Quick material taking and placing mechanism and automatic laminating all-in-one machine applying same

A pick-and-place and all-in-one machine technology, applied to conveyor objects, transportation and packaging, etc., can solve the problems of inability to meet mass production, easy to produce defective products, low yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

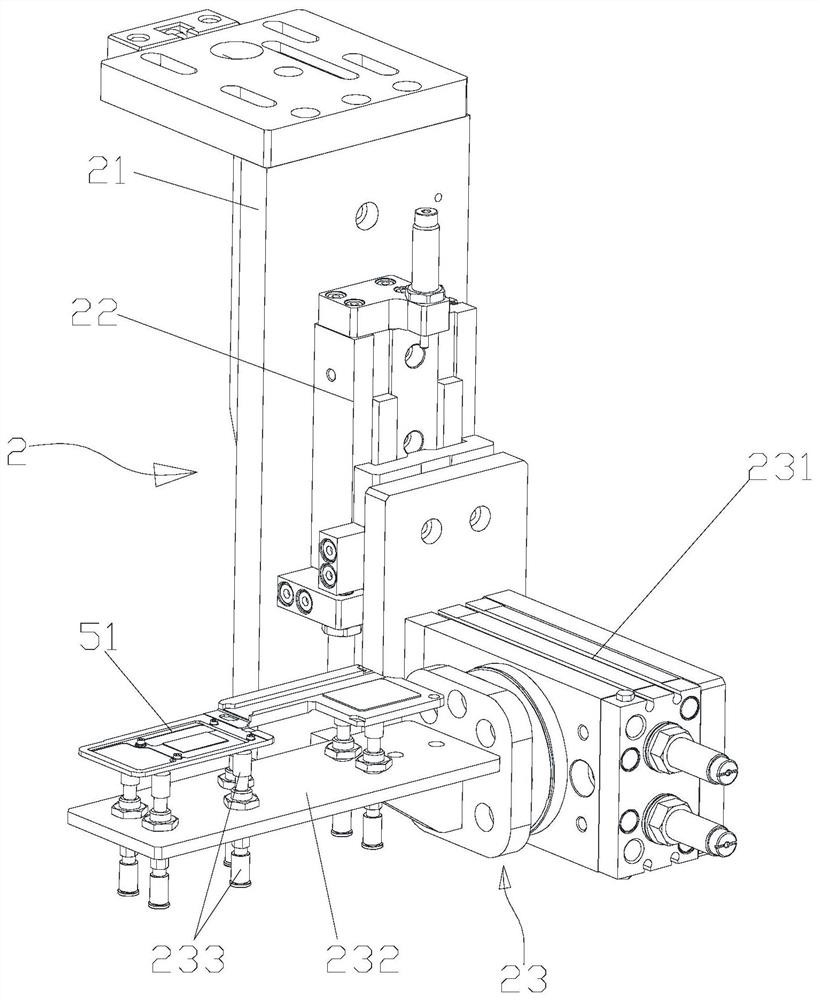

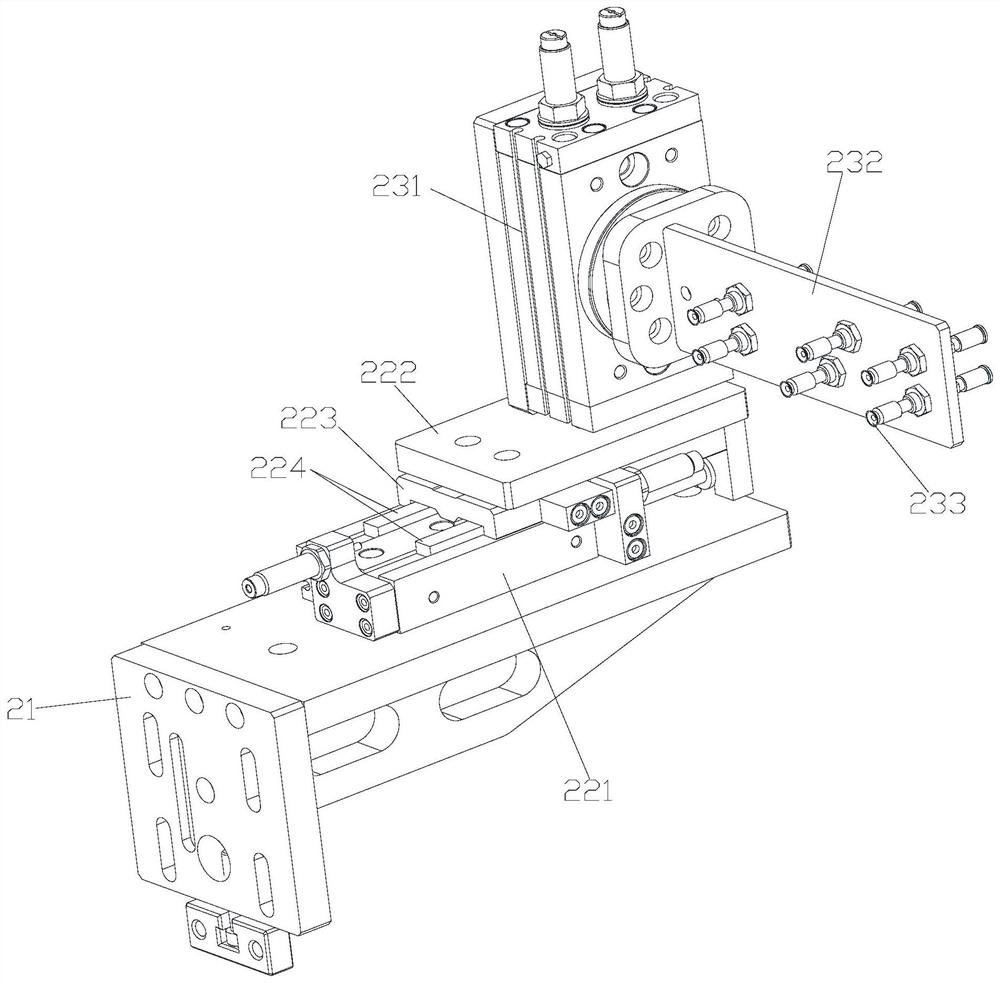

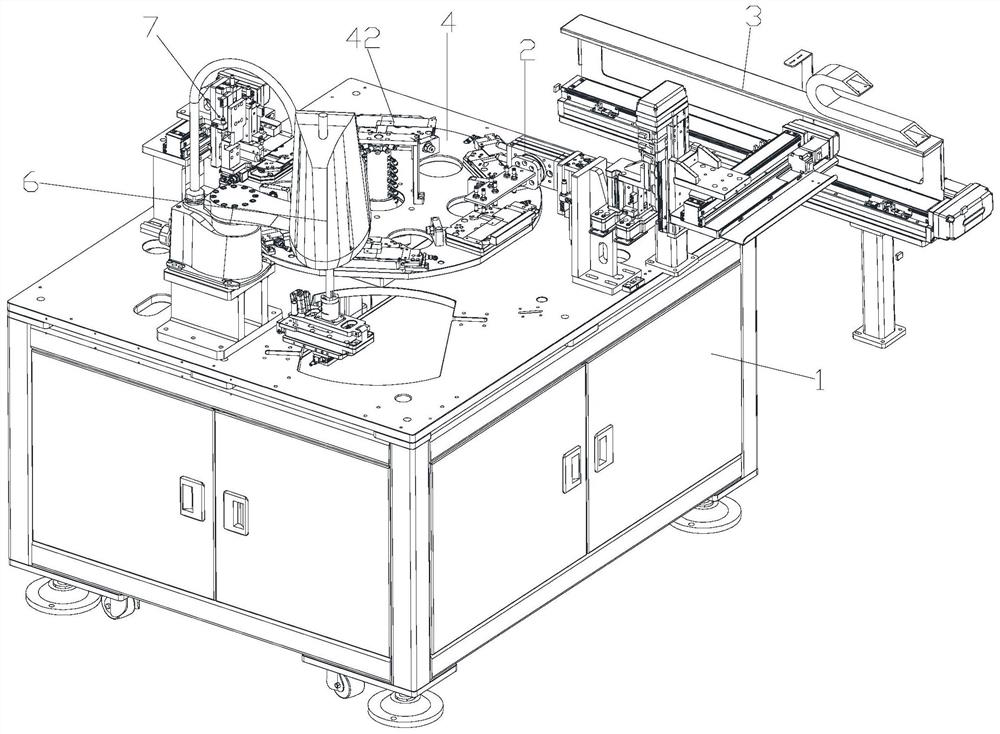

[0034] Figure 1~2 A quick pick-and-discharge mechanism according to an embodiment of the present invention is schematically shown.

[0035] Such as Figure 1~2 As shown, the quick pick-and-place mechanism 2 includes a pick-and-place material 51 . The quick loading and unloading mechanism 2 includes a mounting frame 21 , a lifting drive assembly 22 and a turning assembly 23 . The lifting drive assembly 22 is installed on the mounting frame 21, and the turning assembly 23 is installed on the lifting driving assembly 22. The turning assembly 23 includes a first driving member 231 and a rotating plate 232, and the rotating plate 232 is installed on the driving end of the first driving member 231. The driving member 231 is installed on the lifting driving assembly 22 , and a plurality of suction cups 233 are installed on the upper and lower ends of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com