Sheet feeding system

A sheet and rack technology, applied in the direction of unstacking of objects, conveyors, conveyor objects, etc., can solve the problems of high labor intensity, damage to ceramic sheets, low efficiency, etc., and achieve the effect of improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

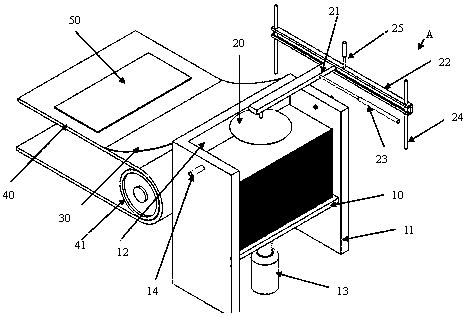

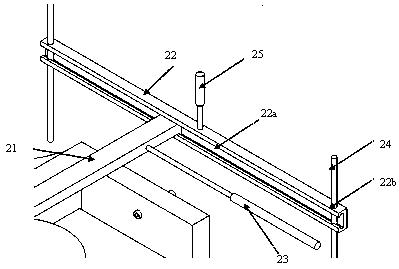

[0020] see figure 1 , figure 2 , In a specific embodiment of the present invention, the sheet feeding system includes a sheet placement rack, a sheet fetching device, and a conveying device.

[0021] The sheet placement rack includes a bottom plate 10, which is roughly in the shape of a square plate, and stacks of sheets 50 are stacked above the bottom plate 10. In this embodiment, the sheets 50 are roughly in the shape of a square plate. , so the stack of sheets 50 forms a square shape with a certain height, of course these sheets 50 can also be other shapes, such as circular, oval, when having these shapes, then the stack of sheets 50 formed has A cylindrical shape corresponding to the shape of the sheet 50, if the sheet 50 is circular, a cylindrical stack is formed.

[0022] The sheet 50 described in this embodiment is a ceramic sheet, and it can be understood that the sheet 50 can also be other sheet 50 materials, such as wood chips, metal sheets, plastic sheets, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com