Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Protection against splashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

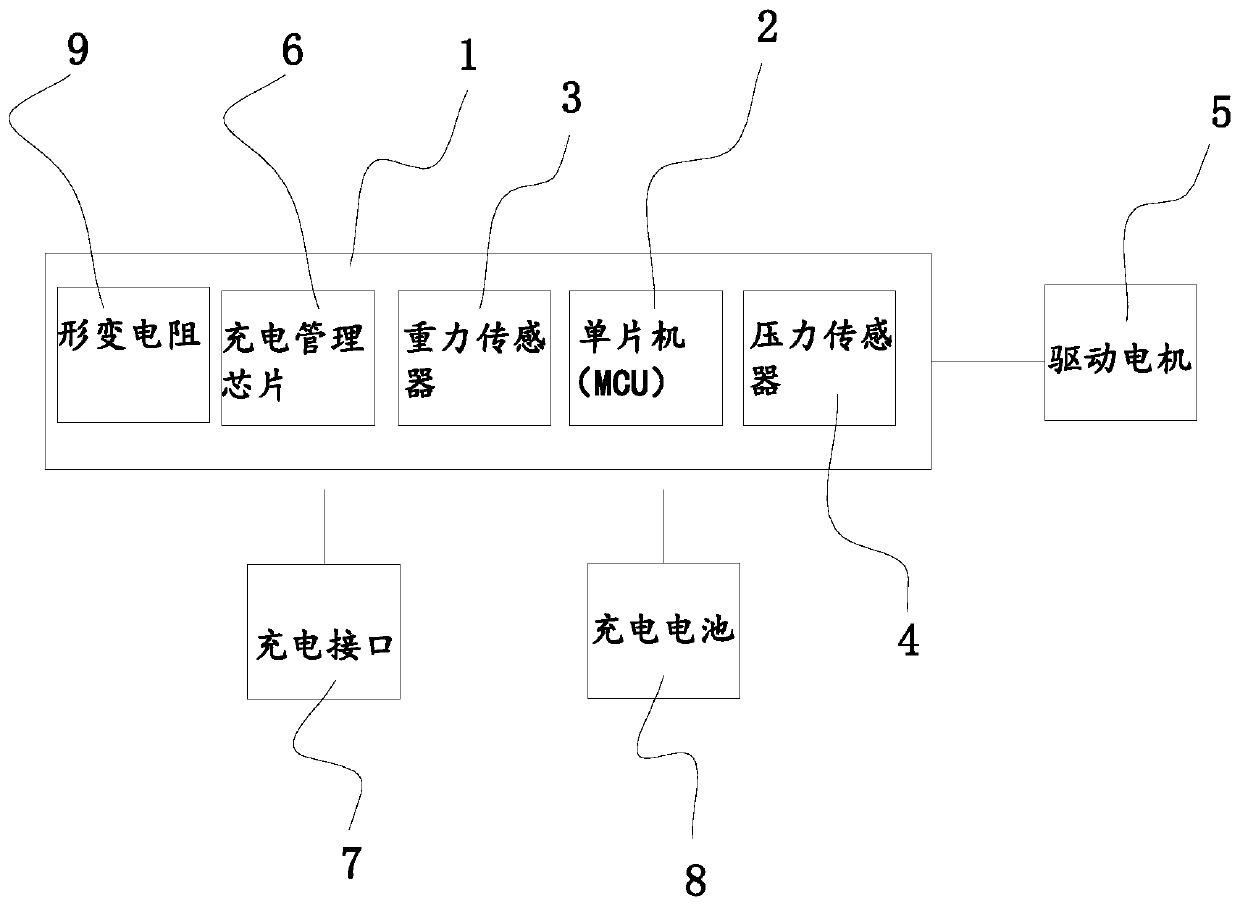

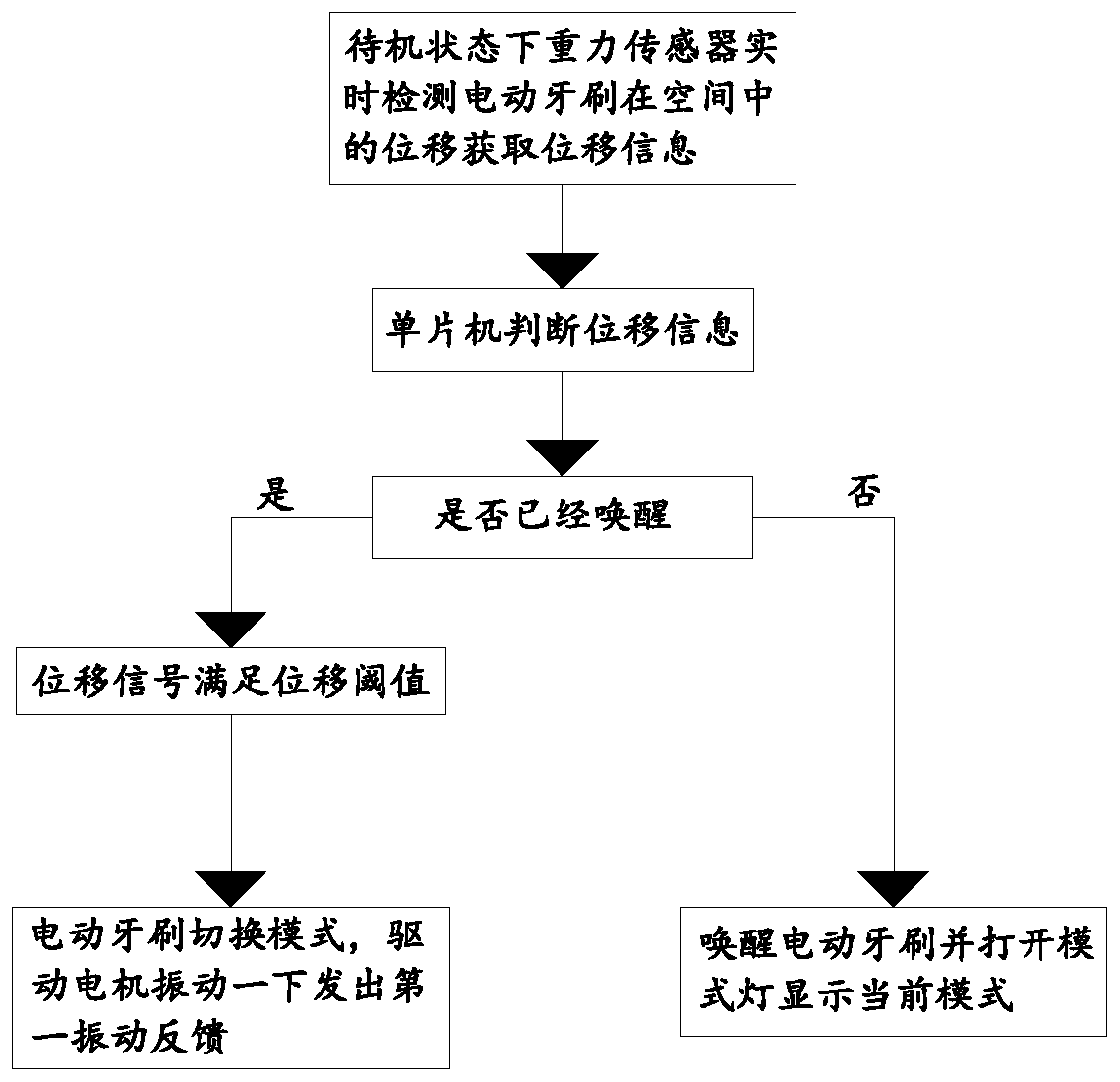

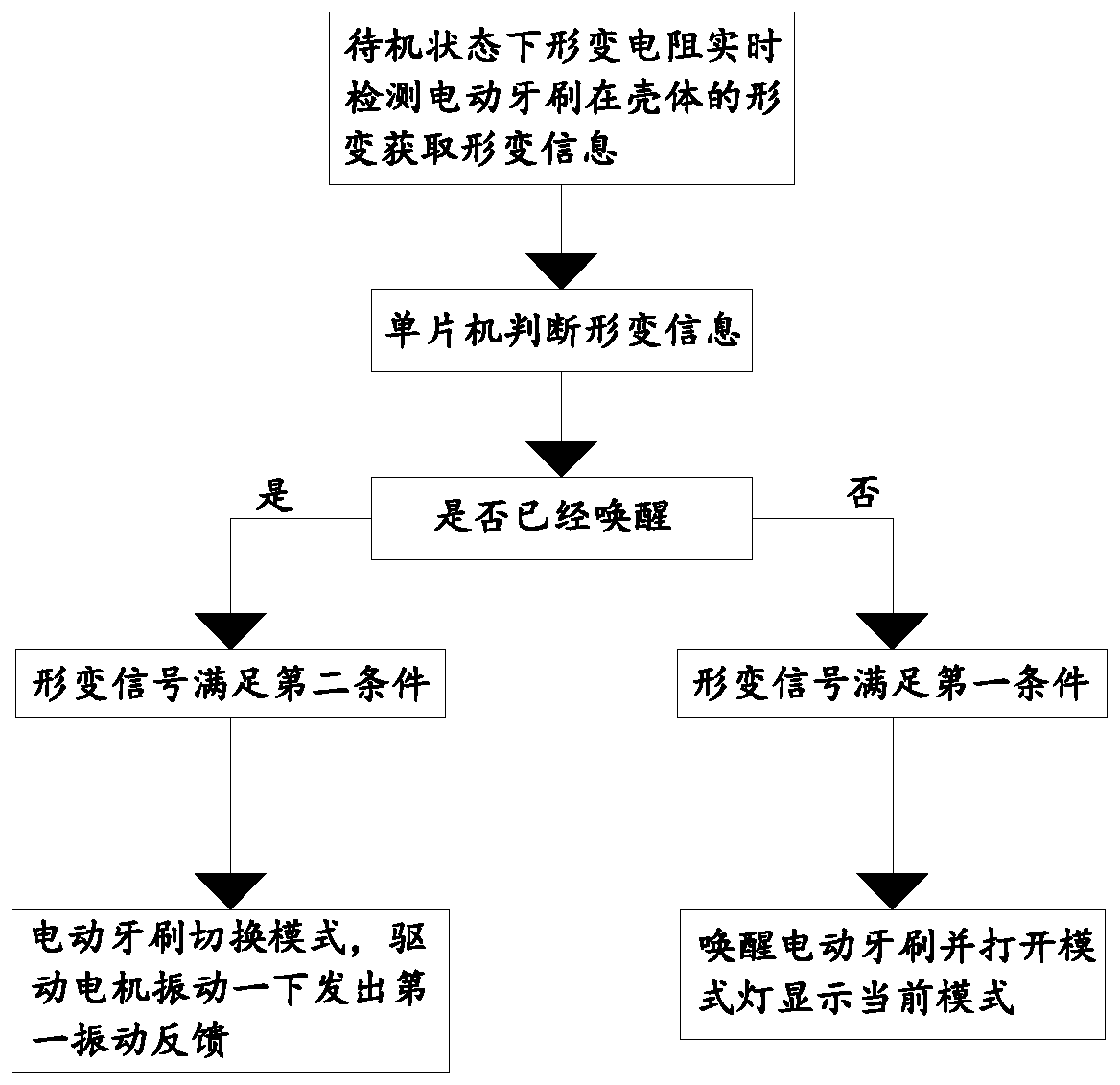

Control method of electric toothbrush

ActiveCN111297506AImprove the degree of intelligent controlImprove user experienceProgramme controlMeasurement devicesElectric machineryEngineering

The invention discloses a control method of an electric toothbrush. The electric toothbrush comprises a pressure sensor, a deformation resistor and a control board. The control method comprises the following steps that the electric toothbrush is controlled by the control board to enter an awakening state; after the electric toothbrush enters the awakening state, when the deformation produced by ahousing of the electric toothbrush is detected by the deformation resistor, a deformation signal is transmitted, and the electric toothbrush is controlled by the control board to switch modes; when pressure information stressed on a toothbrush head is detected by the pressure sensor, a pressure signal is transmitted, a driving motor in the electric toothbrush is controlled by the control board tobe started, and the electric toothbrush enters a tooth brushing state; and after the tooth brushing state is entered, if the situation that the pressure information stressed by the toothbrush head isan initial pressure value is detected by the pressure sensor, the driving motor is controlled by the control board to be switched off, and the electric toothbrush enters the awakening state. Through the adoption of the control method disclosed by the invention, functions of non-key automatic awakening, automatic starting and automatic mode switching of the electric toothbrush can be realized.

Owner:广州舒客实业有限公司

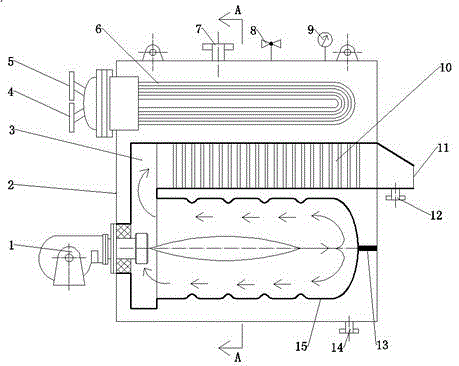

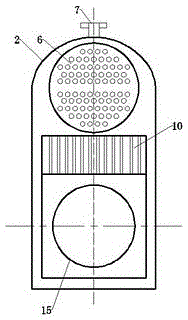

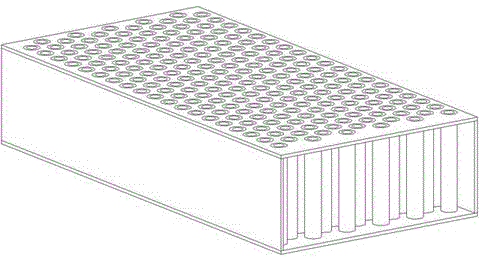

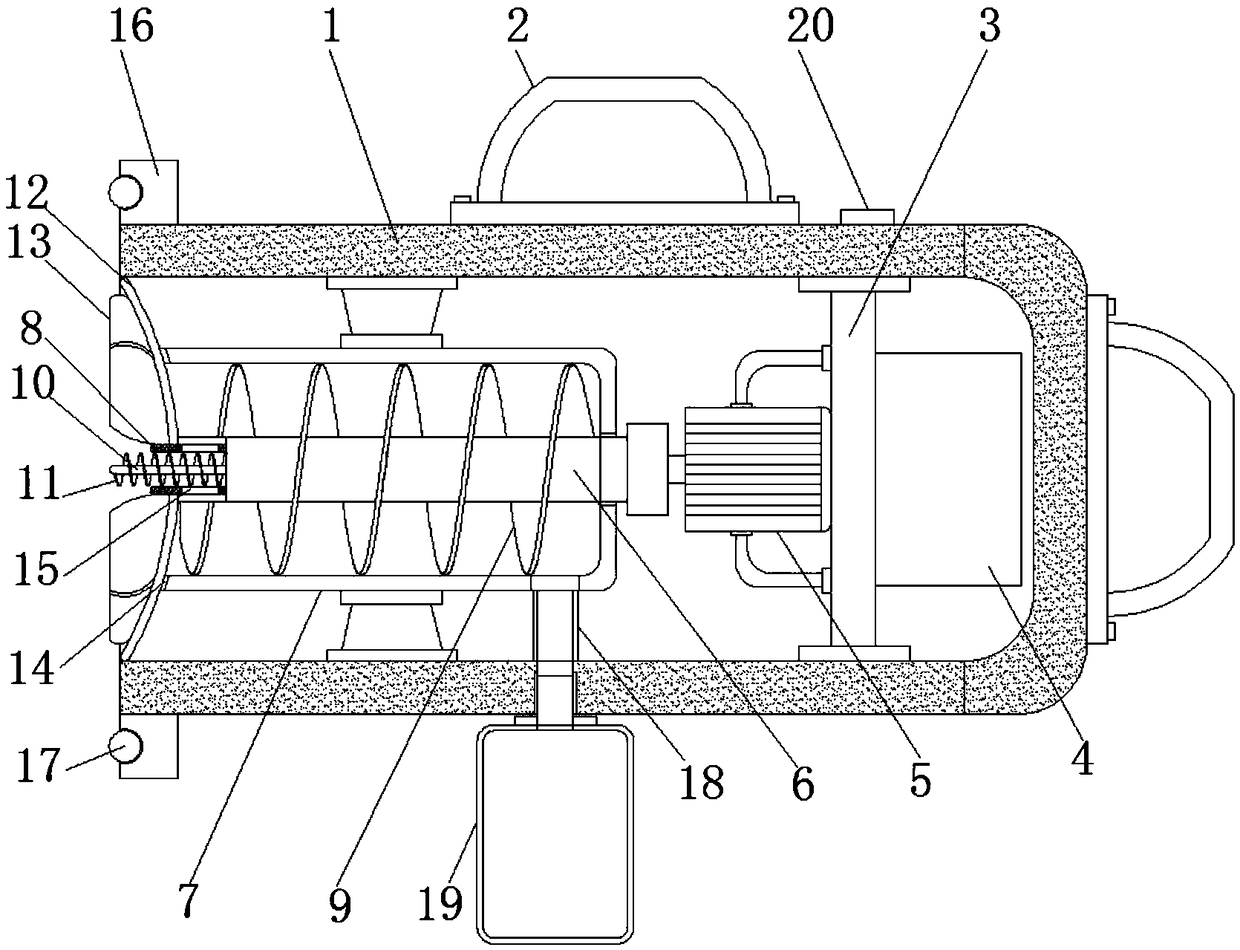

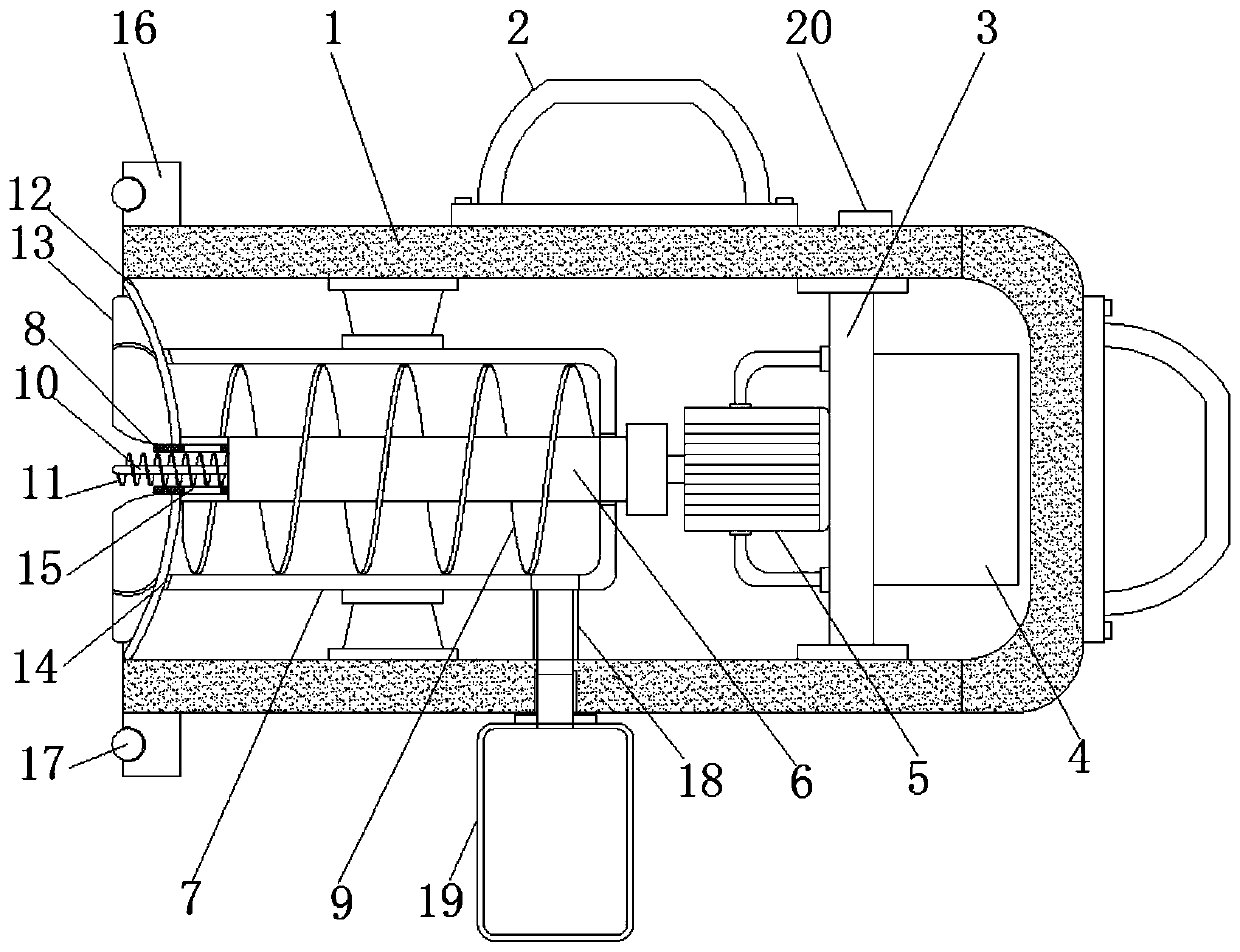

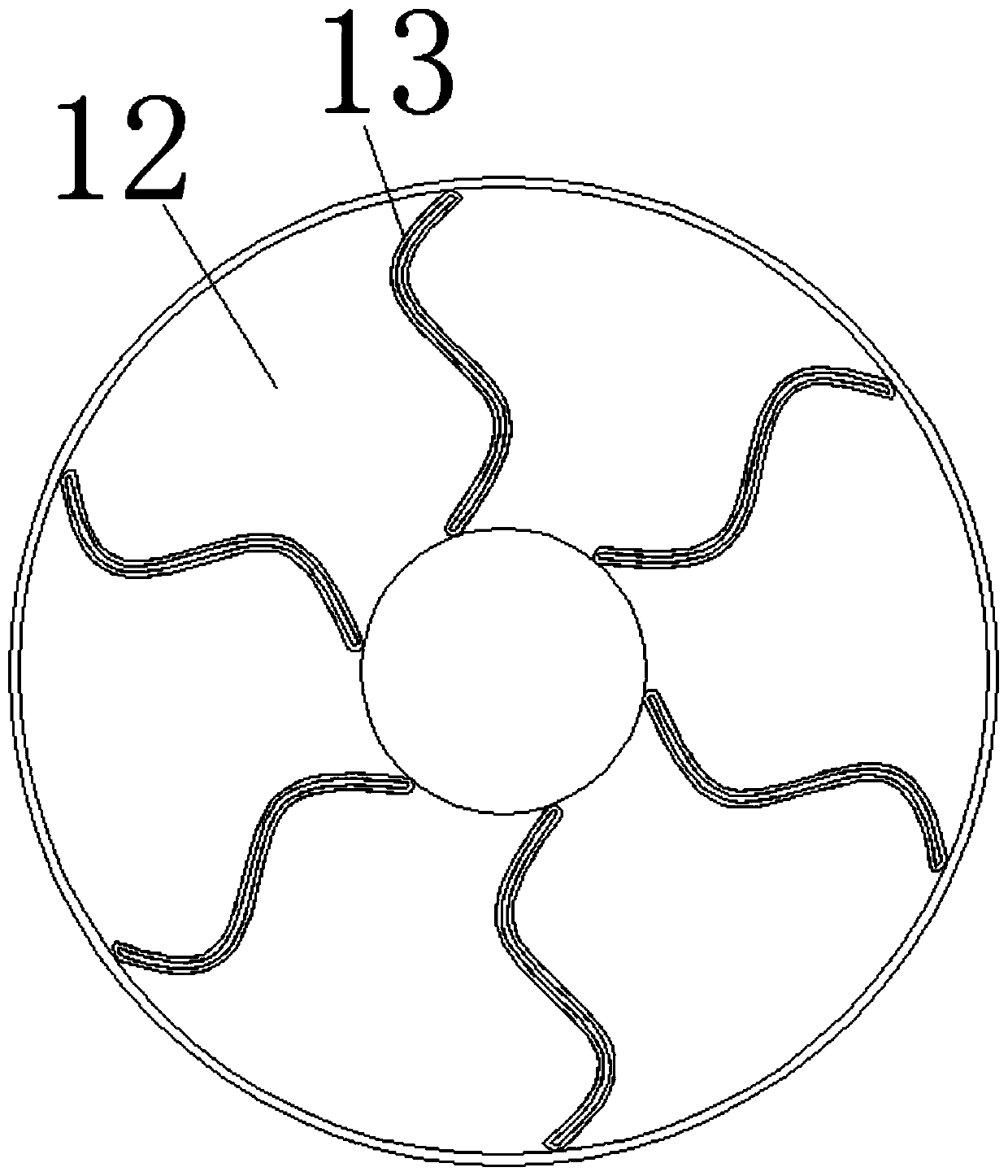

Water tube type vacuum boiler with central reverse flames

The invention discloses a water tube type vacuum boiler with central reverse flames. The vacuum boiler mainly comprises a combustor, a casing, a flue gas transfer chamber, a container, a water tube type heat exchanger and a U-shaped tube heat exchanger. The vacuum boiler is characterized in that the boiler casing is formed by butt-jointing an upper arc-shaped barrel and a lower cuboid casing, the U-shaped tube heat exchanger is located at the upper part of the casing, and the container, the flue gas transfer chamber and the water tube type heat exchanger are located at the lower part of the casing; the container is waved, the front end of the container is welded on the flue gas transfer chamber, and the back end is welded on an ellipsoidal gland; a central reverse flame combustion manner is adopted; a plurality of vertical heat exchange tubes are arranged in the water tube type heat exchanger, flue gas inlets of the heat exchange tubes are welded on the flue gas transfer chamber, and flue gas outlets are connected with an exhaust tube. The boiler keeps a certain vacuum degree inside during running, boiler water boils at the temperature lower than 100 DEG C after being heated, steam rises and condenses outside the U-shaped tube heat exchanger to release heat to heat return water in the tube, and condensate water flows back into the boiler. The boiler is compact in structure and higher in heat efficiency and occupies small area, and no external heat exchanger is required.

Owner:ZHENGZHOU UNIV

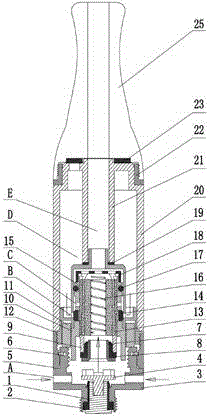

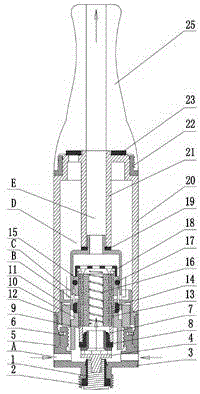

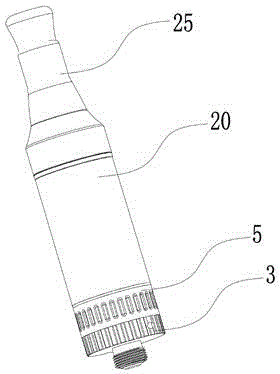

Cylinder plug type fully-sealed electronic cigarette atomizer

The invention discloses a cylinder plug type fully sealed electronic smoke atomizer, which includes a PC tube, an air intake component, an oil control component and an atomization component, wherein the inside of the PC tube is a cavity structure, and the inside of the PC tube is provided with The upper end of the smoke tube is set on the top of the PC tube and extends downwards. An annular oil storage space is formed between the PC tube and the smoke tube, and the oil storage space is filled with smoke oil; the above-mentioned atomization components are set in the PC tube. And connected to the lower end of the smoke pipe, the oil control component is set between the oil storage space and the atomization component, so as to control the entry and exit of the smoke oil; the above-mentioned air intake component is set at the lower end of the atomization component, and the air intake component is connected to the inside of the PC tube and the outside space. The invention has compact structure and reasonable design, and solves the oil leakage problem of the product in the working state and non-working state.

Owner:SHENZHEN NEXCII TECH CO LTD

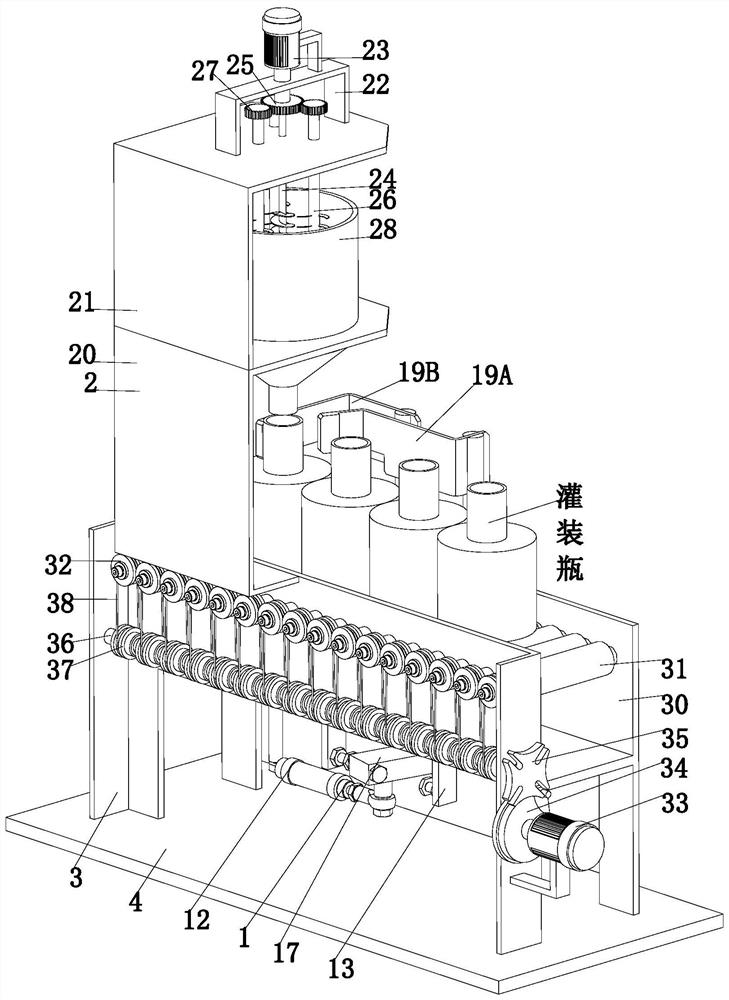

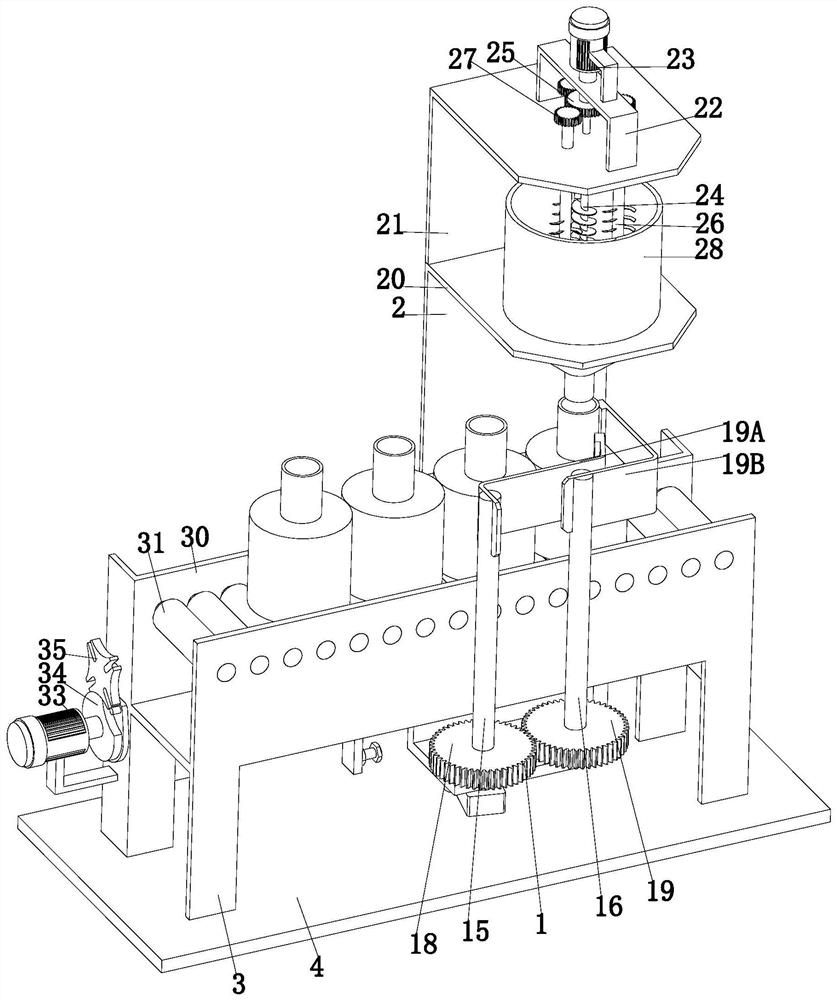

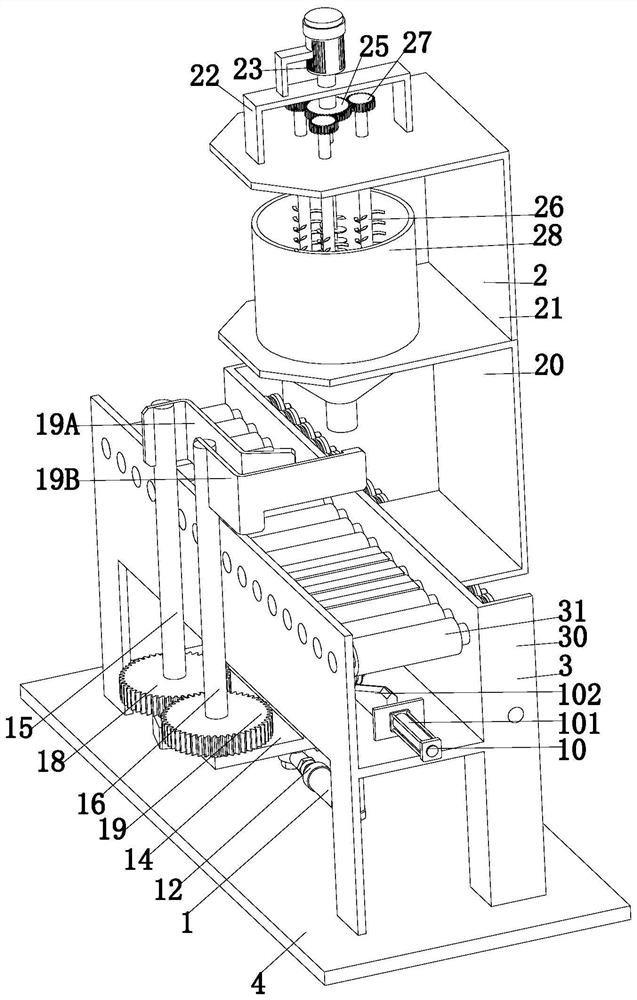

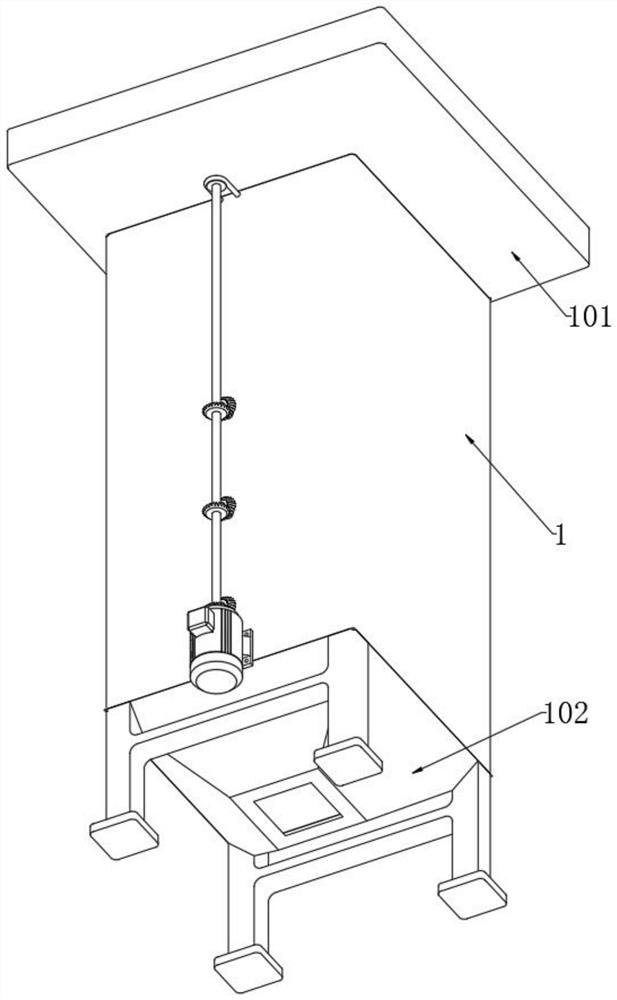

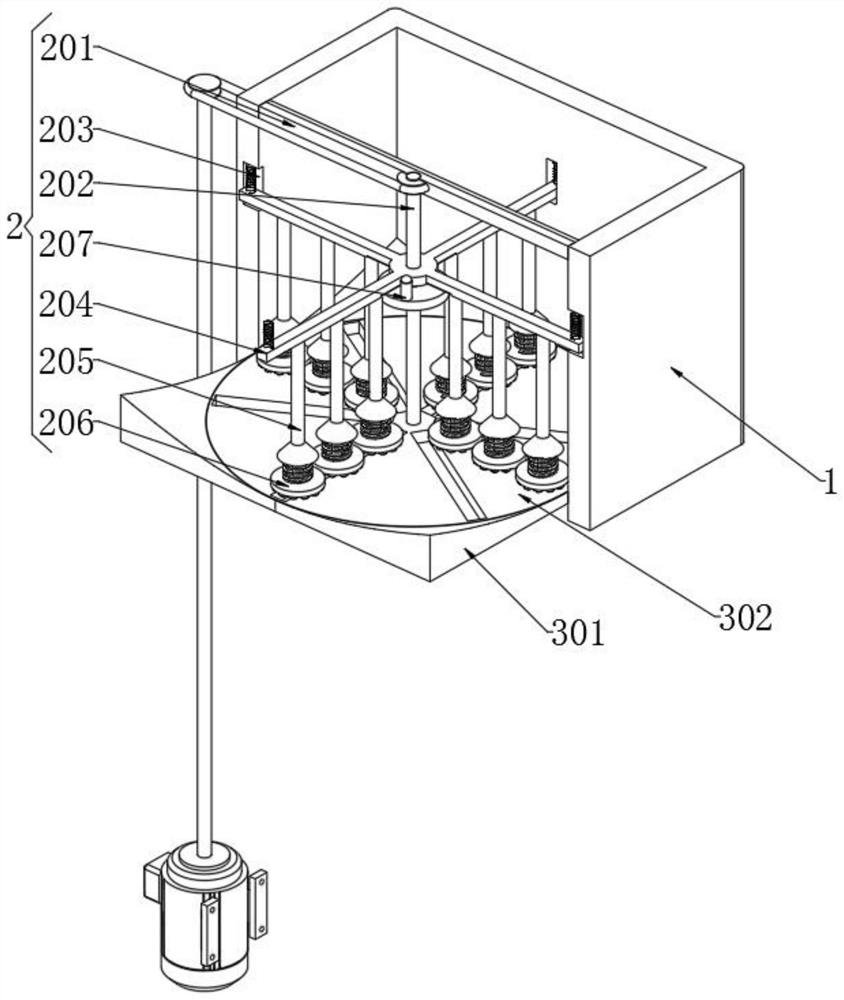

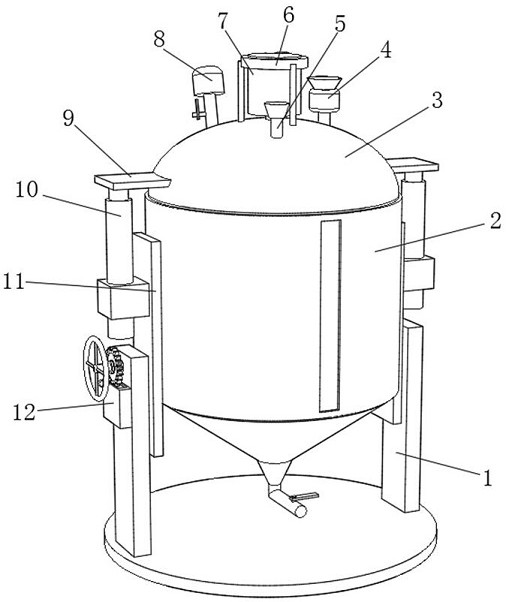

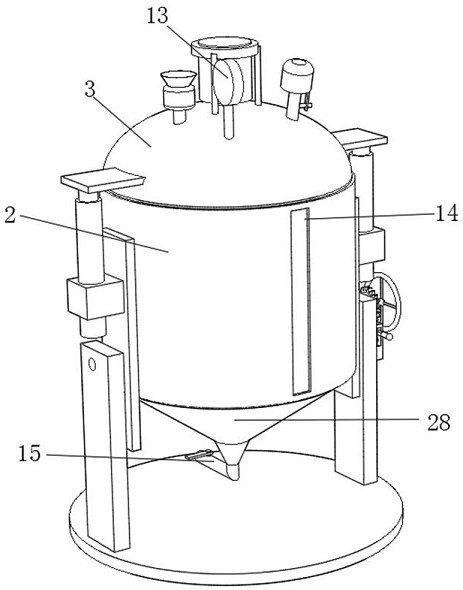

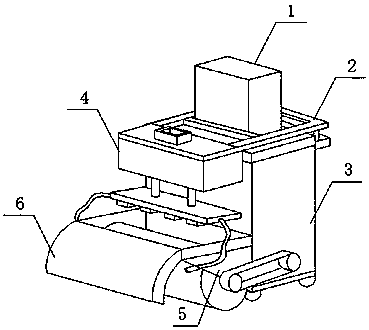

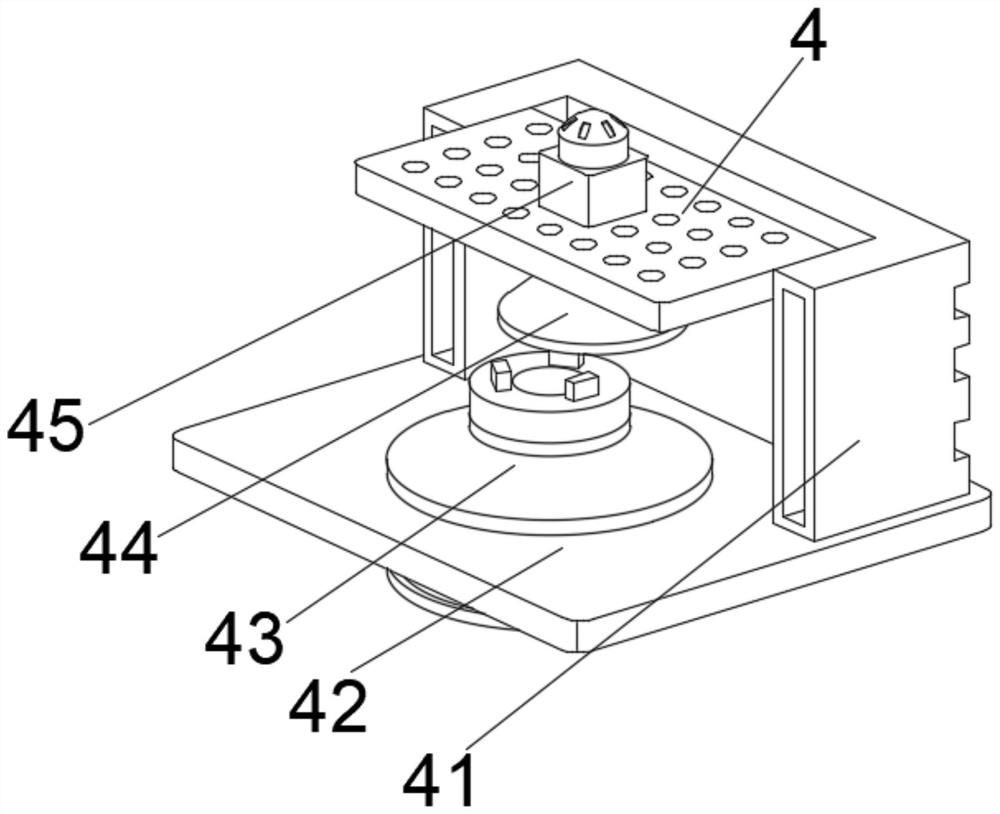

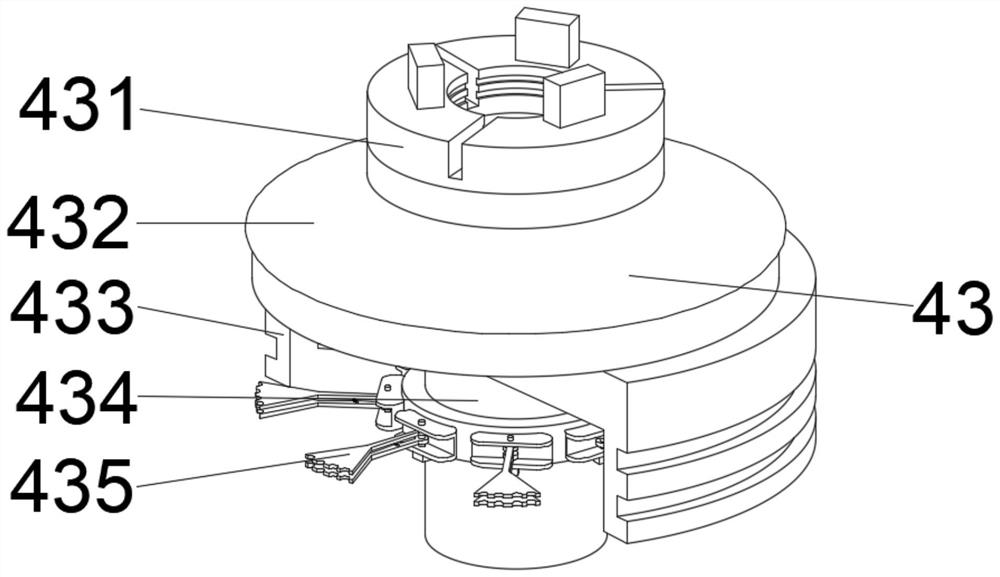

Intelligent filling machine for skin care product preparation and filling method

The invention provides an intelligent filling machine for skin care product preparation and a filling method. The intelligent filling machine comprises a directional stopping mechanism, a discharging mechanism, a conveying mechanism and a bottom plate. The intelligent filling machine solves the following problems existing in the current skin care product filling process that after filling, manual reloading is needed, then filling of a next group of skin care product bottles is carried out, continuous operation cannot be carried out, the intensity of workers is improved, and consequently the automation and intelligence degree is low; a certain distance exists between a filling liquid outlet and filling bottle openings, the situation of splashing is prone to occurring in the filling process, skin care products can be splashed to the bottle openings and even the outer portions of bottle bodies, waste is caused, and proceeding of the next procedure is affected; and in the filling process, the bottles need to be moved, it is difficult to guarantee whether the bottle openings are aligned with a filling point or not, accurate filling cannot be achieved, the emulsion skin care products are prone to precipitation in the filling process, the quality effect of prepared emulsion is not ideal enough, and the emulsion skin care products can be unevenly filled.

Owner:夏华正

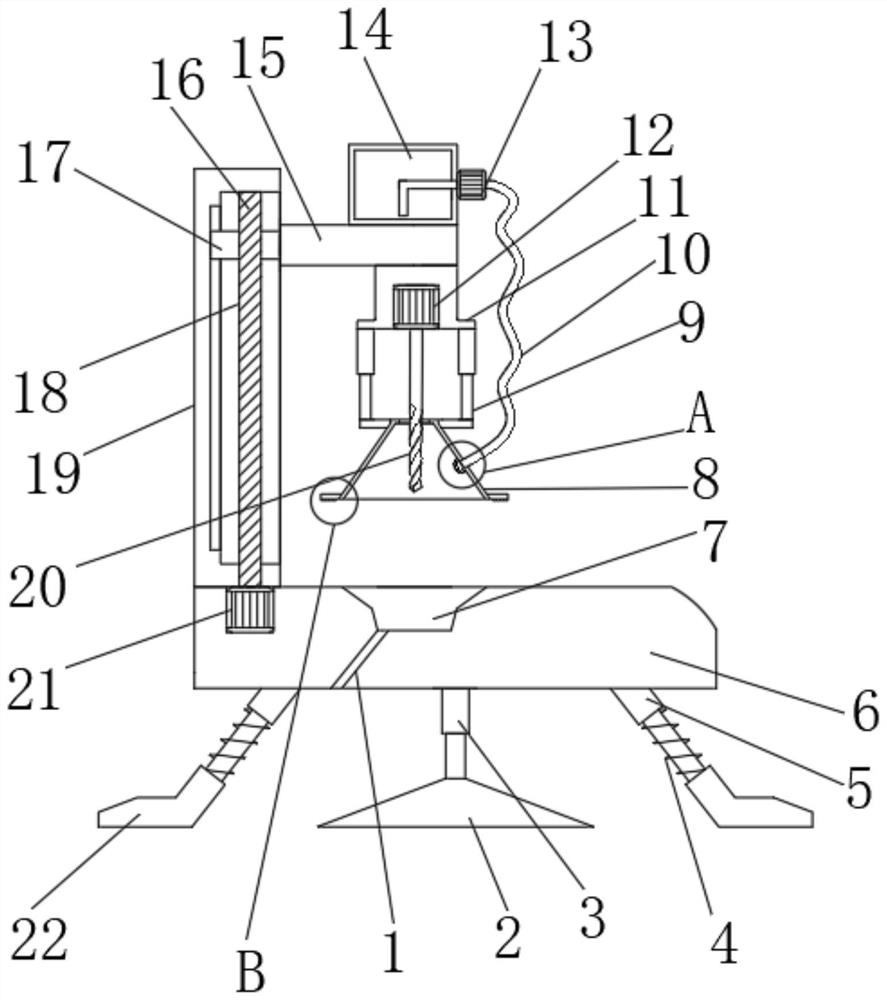

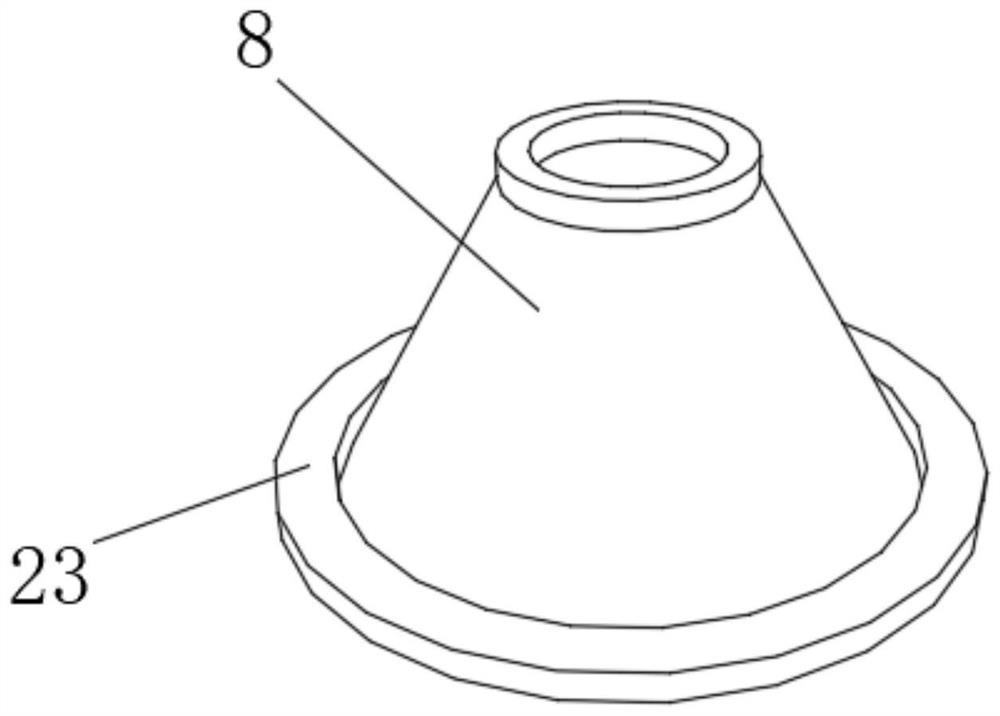

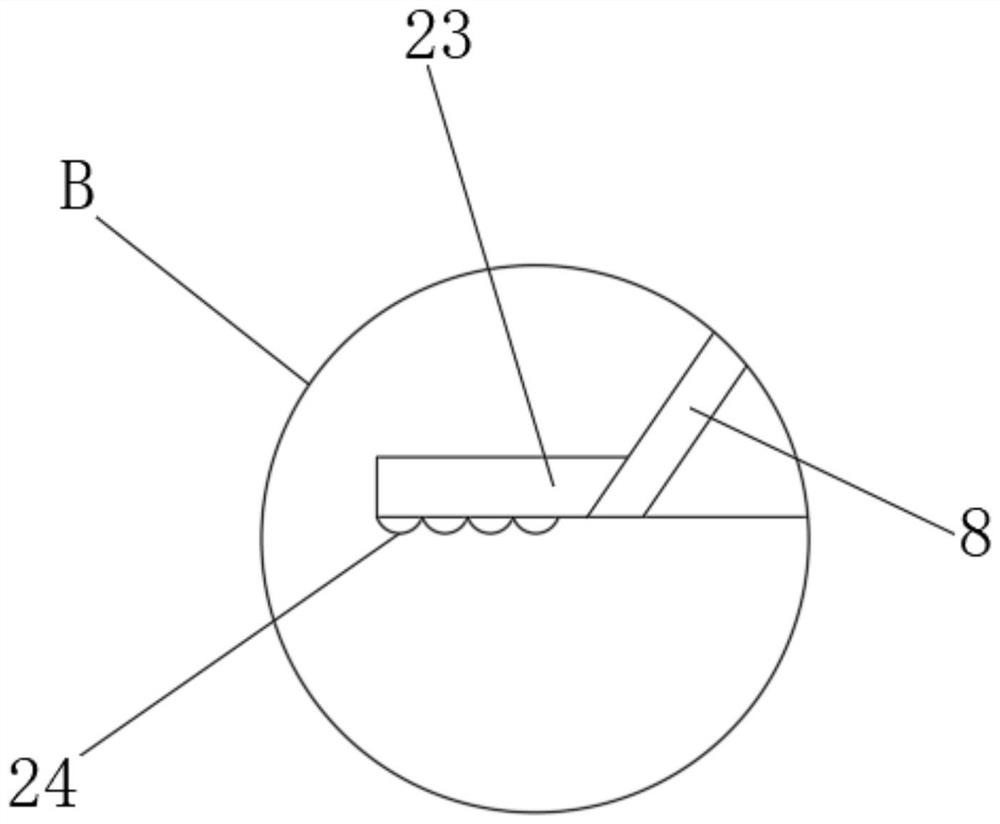

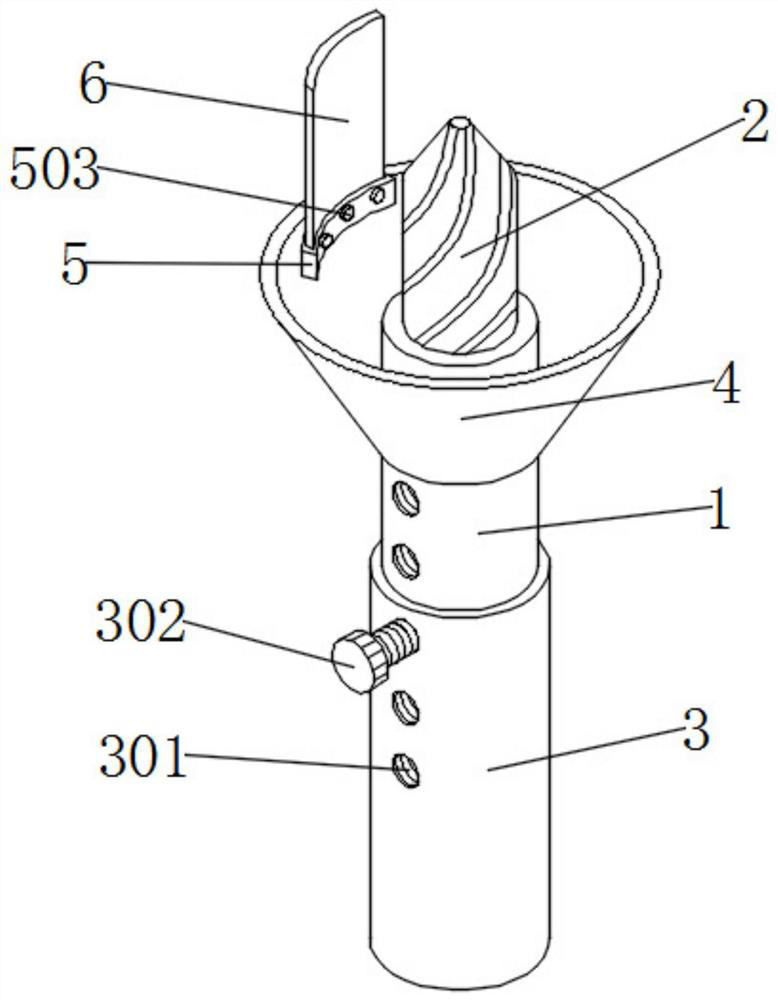

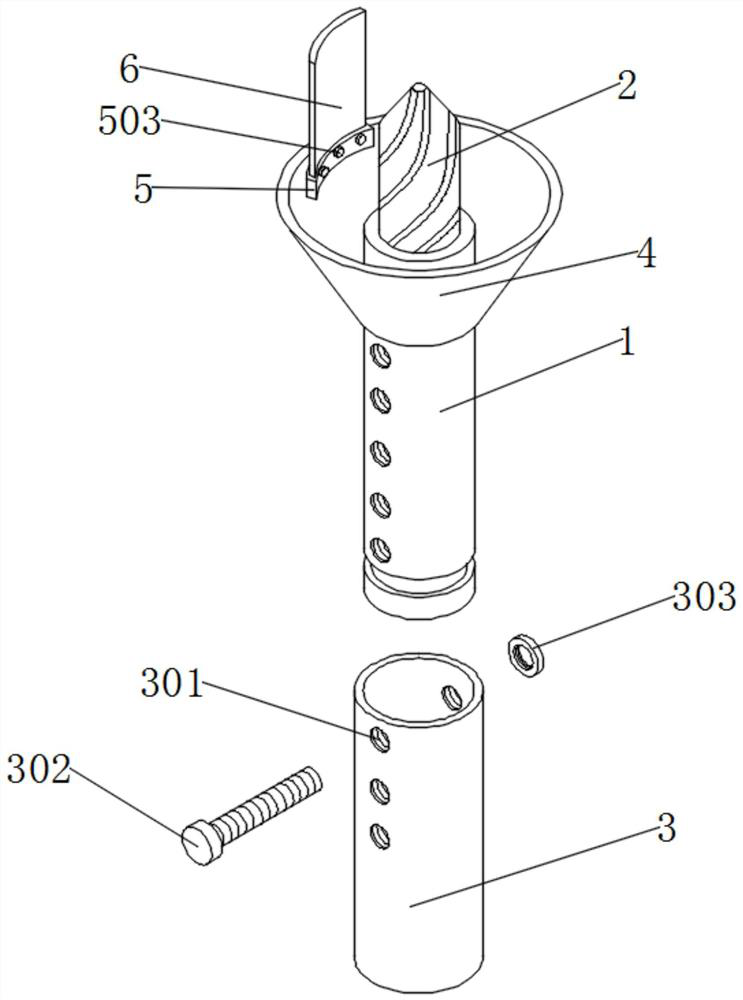

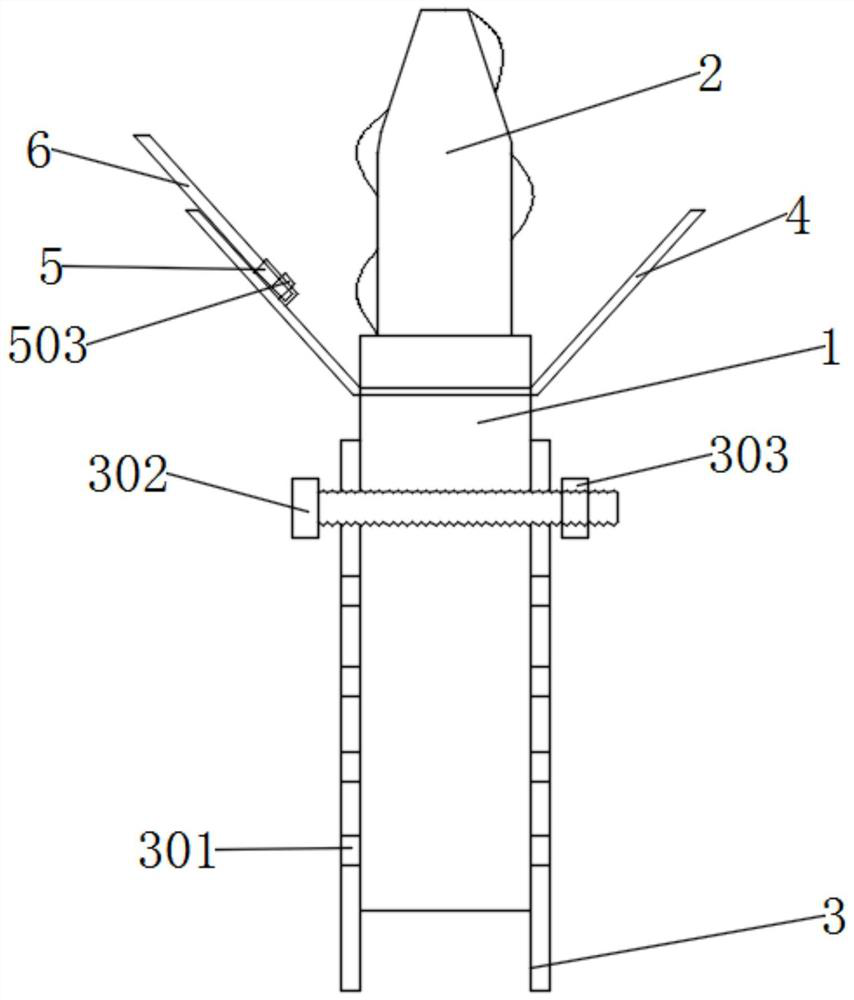

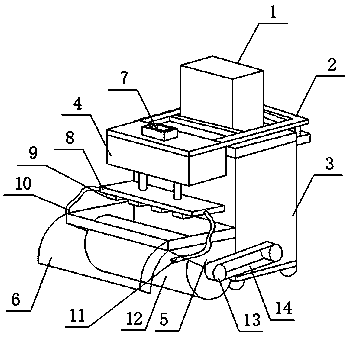

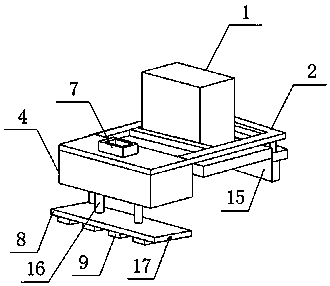

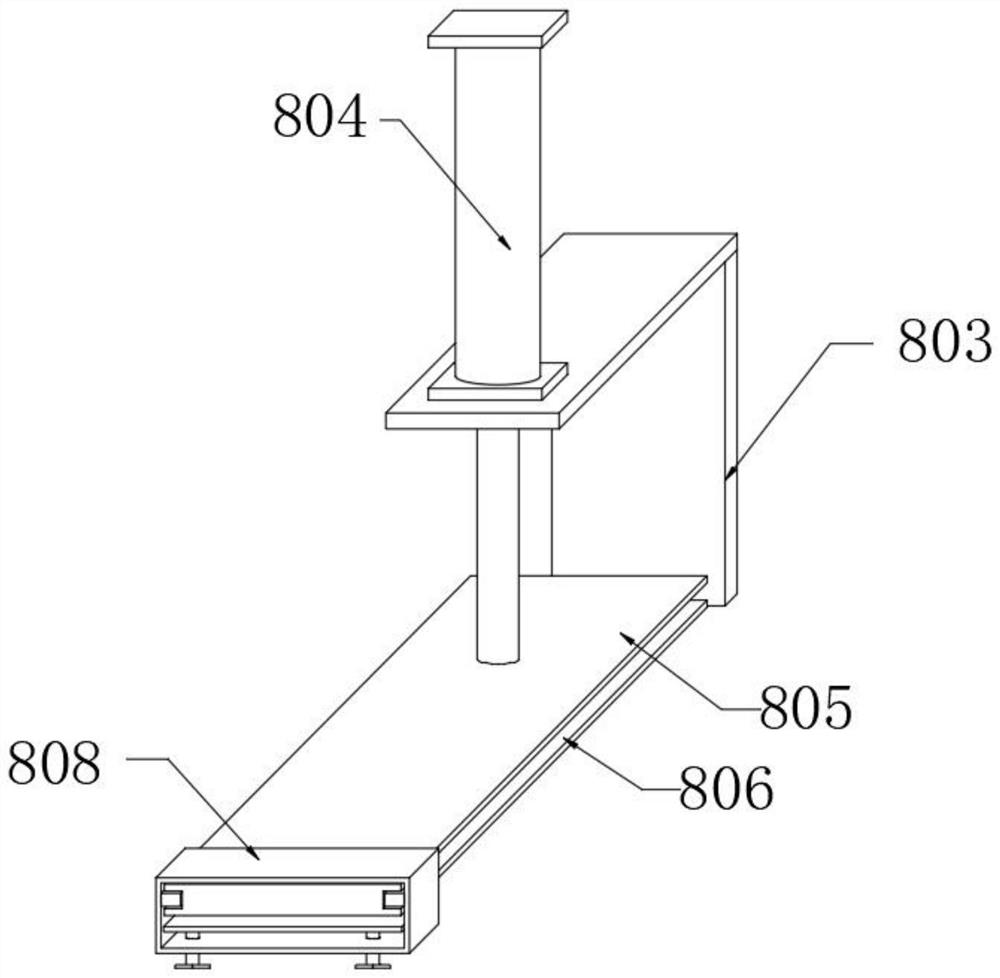

Mechanical drilling device

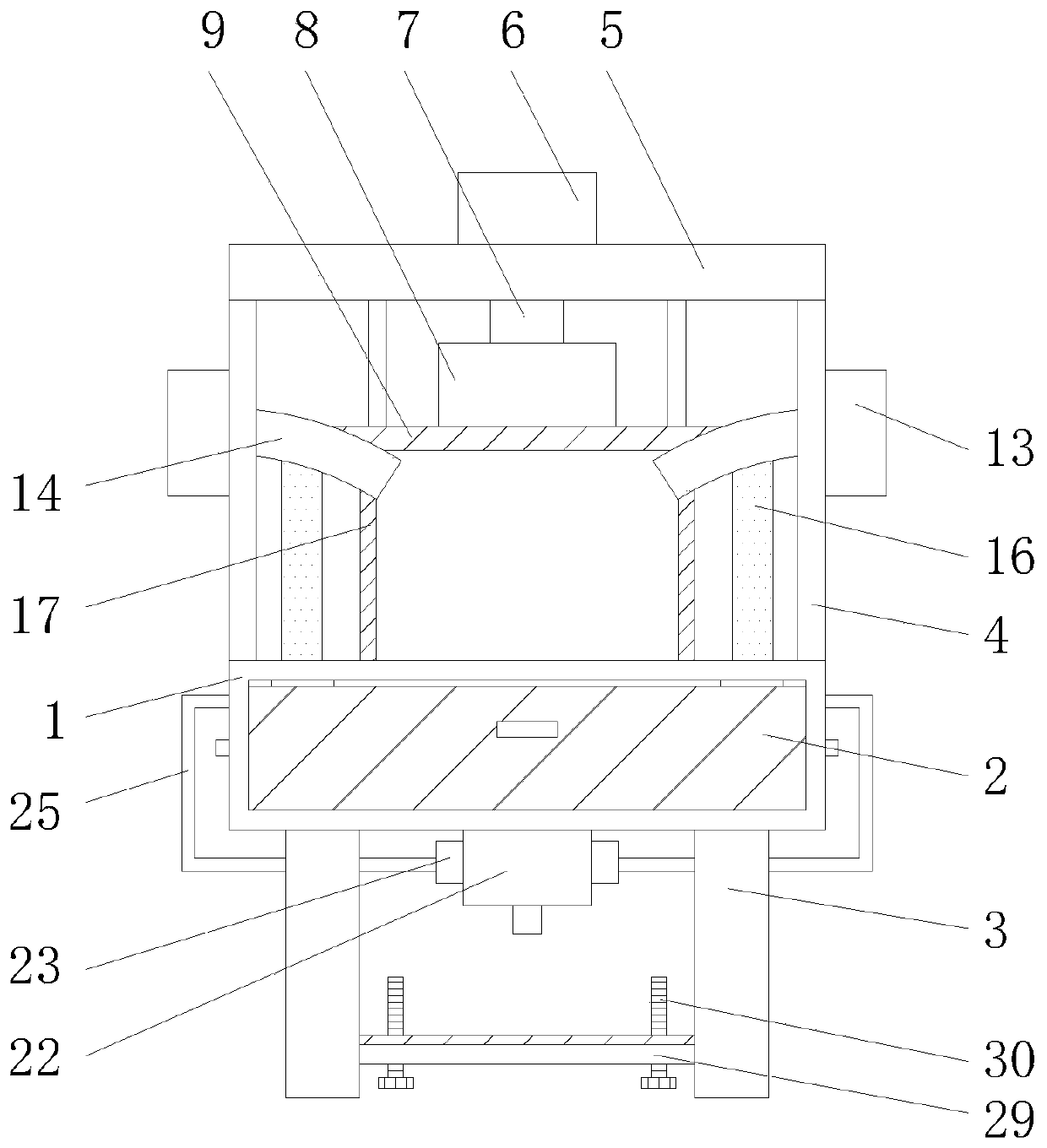

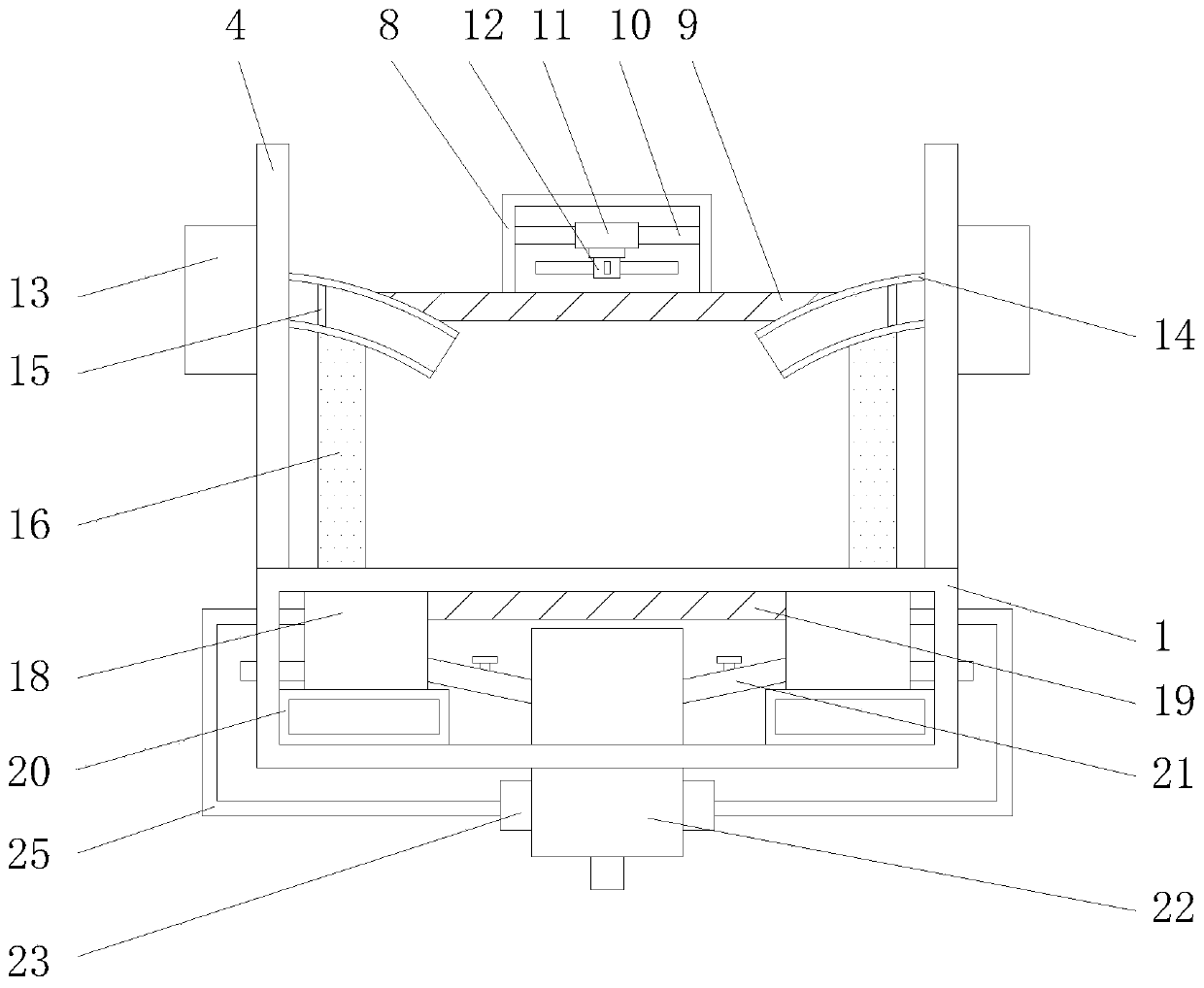

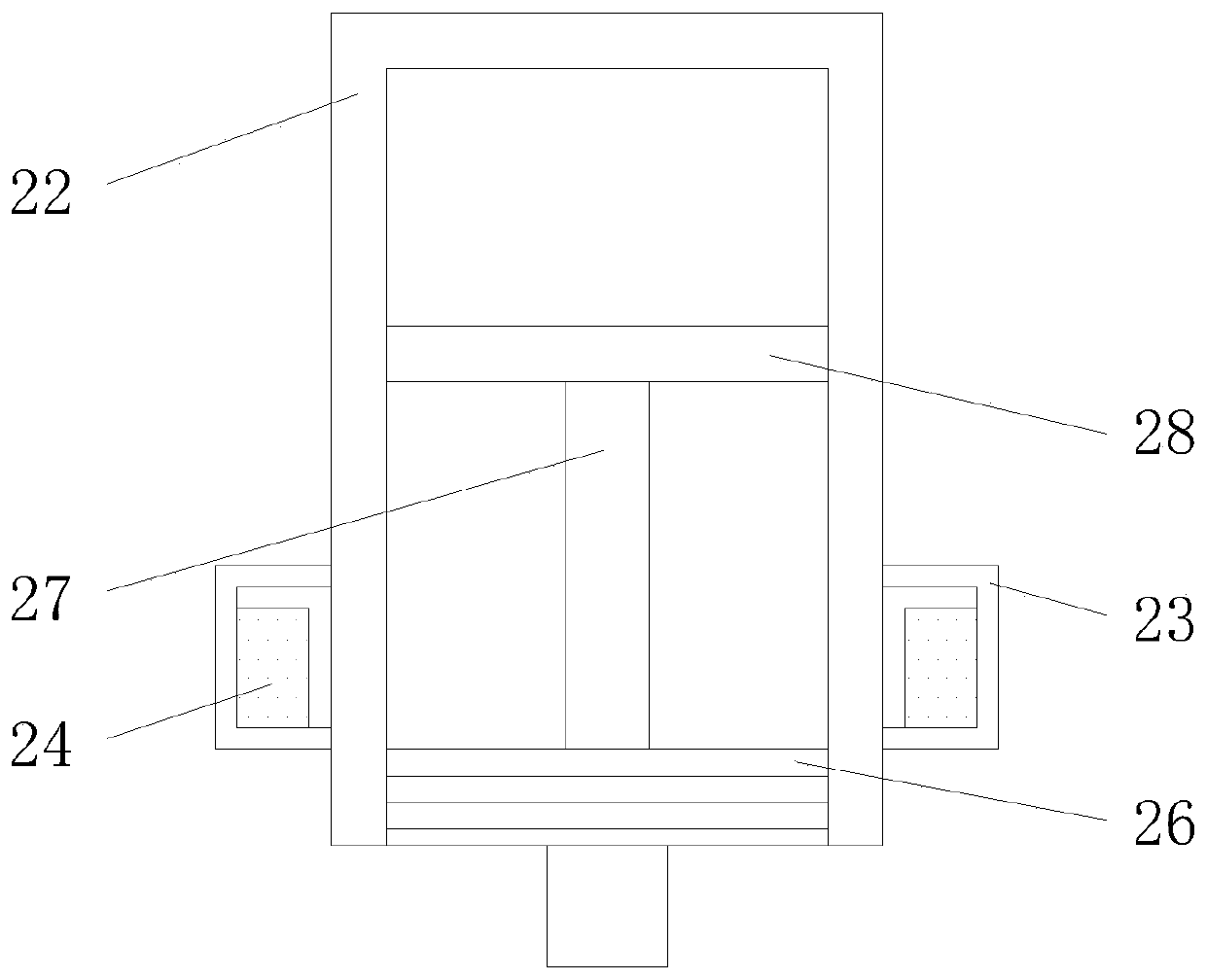

InactiveCN111842989AProtection against splashingReduce pollutionNon-rotating vibration suppressionPositioning apparatusMechanical equipmentSlide plate

The invention belongs to the technical field of mechanical equipment, and particularly relates to a mechanical drilling device. The mechanical drilling device aims to solve the problems that drillingdevice in the above patent is simple in design structure, dust flying is prone to being caused in the drilling process, and the surrounding environment is prone to being polluted. According to the scheme, the mechanical drilling device comprises a workbench, wherein a fixing column is fixed to one side of the outer wall of the top of the workbench through screws; a servo motor is fixed to the outer wall of the bottom of the fixing column through screws; an output shaft of the servo motor is connected with a screw rod through a coupler; a groove is formed in the outer wall of one side of the fixing column; and the outer wall of the screw rod is sleeved with a sliding plate. In the drilling process, an electric push rod piston rod is controlled to extend, a dust blocking hopper can be in firm contact with a steel plate, and therefore the steel plate is firmly fixed to the workbench, the dust blocking hopper can prevent chippings from splashing in the drilling process, and pollution to the surrounding environment is greatly reduced.

Owner:楼梦楚

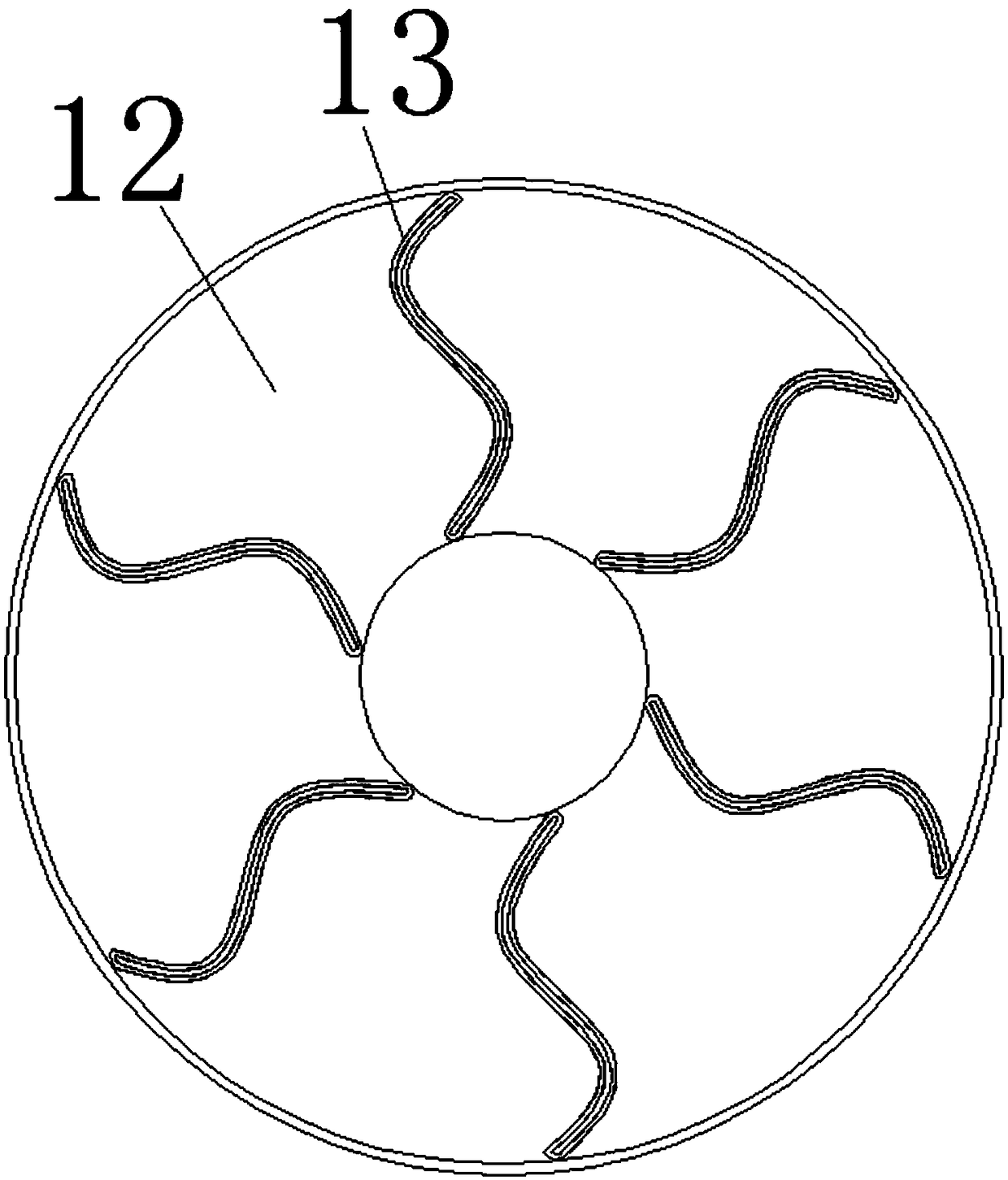

Small household food processer

InactiveCN108042015AEffective cutting and crushingEfficient crushingKitchen equipmentEngineeringFood material

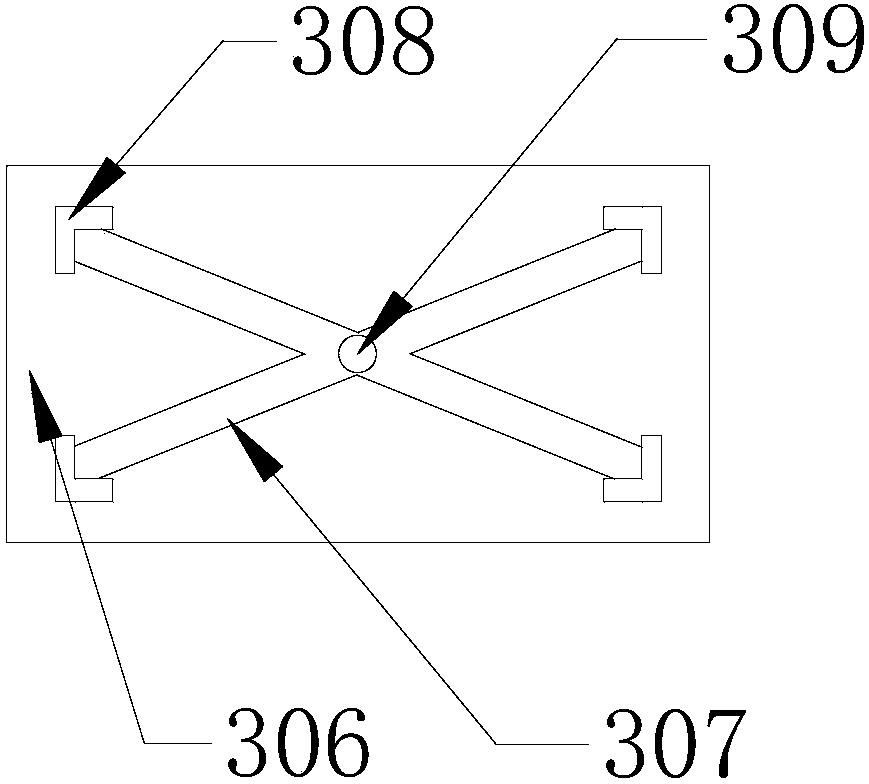

The invention relates to a small household food processer. The food processer includes a base, a stirring cup, a handle, an outer cover and an inner cover; multiple supporting legs are arranged on thelower surface of the base, a motor is arranged in the base, and a motor support is arranged below the motor; the motor is fixedly connected with the bottom surface of the interior of the base throughthe motor support, a placing table is arranged above the base, a groove is formed in the center of the placing table, and an output end of the motor penetrates through the placing table and stretchesinto the groove. By adopting a leading screw as a rotating rod and connecting a knife rest with the rotating rod, the rotating rod rotates in a reciprocating mode under the action of the servo motor;meanwhile, the knife rest rotates with the rotating rod and moves up and down in a reciprocating mode, and food materials within each horizontal plane can be effectively cut and smashed; meanwhile, the cross section of the blade point of a supporting rod on the knife rest is in a cross shape, not only is a horizontal cutting force provided during rotation, but also the food materials in the vertical direction can be cut when the knife rest moves up and down, the speed rate of smashing the food materials is further increased correspondingly, and the obtained food materials are fully smashed.

Owner:余国兰

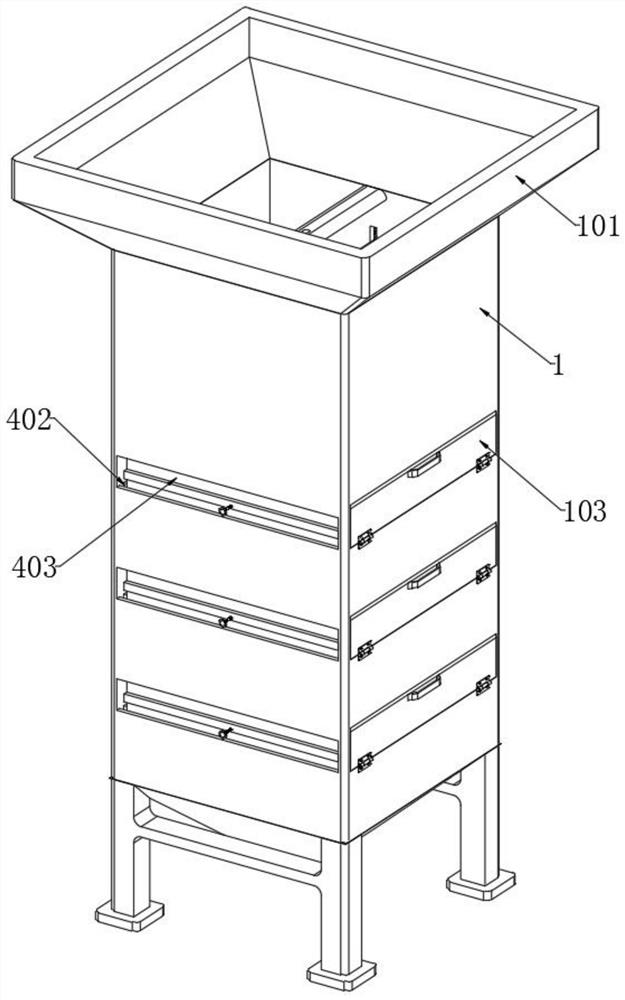

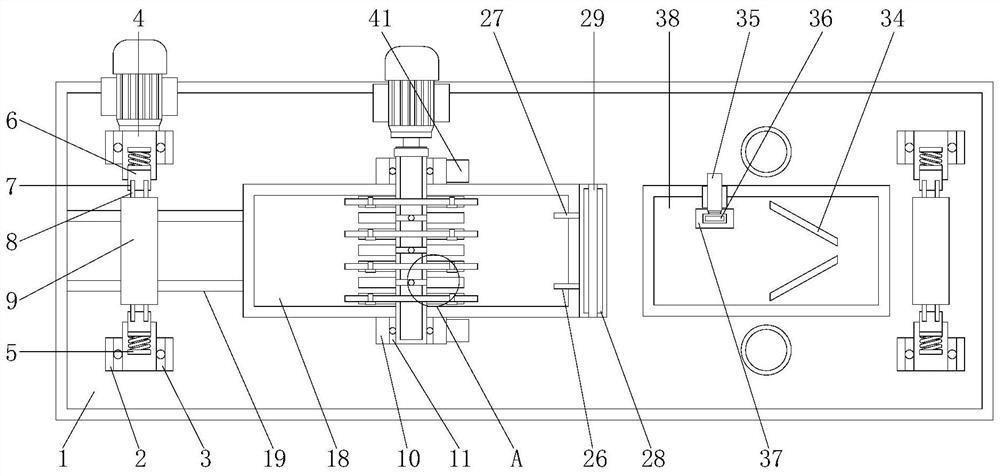

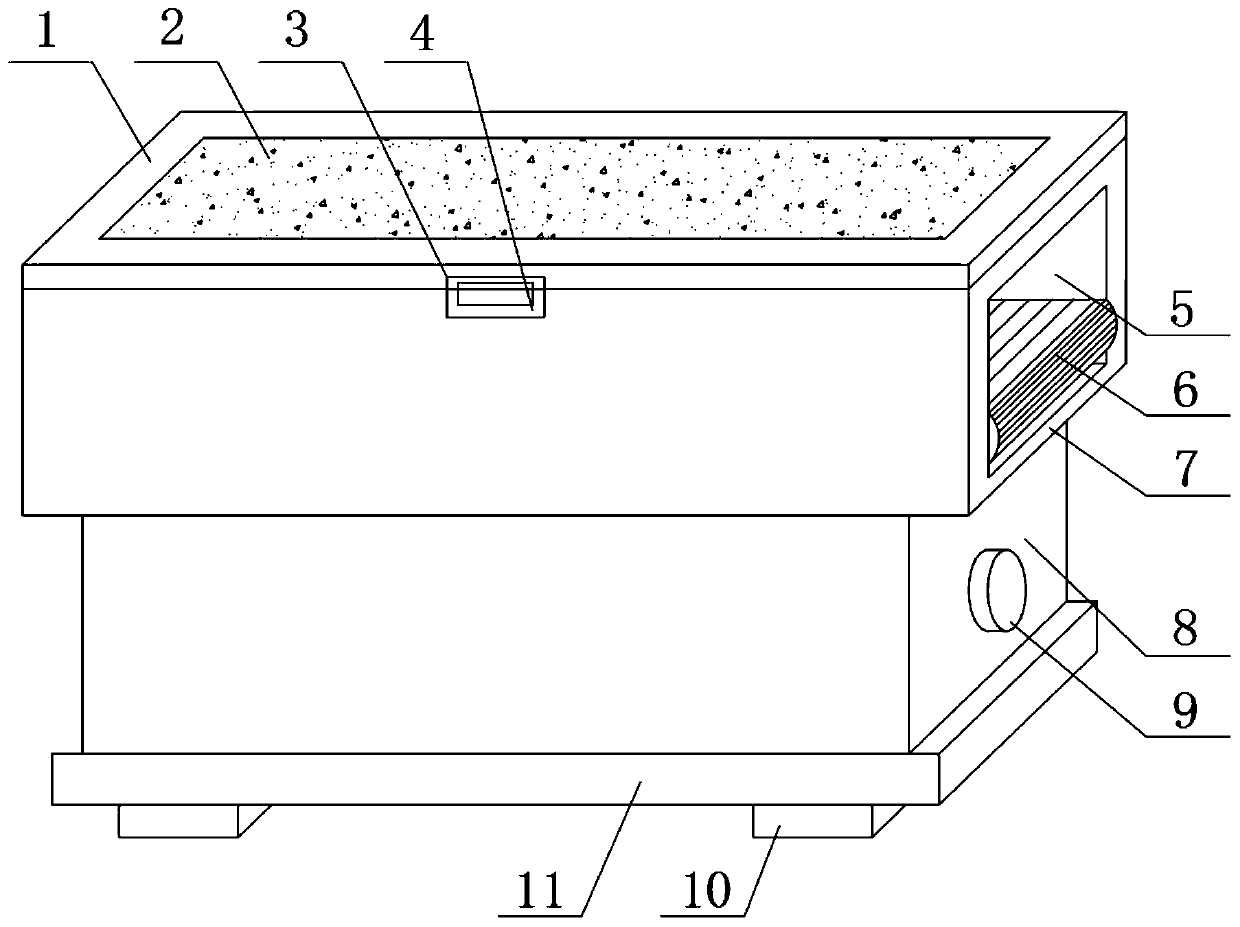

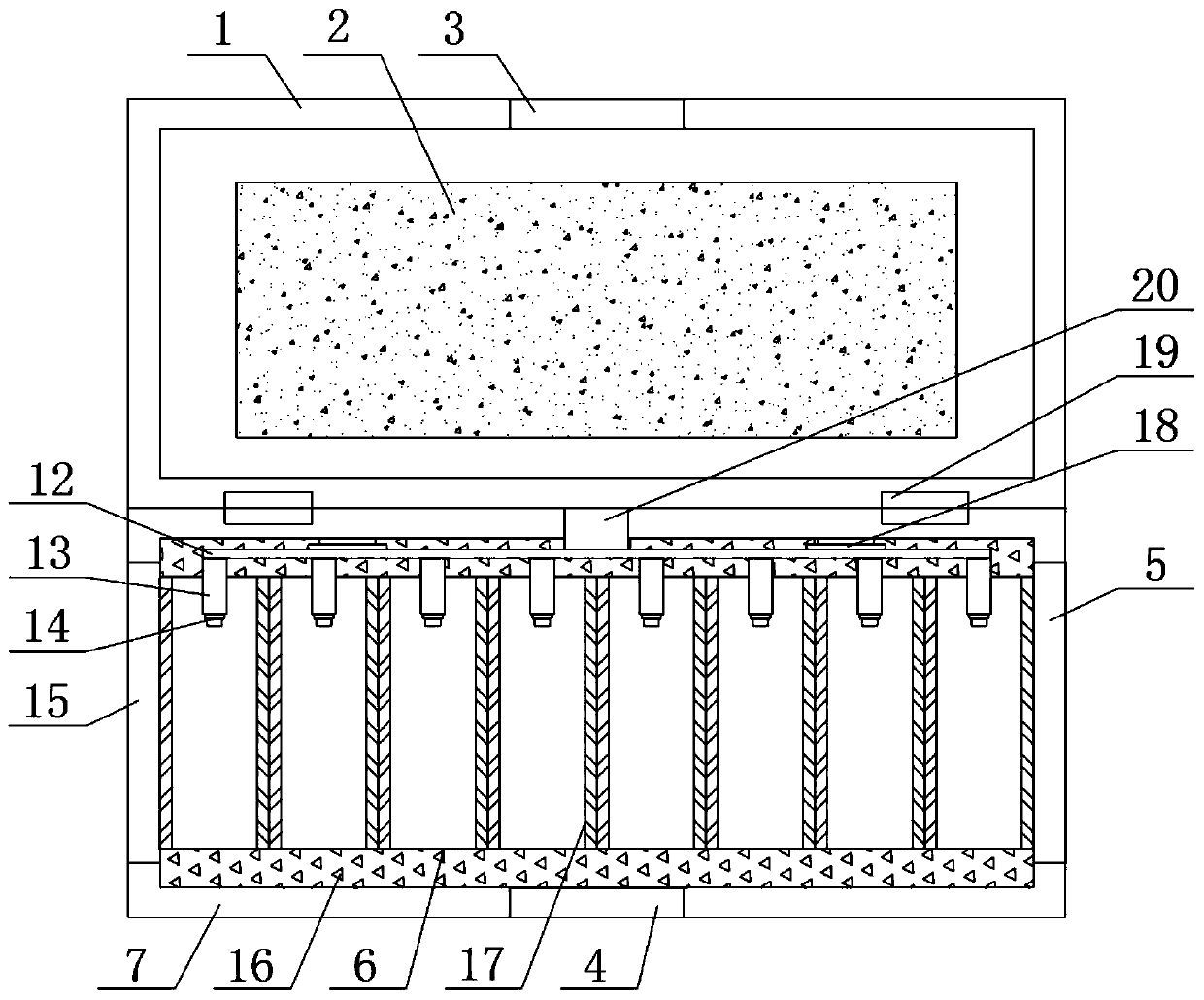

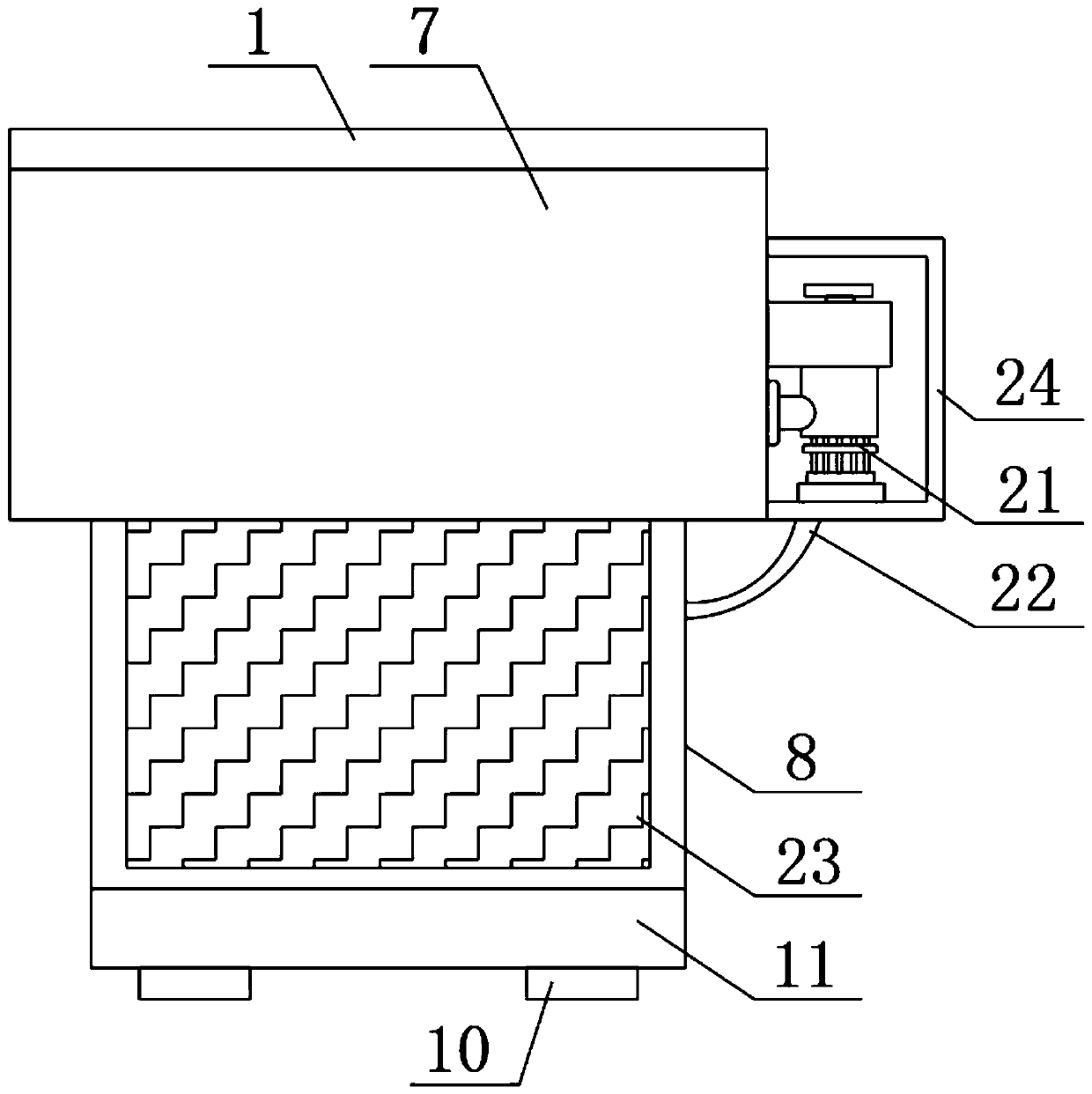

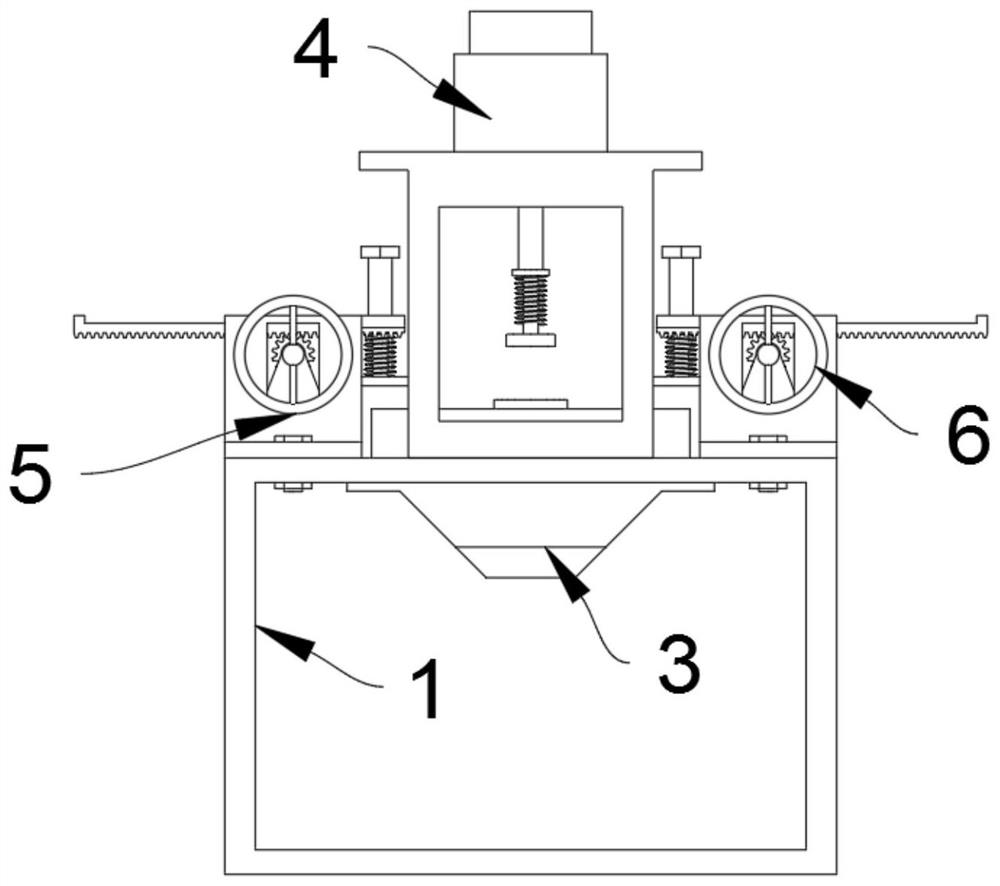

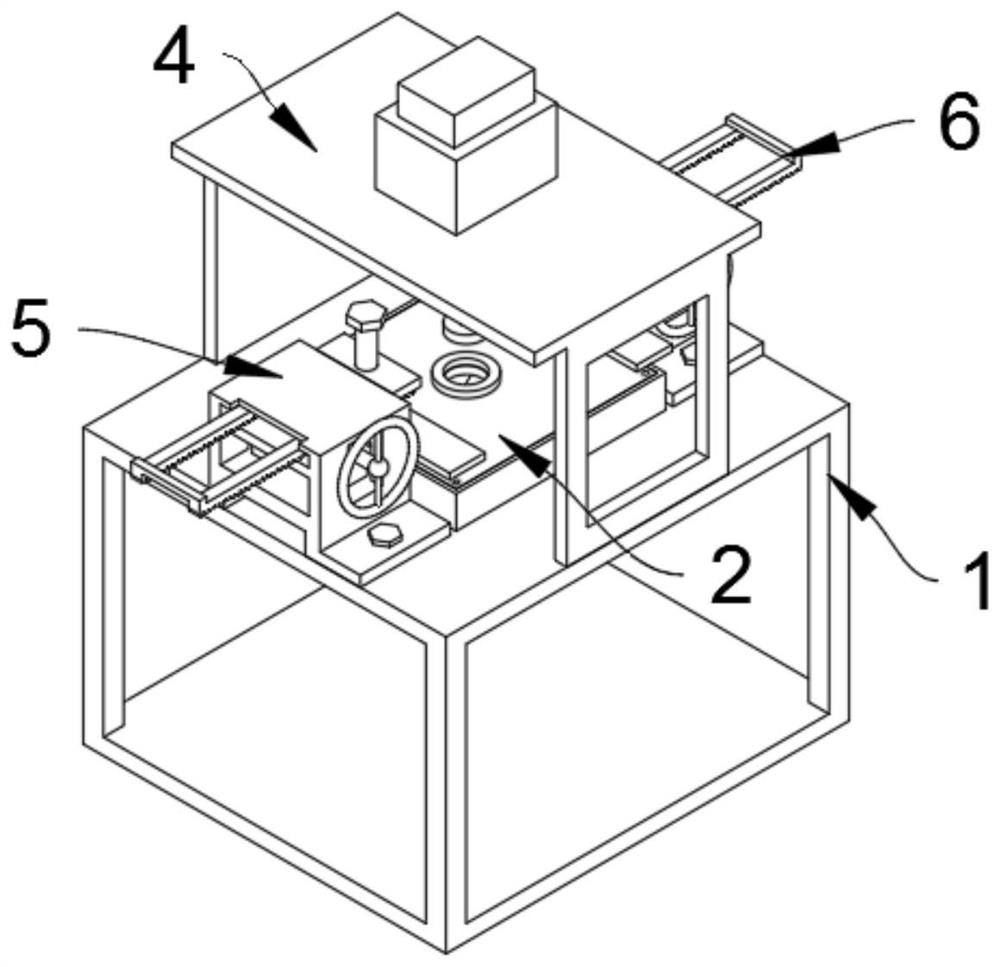

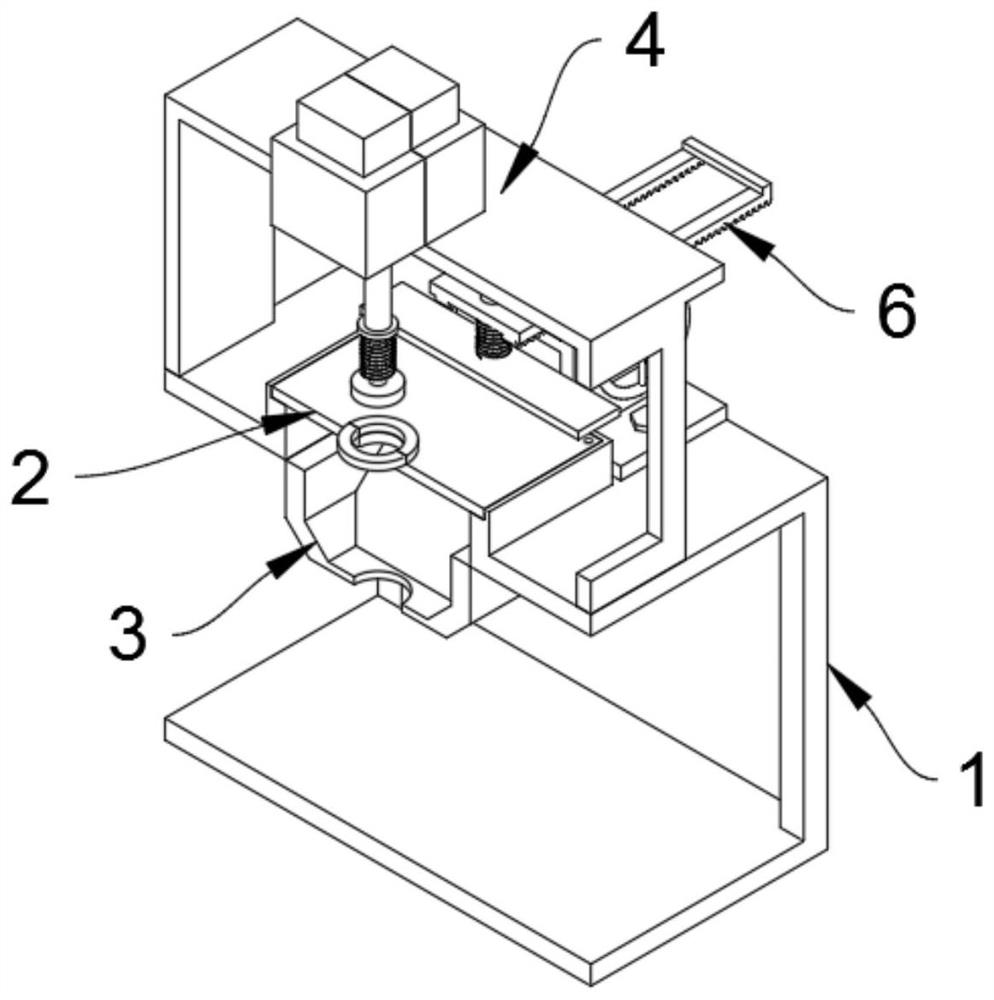

Multi-stage screening and impurity removing device for high-purity industrial salt production

ActiveCN113842976AImprove work efficiencyProtection against splashingSievingScreeningStructural engineeringProcess engineering

The invention provides a multi-stage screening and impurity-removing device for high-purity industrial salt production, relates to the technical field of industrial salt processing equipment, and aims to solve the problem that industrial salt is easy to cake and inconvenient to discharge quickly when existing industrial salt is subjected to screening and impurity-removing. The multi-stage screening and impurity-removing device comprises a main body, a crushing mechanism, a material scattering mechanism and a screening mechanism, wherein supporting legs are mounted at the included angle positions of the bottom edge of the main body; the crushing mechanism is mounted in the main body; a transverse plate in the crushing mechanism is mounted at the top of the main body, and a circular convex block is arranged on the outer side of a vertical rod in the crushing mechanism; the material scattering mechanism is installed in the main body, the material scattering mechanism is located below the crushing mechanism, and a shifting plate in the material scattering mechanism is installed at the bottom of the vertical rod; and the screening mechanism is installed in the main body, and an inner groove in the screening mechanism is formed in the inner side of the main body. Supporting plates slide on the outer side of the vertical rod, so that pressing plates at multiple positions extrude the caked industrial salt, and the caked industrial salt is in a bulk state.

Owner:洪泽大洋盐化有限公司

Coke quenching spraying anti-coke-sputtering device

The invention relates to a coke quenching spraying anti-coke-spattering device, which comprises a coke quenching tower, a coke quenching car, a sprayer, a positioner, a spattering prevention baffle, an image collector and a controller. According to the invention, a spattering prevention baffle is arranged in a coke quenching tower, and a controller controls a lifting mechanism to adjust the heightof the spattering prevention baffle, so that when the device is used for quenching coke in a coke quenching car, the situation that spraying equipment is damaged due to coke splashing is effectivelyprevented; and by arranging the controller, the water inlet amount and the water supplementing amount of the sprayer can be flexibly adjusted according to the actual temperature of coke, so that the situation of coke splashing caused by too large temperature difference in the tower is effectively prevented, and the coke quenching efficiency of the device is effectively improved.

Owner:乌海市广纳煤焦化有限公司

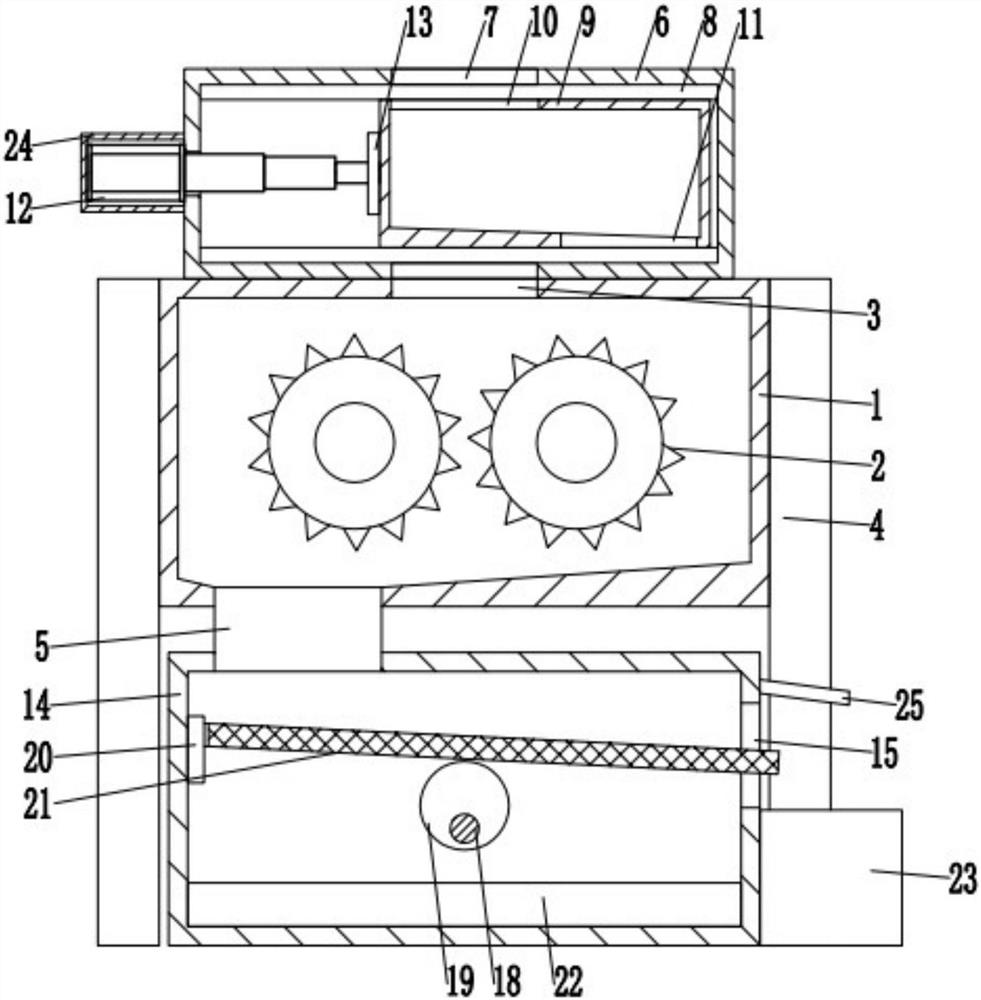

Waste lithium battery crushing and sorting device

InactiveCN112275386AReasonable structureLow costSievingScreeningElectric machineryProcess engineering

The invention discloses a waste lithium battery crushing and sorting device. The waste lithium battery crushing and sorting device comprises a crushing box, a crushing mechanism is arranged in the crushing box, the other end of a discharging pipe is connected with a screening structure, and integration of crushing and sorting is achieved; due to the arrangement of a feeding protection structure, the situation that waste chips or waste blocks generated when a worker crushes the waste lithium batteries by the crushing mechanism in the feeding process are splashed and injured is effectively prevented, the safety of the worker is guaranteed, and meanwhile production accidents are also prevented from happening; and a motor in the screening structure drives a rotating rod and an eccentric wheelto rotate, so that a screen can move up and down to screen the crushed waste lithium batteries falling onto the screen, rare metal powder can enter a collecting box through the screen to be collected,and the other waste lithium batteries can enter a waste box through the screen. Full automation of screening is achieved, and the labor cost is saved.

Owner:JIANGSU HUAHONG TECH STOCK

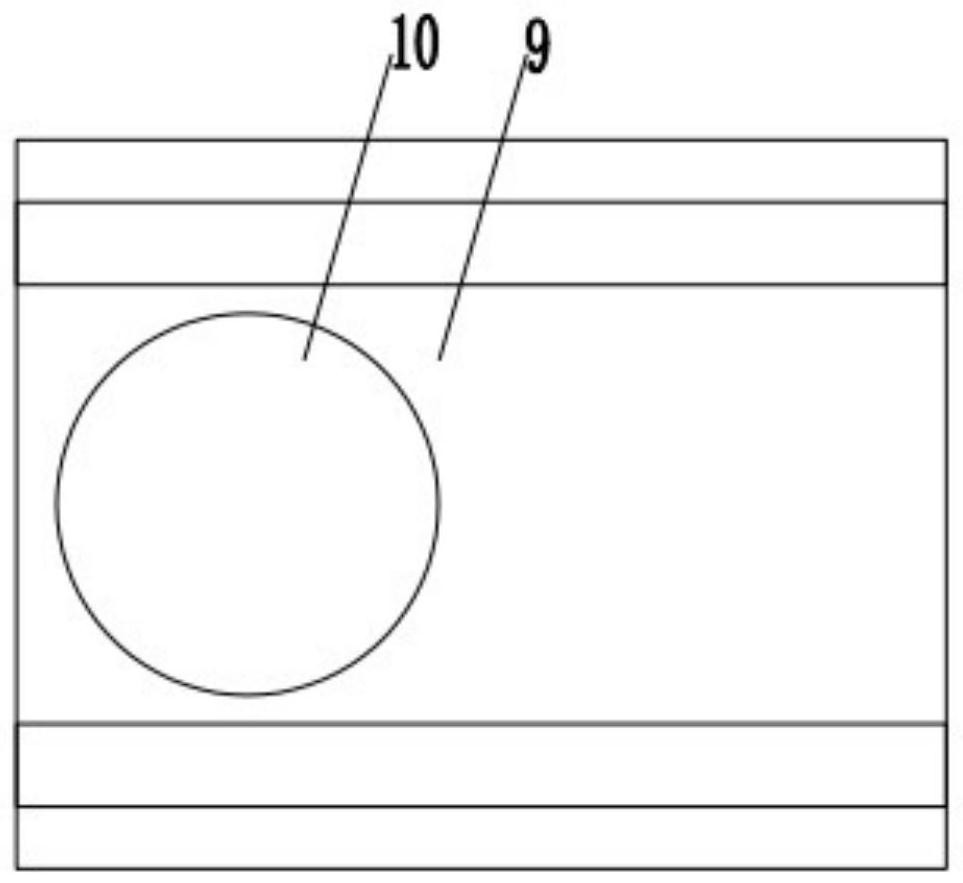

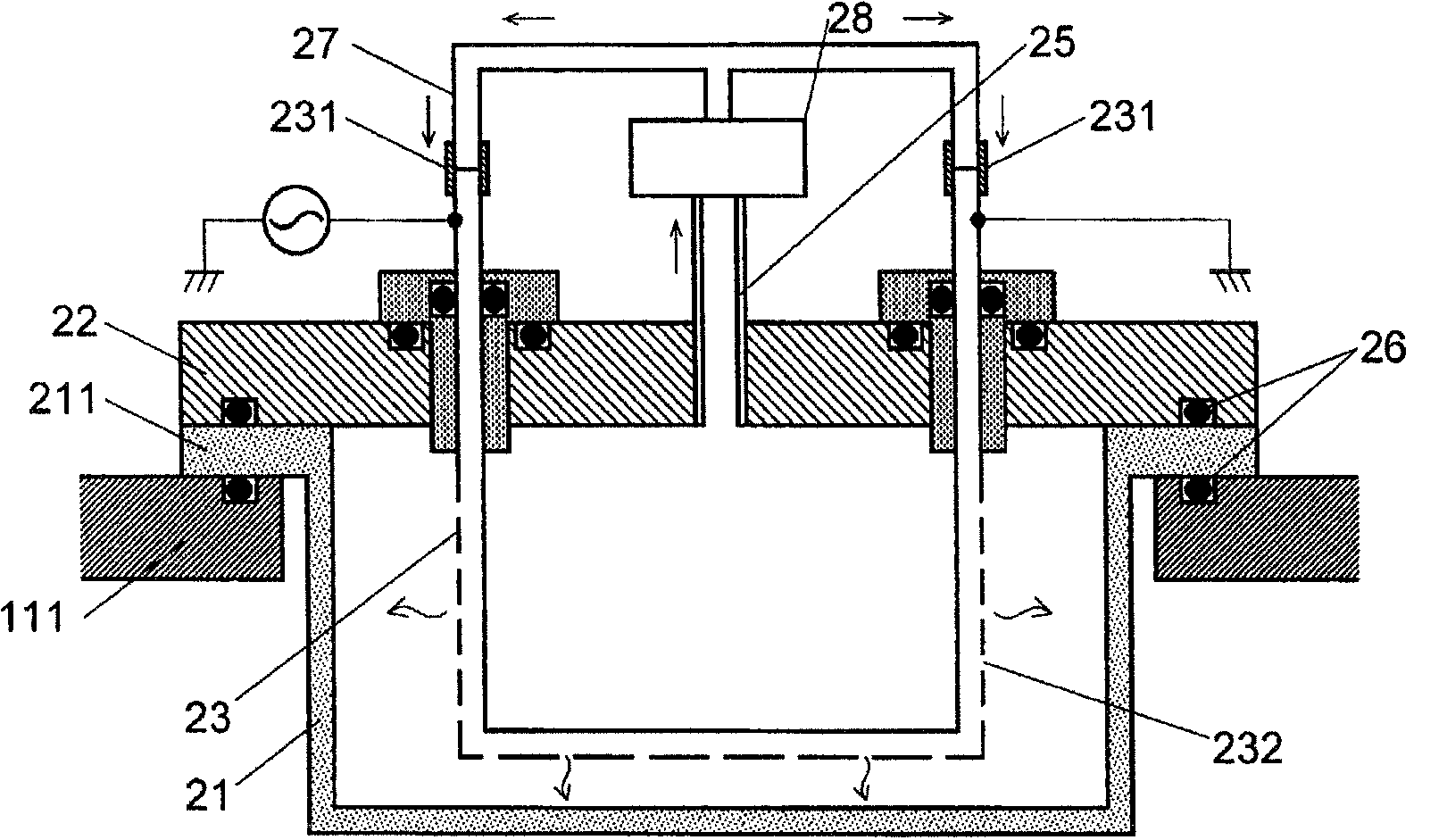

Plasma processing apparatus

ActiveCN103155718AIncrease temperatureProtection against splashingElectric discharge tubesSemiconductor/solid-state device manufacturingTrombe wallRadio frequency

The present invention provides an internal antenna type plasma processing device which is easily maintained and capable of producing stable plasma. The plasma processing device has a plurality of antenna units 20 provided in the top wall 111 of a vacuum chamber 11. Each of the antenna units 20 includes: a dielectric housing 21 provided to protrude into the vacuum chamber 11 from the top wall 111 of the vacuum chamber 11; a cover 22 having a second gas discharge port 25 for discharging the atmosphere in the housing to the outside of the vacuum chamber; and a radio-frequency antenna 23 formed by a conductor tube which is fixed to the cover 22 by way of a feedthrough 24 and has gas passage holes 232 in its tube walls. An inert gas is supplied into the tube of the radio-frequency antenna 23, and the inside of the housing 21 is filled with the inert gas provided through the gas passage holes 232. The inert gas is discharged to the outside of the vacuum chamber 11 through the second gas discharge port 25.

Owner:ELECTRO-MOTIVE DIESEL

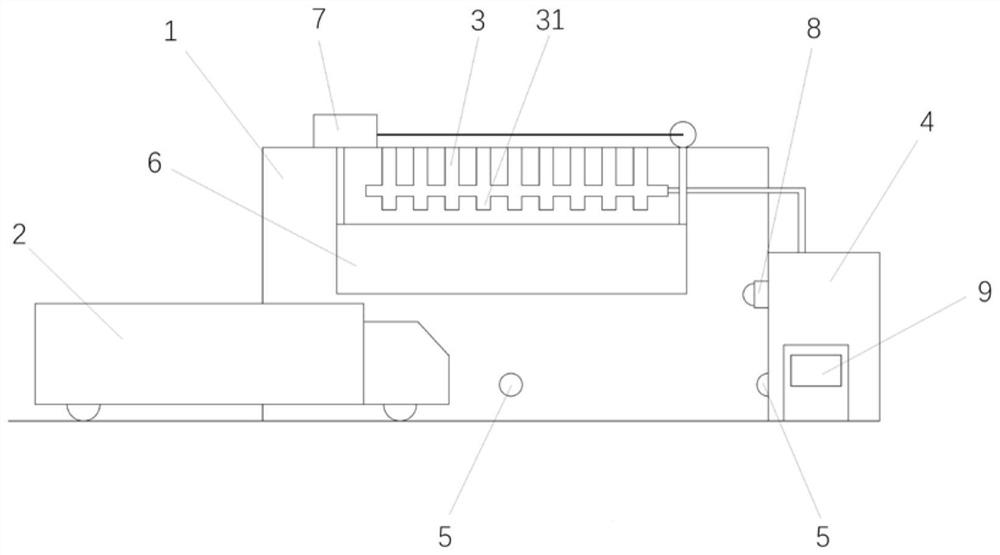

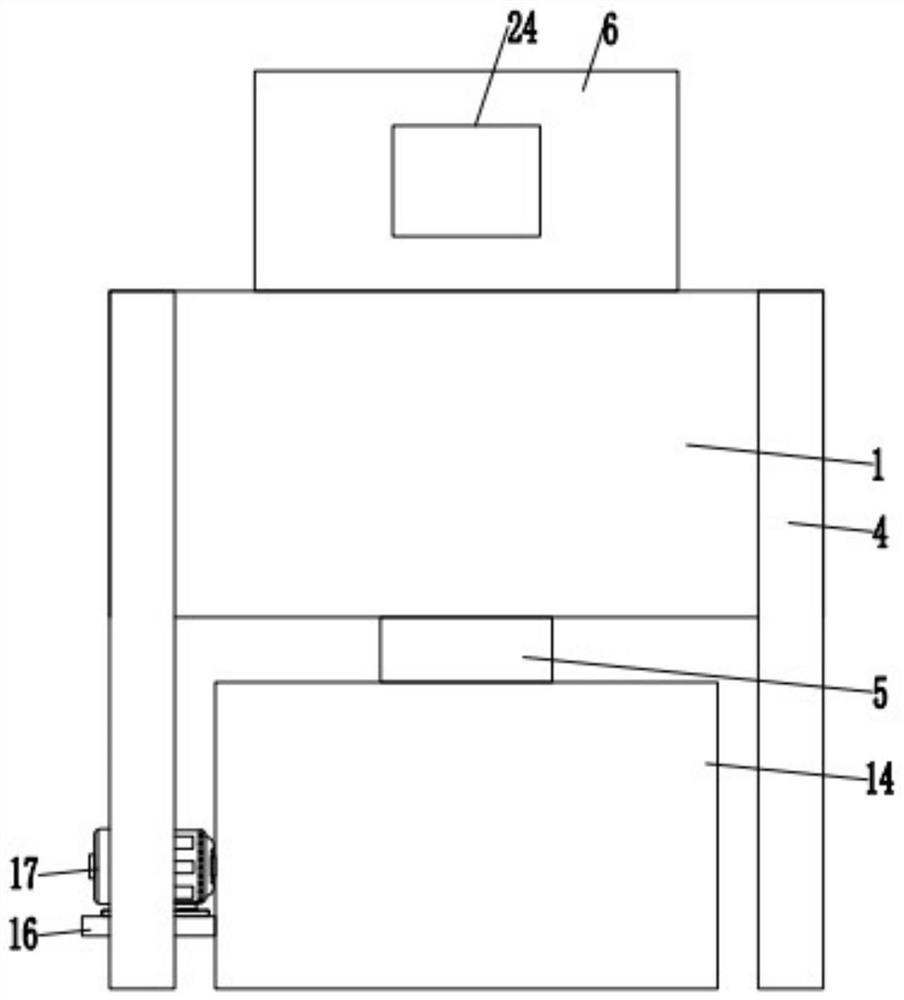

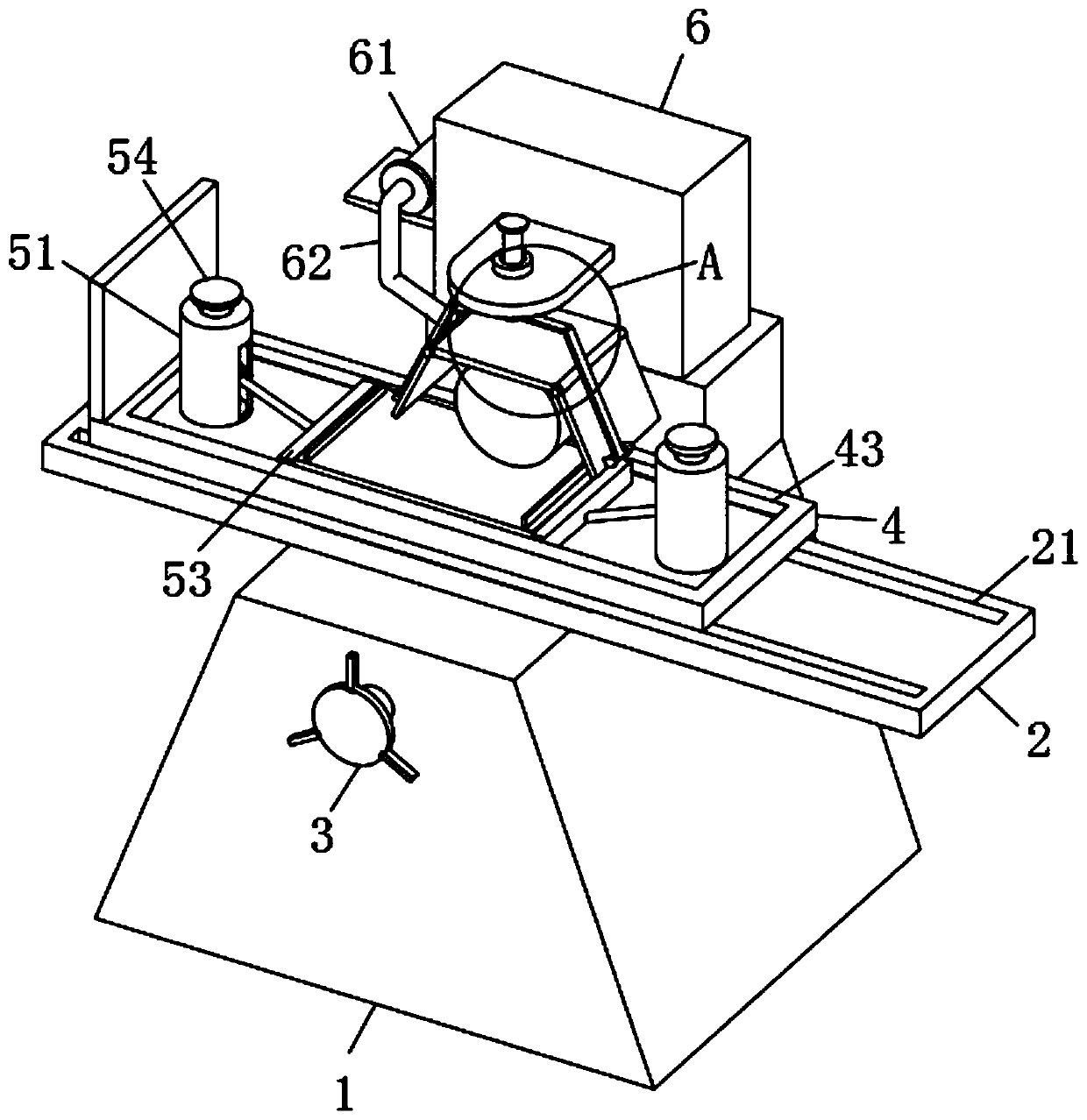

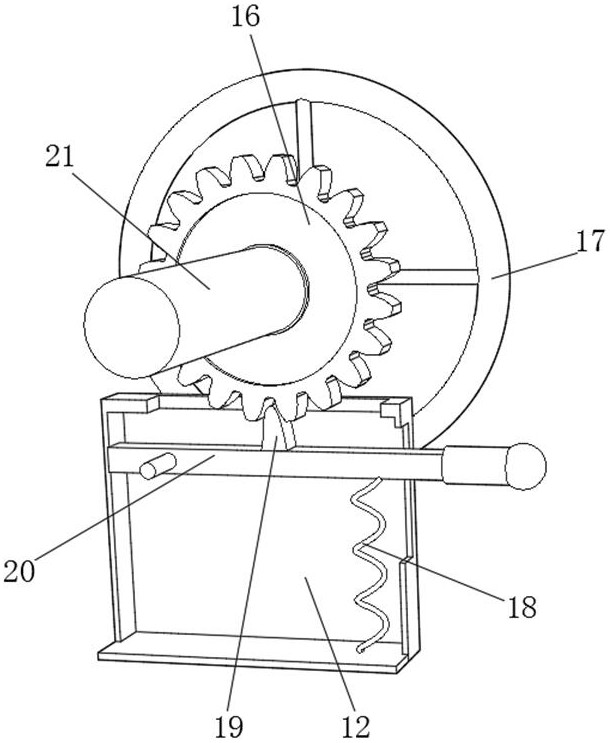

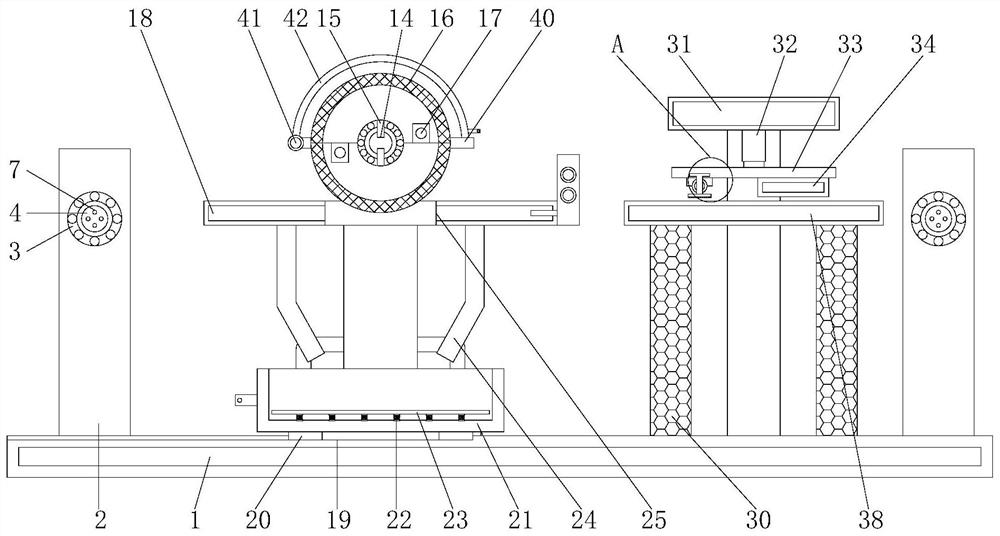

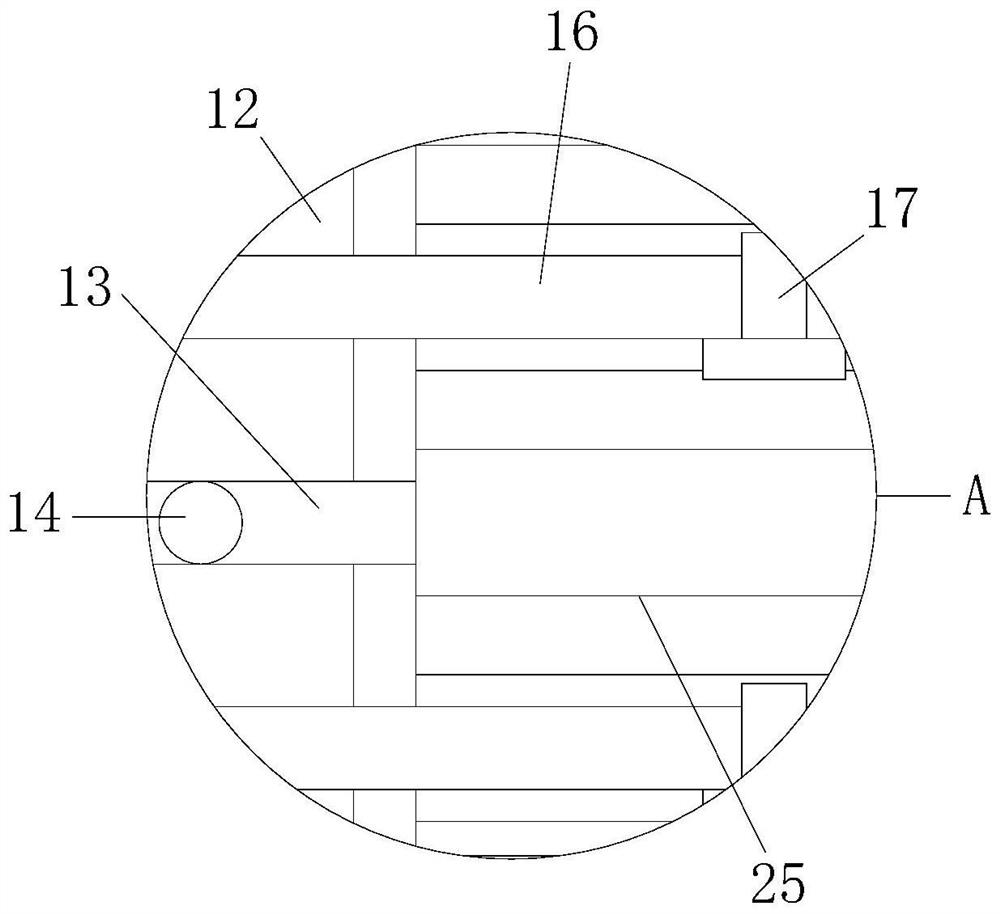

Grinding machine with positioning device for preventing sweeps from splashing

InactiveCN110509157AEasy height adjustmentProtection against splashingGrinding carriagesGrinding machinesEngineeringMechanical engineering

The invention discloses a grinding machine with a positioning device for preventing sweeps from splashing. The grinding tool comprises a base, a machine bed, a sliding frame and a protection cover. Asupporting plate is welded to the upper surface of the base, and the sliding frame is movably arranged on the upper surface of the supporting plate. A rotary rod is rotationally inserted into one side of the base, and a gear is welded to one end of the rotary rod. A first lead screw is pushed, so that the first lead screw extrudes a movable ring downwards, a guide rod is stressed and pushes a push plate to slide at this moment, and finally the end of a workpiece is clamped. One end of a spring is connected with the upper surface of the movable ring, the height of the movable ring in a limiting frame can be adjusted conveniently, and finally the position of the push plate on the surface of the sliding frame is controlled. By changing the position of a first connecting rod, so that one endof a second connecting rod drives the included angle between the one end of a protection plate and the protection cover to change, and therefore the surfaces of workpieces with different lengths are covered, and the situation of sweep splashing is avoided.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

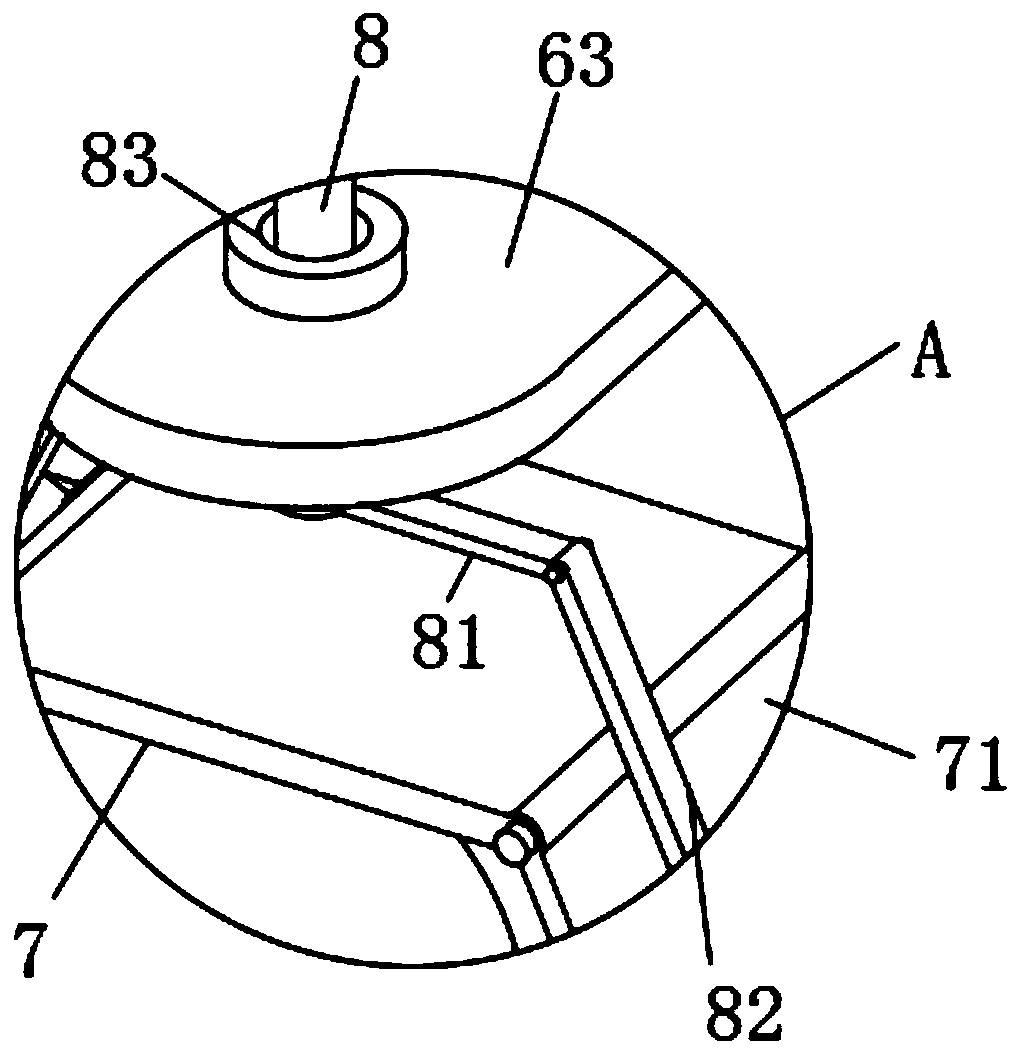

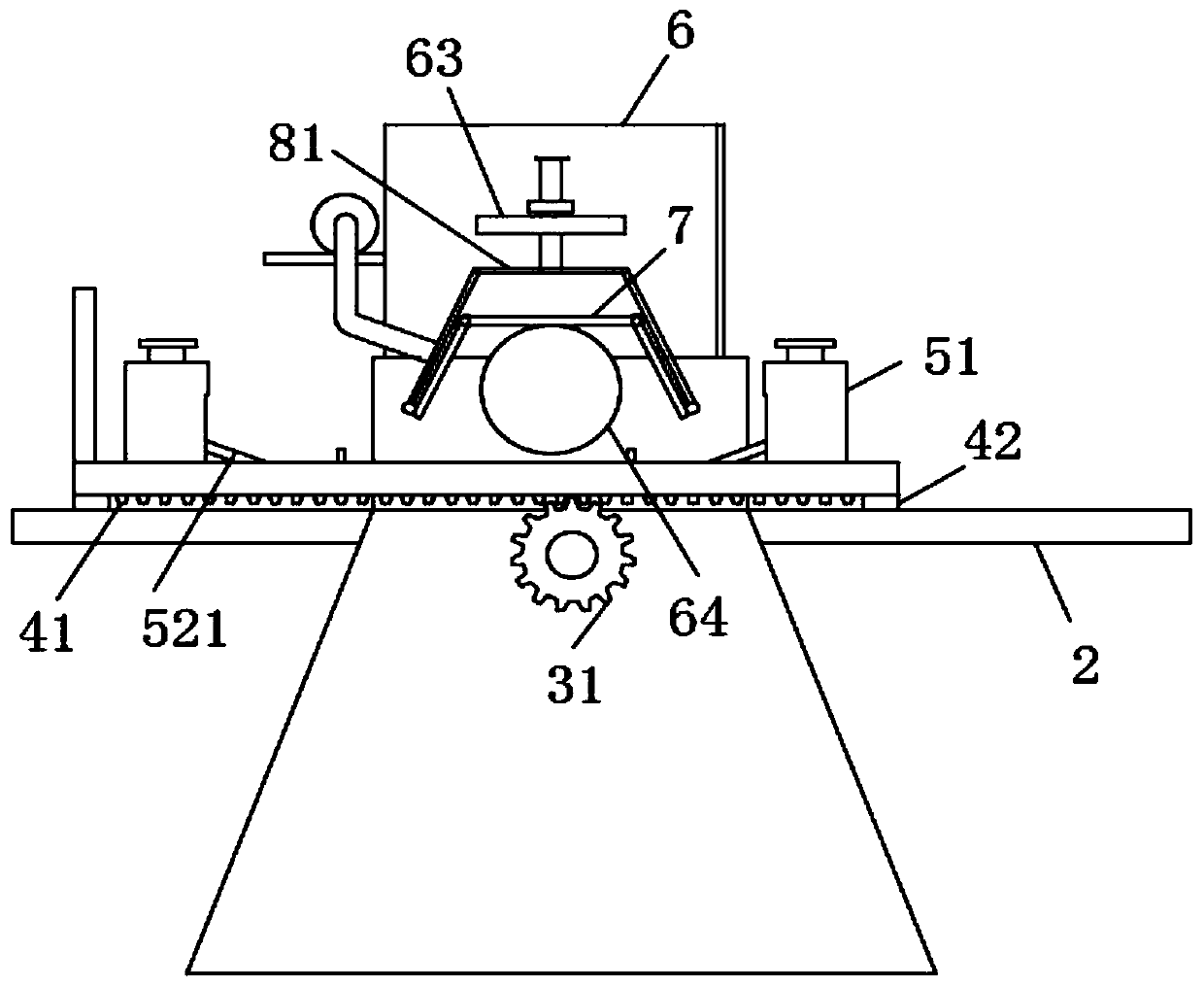

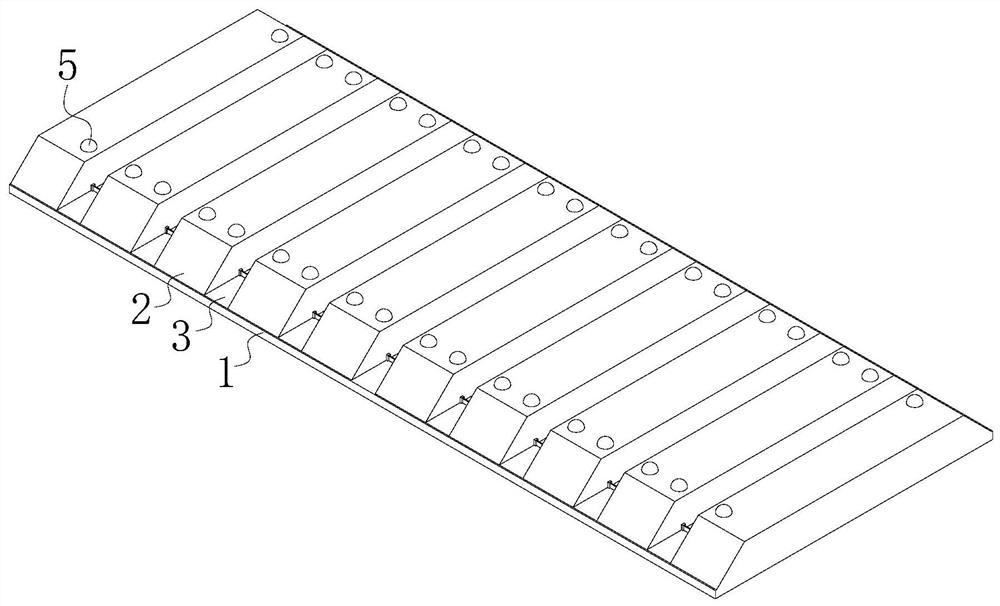

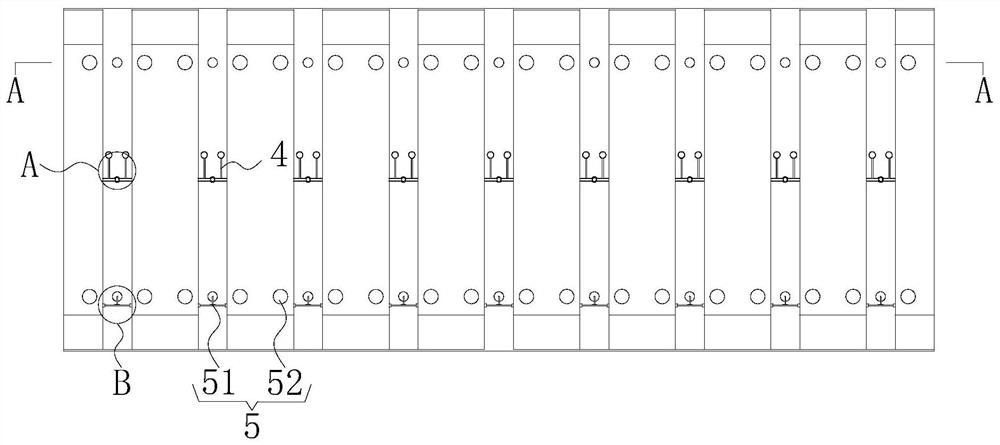

Self-adaptive pavement deceleration strip

InactiveCN112030802AWill not be blockedAvoid affecting drainageTraffic signalsRoad signsSpeed bumpStructural engineering

The invention discloses a self-adaptive pavement deceleration strip, and relates to the technical field of deceleration strips. The self-adaptive pavement deceleration strip comprises a bottom plate,a casting is welded to the top of the bottom plate, drainage grooves distributed in a row shape at equal intervals are formed in the casting, front ends and rear ends of the drainage grooves penetratethrough the front side and the rear side of the casting correspondingly, a water accumulation preventing mechanism is arranged in the middle of each drainage groove, and a splashing preventing mechanism is arranged in each drainage groove; and the water accumulation preventing mechanism comprises a water collecting tank, a pin shaft, a sliding cylinder, a rotating piece, an air bag, a wire grooveand a stretching soft rib. According to the self-adaptive road surface deceleration strip, the water accumulation prevention mechanism is matched with the splash preventing mechanism, the height of accumulated water on the road surface serves as a signal for autonomous operation, flowing of road surface runoff in the direction towards a road surface drainage facility is effectively promoted, thedrainage effect is improved, and meanwhile the height of accumulated water around the deceleration strip can be controlled; and a road runoff flow velocity can also be hindered by reducing the accumulated water height.

Owner:ZHEJIANG AGRI BUSINESS COLLEGE

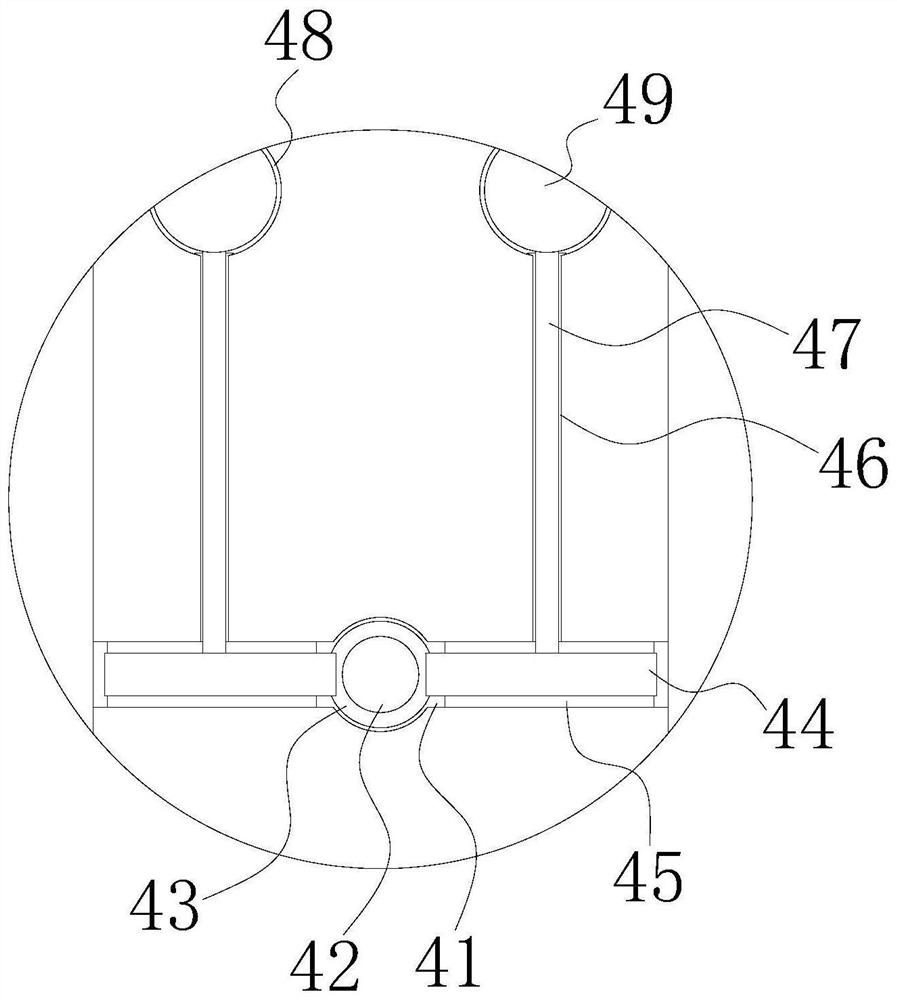

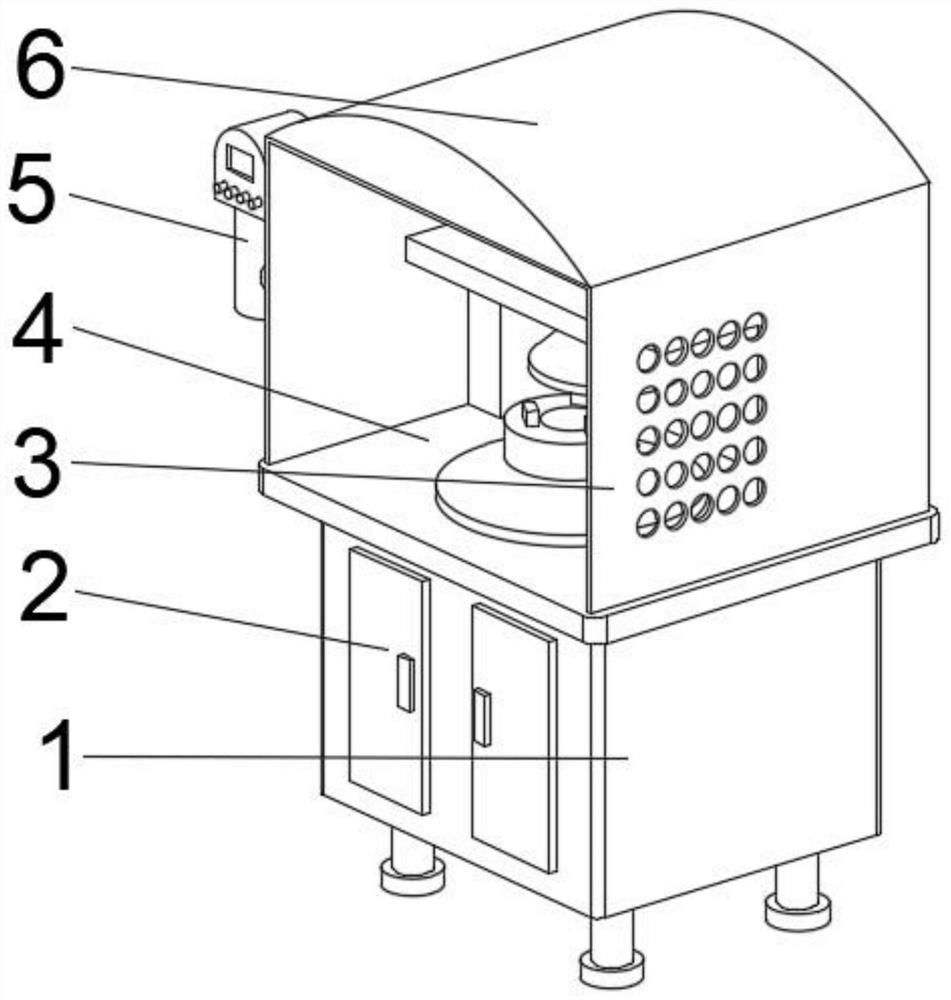

Anti-splashing mechanism of stirring pot for preparation of cosmetics made of animal and plant extract

InactiveCN112295470AImprove securityReduced cross-sectional areaShaking/oscillating/vibrating mixersTransportation and packagingMechanical engineeringBiotechnology

The invention relates to the technical field of cosmetic preparation, and discloses an anti-splashing mechanism of a stirring pot for preparation of cosmetics made of animal and plant extract. The anti-splashing mechanism comprises a rack, wherein the top of the rack is movably connected with two rotating shafts, one side of each rotating shaft is fixedly connected with a rotating plate, one sideof each rotating plate is fixedly connected with a stirring barrel, a plurality of guide rails are fixedly connected to the inner wall of one side of the stirring barrel, a material removing plate isfixedly connected to the inner wall of one side of the stirring barrel, a plurality of scraping grooves are formed in the upper surface of the material removing plate, and a top cover is fixedly connected to the top of the stirring barrel. According to the invention, raw materials remaining on a stirring frame can be removed, splashing of the raw materials when the top cover is opened is prevented, working safety is improved, the cross sectional area of the raw materials during discharging can be reduced when the impact of the raw materials on the material blocking frame is large, splashing ofthe raw materials is prevented, and a hand wheel can be rotated to enable a stirring barrel to incline and shake, so stirring is more sufficient, and working efficiency is improved.

Owner:湖南华联康生物科技有限公司

Anti-fracture titanium alloy milling cutter

PendingCN113909546APrevent debris from flyingImprove securityMilling cuttersWorkpiecesMilling cutterTitanium alloy

The invention discloses an anti-fracture titanium alloy milling cutter which comprises a milling cutter main body and a protective sleeve. The outer surface of the milling cutter main body is sleeved with the protective sleeve; first connecting holes are formed in the outer surfaces of the protective sleeve and the milling cutter main body in a penetrating manner, threads are arranged on the inner surfaces of the first connecting holes, and a threaded rod is mounted in the first connecting holes; and one end of the threaded rod is in threaded connection with a nut. According to the anti-fracture titanium alloy milling cutter, by installing the protective sleeve, the first connecting holes, the threaded rod and the nut, the milling cutter main body is inserted into the protective sleeve firstly, then the milling cutter main body is pulled up and down, the length of the portion, exposed out of the protective sleeve, of the milling cutter is adjusted, and then the threaded rod is connected with the first connecting holes, so that the milling cutter main body and the protective sleeve can be fixed, and the situation that the milling cutter is broken due to the fact that the exposed length of the milling cutter main body is too long can be avoided to a certain extent.

Owner:苏州馨威盛切削工具有限公司

Method for detecting heavy metals in nutrition ground rice

ActiveCN106970170AReduce testing costsHigh detection sensitivityComponent separationNutritionPeak area

The invention discloses a method for detecting heavy metals in nutrition ground rice. The method comprises the following steps that 1, taking a to-be-tested sample, adding nitric acid for heating and teaming, and adding concentrated sulfuric acid for programming temperature increasing treatment; 2, performing ashing three times on the treated sample; 3, adding hydrochloric acid into the sample ashed in the step 2, performing sealing and soaking, then, adding a methyl alcohol-water mixed solution into the soaking solution, placing the solution into an ultrasonic apparatus for performing ultrasonic treatment, performing cooling to reach the room temperature, adjusting the pH to be neutral, transferring the solution into a volumetric flask and adopting the methyl alcohol-water mixed solution for the constant volume to obtain the treated to-be-tested sample; 4, adopting a high performance liquid chromatograph for detecting the treated to-be-tested sample, and calculating the content of heavy metals in the to-be-tested sample through the peak area. According to the heavy metals detection method, the detection flexibility is high, the repeatability is good, the detection accuracy is high, the apparatus and equipment are easy to use, low in detection cost and easy to obtain, and detection of various heavy metals can be performed at the same time.

Owner:广东一家人食品有限公司

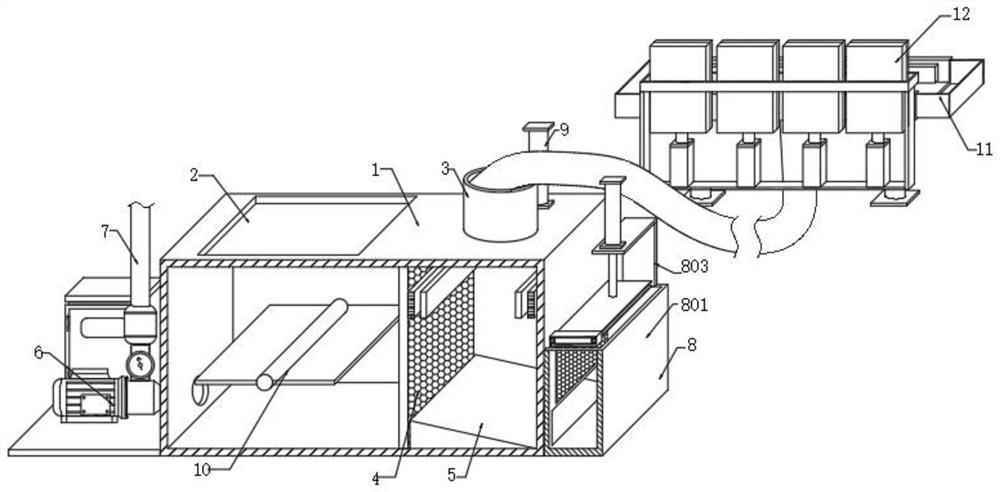

Grinding device used for solid waste recovery

InactiveCN107930758AProtection against splashingSafe and stable structureGrain treatmentsFixed framePulp and paper industry

The invention discloses a grinding device used for solid waste recovery. The grinding device used for solid waste recovery comprises a power box, a fixing frame, a case, a water tank, a bottom frame,a baffle, a water inlet, a spraying frame, nozzles, water pipes, spraying pipes, a roller, a rotary shaft, a conveying belt, a clamping plate, connecting pipes and a connecting hole. The grinding device used for solid waste recovery has the beneficial effects that the baffle of an arc-shaped structure is installed on the side wall of the bottom frame and used for sheltering waste splashed in the grinding process of the roller, and thus the situation that waste is splashed when ground is effectively prevented; the water tank is installed at the top of the bottom frame and connected with the spraying frame right facing the roller through the two connecting pipes so that sundries adhering to the roller can be washed away by water sprayed out from the nozzles after the roller is used, and manual cleaning by workers is not needed; and the spraying pipes are obliquely installed on the outer walls of the two sides of the bottom frame and connected with the spraying frame through the water pipes, and the spraying pipes right face the inner wall of the baffle so that waste adhering to the baffle can be washed away by the spraying pipes after the baffle is used.

Owner:FOSHAN TIANSHUN TECH CO LTD

Metal cutting fluid recycling and circulating flow purification equipment

ActiveCN113563961AEasy to recycleImprove recycling efficiencyMaintainance and safety accessoriesLubricant compositionProcess engineeringSewage

The invention discloses metal cutting fluid recycling and circulating flow purification equipment which is characterized by comprising a box body, a liquid adding opening formed in one side of the upper end of the box body, and a purification assembly arranged on one side, far away from a circulating pump, of the box body, wherein a liquid feeding pipe penetrates through the other side of the upper end of the box body in an embedded mode, a filter screen partition plate is fixed to an inner cavity of the box body, a sewage draining plate fixed to the inner cavity of the box body is installed on one side of the filter screen partition plate, the circulating pump is fixed to the output end of the box body, and a liquid draining pipe is fixed to the output end of the circulating pump. According to the equipment, cutting fluid can be directly recycled from different machining equipment for recycling and purifying, the equipment can be matched with the fluid discharging ends of cutting devices of different models through a material collecting groove with the telescopic size, and the cutting fluid of the cutting devices of different models can be recycled; the mode that according to an existing purification device, cutting fluid needs to be recycled and collected through equipment in advance and then poured into purification equipment is solved, and metal cutting fluid recycling is more convenient and faster.

Owner:YINGTAN HEXING FIBER COMM COMPONENTS

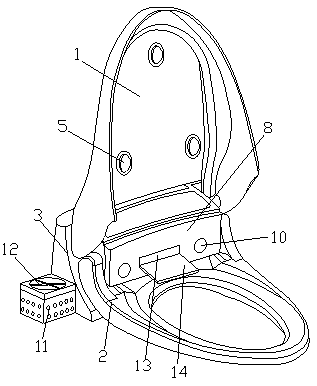

Intelligent closestool cover based on data analysis of Internet of Things

InactiveCN108420352AEasy to assemble and disassemblePlay a buffer roleBathroom coversLavatory sanitoryActivated carbonRemote control

The invention discloses an intelligent closestool cover based on data analysis of Internet of Things. The intelligent closestool cover comprises a cover body, a closetool ring and a connecting seat, wherein the cover body and the closetool ring are in hinged connection with the connecting seat, a joint bearing is arranged on the back side of the cover body and is provided with an ultraviolet disinfection lamp, an embedding groove is formed in the back side of the closetool ring, a weight sensor is arranged in the embedding groove, a rubber buffer pad is arranged on the weight sensor, the tailend of the rubber buffer pad is located outside the embedding groove, a case is arranged on the connecting seat, an Internet of Things remote-control mainframe is arranged in the case, an acrylic boxbody is arranged on the side face of the connecting seat, cellular activated carbon is arranged in the acrylic box body, an exhaust fan for drafting outside air into the acrylic box body is arranged on the acrylic box body, and the acrylic box body is hollow-out. The intelligent closestool cover based on data analysis of Internet of Things has remote control and disinfection functions.

Owner:魔水科技(北京)有限公司

A butterfly valve welding station

ActiveCN109128592BEasy to handleProtection against splashingWelding/cutting auxillary devicesDirt cleaningElectric machineryButterfly valve

The invention discloses a butterfly valve welding table. The butterfly valve welding table comprises a shell; a door sheet is movably connected in front of the top of the inner side of the shell through a hinge; support legs are fixedly connected to two sides of the bottom of the shell; vertical plates are fixedly connected to two sides of the top of the shell; the tops of the two vertical platesare connected with the bottom of a top plate; a fog cooler is fixedly connected to the top center of the top plate; and an output end of the fog cooler is in communication connection with a conveyingpipe. Through cooperative use of the shell, the vertical plates, the too plate, the fog cooler, the conveying pipe, a cylinder, a fixed shell, a connecting rod, a motor, a fan, an air sucking machine,a bent pipe, a filter plate, a vertical pipe, a water tank, a magnet, an inclined pipe, a thick pipe, a connecting shell, a water pump, a connecting pipe, a round plate, a vertical rod and a leakageplate, the butterfly valve welding table can preferably treat sparks generated in welding of butterfly valves, prevents the spark splashing condition, and prevents hidden troubles of fire.

Owner:繁昌县长城铸造厂(普通合伙)

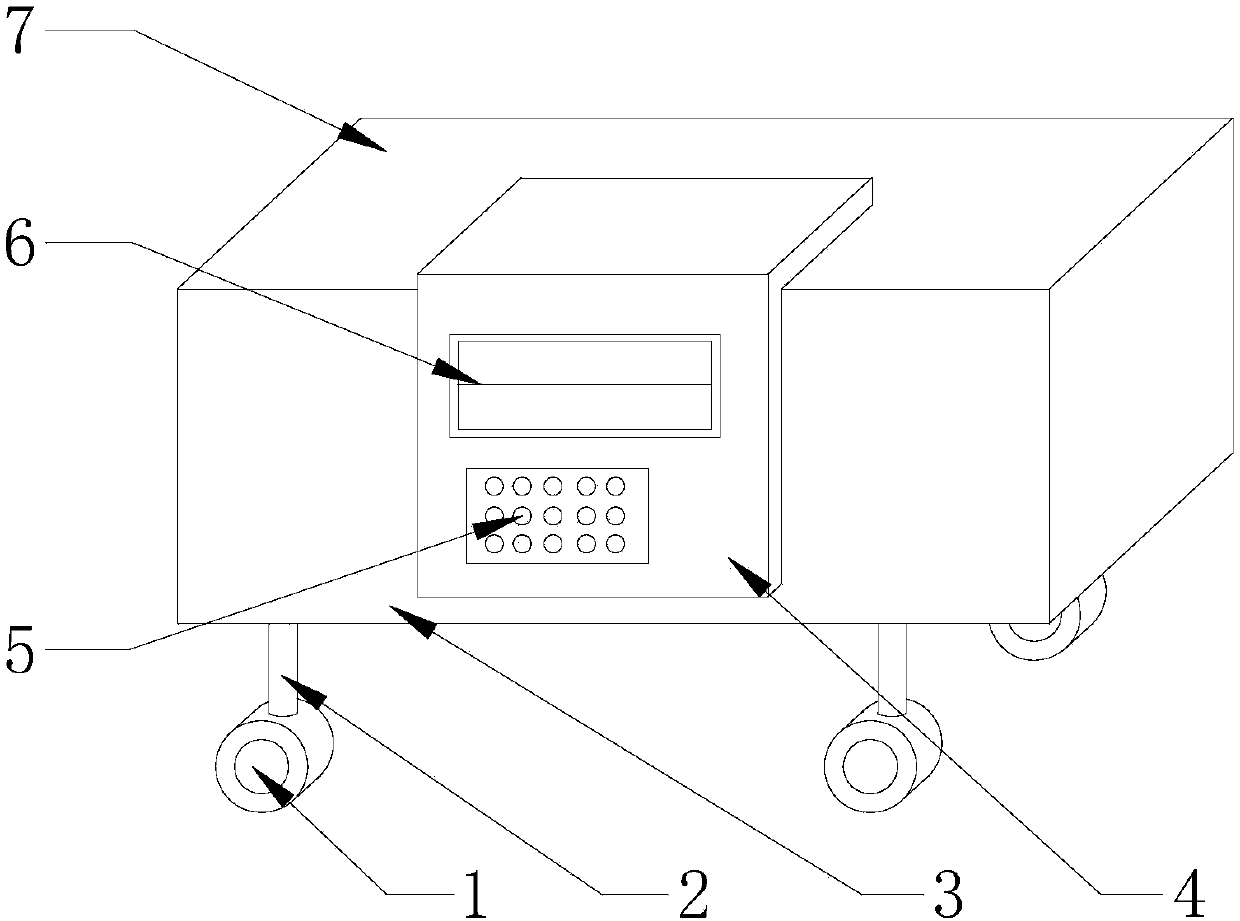

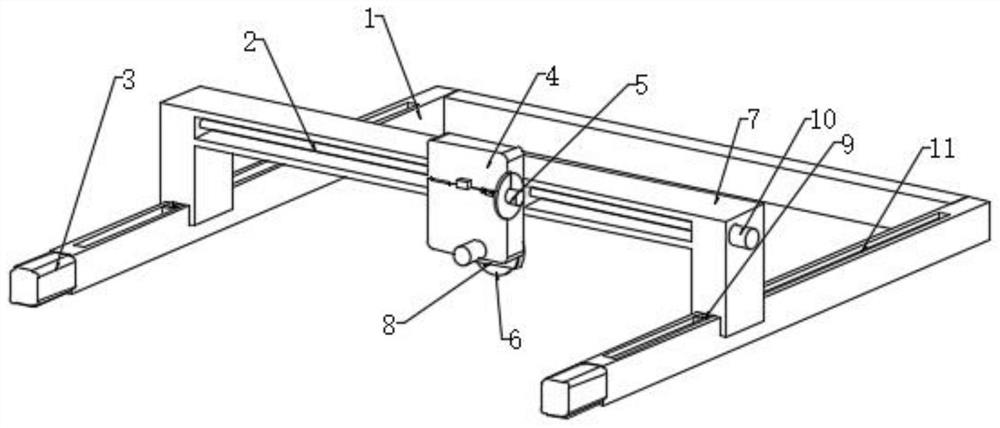

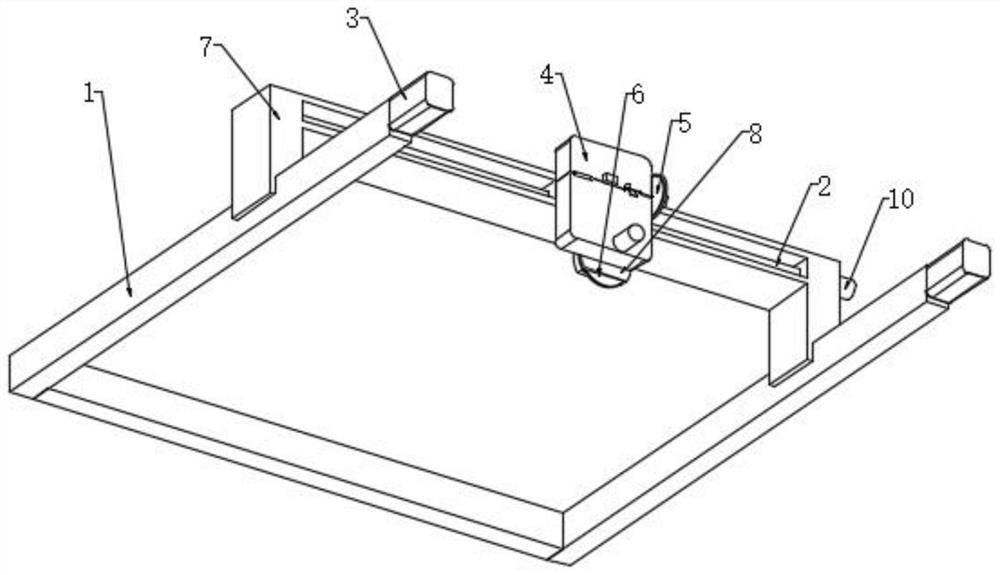

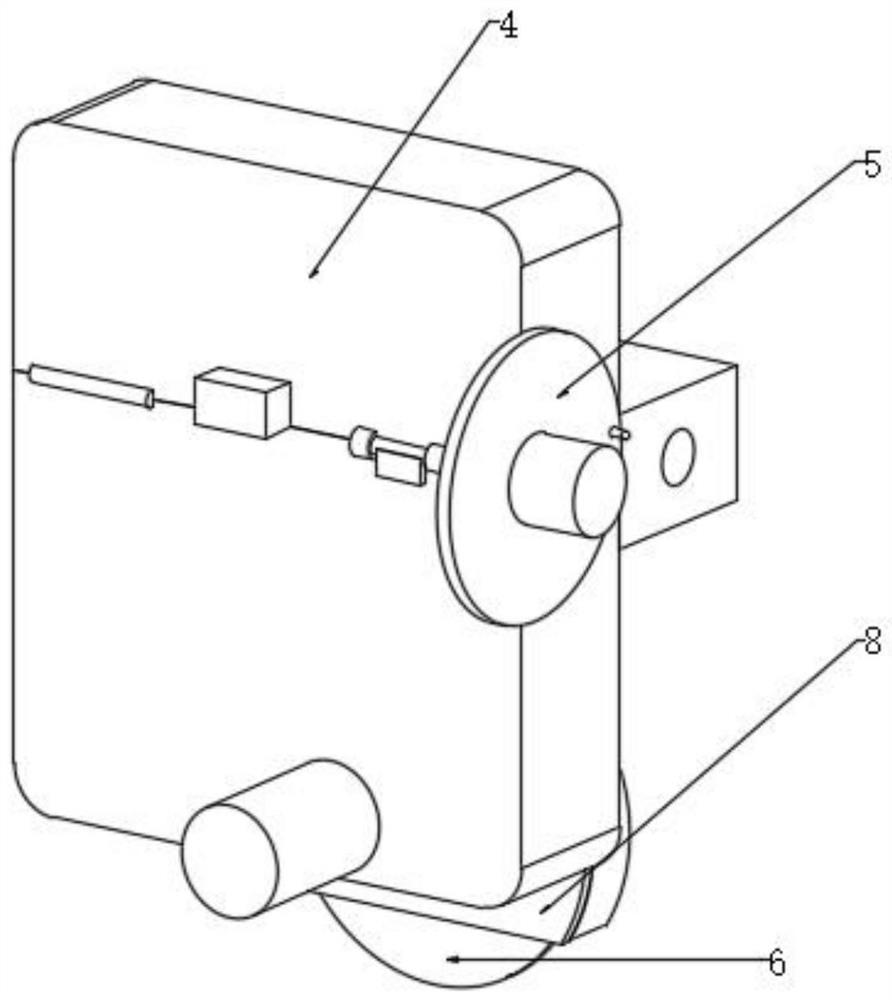

Automatic accurate cutting device for foam machining

InactiveCN108015433AEasy accessProtection against splashingLaser beam welding apparatusPulp and paper industryLaser cutting

The invention discloses an automatic accurate cutting device for foam machining. The automatic accurate cutting device for foam machining comprises a cutting device main body, a cutting device box, afixed bottom plate and a laser cutting machine. Four evenly-distributed supporting rods are fixed to the bottom of the cutting device box, and wheels are fixed to the bottoms of the supporting rods. Amovable cover plate is movably connected to the middle of the front end of the cutting device box, and a control panel is fixed to the lower portion of the front end of the movable cover plate. According to the cutting device for foam machining, the movable cover plate is arranged and movably connected with the cutting device box, the wheels are movably connected with the cutting device box, users place foam in the cutting device box, and thus through left-right movement of the movable cover plate and the cutting device box, the foam can be conveniently stored and taken by the users so as tobe machined; the foam in the cutting device box is machined in an sealed space, so that the situation that the foam splashes in the cutting process is avoided; and the automatic accurate cutting device for foam machining is suitable for production and application and has good development prospects.

Owner:江西华雅包装材料有限公司

Hand-held preliminary scraping device for peeling paint off wall surface

The invention relates to the technical field of wall surface paint processing and discloses a hand-held preliminary scraping device for peeling paint off a wall surface. The device comprises a cylinder body, a right end surface and a top part of the cylinder body are fixedly connected with a hand-held handle, a mounting plate is fixedly connected between an inner top part and a bottom part of thecylinder body, a storage battery is fixedly arranged on a right side face of the mounting plate, a left side face of the mounting plate is fixedly connected to a driving motor via a fixing frame, an output shaft of the driving motor is fixedly connected with a moment rotating shaft through a shaft coupling, and an inner side of the cylinder body is fixedly connected with a discharging tube througha mounting rack; one end, positioned far away from the driving motor, the moment rotating shaft runs through a right end surface of the discharging tube and extends to an inner side of the discharging tube; one end, positioned far away from the driving motor, of the moment rotating shaft runs through a right end surface of the discharging tube and extends to the inner side of the discharging tube. Via the hand-held preliminary scraping device for peeling paint off the wall surface, paint can be prevented from splashing when being scraped; all scraped paint residues can be conveyed, eliminatedand collected; preliminary processing of the paint peeled off a wall body can be facilitated.

Owner:浙江企信检测有限公司

Raw material rolling and slitting device for packaging box processing

InactiveCN113120667AEasy to adjustAvoid Productivity InefficienciesArticle deliveryWebs handlingStructural engineeringRaw material

The invention discloses a raw material rolling and slitting device for packaging box processing. The raw material rolling and slitting device comprises a bottom plate, a supporting column and a stabilizing support. The top of the bottom plate is fixedly connected with a supporting plate, the side of the supporting plate is fixedly provided with a first bearing, the inner wall of the first bearing is fixedly connected with a connecting rod, and the inner wall of the connecting rod is fixedly connected with a limiting spring. According to the raw material rolling and slitting device for packaging box processing, when a worker needs to adjust the distance between cutters, a mounting rod is aligned to a second clamping groove, the cutters are aligned to mounting grooves to be mounted on the outer wall of the connecting column, and then the other cutter is grabbed. Clamping blocks are installed in third clamping grooves to assemble the two cutters, and finally the two cutters are fixed through fixing bolts, so that adjustment of the distance between the cutters by the worker is made more convenient and faster, and the situation that the worker spends a large amount of time to adjust the distance between the cutters, and consequently the production efficiency is low is avoided. And the device can produce the raw materials of more specifications.

Owner:邵立

Plasma arc welding machine

PendingCN113828902AReduce the impactSimple positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPlasma arc welding

The invention discloses a plasma arc welding machine which comprises a main body box. Maintenance box doors are arranged on the two sides of the middle of the front face of the main body box, a welding device is fixedly connected to the top of the main body box, protection plates are fixedly connected to the two sides of the top of the welding device, a controller is fixedly connected to the middle of the outer wall of the right side of each protection plate, and the top of each protection plate is fixedly connected with a collection box. The plasma arc welding machine provided by the invention relates to the technical field of metal welding. According to the plasma arc welding machine, the situation that chippings splash everywhere on a working platform is prevented; the arranged plasma welding machine can move along with a vertical supporting frame, so that the situation that welding positioning deviates is avoided; the device can be separated through the supporting frame, so that the phenomenon that cleaning is not thorough due to the fact that the chippings splash everywhere during welding is prevented; and sparks generated during welding can be blocked through a protection mechanism, so that the influence of the sparks on workers is effectively reduced, and the labor intensity of the workers is conveniently reduced.

Owner:任伟

Roller internal water cooling device for rolling mill accessory machining

InactiveCN110961461AReduce consumptionTo achieve the effect of circulating water coolingRollsMetal rolling arrangementsWater filterElectric machinery

The invention discloses a roller internal water cooling device for rolling mill accessory machining. The cooling device comprises a machine body; a base is fixedly mounted at the bottom of the machinebody; a workbench is arranged at the top of the machine body. A pressing plate is arranged at the top of the workbench. A water tank is arranged in the machine body; a conveying belt is arranged in the workbench. Roller clamping grooves are formed in the surface of the conveying belt. Two belt wheels are rotationally connected to the two sides of the interior of the conveying belt. A motor box isarranged in the middle in the conveying belt; a motor is arranged in the motor box; a motor shaft is arranged at one end of the motor; by means of a circulating water pump, water in the water tank can be pumped through the circulating water pump and then sprayed out of a water spraying head through a roller inserting rod, so that water cooling treatment is conducted on the interior of the hollowroller, the sprayed water is filtered through the water filtering plate and falls back to the water tank again, the circulating water cooling effect is achieved, and consumption of water resources isgreatly reduced.

Owner:MAANSHAN XINJIA MACHINERY MFG

Stamping device for automobile chassis part production

PendingCN112222318AAvoid damageProtection against splashingMetal-working feeding devicesShaping safety devicesMotor vehicle partRack and pinion

The invention provides a stamping device for automobile chassis part production, relates to the technical field of automobile part stamping, and solves the problem that when an existing automobile part is stamped, scraps cut off by stamping are prone to splashing under the influence of pressure acting force, the splashed scraps with certain penetrating forces will damage staff around the equipmentand an electromagnetic clamp cannot play a fastening role as some parts are not made of steel and iron materials. The stamping device for automobile chassis part production comprises a bracket mechanism, a first limiting mechanism and a second limiting mechanism, wherein a platen mechanism is fixedly connected to the middle of the top of the bracket mechanism. When the device is used, a part, needed to be stamped, of an automobile is placed on a placement plate, the position, needed to be stamped, of the part is located over an alignment hole, and at the moment, a worker rotates an annular disc at the front end of a rotating shaft A clockwise to enable a rack A to slide rightward.

Owner:赵敏

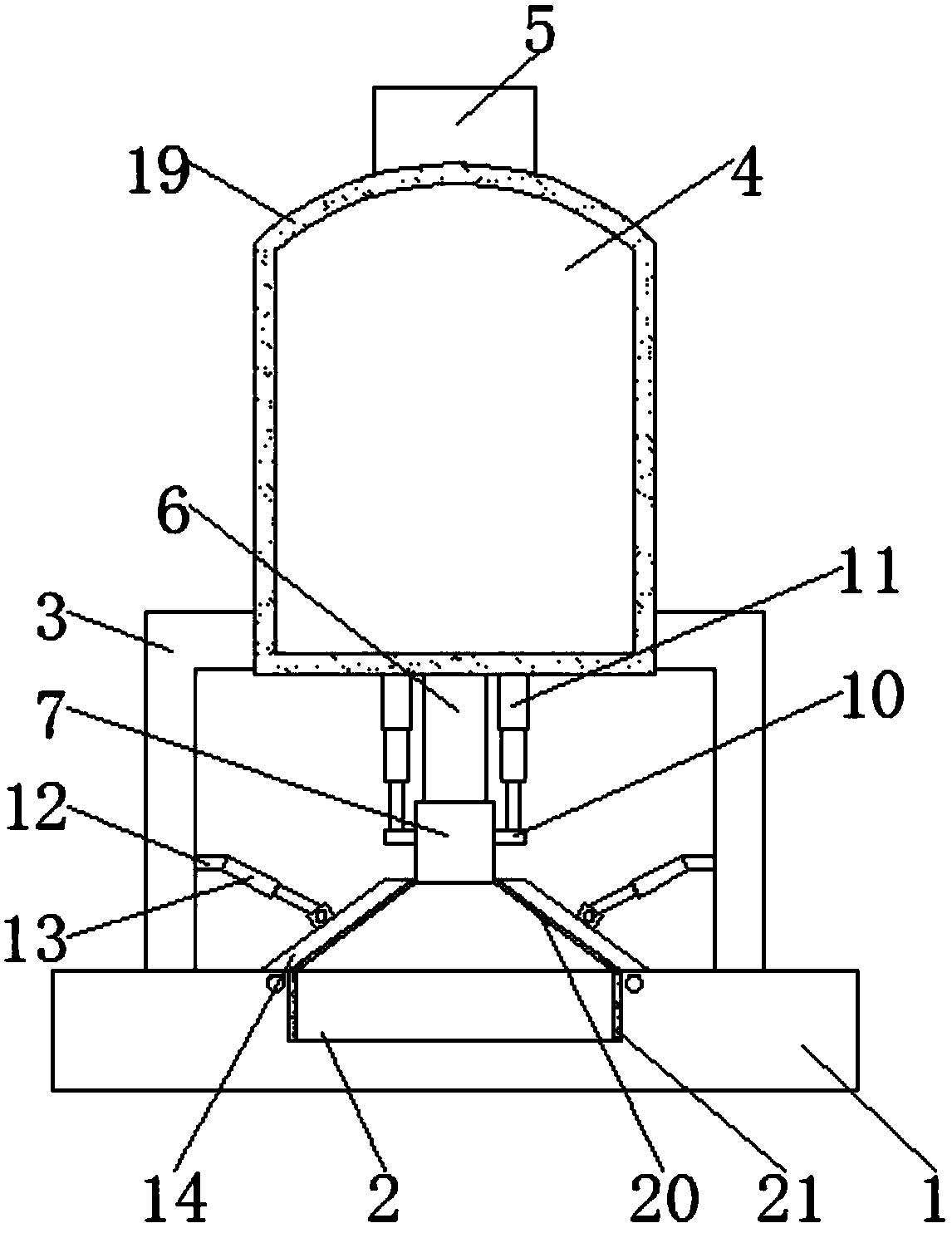

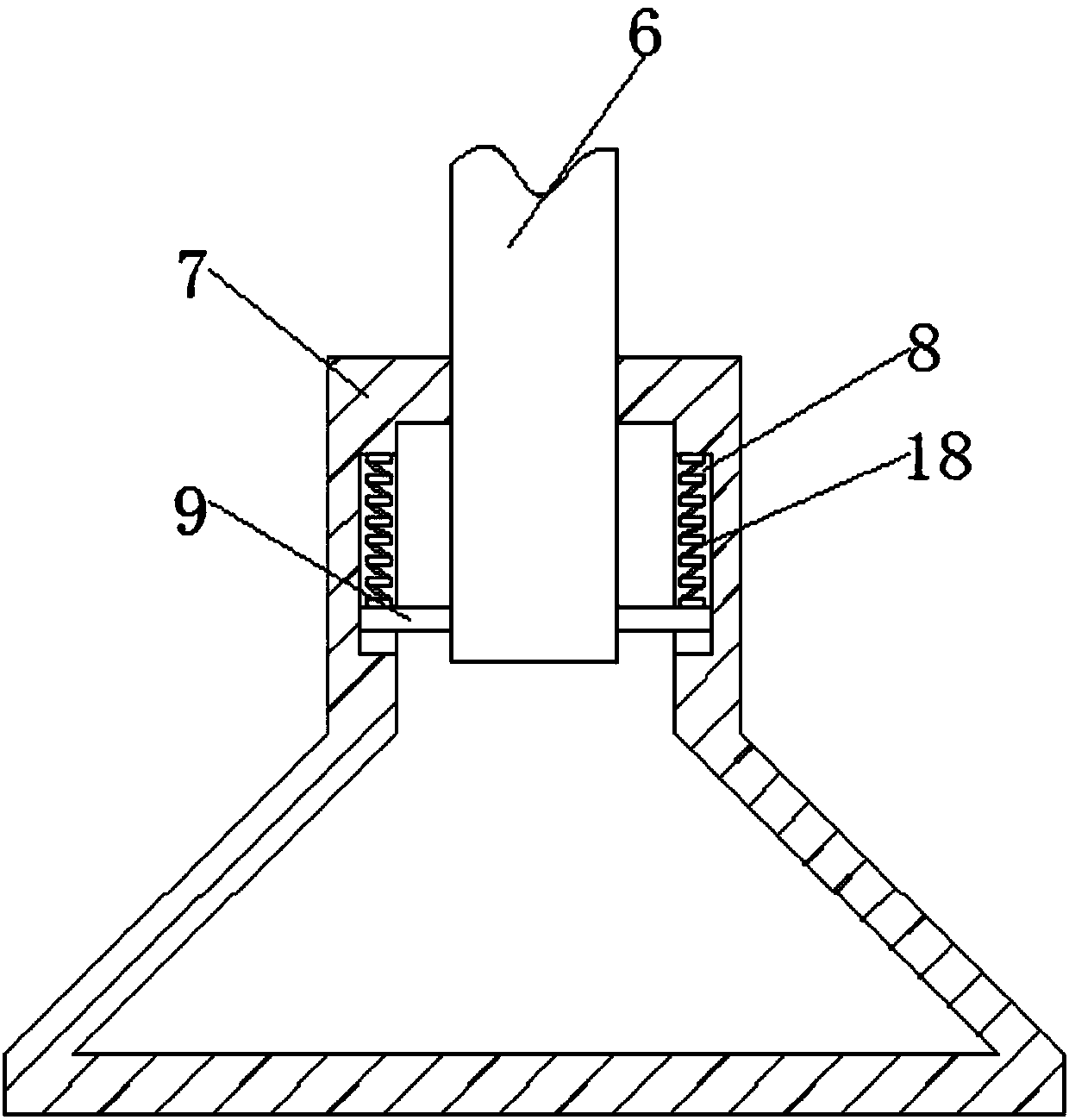

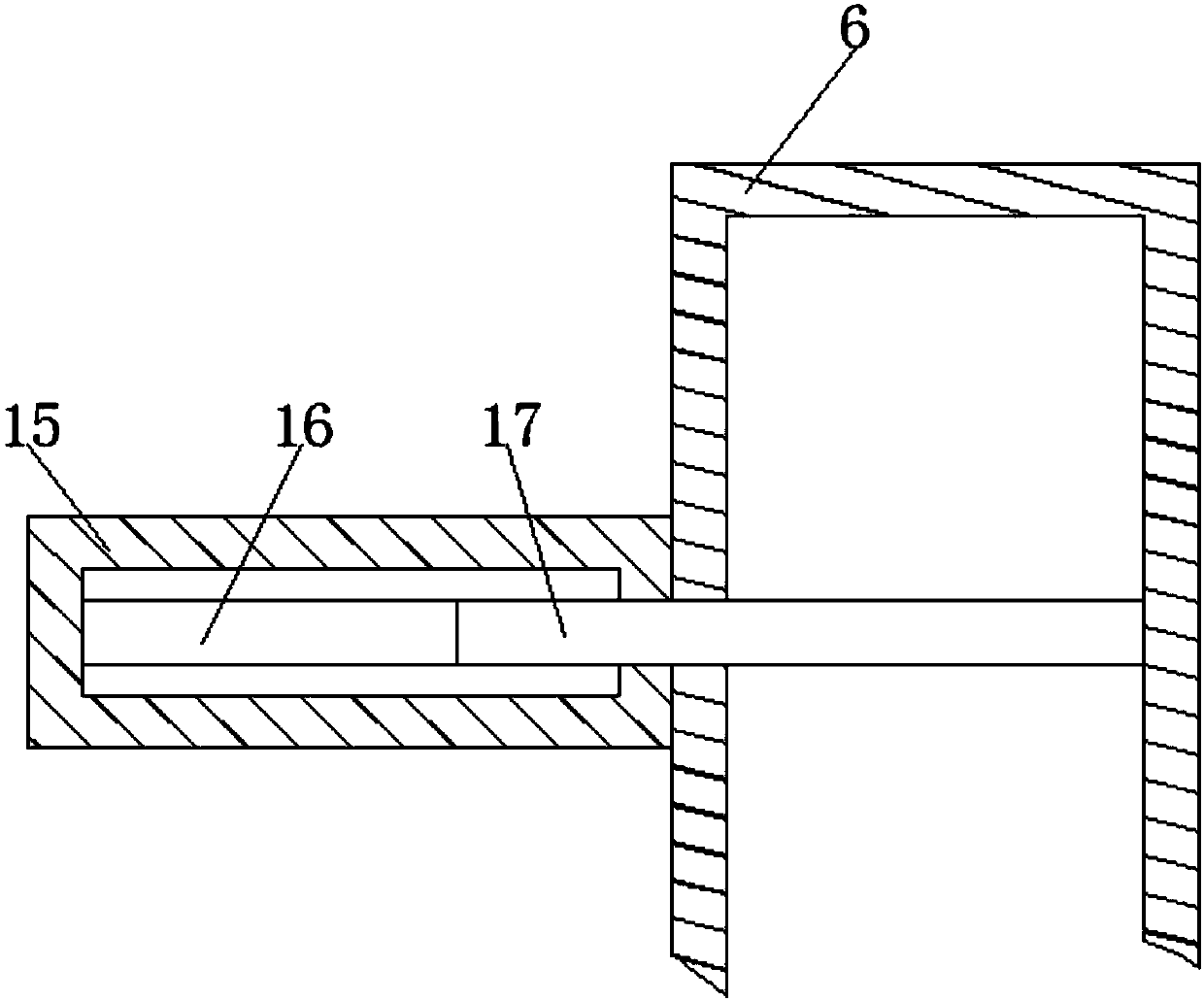

New energy automobile hub casting device

InactiveCN110434295AImprove securityProtection against splashingFoundry mouldsFoundry coresCombustionNew energy

The invention discloses a new energy automobile hub casting device. The device comprises a base, a hub casting mold is arranged at the center of the top of an inner cavity of the base, supporting legsare fixedly connected to the two sides of the top of the base, a combustion furnace is fixedly connected to the inner sides of the supporting legs, a feeding hopper is arranged at the top of an innercavity of the combustion furnace in a communicating mode, and a discharging hopper is arranged at the bottom of the inner cavity of the combustion furnace in a communicating mode. According to the hub casting device, the base, the hub casting mold, the supporting legs, the combustion furnace, the feeding hopper, the discharging hopper, a hopper-shaped steel frame pipe, a sliding groove, a slidingblock, a fixing seat, a hydraulic telescopic rod, a supporting seat, an electric telescopic rod and a protective cover are matched, so that the safety of the hub casting device is improved, the problem of low safety of an existing hub casting device is solved,a casting material is prevented from splashing, a user can be protected, the damage caused by splashing of the casting material to the lifesafety of the user is avoided, and the device is worthy of popularization and application.

Owner:江苏久久车轮有限公司

Novel cutting-off device for cutting off pouring gate

PendingCN114192874AProtection against splashingRealize functionMetal sawing devicesMaintainance and safety accessoriesElectric machineryStructural engineering

The novel cutting device comprises a first fixing frame, a cutting machine, a second fixing frame and a second lead screw, the first lead screw is arranged in the second fixing frame, a vertical frame is arranged on the second fixing frame, and the vertical frame is connected with the cutting machine through a rotating device. And the cutting machine comprises a motor and a saw blade, a protection device is arranged on the cutting machine, and a buffer device is arranged on the second lead screw in the first fixing frame. According to the novel cutting-off device for cutting off the pouring gate, the novel cutting-off device belongs to the technical field of die-casting dies, a cutting machine blade is used for cutting pouring gate castings in the vertical and horizontal directions, chippings generated during cutting of a cutting machine are shielded through a telescopic plate, and the situation that the chippings splash towards the side edge can be prevented; and chippings on a second lead screw can be cleaned through a cleaning piece and cleaning bristles at the lower end of a clamping block, and the function that the saw blade can move in a plane according to any track is achieved.

Owner:YUTAKA ELECTRONICS SH

A hand-held preliminary scraping device for wall peeling paint

ActiveCN109025341BEfficient scrapingProtection against splashingBuilding repairsElectric machineCoupling

The invention relates to the technical field of wall paint treatment, and discloses a hand-held preliminary scraping device for peeling paint on the wall, which includes a cylinder body, the right end surface and the top of the cylinder body are fixedly connected with hand-held handles, and the inner top of the cylinder body is A mounting plate is fixedly connected with the bottom, the right side of the mounting plate is fixedly equipped with a battery, the left side of the mounting plate is fixedly connected with a drive motor through a fixing frame, and the output shaft of the drive motor is fixedly connected with a torque shaft through a coupling , the inner side of the cylinder is fixedly connected with the discharge pipe through the mounting frame, the torque shaft runs through the right end face of the discharge pipe at the end away from the drive motor and extends to the inner side of the discharge pipe, and the torque shaft runs through the discharge at the end far away from the drive motor right end of the tube and extends to the inside of the discharge tube. The hand-held preliminary scraping device for peeling paint on the wall prevents the scraping paint from splashing, conveys, removes and collects the scraped paint residue, and facilitates the preliminary treatment of the peeling paint on the wall.

Owner:浙江企信检测有限公司

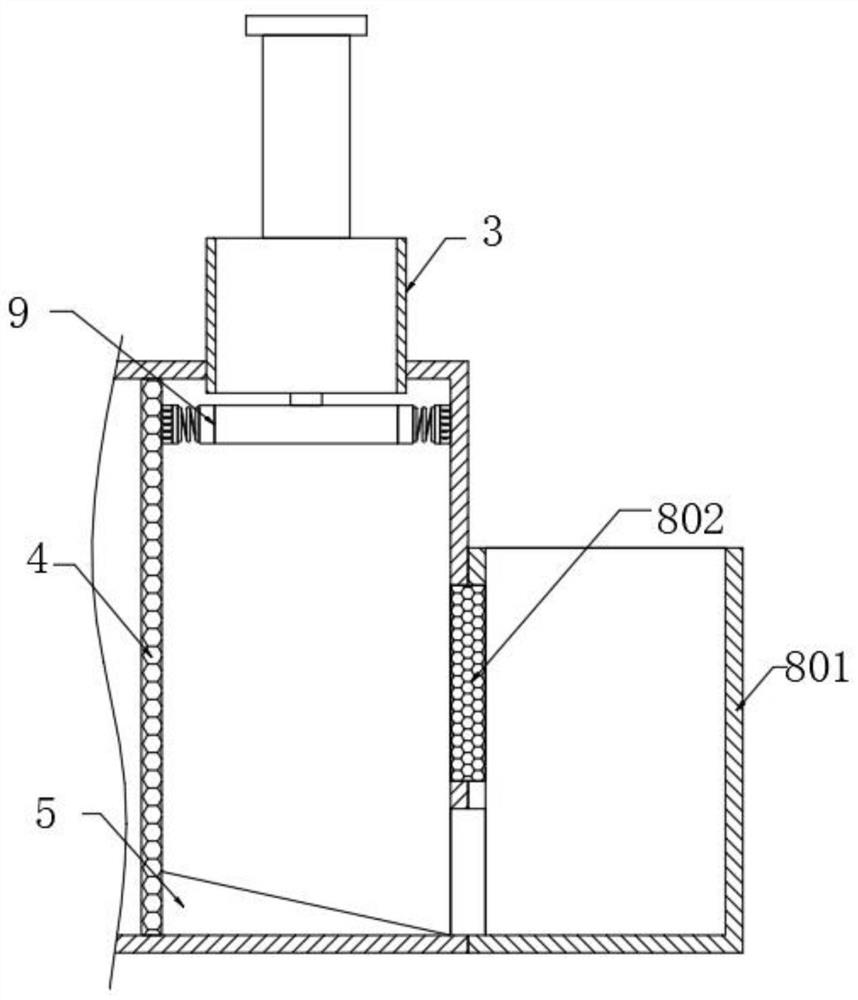

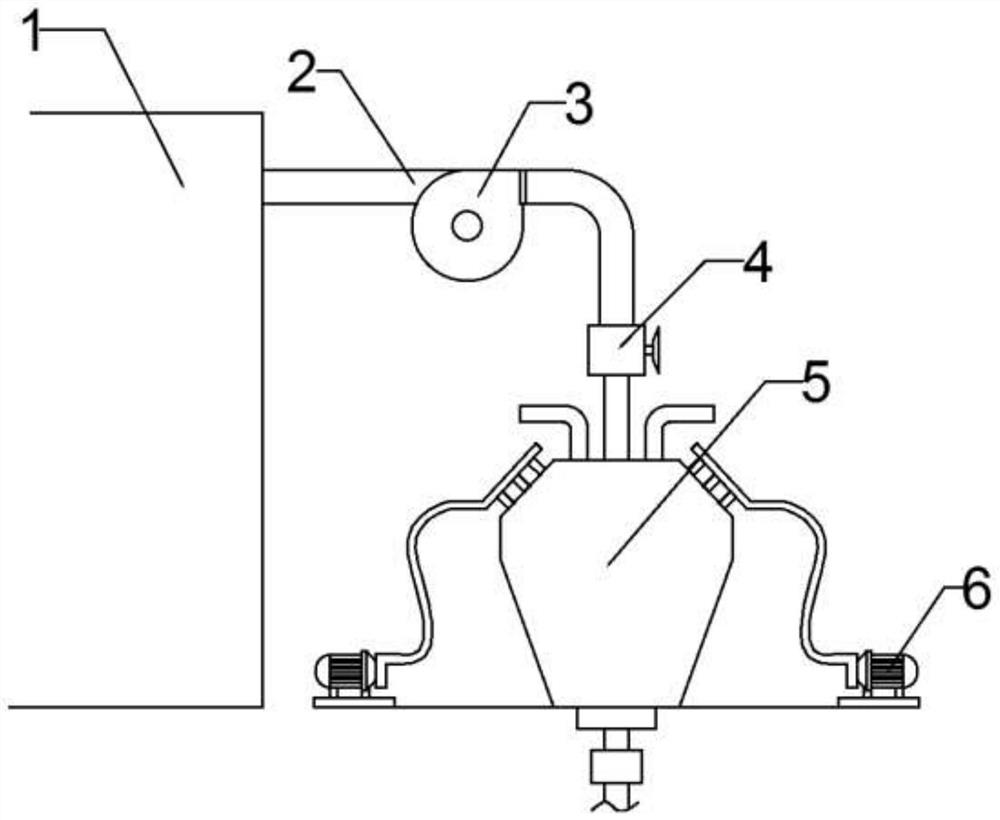

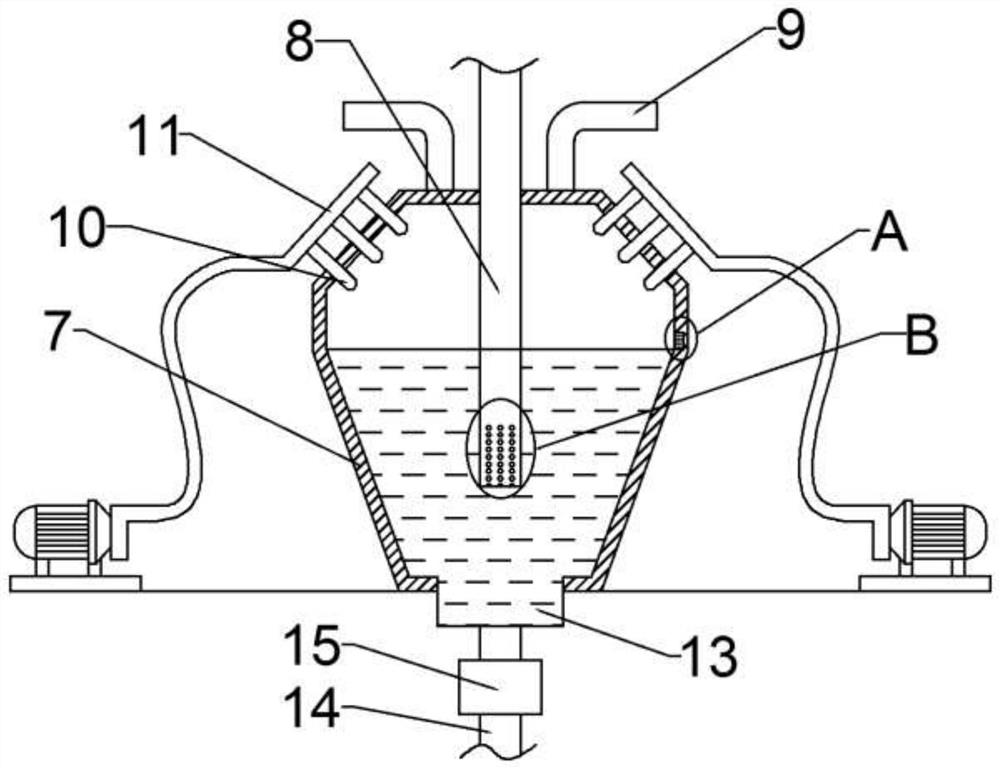

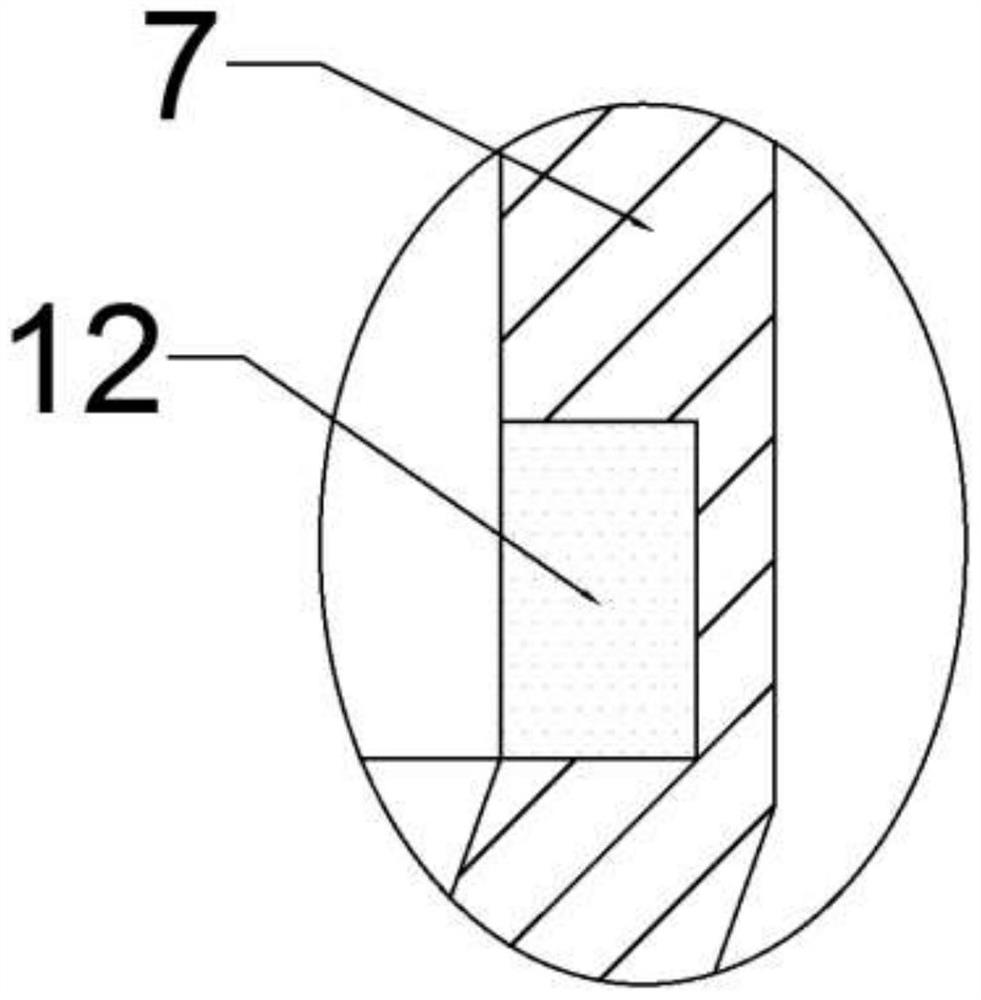

Dust removal device for traditional Chinese medicine crushing equipment

InactiveCN112807892AEfficient removalIncrease flow rateUsing liquid separation agentSeparation devicesAfter treatmentDust control

The invention provides a dust removal device for traditional Chinese medicine crushing equipment. The dust removal device is characterized by comprising a traditional Chinese medicine crushing chamber, an air inlet pipeline, a fan, a gas flow control valve, a gas washing device and a water pump, the right side of the traditional Chinese medicine crushing chamber is connected with the air inlet pipeline, the air inlet pipeline is connected with the fan, and the gas flow control valve is mounted at the bottom of the air inlet pipeline; and the gas washing device is connected below the gas flow control valve and consists of a gas washing barrel, a gas spraying pipe, an exhaust pipe and an atomizing water spraying head, the top of the gas spraying pipe is connected with the gas flow control valve, the gas spraying pipe is connected with the top of the gas washing barrel, and the atomizing water spraying head is arranged on the inclined surface of the top of the gas washing barrel. Gas with dust passes through water in the gas washing barrel, the dust can be dissolved in the water, water mist sprayed by the atomization water spraying head drives the water to settle to the water surface, most of the dust can be effectively removed, and the discharged gas after treatment is clean. A device for blocking air movement is not arranged in the dust removal device, so that blockage is avoided, and the efficiency is improved.

Owner:鲲鹏神农制药设备(天津)有限公司

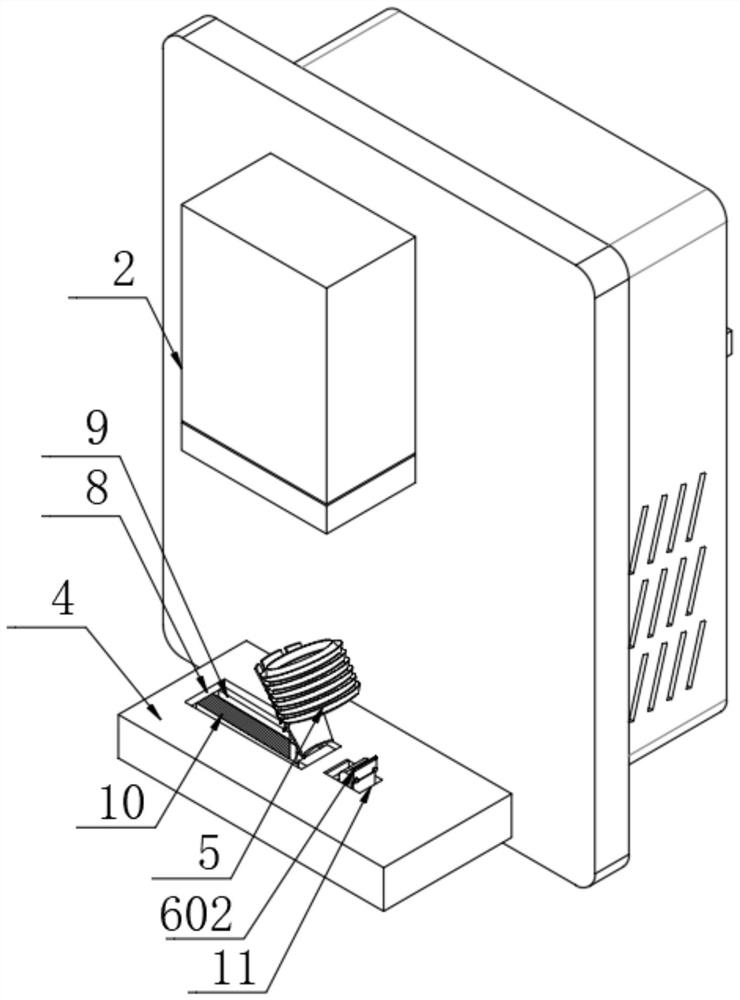

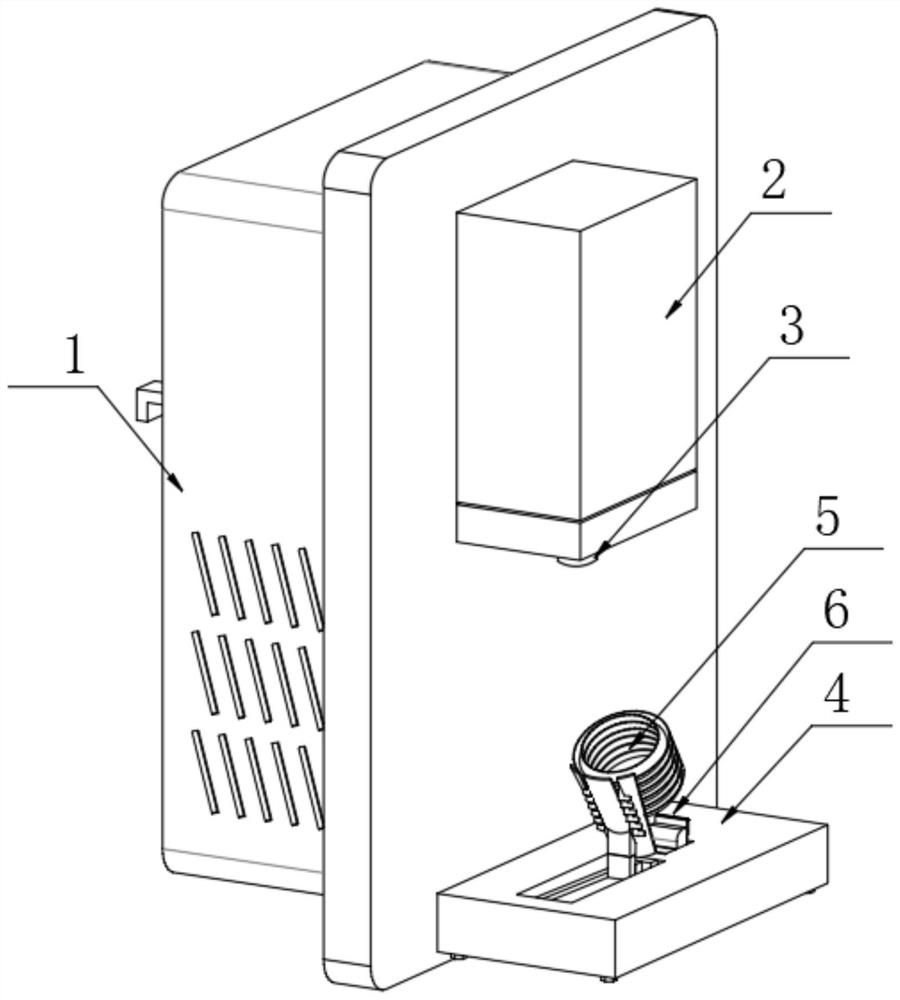

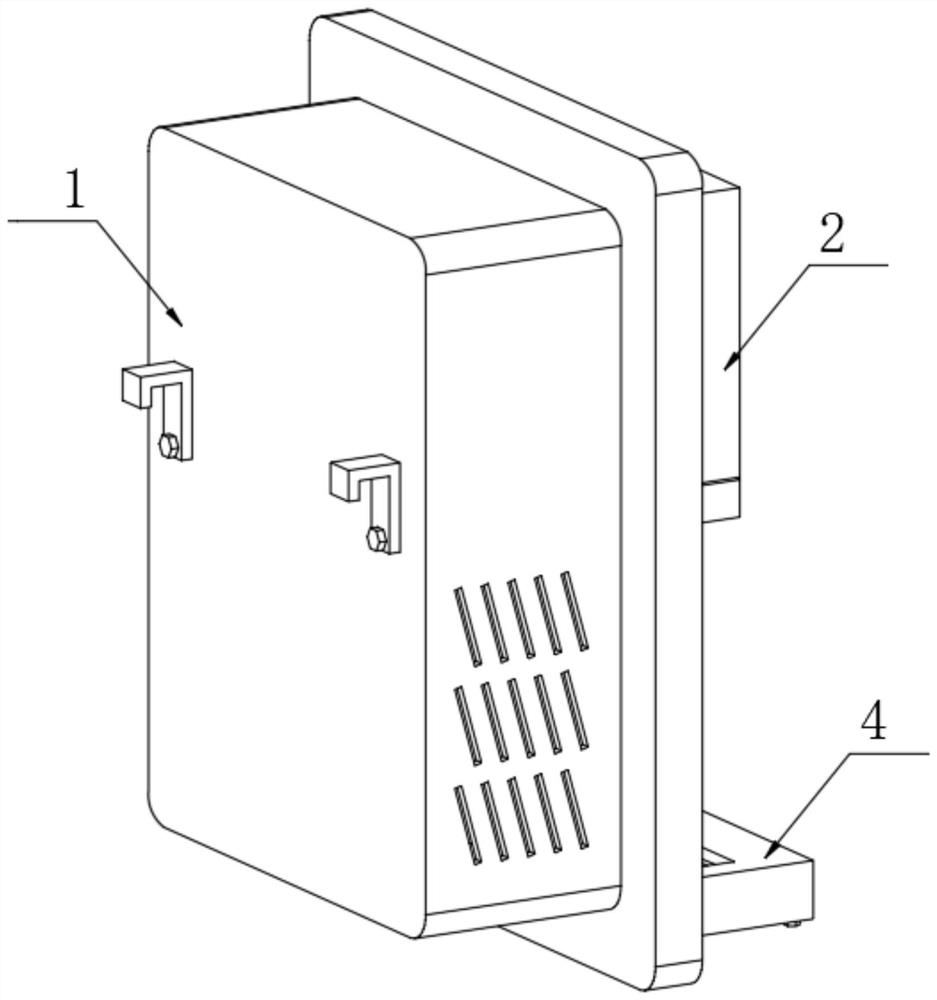

Wall-mounted water purifier

The invention discloses a wall-mounted water purifier which comprises a water purifier body, a shell is arranged on the outer side of the water purifier body, one side of the shell is rotationally connected with a placing mechanism, and the placing mechanism tends to be in a vertical state when the input end is in a weighing state; a supporting assembly used for supporting a bearing object at the input end of the placing mechanism is arranged on one side of the placing mechanism, the supporting assembly is compressed when the placing mechanism bears the bearing object and tends to be vertical, and a driving assembly used for driving the supporting assembly to move in the horizontal direction is arranged on the outer side of the supporting assembly. A disposable cup is obliquely placed on the placing mechanism, at the moment, the water outlet pipe at the bottom end of the water outlet mechanism is just aligned with the inner side wall of the disposable cup, and water falling from the water outlet pipe just falls on the side wall of the cup and then flows downwards along the side wall, so that compared with a traditional mode that the disposable cup is directly and vertically placed for water taking, water can be prevented from falling to the bottom of the cup and splashing, and hands can be prevented from being scalded.

Owner:三河市朝夕科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com