Tinning mechanism

A technology of tin dipping and servo motor, which is applied to tin feeding devices, auxiliary devices, metal processing equipment, etc., can solve the problems of irregular appearance and size, large randomness, etc., and achieve precise angle, high work efficiency and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

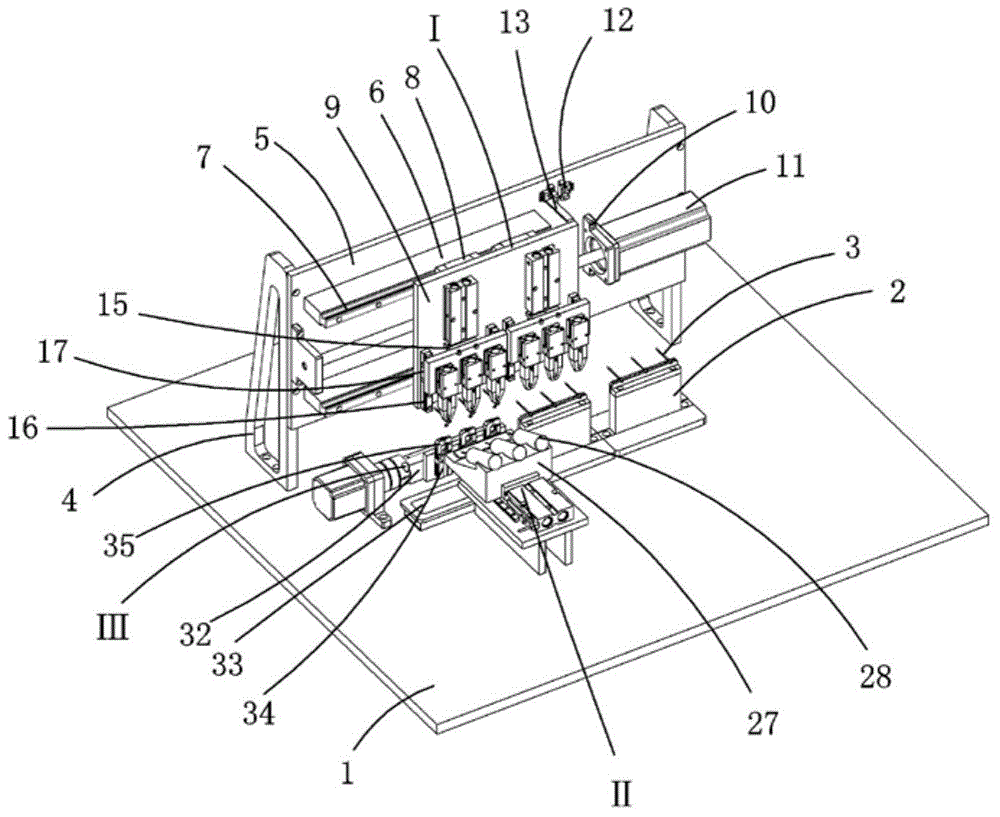

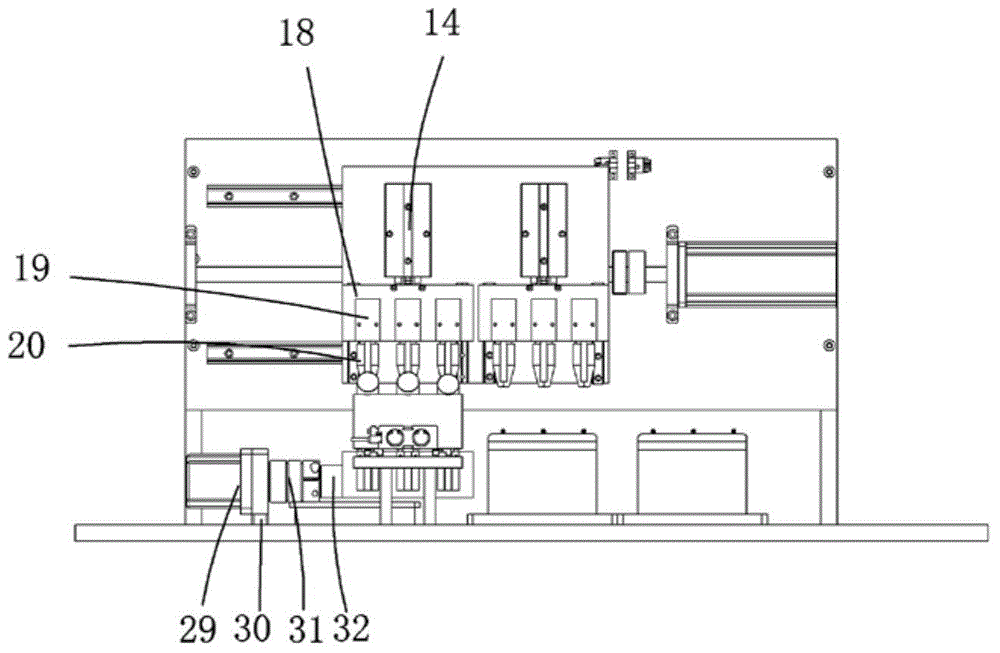

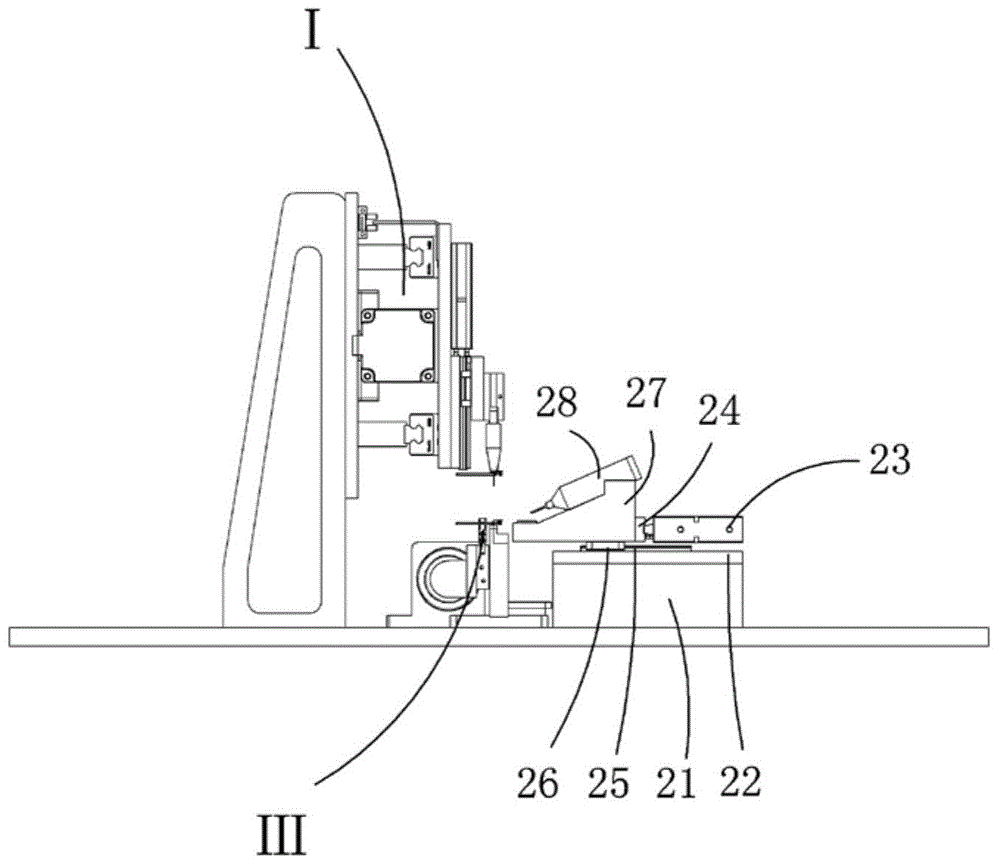

[0025] Examples, see attached Figure 1~3 , a tin dipping mechanism, which includes a bottom plate 1, a carrier 2, a product 3, a retrieving mechanism I, an automatic flux point module II and a material receiving jaw module III, and two sets of carriers are installed on the bottom plate , There are three sets of products placed on each set of carriers. The product is an assembly product formed by winding connectors and terminals. After winding, the appearance and size are irregular, and the randomness is large. At the same time, two sets of carriers can realize continuous operation, which improves the equipment utilization.

[0026] The retrieving mechanism includes a support plate 4, a vertical plate 5, a height block 6, a slide rail 7, a slider 8, a moving plate 9, a motor holder 10, a servo motor 11 and a reclaiming module, and the support plate has two, respectively installed on the bottom plate, two vertical plates are installed on the two support plates, and the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com