Automatic taking-placing and milling cutting apparatus and automatic taking-placing and milling cutting method

An automatic pick-and-place, milling technology, applied in the coating and other directions, can solve the problem of inability to pick and place products automatically, and achieve the effect of saving manpower and time, avoiding injury and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

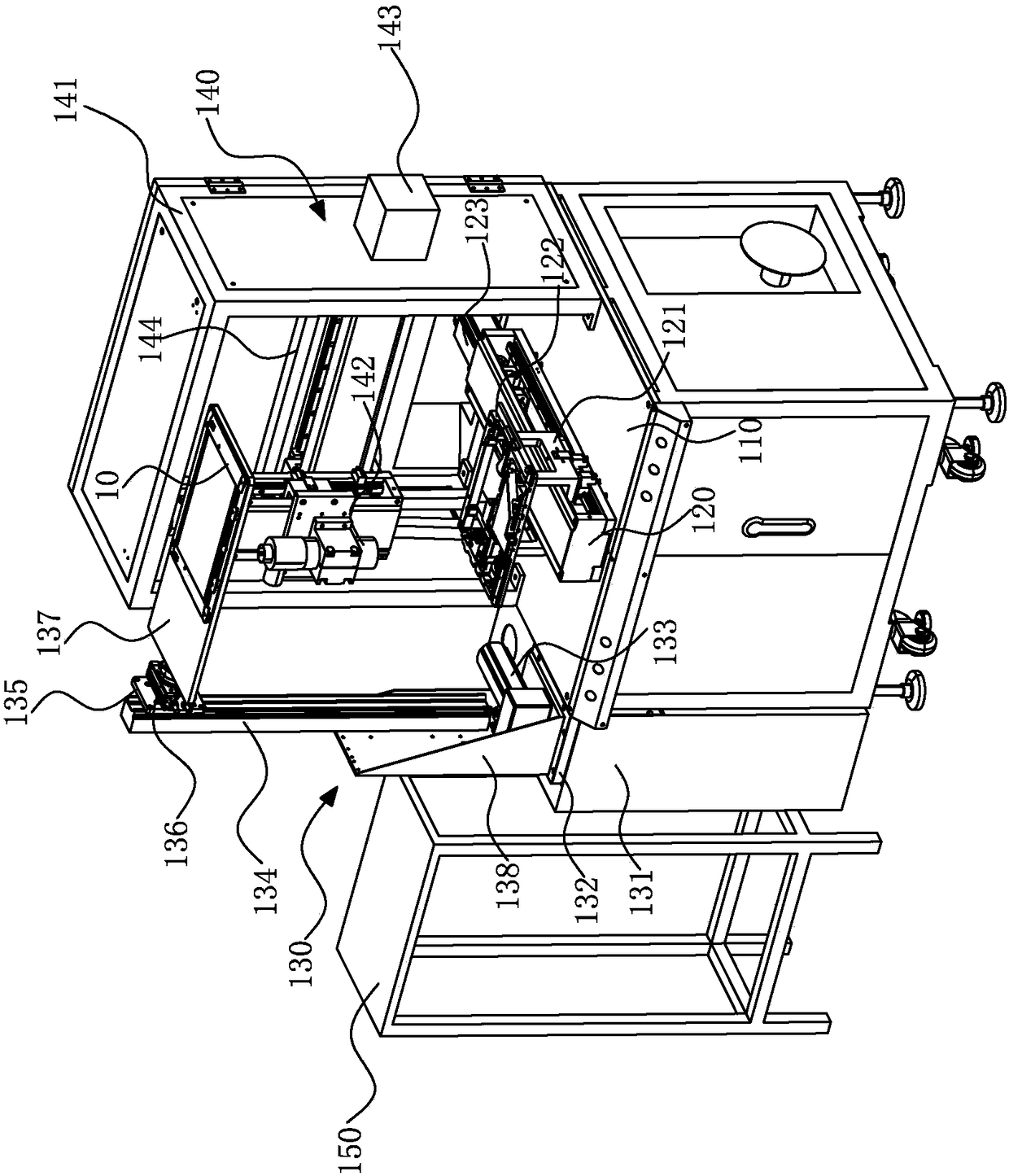

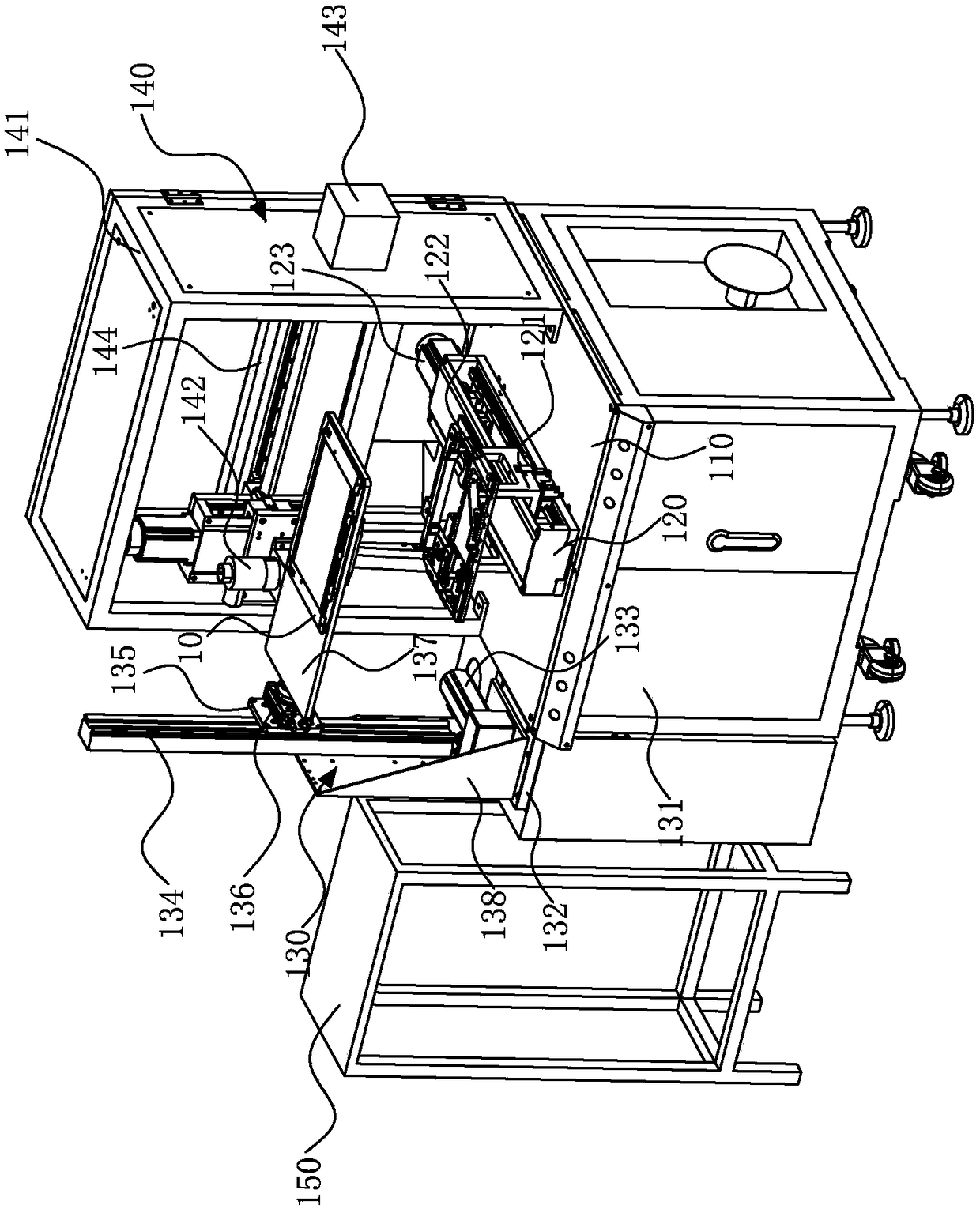

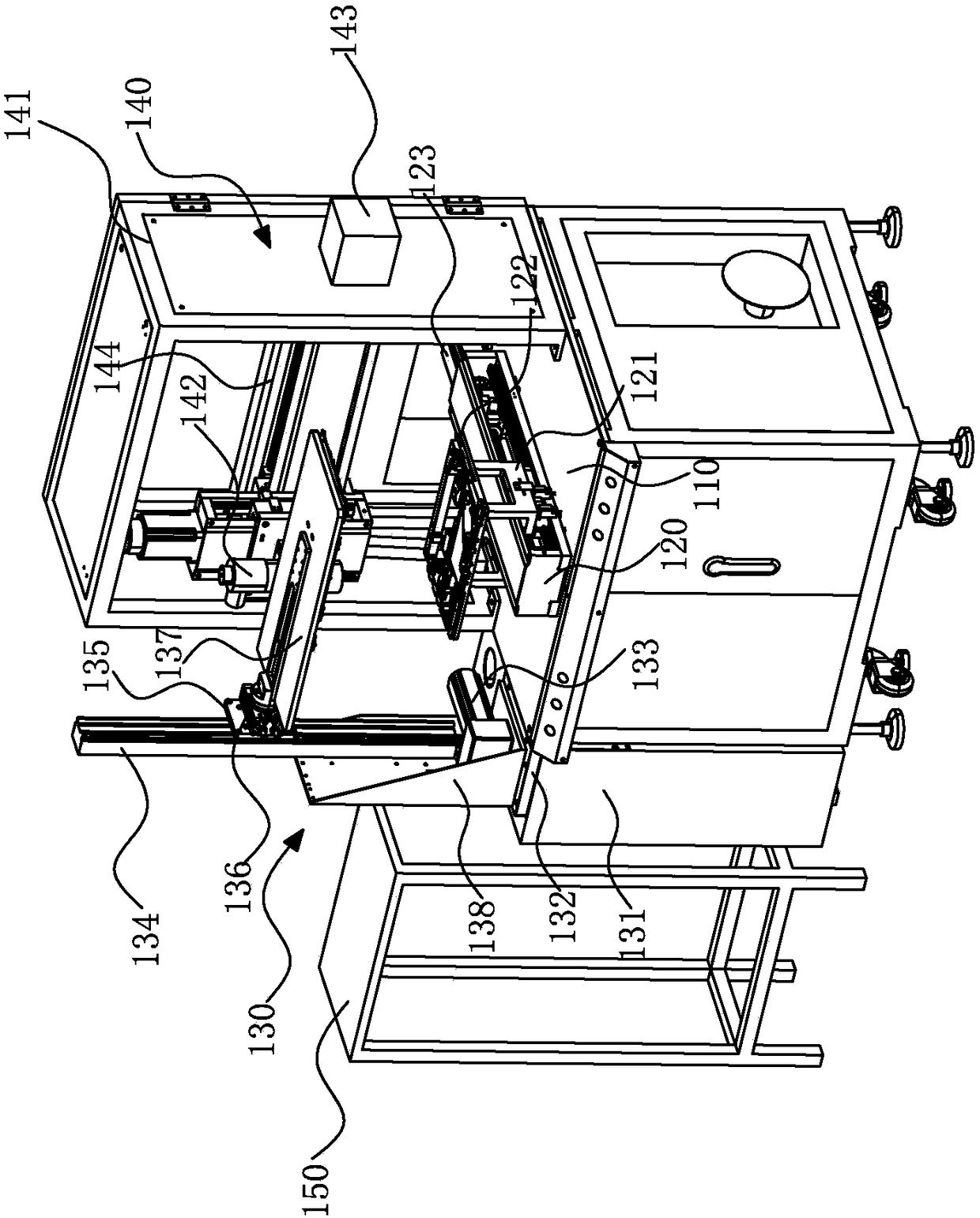

[0040] Please refer to figure 1 , figure 1 It is a schematic structural view of the automatic pick-and-place milling device of the present invention.

[0041] In order to achieve the above object, the automatic pick-and-place milling device 100 provided by the present invention is used for pick-and-place and milling of the product 10, and the automatic pick-and-place milling device 100 includes:

[0042] The workbench 110 is provided with a carrier plate slide rail 120, and the carrier plate slide rail 120 is provided with a sliding bracket 121, and a carrier plate 122 is fixed on the sliding bracket 121;

[0043] The receiving device 130 is fixed on one side of the slide rail 120, and the receiving device 130 includes: an electric control box 131, a rotating mechanism 132, an electromechanical module 133, a slide rail module 134, and a slider module 135. A rotating cylinder 136 and a receiving positioning plate 137, wherein the rotating mechanism 132 and the electromechanic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com