Full-automatic taking and placing grinding device for optical lens machining

A technology for optical lenses and grinding devices, applied in grinding/polishing safety devices, grinding drive devices, metal processing equipment, etc., can solve the problem of troublesome manual lens picking and placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

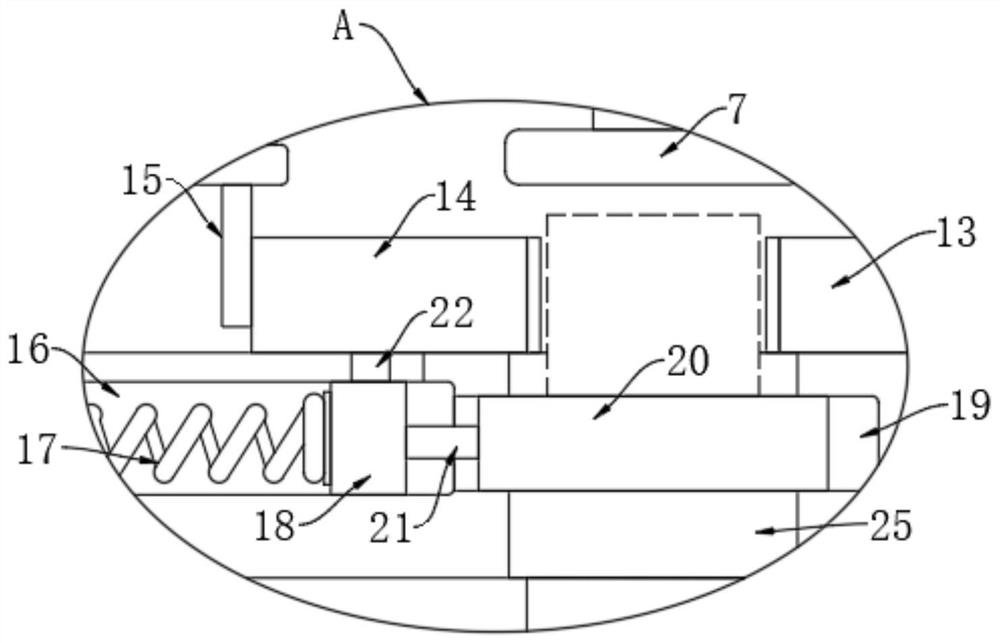

[0024] refer to Figure 1-3 , a fully automatic pick-and-place grinding device for optical lens processing, including a housing 1, and a switchable sliding door (not shown) can be installed on the front side of the housing 1 to facilitate the removal of the lens. There is a grinding chamber 2, which is provided with a device plate 4 for sliding up and down. The inner walls of both sides of the grinding chamber 2 are provided with guide grooves, and two guide grooves are provided with sliding guide blocks. The two guide blocks are respectively It is fixedly connected with both sides of the device plate 4, and the movement of the device plate 4 is started to guide. Two electric telescopic rods 5 are installed on the inner bottom of the grinding chamber 2, and the telescopic ends of the two electric telescopic rods 5 are connected to the ends of the device plate 4. The lower end is fixedly connected, and the telescopic expansion of the two electric telescopic rods 5 drives the de...

Embodiment 2

[0032] refer to Figure 4-5 , The difference between this embodiment and Embodiment 1 is that the inner bottom of the grinding chamber 2 is provided with a reciprocating screw rod 26 for rotation, and the reciprocating screw rod 26 and the rotating rod 6 are equipped with transmission wheels 27. Wheel 27 is connected by drive belt 28 transmission, and the rotation of rotating rod 6 is driven the rotation of reciprocating screw mandrel 26 by the transmission of drive wheel 27 and drive belt 28, and the upper end of housing 1 is equipped with water tank 35, offers water inlet on the water tank 35, facilitates Water is added, and the inner top of the grinding chamber 2 is fixedly connected with two fixed rods 29, and the lower ends of the two fixed rods 29 are fixedly connected with a fixed plate 30. The rods 26 are threaded, and the two fixed rods 29 guide the movement of the threaded block. An air bag 31 is installed between the lower end of the threaded block and the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com