Membrane flux restoration method after separation membrane filters pcb wastewater

A recovery method and technology of membrane flux, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of blocking membrane, unable to restore membrane flux, etc., achieve simple operation, expand the application market, extend the Effect of expiry date

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

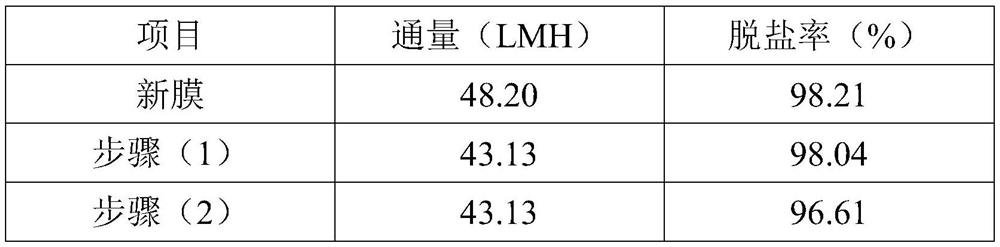

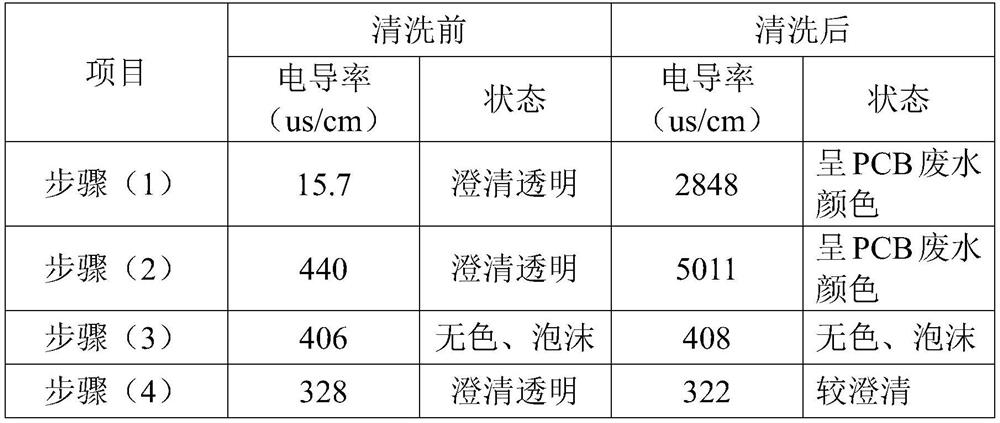

Embodiment 1

[0017] Embodiment 1 proposes a kind of membrane flux restoration method after separation membrane filters PCB waste water, comprises the following steps:

[0018] (1) Lead the flushing water into the cleaning water tank of the separation equipment, then turn on the cleaning equipment for low-pressure circular flushing, and then use a conductivity meter to measure the conductivity of the discharge outlet water. When the conductivity of the discharge outlet water is 10% of the conductivity of the inlet water, Stop flushing. Among them, the time for low-pressure circular flushing is 25 minutes, the inlet water pressure is 3 bar, and low-pressure circular flushing is performed 3 times. The water is product water with hardness removed, free of metal ions and residual chlorine, and the cleaning temperature is 25°C.

[0019] (2) Add sodium hydroxide powder in water, adjust the pH to be 12.5, obtain the first cleaning solution, then open the cleaning equipment and carry out circular ...

Embodiment 2

[0024] Embodiment 2 proposes a kind of membrane flux recovery method after separation membrane filters PCB waste water, comprises the following steps:

[0025] (1) Lead the flushing water into the cleaning water tank of the separation equipment, then turn on the cleaning equipment for low-pressure circular flushing, and then use a conductivity meter to measure the conductivity of the discharge outlet water. When the conductivity of the discharge outlet water is 20% of the conductivity of the inlet water, Stop flushing. Among them, the time of low-pressure circular flushing is 15 minutes, the inlet water pressure is 4 bar, and low-pressure circular flushing is performed twice. The water is deionized water that removes hardness and does not contain metal ions and residual chlorine, and the cleaning temperature is 30°C.

[0026] (2) Add sodium hydroxide powder in water, adjust the pH to be 11.5, obtain the first cleaning solution, then open the cleaning equipment and carry out c...

Embodiment 3

[0031] Embodiment 3 proposes a kind of membrane flux restoration method after separation membrane filters PCB waste water, comprises the following steps:

[0032] (1) Lead the flushing water into the cleaning water tank of the separation equipment, then turn on the cleaning equipment for low-pressure circular flushing, and then use a conductivity meter to measure the conductivity of the water at the discharge outlet. When the conductivity of the water at the discharge outlet is 15% of the conductivity of the inlet water, Stop flushing. Among them, the time for low-pressure circular flushing is 20 minutes, the inlet water pressure is 4 bar, and low-pressure circular flushing is performed twice. The water is product water with hardness removed, free of metal ions and residual chlorine, and the washing temperature is 27°C.

[0033](2) Add sodium hydroxide powder in water, adjust the pH to be 12, obtain the first cleaning solution, then open the cleaning equipment and carry out c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com