Automatic equipment for plastic molding

An automated equipment, plastic molding technology, applied in the direction of coating, can solve the problems of quality and safety hazards, high labor intensity, low efficiency, etc., to achieve the effect of improving production efficiency, reliable operation, and liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

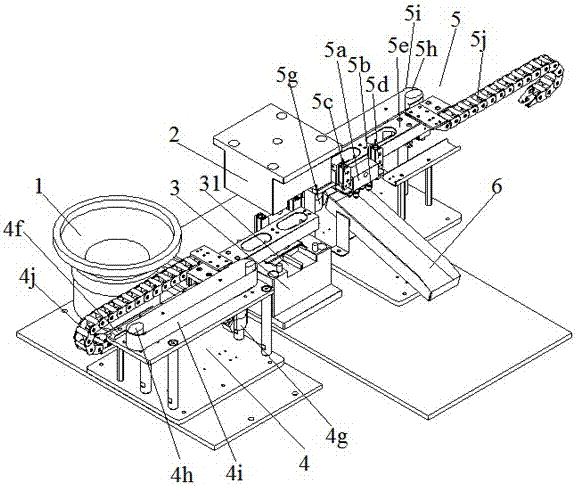

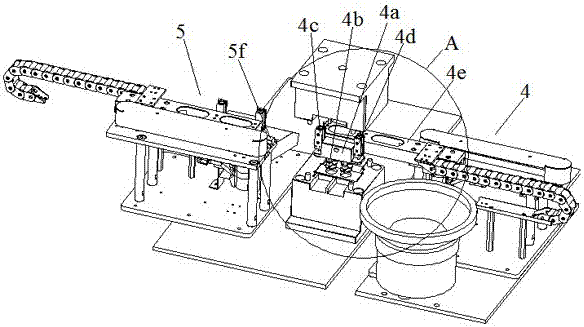

[0017] see figure 1 and figure 2 , the automatic equipment suitable for plastic molding of the present invention includes: a vibrating plate 1 for feeding, an injection molding machine for injection molding, a feeding mechanism 4 for taking raw materials from the vibrating plate 1, and a take-off for finished products from the injection molding machine Material mechanism 5.

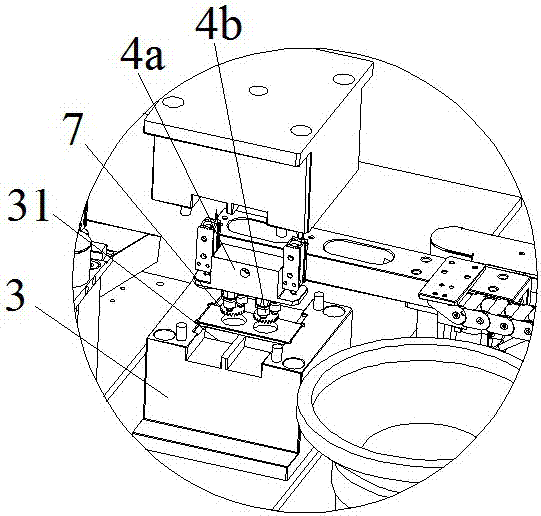

[0018] The injection molding machine adopts the vertical injection molding machine commonly used in the prior art, and its specific structure is not described in detail, mainly including: an injection molding machine body 2 provided with an injection port (not shown in the figure), a mold 3 positioned below the injection port, and A mold core 31 is formed on the mold 3 for placing the raw material product (such as the crown gear 7 ) to be inlaid.

[0019] The fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com