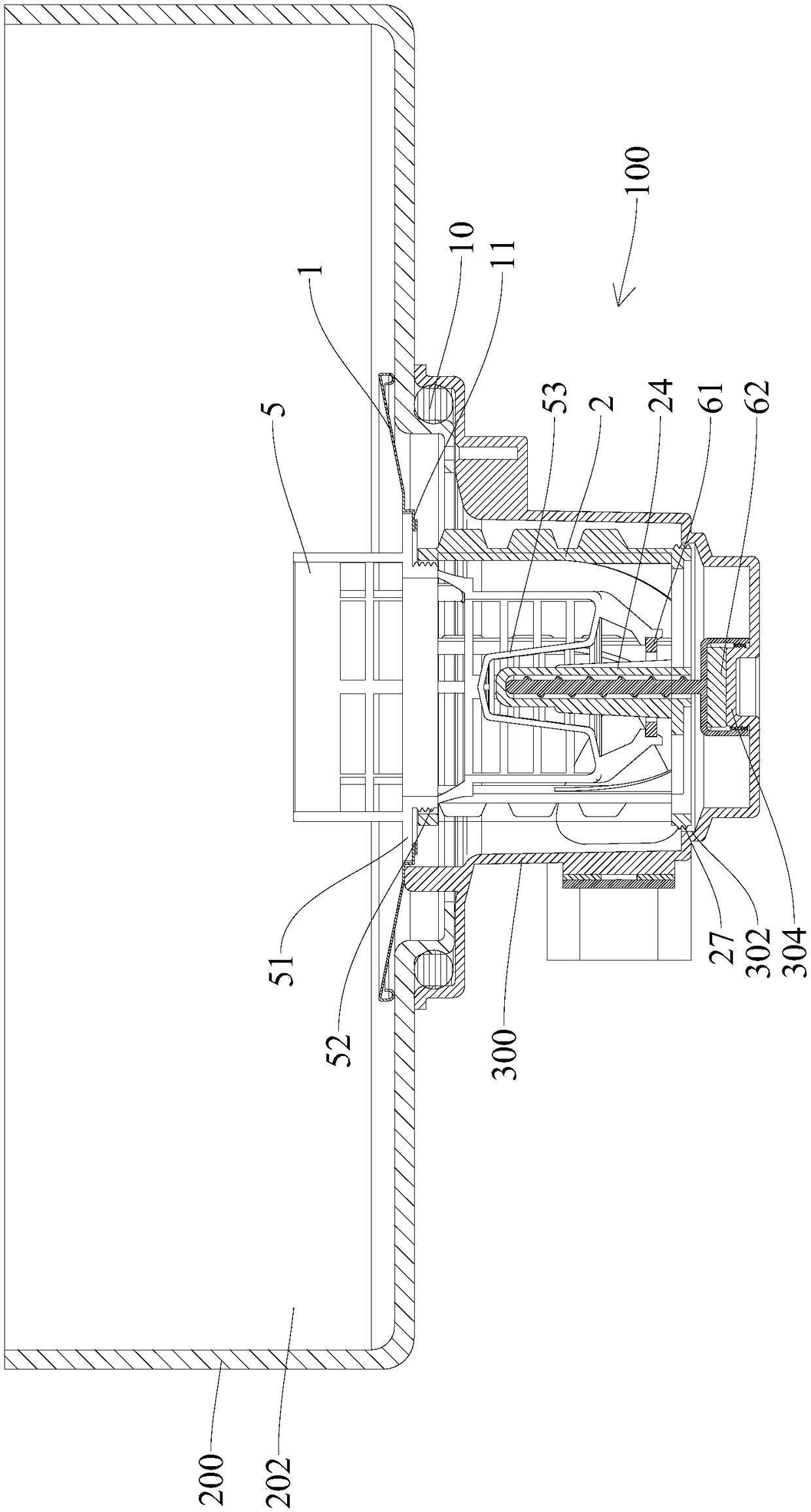

Bowl washing machine and filtering system thereof

PendingCN108514395ASolve the accumulationReduce energy consumptionTableware washing/rinsing machine detailsFilter systemFilter effect

The invention provides a bowl washing machine and a filtering system thereof. The bowl washing machine comprises a water collecting cup and a washing pump, and the washing pump is used for pumping water out of the water collecting cup. The filtering system comprises a planar filtering part and a cylindrical filtering part, wherein the planar filtering part is arranged above the water collecting cup, the cylinder filtering part is cylindrical and can be rotatably arranged in the water collecting cup, and when the washing pump pumps water, the cylindrical filtering part rotates. According to thefiltering system, the cylindrical filtering part can be self-cleaned, and the filtering effect is guaranteed.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Refinement method of cisatracurium besylate

ActiveCN104292161AReduce consumptionSimplify the refining processOrganic chemistryCisatracurium BesylateChromatographic column

The invention relates to an industrial preparation method of cisatracurium besylate. The preparation method simplifies the refinement operation process, and obtains the high-purity cisatracurium besylate in a non-chromatographic column chromatography preparation mode under the condition of not changing the salt base for the first time. The preparation method can greatly shorten the production cycle, enhance the productivity and increase the yield to 45% above. In the product, the content of cisatracurium besylate is not lower than 98%, the content of total impurities does not exceed 2%, the content of mono quaternary ammonium salts does not exceed 0.2%, the content of other maximum individual impurities does not exceed 0.3%, and the content of isomers does not exceed 0.1%.

Owner:大道隆达(北京)医药科技发展有限公司

Composite type air cleaner for pipeline descaling

ActiveCN106964611AImprove surface propertiesAchieve the purpose of cleaningHollow article cleaningResonant cavitySingle stage

The invention discloses a composite type air cleaner for pipeline descaling. The composite type air cleaner comprises a blade cleaning mechanism and a nozzle. The blade cleaning mechanism and the nozzle are connected into a whole through self-lock threads. The blade cleaning mechanism comprises inner-layer blades and outer-layer blades. The inner-layer blades and the outer-layer blades are staggered and stacked together. The nozzle is composed of an inlet cavity, a cavitation resonant cavity and small jet flow holes. Due to the fact that the cavitation mechanism is adopted for cleaning a pipeline, the cleaning efficiency is much higher compared with traditional cleaning ways. By the adoption of two-stage composition of the blade cavitation cleaner and the cavitation nozzle, the cavitation effect is improved compared with a single-stage cavitation cleaner. By the adoption of the composite type air cleaner, needed driving pressure is lower than 10 MPa, and the risk is lowered compared with traditional high-pressure water jet flow cleaning technology. The cavitation cleaner is simple in structure and low in manufacturing cost, and therefore the needed cost is lower compared with traditional PIG cleaning technology.

Owner:DALIAN MARITIME UNIVERSITY +1

Kitchen garbage cleaning equipment and method

InactiveCN109127662AReduce the pressure of cleaningImprove cleaning effectTransportation and packagingSolid waste disposalPower equipmentWinnowing

The invention relates to the technical field of environmental protection, in particular to kitchen garbage cleaning equipment. The kitchen garbage cleaning equipment comprises a garbage collecting tower, a centrifugal dehydrating device, a sorting table, a garbage raking machine, a rotary-cutting crusher, a tunnel drying machine, a winnowing device, a vibratory separating and screening device, a rack, a conveying belt, a hoister, a cleaning device, a garbage shoveling and conveying device and power equipment. Kitchen garbage is minced and broken in a garbage collecting tower to remove water byextrusion, after centrifugal dehydrating is carried out, large packing objects and the like are sorted through intelligent equipment, and strip-shaped thin-film plastic packing objects and residual packing ropes are sorted out by the garbage raking machine; then secondary mincing and breakage and hot-air drying are carried out until the garbage is loose; then small packing objects and light plastics and foams are removed by winnowing; and finally, light plastic blocks and heavy objects such as glass, metal and bricks are separated by a vibrating sieve, available kitchen garbage is obtained, the circumstances that harmful garbage such as plastic packing objects enter a kitchen garbage recycling system again are reduced effectively, and ecological benefit and economic benefit of utilizationof the kitchen garbage are increased.

Owner:王桂生

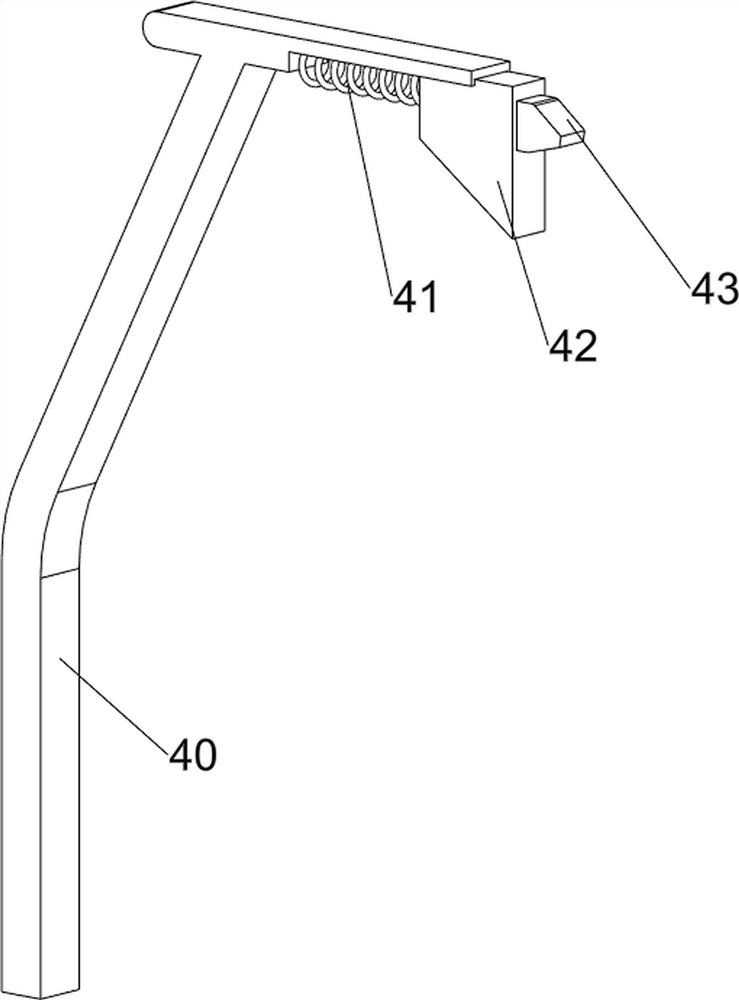

Brush roller trimming device

InactiveCN108713854AImprove working environmentReduce cleaning pressureBristleDrive shaftTransmission belt

The invention discloses a brush roller trimming device which comprises a device body. A sliding supporting frame is slidably arranged on the device body. A cylinder I is arranged on the sliding supporting frame, a trimming device is arranged at the end of the cylinder I, a driving shaft is arranged at one side of the device body, the driving shaft is in transmission connection with a motor I through a transmission belt, a driven shaft is arranged at the other side of the device body, the driven shaft is connected with one end of a cylinder II, the ends of the driven shaft and the driving shaftare each provided with a connecting device, a brush roller is connected between the two connecting devices, a supporting device is arranged between the brush roller and the device body, the trimmingdevice comprises a protective cover, a motor II, a trimming blade and a protective net, the protective cover is connected with one end of the cylinder I, the motor II is arranged inside the protectivecover, the motor II is connected with the trimming blade, the protective net is arranged at the opening end of the protective cover, a dust suction device is arranged inside the protective cover, byarranging the protective cover and the protective net, fragments in the trimming process cannot fly around, the dust suction device can remove fragments inside the protective cover, and the working environment of workers is improved.

Owner:安徽六顺达刷业有限公司

Method for preparing special material of recycled polyester for high-purity chemical fibers

InactiveCN103831911AExtended service lifeImprove cleanlinessPlastic recyclingMechanical material recoveryFiberPolyester

The invention discloses a method for preparing a special material of recycled polyester for high-purity chemical fibers. The method comprises the following eleven process steps: unpacking, removing metal impurities, performing rotary impurity removal, performing near-infrared separation, performing visible light separation, performing whole-bottle cleaning, performing fragment pre-cleaning, removing pre-cleaning impurities, performing main washing, separating and purifying, conveying bottle chips to a storage bin. According to the method for preparing the special material of recycled polyester for the high-purity chemical fibers, metal impurities in bottle bricks are removed by adopting a metal detection device, the service lives of mechanical screw, grinding tools and other equipment can be effectively prolonged, shear stress is generated to strong marks on the surfaces of the bottle chips by utilizing centrifugal force of turbo prop, buoyancy of water and gravity of bottle chips, and bottle marks on the bottle chips are removed, so that the bottle chips can keep high cleanliness and are subjected to the main washing process, and the liquid replacement frequency during main washing is reduced. Meanwhile, the cleaning time and pressure during main washing can be effectively reduced, and the glossiness and transparency of the bottle chips are ensured.

Owner:江苏中再再生资源有限公司

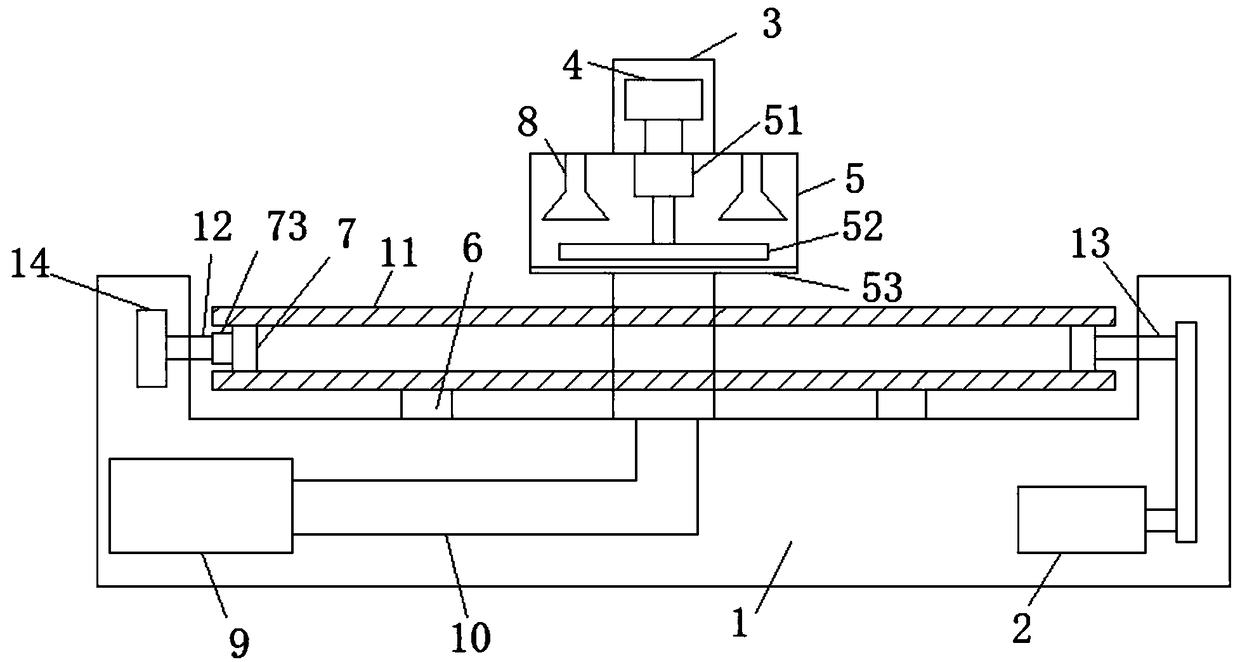

Efficient and intelligent solar cell panel cleaning device

ActiveCN104550160AReduce cleaning dead spaceReduce the phenomenon of water flow awayPhotovoltaicsFlexible article cleaningPhysicsWater pipe

The invention relates to cleaning devices, particularly to an efficient and intelligent solar cell panel cleaning device. The efficient and intelligent solar cell panel cleaning device is characterized by comprising a device body; in the moving direction of the device body, the left end and the right end of the lower surface of the device body are provided with three six-stage hairbrush devices respectively which are distributed in an S shape; meanwhile, the middle of the lower surface of the device body is provided with an efficient atomizing spray device, and the upper side and the lower side of the efficient atomizing spray device are provided with roller type hairbrushes; the rear end of the lower surface of the device body is provided with an absorbing port, and correspondingly, the front end of the lower surface of the device body is provided with a traction plate; the front surface of the device body is fixedly provided with a glass sheet; the glass sheet is provided with a rain sensor; the upper surface of the device body is fixedly provided with a water pipe, one end of the water pipe is connected with a water tank device fixed onto one side surface of the device body, and the other end of the water pipe is connected with the efficient atomizing spray device. The efficient and intelligent solar cell panel cleaning device can clean solar cell panels scientifically and efficiently.

Owner:JIANGSU UNIV

Dish-washing machine and filtering system thereof

PendingCN108498040AGuaranteed cleaning effectAvoid accumulationTableware washing/rinsing machine detailsCleaning equipmentFilter systemWater collection

The invention discloses a dish-washing machine and a filtering system thereof. The dish-washing machine comprises a water collection cup and a washing pump, wherein the washing pump is used for pumping water from the interior of the water collection cup. According to the embodiment, the filtering system of the dish-washing machine comprises a cylindrical filtering part and an ultrasonic generator,wherein the cylindrical filtering part is arranged in the water collection cup; and the ultrasonic generator is arranged in a mode of being close to the cylindrical filtering part. According to the dish-washing machine provided by the embodiment, the cylindrical filtering part can be cleaned via the ultrasonic generator, so that an effect of cleaning the cylindrical filtering part can be improved, and subsequently, a washing effect of the dish-washing machine can be improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Wool washing production process

InactiveCN106884308AImprove cleanlinessIncrease concentrationDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsAlcoholWastewater

The invention relates to a wool washing production process. The wool washing production process is characterized in that wool is dried after being subjected to tank I washing, tank II washing, tank III washing, tank IV washing, tank V washing, tank VI washing and tank VII washing. Through seven-tank washing, the wool cleaning effect can be ensured; during tank I washing, no cleaning agent is added; during tank II washing and tank III washing, wool fibers are washed by sodium carbonate washing liquors of different concentrations; tank I washing is mainly used for wetting wools and washing off a part of sandy soil impurities; during tank II washing, a low-concentration sodium carbonate washing liquor is adopted, so that a part of wool fat is removed while the wools are further wetted; during tank III washing, the concentration of the sodium carbonate washing liquor is increased, so that the aim of removing the wool fat well is fulfilled; during tank IV washing, the wools are further washed by protease, so that the wool cleaning effect is ensured; during tank V washing, an alcohol type washing liquor is used for cleaning; during tank VI washing and tank VII washing, clear water is used for rinsing. By adopting the wool washing production process, washing pressures on subsequent two sides can be lowered, waste water can be collected according to each tank, and the pollution of the waste water is lowered.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

A kind of refining method of atracurium besylate

ActiveCN104292161BReduce cleaning pressureQuality assuranceOrganic chemistryCisatracurium BesylateChromatographic column

The invention relates to an industrial preparation method of cisatracurium besylate. The preparation method simplifies the refinement operation process, and obtains the high-purity cisatracurium besylate in a non-chromatographic column chromatography preparation mode under the condition of not changing the salt base for the first time. The preparation method can greatly shorten the production cycle, enhance the productivity and increase the yield to 45% above. In the product, the content of cisatracurium besylate is not lower than 98%, the content of total impurities does not exceed 2%, the content of mono quaternary ammonium salts does not exceed 0.2%, the content of other maximum individual impurities does not exceed 0.3%, and the content of isomers does not exceed 0.1%.

Owner:大道隆达(北京)医药科技发展有限公司

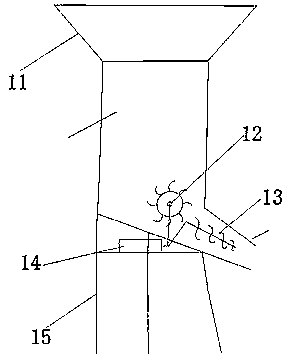

High-rise building civil rubbish automatic conveying system

PendingCN110304383AEasy to handleImprove processing efficiencyRefuse transferringGrain treatmentsTransport systemHigh rise

The invention discloses a high-rise building civil rubbish automatic conveying system. The system comprises a building body and a rubbish conveying and processing system, wherein a rubbish processingwell is arranged in the building body, rubbish throwing grooves are symmetrically formed in each layer of passageway in the building body, and the rubbish throwing grooves communicate with the rubbishprocessing well. The invention relates to the technical field of building rubbish processing, rubbish throwing points are arranged in each layer of passageway in the high-rise building, so that residents only need to throw rubbish into the rubbish throwing points in the passageways, the rubbish is concentrated into the rubbish processing well in the building, and after being subjected to dust removing, crushing and extruding, the rubbish is finally conveyed out at the bottom of the building; and in the whole process, property cleaning does not need to participate basically, meanwhile, the purpose of processing the rubbish in real time is achieved, so that the pressure of the property cleaning is greatly reduced, the rubbish can be rapidly processed, the peculiar smell is prevented from being generated, and the rubbish processing efficiency is greatly improved.

Owner:JINLING INST OF TECH

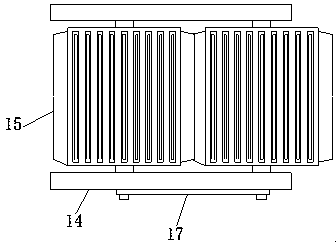

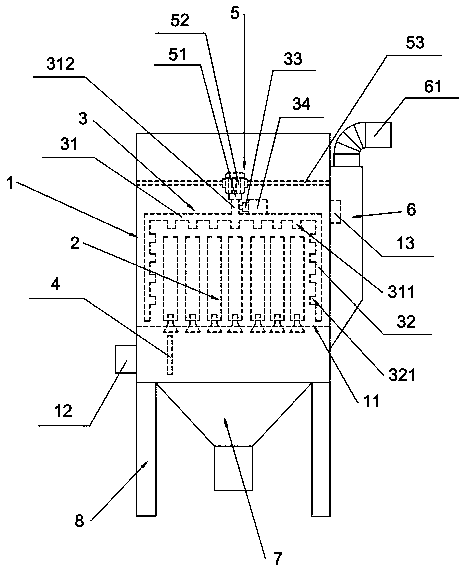

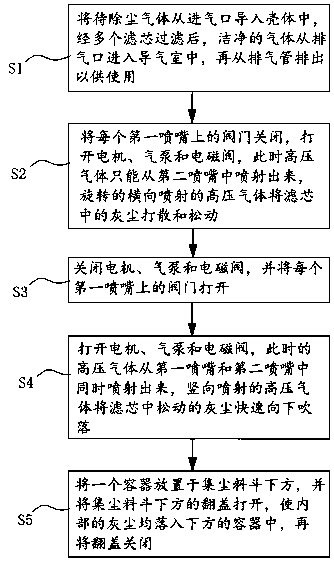

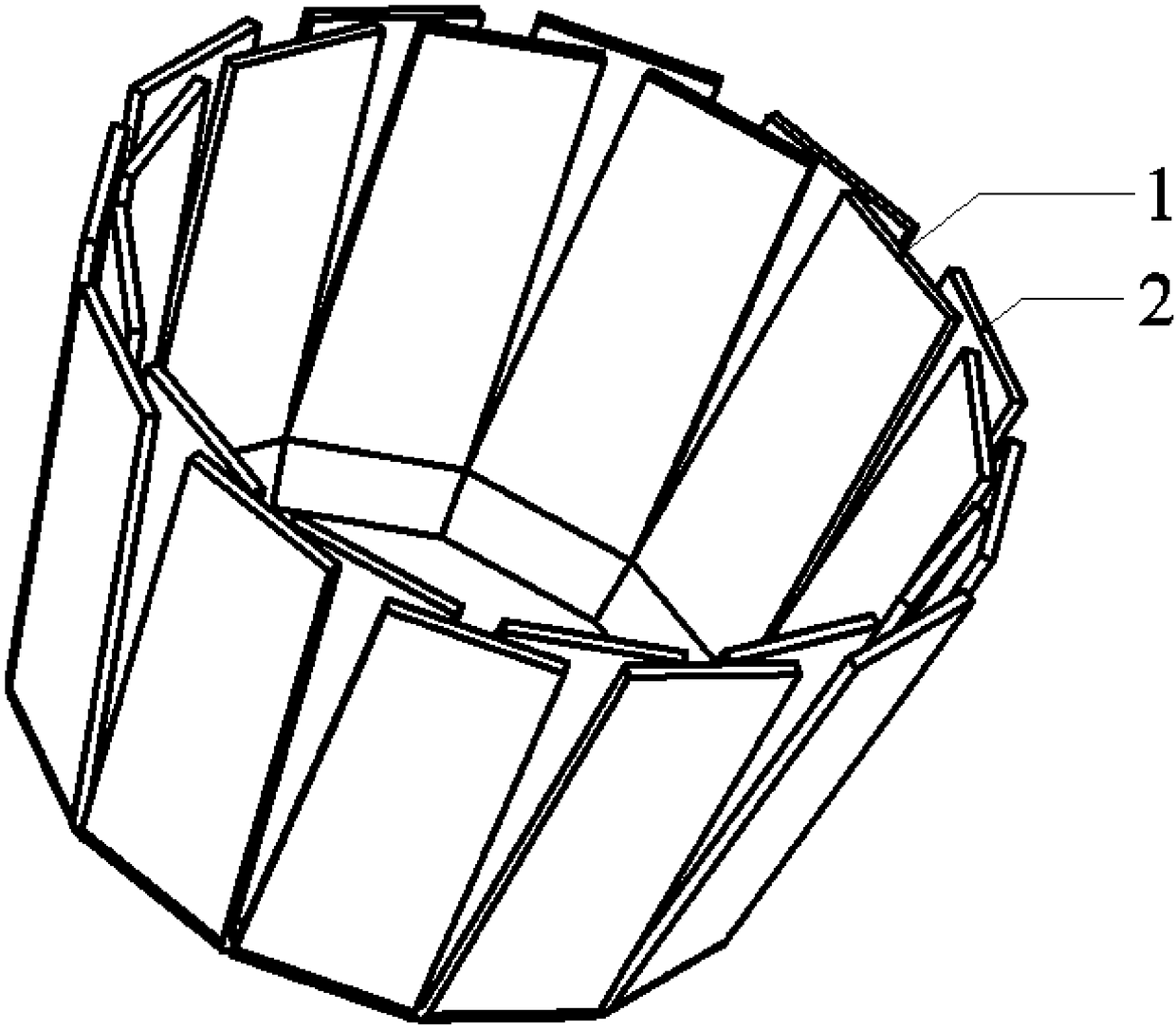

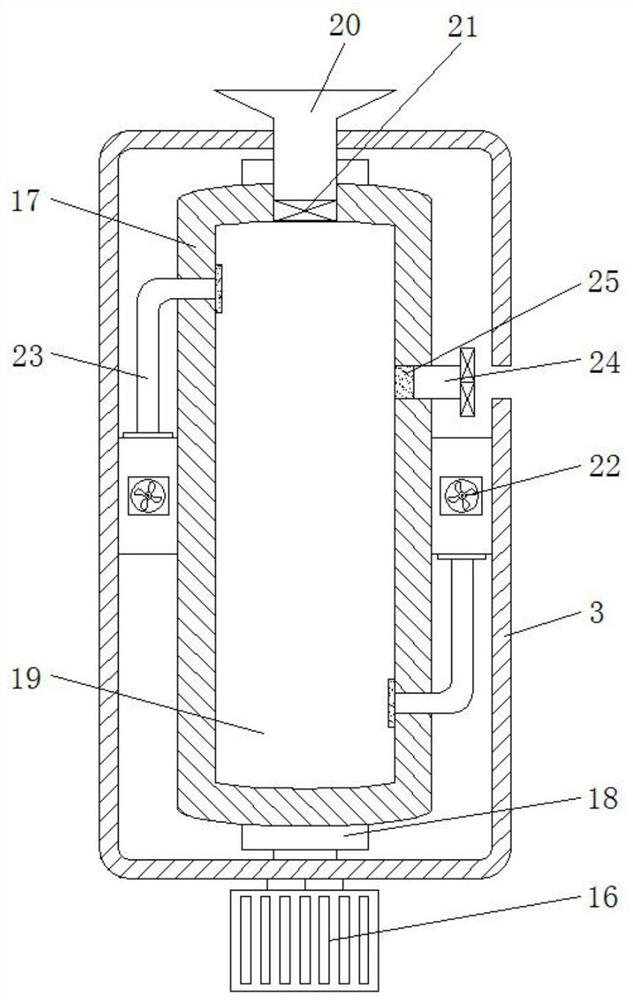

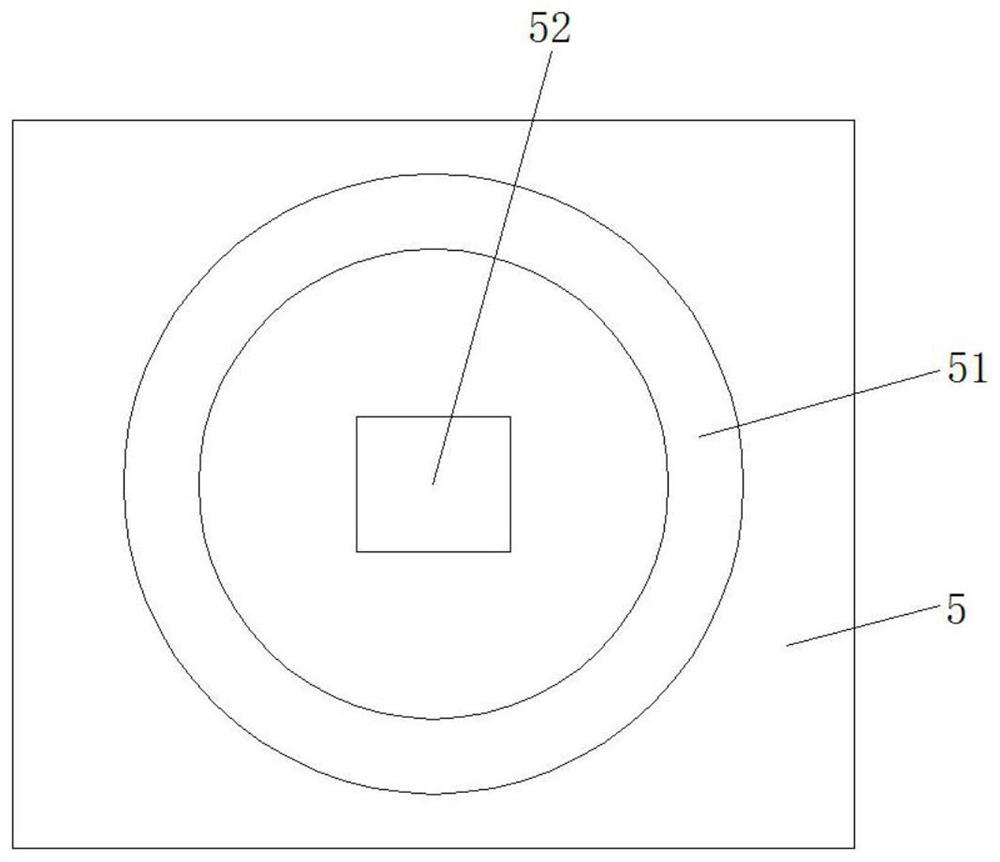

Rotatable dust remover for automatically cleaning dust and use technology thereof

PendingCN109432894AReduce workloadLow cleaning pressureDispersed particle filtrationTransportation and packagingEngineeringHigh pressure

The invention provides a rotatable dust remover for automatically cleaning dust. The rotatable dust remover comprises a shell, a plurality of filter elements, a dust cleaning device and an intercepting plate; the shell is of a cylindrical shape; the filter elements are encircled into multiple layers of circles from center to outer periphery; a connector is arranged in the shell; the bottom of thefilter elements is respectively and fixedly connected with the connector; the connector is fixedly connected with an inner wall of the shell; the dust cleaning device comprises a horizontal pipe, twovertical pipes and a solenoid valve; the horizontal pipe which is horizontally arranged is positioned above the filter elements, and the two ends of the horizontal pipe both extend out of the filter elements; the two vertical pipes which are vertically arranged are respectively and fixedly connected with the two ends of the horizontal pipe; and the two vertical pipes are communicated with the horizontal pipe. According to the invention, a rotatable dust cleaning technology is adopted by the dust remover; the dust cleaning device can quickly rotate and jet high-pressure air; in addition, the vertical pipes which are vertically arranged are arranged at the two ends of the horizontal pipe in the dust cleaning device; the horizontal pipe is used for longitudinally cleaning the filter elements,and the vertical pipes are used for horizontally cleaning the filter elements from lateral edge; and the cleaning scope while rotating is omnibearing and free from a dead angle.

Owner:泰州市大润机械有限公司

Composite cavitation cleaner for pipe descaling

ActiveCN106964611BImprove surface propertiesAchieve the purpose of cleaningHollow article cleaningResonant cavitySingle stage

The invention discloses a composite type air cleaner for pipeline descaling. The composite type air cleaner comprises a blade cleaning mechanism and a nozzle. The blade cleaning mechanism and the nozzle are connected into a whole through self-lock threads. The blade cleaning mechanism comprises inner-layer blades and outer-layer blades. The inner-layer blades and the outer-layer blades are staggered and stacked together. The nozzle is composed of an inlet cavity, a cavitation resonant cavity and small jet flow holes. Due to the fact that the cavitation mechanism is adopted for cleaning a pipeline, the cleaning efficiency is much higher compared with traditional cleaning ways. By the adoption of two-stage composition of the blade cavitation cleaner and the cavitation nozzle, the cavitation effect is improved compared with a single-stage cavitation cleaner. By the adoption of the composite type air cleaner, needed driving pressure is lower than 10 MPa, and the risk is lowered compared with traditional high-pressure water jet flow cleaning technology. The cavitation cleaner is simple in structure and low in manufacturing cost, and therefore the needed cost is lower compared with traditional PIG cleaning technology.

Owner:DALIAN MARITIME UNIVERSITY +1

Waste plastic cleaning device

InactiveCN113696379AFull agitationEasy deep cleaningPlastic recyclingMechanical material recoveryEnvironmental engineeringMechanical engineering

The invention provides a waste plastic cleaning device, and relates to the field of resource cyclic utilization. The waste plastic cleaning device comprises a cleaning barrel used for cleaning waste plastic, a supporting ring used for supporting the cleaning barrel and a telescopic cleaning mechanism used for stirring and cleaning the waste plastic, the supporting ring is fixedly connected to the surface of the cleaning barrel, and a plurality of supporting legs are fixedly connected to the bottom of the supporting ring. The bottoms of the supporting legs are fixedly connected with a cushion plate, and the telescopic cleaning mechanism is arranged on the cleaning barrel. According to the waste plastic cleaning device, a special structure capable of rapidly cutting and comprehensively stirring plastic is designed according to the problem of a poor cleaning effect of existing plastic recycling and pre-cleaning, so that the problems that the pre-cleaning process is simple before common waste plastic products are crushed, a large number of residues in the plastic are difficult to clean out, cutter teeth are still prone to damage during crushing, and the subsequent cleaning pressure cannot be greatly reduced in the early-stage pre-cleaning process are effectively solved.

Owner:雷霄

Novel fireproof cotton feeder for removing mulching film

ActiveCN104233516AIncrease the initial velocityControl outputFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersProduction lineFiber

The invention relates to a novel fireproof cotton feeder for removing a mulching film. The novel fireproof cotton feeder for removing the mulching film comprises a cotton storage box, wherein a horizontal conveying mechanism, a lifting row sprocket, a cotton evening roller and a cotton stripping roller are arranged in the cotton storage box; the lifting row sprocket is slantways arranged; the front part of the lifting row sprocket is higher than the rear part of the lifting row sprocket; a sundries storage pit is arranged below a part between the front end of the horizontal conveying mechanism and the rear side of the lower part of the lifting row sprocket; an arc-shaped guard plate is arranged in front of the cotton stripping roller; an unginned cotton falling channel is arranged below the cotton stripping roller and the lifting row sprocket; a vibration baffle plate is arranged on the rear side of the unginned cotton falling channel; a cotton storage pit located below the cotton storage box is arranged on the lower end of the unginned cotton falling channel; a wind up roller is arranged below the front part of the upper part of the unginned cotton falling channel; an arc-shaped steel wire mesh connected with a front baffle plate and the arc-shape guard plate is arranged outside the wind up roller. The novel fireproof cotton feeder for removing the mulching film adopts a way of slantways lifting to feed cotton, so that high-speed hard impact of the device and stones can be avoided, the self-damage of roller parts and the occurrence of fire disasters are avoided, the number of barbed nail rollers in a production line can be reduced, and the damage to cotton fiber native quality is reduced since the beating number of is reduced.

Owner:ZHENGZHOU COTTON & JUTE ENG TECH & DESIGN RES INST

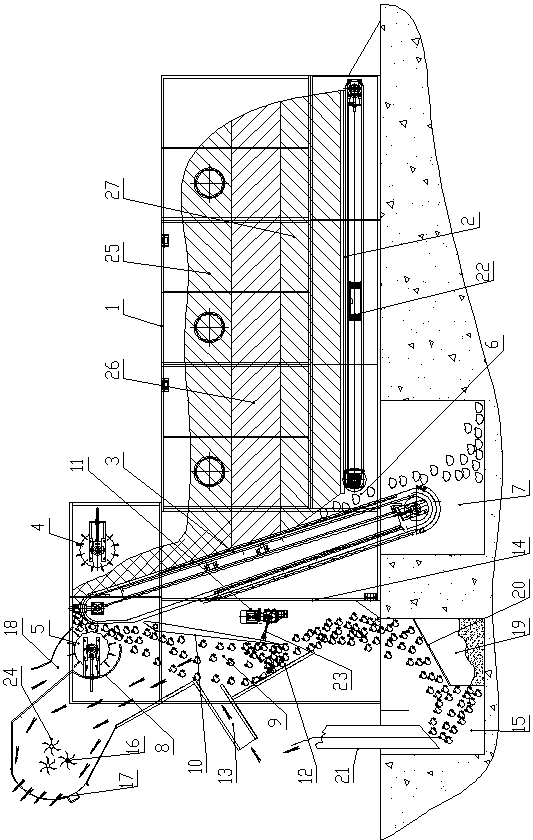

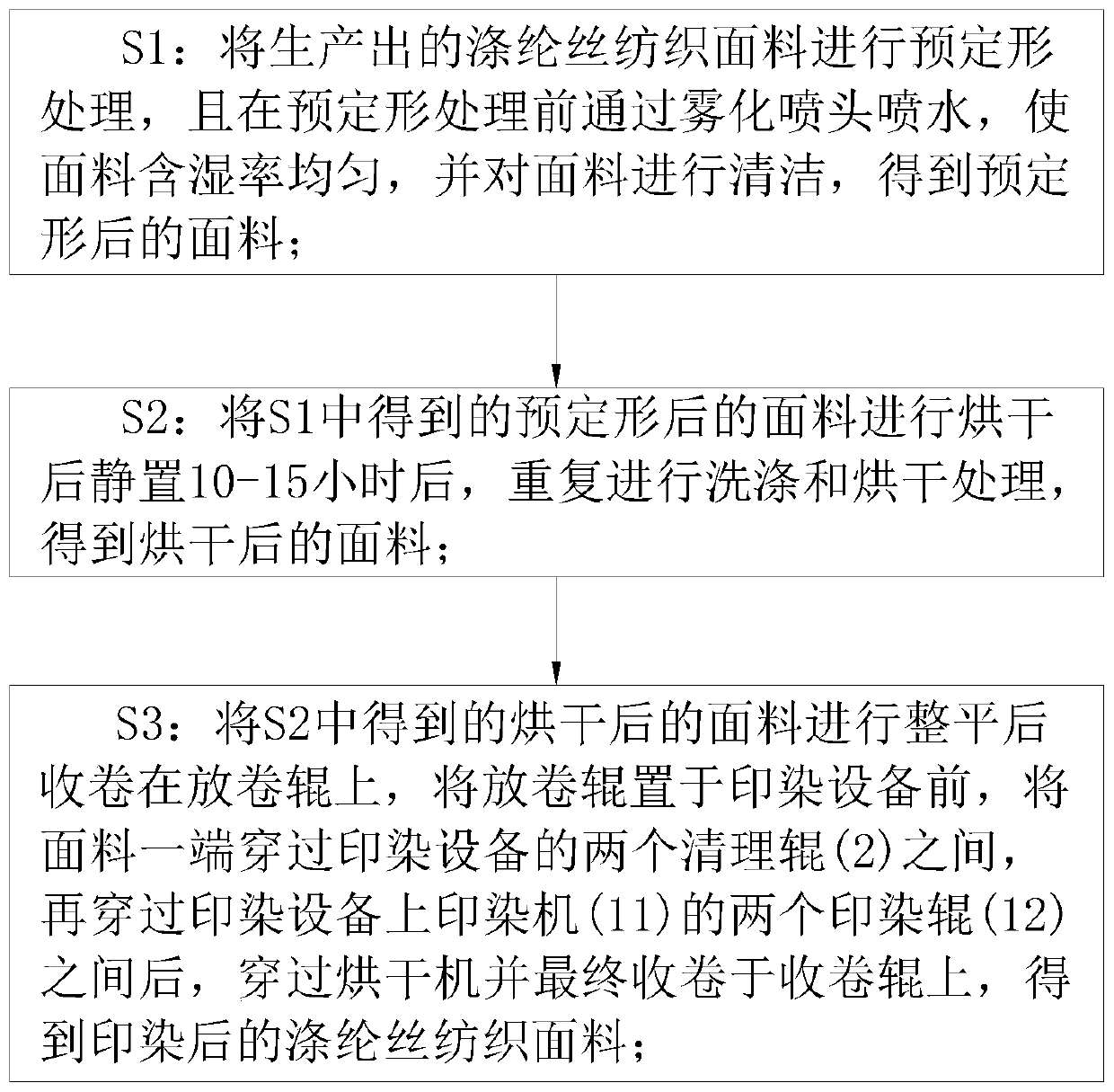

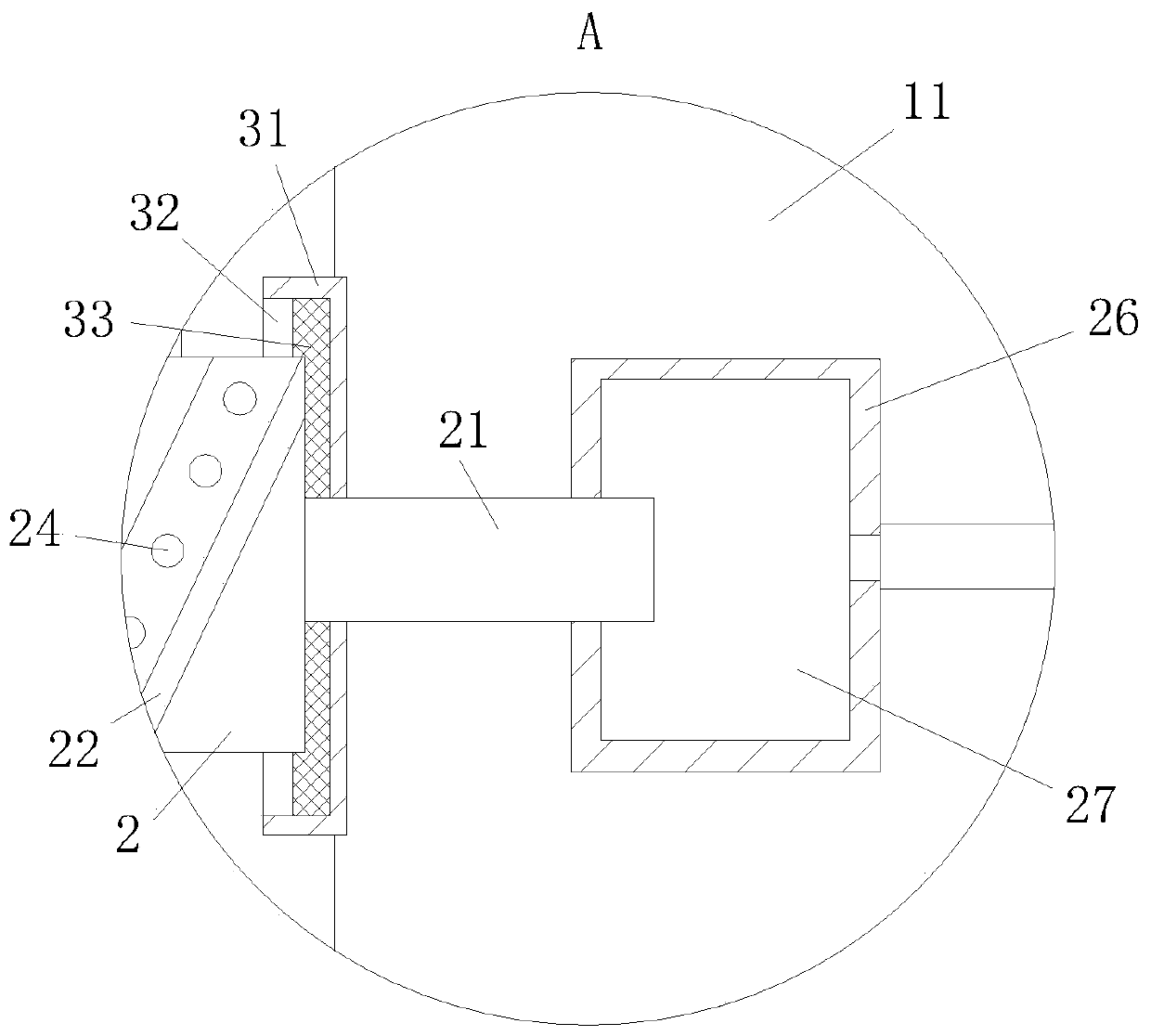

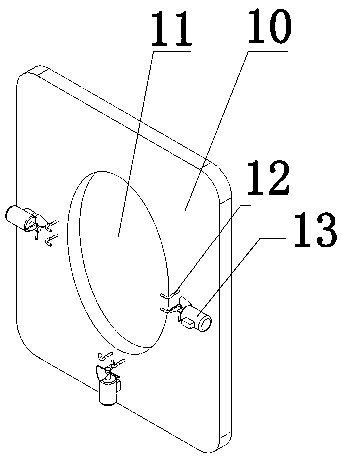

Printing and dyeing process for polyester silk textile fabric

InactiveCN111519418AImprove printing and dyeing production efficiencyReduce liftMechanical cleaningPressure cleaningPolyesterPolymer science

The invention belongs to the technical field of fabric printing and dyeing, and particularly relates to a printing and dyeing process for polyester silk textile fabric. A printing and dyeing device comprises a machine body, a printing and dyeing machine is arranged on the upper side of the machine body, printing and dyeing rollers are arranged on the inner side of the printing and dyeing machine,a control box is arranged on the left side of the printing and dyeing machine, and two clearing rollers which are correspondingly arranged are arranged at the positions, on the front side of the printing and dyeing rollers, of the printing and dyeing machine; the clearing rollers are rotationally connected to the surface of the printing and dyeing machine through rotating shafts, and the diameterof the clearing rollers is smaller than that of the printing and dyeing rollers; and the surfaces of the clearing rollers are fixedly connected with hairbrush layers, the hairbrush layers are composedof uniformly arranged hairbrushes, the hairbrush layers are spirally arranged from the middles of the clearing rollers to the two sides, and the hairbrush layers arranged from the middles to the twosides are opposite in spiral directions. According to the device, before the fabric is printed and dyed, the fabric surface dust clearing effect is high, and the clearing efficiency is high; and meanwhile, dust raising cannot be caused in the clearing process, so that the clearing effect is effectively improved, and the fabric printing and dyeing effect can be promoted.

Owner:孟学三

Nursing bed

The invention relates to a nursing instrument. In order to solve the existing technical problems in the prior art, the invention provides a nursing bed, the nursing bed comprises a bed board, a stoolpan and a sealing plate are arranged below the bed board, the stool pan and the sealing plate can block a stool pan hole, the nursing bed is characterized in that the stool pan comprises a seat ring,a plurality of hanging hooks are sequentially arranged on the parts, close to the edge of the stool pan hole, of the bottom of the seat ring, each hanging hook is composed of two L-shaped hook bodies,horizontal rods of the L-shaped hook bodies face the stool pan hole, and an air blowing device is arranged at the back of each group of the hanging hook. The nursing bed has the advantages that the structure is simple, the aligning among the stool pan, the sealing plate and the stool pan hole is ensured to be accurate at any time, the stool pan is provided with a foul resisting device to effectively protect the stool pan from contamination, and cleaning pressure is reduced.

Owner:李学华

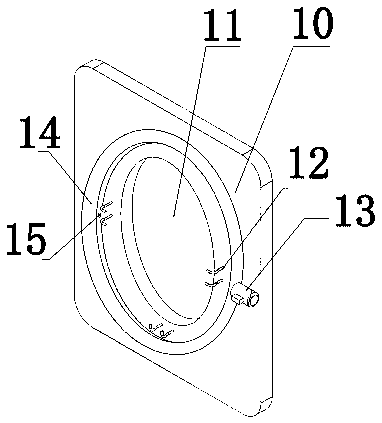

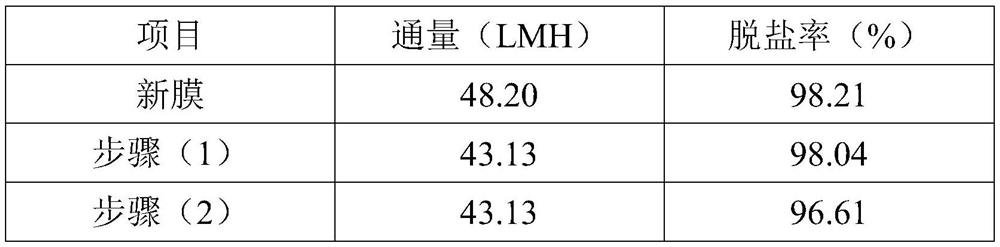

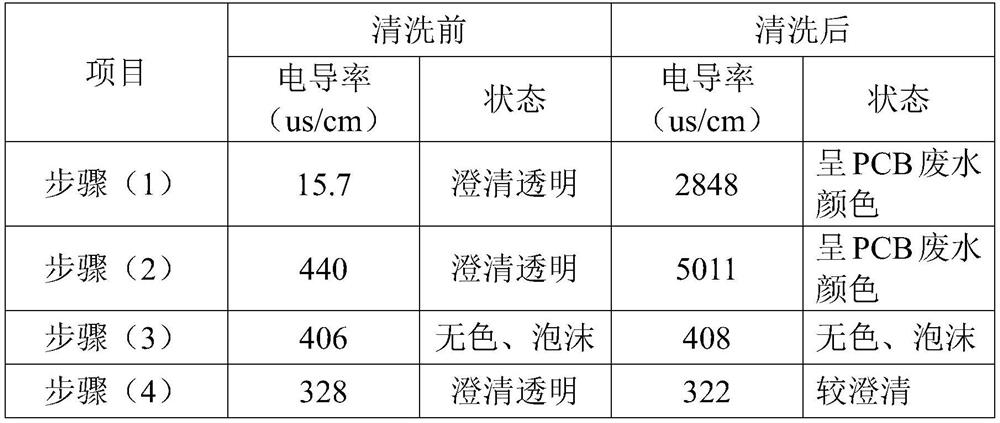

Membrane flux restoration method after separation membrane filters pcb wastewater

ActiveCN110237715BAvoid secondary pollutionReduce use costSemi-permeable membranesSpecific water treatment objectivesFiltrationWastewater

The invention relates to a method for recovering membrane flux after a separation membrane filters PCB waste water, which includes one physical cleaning and three chemical cleanings. In the membrane flux recovery method after the separation membrane filters PCB waste water of the present invention, only isobaric flushing is used in the cleaning process, and no backwashing device is needed; the cleaning water is clean, hardness-removed, and does not contain metal ions and residual chlorine. The product water avoids secondary pollution of the membrane elements; the cleaning working pressure is lower than or equal to 4bar, the energy consumption is low, and the operation is simple. Through the combination of physical cleaning and chemical cleaning, select a specific cleaning agent, and completely restore the flux of the special separation membrane polluted by PCB wastewater, thereby greatly reducing the use cost of the membrane module, prolonging the service life of the membrane element, and expanding the membrane module. application market.

Owner:埃姆媞(无锡)分离技术有限公司

Stirring equipment for florfenicol powder production

InactiveCN114130272AEasy to cleanStir wellTransportation and packagingMixer accessoriesElectric machineEngineering

The invention discloses stirring equipment for florfenicol powder production, and relates to the technical field of florfenicol powder production equipment.The stirring equipment comprises a base, a U-shaped supporting frame and a stirring barrel, the U-shaped supporting frame is slidably installed on the upper surface of the base, and the stirring barrel is rotatably installed on the side wall of the U-shaped supporting frame through a connecting rod; the stirring barrel is driven by the horizontal motor to turn up and down, meanwhile, the vertical motor is fixedly installed on the side wall of the bottom of the stirring barrel, and the vertical motor is connected to the bottom of the inner barrel through the vertical rotating shaft, so that the inner barrel is driven by the vertical motor to rotate in the stirring barrel; meanwhile, one side of a U-shaped supporting frame is in sliding contact with the side wall of a cam through a push rod, the cam is driven to rotate through a rotating motor, the U-shaped supporting frame is driven to slide left and right on the surface of the base, and therefore florfenicol powder in the inner barrel is driven to rotate in six dimensions, stirring of the florfenicol powder is more sufficient, and the stirring efficiency is improved. The stirring effect of the device is better.

Owner:HUBEI ZHONGMU ANDA PHARMACEUTICAL CO LTD

Household apple slicing equipment

ActiveCN113715071AEasy to collectPrevent splashFruit stoningMetal working apparatusMechanical engineeringIndustrial engineering

The invention relates to slicing equipment, in particular to household apple slicing equipment. The household apple slicing equipment is high in speed, high in efficiency, short in consumed time and capable of automatically cutting fruits. According to the technical scheme, the household apple slicing equipment comprises bases, a mounting plate, a slicing mechanism and a kernel removing mechanism; the number of the bases is four; the mounting plate is arranged among the tops of the bases; the slicing mechanism is arranged at one side of the mounting plate; the slicing mechanism comprises a supporting frame arranged at one side of the mounting plate, an air cylinder arranged at one side of the supporting frame, a slicer arranged at the bottom of the air cylinder, and a first special-shaped rod arranged at one side of the slicer; and the kernel removing mechanism is arranged at one side of the mounting plate. Under the action of a pulp collecting mechanism, the collecting time of people can be saved.

Owner:南京市淑先科技有限公司

A kind of method that corn flour prepares solid fructose

ActiveCN108486194BReduce pollutionQuality improvementFructose productionFermentationBiotechnologyFructose

The invention relates to a method for preparing solid fructose from corn flour, which belongs to the technical field of corn deep processing. Including corn flour liquefaction, saccharification, refining, isomerization and drying granulation steps, the present invention uses activated carbon to decolorize and directly carry out stainless steel microfiltration membrane filtration, not only can remove soluble protein and insoluble fat substances, colloids and pigments can also be thoroughly removed, sugar The liquid quality is good, the pressure of membrane cleaning is reduced, the equipment capacity can be significantly improved, the equipment investment can be significantly reduced, and the output can be expanded; The fructose granules made by granule technology have uniform particle size, smooth surface, hemispherical transparent granules, obviously not easy to agglomerate, long shelf life, easy to use, and the sugar granules have no agglomeration for 120 days.

Owner:JILIN ACAD OF AGRI SCI

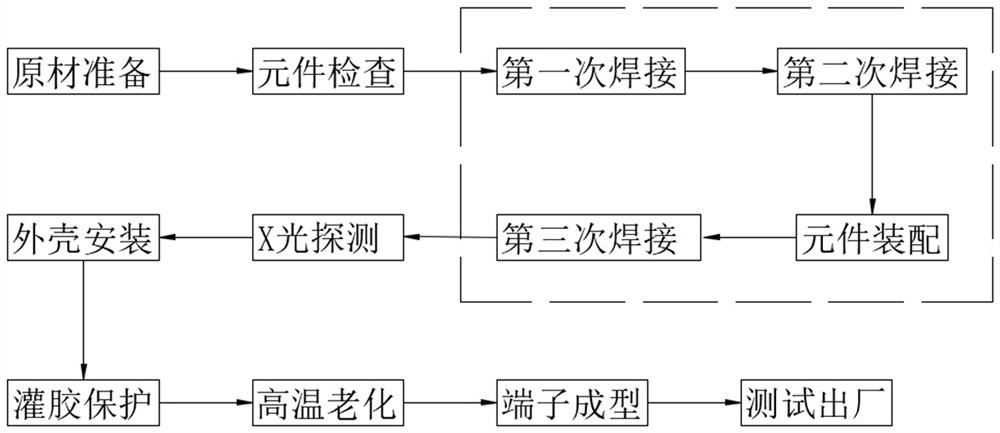

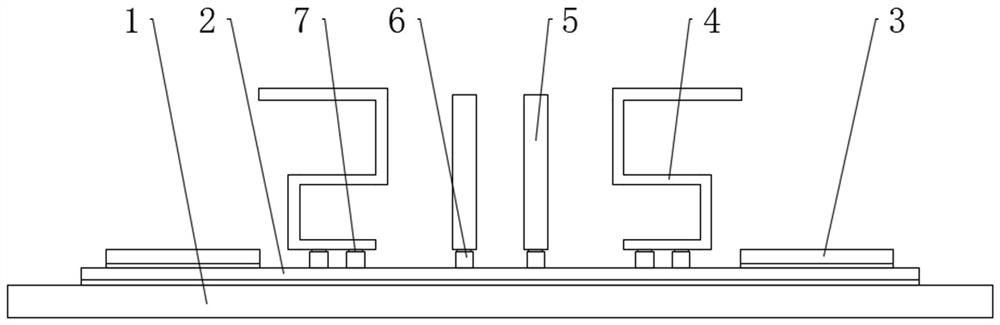

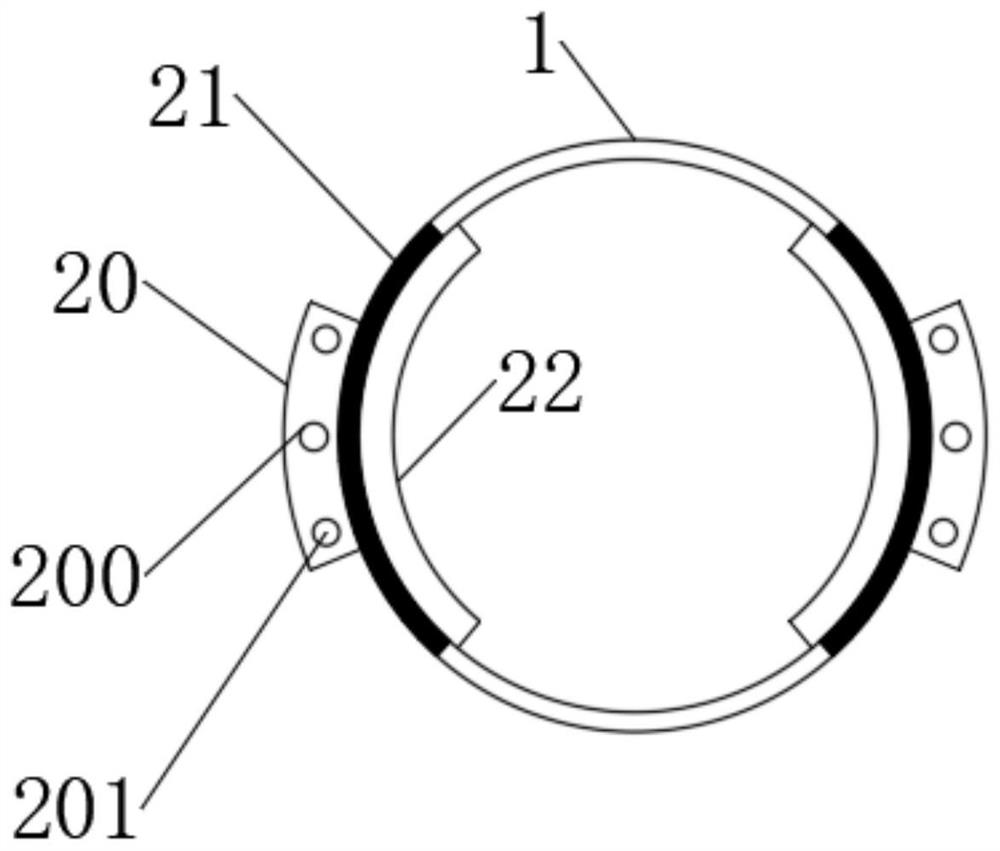

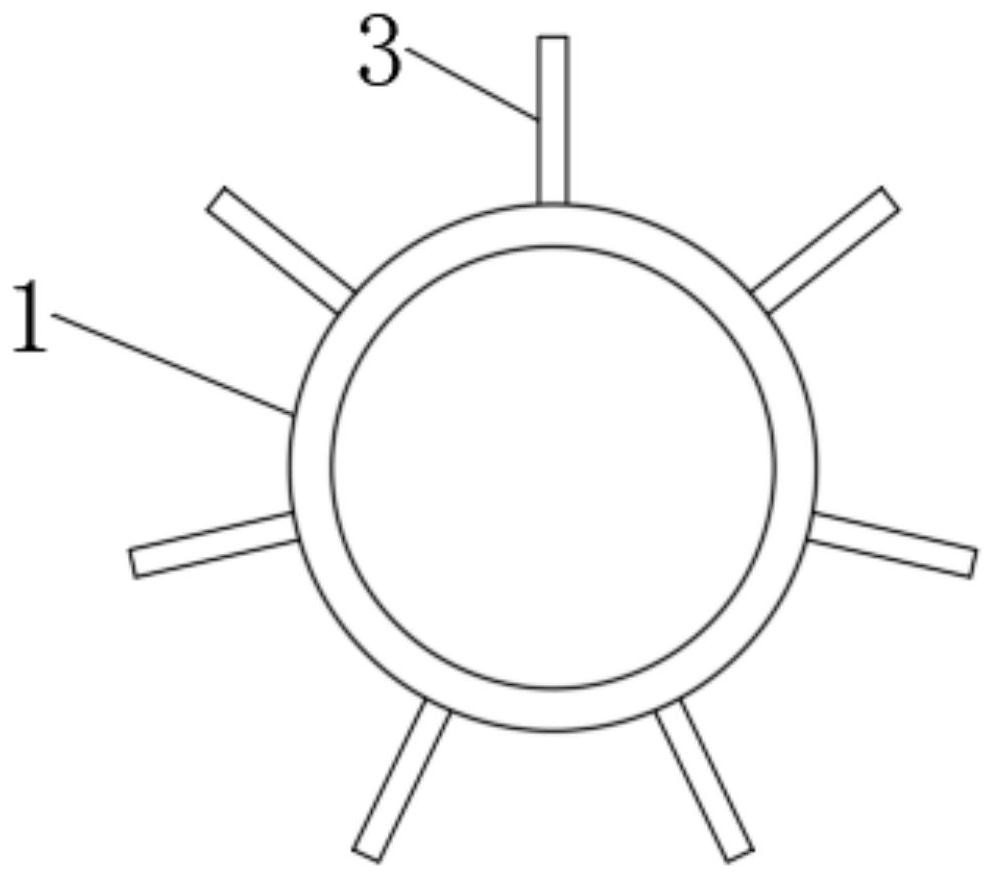

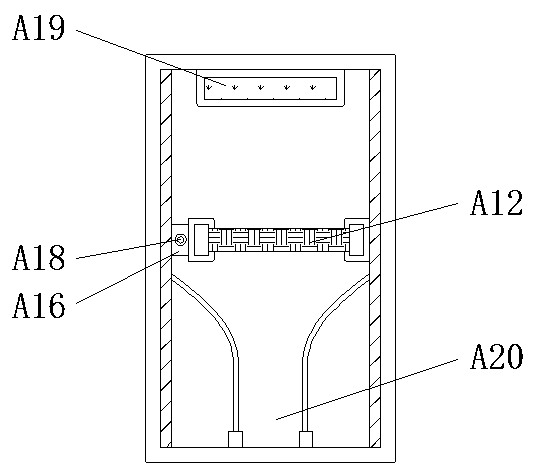

A new preparation process of busbar based on igbt module

ActiveCN110534437BAvoid factors affecting product qualityReliable electrical connectionSolid-state devicesSemiconductor/solid-state device manufacturingBusbarElectrical connection

The invention discloses a novel manufacturing process of a busbar based on an IGBT module. When electronic components such as a busbar, an electrode and the like are adopted, a traditional bonding padform is abandoned. A novel positioning cylinder form is adopted. Through a pre-designed extended conductive component, on one hand, stable electrical connection is realized; on the other hand, an existing tool can be replaced to achieve an initial positioning effect. After a soldering paste is dropwise added, a welding procedure is directly performed. Cost and the assembling complexity are greatly reduced, an amount of the used soldering paste is greatly reduced compared with that in a traditional process, accurate and stable welding can be achieved only by dropwise adding a very small amountof soldering paste into a positioning cylinder, then cleaning pressure of a subsequent process is reduced, and even a cleaning-free state is achieved under a condition that a dropwise adding amount is strictly controlled. The IGBT module manufactured by adopting the novel process has incomparable advantages in cost and efficiency, many factors influencing product quality are avoided, and an extremely high market promotion value is possessed.

Owner:宜兴市三鑫电子有限公司

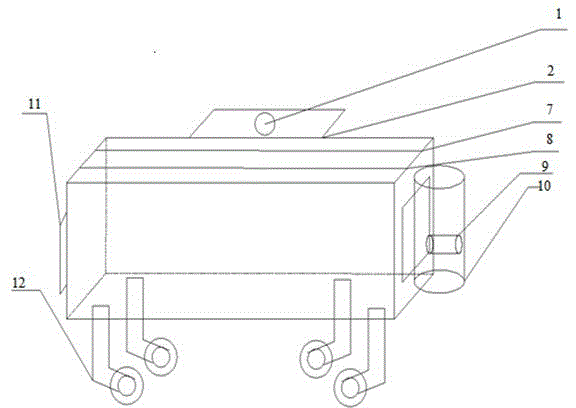

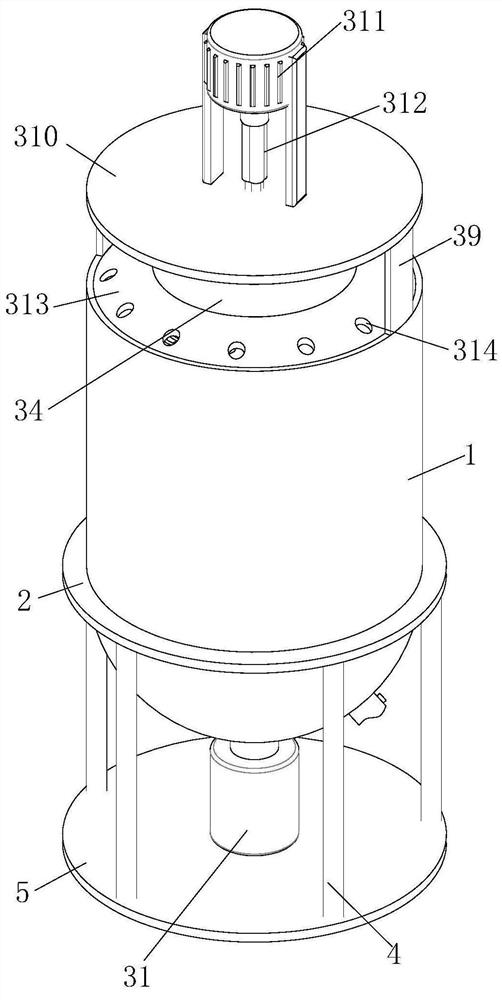

Ore pass dust treatment device

InactiveCN112843966AReduce cleaning pressureRealize purificationCombination devicesMining engineeringStructural engineering

The invention discloses an ore pass dust treatment device, relates to the technical field of ore pass dust treatment, and mainly solves the problem that the existing ore pass dust cleaning cost is relatively high. The device comprises an installation box installed on the side edge of a mine; wherein upper suction pipes are arranged on the upper side of the installation box and evenly distributed on the periphery of the mine, suction pumps are arranged in the upper suction pipes, the upper suction pipes are connected with an air guide pipe, the air guide pipe is connected with a confluence pipe, and the confluence pipe is connected with a filter cartridge. A stirring device is arranged in the filter cartridge, an electrostatic adsorption plate is arranged between the mounting box and the mine, a scraping plate is arranged on the electrostatic adsorption plate, a magnet is arranged on the scraping plate, a lifting block is arranged on the outer side of the electrostatic adsorption plate, and the lifting block is connected with a lifting device and is an iron block. A guide groove is formed in the bottom of the mine, a funnel groove is formed in the bottom of the guide groove, and a discharging pipe is arranged at the bottom of the funnel groove.

Owner:凌源日兴矿业有限公司

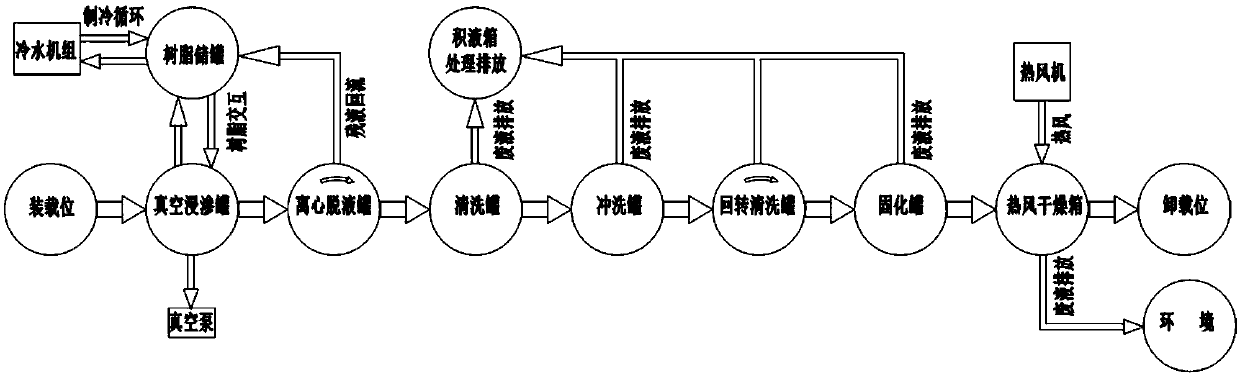

Environment-friendly energy-saving infiltration process

InactiveCN109590182AAvoid affecting product qualityWill not cause mutual leakage phenomenonLiquid surface applicatorsCoatingsEnvironmental resistanceFiltration

The invention discloses an environment-friendly energy-saving infiltration process. The environment-friendly energy-saving infiltration process comprises the following steps of a, carrying out vacuuminfiltration on a workpiece; b, carrying out centrifugal degassing on the workpiece subjected to vacuum infiltration; c, washing the workpiece subjected to centrifugal degassing, and then centrifugingto remove the liquid again; d, washing the workpiece subjected to centrifugal degassing again for the third time; e, carrying out curing polymerization on the workpiece subjected to the third centrifugal degassing; and f, after the workpiece is solidified and polymerized, the workpiece is lifted above the liquid level to carry out centrifugal degassing. The environment-friendly energy-saving infiltration process has the advantages that the centrifugal dehydration is carried out for many times, and the quality of the product caused by the series liquid is avoided; the drying is integrated in the curing polymerization, the waste heat is fully utilized, and the time and the cost are saved; the effective recovery and filtration of the sealant are increased, the utilization rate of the sealantand the lotion solution is high, and the pollution of the enterprise cost and the waste liquid discharge to the environment is low; the liquid circulation self-cleaning process is adopted, the product is not prone to cause secondary pollution, the liquid replacement frequency is greatly reduced, and the pollution to the environment due to chemical solvent pollution is avoided.

Owner:成都苔岑智能设备有限公司

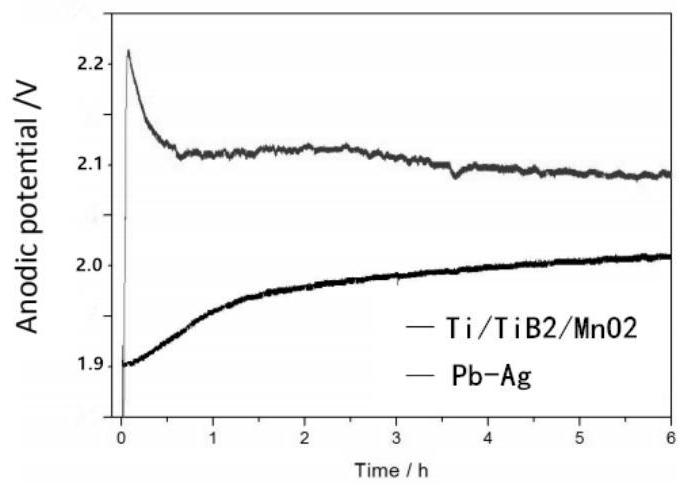

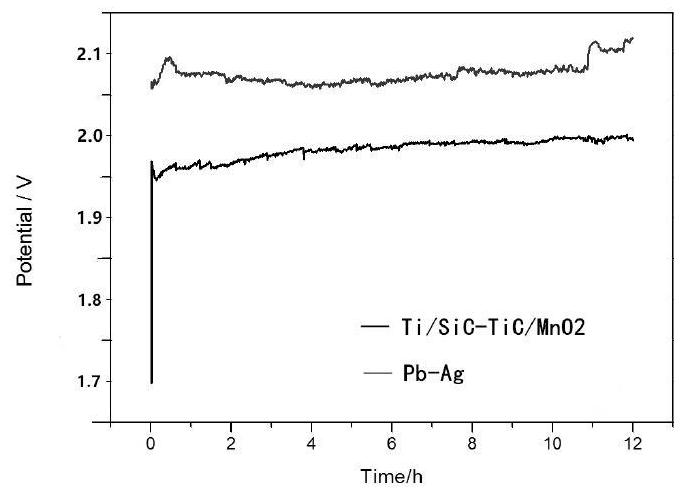

Composite anode for hydrometallurgy and its preparation method and application

The invention discloses a composite anode for hydrometallurgy and its preparation method and application. The structure of the composite anode is metal substrate / non-oxide intermediate layer / selective electrocatalytic oxygen evolution layer, wherein the non-oxide intermediate layer can isolate Oxygen diffuses to the metal substrate to avoid passivation of the metal substrate, and the selective electrocatalytic oxygen evolution layer can selectively catalyze oxygen evolution while inhibiting Mn in the electrolyte 2+ depletion. The composite anode can be used in the electrochemical metallurgical process of non-ferrous metals such as zinc, manganese, copper, etc., and when it is used for the electrodeposition of metal manganese, it can realize the equal current density of the cathode and the anode and the electrodeposition without diaphragm, which greatly reduces the energy of the electrodeposition process. Consumption, inhibition of Mn 2+ Oxidation losses at the anode improve cathodic current efficiency.

Owner:CENT SOUTH UNIV

Cotton feeding machine for fire prevention and plastic film removal

ActiveCN104233516BPrecisely control the feeding amountLess hitFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersProduction lineFiber

Cotton feeding machine for fire prevention and plastic film removal, including cotton storage box, which is equipped with horizontal conveying mechanism, lifting chain, cotton leveling roller and cotton stripping roller. There is a miscellaneous storage pit between the lower part of the lifting chain and the front of the stripping roller. The baffle, the lower end of the seed cotton drop channel is provided with a cotton storage pit located below the cotton storage box, the upper front of the upper part of the seed cotton drop channel is provided with a winding roller, and the outside of the winding roller is provided with an arc connected with the front baffle and the arc guard. wire mesh. The present invention adopts the mode of incline raising and feeding cotton. This can not only avoid high-speed hard impact with stones, avoid damage to the roller parts and the occurrence of fire, but also reduce the total number of spike rollers in the production line, reduce the number of strikes and reduce the damage to the original quality of cotton fibers.

Owner:ZHENGZHOU COTTON & JUTE ENG TECH & DESIGN RES INST

Fixing device for medical nuclear magnetic resonance

PendingCN109567804ARelieve stressNo repulsionDiagnostic recording/measuringSensorsNMR - Nuclear magnetic resonanceArchitectural engineering

The invention discloses a fixing device for medical nuclear magnetic resonance. The fixing device comprises a base body and a sliding platform, wherein the upper end of the base body is connected witha fixed rod; a shell is arranged at the right side of the fixed rod; a handrail plate is connected to the inner side of the shell; a handhold block is fixed at the right side of the handrail plate; adetection device is mounted above the right side of the handhold block; connection blocks are arranged below the detection device; the lower ends of the connection blocks are connected with a supporting platform; a sliding groove is formed below the supporting platform; a sliding platform is connected to the outer side of the sliding groove; a detection platform is arranged at the upper end of the sliding platform. According to the fixing device for the medical nuclear magnetic resonance, the handhold block and the handrail plate is of an integrated structure, hands of a user can hold the handhold block at the upper end of the handrail plate and the hands of the user can be fixed; the psychological pressure of the user is alleviated through such a fixing manner, so that the users can moreeasily accept the nuclear magnetic resonance and excessive repellent psychology is not generated.

Owner:深圳市大豪斯智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com