Automatic pressing board loading and unloading mechanical arm

A technology of automatic loading and unloading and manipulators, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., to achieve the effects of reducing labor intensity, accurate position, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

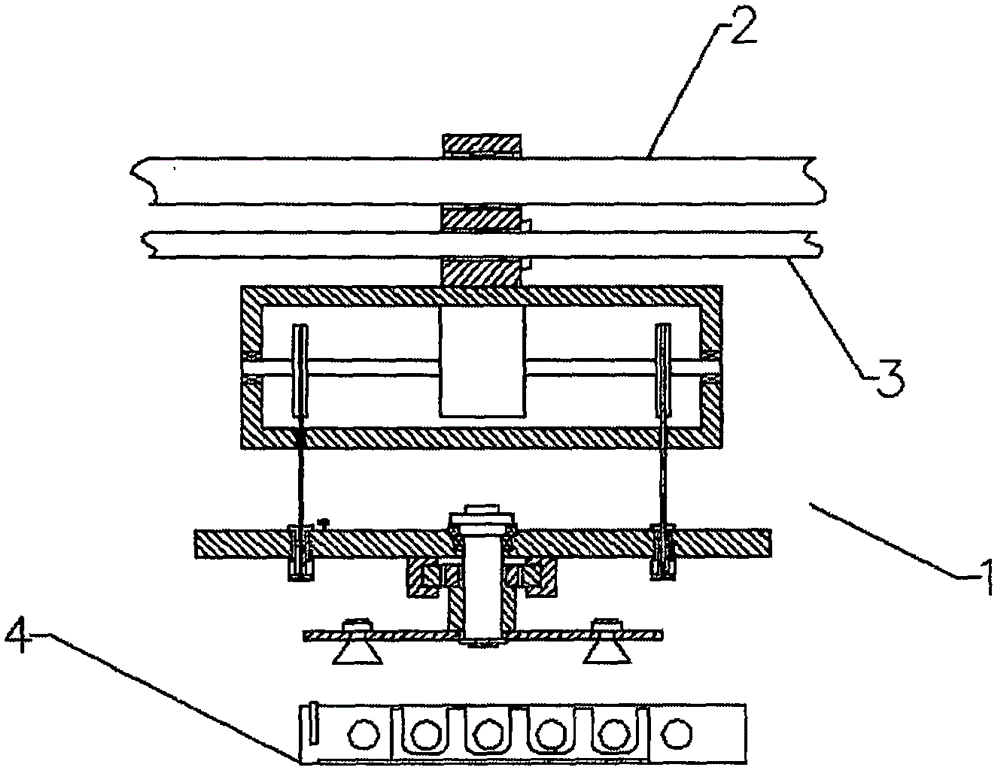

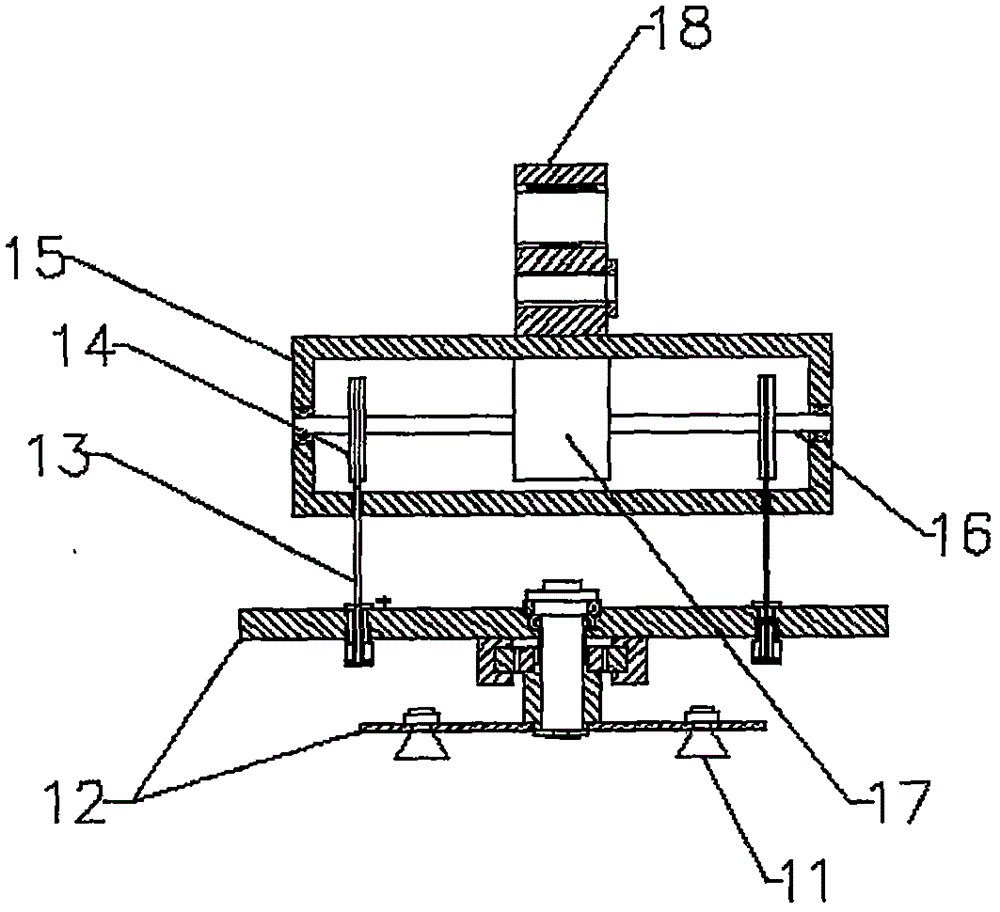

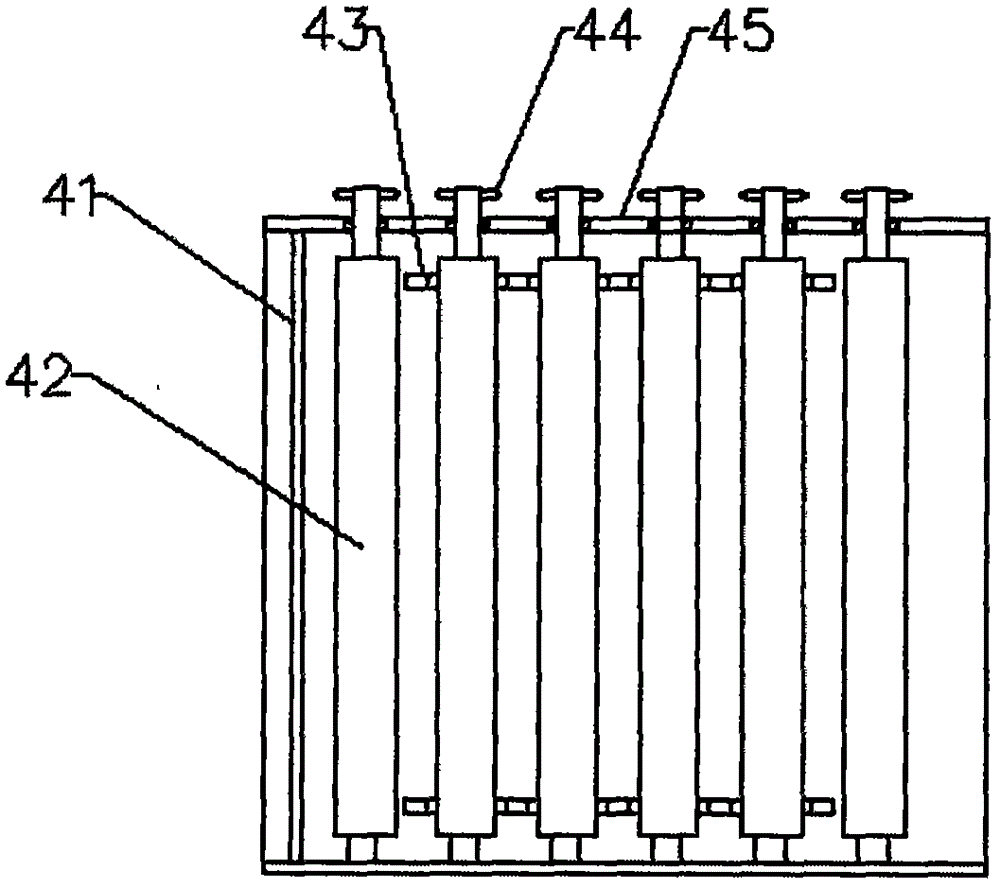

[0019] Such as Figure 1-6 As shown, a pressing plate (5) automatic loading and unloading manipulator includes a pressing plate pick-and-place mechanism (1), guide rail (2), lead screw (3) and guiding mechanism (4), directly above the corrugated cardboard stack (6) A guide rail (2) and a lead screw (3) are provided, a pressing plate pick-and-place mechanism (1) is arranged on the guide rail (2) and the lead screw (3), and the guide mechanism (4) is placed on the corrugated cardboard stack (6) above. The platen pick-and-place mechanism (1) can move left and right along the guide rail (2) under the drive of the lead screw (3). When the platen (5) needs to be grasped, the platen pick-and-place mechanism (1) moves to the platen stack (7) Grab the pressing plate (5) and move it to the top of the corrugated cardboard stack (6), then guide the pressing plate (5) through the guiding mechanism (4) and place it on the top surface of the corrugated cardboard stack (6) . The platen pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com