Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Realize automatic pick and place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

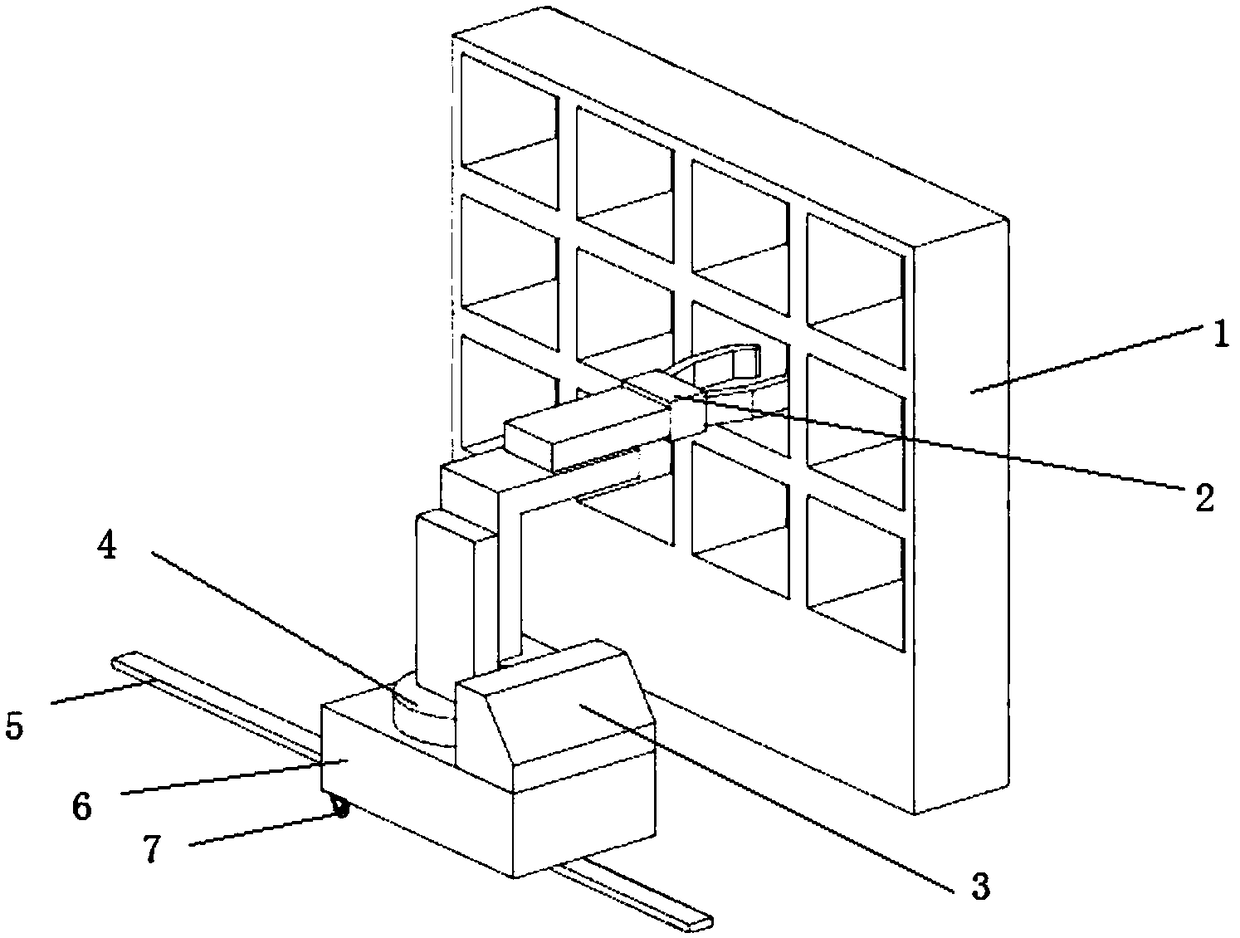

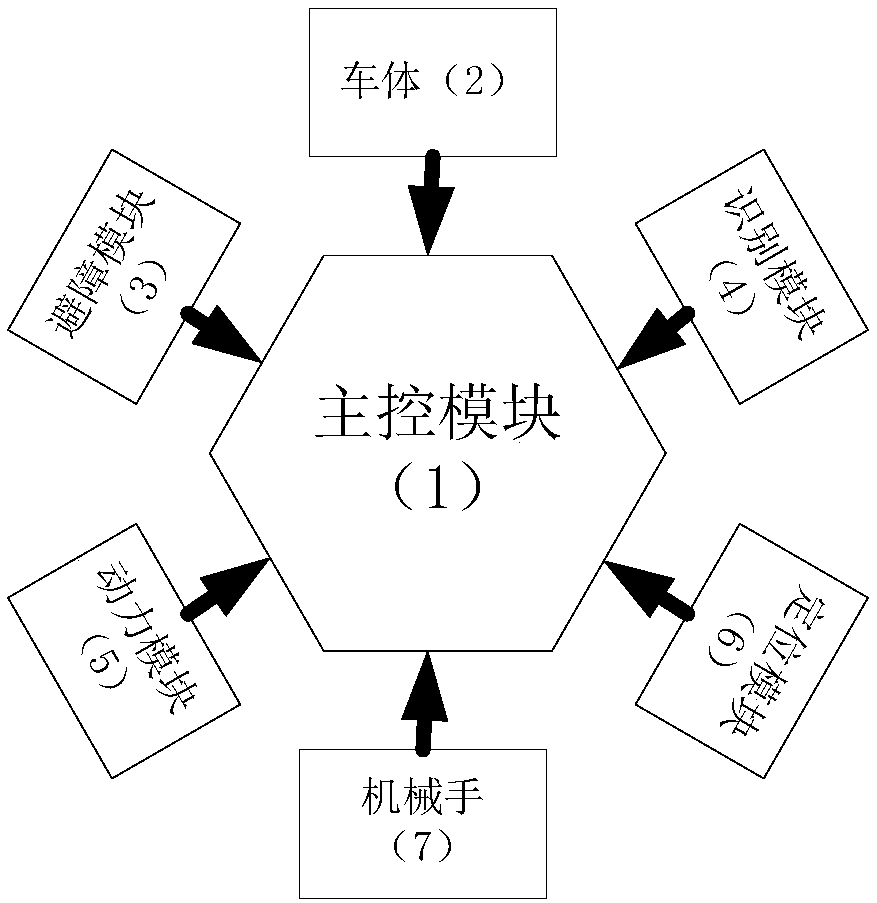

Self-service express item fetching trolley and self-service express item fetching control method thereof

PendingCN108100557ARealize automatic pick and placeSolve stressStorage devicesManipulatorEngineering

The invention discloses a self-service express item fetching trolley and a self-service express item fetching control method thereof. The self-service express item fetching trolley comprises a trolleybody, a connecting arm and a manipulator, wherein the manipulator is connected to the connecting arm, and the manipulator is provided with a horizontal stretchable mechanism; the connecting arm is connected to the trolley body through a rotating turret, and the connecting arm is connected with a vertical lifting device; a magnetic guide rail is arranged in front of a goods shelf, a magnetic stripe recognizer is arranged at the bottom of the trolley body, and the trolley body moves along the magnetic guide rail through the magnetic stripe recognizer; and a main control module is arranged in the trolley body, and the main control module is connected with the manipulator, the connecting arm and the trolley body. According to the self-service express item fetching trolley and the self-serviceexpress item fetching control method thereof, automatic fetching and automatic placing of goods are realized by means of cooperation of the self-service express item fetching trolley with the self-service express item fetching control method, so that personnel configuration and distribution cost pressure of Cainiao Yizhan is relieved, and a wide application space is realized.

Owner:山东理工精密机械有限公司 +1

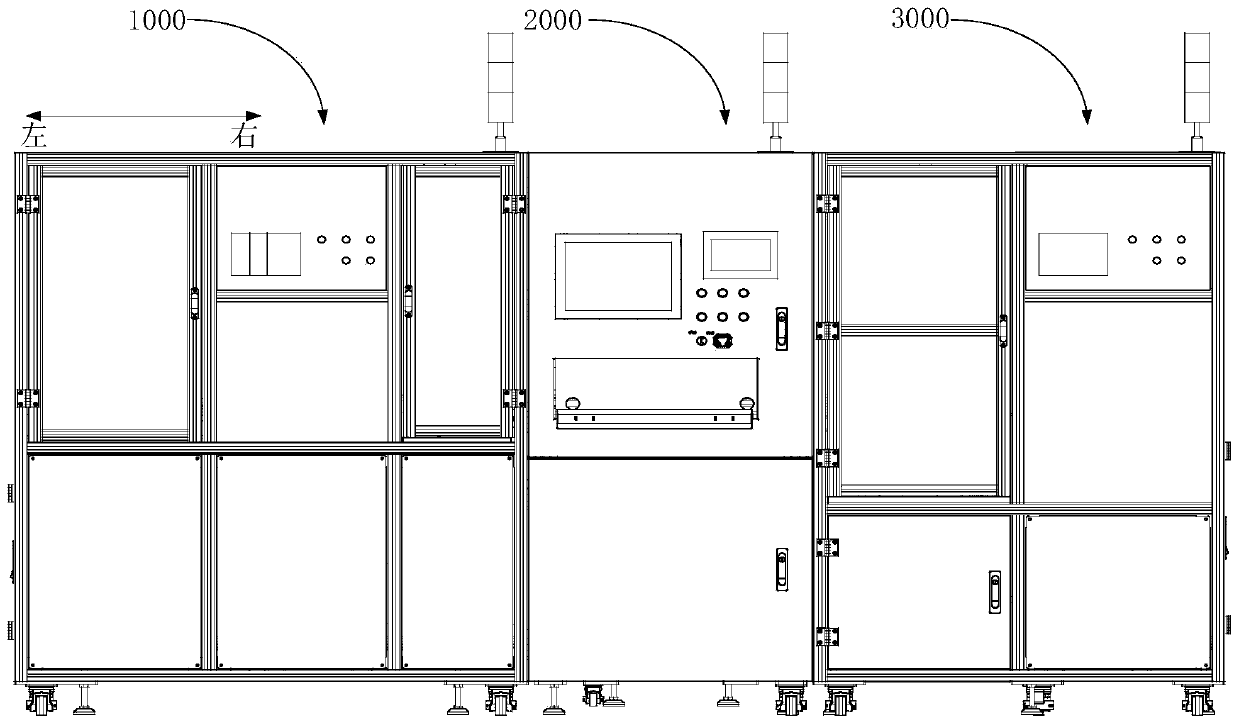

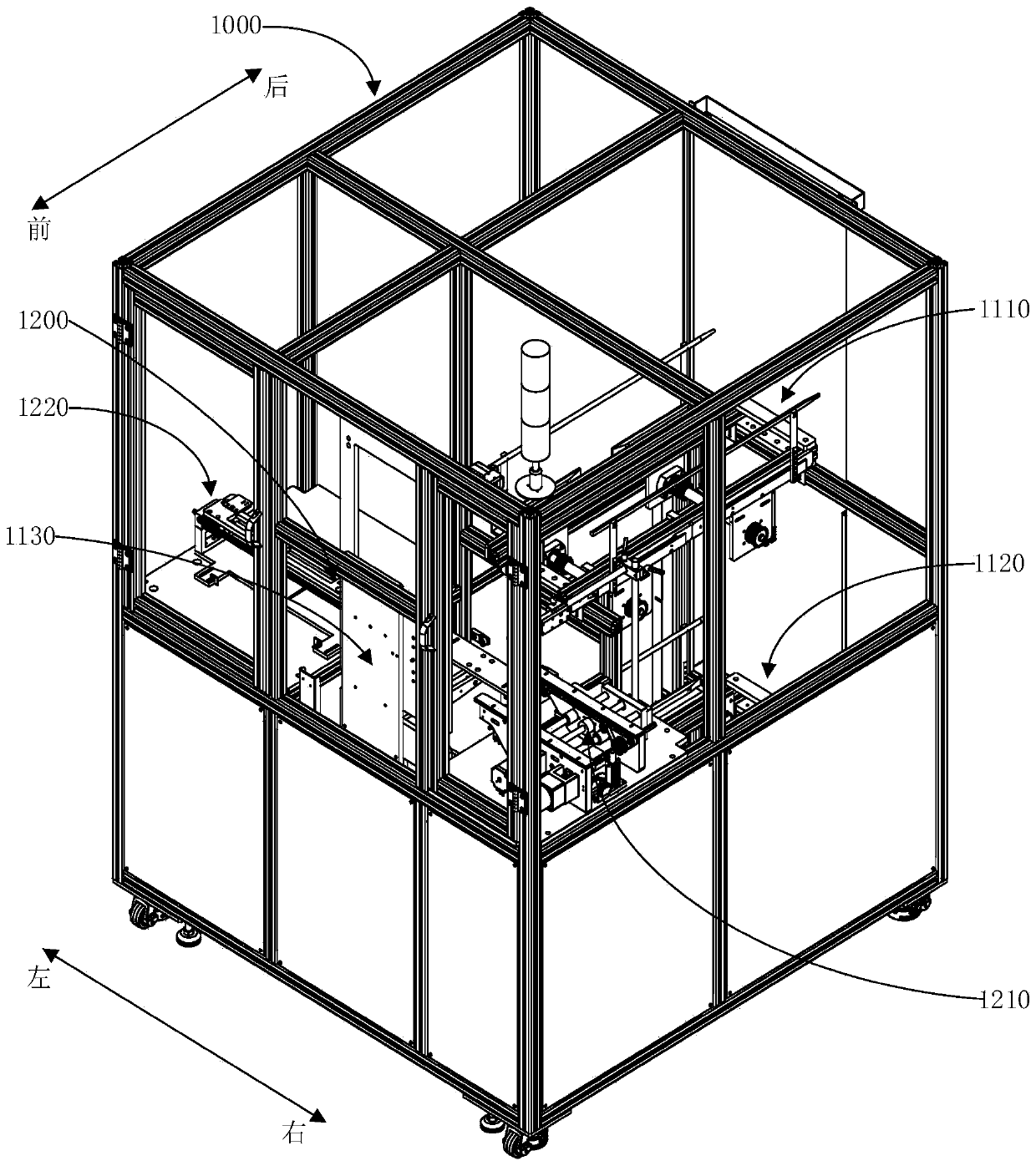

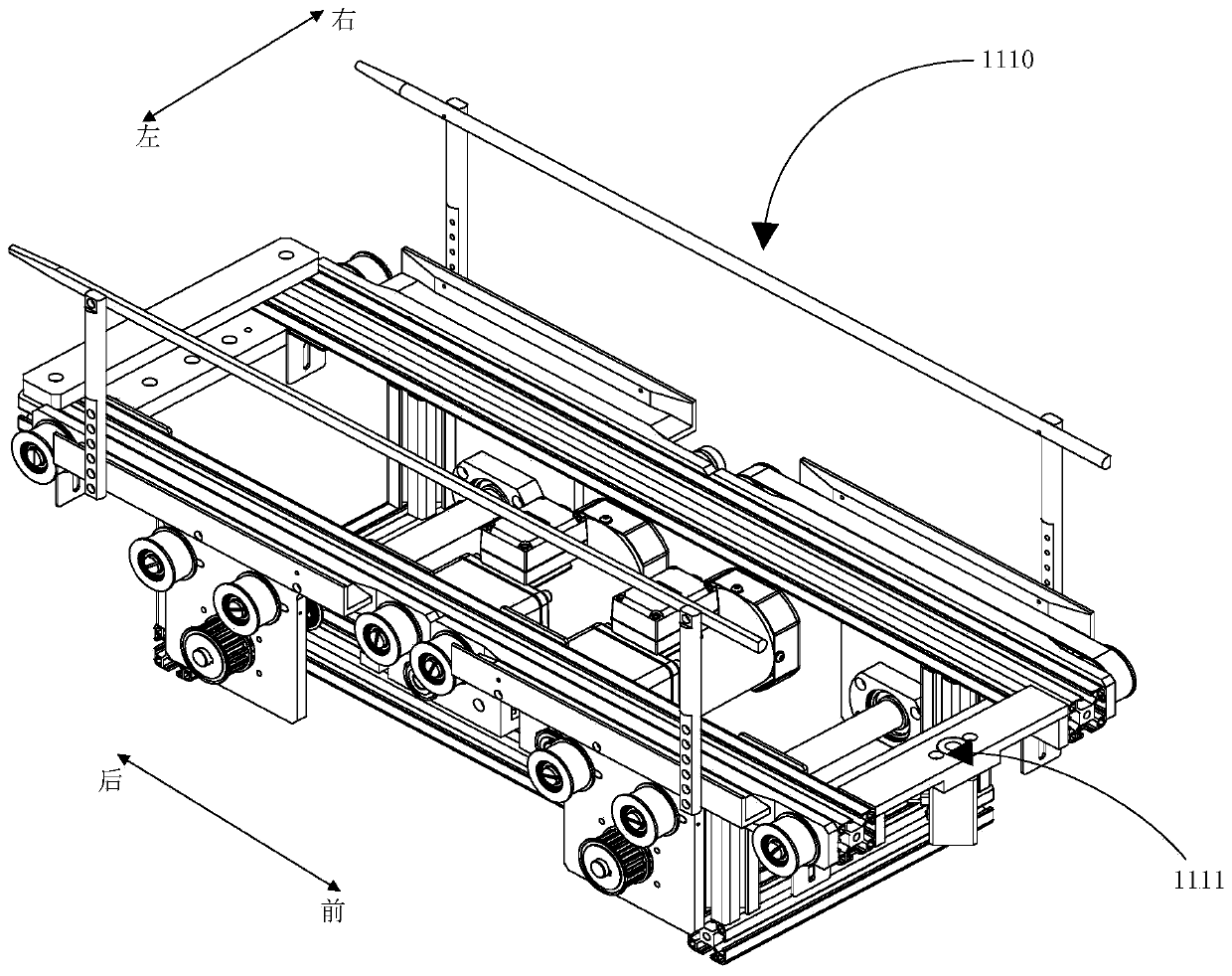

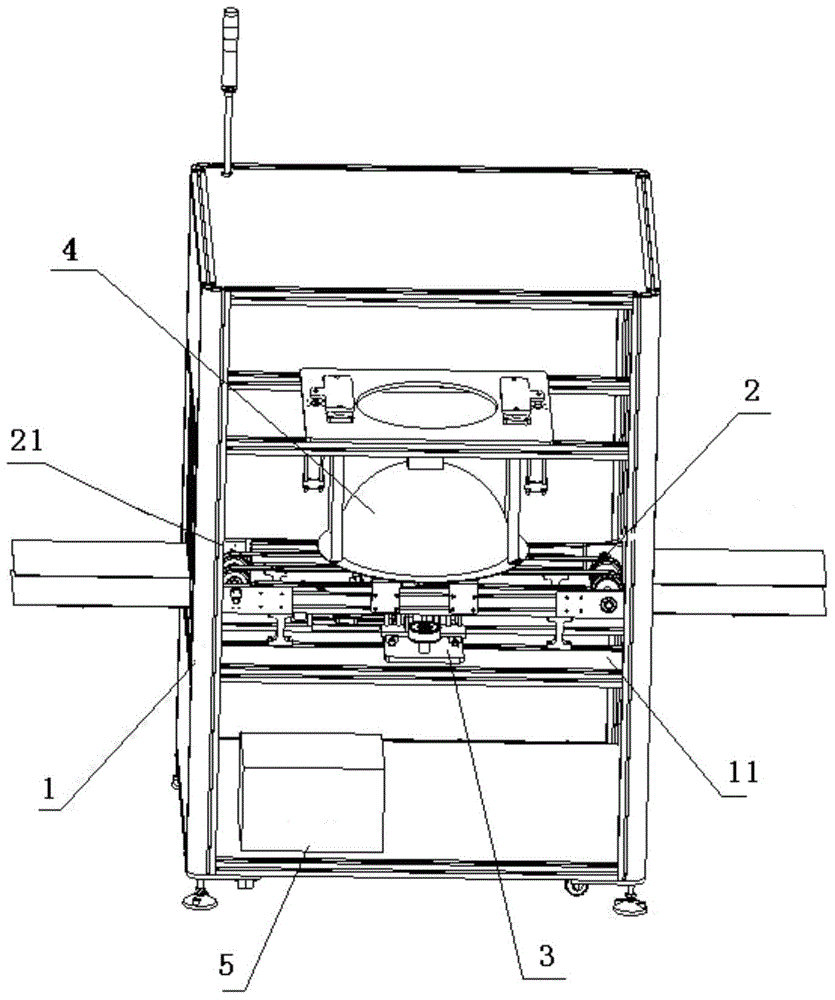

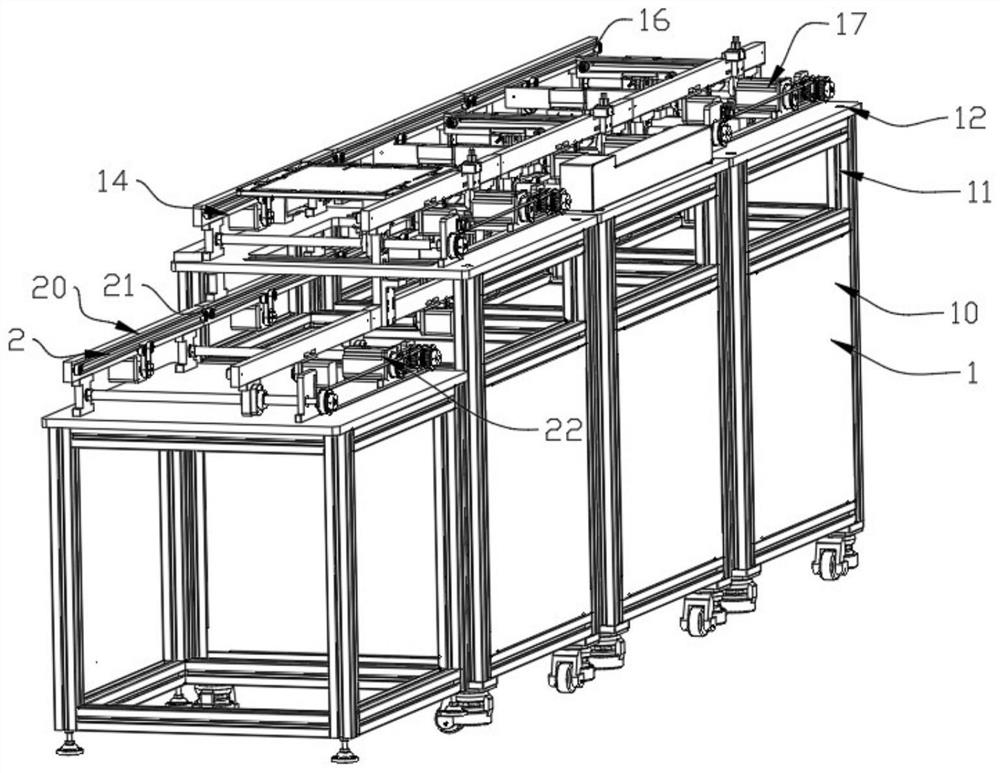

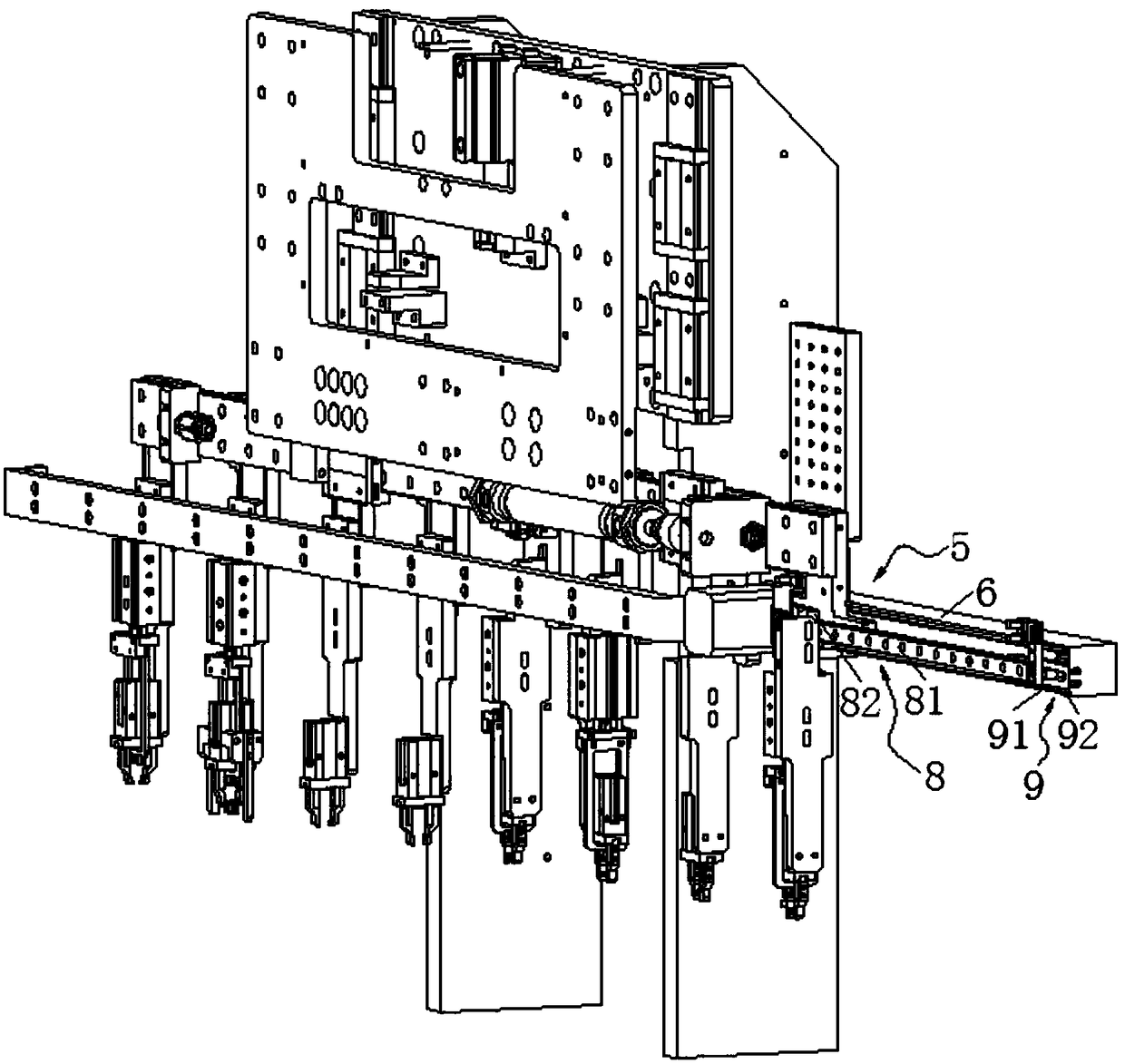

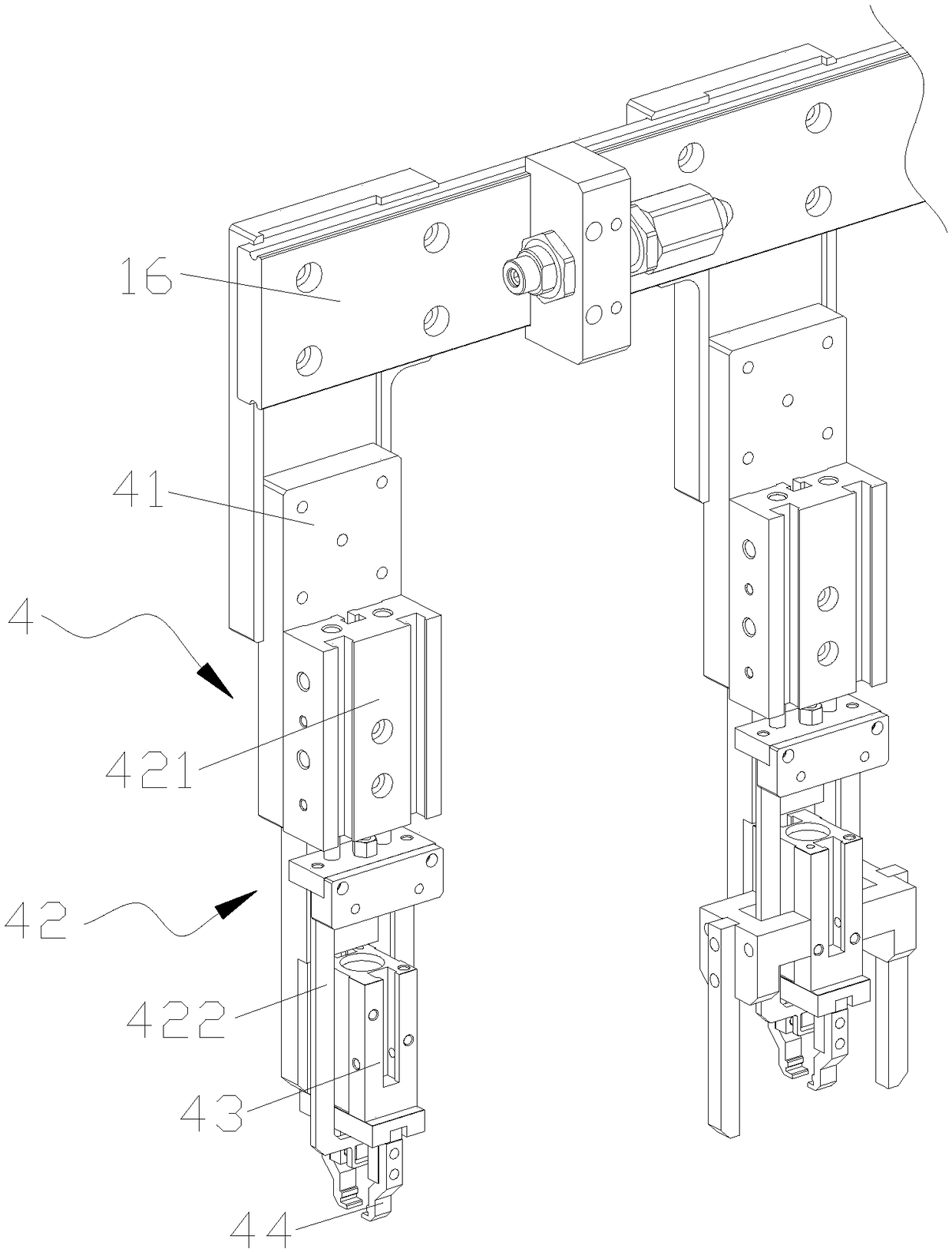

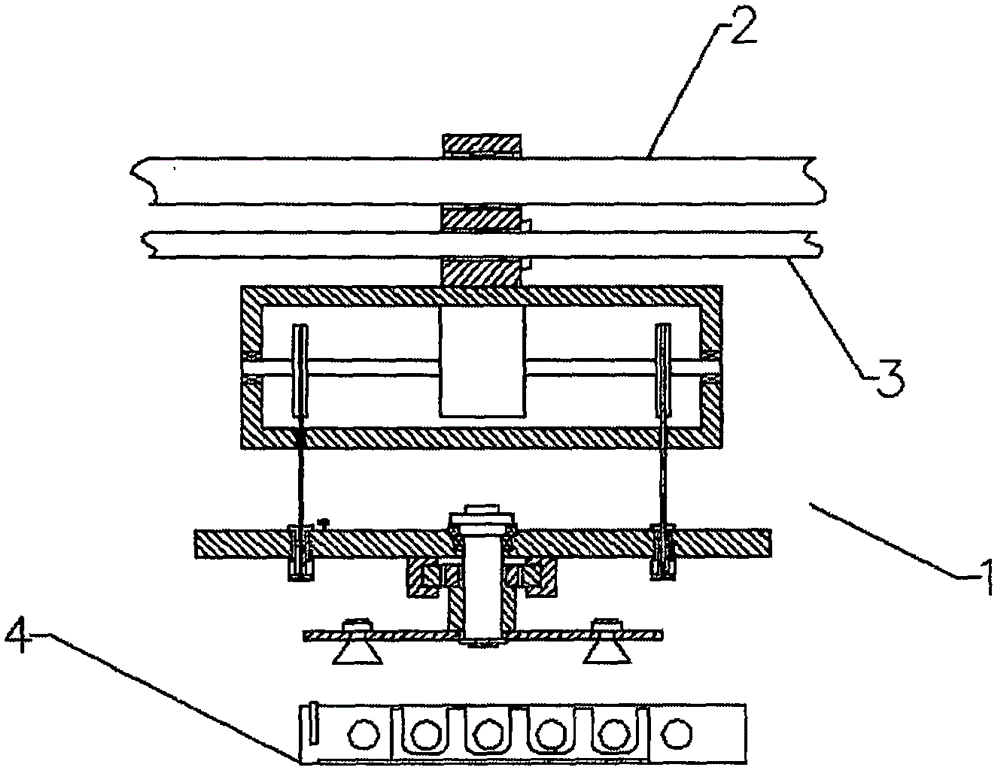

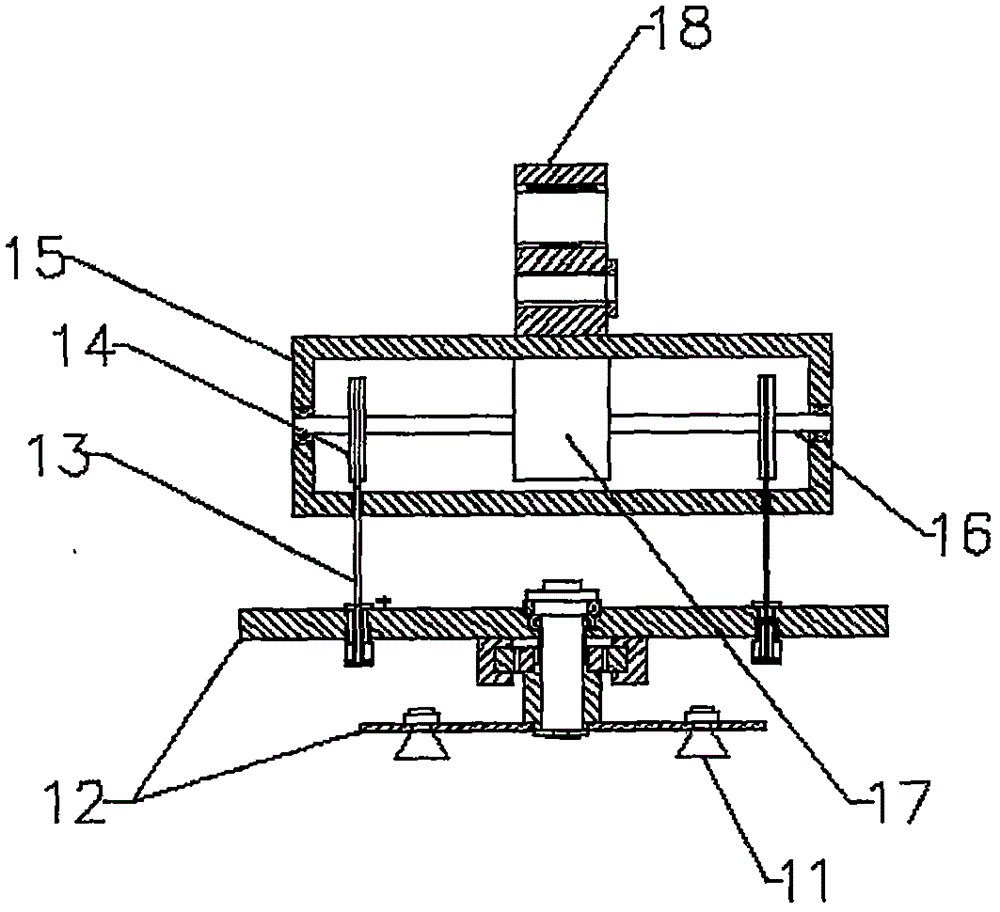

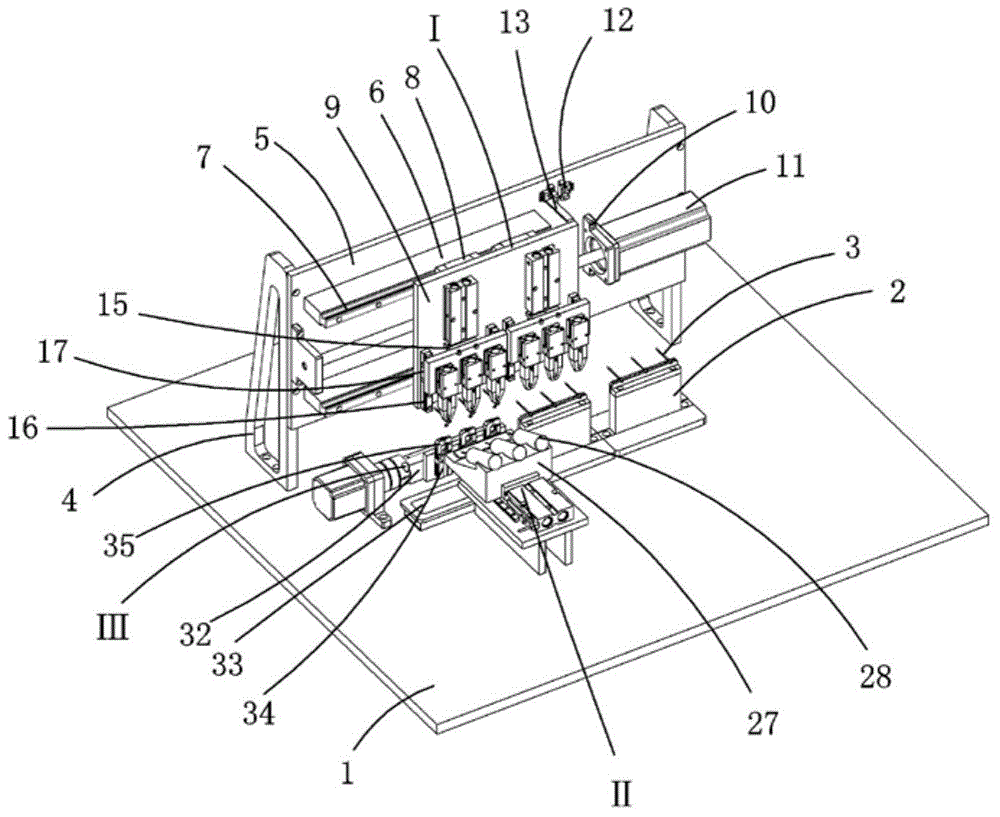

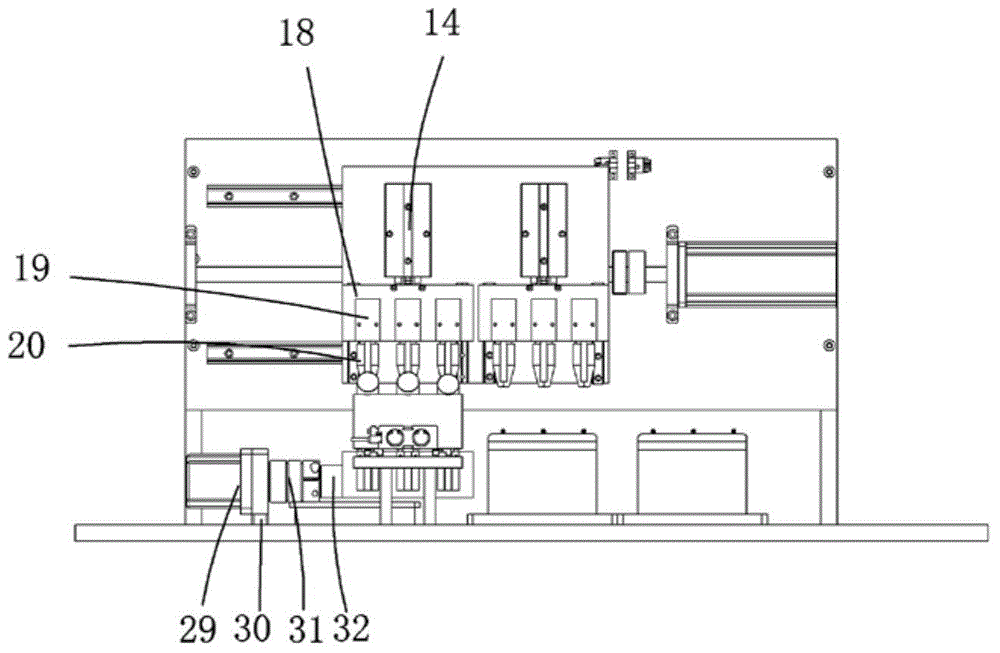

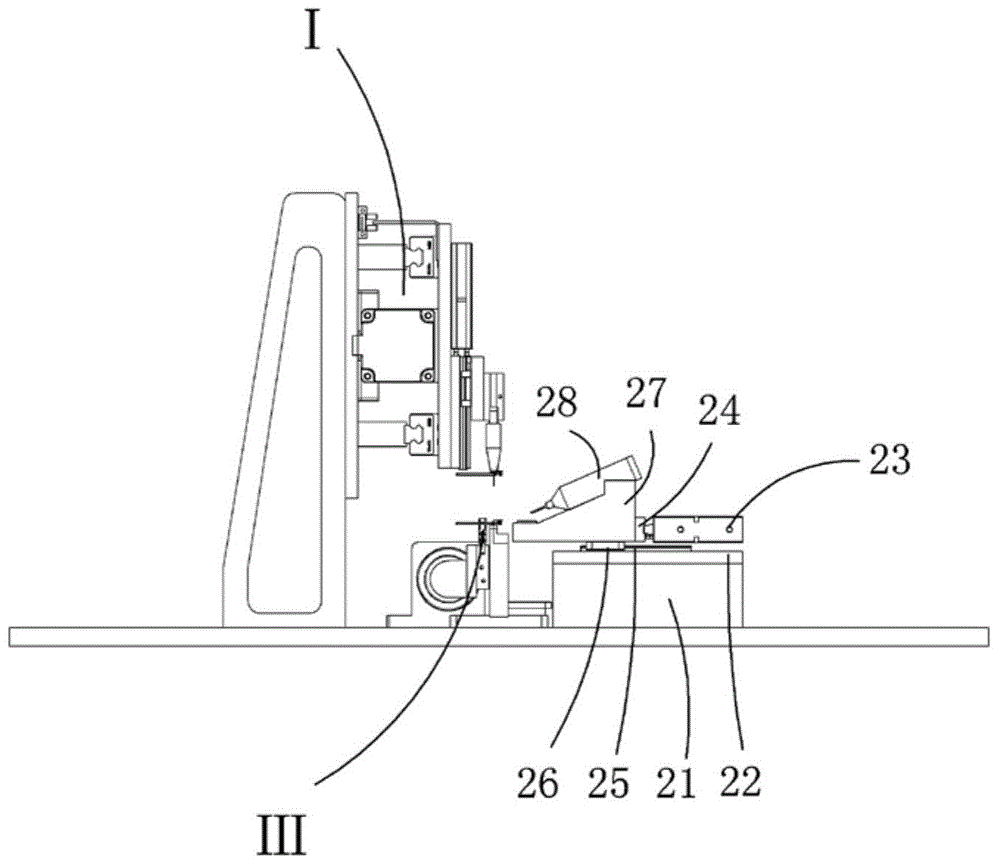

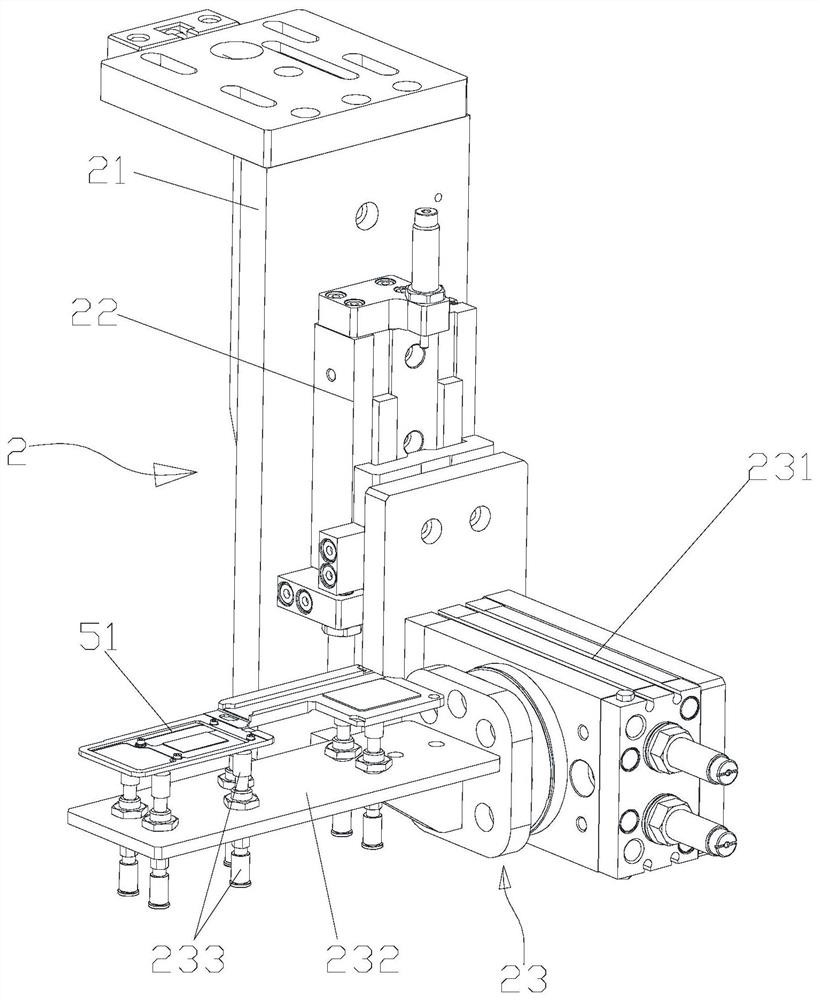

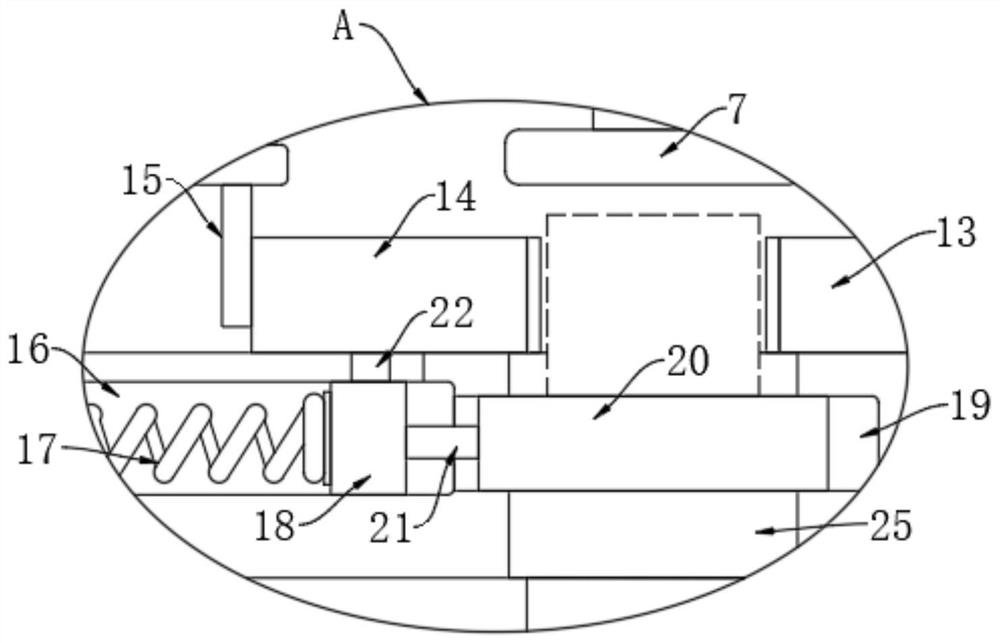

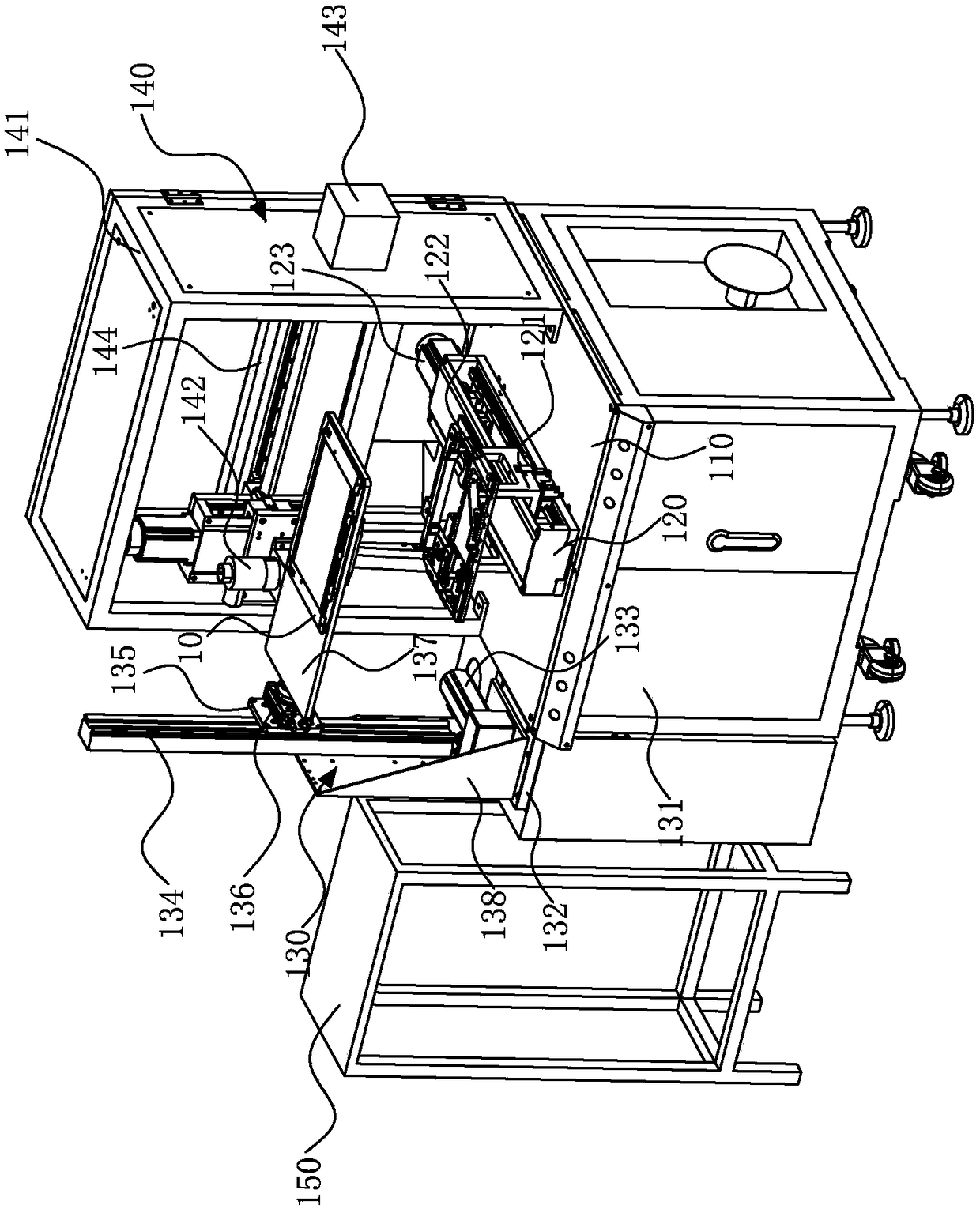

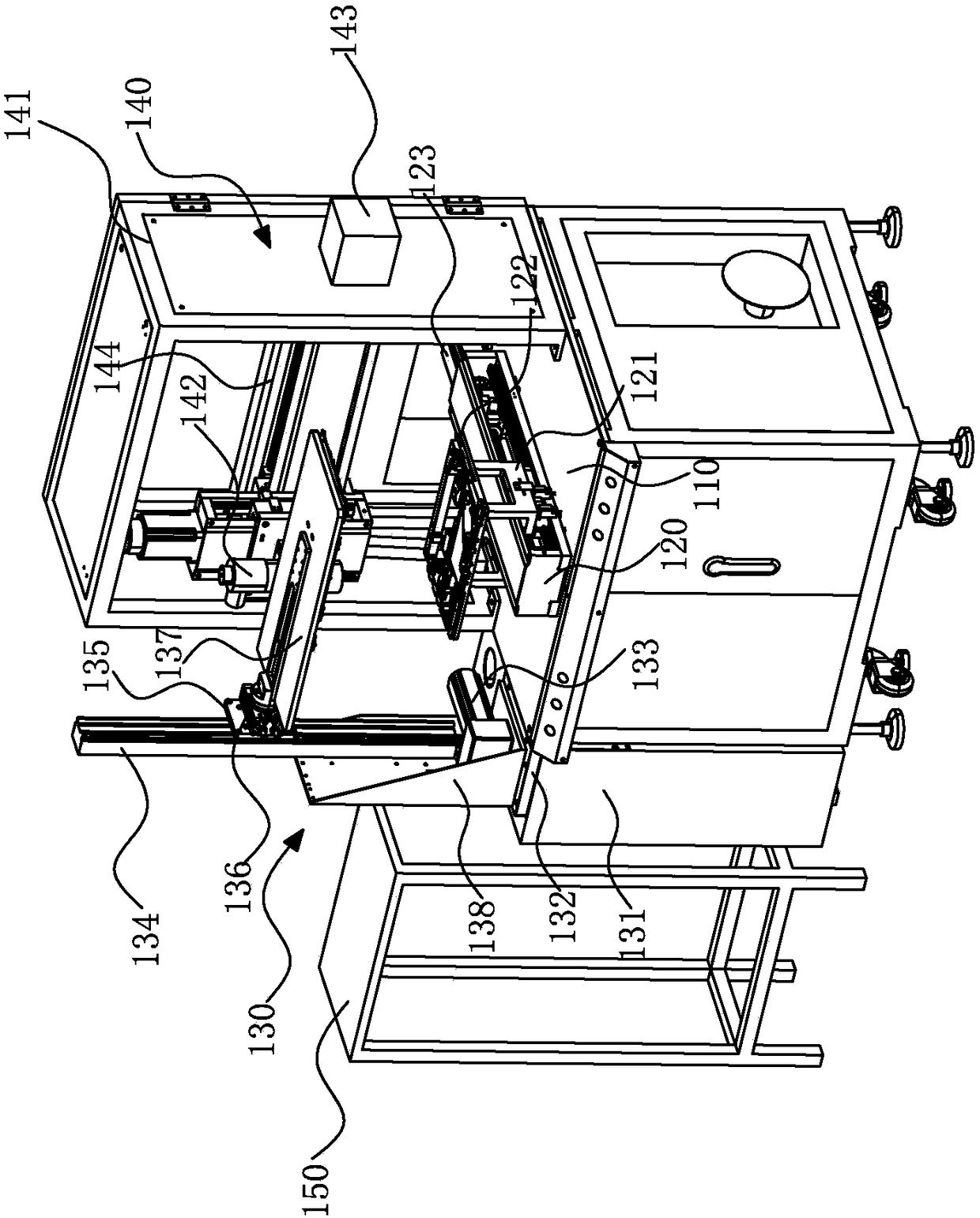

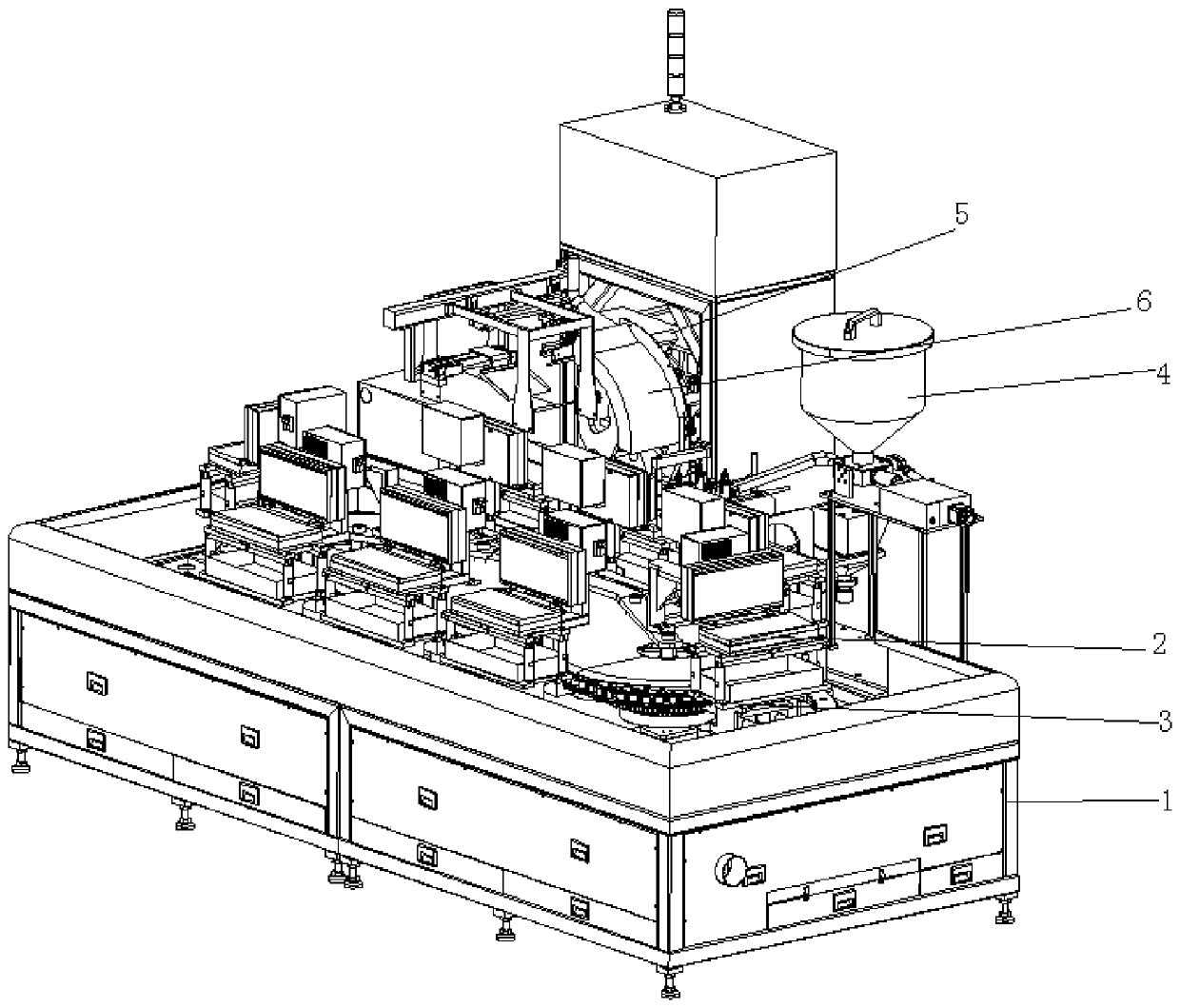

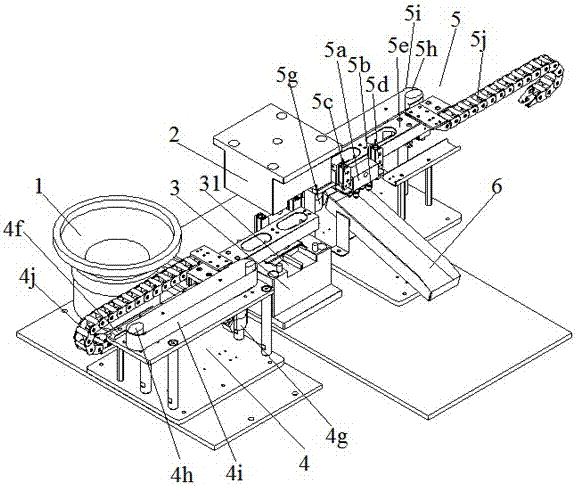

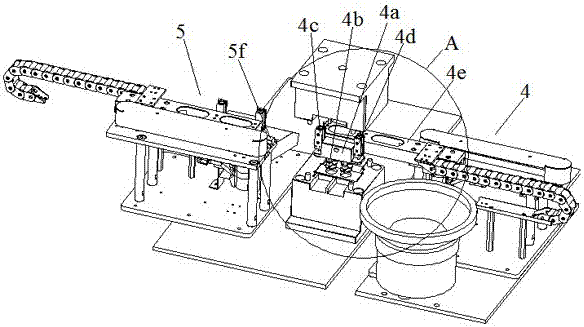

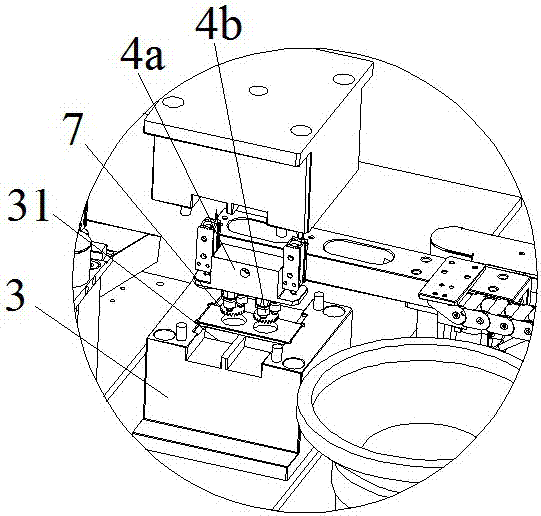

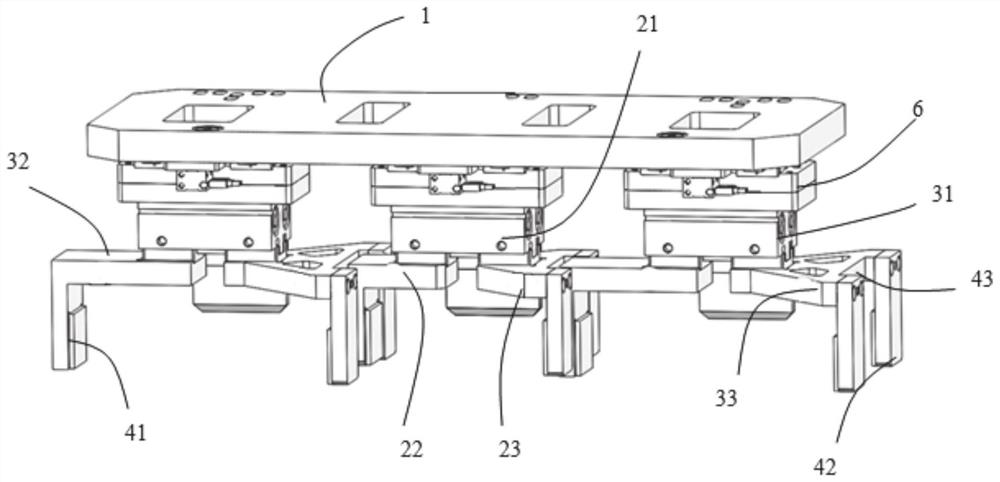

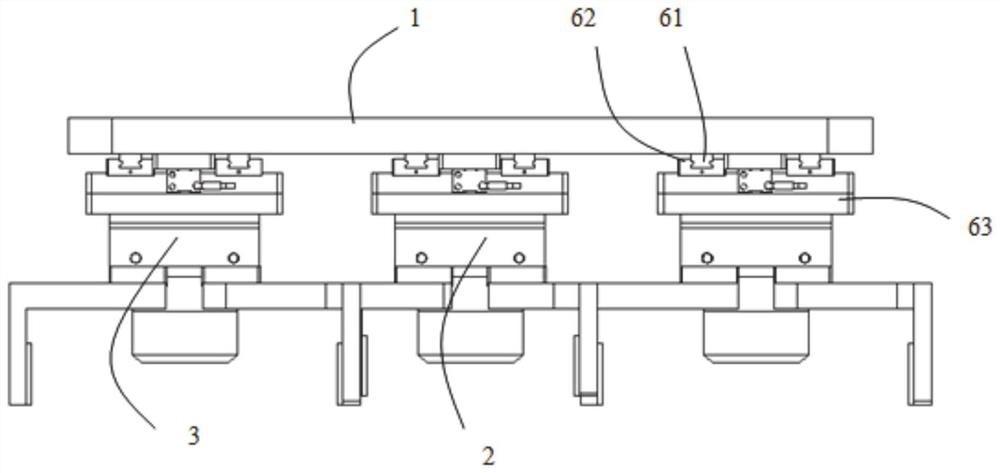

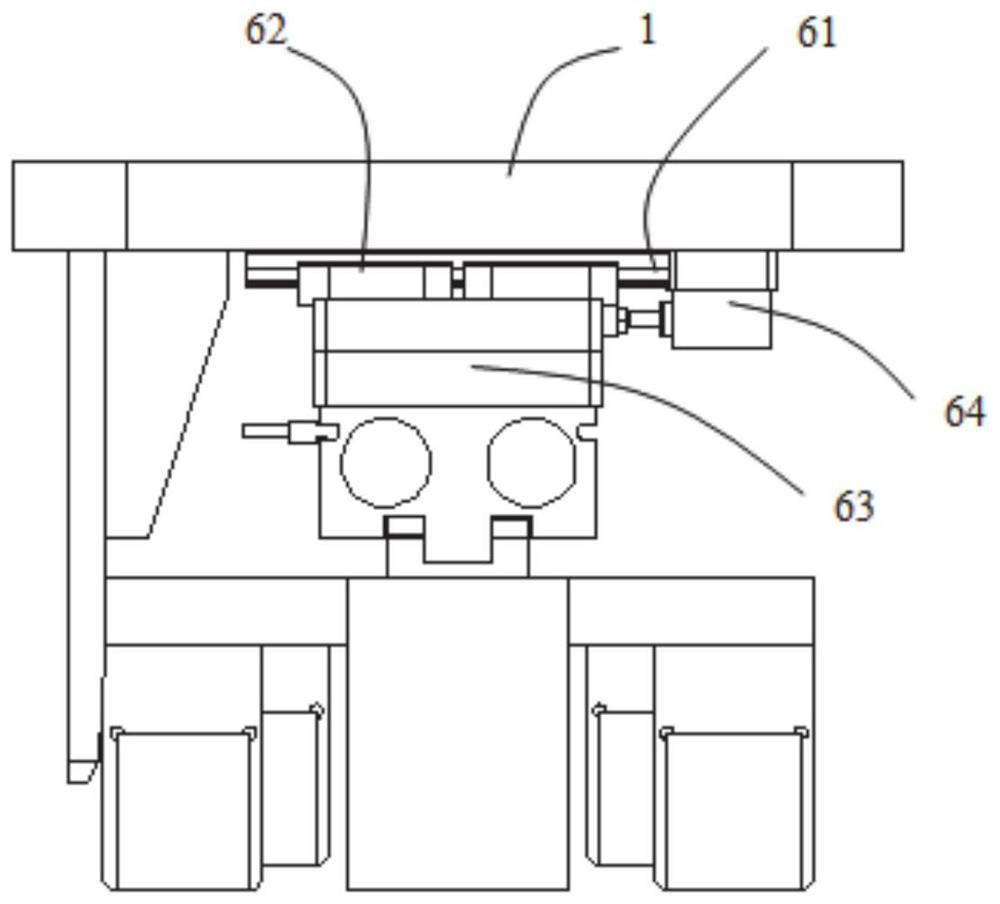

Automatic testing equipment for PCB

PendingCN110187257ARealize automatic pick and placeEasy to detectPrinted circuit testingSortingAutomatic test equipmentAutomatic testing

The invention discloses automatic testing equipment for a PCB. The equipment comprises a machine base, a feeding unit, a detection unit, a discharging unit and a controller, wherein a feeding station,a detection station and a discharging station are sequentially formed on the machine base; the feeding unit is arranged on the machine base corresponding to the feeding station and is used for conveying a PCB (printed circuit board) in a material frame to the detection station; the detection unit is arranged on the machine base corresponding to the detection station and is used for detecting thePCB and conveying the detected PCB to the discharging station; the discharging unit is arranged on the machine base corresponding to the discharging station and is used for separately discharging a qualified PCB and an unqualified PCB; and the controller is arranged on the machine base and is electrically connected with the feeding unit, the detection unit and the discharging station, so that theautomatic operation of the equipment is realized. The PCB automatic testing equipment is intelligent and convenient, replaces manual placing and detecting, achieves the functions of automatic taking and placing, detecting and sorting of the PCB, reduces labor cost, improves production efficiency, and greatly enhances testing accuracy.

Owner:深圳市世纪福科技有限公司

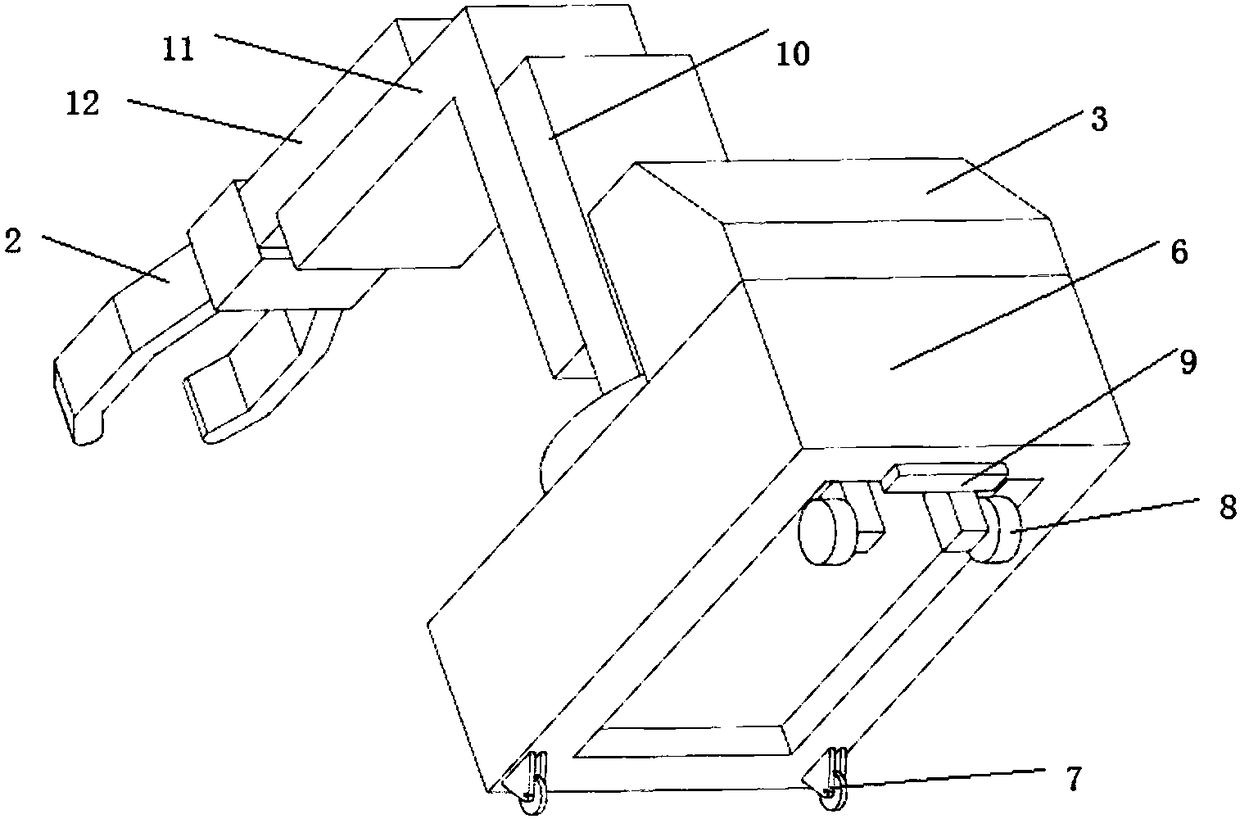

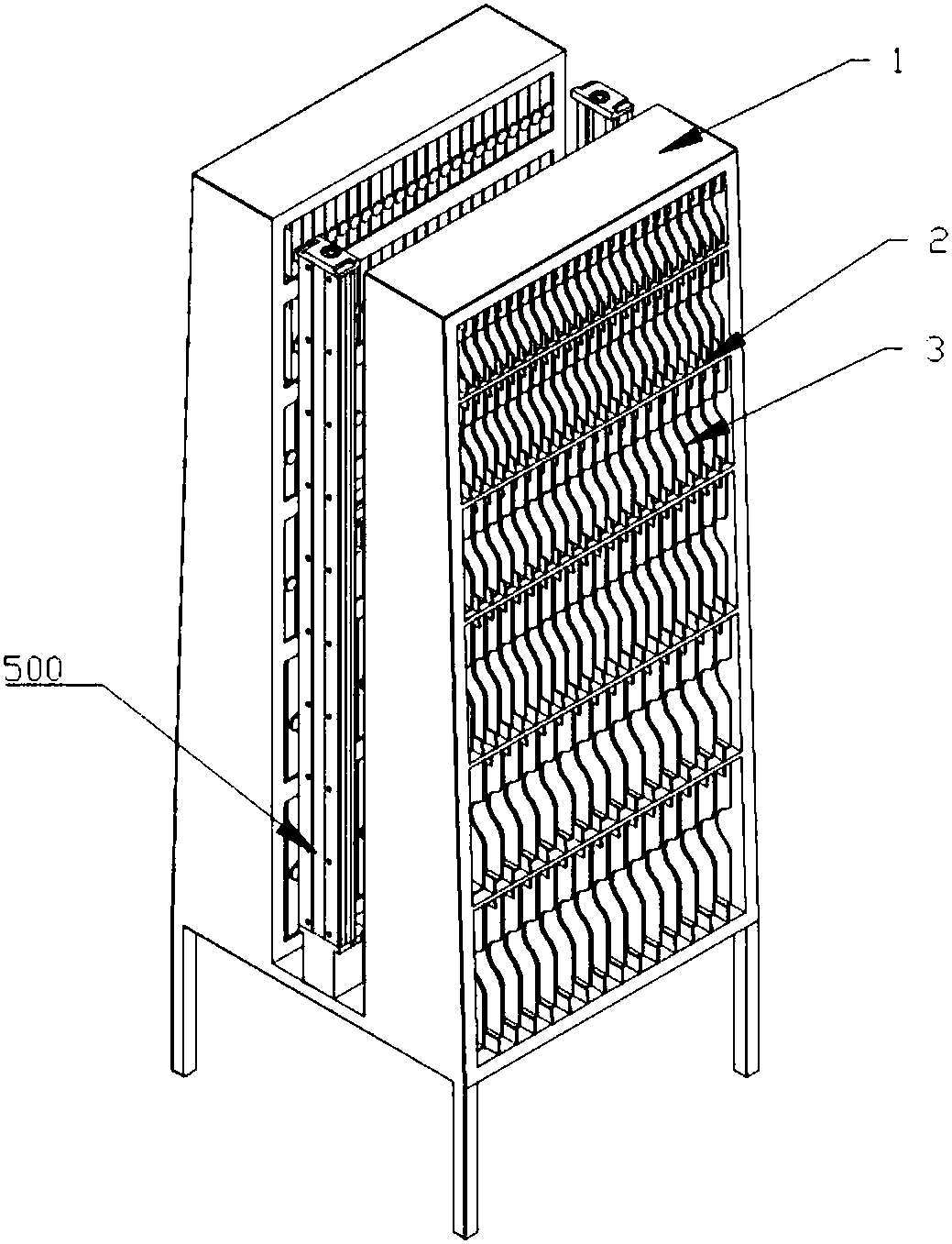

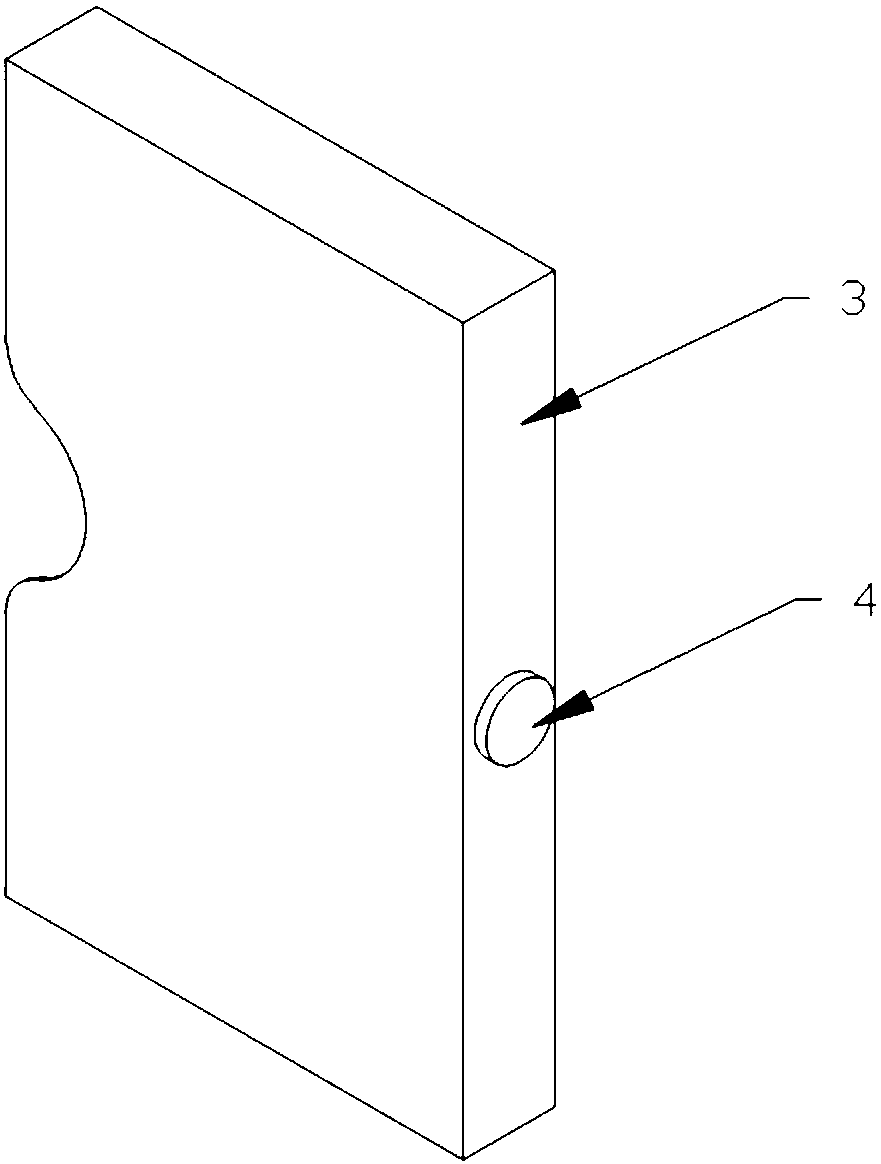

Intelligent article picking and placing mechanism

PendingCN108244848AImprove protectionRealize automatic pick and placeBook cabinetsFlexible MechanismsMotor drive

The invention discloses an intelligent article picking and placing mechanism, which comprises a bidirectional frame body with a base, several layers of grids arranged at the inner part of the bidirectional frame body, article boxes placed in the grids, electromagnet arranged at the back faces of the article boxes, and a movable flexible mechanism arranged in the middle of the bidirectional frame body; a vertical moving motor drives a first screw to rotate and realize the vertical lifting of a U-type cross rod as well as the picking and placing of articles at different grid layers; the horizontal moving motor drives the second screw to rotate and realize the horizontal movement of the moving slide block as well as pick and place articles at different grids; a flexible motor drives the screwto rotate in front and back directions, and the top block is pushed to move forwards and backwards, the article boxes are pushed out to suck with the electromagnets and then contracted; the mechanismsaves labor force, is convenient and intelligent; the design of the article boxes can well protect the articles; meanwhile, the bidirectional design of the frame body can store more articles and savespace.

Owner:深圳市三维通机器人系统有限公司

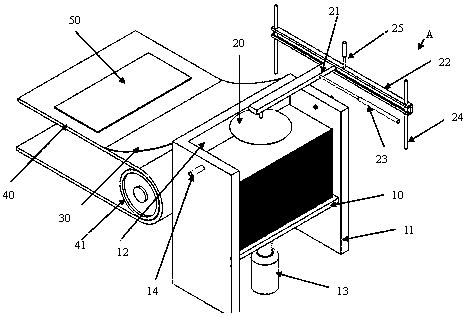

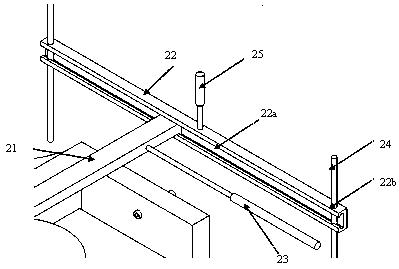

LED (Light-Emitting Diode) light bar photoelectric property detection mechanism

ActiveCN104360292ARealize automatic pick and placeImprove detection efficiencyLamps testingTesting optical propertiesEngineeringLED lamp

The invention discloses an LED (Light-Emitting Diode) light bar photoelectric property detection mechanism comprising a frame, a transmission component, a positioning component, a photoelectric detection component and an electrical detection component, wherein the positioning component comprises a supporting frame, a blocking device, a detection supporting block, an aligning device and a detection point lifting device; the blocking device can be used for blocking to-be-detected LED light bars conveyed from the transmission component to ensure that the to-be-detected LED light bars are positioned on the detection supporting block, the aligning device can be used for automatically performing position alignment on the to-be-detected LED light bars, the detection point lifting device can be used for automatically adsorbing the to-be-detected LED light bars subjected to position alignment and transporting the to-be-detected LED light bars to a detection position by pushing the detection supporting block, and the photoelectric detection component and the electrical detection component can be used for testing optical and electrical properties of the to-be-detected LED light bars conveyed to the detection position. According to the LED light bar photoelectric property detection mechanism disclosed by the invention, optical detection and electrical detection are integrated on one set of equipment, so that the detection process can be simplified, the manpower cost can be saved, and the detection efficiency of the LED light bars can be improved.

Owner:SUZHOU JINGLAI OPTO CO LTD

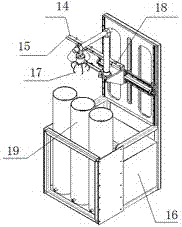

Full automatic breakfast making and selling machine

PendingCN107025729ARealize automatic pick and placeCoin-freed apparatus detailsApparatus for meter-controlled dispensingRice flourEngineering

The invention discloses a full automatic breakfast making and selling machine which comprises an overall machine, wherein the overall machine comprises a case; a display screen, a food display region and a food take opening are arranged at the front end of the case; the food take opening comprises a steamed vermicelli roll take opening and a stuffing steamed bun and drink take opening; a stuffing steamed bun and drink selling mechanism, a steamed vermicelli roll steaming mechanism, a rice milk and rice noodle supply mechanism, a steamed vermicelli roll packing mechanism, a fast food box supply mechanism, a conveyer and an egg and minced meat adding mechanism are arranged inside the case; and a rack and a bottom plate are arranged at the bottom of the case. The full automatic breakfast making and selling machine disclosed by the invention realizes full automatic making and selling of instant breakfast, steamed vermicelli roll, rice noodles, fried rice noodles and steamed noodles and also realizes automatic taking and placing of pastry breakfast and drink.

Owner:刘先阳

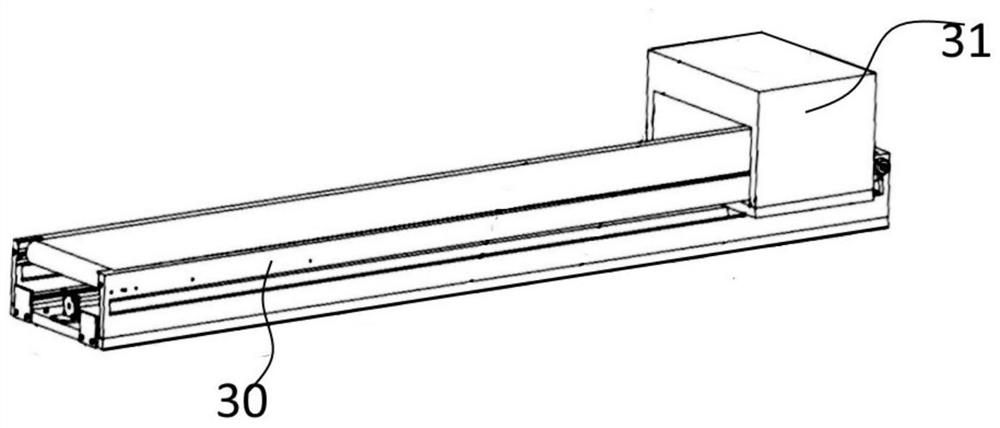

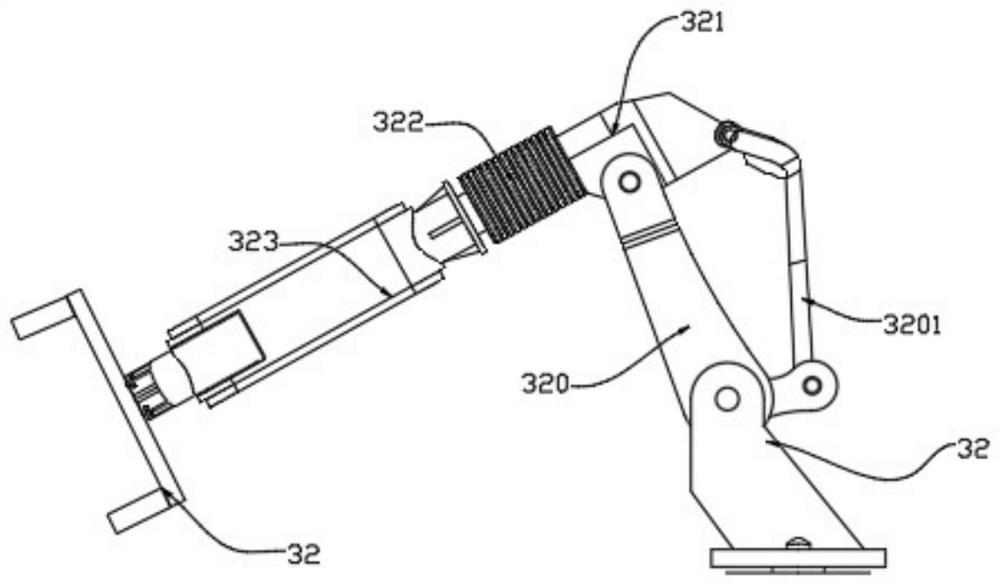

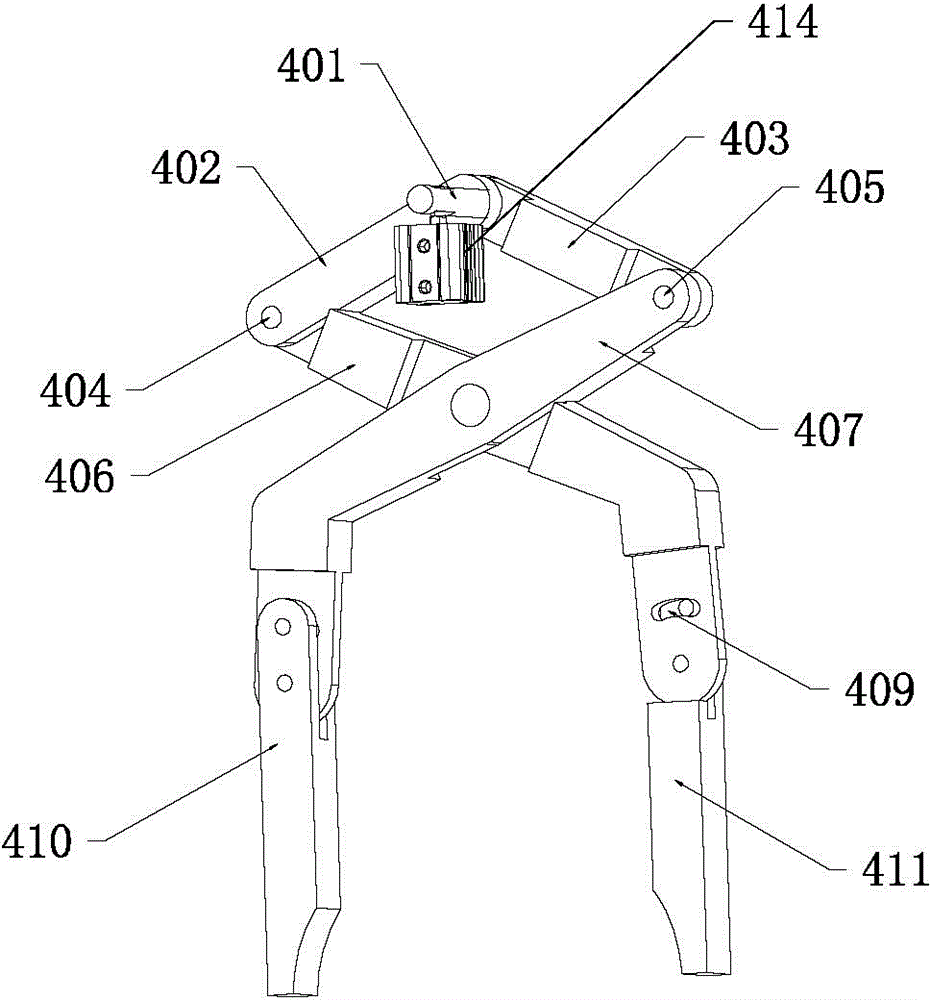

Defective battery discharging device on battery production line and working method thereof

InactiveCN112058714AIncrease the force contact areaStable water levelSortingConveyor partsElectrical batteryControl system

The invention discloses a defective battery discharging device on a battery production line and a working method thereof. The defective battery discharging device on the battery production line is arranged on a battery conveying production line, is used for discharging defective batteries which do not pass an electrical test, and comprises a linear guide rail assembly arranged on one side of a battery conveying machine body, a mechanical arm installed on the linear guide rail assembly in a transmission mode, and a special clamp is fixedly installed on the mechanical arm; and a linear driving device and a positioning mechanism are arranged on one side of the linear guide rail set, and the linear driving device is in communication with a control system. A lithium battery production line anda fire-fighting conveying line are synchronously arranged, the fire-fighting path and waiting time are shortened for solving the fire problem of the production line, and the distance between clampingjaws can be adjusted by arranging the lead screw assemblies on the connecting parts on the special clamps, so that the clamping jaws adapt to trays of various sizes; and meanwhile, the front and rearclamping parts are synchronously taken and placed to increase the stress contact area of the tray, stabilize the gravity center of the battery in the tray and prevent the battery from falling out of the tray.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

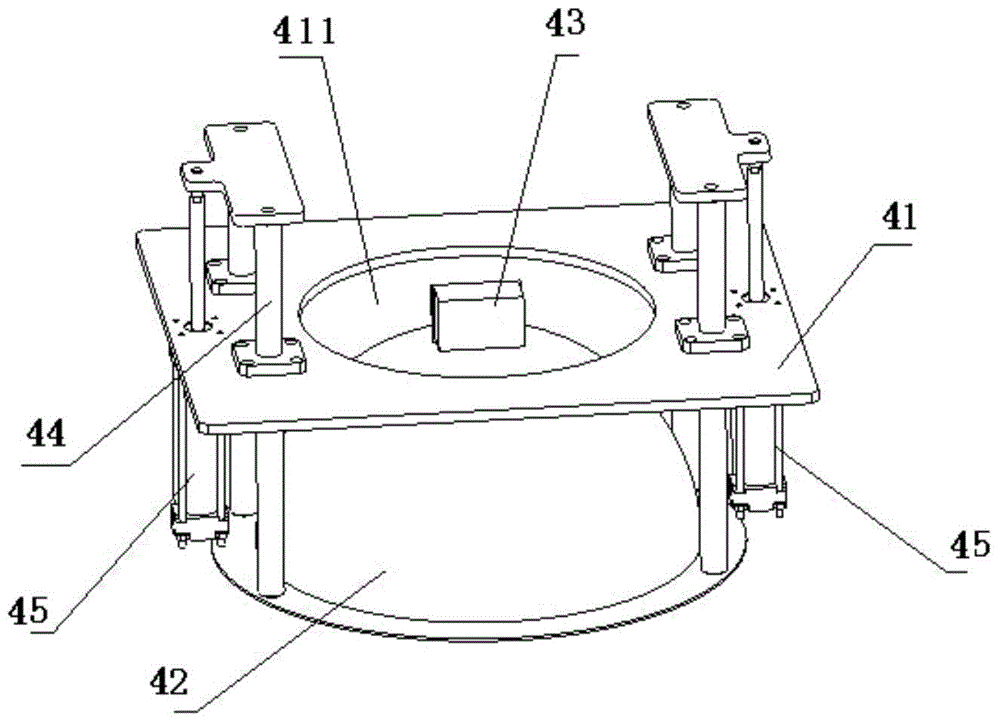

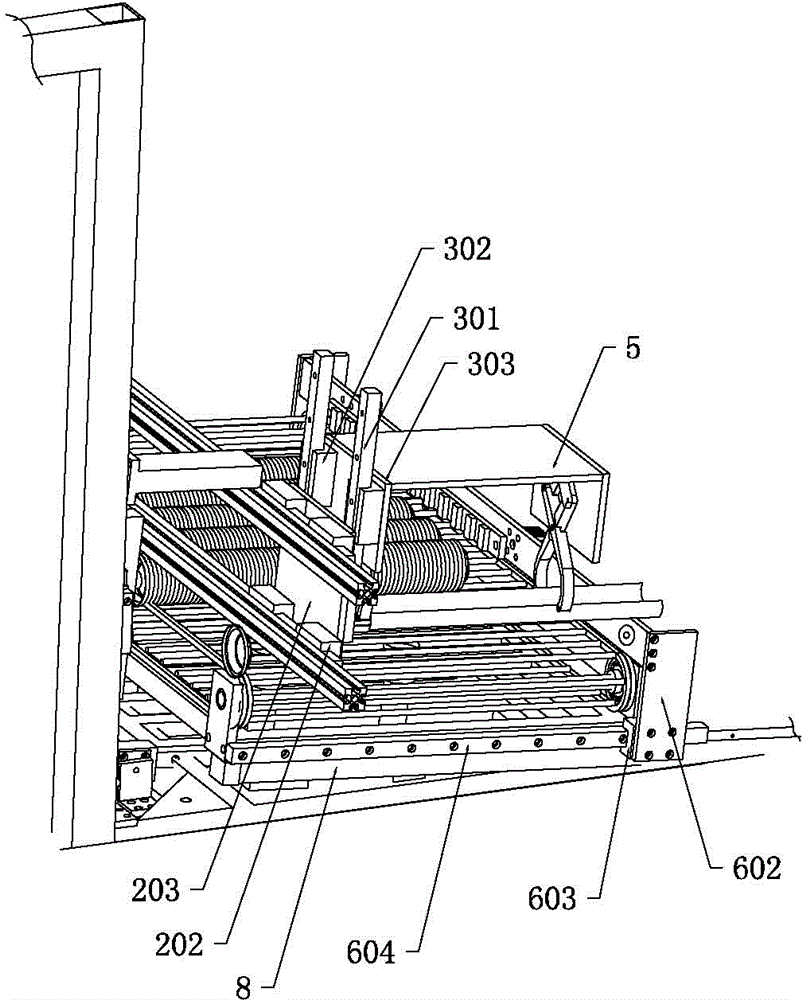

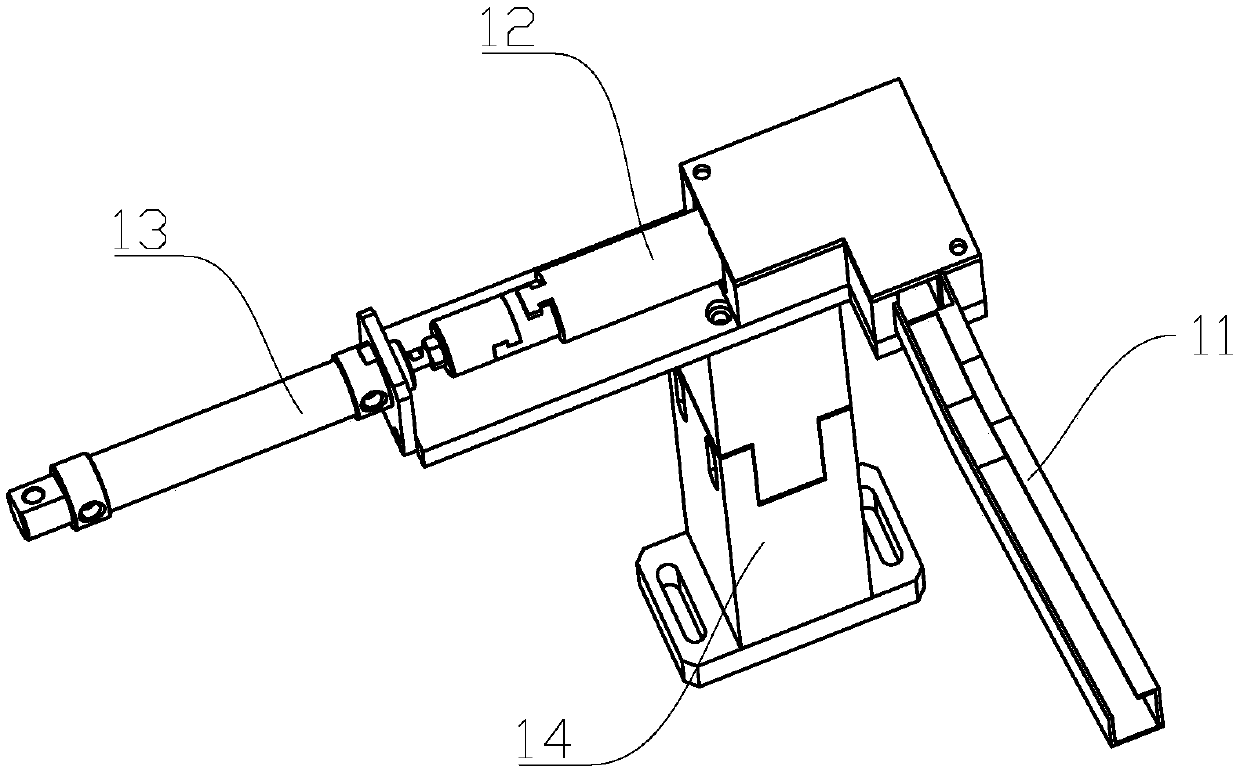

Oral liquid sterilizing automatic bottle-feeding system

ActiveCN103231911AAutomatic bottle loadingRealize automatic pick and placeConveyor partsElectrical controlBottle

The invention relates to an automatic bottle-feeding system, in particular to an oral liquid sterilizing automatic bottle-feeding system and belongs to the field of medical devices. The oral liquid sterilizing automatic bottle-feeding system comprises a machine frame, a motor and an electrical control system. The machine frame (2) is fixed with a bottle tidying table support frame (7), a bottle tidying mechanism (5) is arranged at the top of the bottle tidying table support frame, one end of the bottle tidying mechanism corresponds to a bottle pushing mechanism (8), the other end of the bottle tidying mechanism (5) corresponds to one end of a sterilizing disc (4), the other end of the sterilizing disc (4) corresponds to a bottle blocking mechanism (1), a sterilizing disc blocking rod (14) is arranged between the sterilizing disc (4) and the bottle tidying mechanism (5), a blocking rod automatic taking and placing mechanism (13) is installed at the top of the sterilizing disc blocking rod, the sterilizing disc is arranged at the top of a sterilizing disc conveying unit (3), and the sterilizing disc conveying unit is arranged on the upper portion of the machine frame. Through the oral liquid sterilizing automatic bottle-feeding system, automatic tidying and automatic feeding of oral liquid penicillin bottles and automatic taking and placing of the open type sterilizing disc blocking rod are achieved, production efficiency is improved, labor intensity is reduced, and production cost is low.

Owner:SHINVA MEDICAL INSTR CO LTD

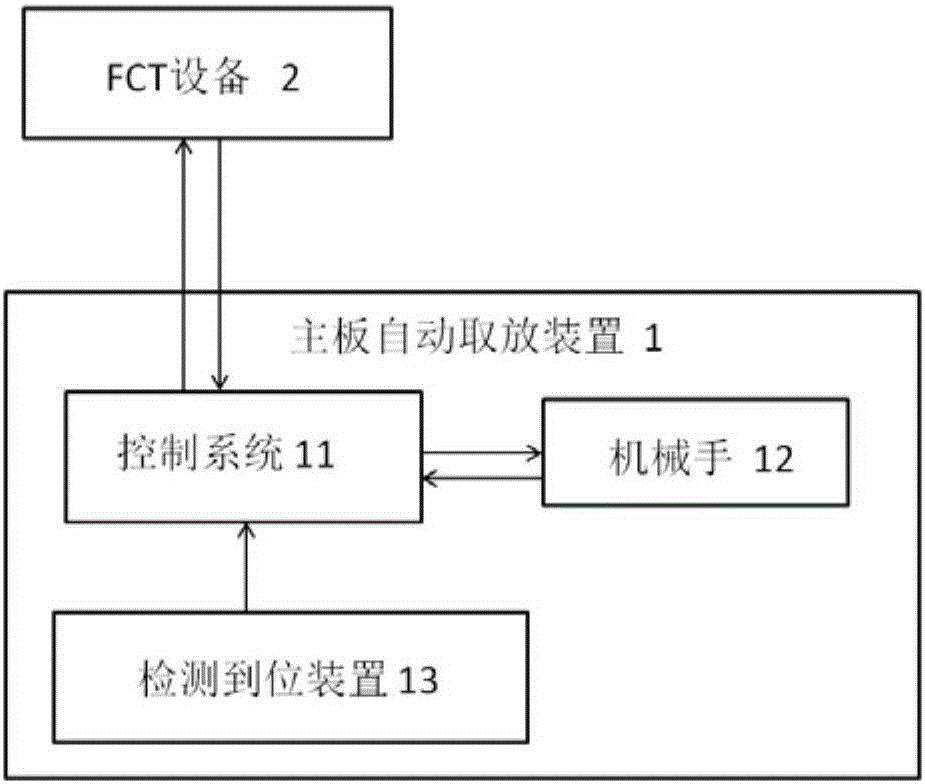

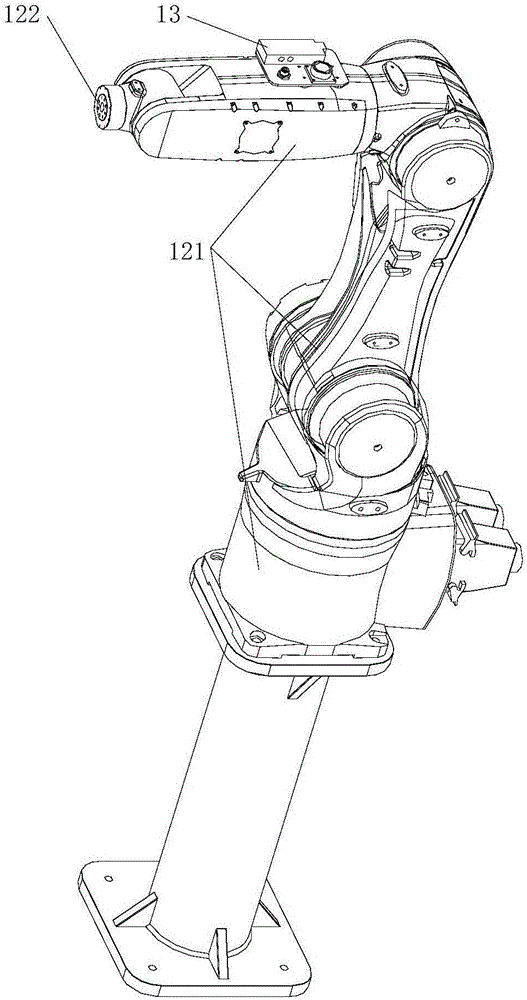

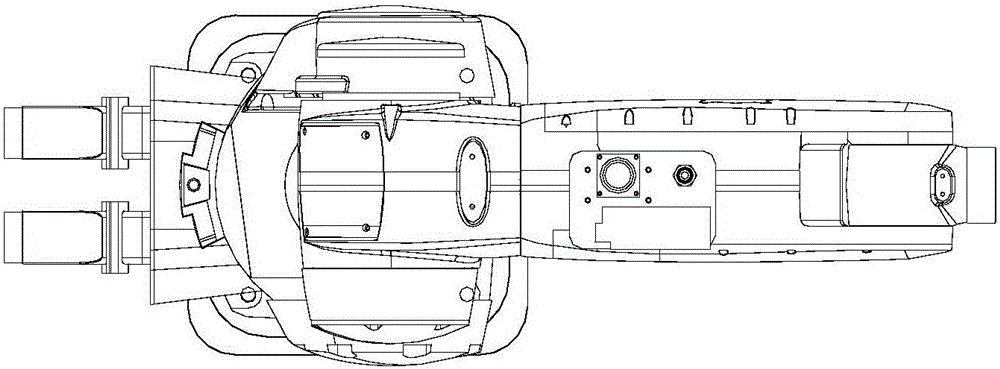

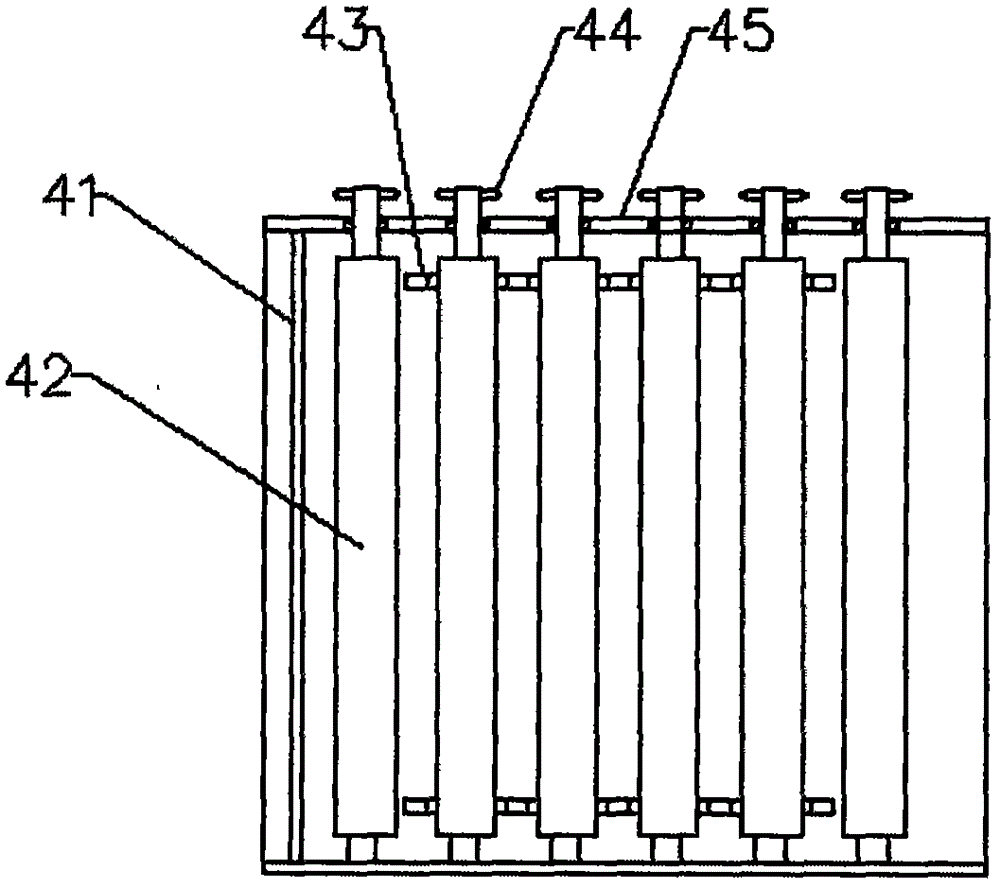

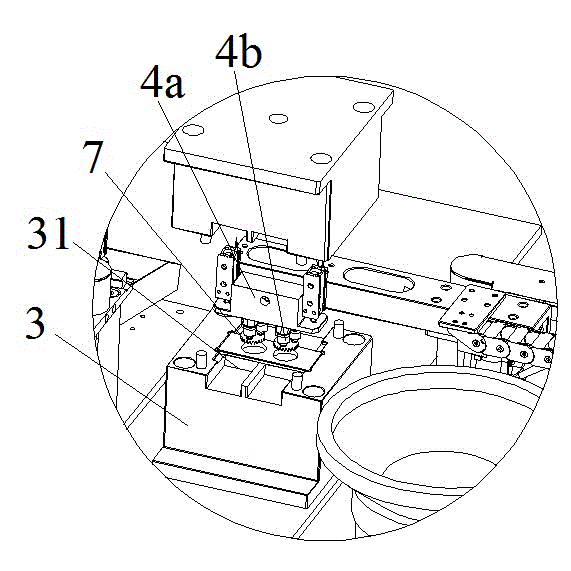

Mainboard automatic picking and placing device and method and FCT device

InactiveCN105738796ARealize automatic pick and placeImprove test efficiencyPrinted circuit testingTest efficiencyControl system

The invention discloses a mainboard automatic picking and placing deviceand method and an FCT device, relating to the mainboard test technology. The invention adopts the scheme that: the mainboard automatic picking and placing device comprises a control system and a manipulator; the control system is connected to the manipulator for controlling the manipulator to pick and place the mainboard; the control system is connected to the FCT device; when the manipulator places the mainboard on the test table of the FCT device, the control system transmits a start test signal to the FCT device, which enables the FCT device to start the test; when the FCT device finishes testing on the mainboard, the control system receives the test result signal transmitted by the FCT device and controls the manipulator to place the main board to a set position according to the test result. The invention adopts the mainboard automatic picking and placing device to realize the automatic picking and placing board on the FCT device. The FCT device comprises the mainboard automatic picking ad placing device. The invention is mainly used for improving the testing efficiency and automation degree of the mainboard testing function.

Owner:GREE ELECTRIC APPLIANCES INC

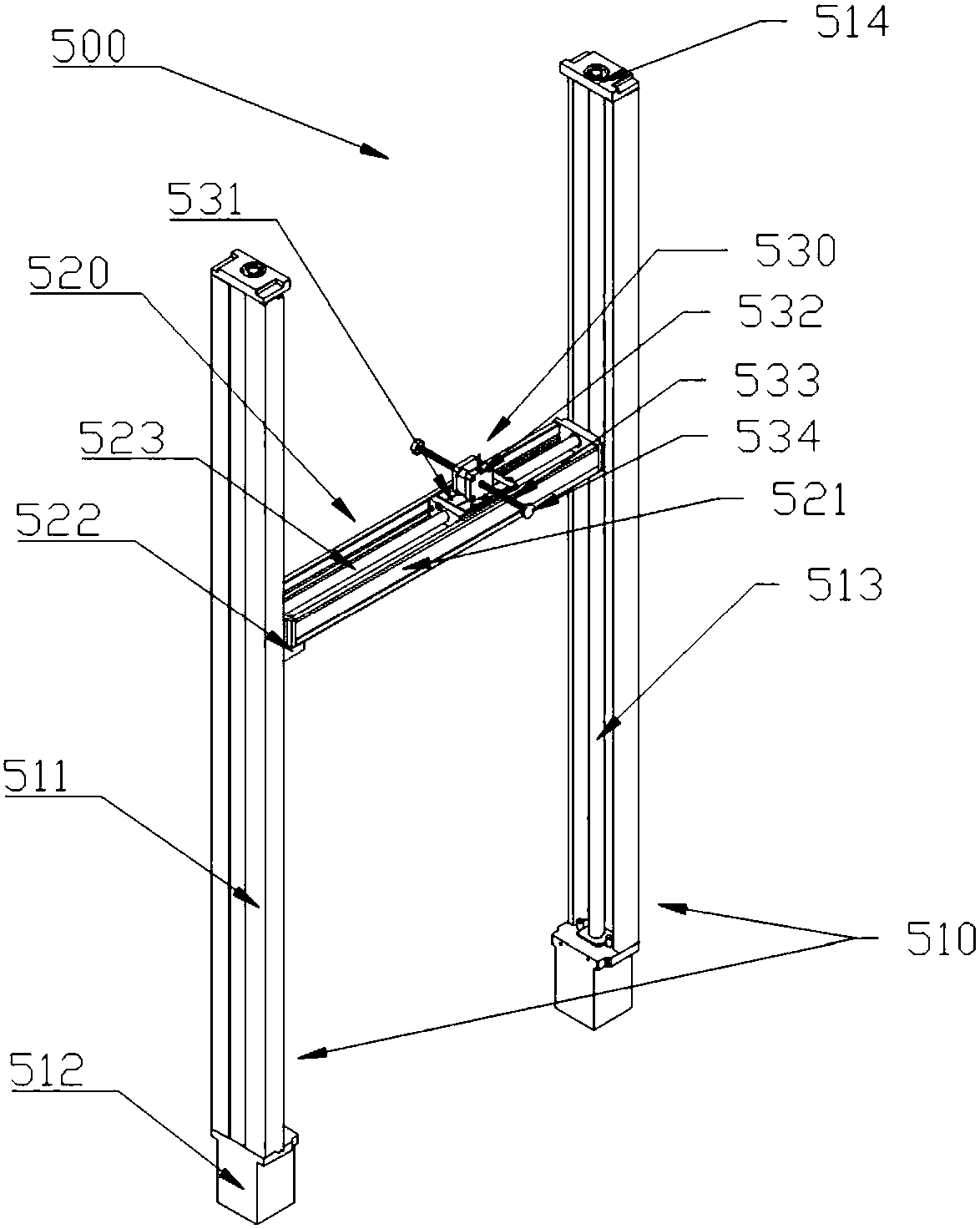

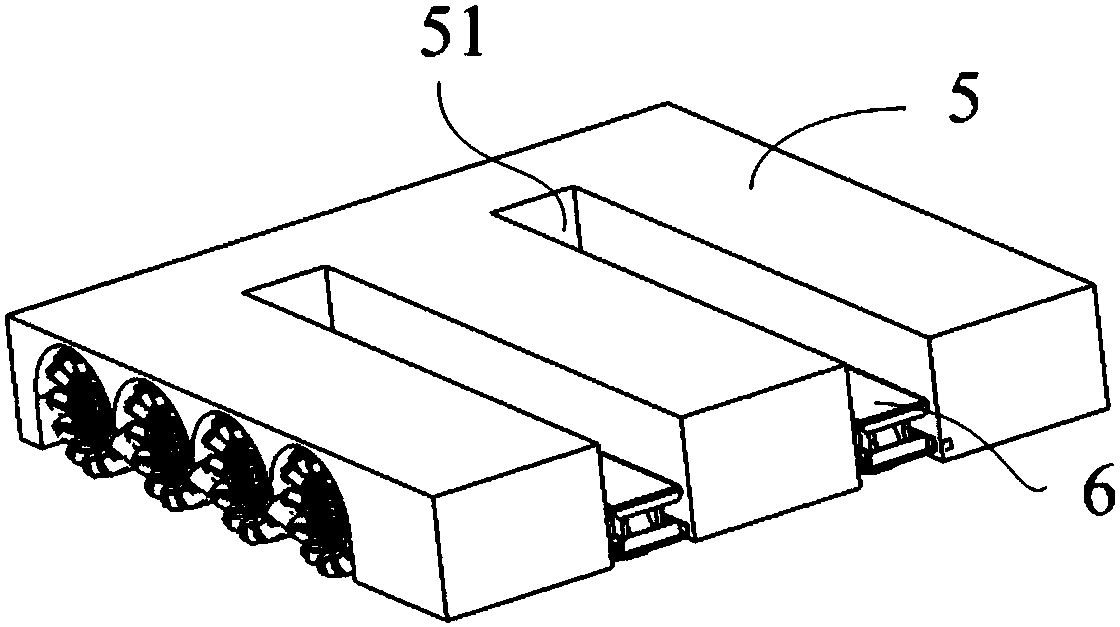

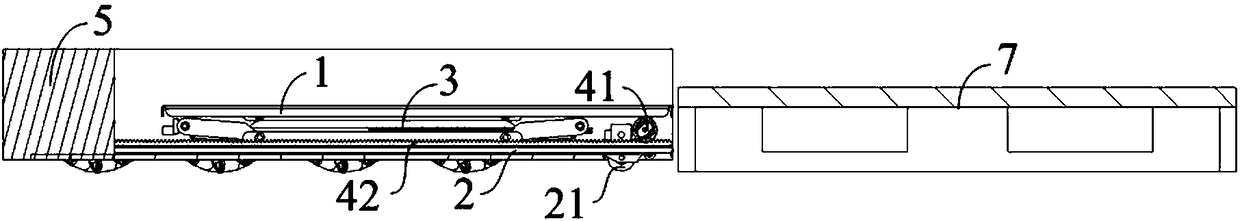

Telescopic arm used for conveying device

Owner:HANGZHOU HIKROBOT TECH CO LTD

Automatic grabbing and shifting manipulator

InactiveCN108237548ASimple structureEasy to operateGripping headsConveyor partsEngineeringManipulator

The invention discloses an automatic grabbing and shifting manipulator. The automatic grabbing and shifting manipulator comprises a longitudinal moving device, a transverse moving device, grabbing andshifting clamping claws and a finished product packaging clamping claw; the longitudinal moving device is arranged on a fixing base; the transverse moving device is arranged on the longitudinal moving device; the plurality of grabbing and shifting clamping claws are uniformly arranged on the transverse moving device; and the finished product packaging clamping claw is arranged at the tail end ofthe transverse moving device. The automatic grabbing and shifting manipulator is simple in structure, the grabbing and shifting clamping claws are driven to move in the X-Y axis direction through thelongitudinal moving device and the transverse moving device, it is achieved that products are automatically taken, put down and placed onto a next station to be machined, operation is flexible, positioning is accurate, it is achieved that the products are taken, put down and shifted continuously at the same time, and the work efficiency of the equipment is effectively improved; and meanwhile, adjusting at different distances of the transverse position is achieved through the finished product packaging clamping claw, the equipment can adapt to packaging boxes in different sizes and distances, automatic packaging of the products is achieved, and the practicability of the equipment is effectively improved.

Owner:DONGGUAN WAN JIANG MACHINERY

Automatic pressing board loading and unloading mechanical arm

InactiveCN106041977AAccurate placementQuality improvementProgramme-controlled manipulatorGripping headsEngineeringManipulator

Owner:王桂英

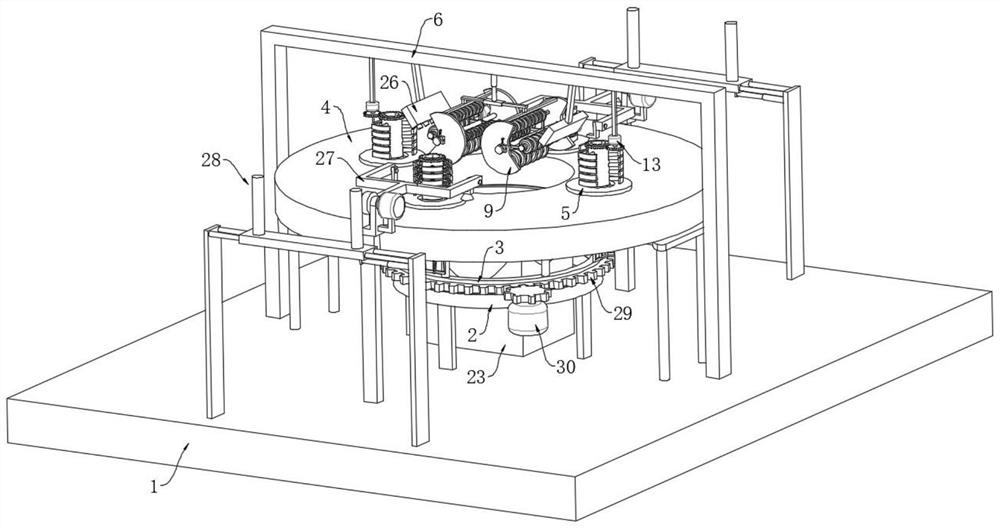

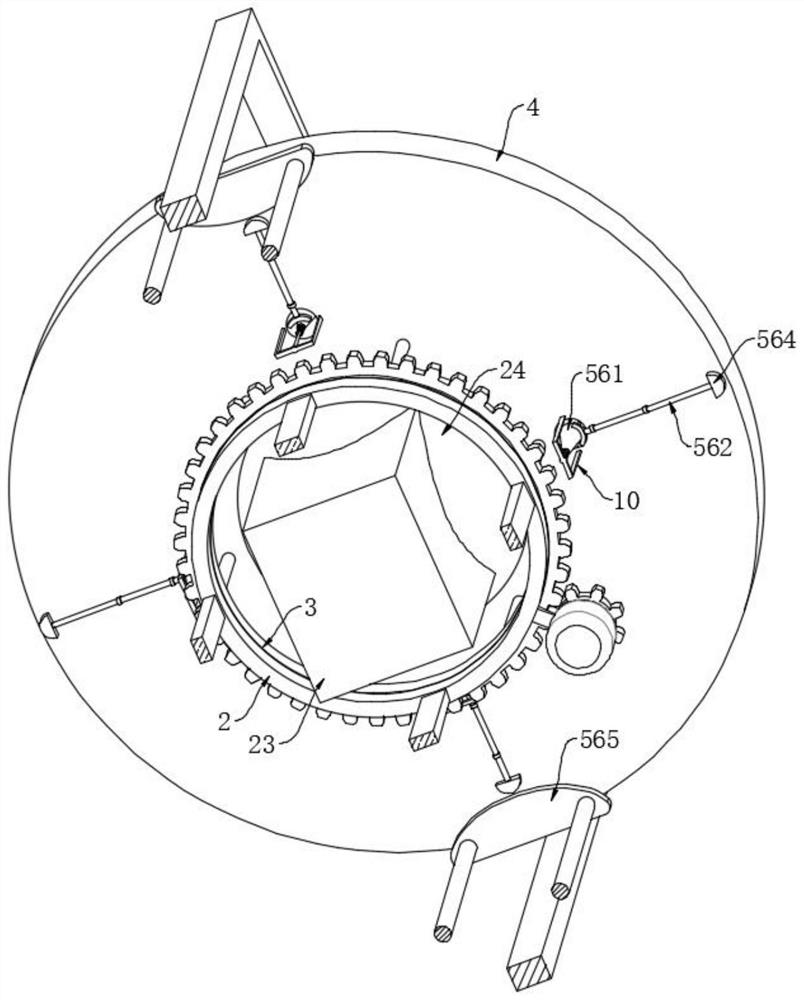

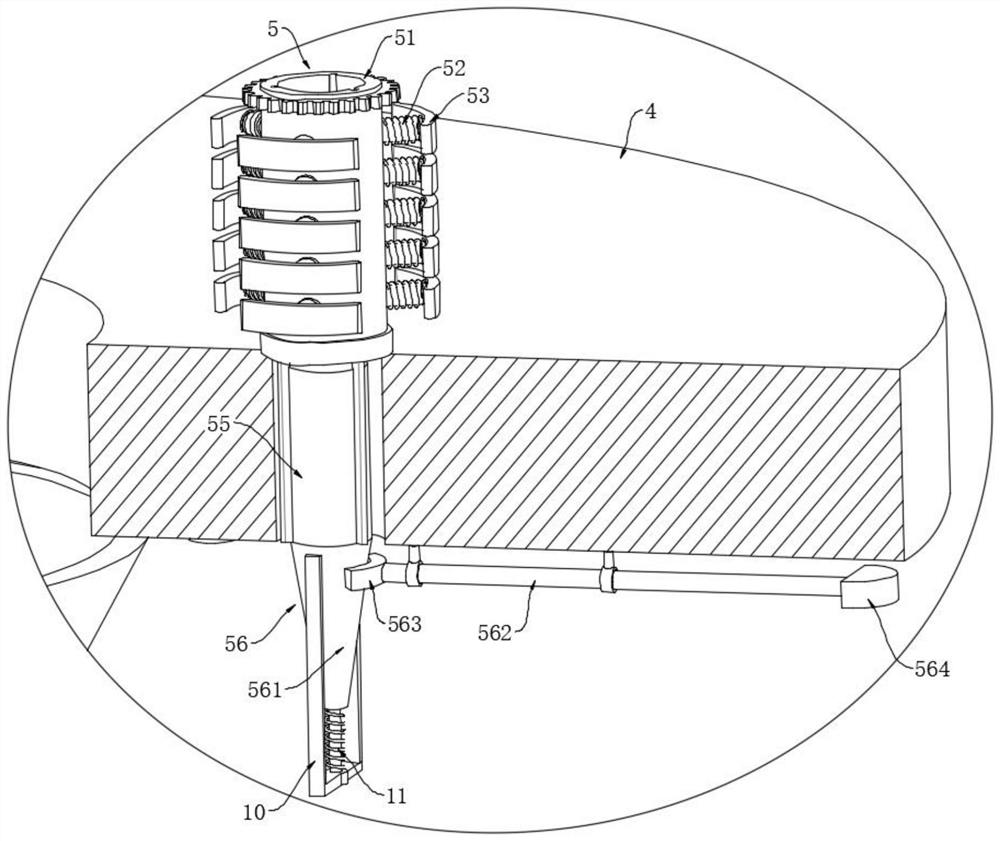

Molding device for driving assembly of wind power generation equipment

ActiveCN114535719AEasy to change and adjustImprove Turning Forming EfficiencyWind energy generationGear-cutting machinesGear wheelEngineering

The invention discloses a forming device for a driving assembly of wind power generation equipment, and relates to the technical field of machining of parts of the wind power generation equipment. The wind power generation equipment driving assembly forming device comprises a supporting plate base, the upper end face of the supporting plate base is fixedly connected with a first mounting ring through a vertical rod, a plurality of clamping mechanisms used for clamping and limiting a gear blank are installed on the circumference of the upper end face of an annular mounting disc at equal intervals, and the upper end face of the supporting plate base is fixedly connected with an n-shaped frame; according to the gear machining device, cutting tools of different specifications can be rapidly switched according to gears of different specifications, operation is easy and convenient, two gear blanks can be machined at the same time, the machining efficiency is improved, the machining cost is reduced, and the machining efficiency is improved. And the processing efficiency is improved.

Owner:睢宁核源风力发电有限公司

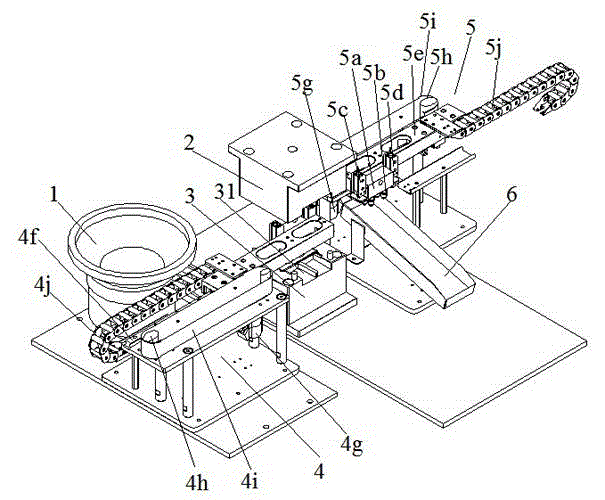

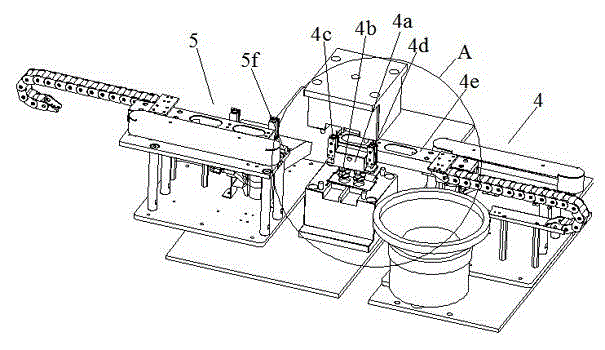

Automation device suitable for plastic molding

ActiveCN104441405ARealize automatic pick and placeLabor savingCoatingsInjection mouldingInjection molding machine

The invention discloses an automation device suitable for plastic molding. The automation device suitable for the plastic molding comprises a vibration plate, an injection molding machine, a feeding mechanism and a material taking mechanism, wherein the vibration plate is used for feeding materials; the injection feeding mechanism is used for performing injection molding, the feeding mechanism is used for taking out raw materials from the vibration plate, and the material taking mechanism is used for taking out finished-products from the injection molding machine; the feeding mechanism and the material taking mechanism are symmetrically arranged on the two sides of a mold cavity and respectively comprise a manipulator, two first air cylinders, fixing plates and a driving device, wherein the first air cylinders drive the manipulator to lift, the fixing plates are arranged on the first air cylinders, and the driving device are used for driving the fixing plates to displace; the displacement directions of a fixing plate of the feeding mechanism and a fixing plate of the material taking mechanism are in the same straight line. The automation device suitable for the plastic molding has the beneficial effects that the feeding mechanism and the material taking mechanism cooperate and match to automatically take out and put down raw materials and finished products; labor is reduced, and the labor cost is saved; the displacement directions of the feeding mechanism and the material taking mechanism are in the same straight line, the device is simple in structure, the operation is reliable, and the production efficiency is greatly improved.

Owner:KUNSHAN SAN TOHNO ELECTRON

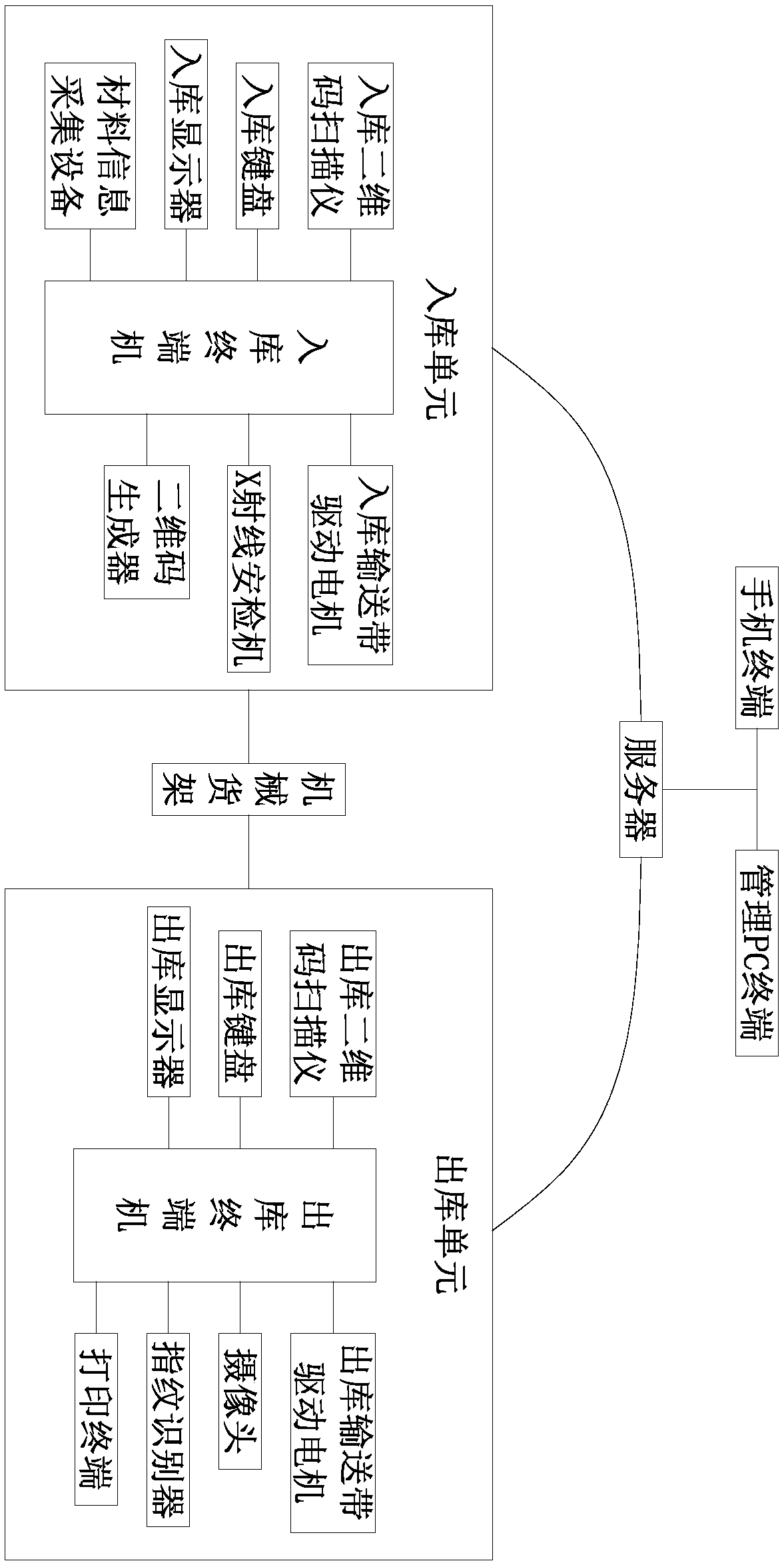

A material warehouse-in warehouse-out management system based on LoRa network

InactiveCN109242399AEasy to collectImprove securityCo-operative working arrangementsLogisticsData warehouseX-ray

The invention relates to a material warehouse-in warehouse-out management system based on LoRa network, comprising a server warehouse-in unit, a warehouse-out unit and a plurality of mechanical shelves. The server is connected with a mobile phone terminal and a management PC terminal. The warehouse-in unit comprises a warehousing terminal, wherein the warehouse-in terminal is connected with a warehousing two-dimensional code scanner, a warehousing keyboard, a warehousing display, a material information acquisition device, a warehousing conveyor belt driving motor, an X-ray security inspectionmachine and a two-dimensional code generator; The warehouse-out unit comprises a warehouse-out terminal machine, wherein the warehouse-out terminal machine is connected with a warehouse-out two-dimensional code scanner, a warehouse-out keyboard, a warehouse-out display, a warehouse-out conveyor belt driving motor, a camera, a fingerprint recognizer and a printing terminal; The invention has the advantages of convenient data storage, high safety, convenient management, saving manpower and effectively reducing labor intensity.

Owner:河南汇纳科技有限公司

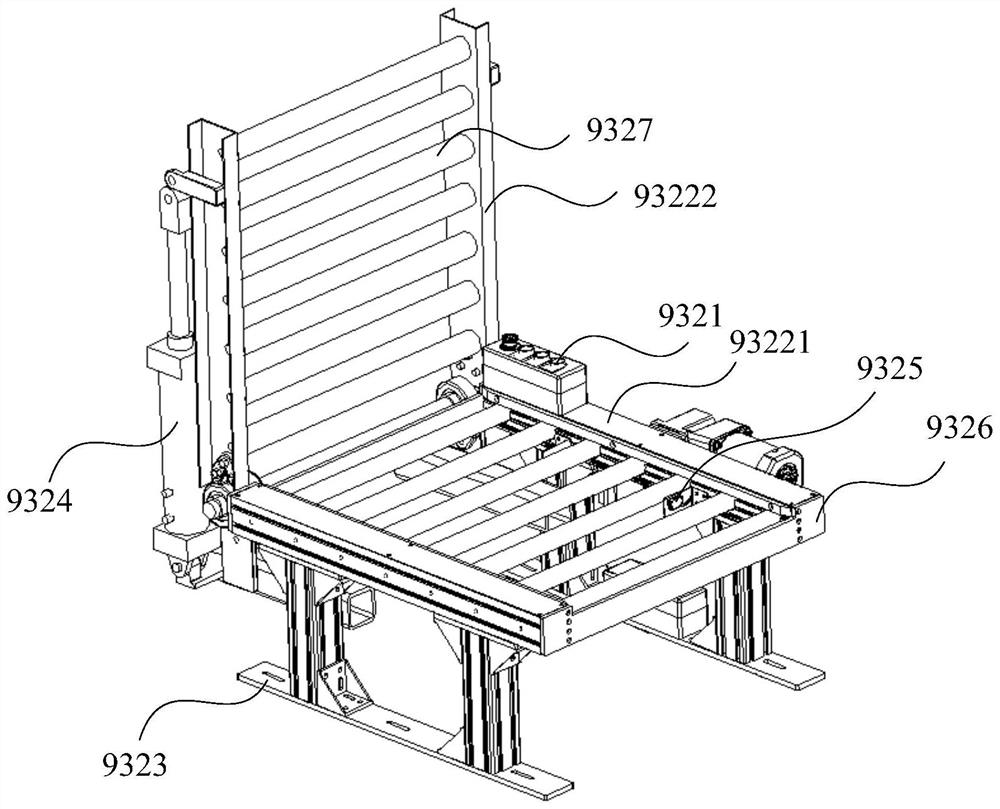

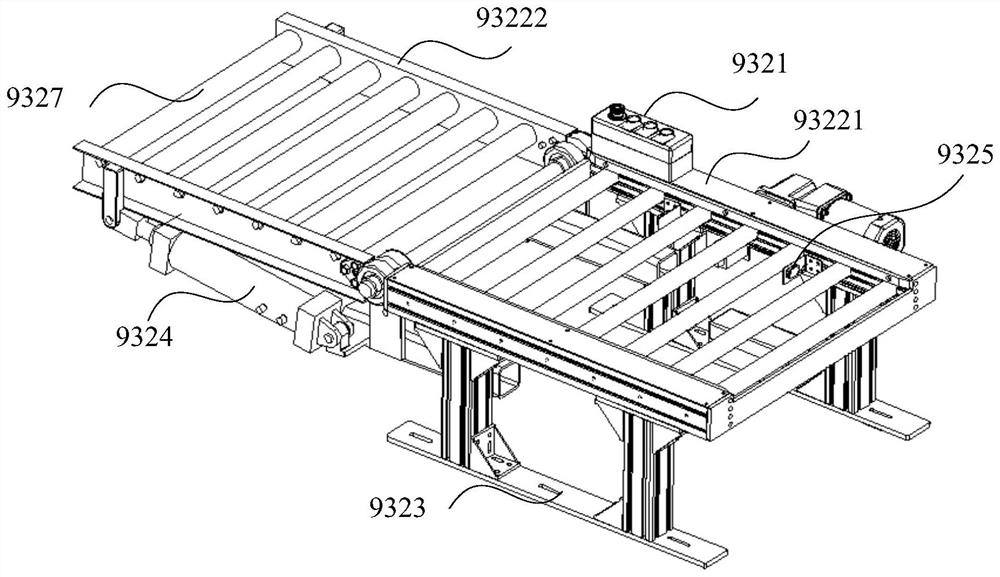

Stacking system of railway vehicle

PendingCN114314435AHigh degree of automationRealize automatic pick-and-placeLifting devicesStorage devicesLogistics managementControl system

The stacking system of the railway vehicle comprises a stacking machine, and the stacking machine comprises a stacking machine rack; the pallet fork is located on the stacking machine rack and used for taking and placing the container; the stacking machine walking driving device is located on the stacking machine rack and used for driving the stacking machine to walk in the railway vehicle; and the control device is used for being connected with a vehicle master control system and is connected with the pallet fork and the stacking machine walking driving device, and the control device is used for controlling the stacking machine walking driving device to walk to the position corresponding to the goods shelf of the railway vehicle and controlling the pallet fork to act to pick and place the container. By means of the arrangement, automatic goods taking and placing are achieved, the automation degree of the rail vehicle is improved, the logistics turnover speed and efficiency are improved, and a foundation is provided for building of a comprehensive traffic transportation network.

Owner:CRRC TANGSHAN CO LTD +1

Tinning mechanism

ActiveCN104148769AImprove work efficiencyAccurate angleSolder feeding devicesSoldering auxillary devicesTinningSoldering

The invention relates to a tinning mechanism which comprises a bottom plate, carriers, products, a material taking mechanism, an automatic soldering flux applying module and a material receiving clamping jaw module. The bottom plate is provided with two carriers, each carrier is provided with one product, the material taking mechanism is used for clamping the products on the carriers and conveying the products to a standard position, the automatic soldering flux applying module is used for automatically applying soldering flux to the products through a glue dispensing pipe, and the material receiving clamping jaw module is used for receiving materials, rotating the products by 90 degrees and returning to an original position after tinning is finished. The tinning mechanism is suitable for a terminal with special appearance, a connector and the terminal are wound together, the appearance and the size are irregular and not fixed after the connector and the terminal are wound, and the problem can be solved with the tinning mechanism. Continuous operating can be achieved, a rotating step motor is used for driving a rotary swing arm, the angle is accurate, adjustment is convenient to achieve, and the tinning mechanism is suitable for different products and can meet different manufacturing process conditions and is flexible in use.

Owner:BOZHON PRECISION IND TECH CO LTD

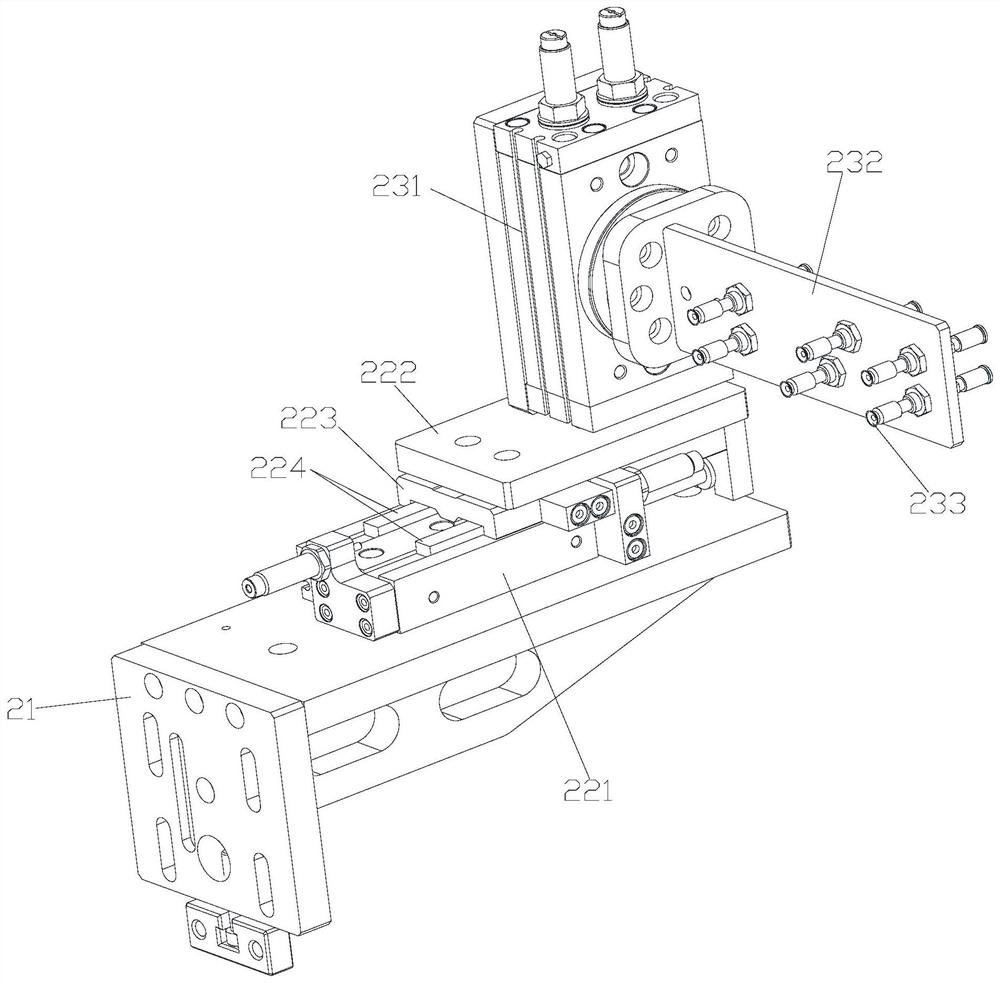

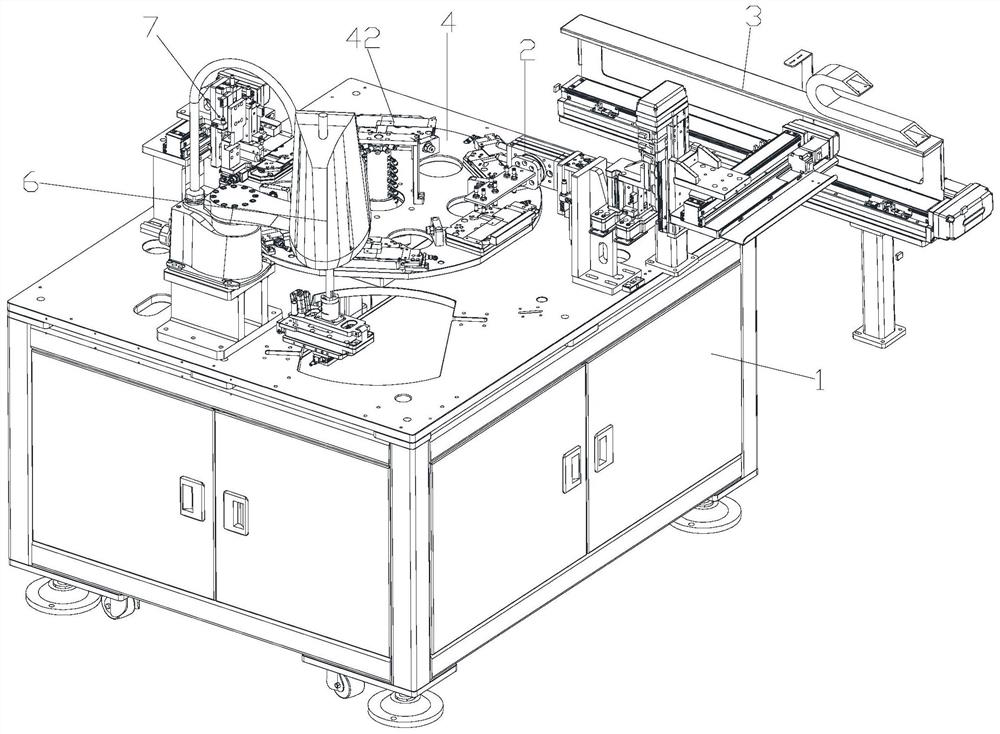

Quick material taking and placing mechanism and automatic laminating all-in-one machine applying same

PendingCN112811173ARealize automatic pick and placeAutomatic pick and place reductionConveyor partsBatch productionManufacturing engineering

The invention discloses a rapid material taking and placing mechanism which comprises a mounting frame, a lifting driving assembly and a turnover assembly. The lifting driving assembly is mounted on the mounting frame, the turnover assembly is mounted on the lifting driving assembly, the turnover assembly comprises a first driving part and a rotating plate, the rotating plate is mounted at the driving end of the first driving part, the first driving part is installed on the lifting driving assembly, and a plurality of suction cups are installed on the upper end face and the lower end face of the rotating plate and matched with material parts. The invention further discloses an automatic laminating all-in-one machine which comprises the rapid material taking and placing mechanism and further comprises a rack, a first feeding mechanism, a second feeding mechanism, a laminating mechanism and a rotary disc mechanism. By means of the rapid material taking and placing mechanism, automatic taking and placing of the material parts can be realized, and the rapid material taking and placing mechanism has the advantages that the production efficiency and precision are high, the product quality and yield are improved, and the large-batch production requirement is met. According to the automatic laminating all-in-one machine, the rapid material taking and placing mechanism is applied, automatic material feeding, taking and laminating work can be achieved, and the production efficiency is high.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Full-automatic taking and placing grinding device for optical lens machining

ActiveCN112775778AEasy to polishRealize automatic pick and placeGrinding drivesGrinding machinesDevice PlateOptic lens

The invention discloses a full-automatic taking and placing grinding device for optical lens machining. The full-automatic taking and placing grinding device comprises a shell and a containing mechanism, a grinding chamber is formed in the shell, a device plate used for sliding up and down is arranged in the grinding chamber, and two electric telescopic rods are installed at the inner bottom of the grinding chamber; the telescopic ends of the two electric telescopic rods are fixedly connected with the lower end of the device plate; and the containing mechanism comprises a containing cylinder fixedly connected to the top in the grinding chamber, the upper end of the containing cylinder penetrates through the shell and communicates with the outside, and two supporting frames are fixedly connected to the upper end of the device plate. When the device is used, the device plate is driven by the two electric telescopic rods to move up and down, lenses can be automatically taken and placed when the device plate moves up and down, workers do not need to manually take and place the lenses, meanwhile, water can be sprayed on grinding rollers when rotating rods rotate, and the situation that chippings fly around is reduced.

Owner:聚科光电科技(武汉)有限公司

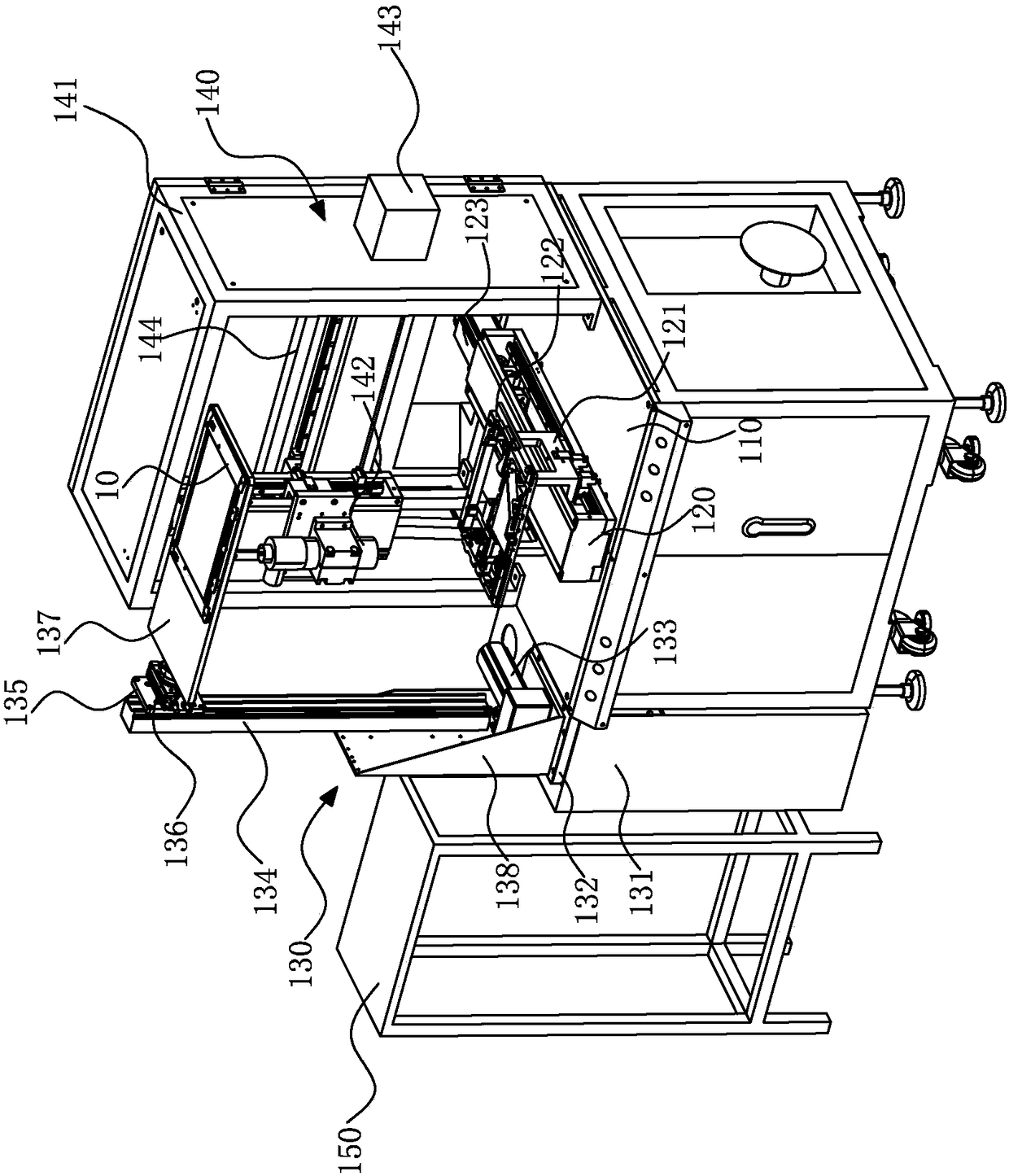

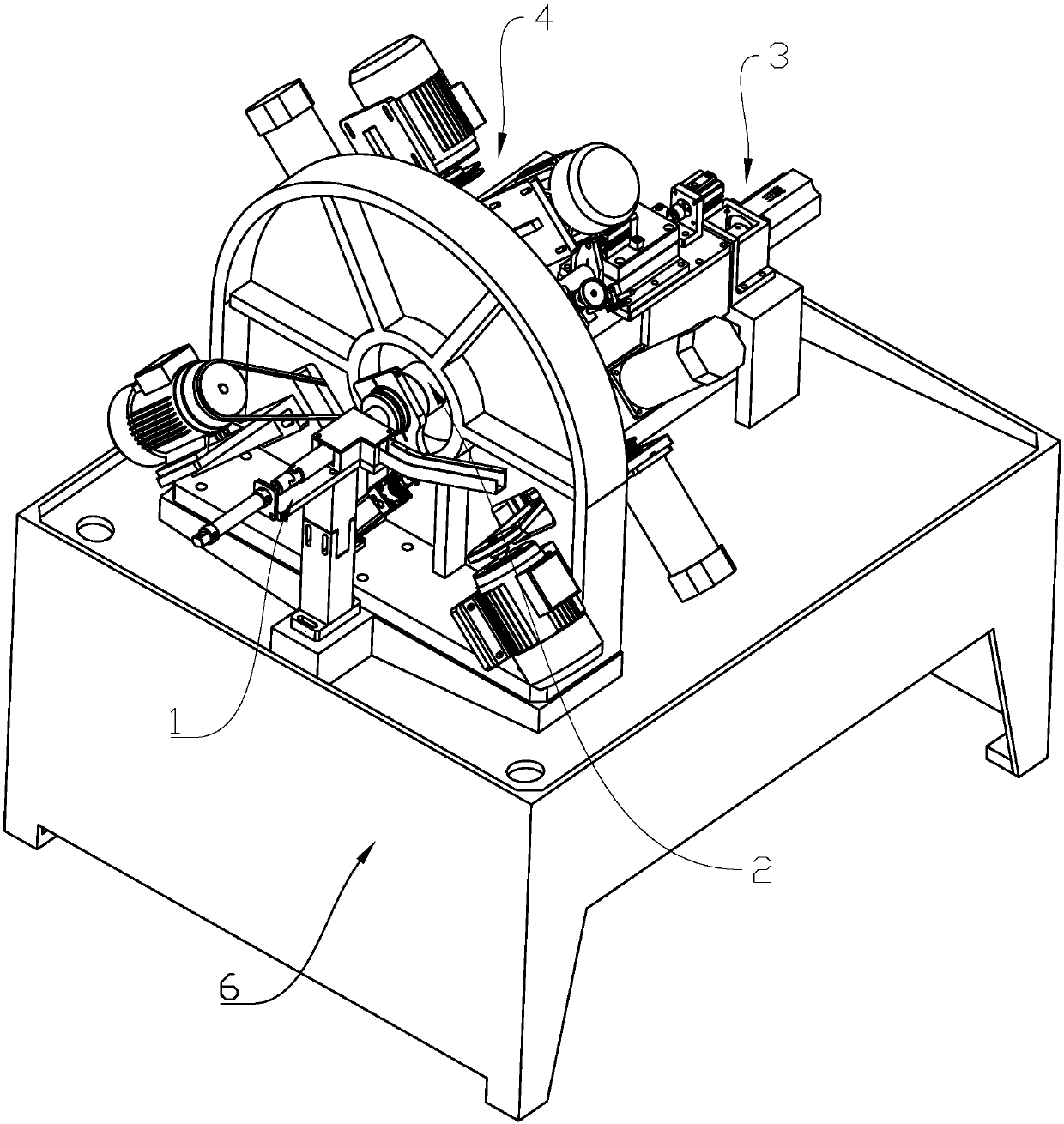

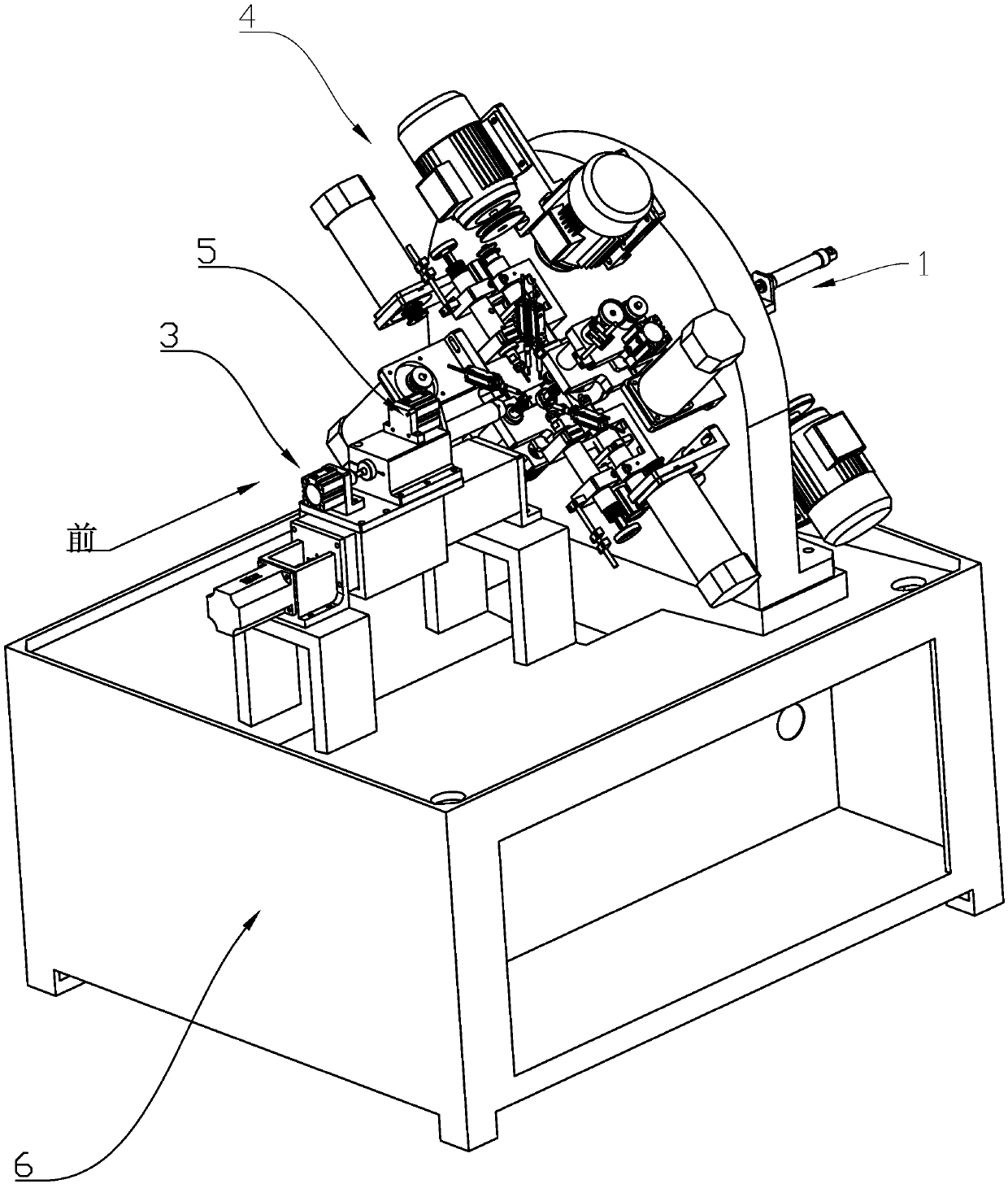

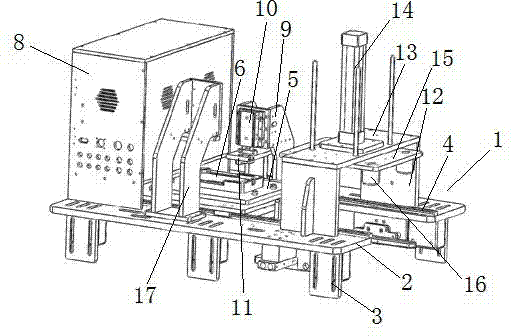

Automatic taking-placing and milling cutting apparatus and automatic taking-placing and milling cutting method

The invention discloses an automatic taking-placing and milling cutting apparatus and an automatic taking-placing and milling cutting method. The automatic taking-placing and milling cutting apparatuscomprises: a work table, wherein a loading plate sliding rail is arranged on the work table and is provided with a sliding bracket, and a loading plate is fixed on the sliding bracket; a bearing device fixed on one side of the sliding rail, wherein the bearing device comprises an electric control box, a rotation mechanism, an electromechanical module, a sliding rail module, a sliding block module, a rotation gas cylinder and a bearing positioning plate; a milling cutting device fixed above the loading plate sliding rail, wherein the milling cutting device comprises a fixed bracket, a millinghead, a first servo motor and a milling cutting sliding rail; and an object storage table positioned on one side of the work table. According to the present invention, with the automatic taking-placing and milling cutting apparatus, through the matched use of the bearing device and the milling cutting device, the automatic taking-placing and milling cutting of the product is achieved, the harm caused by the manual taking-placing of the product is avoided, the work efficiency is substantially improved, and the manpower and the time are saved.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

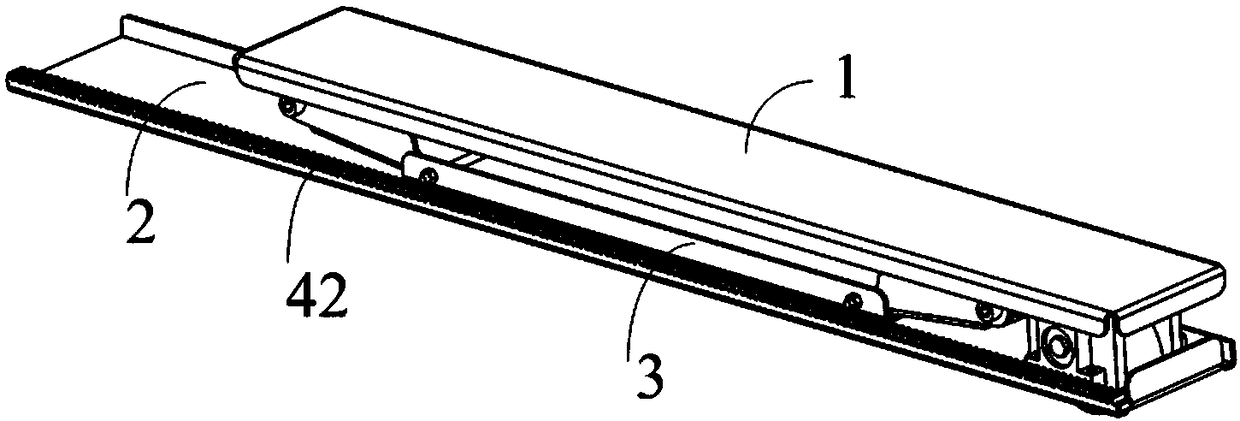

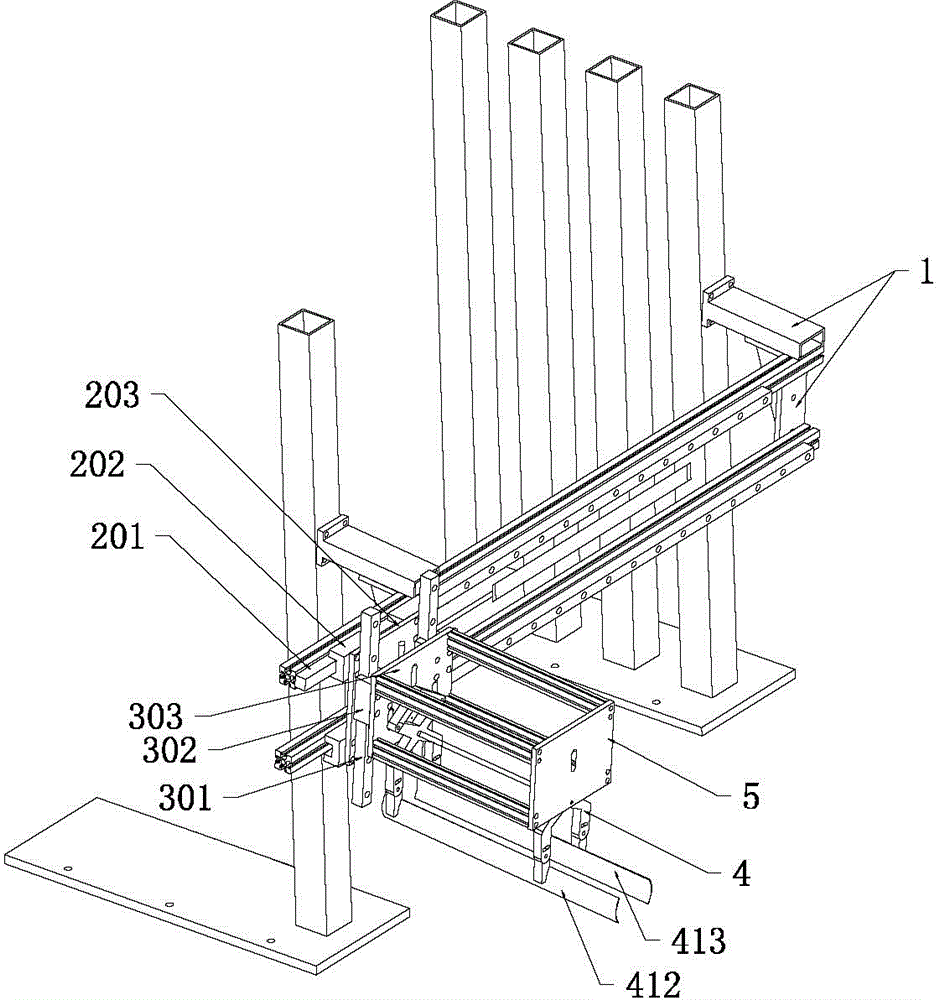

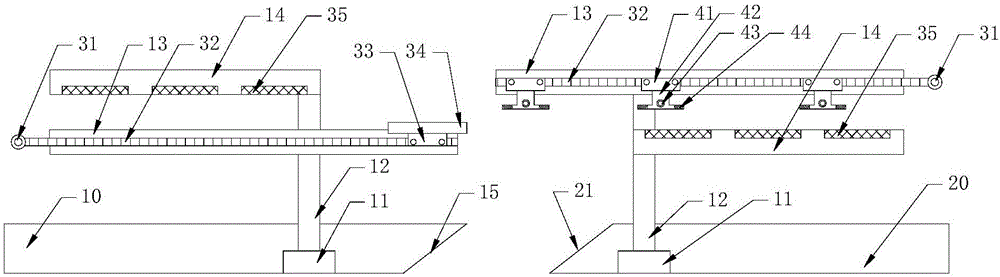

Sheet feeding system

ActiveCN107758280ARealize automatic pick and placeSave human effortConveyorsDe-stacking articlesEngineeringHuman power

The invention provides a sheet feeding system. The sheet feeding system comprises a sheet containing frame, a sheet taking device and a conveying device; the sheet containing frame comprises a bottomplate which is used for sheets to be placed and stacked; the sheet taking mechanism comprises a suction cup; a sucking and taking port of the suction cup faces downwards and is close to the top end ofstacking of the sheets, and is used for sucking and taking the sheets from the top end of stacking of the sheets; the sheet taking mechanism further comprises a transferring device which is used fortransferring the sheets sucked and taken by the suction cup to the conveying device; the conveying device is used for receiving the sheets transferred by the transferring device, and transferring thesheets to the preset position; by arranging the sheet containing frame, the sheet taking device and the conveying device and arranging the transferring device on the sheet taking device, the sheet taking mechanism is made to suck and take the sheets from the sheet containing frame and transfer the sheets onto the conveying device, the sheets are conveyed to a preset site through the conveying device, automatic sucking and placing of the sheets are achieved, manual work is replaced, human power is saved, and efficiency is greatly improved.

Owner:九豪精密陶瓷(昆山)有限公司

Material clamp and multifunctional manipulator shift conveyer of cup-making stack equipment

ActiveCN104401714ARealize automatic pick and placeMeet the needs of picking and placing materials of different diametersConveyor partsEngineeringManipulator

The invention discloses a multifunctional manipulator shift conveyer of cup-making stack equipment. The multifunctional manipulator shift conveyer comprises a controller, a material clamp support frame, a material clamp, a material clamp clutch cylinder, a translation driving unit and a lifting driving unit, wherein the material clamp clutch cylinder, the translation driving unit and the lifting driving unit are electrically connected with the controller respectively. The material clamp disclosed by the invention is simple in structure; materials are grabbed or loosened under the action of the material clamp clutch cylinder. The multifunctional manipulator shift conveyer is provided with the translation driving unit and the lifting driving unit, so that the material clamp can carry out translation and lifting motion; the material clamp moves to different positions to grab the materials and convey the materials to the pointed positions to put down; the multifunctional manipulator shift conveyer can be applied to plastic vessels, such as covers which are stacked to strips, of which the diameters are close to or greater than the heights; the condition that the plastic vessels or lids do not collapse or are not scattered in the conveying process is ensured. Compared with the prior art, the multifunctional manipulator shift conveyer is high in automatic degree, high in production efficiency, low in human cost, and good in material conveying effect, and is capable of well conveying the plastic vessels or the lids, of which the diameters are close to or greater than the heights.

Owner:GUANGDONG LONGXING PACKAGING IND

Egg roll processing device

PendingCN111280191ASimple structureRealize automatic heatingSpecial goods bakingEngineeringMechanical engineering

The invention provides an egg roll processing device. The egg roll processing device comprises a rack; a baking tray assembly which comprises an upper baking tray and a lower baking tray hinged to theupper baking tray, wherein the upper baking tray can rotate relative to the lower baking tray, so that the upper baking tray has a closing position covering the lower baking tray and an opening position separated from the lower baking tray; a guide part which is arranged on the upper baking tray, wherein the length extension direction of the guide part is parallel to the tray surface of the upperbaking tray; a moving assembly which is movably arranged on the rack, is connected with the lower baking tray and is used for driving the baking tray assembly to move relative to the rack; and a guide rail which comprises a horizontal section and a twisted section connected to at least one end of the horizontal section; wherein the shape of the twisted section is matched with the moving track ofthe guide part when the baking tray assembly moves relative to the rack and the upper baking tray rotates relative to the lower baking tray, the guide part abuts against the guide rail, when the baking tray assembly is located at the position corresponding to the horizontal section, the upper baking tray is kept at the opening position, and when the baking tray assembly is located at the positioncorresponding to the twisted section, the upper baking tray is located at the closing position.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Taking device used in contact riveting process

InactiveCN105414935ARealize pick and placePrecise pick and placeMetal working apparatusEngineeringAutomation

The invention relates to a taking device used in a contact riveting process. The taking device comprises a support structure and a transverse material channel, wherein the transverse material channel is formed in the support structure, a top material channel plate is arranged on the top end of the transverse material channel, and a material vibrating disk is connected to the tail end of the transverse material channel; a top material channel cover plate is arranged above the top material channel plate, an upward ejector pin is arranged below the top material channel plate, and an upward air cylinder is installed on the support structure; a lifting mounting support and a translational air cylinder are arranged on the support structure; a finger air cylinder mounting support and a lifting air cylinder are arranged on the lifting mounting support; a finger air cylinder is arranged on the left end of the finger air cylinder mounting support, left and right clamping jaws and a prepressing ejector pin mounting plate are arranged on the finger air cylinder, and a downward ejector pin is arranged on the prepressing ejector pin mounting plate. According to the taking device, the problems of low degree of automation and production efficiency and high labor cost caused by manually taking a contact and putting on a to-be-riveted product first and then riveting in an existing contact riveting process can be effectively solved.

Owner:昌辉汽车电器(黄山)股份公司

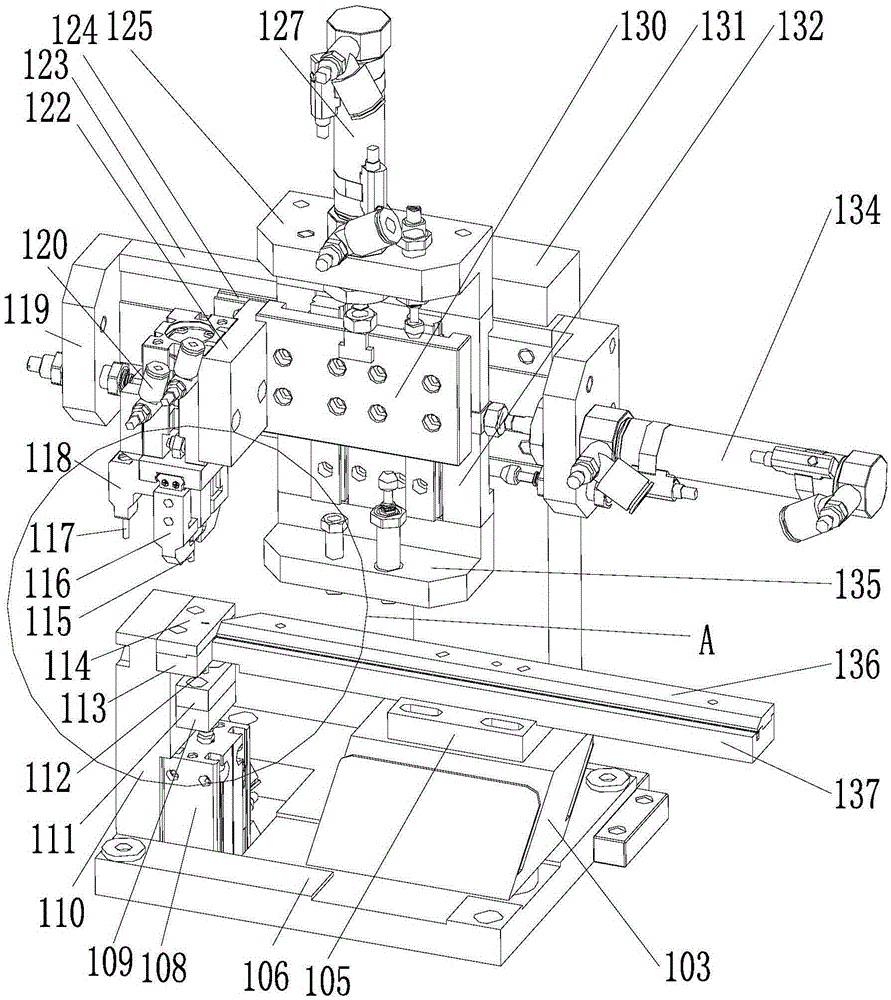

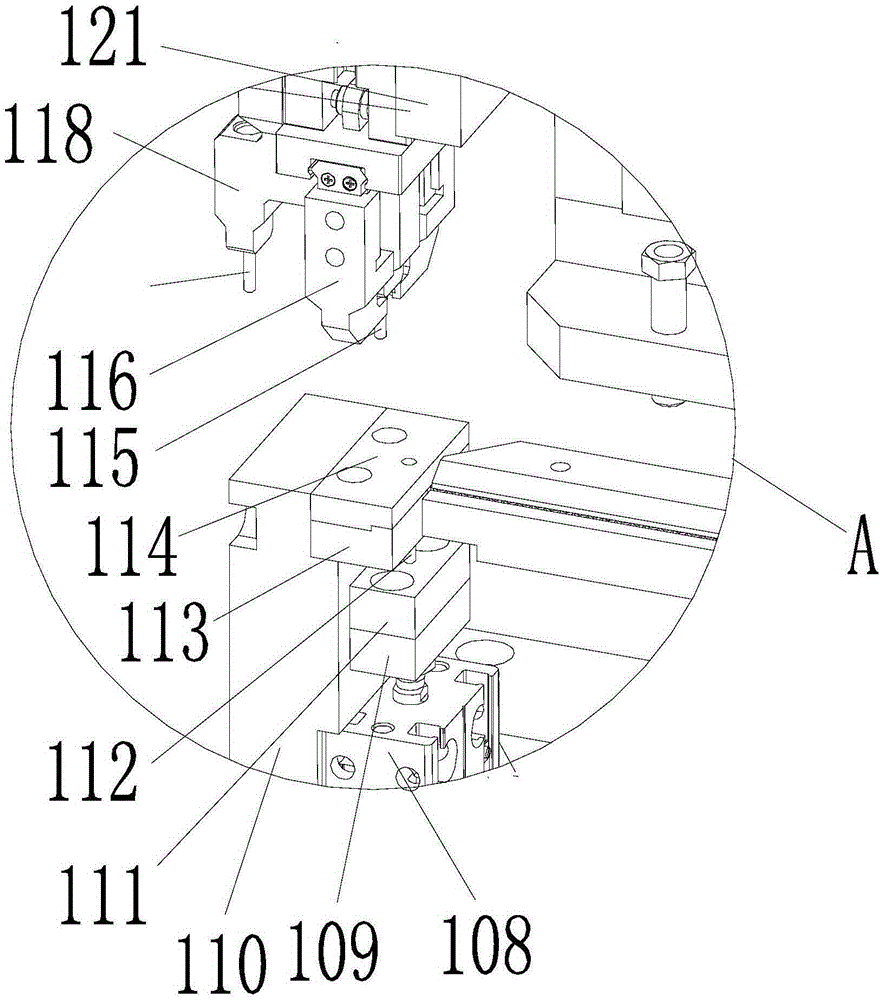

Full-automatic perforating and tapping combined device for annular workpiece

PendingCN107866674ARealize automatic pick and placeRealize automatic transportationOther manufacturing equipments/toolsPositioning apparatusEngineeringFrustum

The invention discloses a full-automatic perforating and tapping combined device for an annular workpiece and belongs to the technical field of annular workpiece machining equipment. A feeding mechanism of the full-automatic perforating and tapping combined device pushes the annular workpiece into a fixed guide sleeve; an elastic chuck piece moves towards the annular workpiece, the end in a cone-frustum-shaped structure of the elastic chuck piece is inserted into a gap between the fixed guide sleeve and the annular workpiece, abuts against the outer circle wall surface of the annular workpieceand accordingly clamps the annular workpiece; an inner support assembly stretches into an inner hole of the annular workpiece and supports the annular workpiece; and a transverse-moving assembly drives the inner support assembly and the annular workpiece to move to the position below a perforating and tapping mechanism, and thus automatic taking, placing, perforating and tapping of the annular workpiece are achieved. According to the full-automatic perforating and tapping combined device, the links of automatic conveying, taking, placing, perforating, tapping and the like of the annular workpiece can be achieved, the automation degree of annular workpiece machining equipment is improved, and manpower is saved.

Owner:浙江盛业科技有限公司

Automatic equipment for plastic molding

The invention discloses an automation device suitable for plastic molding. The automation device suitable for the plastic molding comprises a vibration plate, an injection molding machine, a feeding mechanism and a material taking mechanism, wherein the vibration plate is used for feeding materials; the injection feeding mechanism is used for performing injection molding, the feeding mechanism is used for taking out raw materials from the vibration plate, and the material taking mechanism is used for taking out finished-products from the injection molding machine; the feeding mechanism and the material taking mechanism are symmetrically arranged on the two sides of a mold cavity and respectively comprise a manipulator, two first air cylinders, fixing plates and a driving device, wherein the first air cylinders drive the manipulator to lift, the fixing plates are arranged on the first air cylinders, and the driving device are used for driving the fixing plates to displace; the displacement directions of a fixing plate of the feeding mechanism and a fixing plate of the material taking mechanism are in the same straight line. The automation device suitable for the plastic molding has the beneficial effects that the feeding mechanism and the material taking mechanism cooperate and match to automatically take out and put down raw materials and finished products; labor is reduced, and the labor cost is saved; the displacement directions of the feeding mechanism and the material taking mechanism are in the same straight line, the device is simple in structure, the operation is reliable, and the production efficiency is greatly improved.

Owner:KUNSHAN SAN TOHNO ELECTRON

Electric energy meter taking and putting device, manipulator and verification assembly line

InactiveCN112025742AAchieve replacementImprove compactnessTesting dielectric strengthGripping headsOral problemsEngineering

The invention discloses an electric energy meter taking and putting device, a manipulator and a verification assembly line, which solves the problem that only a single electric energy meter can be clamped in the prior art and has the beneficial effects of improving the working efficiency and increasing the flexibility of the taking and putting device. The electric energy meter taking and putting device specifically adopts the scheme that the electric energy meter taking and putting device comprises a base, wherein at least two groups of clamping jaw assemblies are installed on the base, multiple groups of clamping jaw assemblies are installed on the same surface of the base and are arranged side by side, clamping jaws can move so as to change the grabbing range of the clamping jaw assemblies, and any clamping jaw assembly comprises at least two clamping jaws, and the clamping jaw on at least one side of any clamping jaw assembly can be embedded into the clamping jaw, which is close tothe clamping jaw on at least one side of any clamping jaw assembly, on one side of the other clamping jaw assembly.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Indoor building material transferring platform

ActiveCN106368439ARealize automatic controlRealize automatic pick and placeBuilding material handlingAutomatic controlMarine engineering

The invention provides an indoor building material transferring platform. The indoor building material transferring platform comprises a fixed operating table and a movable operating table, and the fixed operating table and the movable operating table are arranged on a horizontal base. A supporting connection base is arranged on the fixed operating table. A supporting frame is perpendicularly arranged on the supporting connection base. An operating arm of the fixed operating table comprises a lead screw and a linear sliding rail. An operating arm of the movable operating table comprises lead screw which is horizontally arranged along the operating arm and a linear sliding rail which is matched with the lead screw, wherein sliding rail connection bases are arranged on the linear sliding rail, telescopic rods which perpendicularly move along base bodies are arranged on the sliding rail connection bases, hanging holes are formed in the ends of the telescopic rods, and the end of each telescopic rod is further provided with an electromagnetic suction cup along the two ends of the corresponding hanging hole. According to the indoor building material transferring platform, the functions of moving and transferring various building materials in the construction process can be achieved through cooperation between the fixed operating table and the movable operating table, automatic control over movement of various materials is achieved through cooperation between the lead screws and the horizontal sliding rails, and automatic taking and placing of the materials are achieved through the electromagnetic suction cups.

Owner:新沂市达婷黄沙有限公司

Automatic distance sensing testing device

InactiveCN104330093AGuaranteed reliabilityRealize automatic pick and placeOptical detectionEngineeringTest efficiency

The invention discloses an automatic distance sensing testing device, and the automatic distance sensing testing device comprises a base, a fetching component which is mounted on the base and used for fetching a product, an object carrying table which is in sliding connection with the base, a driving device for driving the object carrying table movement, and a tester arranged on the base. The automatic distance sensing testing device can realize the automatic fetching of the product, reduces the human input, and improves the test efficiency, and in the testing process, the product is stable without moving, and the reliability of detection results can be ensured.

Owner:KUSN MAIZHI FIXTURE TECH

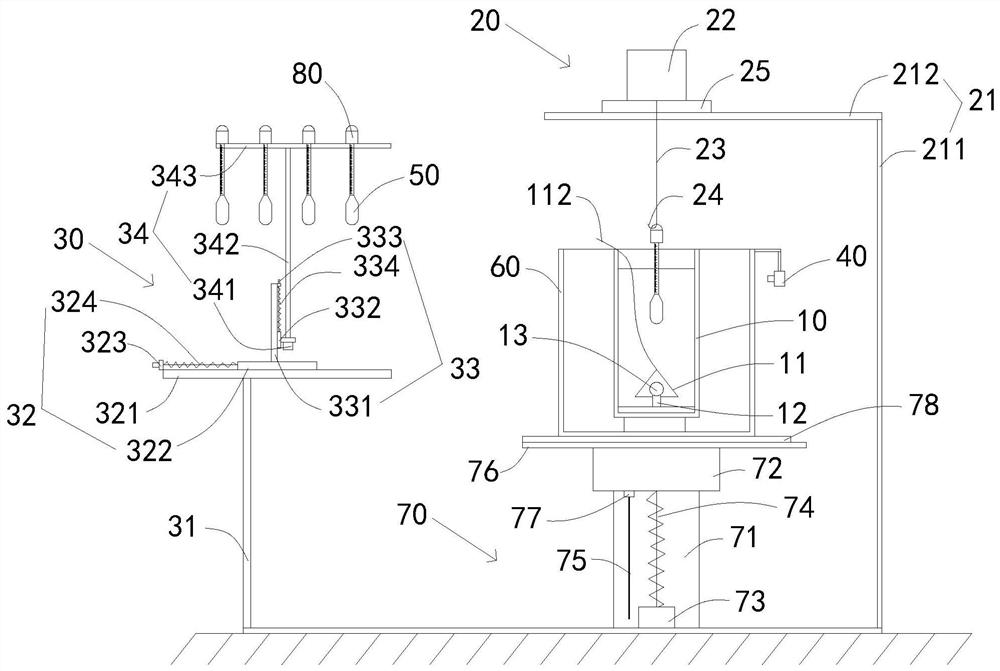

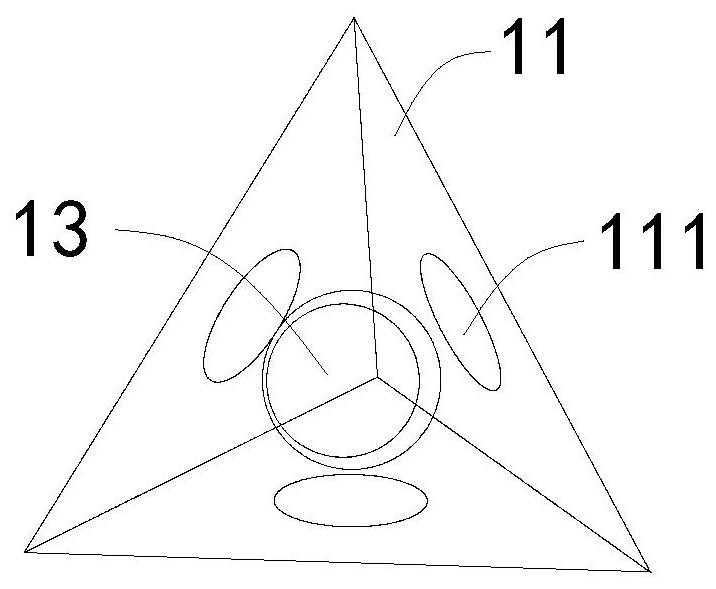

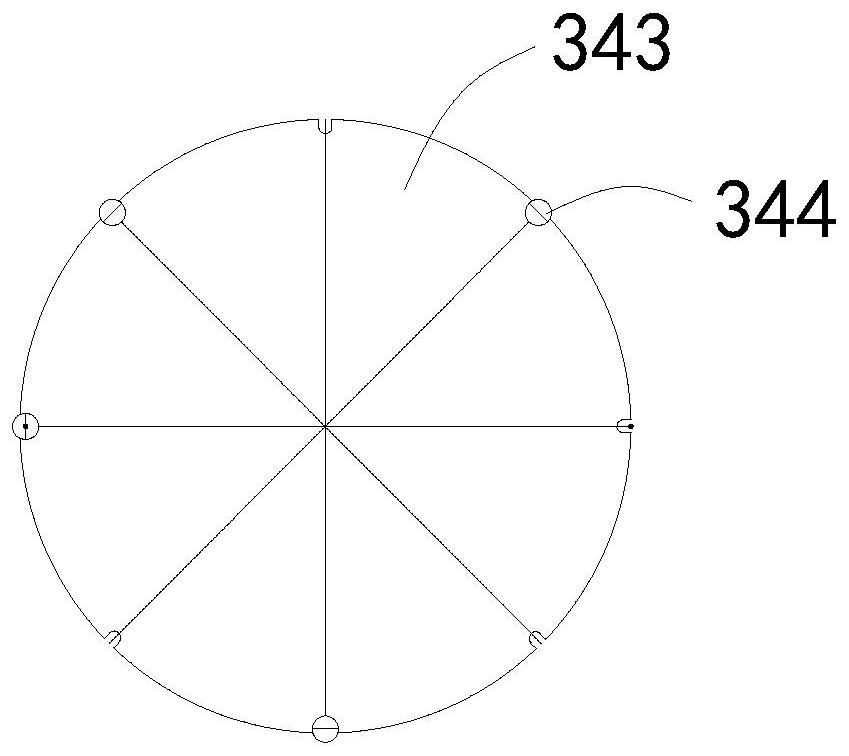

Automatic calibrating device for glass floating meter

PendingCN113075082ARealize automatic pick and placeAutomated verificationSpecific gravity measurementControl theoryMechanical engineering

The invention discloses an automatic calibrating device for a glass floating meter. The automatic calibrating device comprises a transparent stable liquid barrel, a weighing mechanism, a moving mechanism and an image sensor, the stabilizing liquid barrel is of a liftable structure, a bracket and a supporting column are arranged in the stabilizing liquid barrel, a standard ball is arranged in the bracket, and the supporting column penetrates through the bracket and can support the standard ball; the weighing mechanism is arranged above the stabilizing liquid barrel and is used for measuring the weight of an object hung on the stabilizing liquid barrel; the moving mechanism is used for hanging the glass floating meter on the weighing mechanism and taking down the glass floating meter from the weighing mechanism; a shooting area of the image sensor is aligned with a detected scale line of the glass floating meter in the stable liquid barrel; the glass floating meter automatic calibrating device is used for regulating and controlling the lifting height of the stable liquid barrel according to the detection result of the image sensor so as to complete the calibration of the glass floating meter; according to the scheme, automatic hanging, taking down and verification of the glass floating meter are achieved, so that manual operation is omitted, verification efficiency is greatly improved, and the problem that the automation degree is too low in the verification process of an existing glass floating meter is practically solved.

Owner:GUANGZHOU INST OF MEASURING & TESTING TECH

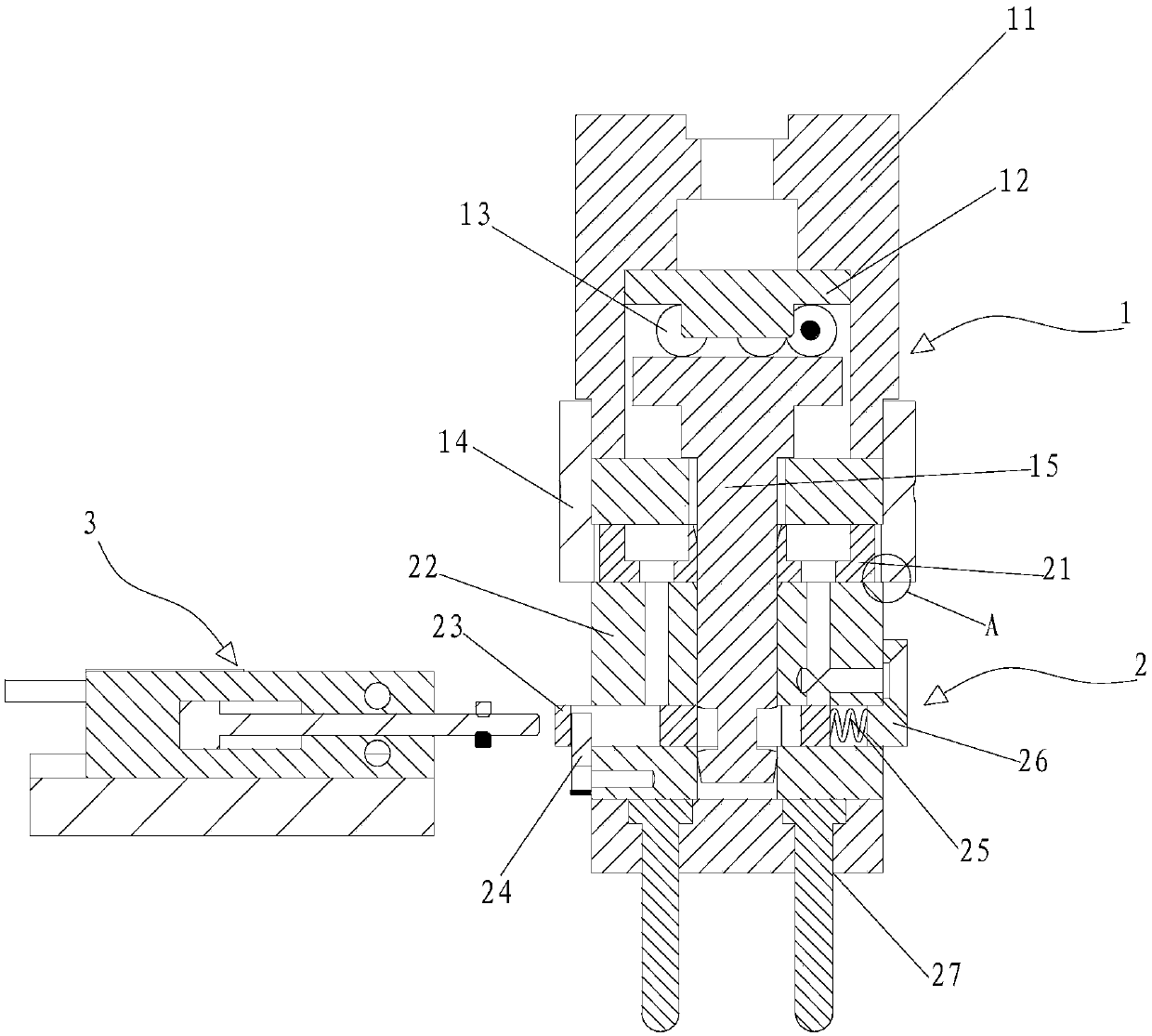

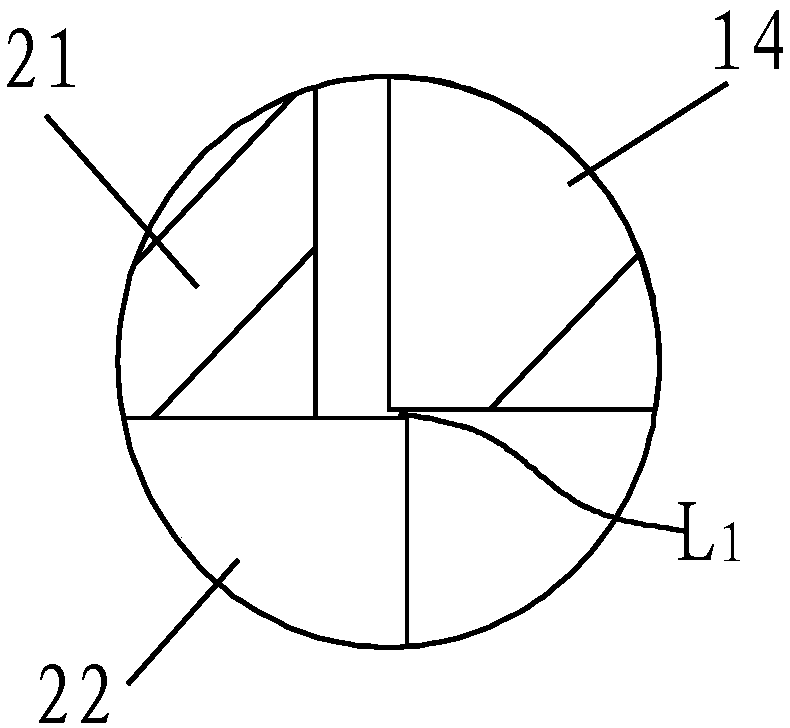

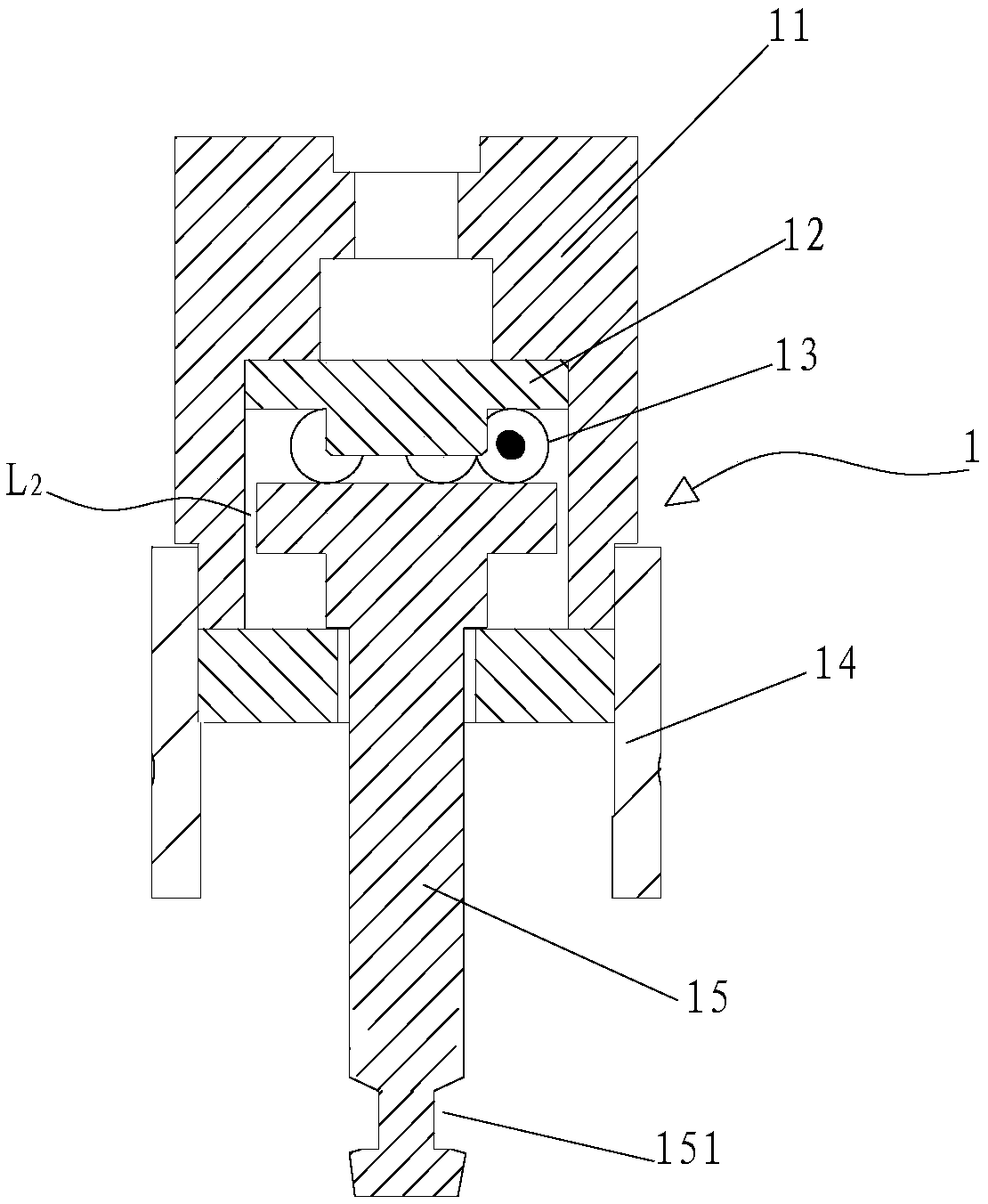

Plug taking and placing mechanism and socket insertion and extraction force detection device

ActiveCN109612621AQuick pick and placeAchieve takeApparatus for force/torque/work measurementManufacturing technologyEngineering

The invention discloses a plug taking and placing mechanism and a socket insertion and extraction force detection device, relates to the field of socket manufacturing technology and aims to improve socket insertion and extraction force detection efficiency. The plug taking and placing mechanism comprises a tapered end, a plug installing base, a tapered end insertion and extraction switching pieceand a pushing piece, wherein the plug installing base is used for installing a plug, and a jack for insertion of the tapered end is formed in the plug installing base; the tapered end insertion and extraction switching piece is installed in the plug installing base and used for clamping the tapered end into the jack or detaching the tapered end from the jack; and the pushing piece is arranged at one side of the plug installing base. The plug taking and placing mechanism and the socket insertion and extraction force detection device are used for improving insertion and extraction force detection efficiency and standardizing detection operation.

Owner:NINGBO BULL ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com