Automatic calibrating device for glass floating meter

A technology of verification devices and buoy gauges, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

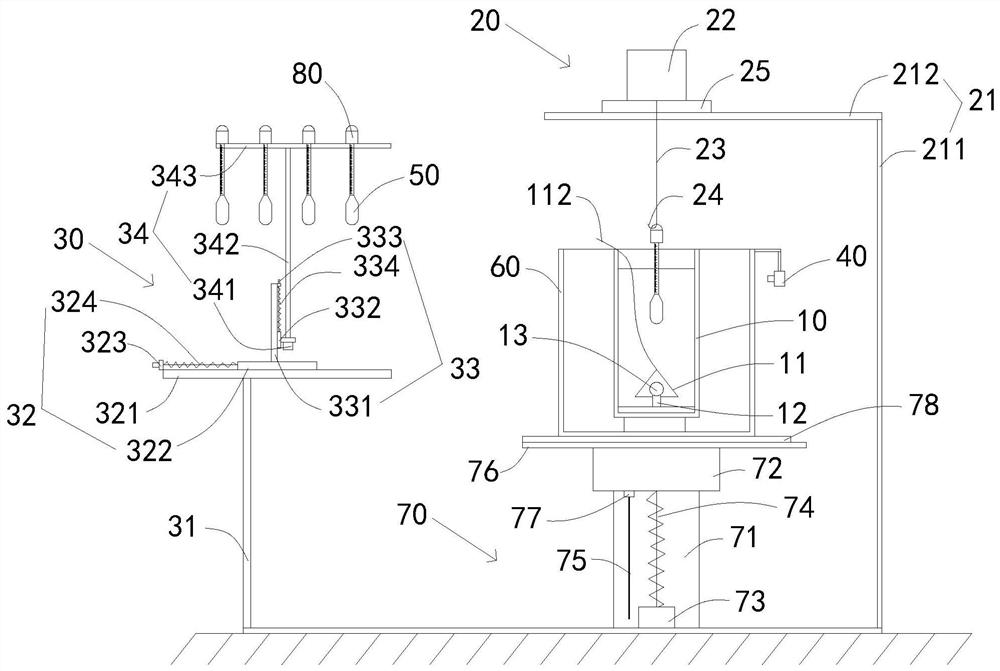

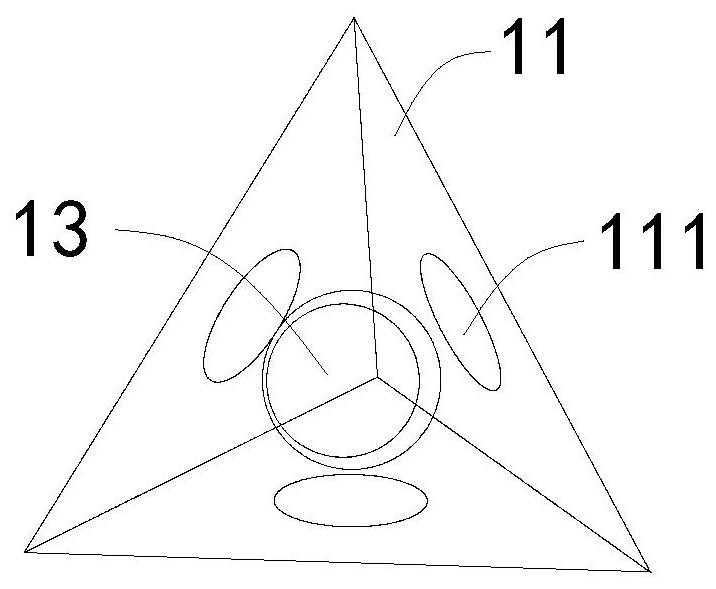

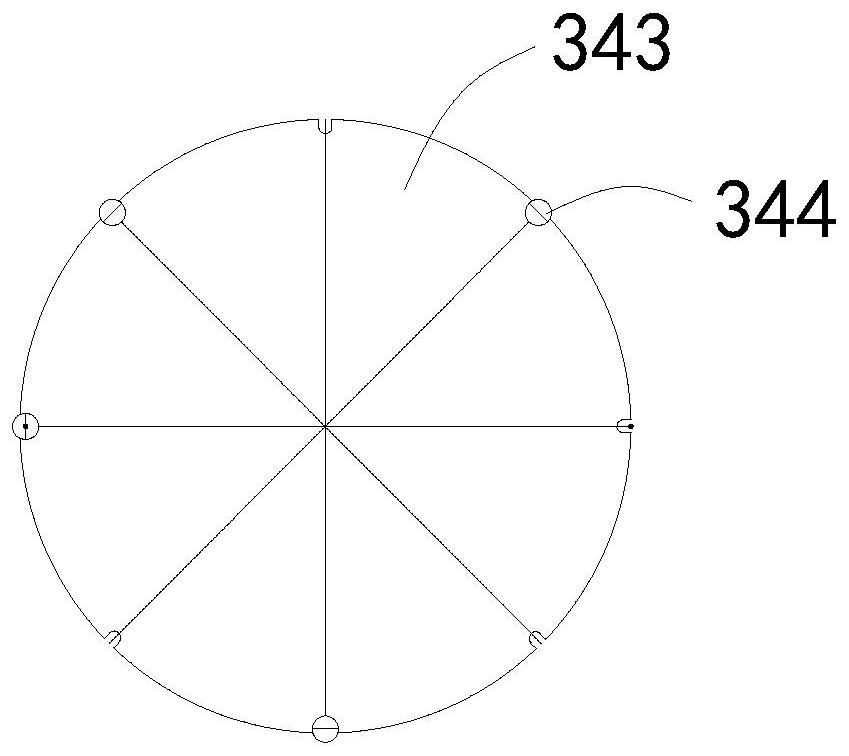

[0037] The invention provides a glass buoy meter automatic verification device, the embodiment of which is as follows figure 1As shown, it includes a transparent stabilizing liquid tank 10, a weighing mechanism 20, a moving mechanism 30 and an image sensor 40; the stabilizing liquid tank 10 is a liftable structure, and the stabilizing liquid tank 10 is provided with a bracket 11 and a pillar 12, and the bracket 11 Moveably placed on the pillar 12, the bracket 11 is provided with a standard ball 13, the pillar 12 passes through the bracket 11 to support the standard ball 13; the weighing mechanism 20 is arranged above the stable liquid barrel 10, and the weighing mechanism 20 is used for Suspension bracket 11 and glass float meter 50, and measure the weight of its suspended obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com