Composite cavitation cleaner for pipe descaling

A composite cleaner technology, which is applied to chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of PIG cleaning method, such as expensive equipment, high risk, and polluting the environment, and achieve good cleaning effect, Effects of reduced risk and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

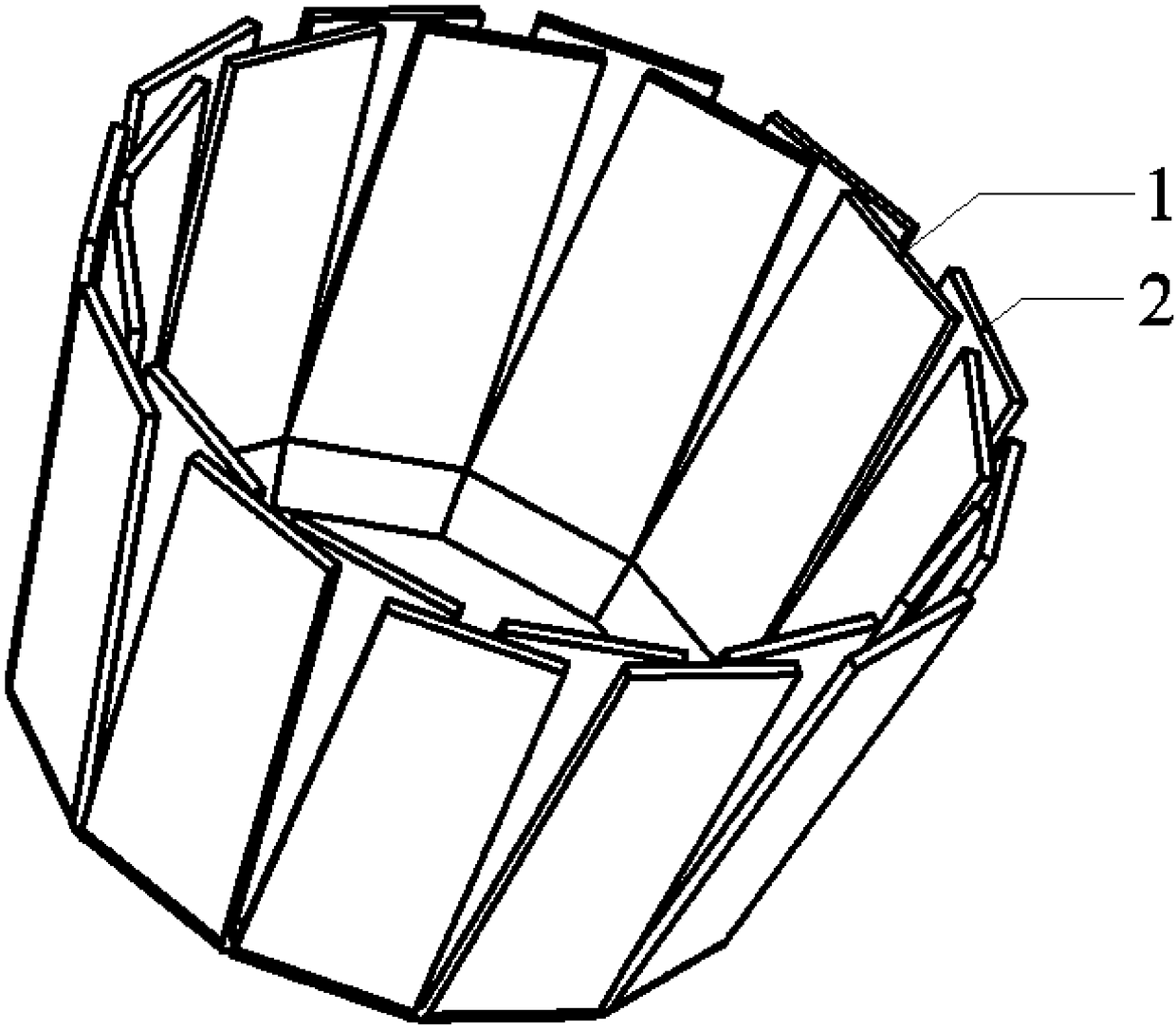

[0035] Such as Figure 1-6 Shown: the subject matter of the present invention is Figure 1-3 The blade cleaning structure shown in the blade cleaning structure produces cavitation effect through the throttling surface formed by the wall surface at the upper end of the blade cleaning structure. Under the condition of the bending angle, the upper bending blade area can quickly generate cavitation, and the lower bending The vacuoles in the leaf region can collapse rapidly.

[0036] Such as image 3 Shown is the upper bending angle θ 1 , down bending angle θ 2 The blade cleaning structure adopts different upper and lower bending angles, and the upper bending angle θ 1 When smaller, the throttle area is smaller and more cavitation bubbles can be generated. And the lower bending angle θ 2 Larger, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com