Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Precision can be ensured" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

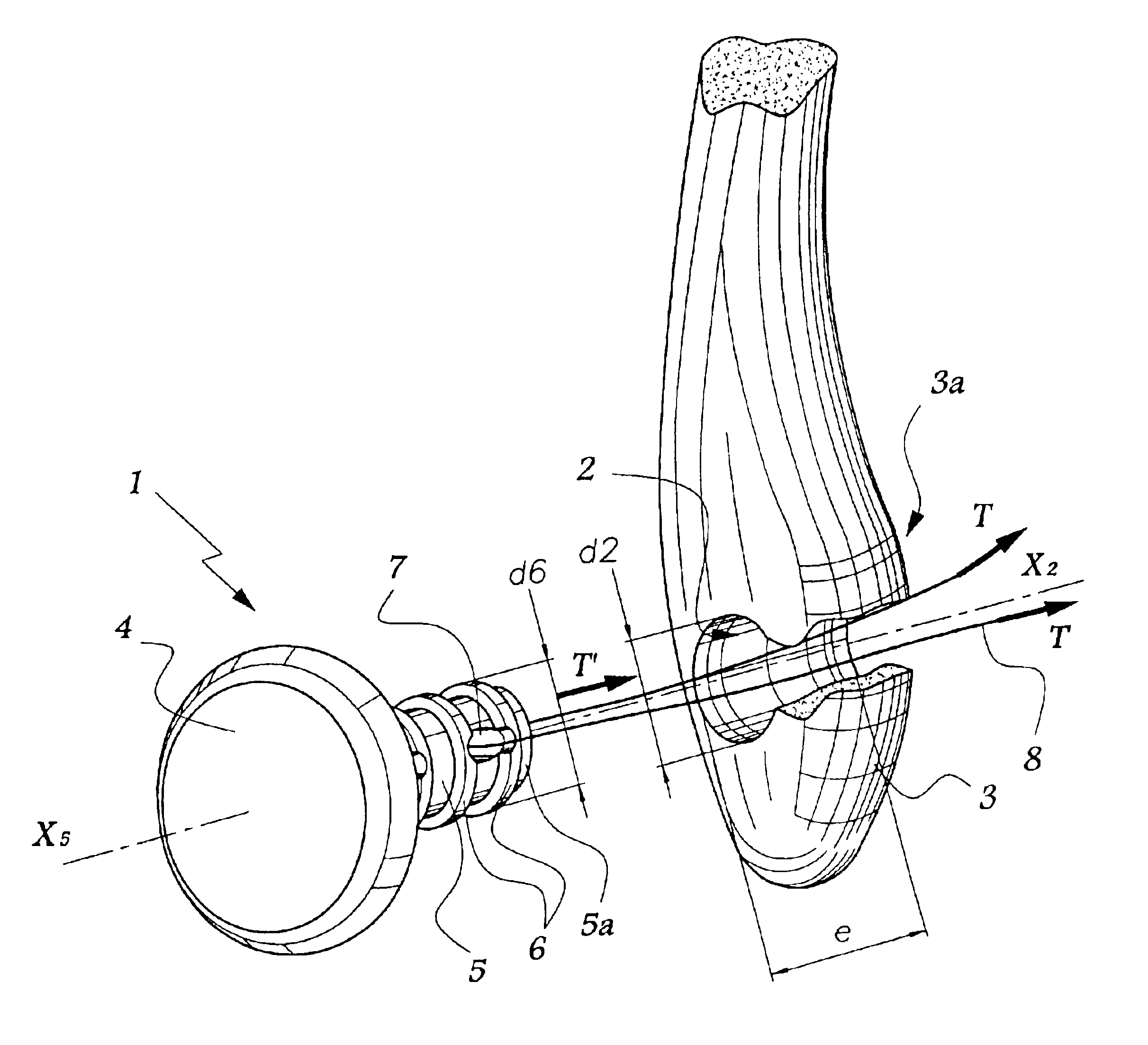

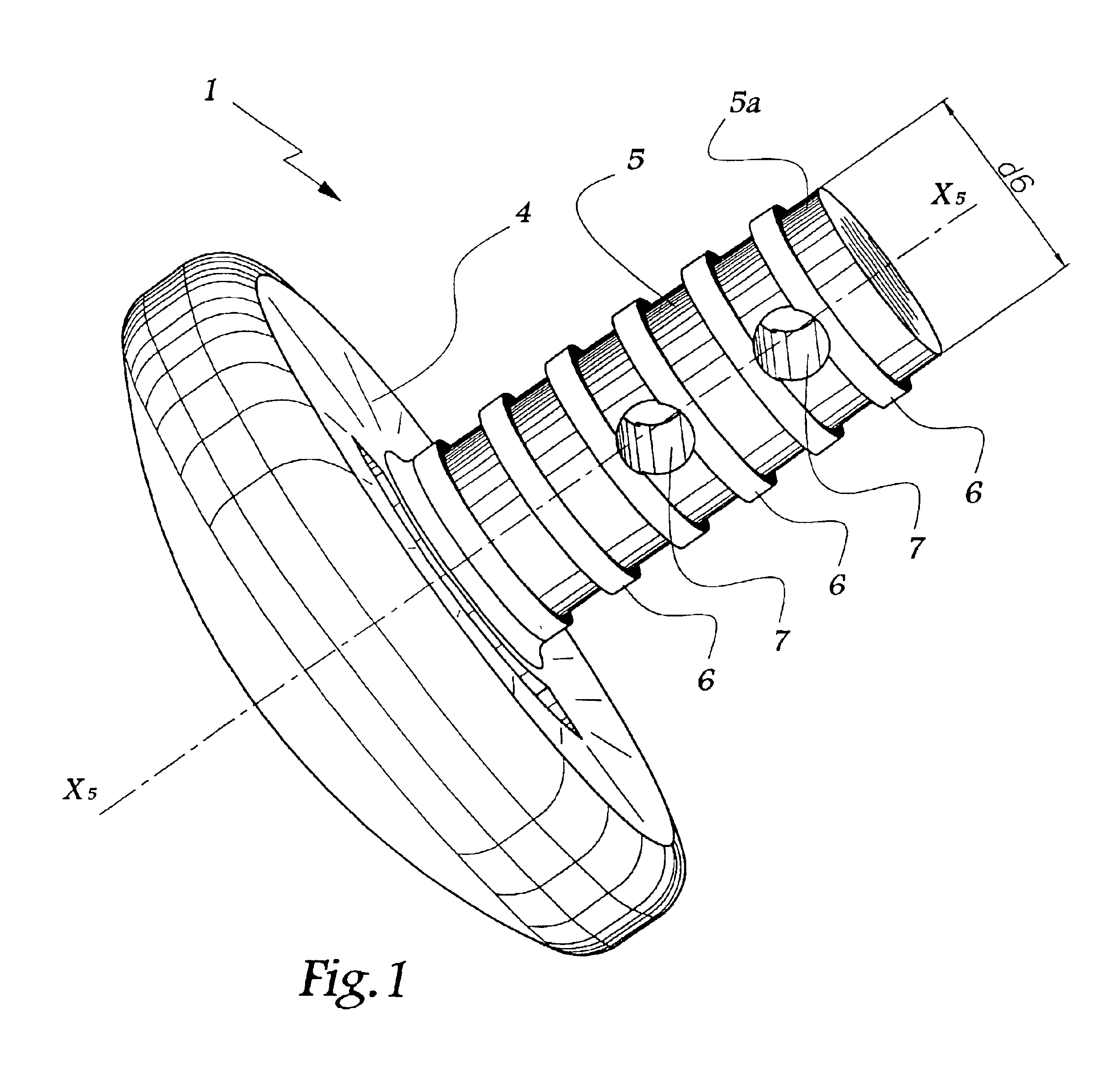

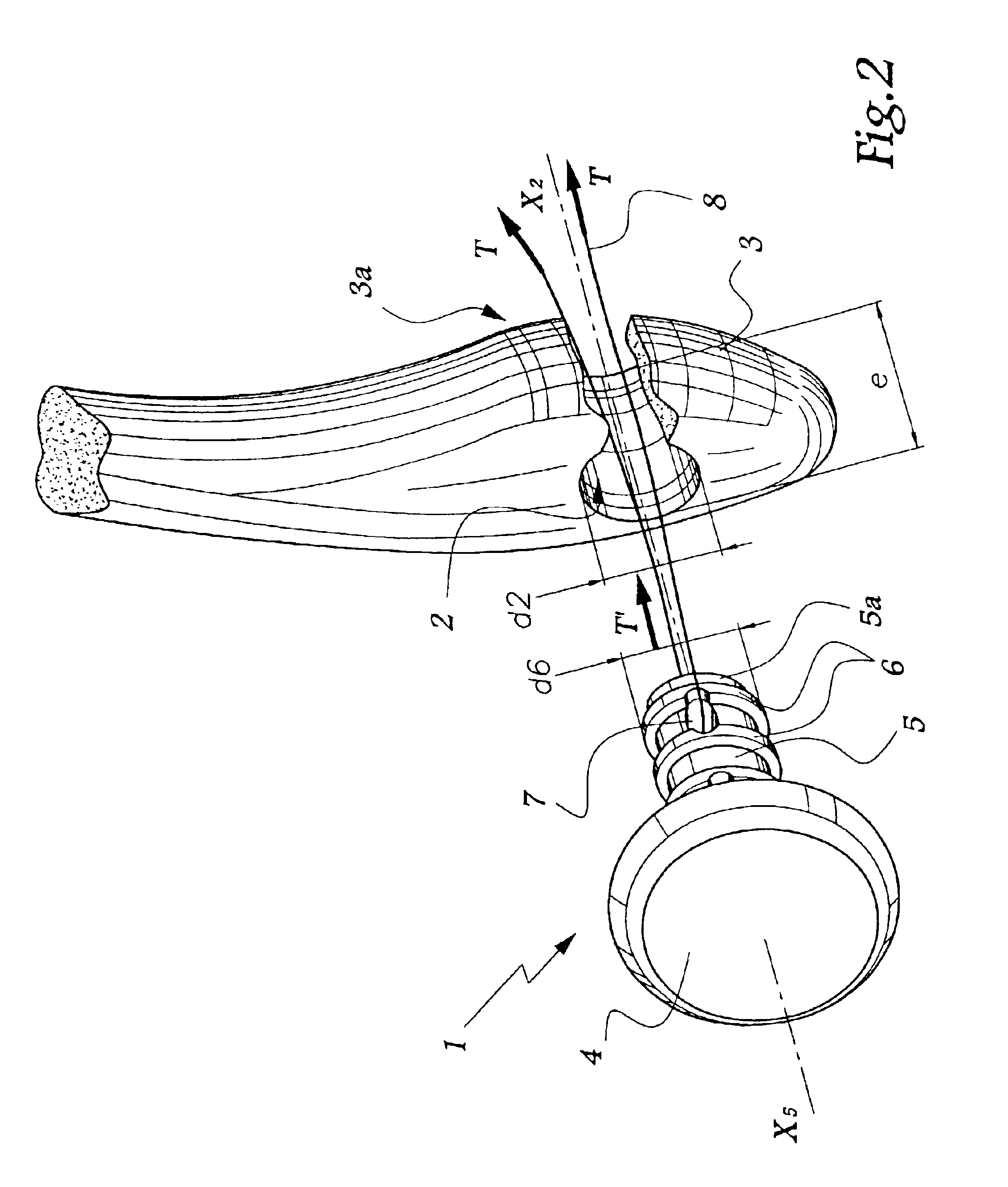

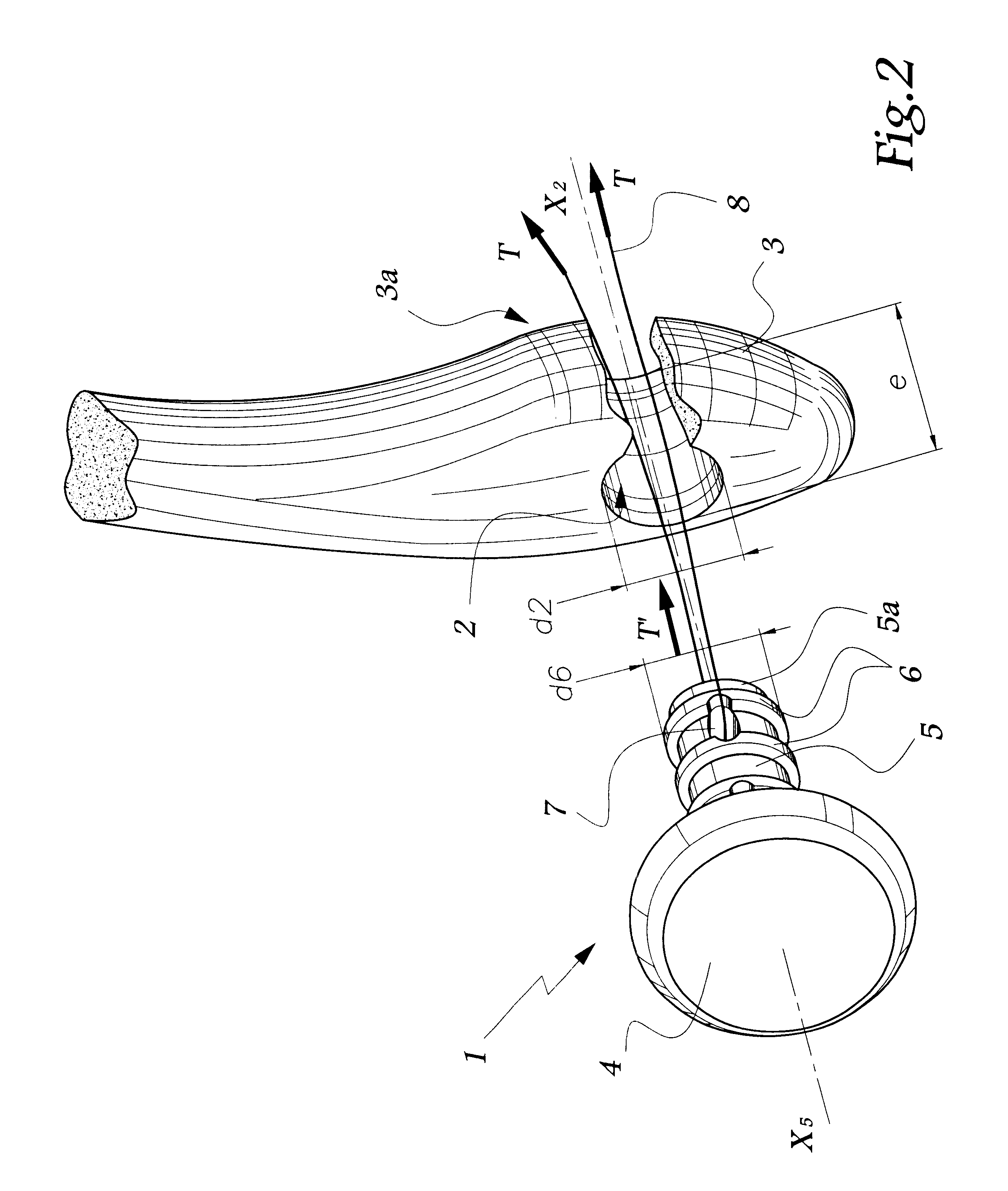

Method of positioning a malleolar implant for partial or total ankle prosthesis

InactiveUS6824567B2Efficient effortPrecise positioningWrist jointsAnkle jointsBiomedical engineeringProsthetic knee

Owner:SMITH & NEPHEW INC

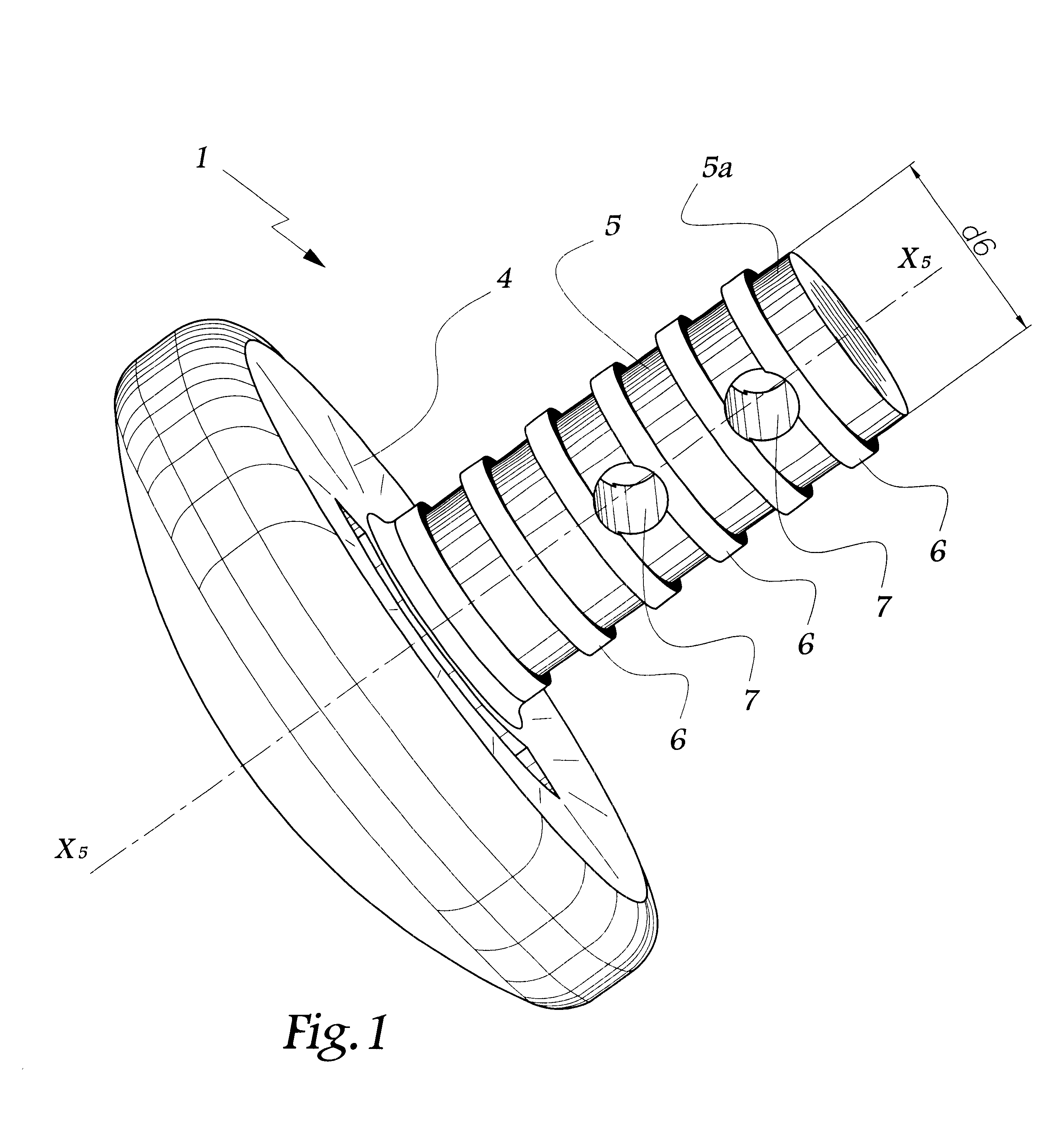

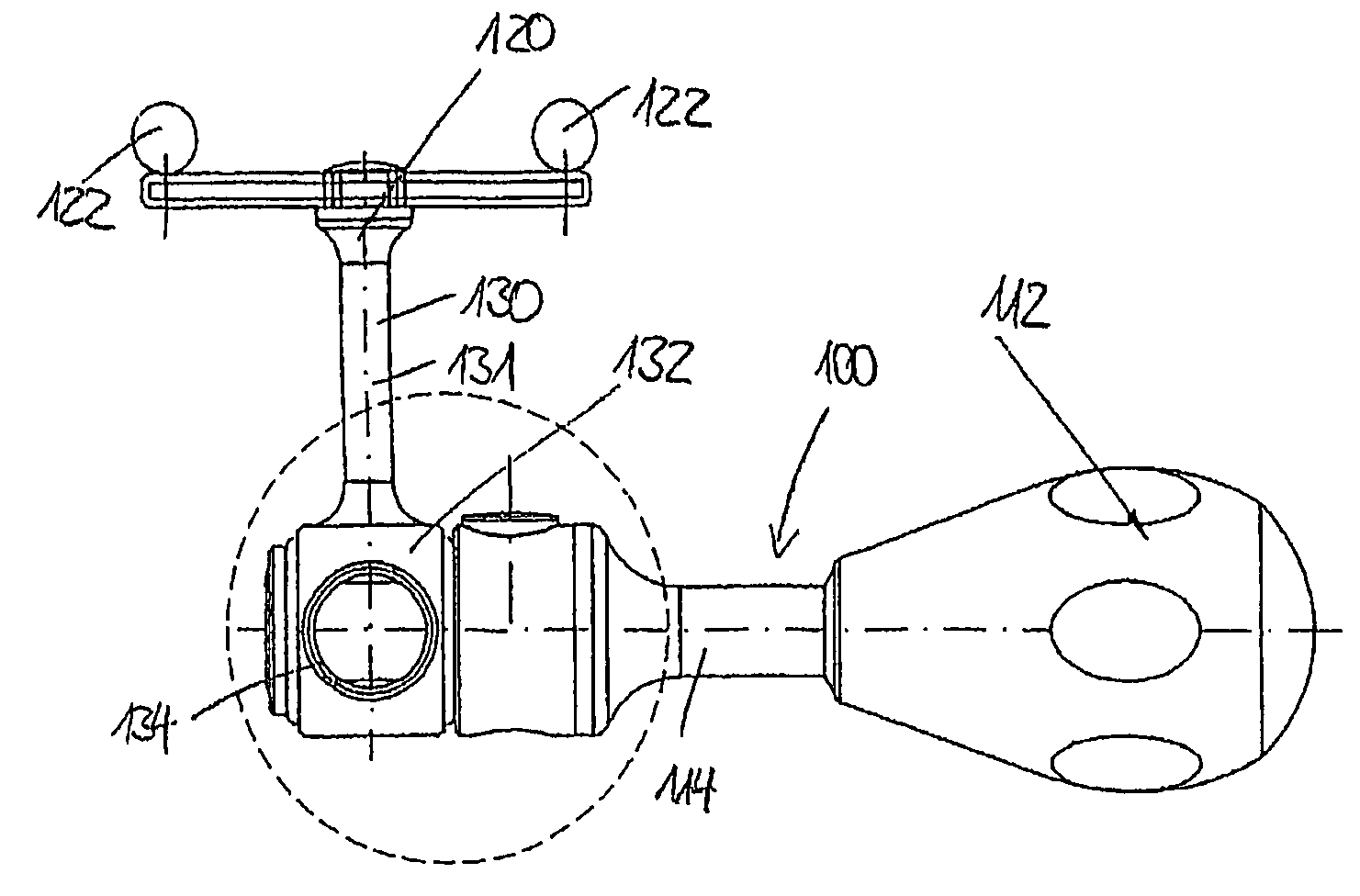

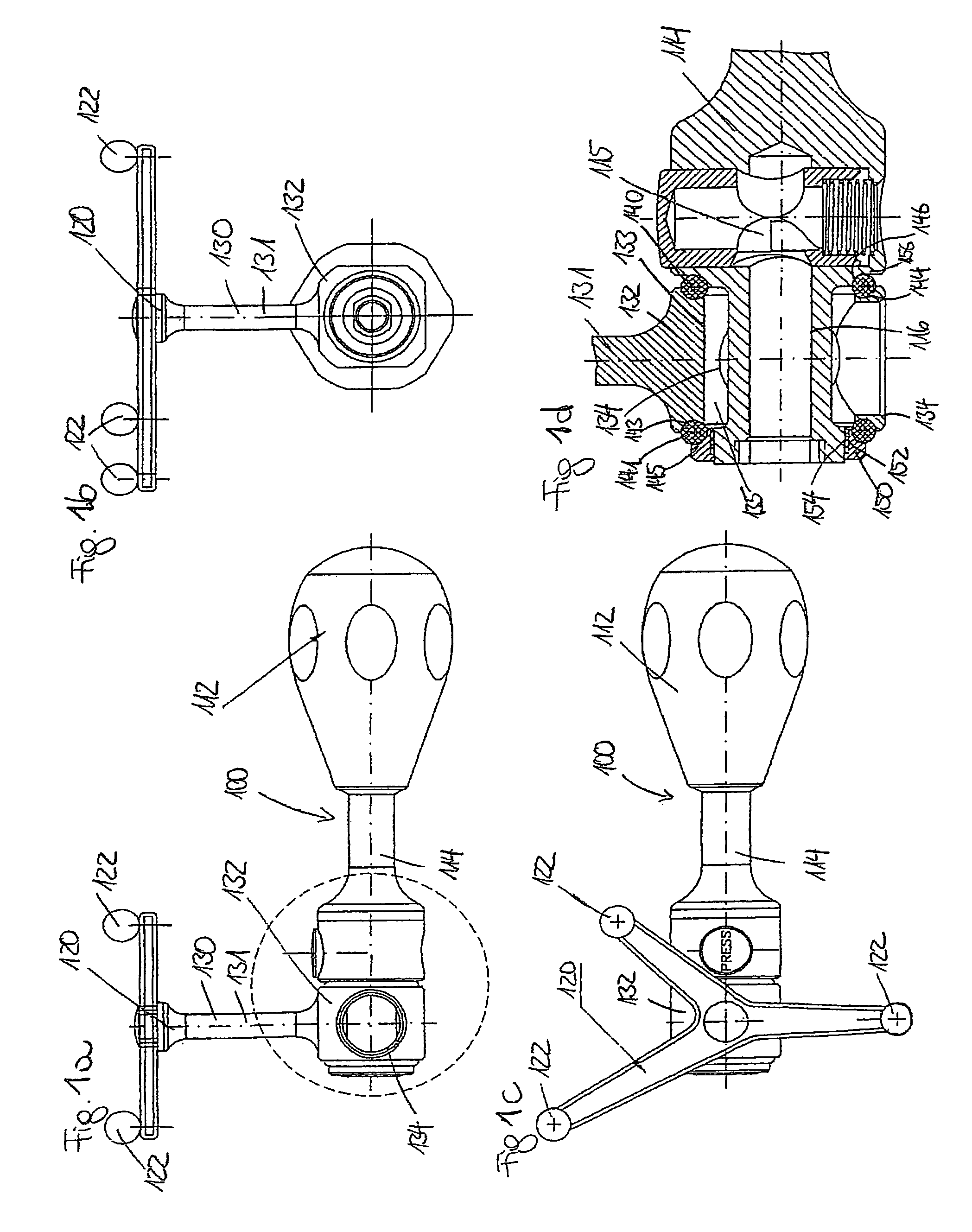

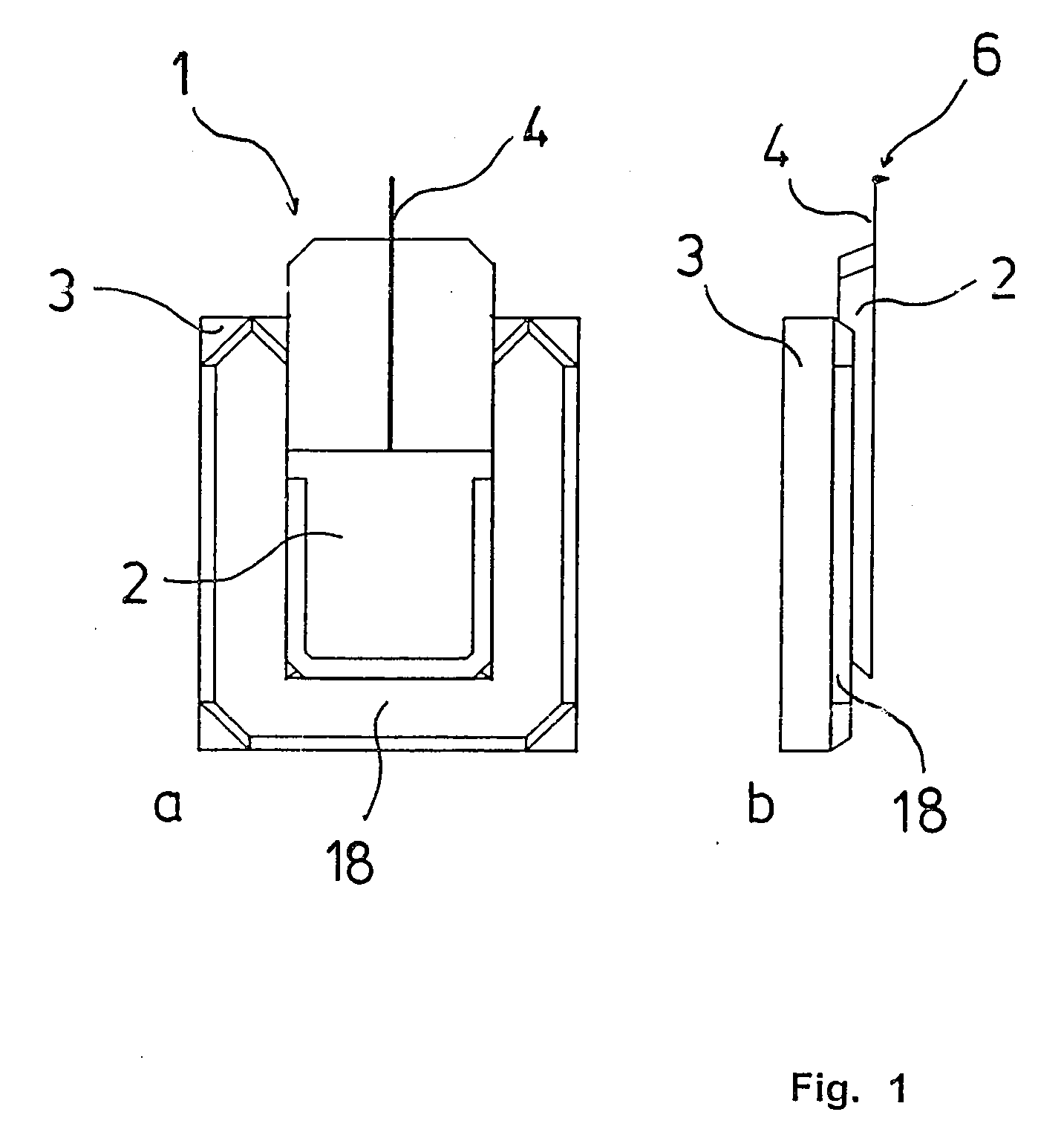

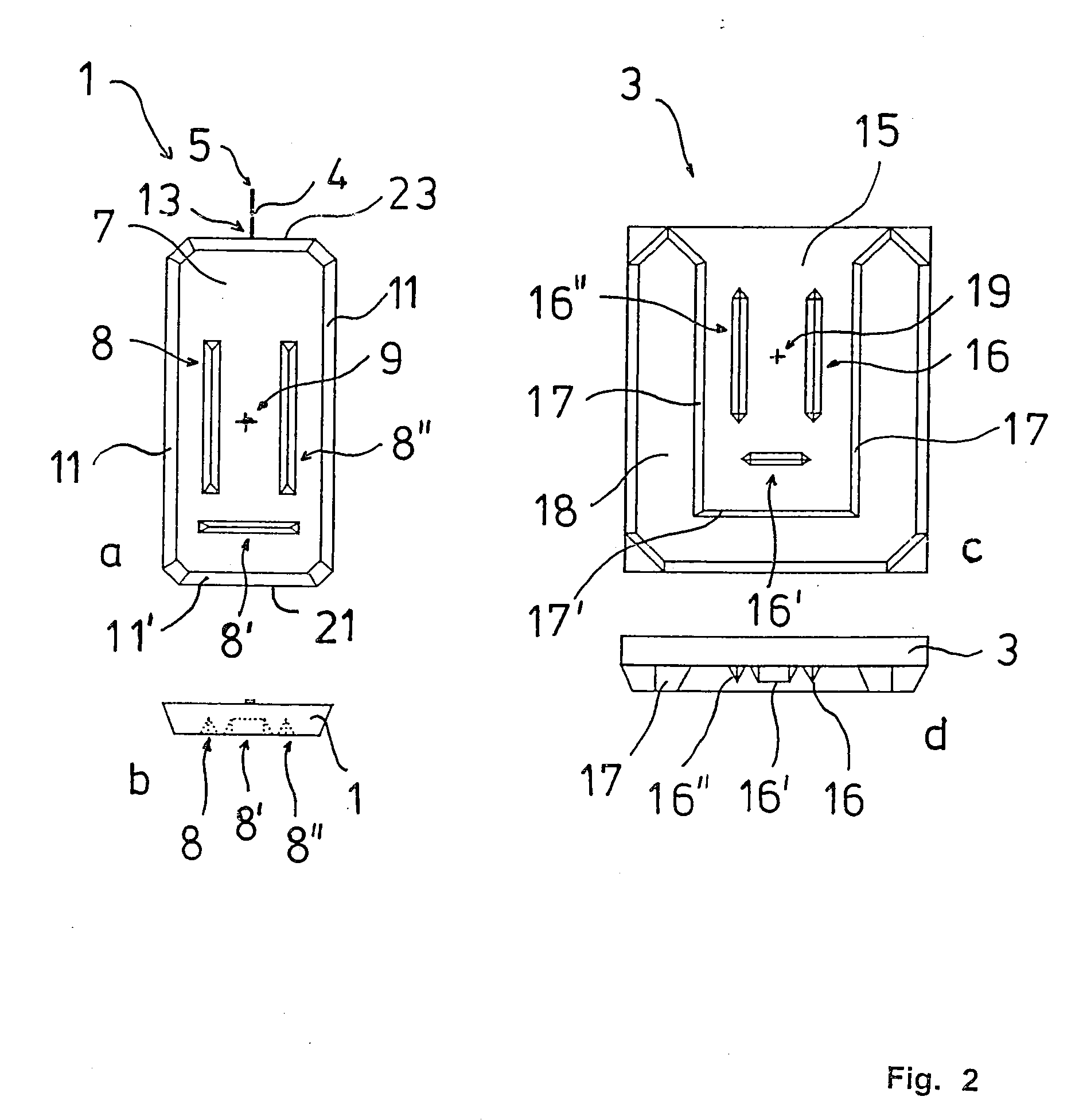

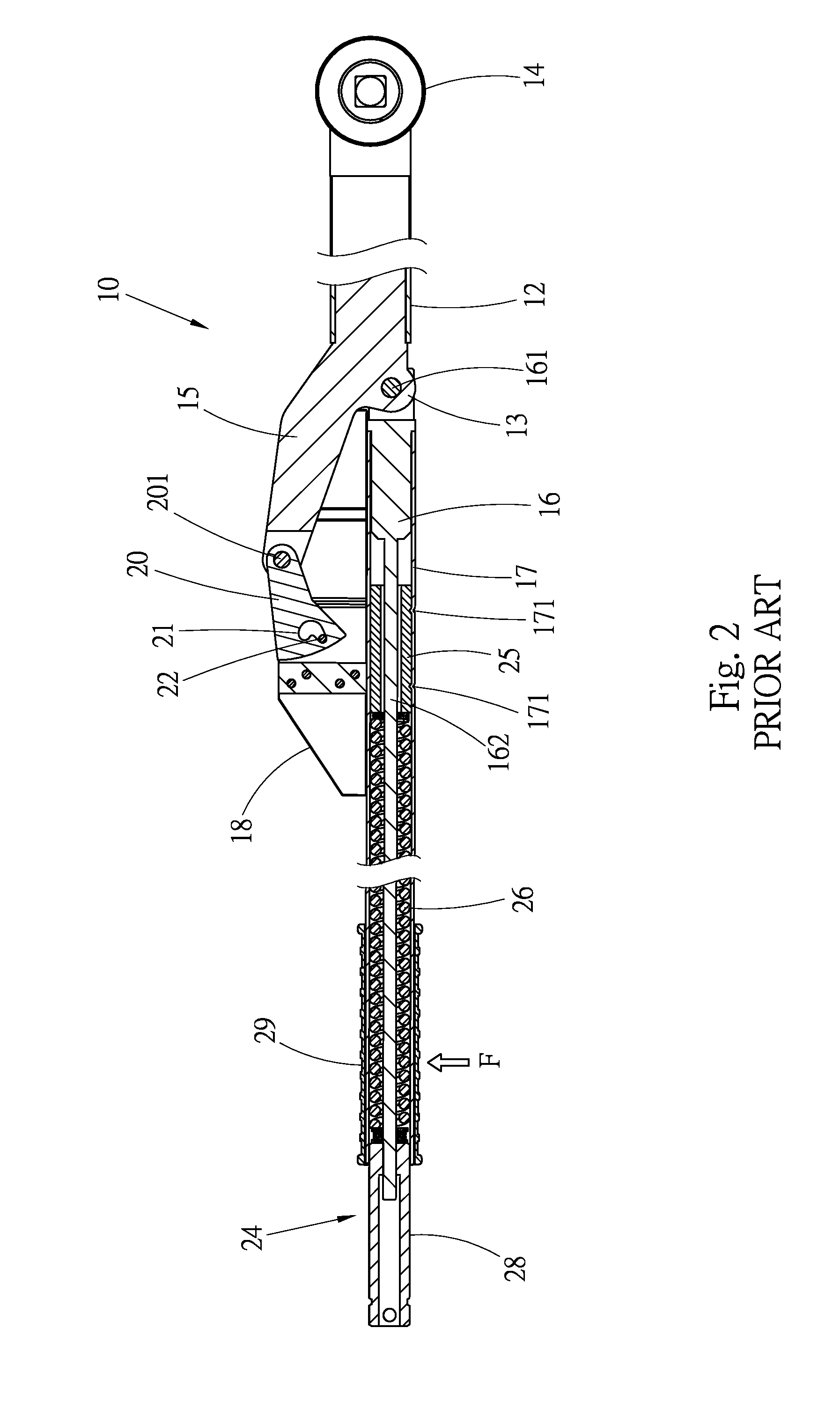

Malleolar implant for partial or total ankle prosthesis

InactiveUS6488712B1Efficient effortPrecise positioningWrist jointsAnkle jointsBiomedical engineeringProsthetic knee

A malleolar implant for partial or total ankle prosthesis which includes a head having a surface to bear against an astragalus or astragalian prosthetic component and from which head extends a shank adapted to be inserted through a bore in a fibula wherein the shank is provided with means for hooking a traction member which is adapted to be inserted through the bore in the fibula in order to apply a force to pull the implant into the bore such that the implant is seated within the bore of the fibula.

Owner:SMITH & NEPHEW INC

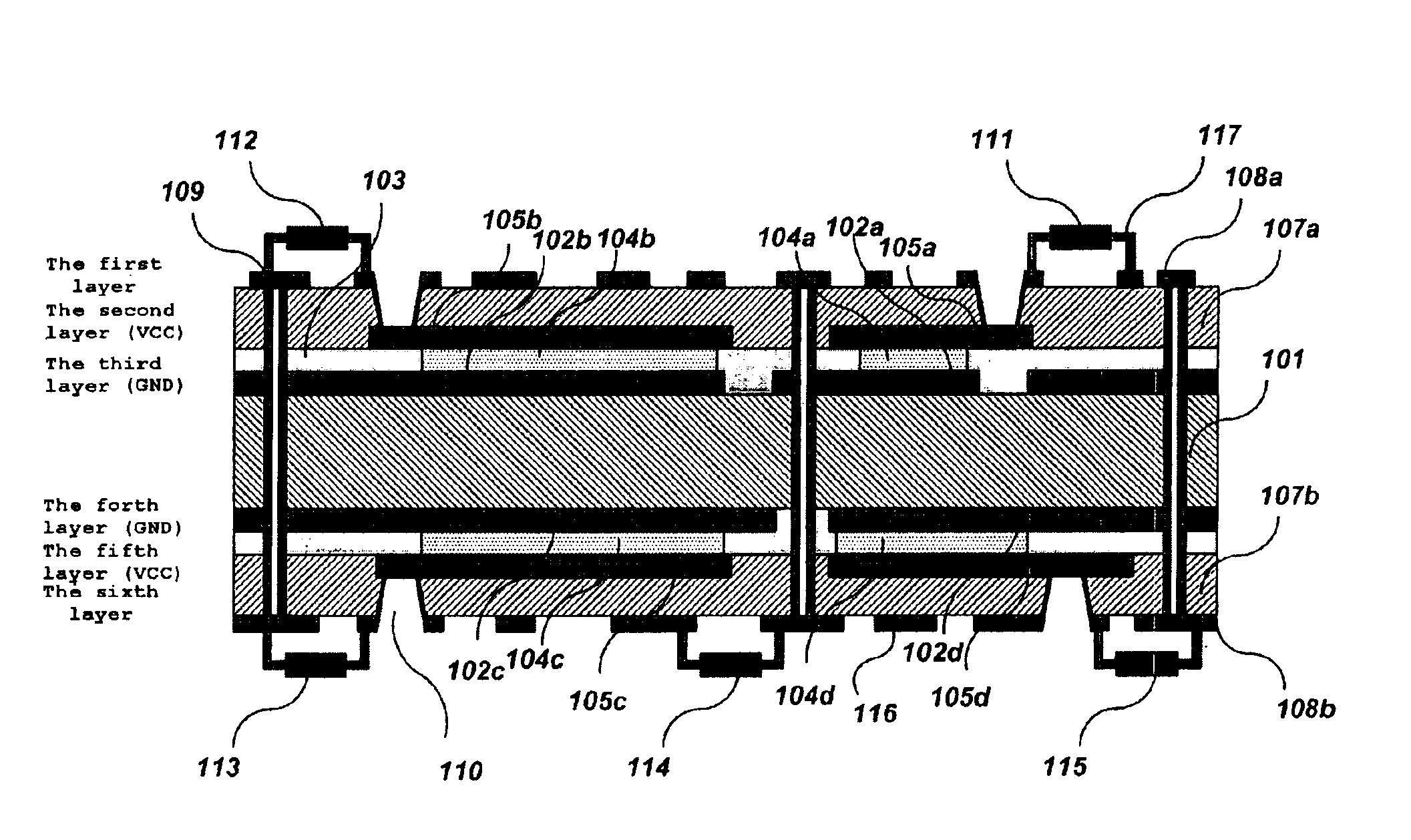

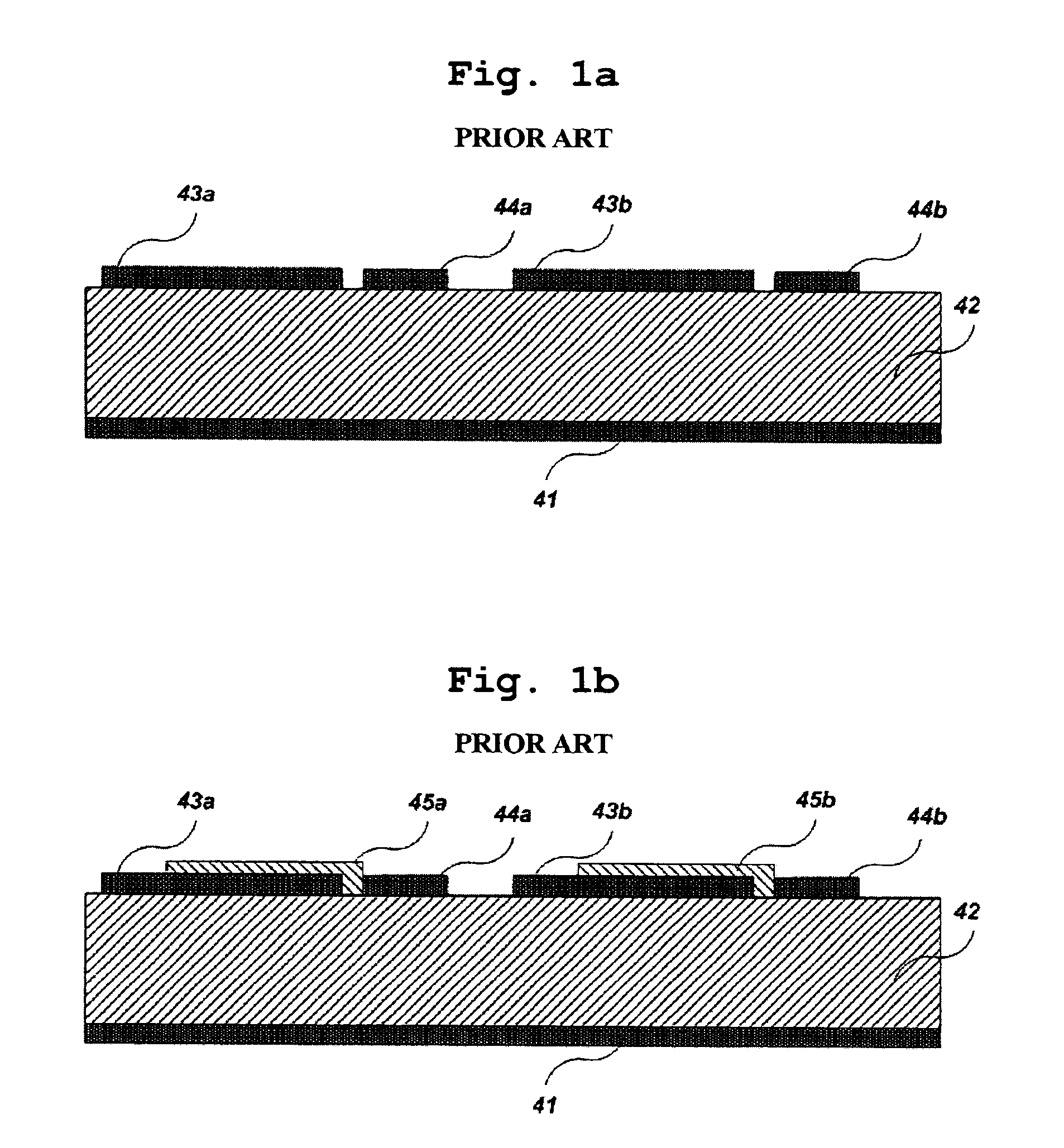

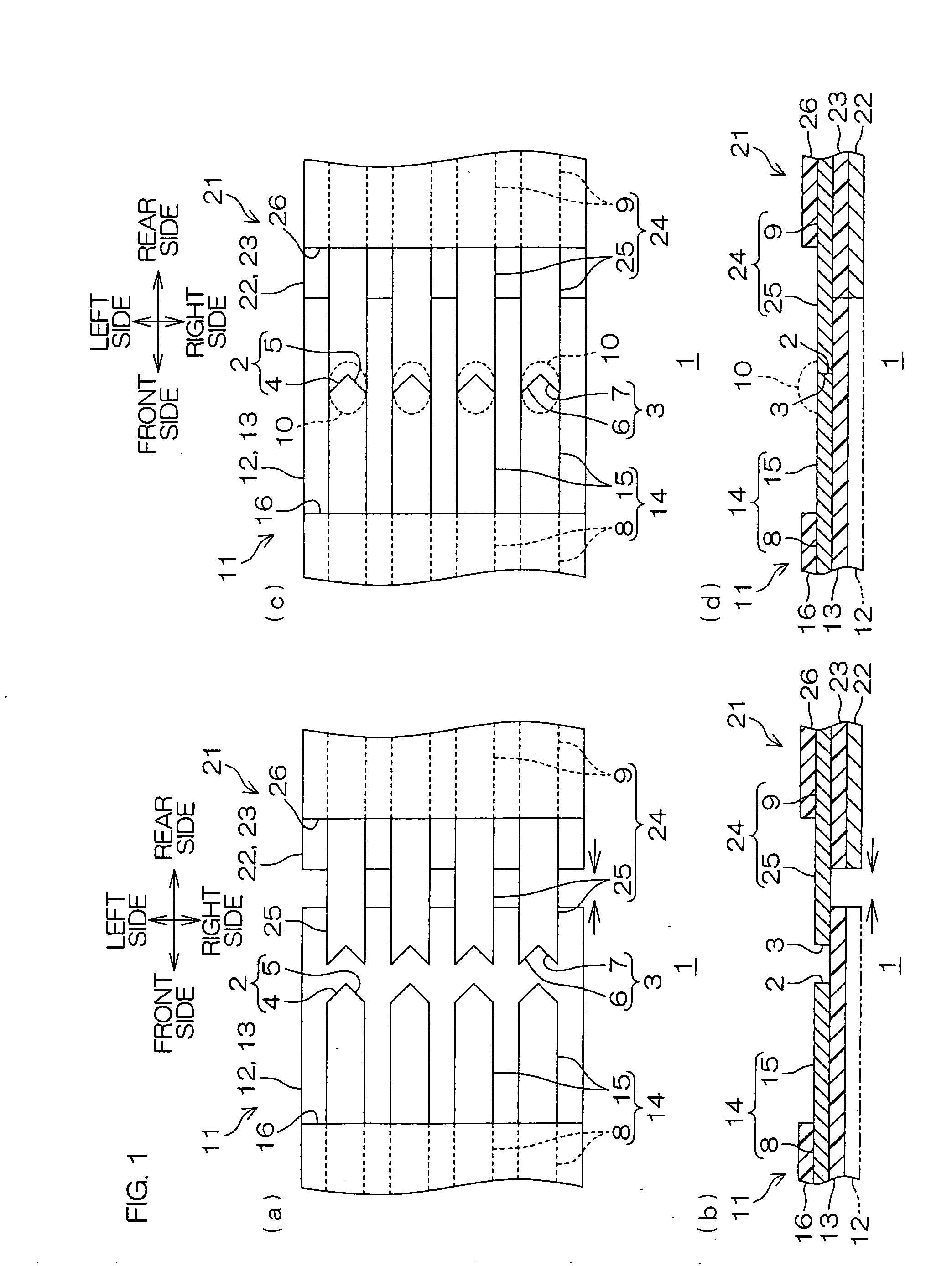

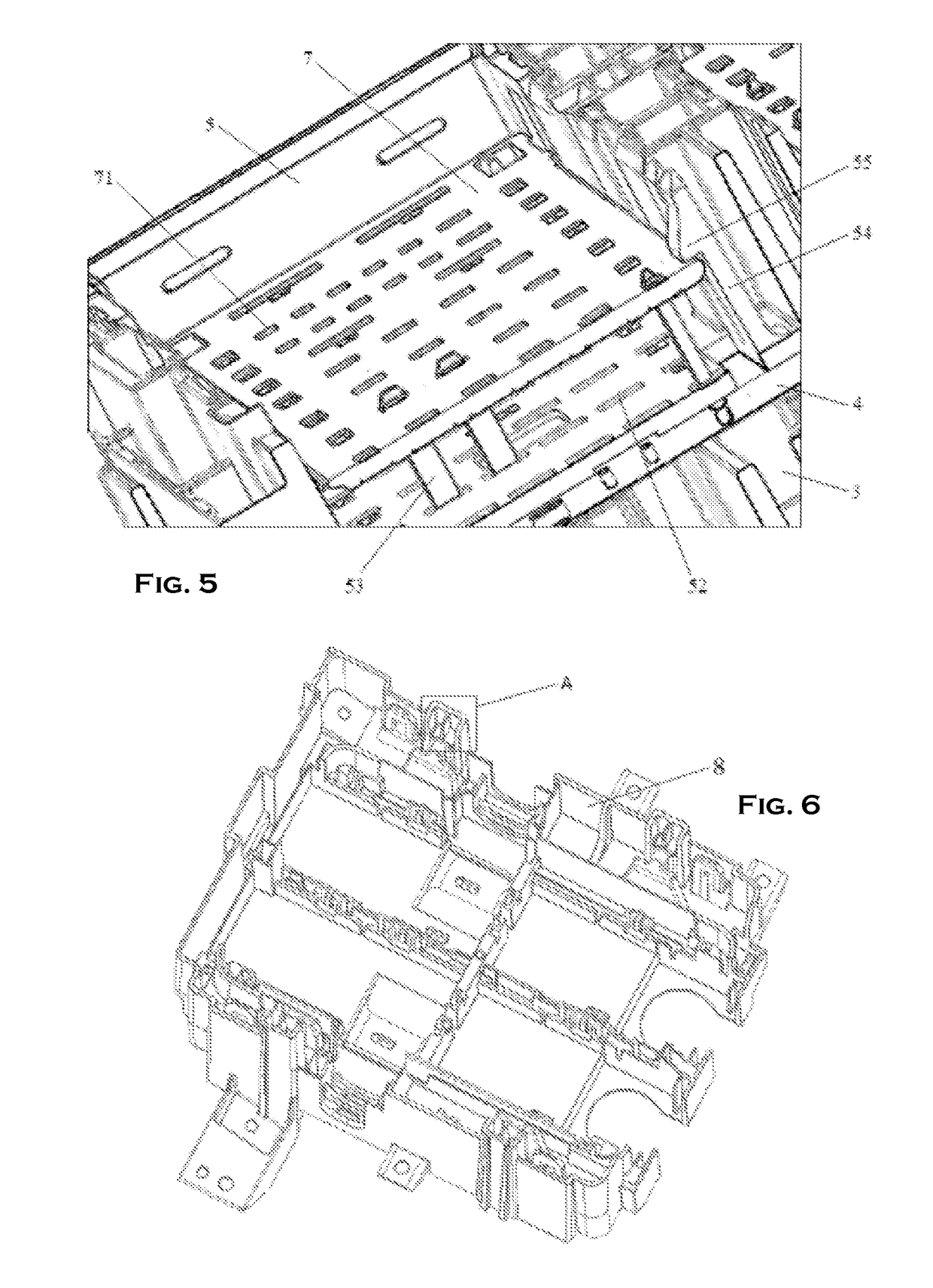

Printed circuit board with embedded capacitors therein, and process for manufacturing the same

InactiveUS6910266B2High capacitance valueIncrease capacitancePrinted circuit assemblingLine/current collector detailsCopper foilCopper plating

Disclosed herein are a printed circuit board with embedded capacitors therein and a process for manufacturing the printed circuit board. The embedded capacitors are formed by applying a photosensitive insulating resin to a printed circuit board inner layer, and applying a high dielectric polymer capacitor paste thereto. The process for manufacturing a printed circuit board with embedded capacitors therein comprises the steps of: i) laminating photoresist dry films to a copper clad FR-4, exposing to light and developing the dry films, and etching copper foils of the copper clad FR-4 to form bottom electrodes for forming capacitors; ii) applying a photosensitive insulating resin to the surfaces of the bottom electrodes, and exposing to light and developing to etch the photosensitive insulating resin; iii) applying a capacitor paste to the etched regions and curing the capacitor paste; iv) plating the upper regions of the cured capacitor paste and the photosensitive insulating resin using an electroless copper plating process to form copper foil layers for top electrodes; v) laminating photosensitive dry films to the copper foil layers for top electrodes, and exposing to light and developing the photosensitive dry films to etch regions of the dry films except for the copper foil layers where the top electrodes are to be formed; and vi) etching the regions of the dry films except for the copper foil layers where the top electrodes are to be formed, and the dry films formed on the top electrodes are removed so that the capacitor paste is discretely positioned between the top electrodes and the bottom electrodes to form discrete capacitors.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

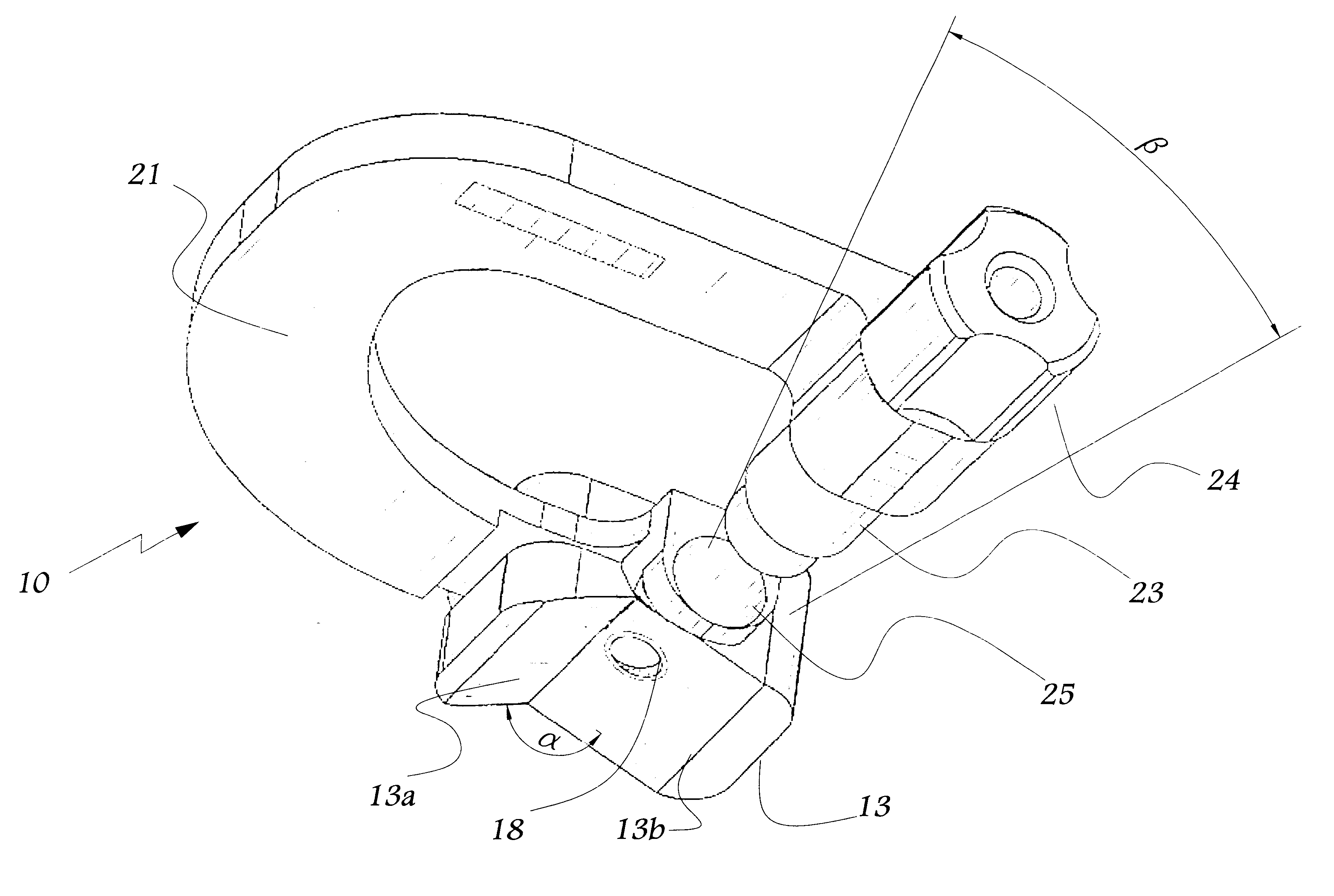

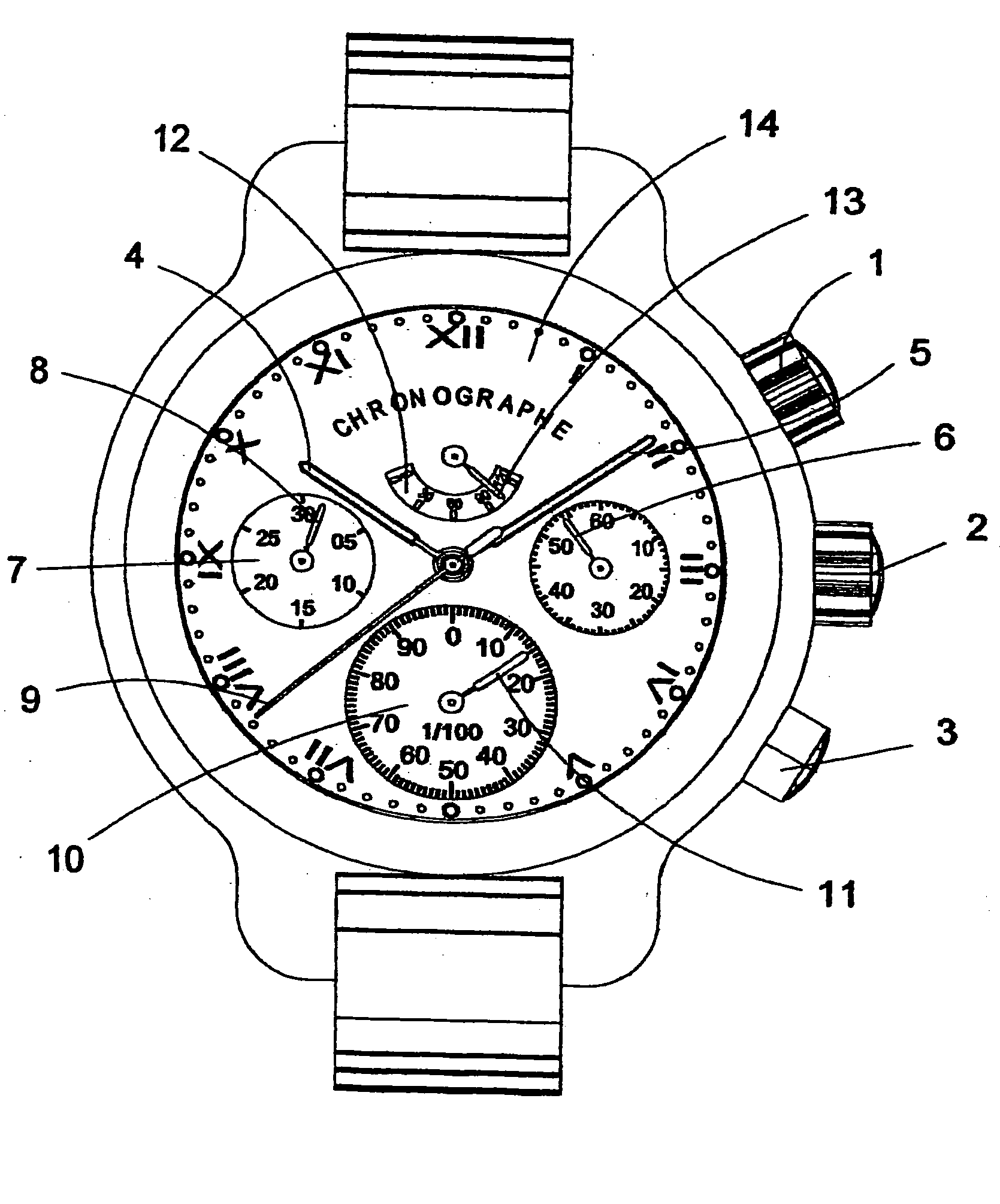

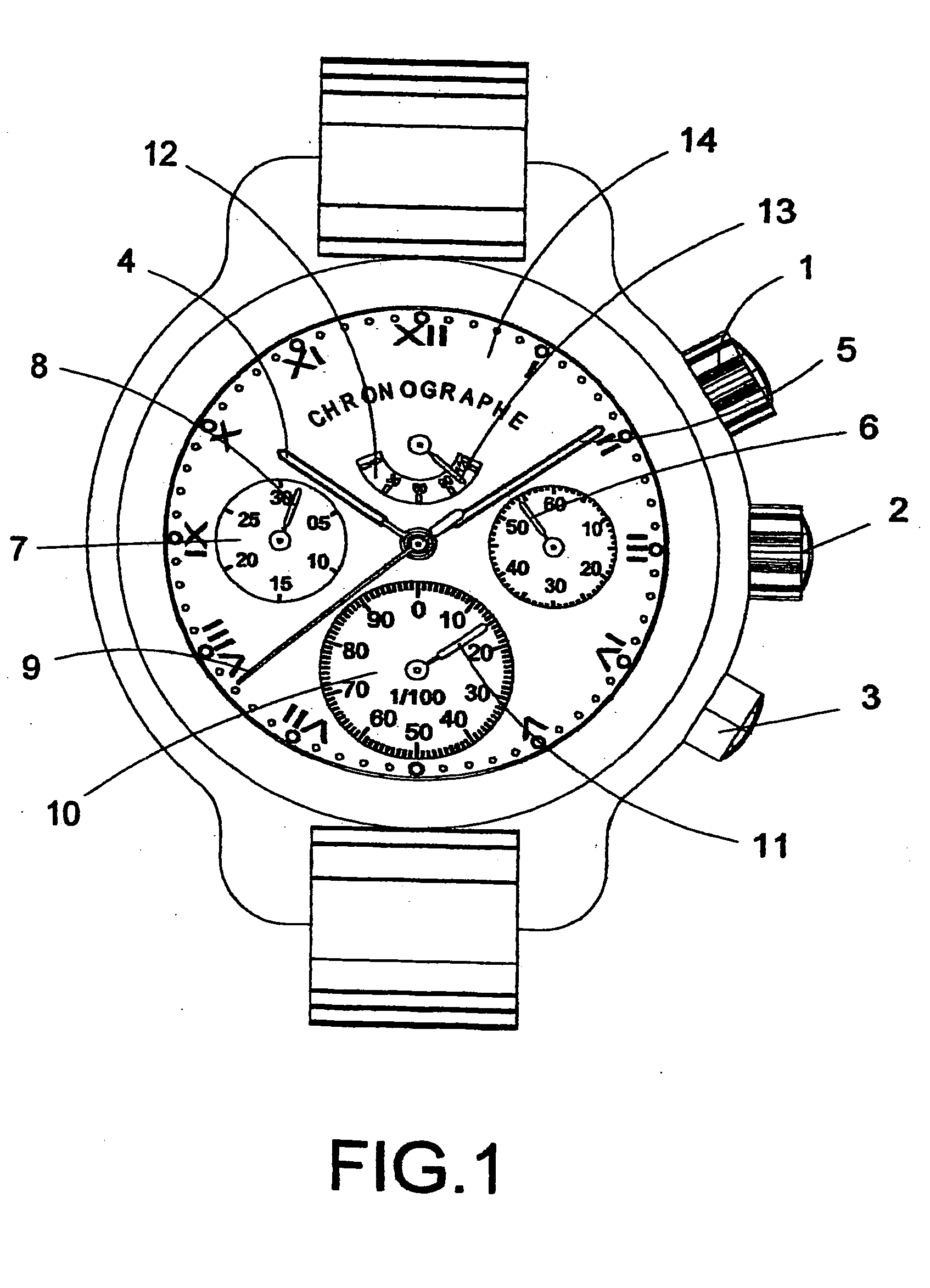

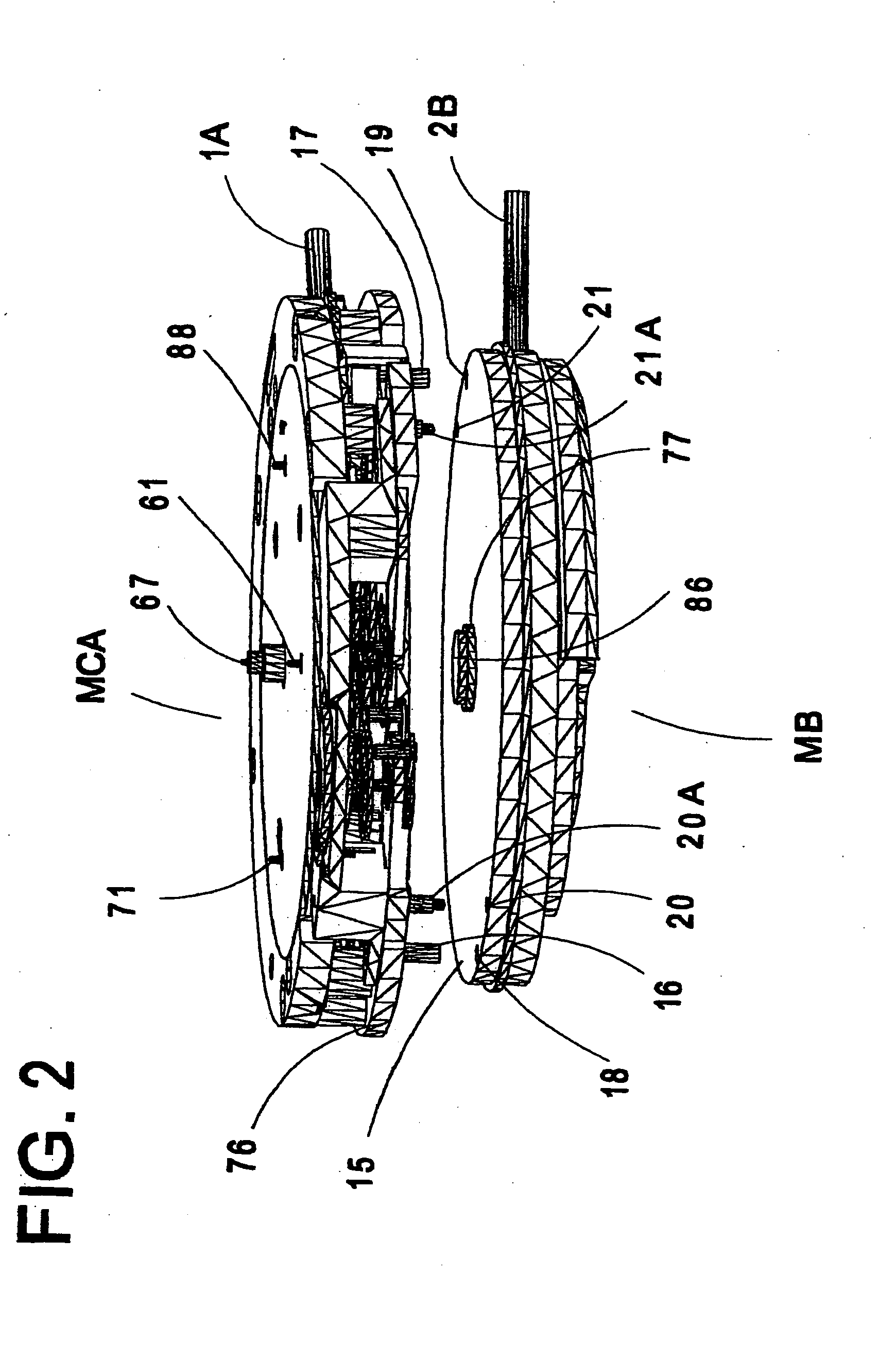

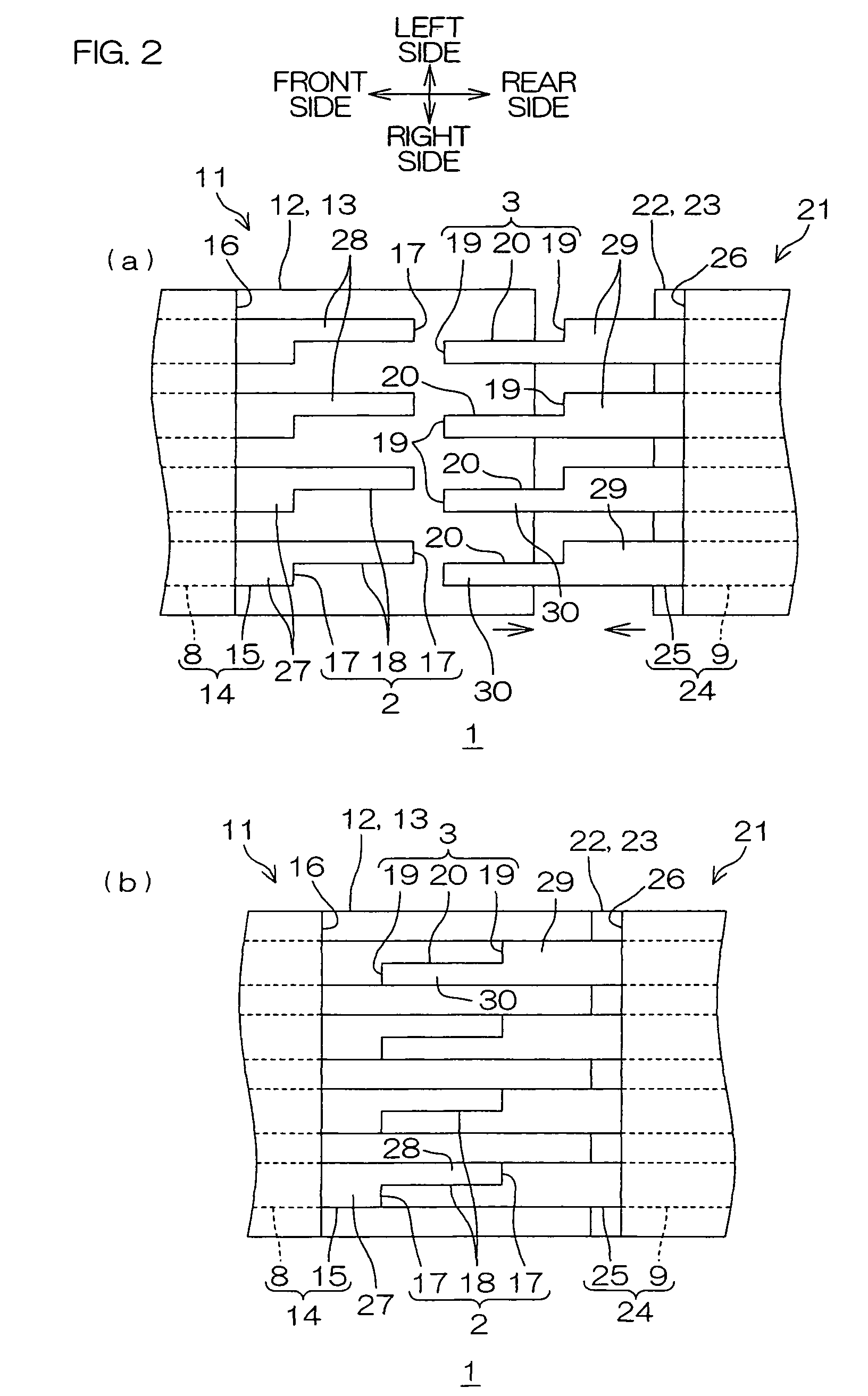

Device comprising a clock movement and a chronograph module

ActiveUS20050007888A1Low costPrecision can be ensuredTime indicationHorological winding mechanismsEngineeringMechanical elements

A device comprises a basic clock movement MB whose time indicators are driven by a first barrel connected to a first wheelwork and a first regulator organ, and an autonomous chronograph module MCA whose indicators are driven by a second barrel independent from the first, connected to a second wheelwork and a second regulator organ. The chronograph module is exclusively composed of mechanical elements. The frequency of oscillation supplied by its regulator is equal N times the frequency of oscillation supplied by the regulator of the base movement, with the coefficient N being definable according to a specific application of the chronograph, so that any chronograph module thus previously defined can work with-the same base movement. The chronograph regulator remains constantly engaged with the corresponding wheelwork. The chronograph module allows a time interval to be read with a minimum precision of a hundredth of second. The organs of the base movement and of the chronograph module are arranged in such a way that in assembled state, the height and overall diameter do not exceed 7.75 mm and 30 mm respectively, the dimensions of the chronograph itself being not greater than 4 mm (height) and 30 mm (diameter) when its elements are mounted on a bottom plate, so that the device can advantageously be integrated in the case of a wrist-watch and affords an aesthetic exterior.

Owner:LVMH SWISS MFG SA

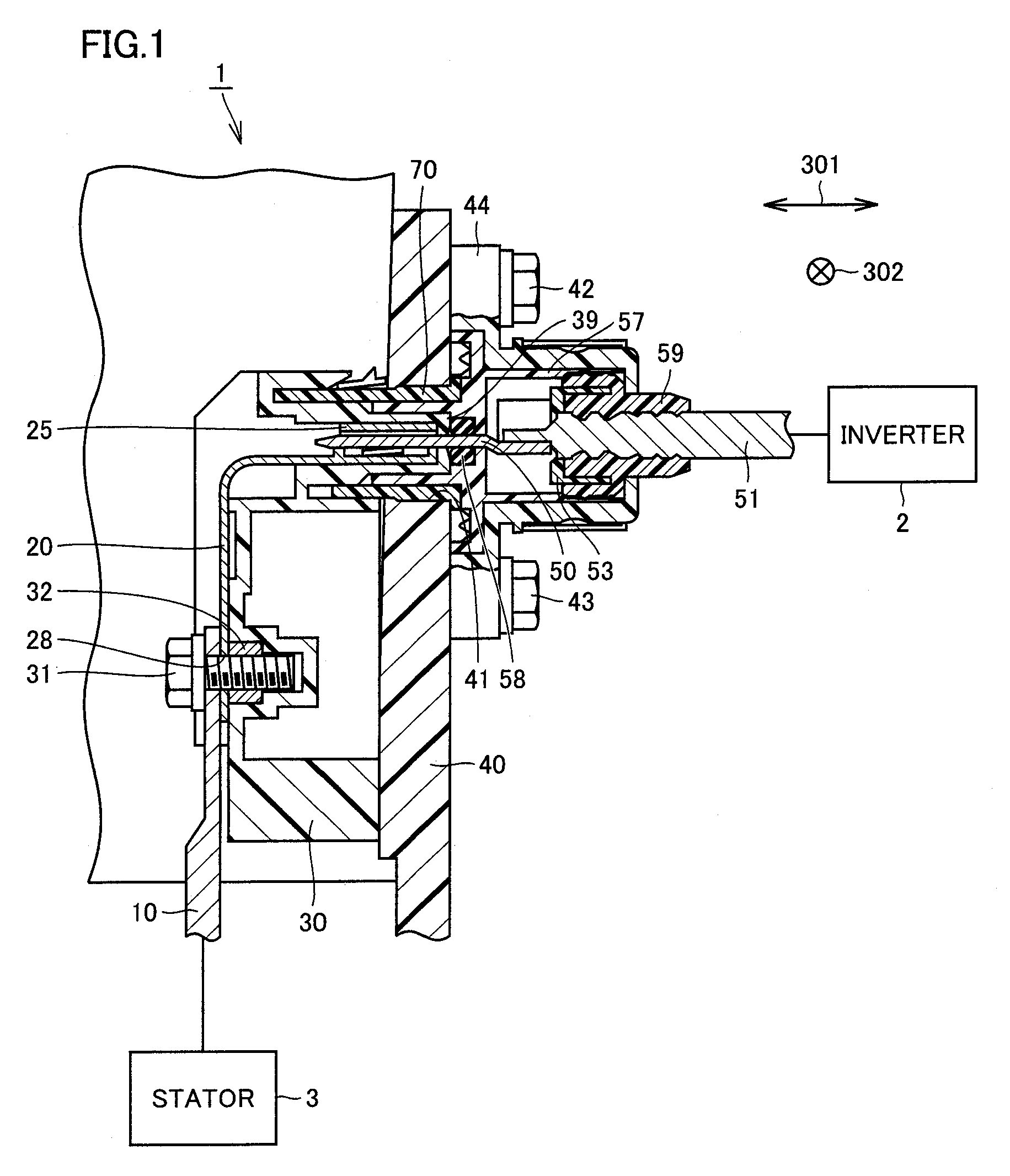

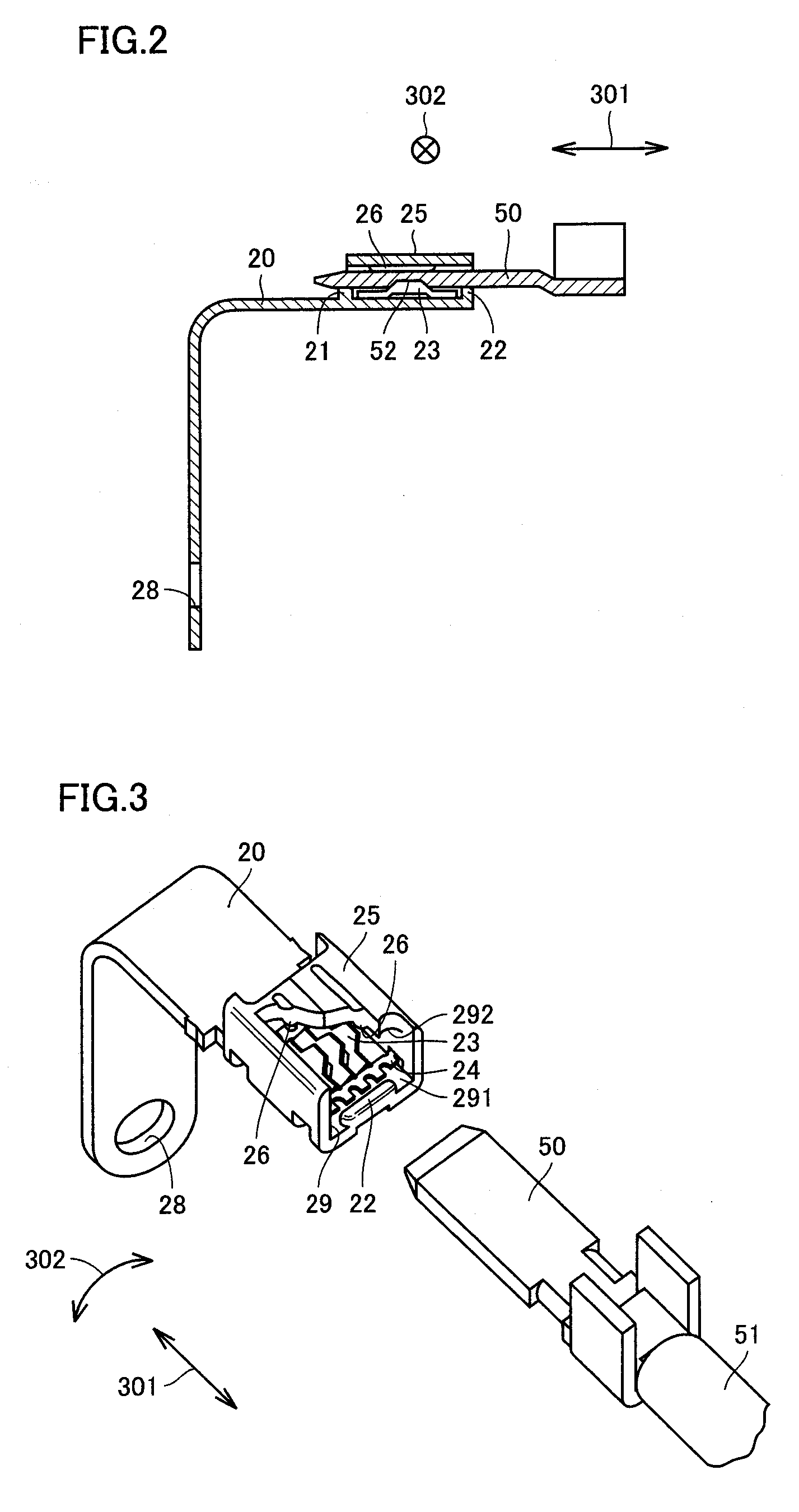

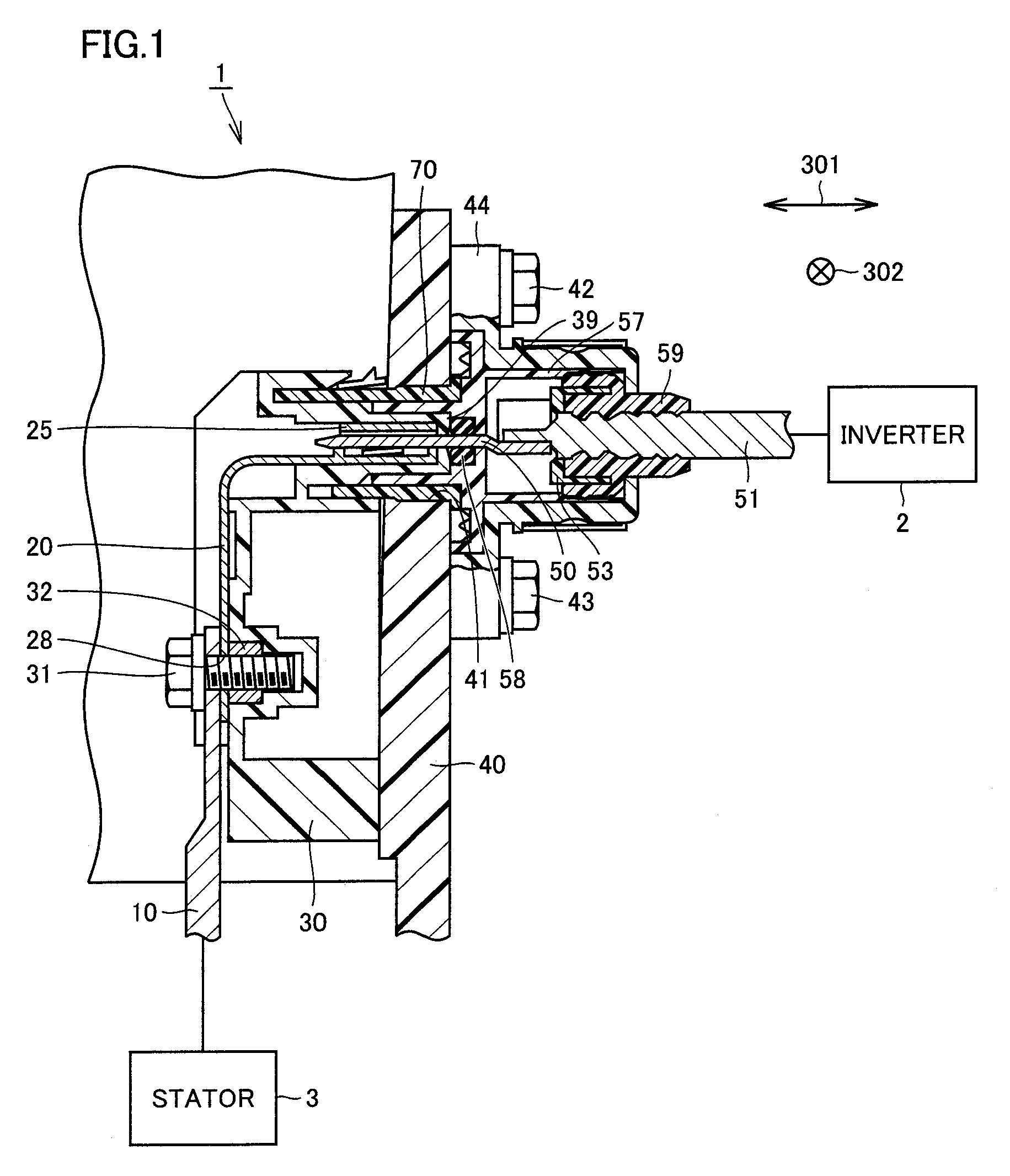

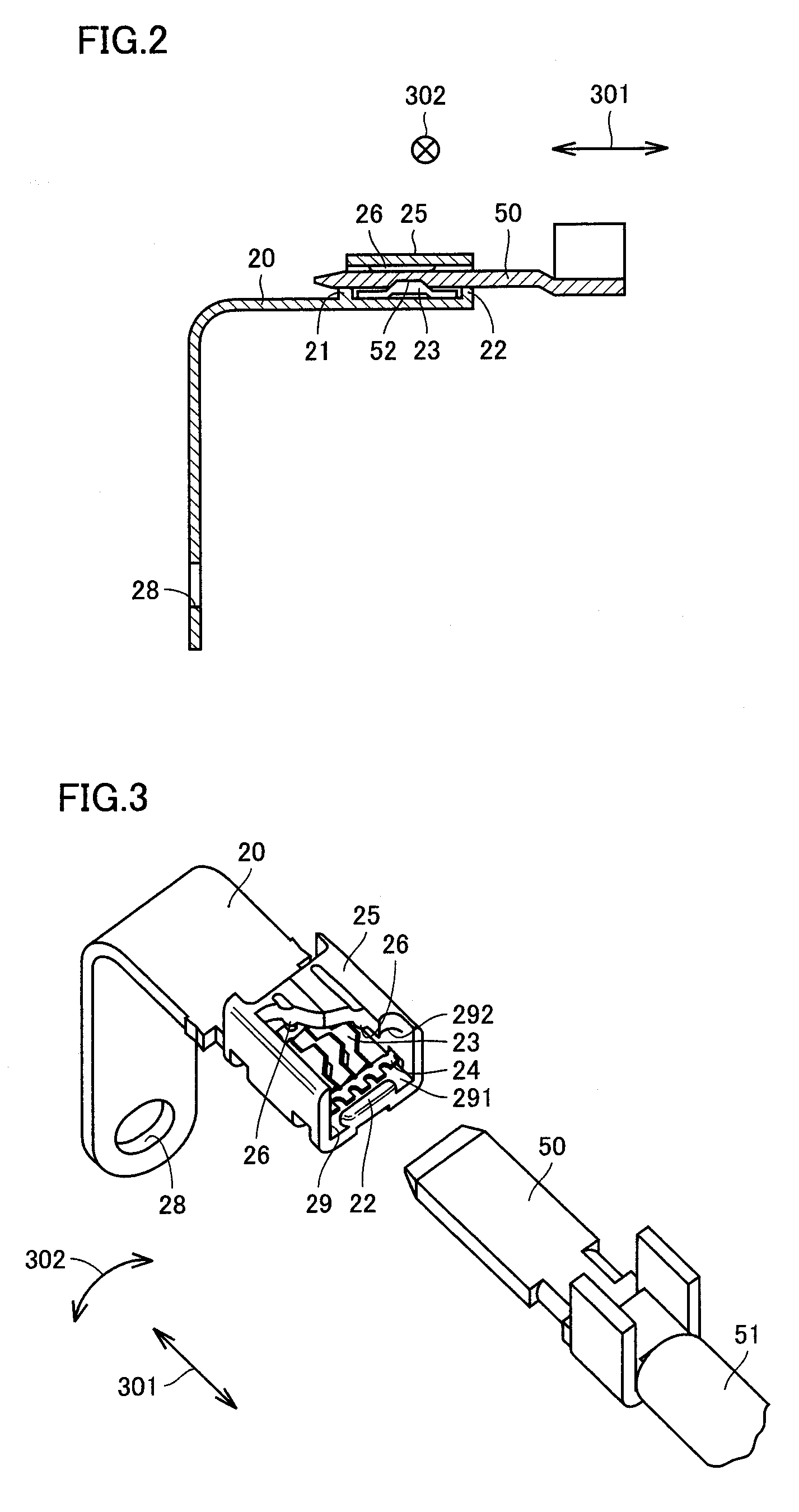

Connector structure and connector type terminal block structure

ActiveUS20070218736A1Ensure electrical connectionReduce manufacturing costOne pole connectionsVehicle connectorsBlock structureMechanical engineering

A connector structure that can ensure connection is provided. In the connector structure, a bus bar and a plate-like terminal mate with each other to establish an electric connection. A lower-side inner surface as a first inner surface defining the opening is provided with a plurality of conductive rotary members that rotate in a direction substantially perpendicular to a direction in which the plate-like terminal is inserted. It is also provided with a frame member that holds the rotary members and that is connected to the bus bar. The rotary members are twisted relative to the frame member and thereby biased relative to the plate-like terminal. By the plate-like terminal being inserted into and pulled out from the bus bar, the rotary members receive force from the plate-like terminal and rotate within a plane substantially perpendicular to a direction in which the plate-like terminal is inserted and pulled out.

Owner:TOYOTA JIDOSHA KK +1

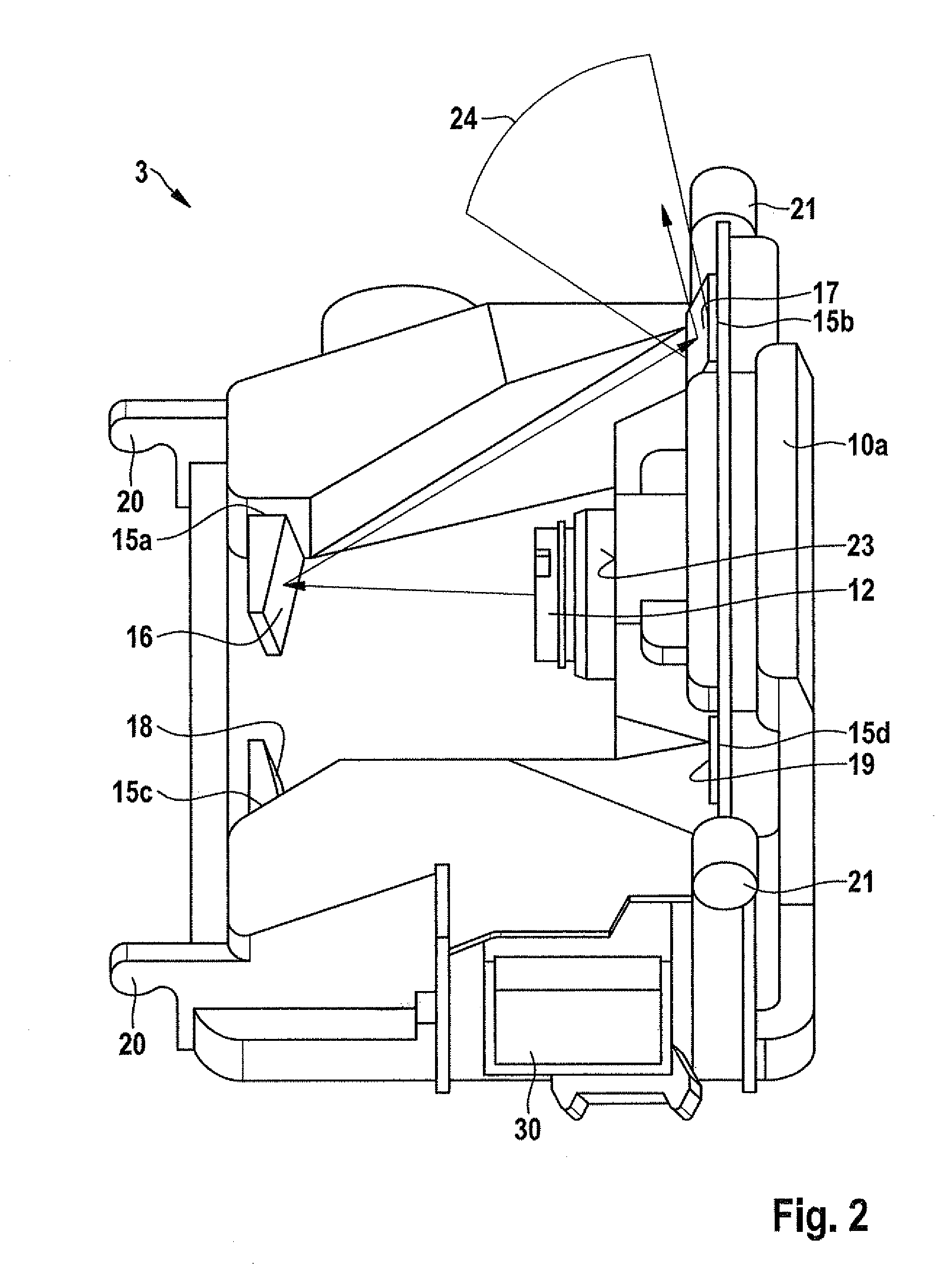

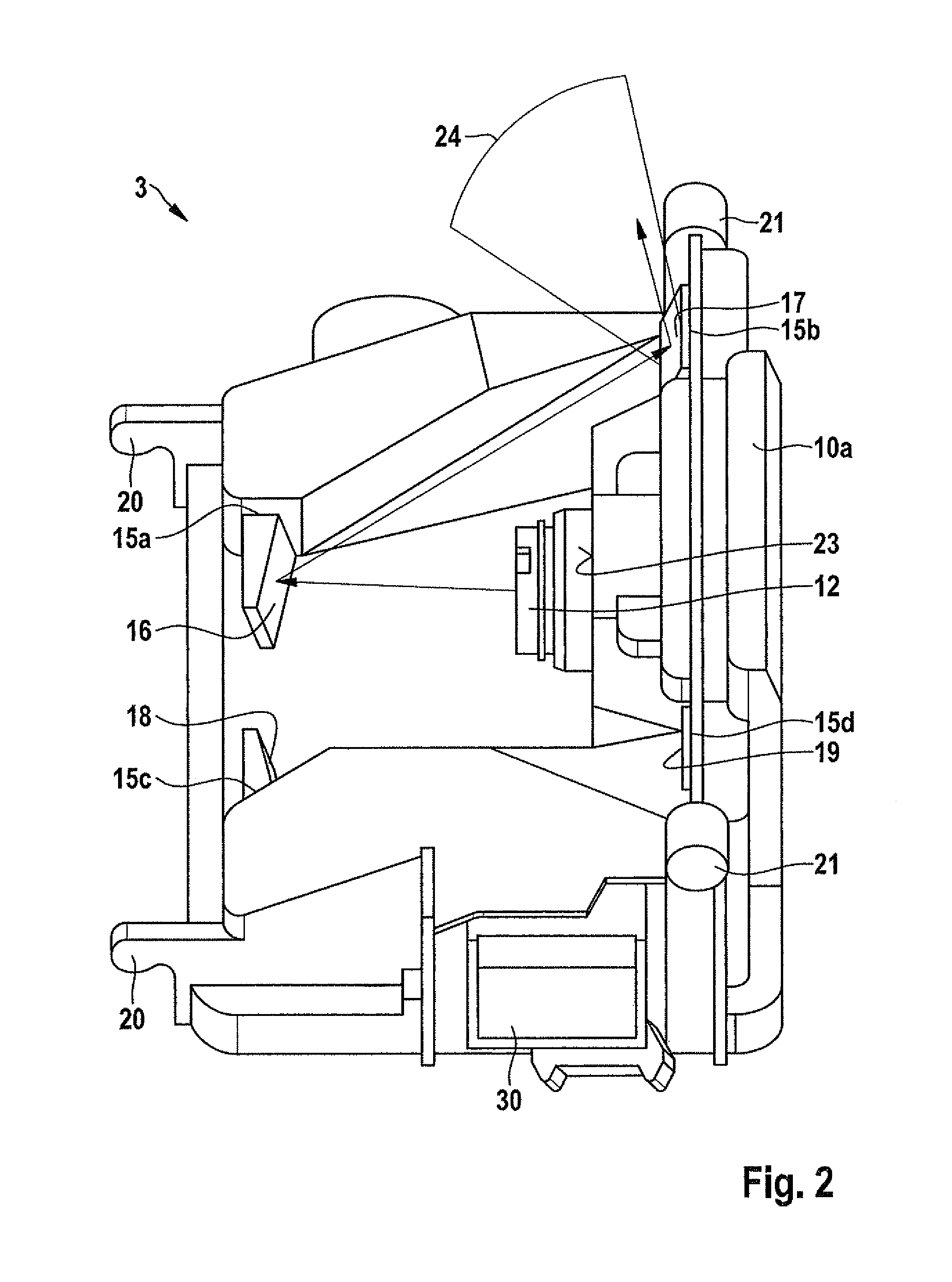

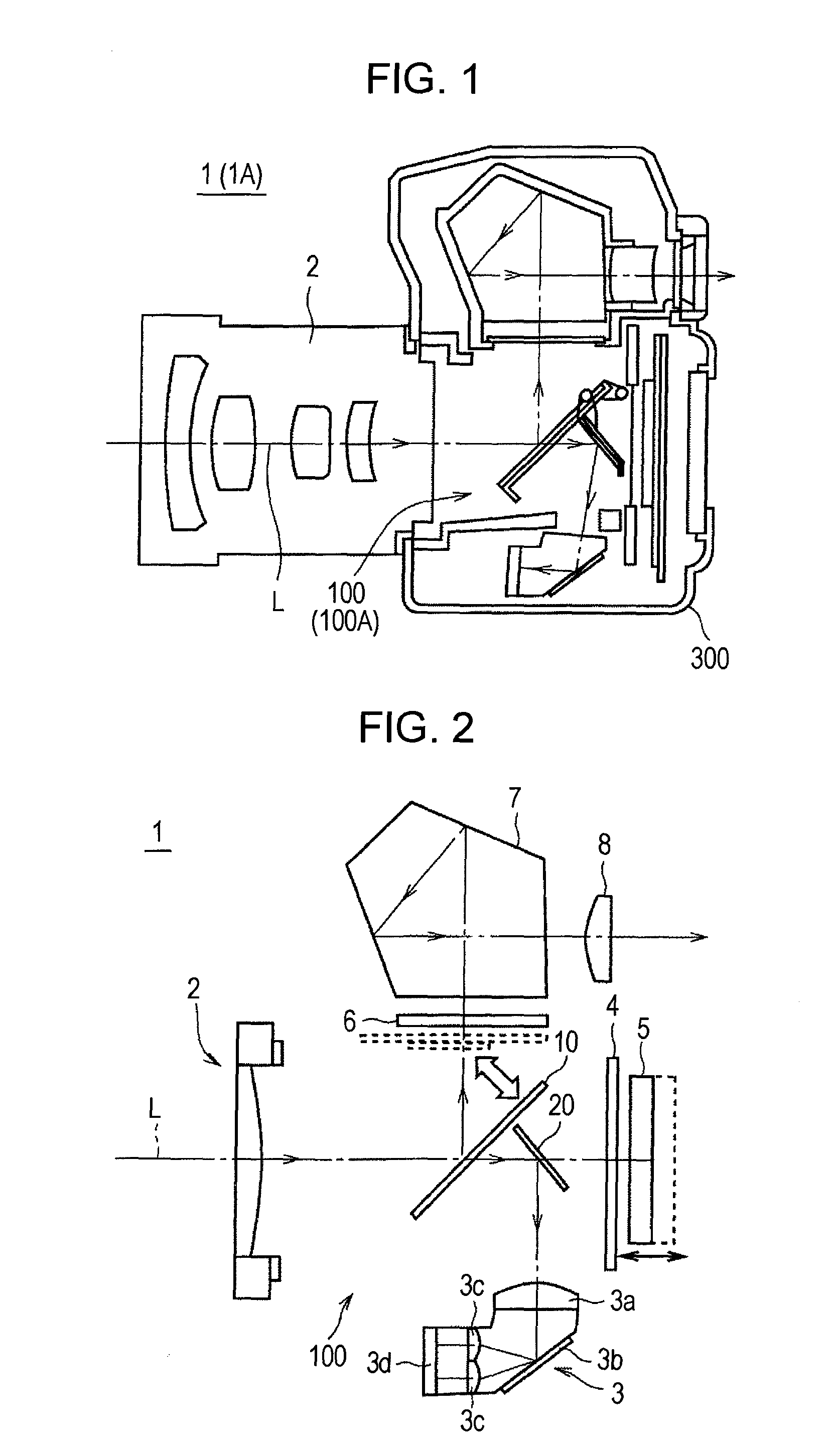

Camera for a vehicle

InactiveUS20120075471A1Expand the scope of detectionPrecise positioningColor television detailsClosed circuit television systemsLight guideOptical mount

A camera for a vehicle is described. The camera has at least one optoelectronic image converter, a camera housing in whose interior the image converter is accommodated, a camera optical element, which is accommodated in an optical mounting reference surface of the camera housing and is provided for imaging a primary detection area on the image converter, and a camera position reference surface for positioning the camera in relation to a vehicle window. At least one receiving surface for at least one light-guiding device e.g., one or a plurality of mirrors, is formed on the camera housing for deflecting light from at least one additional detection area to the camera optical element. The optical mounting reference surface, camera position reference surface, and receiving surface are preferably formed on a single housing component, e.g., an upper shell.

Owner:ROBERT BOSCH GMBH

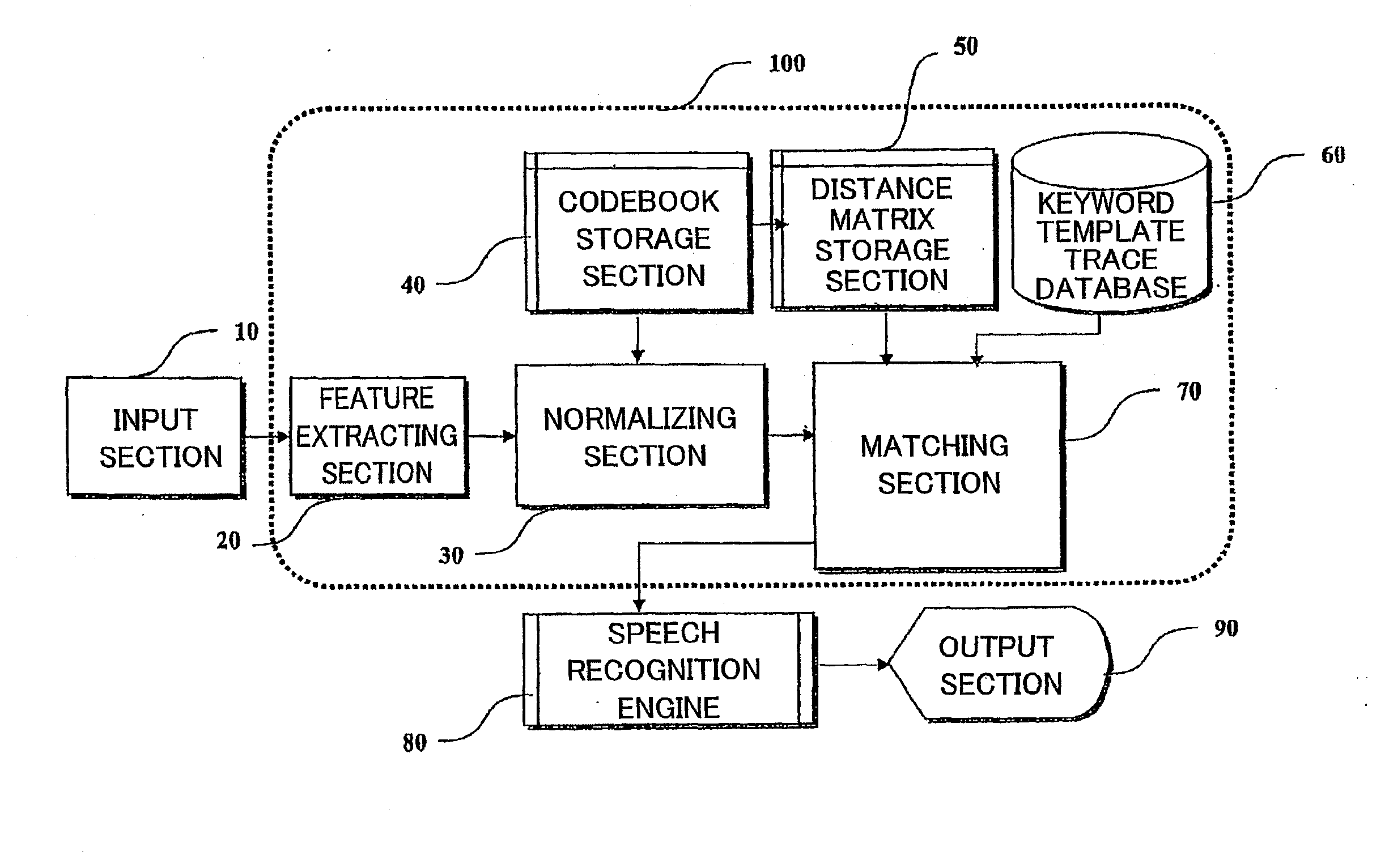

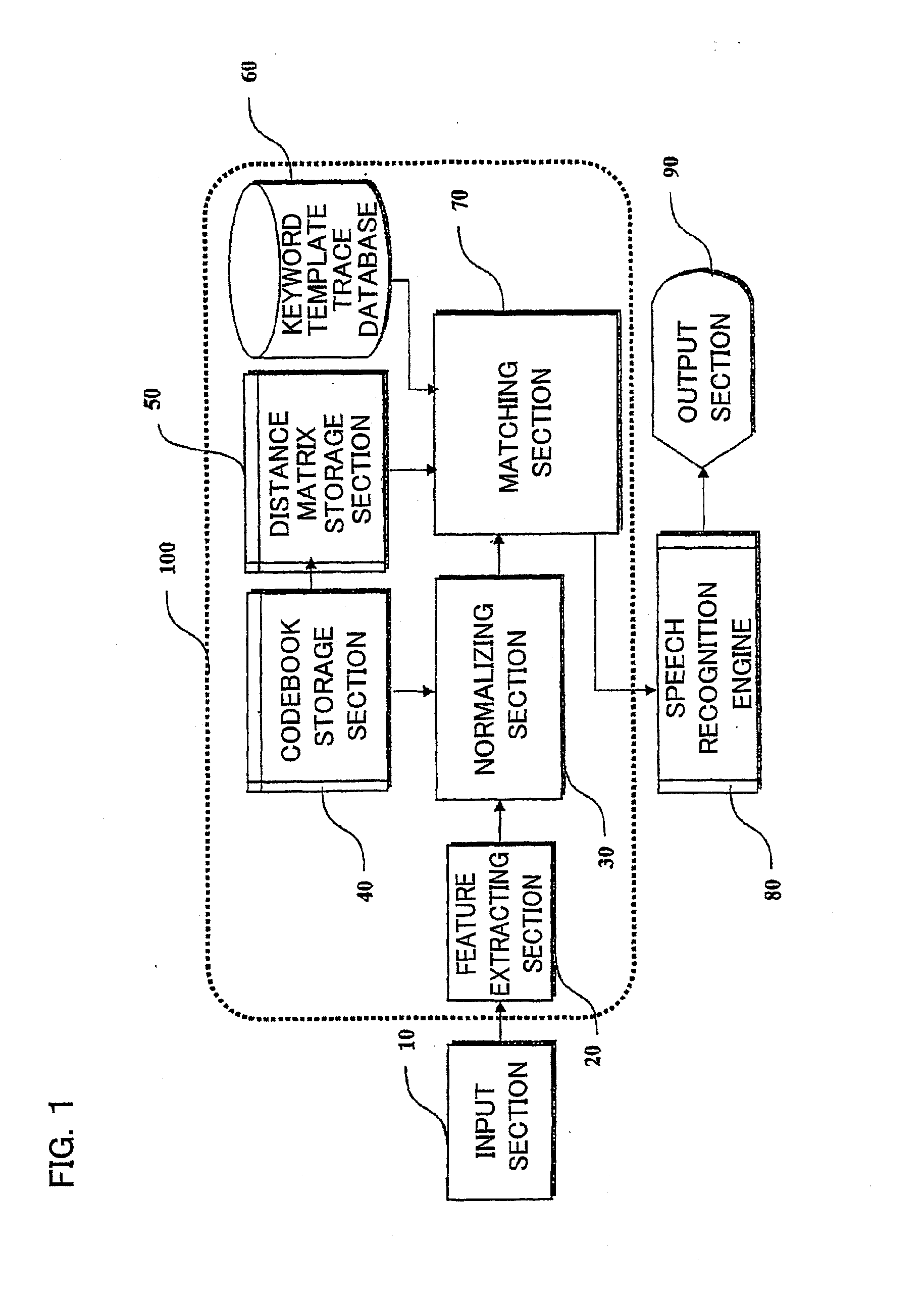

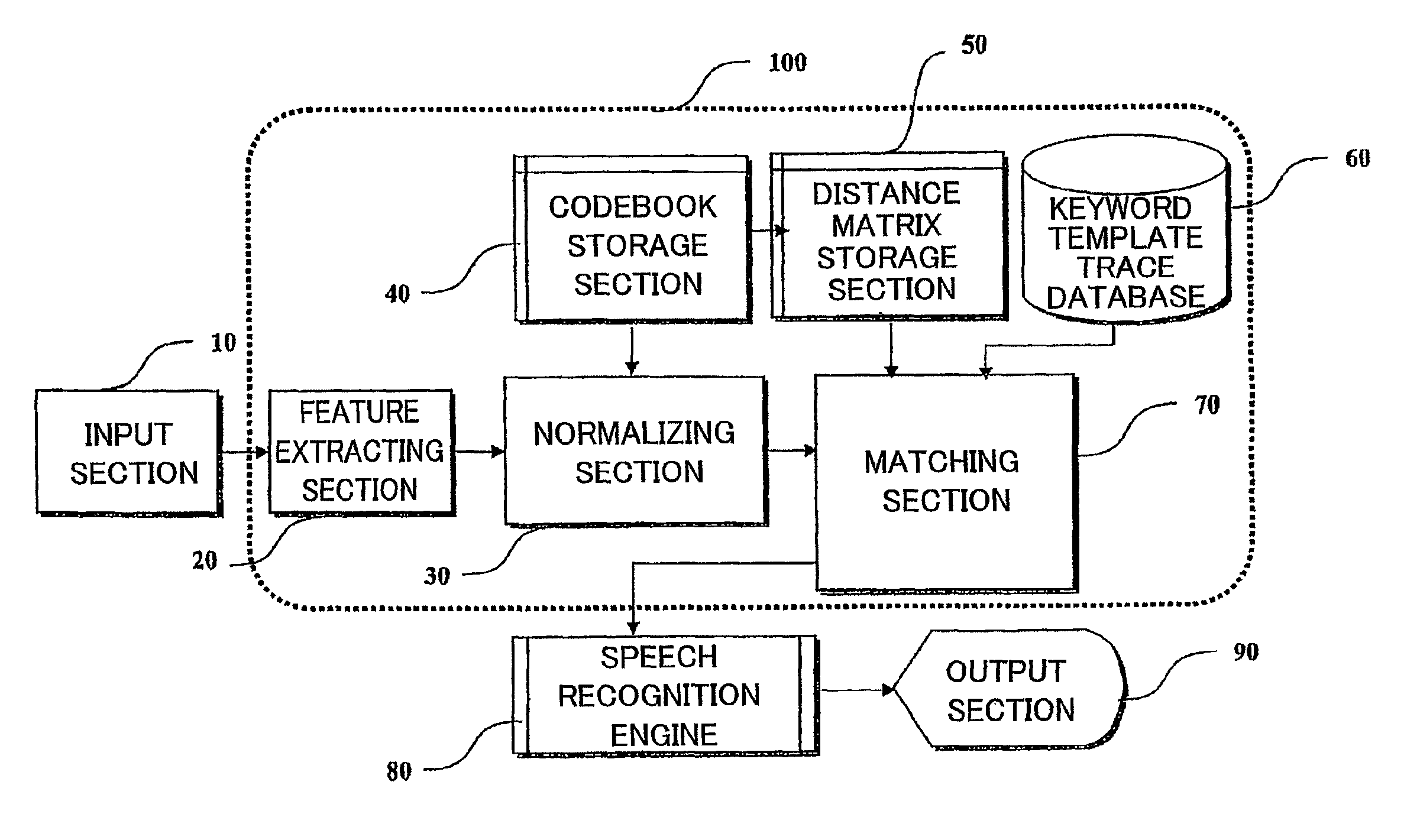

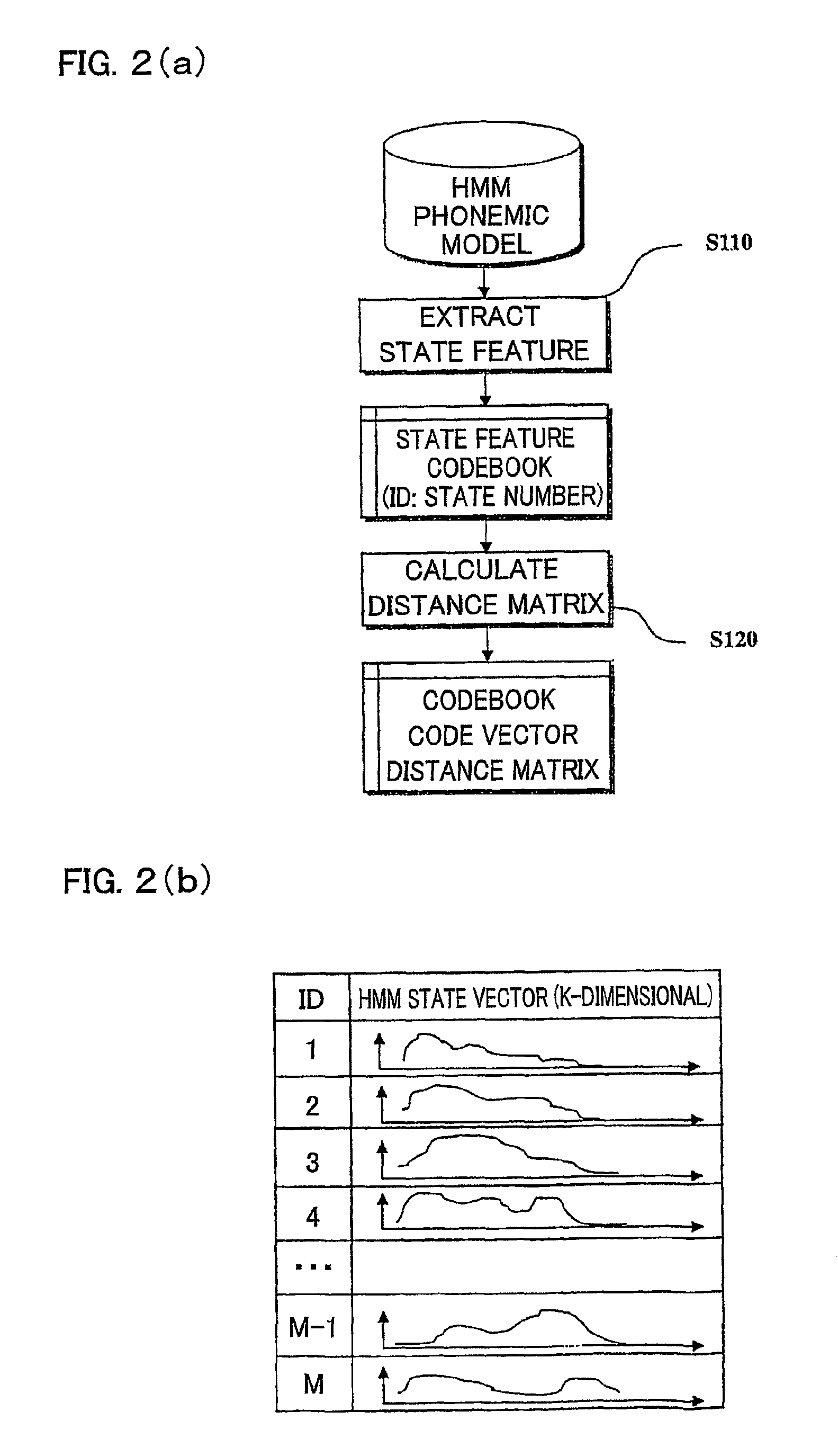

Method and apparatus for locating speech keyword and speech recognition system

InactiveUS20100094626A1Reduce the amount requiredIncrease speedSpeech recognitionFeature structureFeature parameter

It is an object of the present invention to provide a method and apparatus for locating a keyword of a speech and a speech recognition system. The method includes the steps of: by extracting feature parameters from frames constituting the recognition target speech, forming a feature parameter vector sequence that represents the recognition target speech; by normalizing of the feature parameter vector sequence with use of a codebook containing a plurality of codebook vectors, obtaining a feature trace of the recognition target speech in a vector space; and specifying the position of a keyword by matching prestored keyword template traces with the feature trace. According to the present invention, a keyword template trace and a feature space trace of a target speech are drawn in accordance with an identical codebook. This causes resampling to be unnecessary in performing linear movement matching of speech wave frames having similar phonological feature structures. This makes it possible to improve the speed of location and recognition while ensuring the precision of recognition.

Owner:SHARP KK

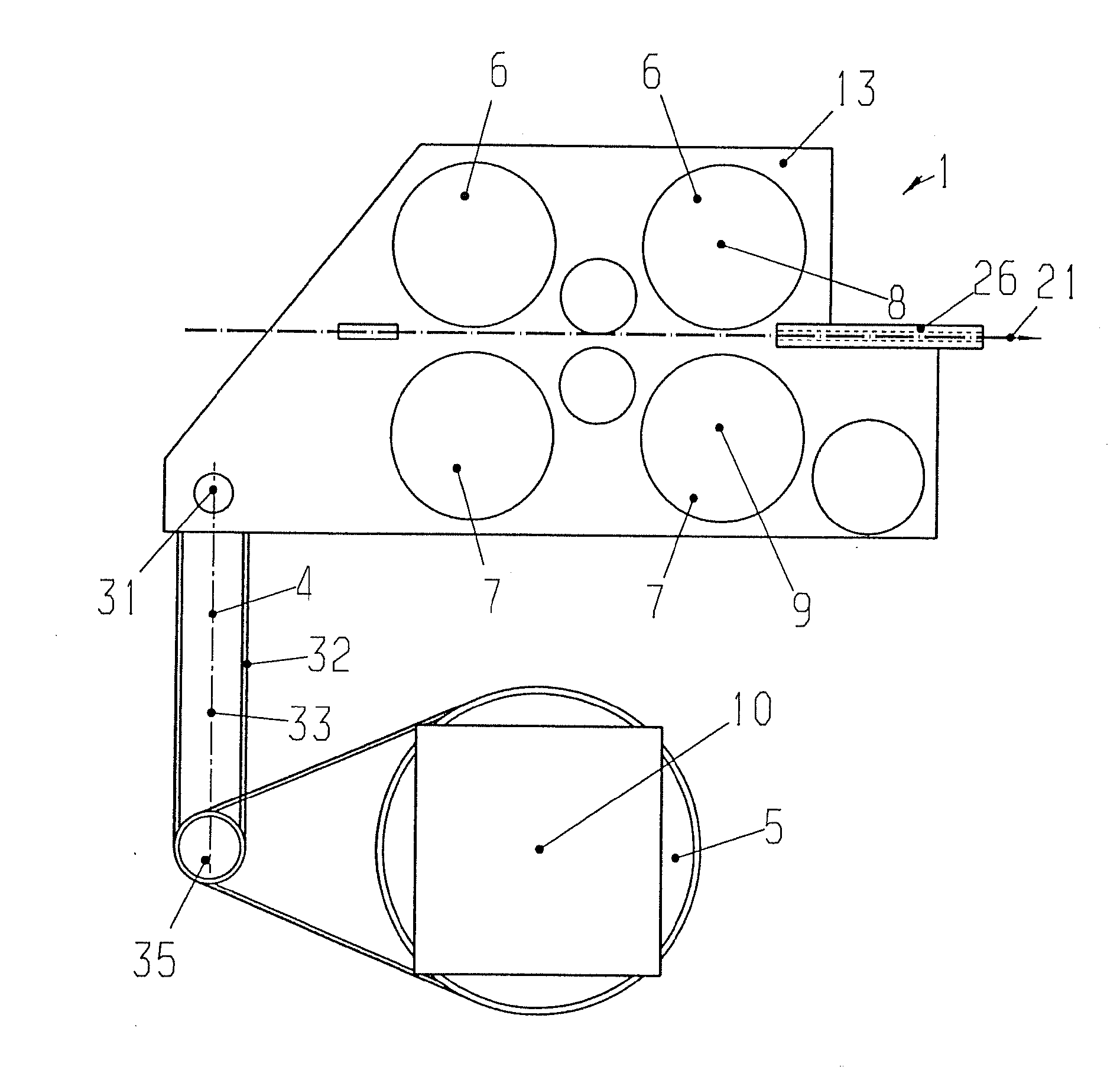

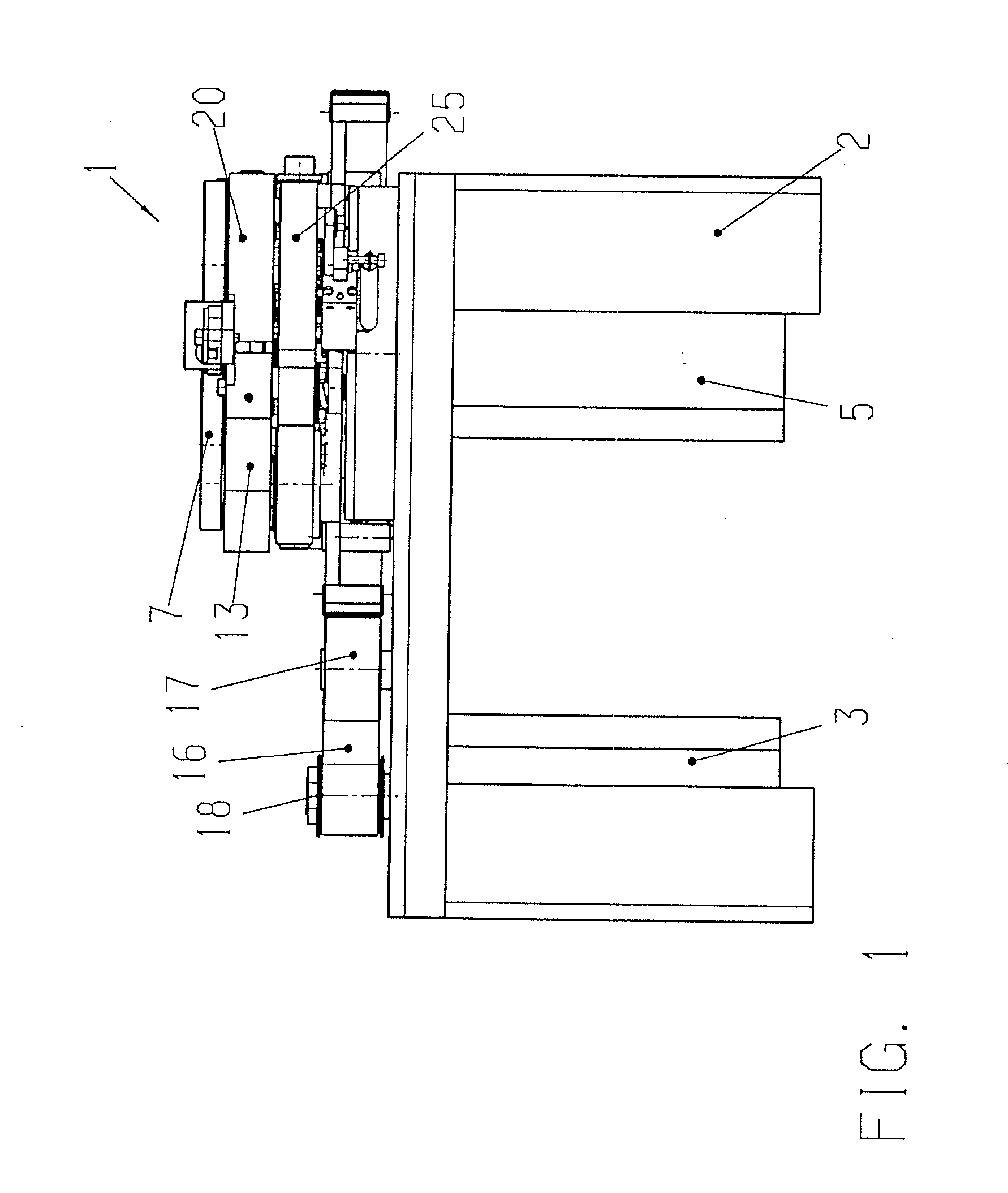

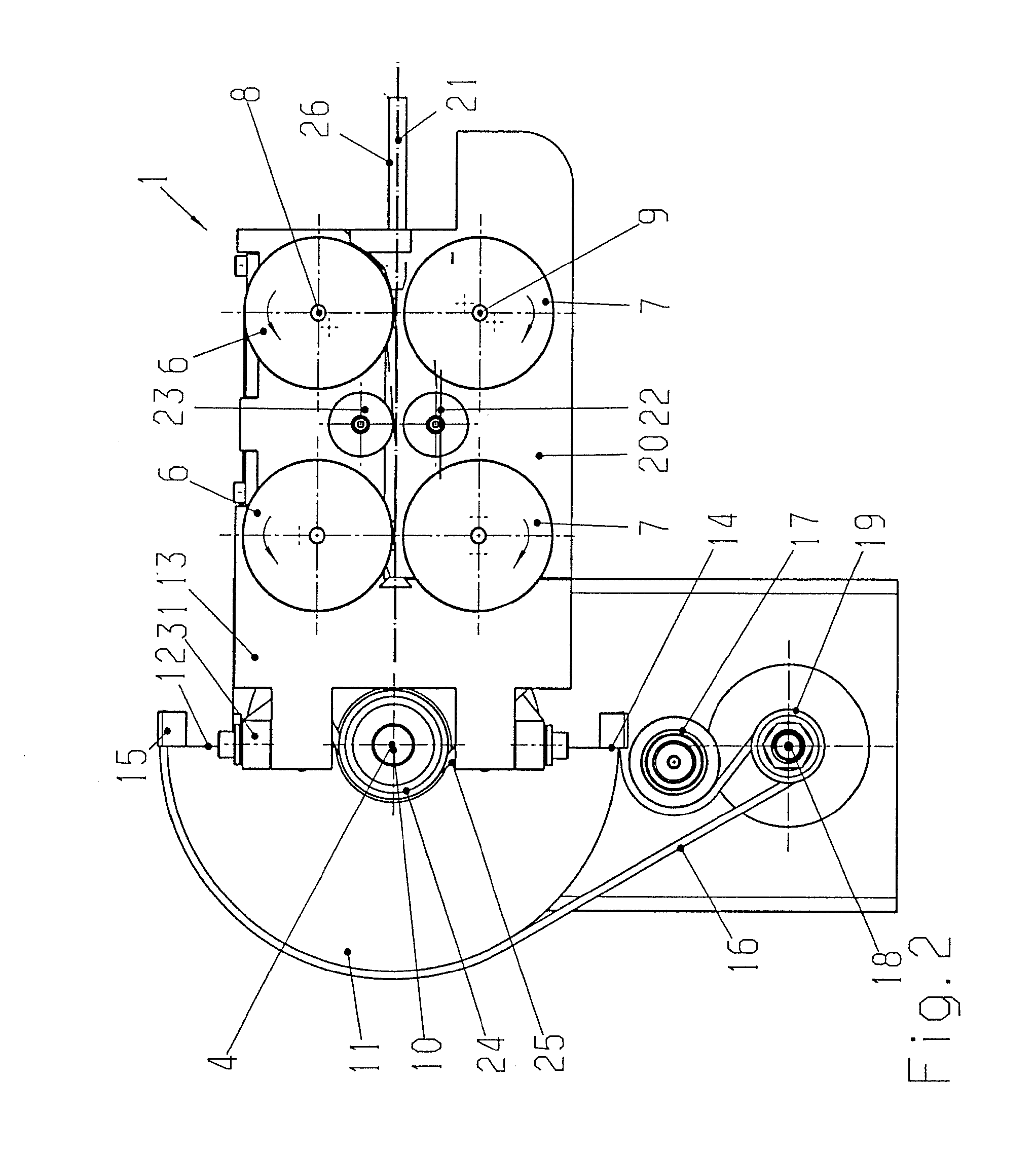

Cable Transport Device

InactiveUS20110049211A1Simple designPrecision can be ensuredLine/current collector detailsFilament handlingCable transmissionEngineering

A cable transport device having a pivotably mounted cable transporter, a first drive means connected in a stationary manner to a base frame and intended for achieving an exactly defined pivot movement of the cable transporter around a pivot axis and a second drive means for synchronous driving of at least two cooperating pressure rollers. The second drive means with a drive axle for the pressure rollers is connected in a stationary manner to the base frame, and the drive axle of the second drive means coincides with the pivot axis for the cable transporter. The transmission of the pivot movement is effected via a toothed belt which is tensioned symmetrically to the center of rotation of the pivot axis between a first intermediate shaft arranged on a base plate of the cable transporter and a second intermediate shaft fixed to the machine frame, the pitch axis of the cable transporter being identical to the axis of the first intermediate shaft.

Owner:SCHLEUNIGER HLDG

Device for detecting spatial position

InactiveUS7877890B2Easy to operateEasy to fixMeasurement devicesSurgical navigation systemsBall bearingEngineering

The invention relates to a device for detecting spatial position, which can be attached via a mounting device to a surgical instrument, which has a longitudinal axis, wherein the mounting device has a through opening, which is penetrated by the instrument, wherein the mounting device is mounted so as to be rotatable around the longitudinal axis of the instrument, and wherein the mounting device can be immobilized in an axial and a radial direction via two angular ball bearings.

Owner:WEBER INSTR

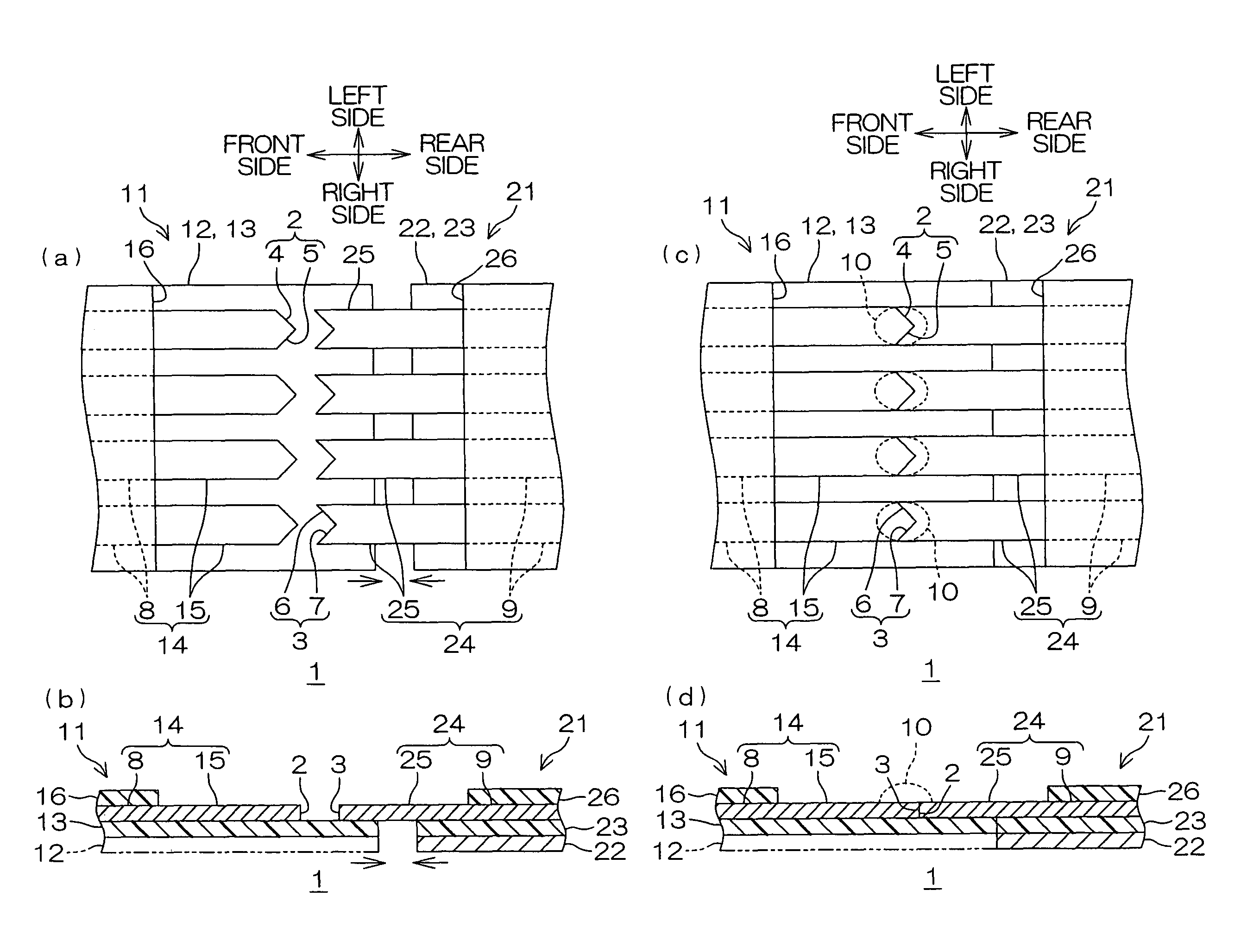

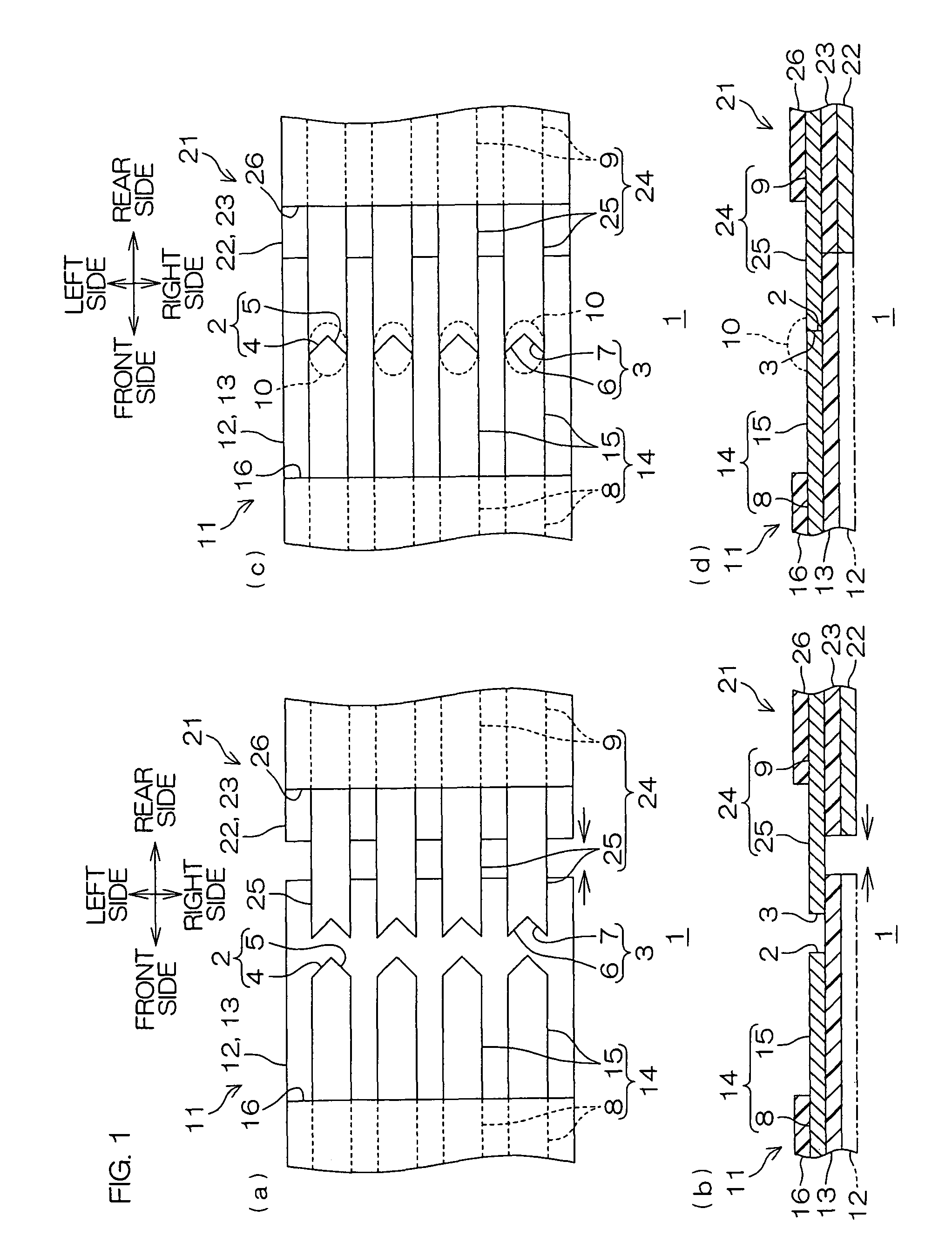

Wired circuit board and connection structure between wired circuit boards

InactiveUS20090044969A1Precise positioningAvoid displacementPrinted circuit aspectsPrinted circuit manufactureEngineeringPrinted circuit board

Owner:NITTO DENKO CORP

Camera for a vehicle

InactiveUS8836786B2Precise positioningPrecision can be ensuredColor television detailsClosed circuit television systemsOptical mountLight guide

A camera for a vehicle is described. The camera has at least one optoelectronic image converter, a camera housing in whose interior the image converter is accommodated, a camera optical element, which is accommodated in an optical mounting reference surface of the camera housing and is provided for imaging a primary detection area on the image converter, and a camera position reference surface for positioning the camera in relation to a vehicle window. At least one receiving surface for at least one light-guiding device e.g., one or a plurality of mirrors, is formed on the camera housing for deflecting light from at least one additional detection area to the camera optical element. The optical mounting reference surface, camera position reference surface, and receiving surface are preferably formed on a single housing component, e.g., an upper shell.

Owner:ROBERT BOSCH GMBH

Focus control device and imaging device

InactiveUS20090066830A1High precision focus controlFast and precise focus controlTelevision system detailsColor television detailsCamera lensHigh-pass filter

An auto focus (AF) circuit includes a high-pass filter and band-pass filter having mutually different frequency characteristics. During contrast AF control prior to an actual shooting, AF evaluation values acquired by using the high-pass filter are used most preferentially in detecting the lens focusing position of a focus lens. In this way, the high-pass filter that emphasizes and extracts high frequency band components, which increase in image data when shooting a typical subject, is set to be used preferentially, thereby making it possible to perform high-precision focusing control with respect to various kinds of subjects.

Owner:SONY CORP

Integrated processing method for sheet steel hot stamping and heat treatment

InactiveUS20130037181A1High strengthCorrection of deformationFurnace typesQuenching agentsHot stampingSheet steel

A processing method is provided integrating hot stamping and controllable subsequent heat treatment in the technical field of hot working for steels. It includes the steps of selecting and preparing a steel blank, hot stamping treatment, controllable temperature quenching, adjusting the temperature of the steel blank to a tempering temperature and fine stamping at the same time. The invention combines the hot stamping and controllable heat treatment to improve the strength of material with precise plastic deformation and save energy as well. The tensile strength of the processed steel is greater than 1900 Ma.

Owner:SHANGHAI JIAO TONG UNIV

Method and apparatus for locating speech keyword and speech recognition system

InactiveUS8255215B2Increase speedPrecision can be ensuredSpeech recognitionLinear motionCharacteristic space

It is an object of the present invention to provide a method and apparatus for locating a keyword of a speech and a speech recognition system. The method includes the steps of: by extracting feature parameters from frames constituting the recognition target speech, forming a feature parameter vector sequence that represents the recognition target speech; by normalizing of the feature parameter vector sequence with use of a codebook containing a plurality of codebook vectors, obtaining a feature trace of the recognition target speech in a vector space; and specifying the position of a keyword by matching prestored keyword template traces with the feature trace. According to the present invention, a keyword template trace and a feature space trace of a recognition target speech are drawn in accordance with an identical codebook. This causes resampling to be unnecessary in performing linear movement matching of speech wave frames having similar phonological feature structures. This makes it possible to improve the speed of location and recognition while ensuring the precision of recognition.

Owner:SHARP KK

Connector structure and connector type terminal block structure

ActiveUS7445529B2Ensure electrical connectionReduce manufacturing costOne pole connectionsVehicle connectorsEngineeringBlock structure

A connector structure that can ensure connection is provided. In the connector structure, a bus bar and a plate-like terminal mate with each other to establish an electric connection. A lower-side inner surface as a first inner surface defining the opening is provided with a plurality of conductive rotary members that rotate in a direction substantially perpendicular to a direction in which the plate-like terminal is inserted. It is also provided with a frame member that holds the rotary members and that is connected to the bus bar. The rotary members are twisted relative to the frame member and thereby biased relative to the plate-like terminal. By the plate-like terminal being inserted into and pulled out from the bus bar, the rotary members receive force from the plate-like terminal and rotate within a plane substantially perpendicular to a direction in which the plate-like terminal is inserted and pulled out.

Owner:TOYOTA JIDOSHA KK +1

Self-aligning scanning probes for a scanning probe microscope

InactiveUS20080018993A1Facilitates self-alignmentPrecision of lateral alignmentNanotechnologyMicroscopesMicroscopeEngineering

Scanning probes are provided for alternative use in a scanning probe microscope. The scanning probes have micro cantilever beams of different lengths whose one end has a scanning tip for scanning a sample and whose other end has a holding element for the non-permanent attachment of the scanning probe to a support element secured in position on a probe holder, and where corresponding alignment elements are incorporated in the holding element and in the support element that align the holding element in automatically reproducible fashion relative to the probe holder when coupled with the support element. The distance between the scanning tip and a defined reference point of the holding element is constant in each case so that an alignment of the scanning probe in longitudinal direction is not necessary when the scanning probe is exchanged.

Owner:NANOWORLD

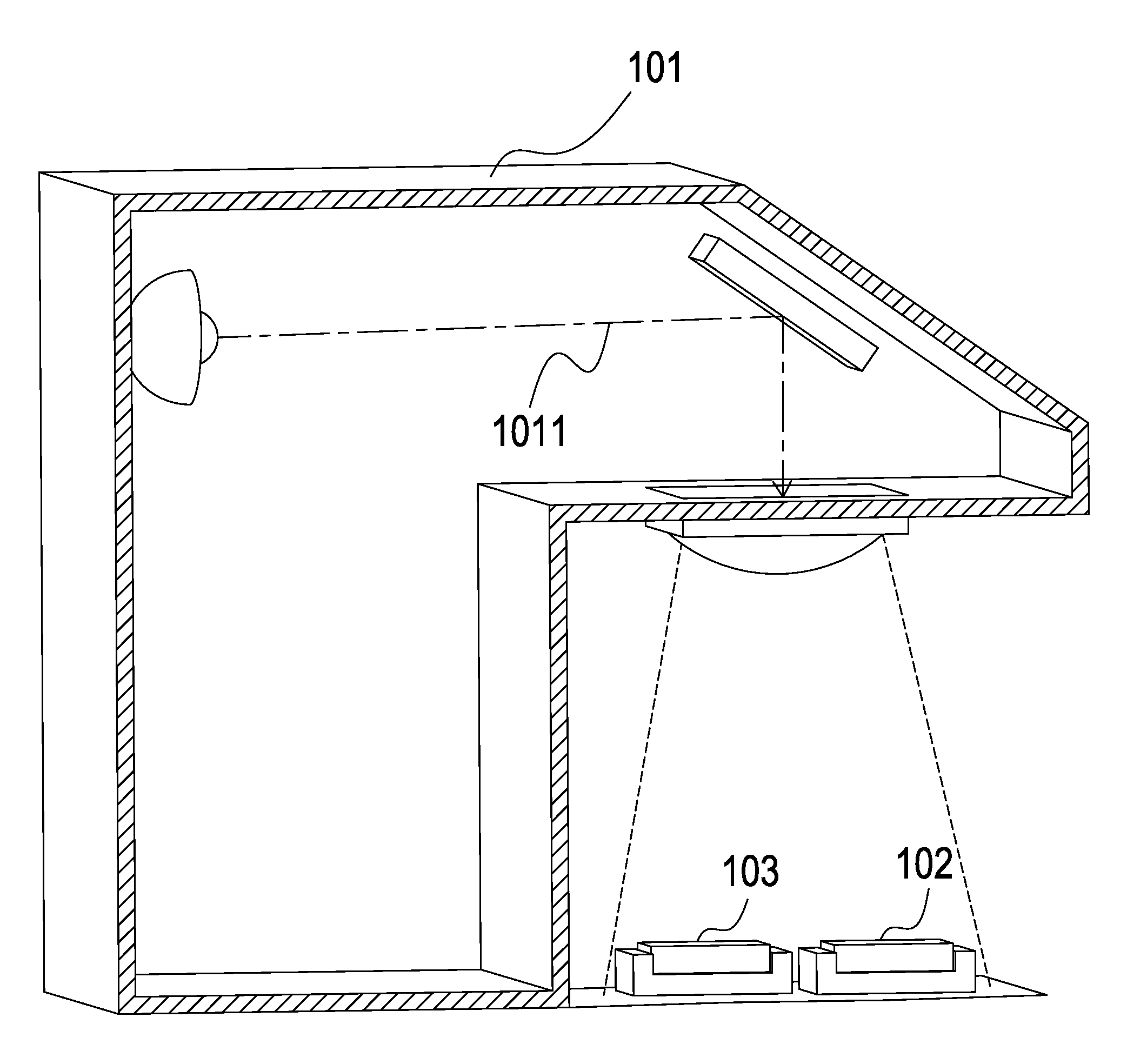

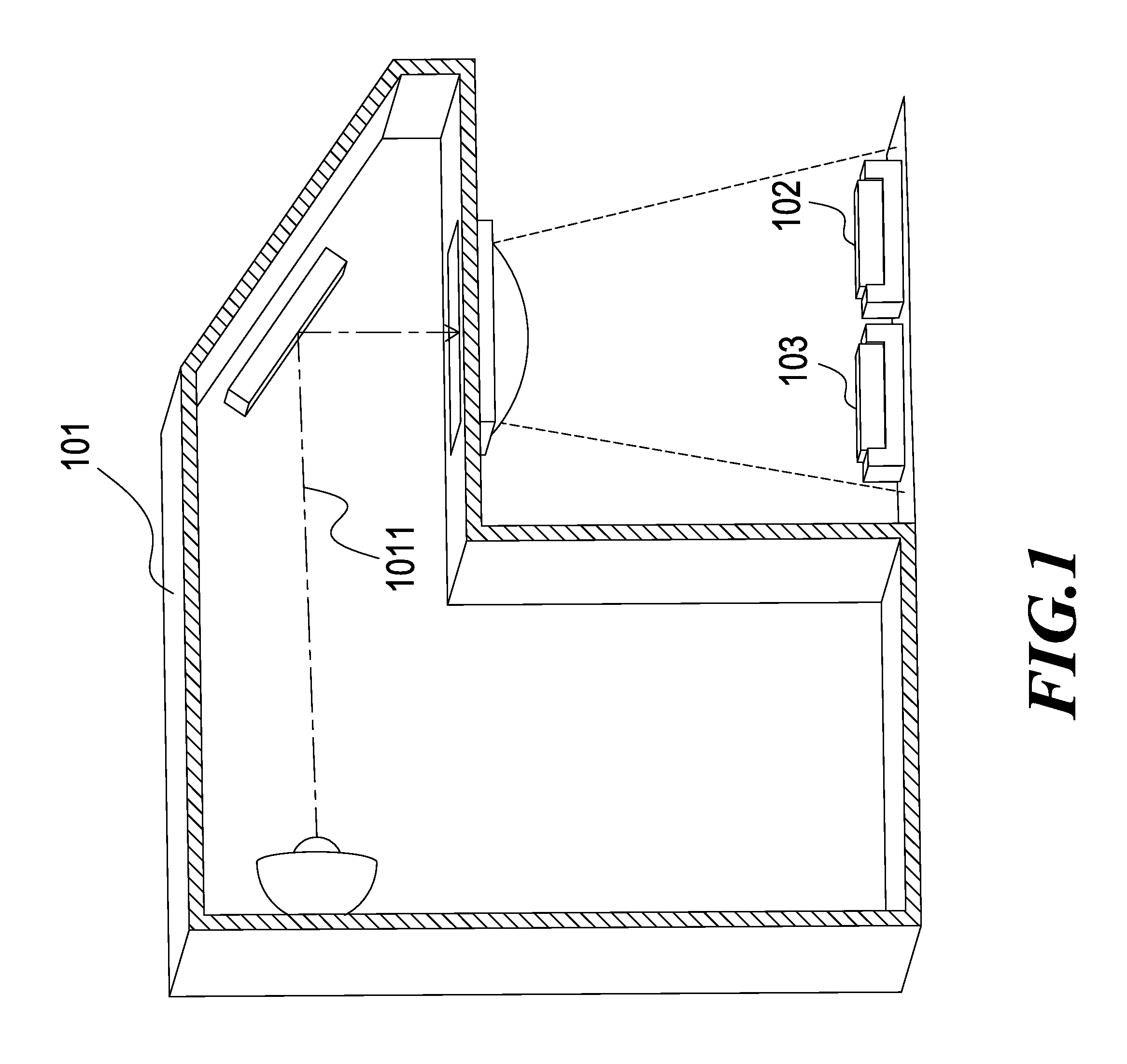

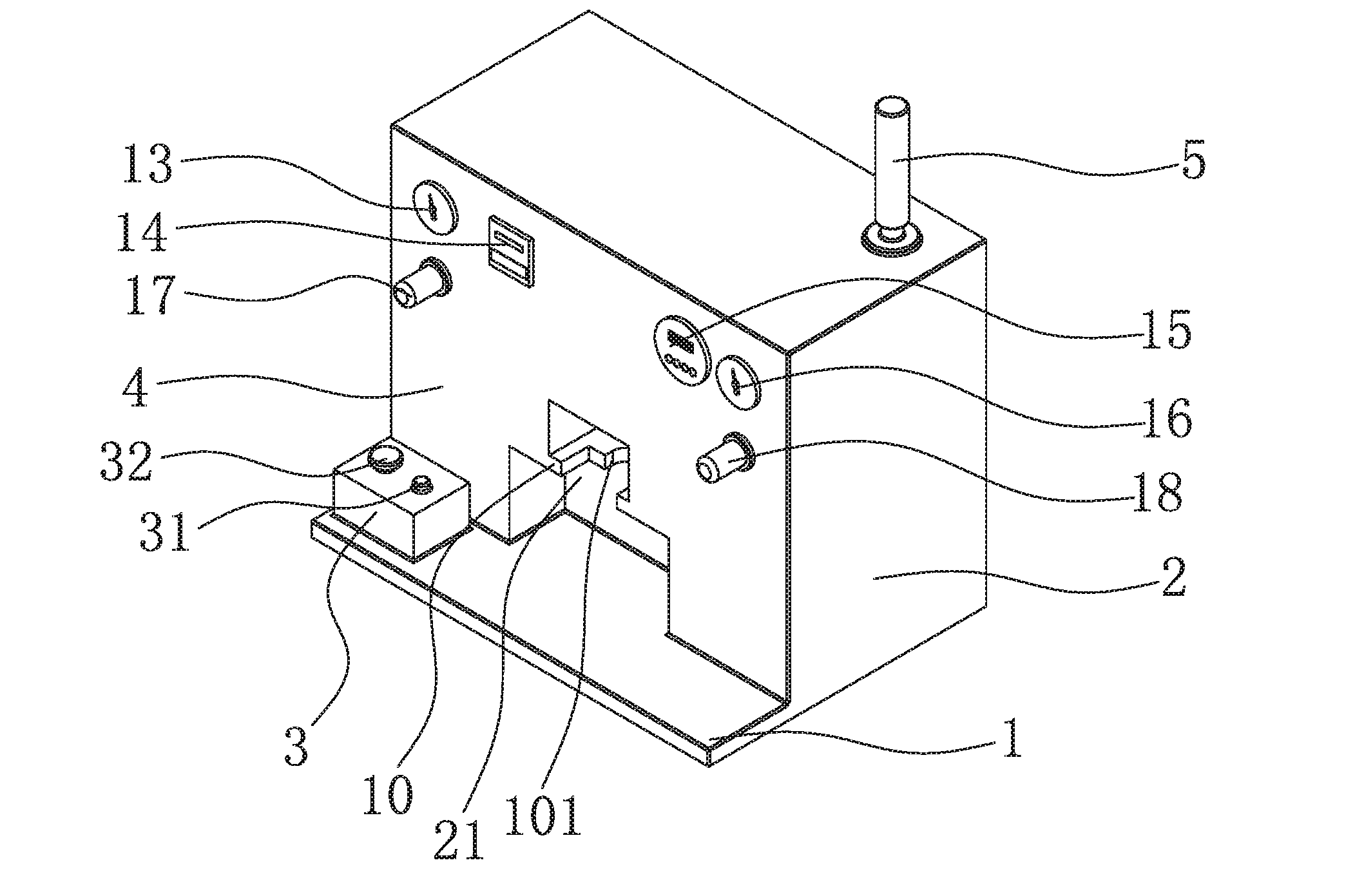

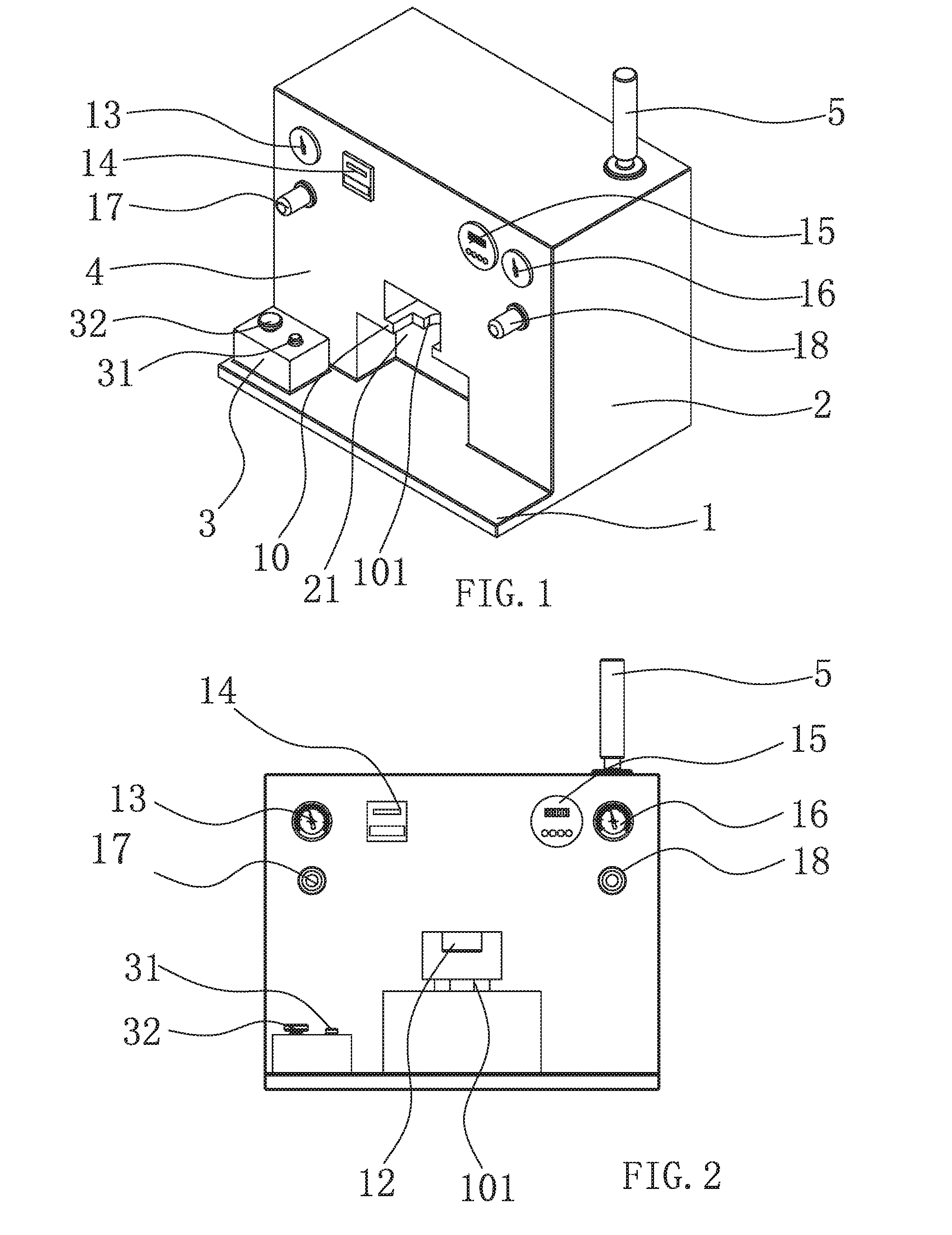

Sunlight simulator

InactiveUS20120025838A1Eliminate useReduce manufacturing costIndividual semiconductor device testingFixed installationLight beamSolar cell

A sunlight simulator and solar cell measuring device consisting of detecting device is disclosed, in which the housing is a closed space consisting of an opening gate, the closed space is internally installed with a light source which is used to emit a light toward the opening gate, and a splitting unit is installed on the travelling path of the light for dividing the light into a first light-beam and a second light-beam, herein the first light-beam is projected onto the solar cell under measurement located at the opening gate as a solar cell measuring device; in addition, a detecting device is installed on the travelling path of the second light-beam for receiving the second light-beam, and then a signal can be outputted by the detecting device in order to monitor the irradiation variation of the light emitted by the light source, thus ensuring the precision of the solar cell measurement.

Owner:CHROMA ATE

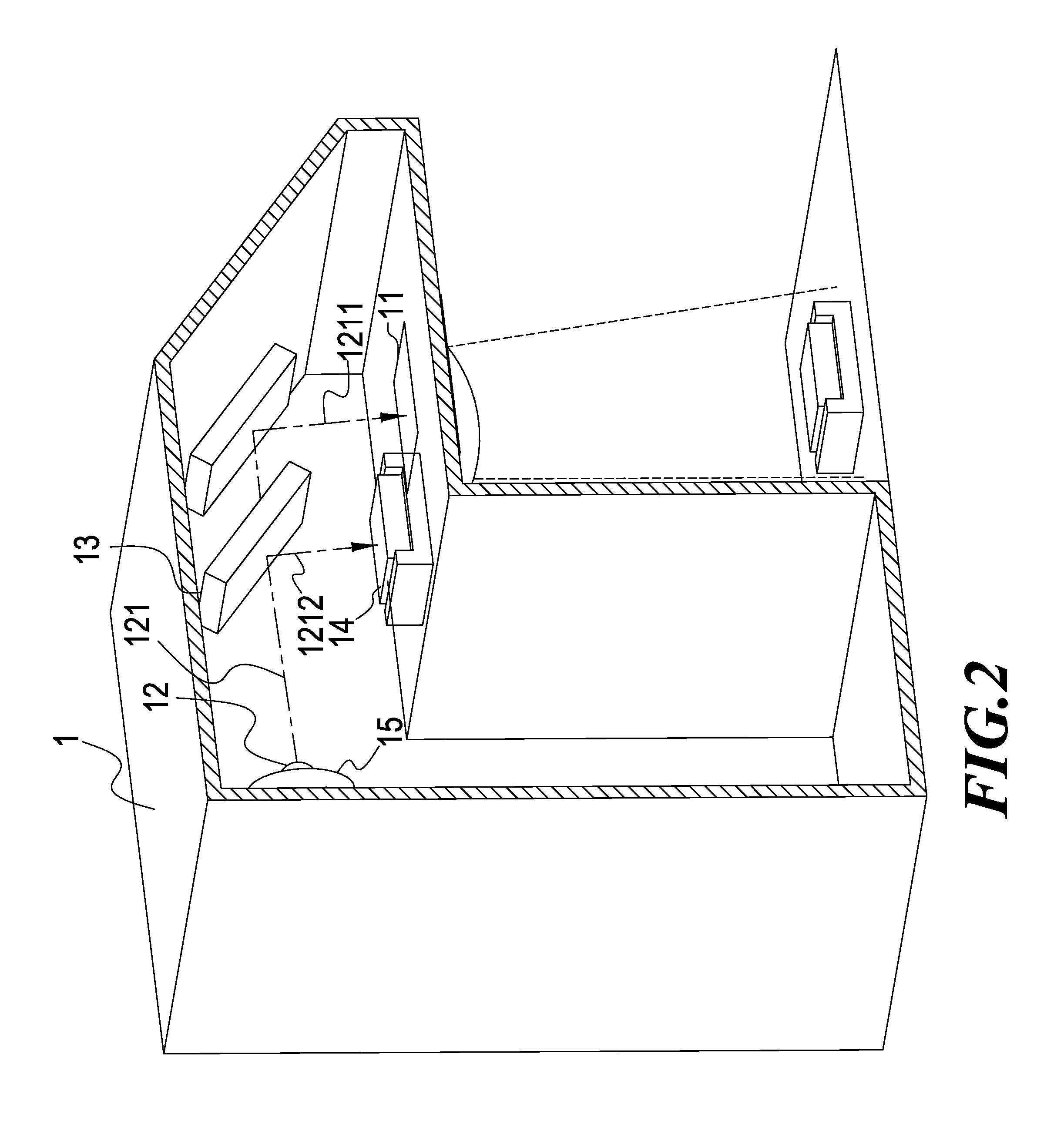

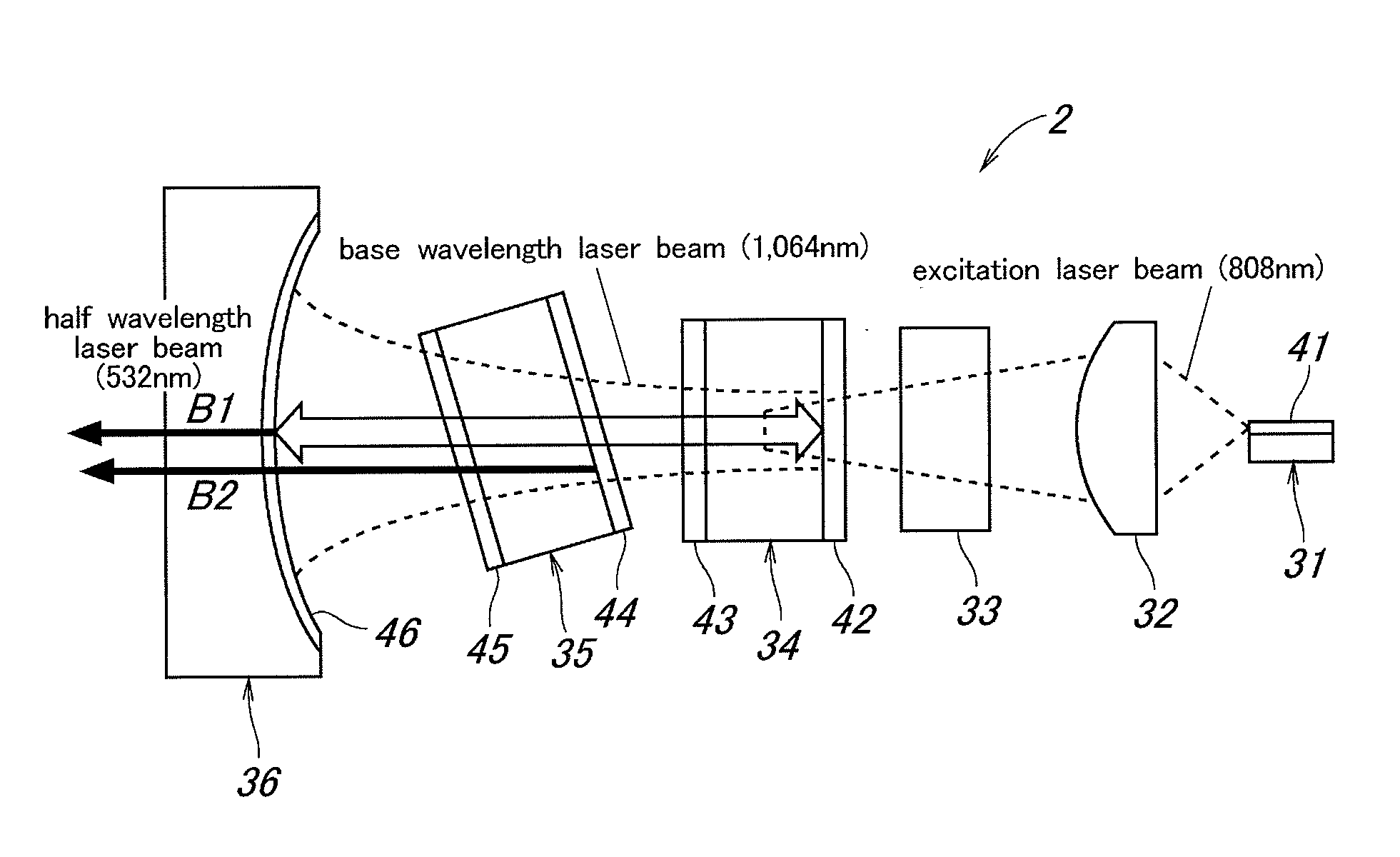

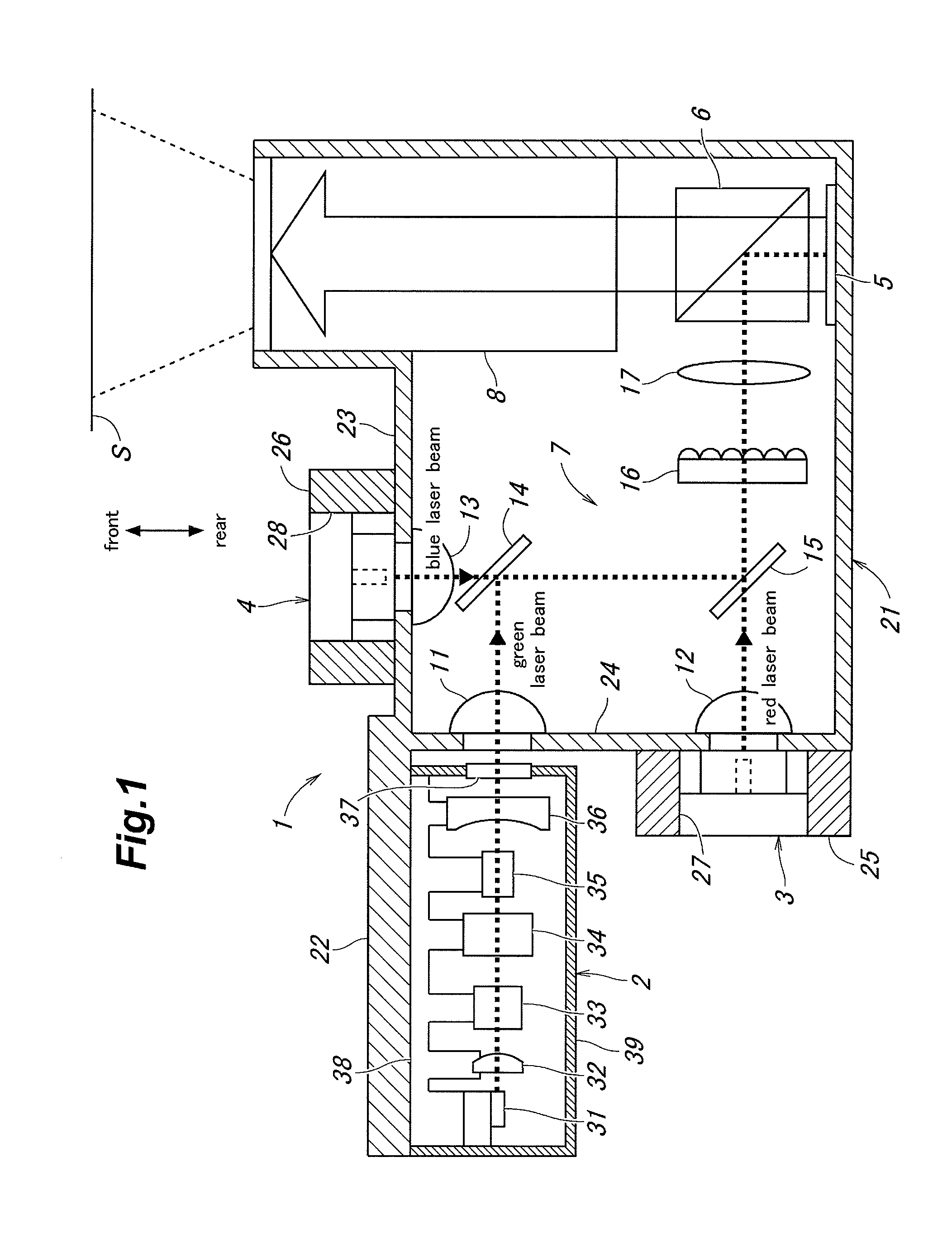

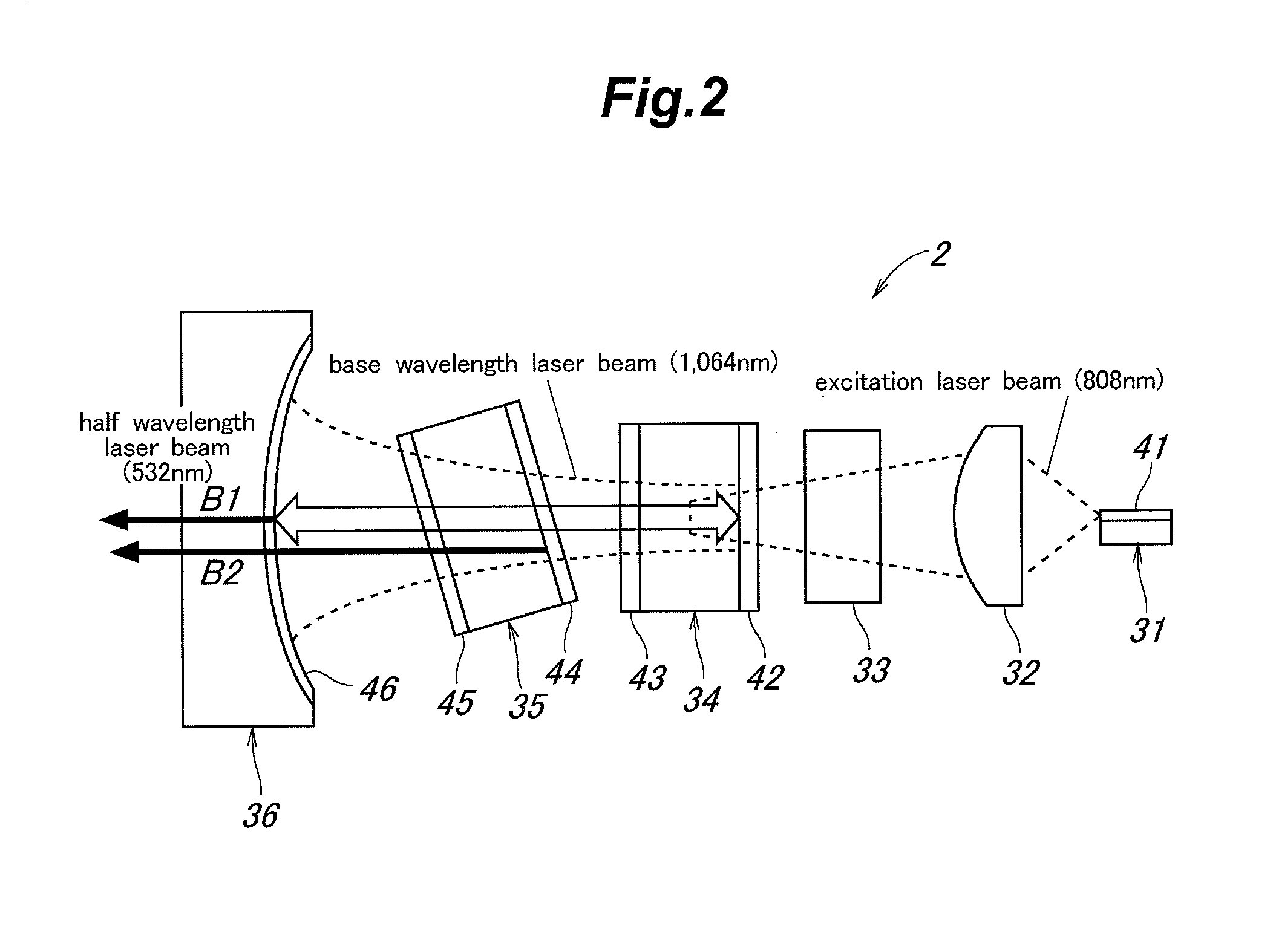

Laser light source apparatus

InactiveUS20120057219A1Simplifies angular adjustmentPrecision can be ensuredProjectorsColor photographyLaser lightWavelength

In a laser light source apparatus using a wavelength converting device (35), the position and angle of the wavelength converting device are allowed to be varied so as to maximize the laser output. The angular adjustment of the wavelength converting device is simplified by accurately positioning the wavelength converting device. A holder (57) for retaining the wavelength converting device may be supported by a support portion (56) formed in a base (38) so as to be moveable in the depthwise direction of the poled inverted domain regions and tiltable with respect to the optical path. Preferably, the holder may be rotatable around an axial line substantially perpendicular to the optical axial line. In particular, the wavelength converting device may be fixedly attached to the holder so as to bring an exit surface (35b) of the wavelength converting device in close contact with a mounting reference surface (841) by using a bonding agent applied to a top surface (35e) and a bottom surface (35f) of the wavelength converting device adjacent to the exit surface, and a bottom surface (207) of a recess (891) formed in the holder adjacent to and in parallel with the mounting reference surface.

Owner:PANASONIC CORP

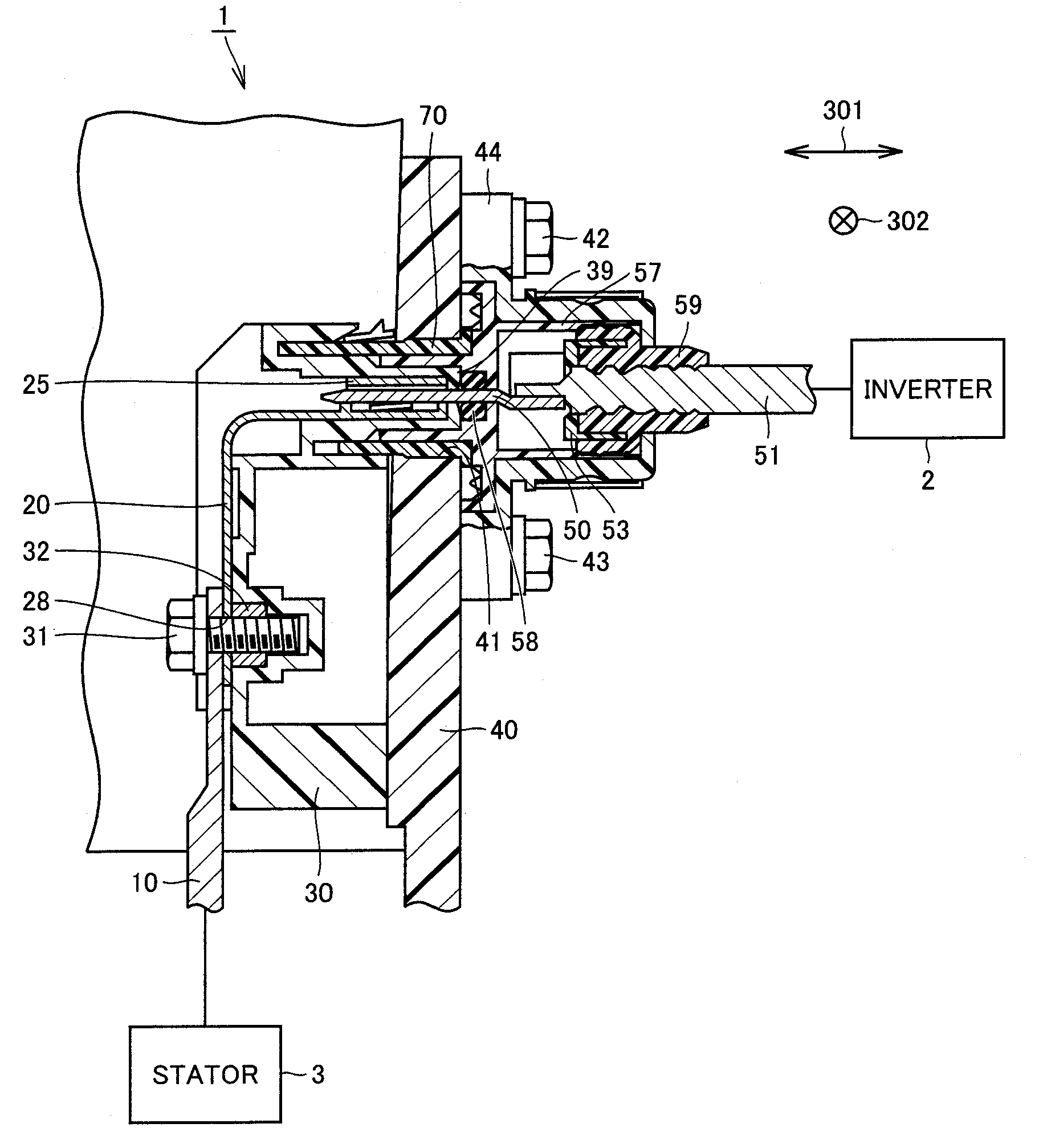

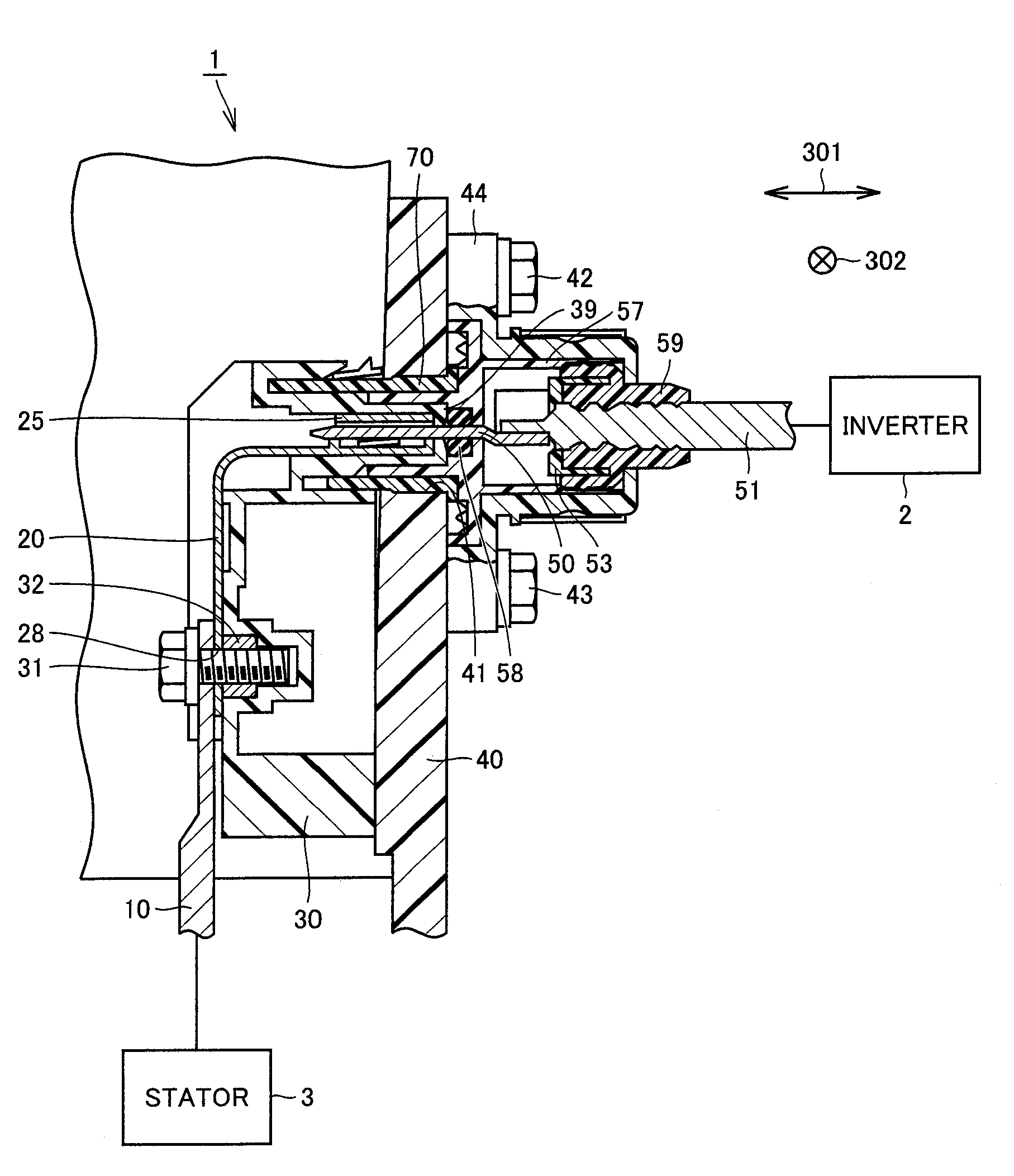

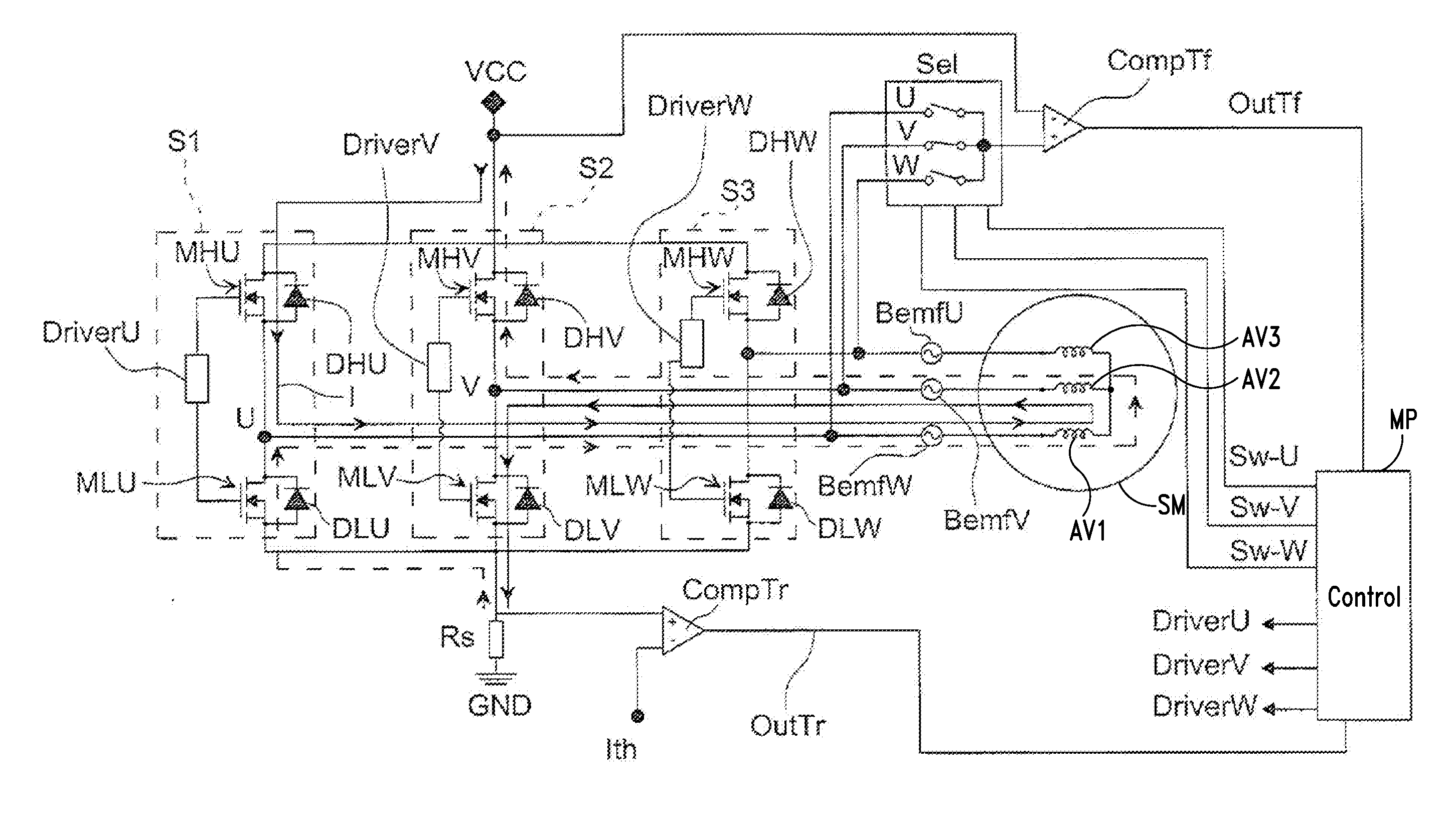

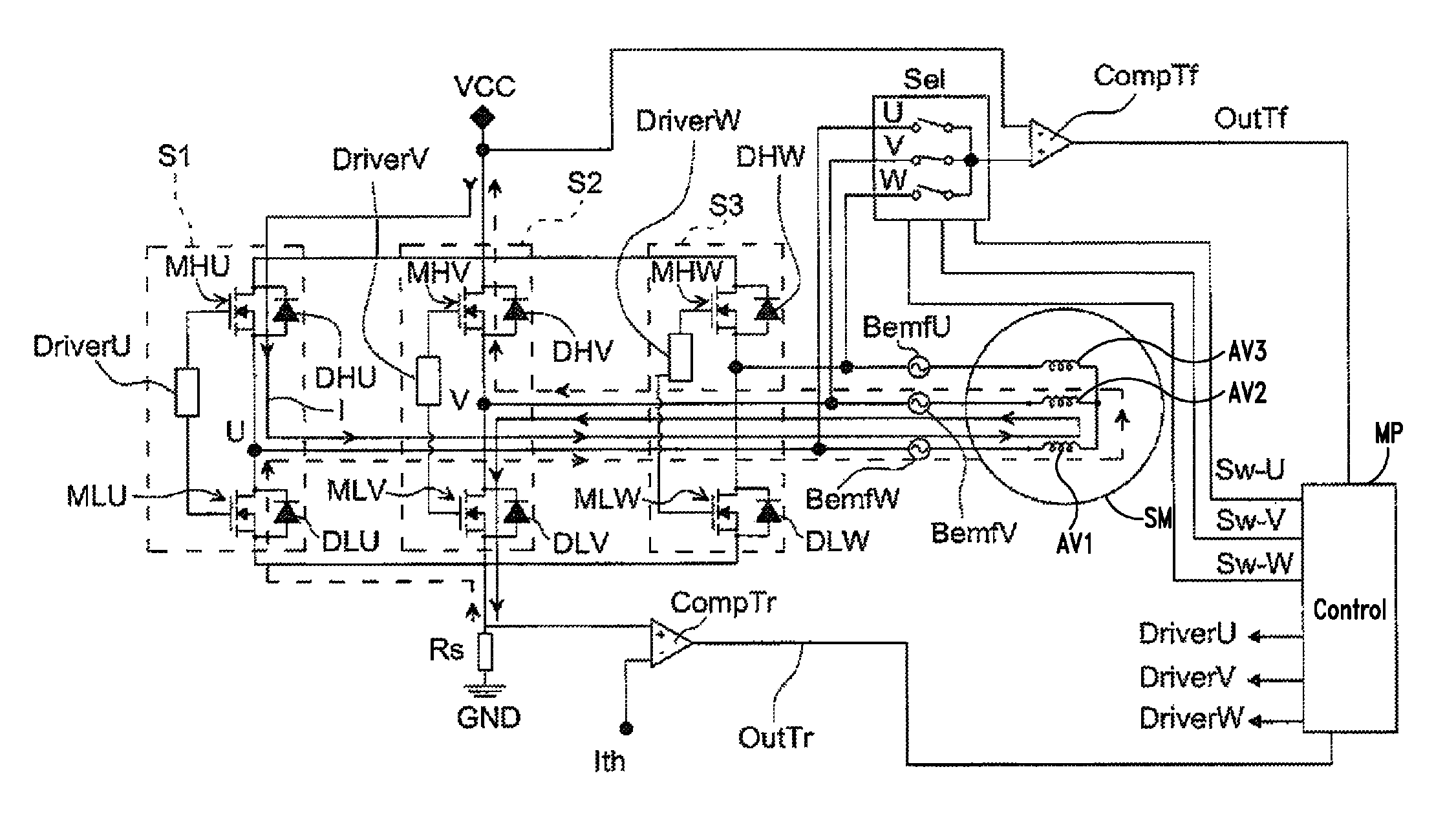

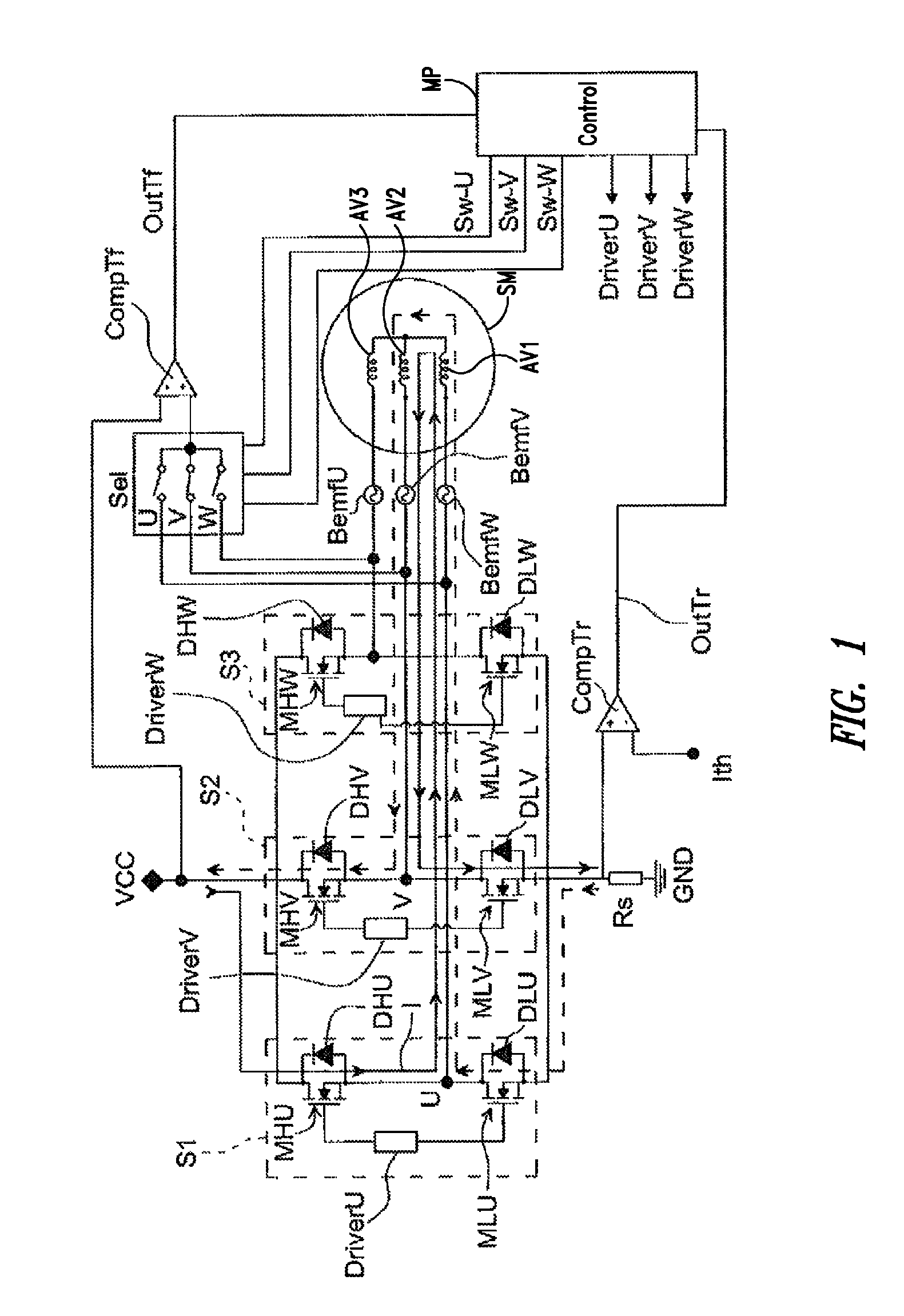

Apparatus for detecting the position of a rotor of an electric motor and related method

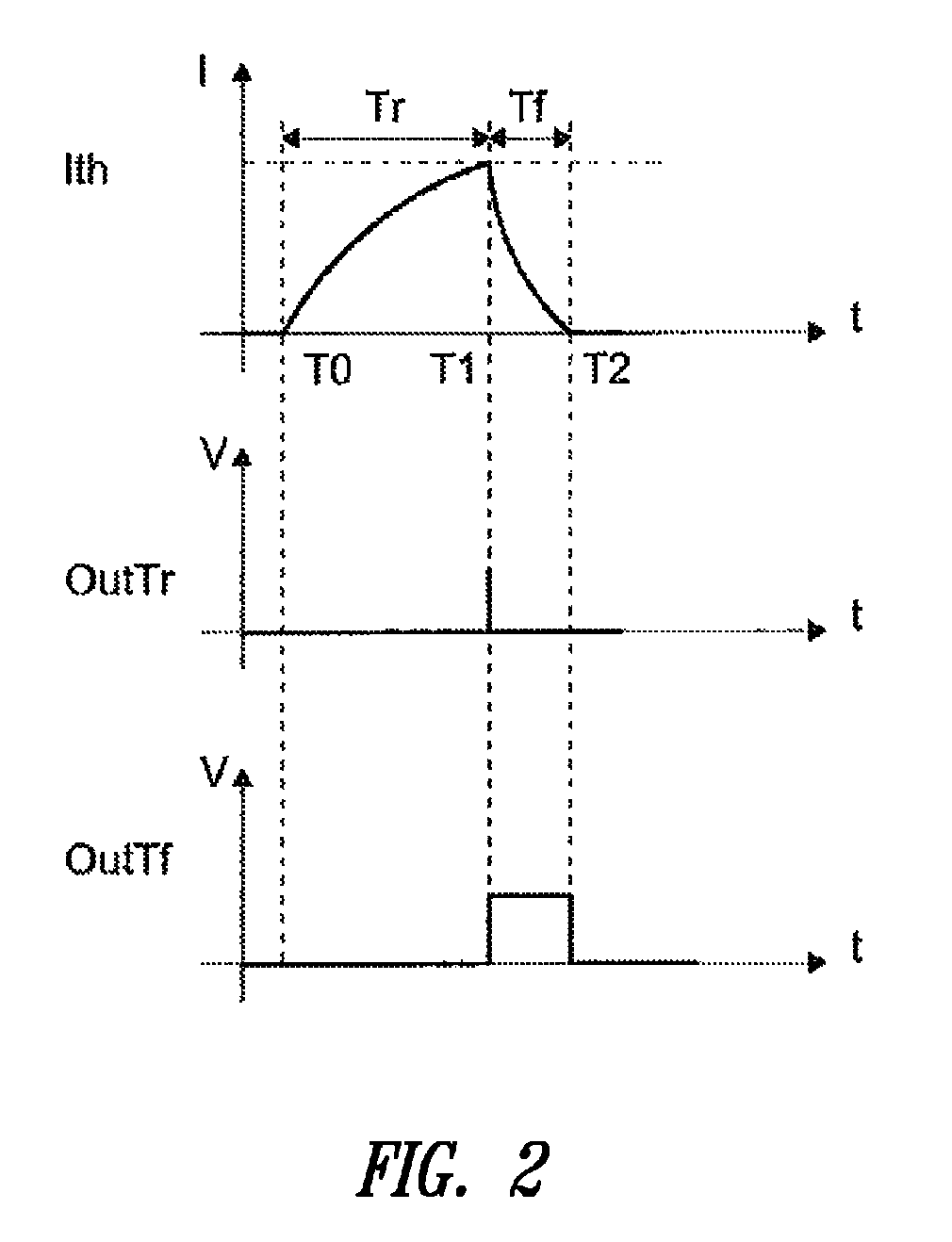

InactiveUS20120098474A1Precision can be ensuredOvercomes drawbackMotor/generator/converter stoppersSynchronous motors startersEngineeringThree-phase

An apparatus detects the position of a rotor of an electric motor having three phases and a plurality of windings. The apparatus includes circuitry configured to connect at least two of said windings between first and second reference voltages according to a first current path disconnect said at least two windings, and allow the current stored in said two windings to be discharged through a second current path. The apparatus comprises a measuring circuit configured to measure the time period between the starting instant of storing the current in the two windings and the final instant of discharging the two windings and a rotor detector configured to detect the rotor position based at least in part on the measured time period.

Owner:STMICROELECTRONICS SRL

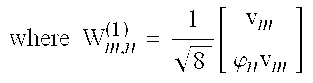

Method and Terminal for Channel State Information Feedback

ActiveUS20120224652A1Improve compatibilityEffective supportModulated-carrier systemsDiversity/multi-antenna systemsControl channelComputer terminal

The present invention discloses a method and terminal for feeding back channel status information, including: when the channel status information is fed back on the physical uplink control channel, code words contained in the used codebook CPUCCH (r) with a layer number or rank being r is a subset of the code words contained in the codebook CPUSCH (r) with a layer number or rank being r in the overall codebook defined in the LTE-A; wherein, the CPUCCH (r) is a single codebook or a single codebook equivalent to dual codebooks; and the CPUSCH (r) is a single codebook or a single codebook equivalent to the dual codebooks; and the single codebook equivalent to the dual codebooks means that the actually used codebook is an actually defined single codebook, however, 2 pre-coding matrix identifiers are required to determine the codebook of the code words therein for an established r. The method described by the present invention can ensure the precision of the PMI feedback under the limited overhead, make the CSI feedback on the PUCCH still be able to more effectively support the pre-coding technology and have good compatibility with the feedback on the PUSCH.

Owner:ZTE CORP

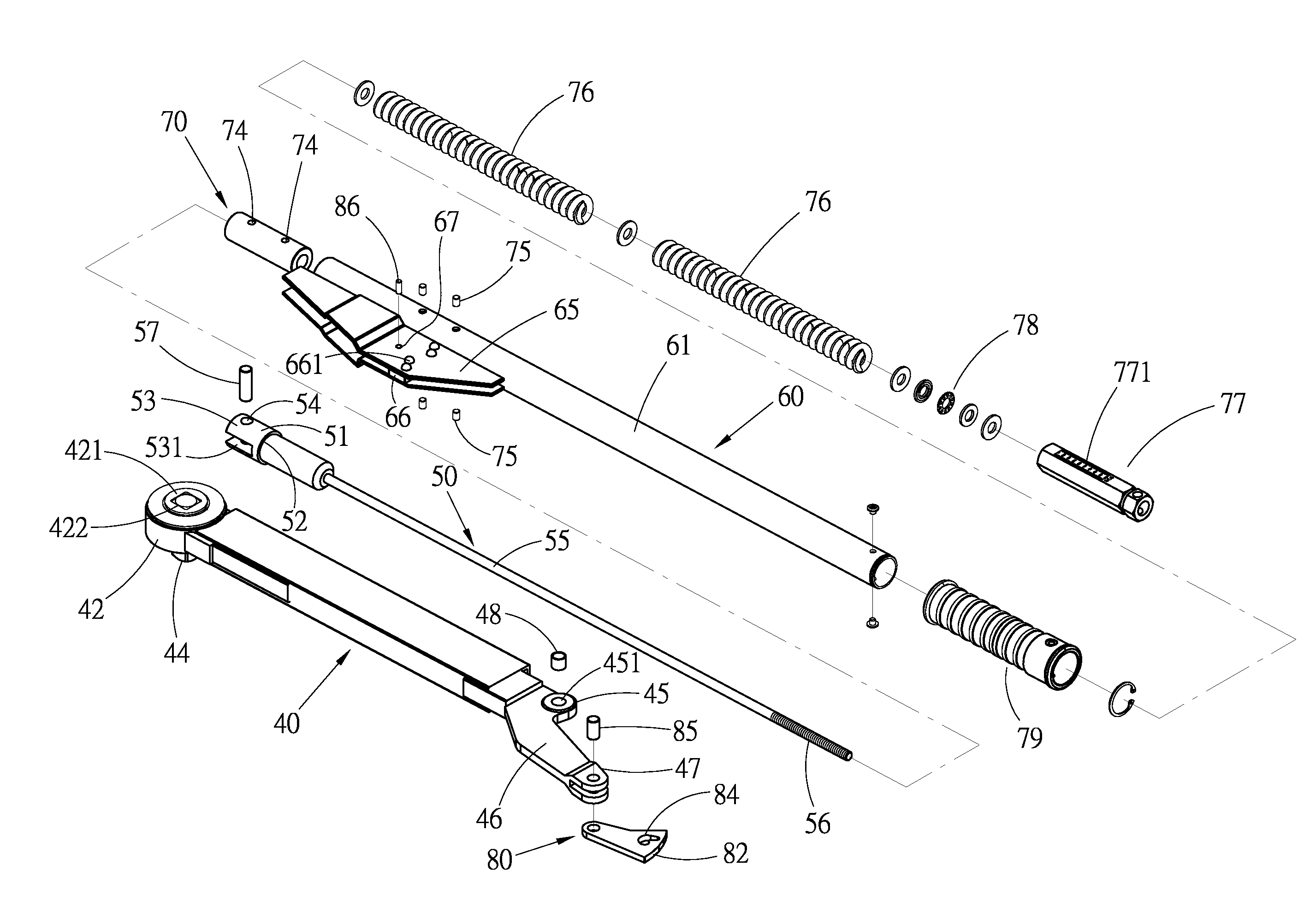

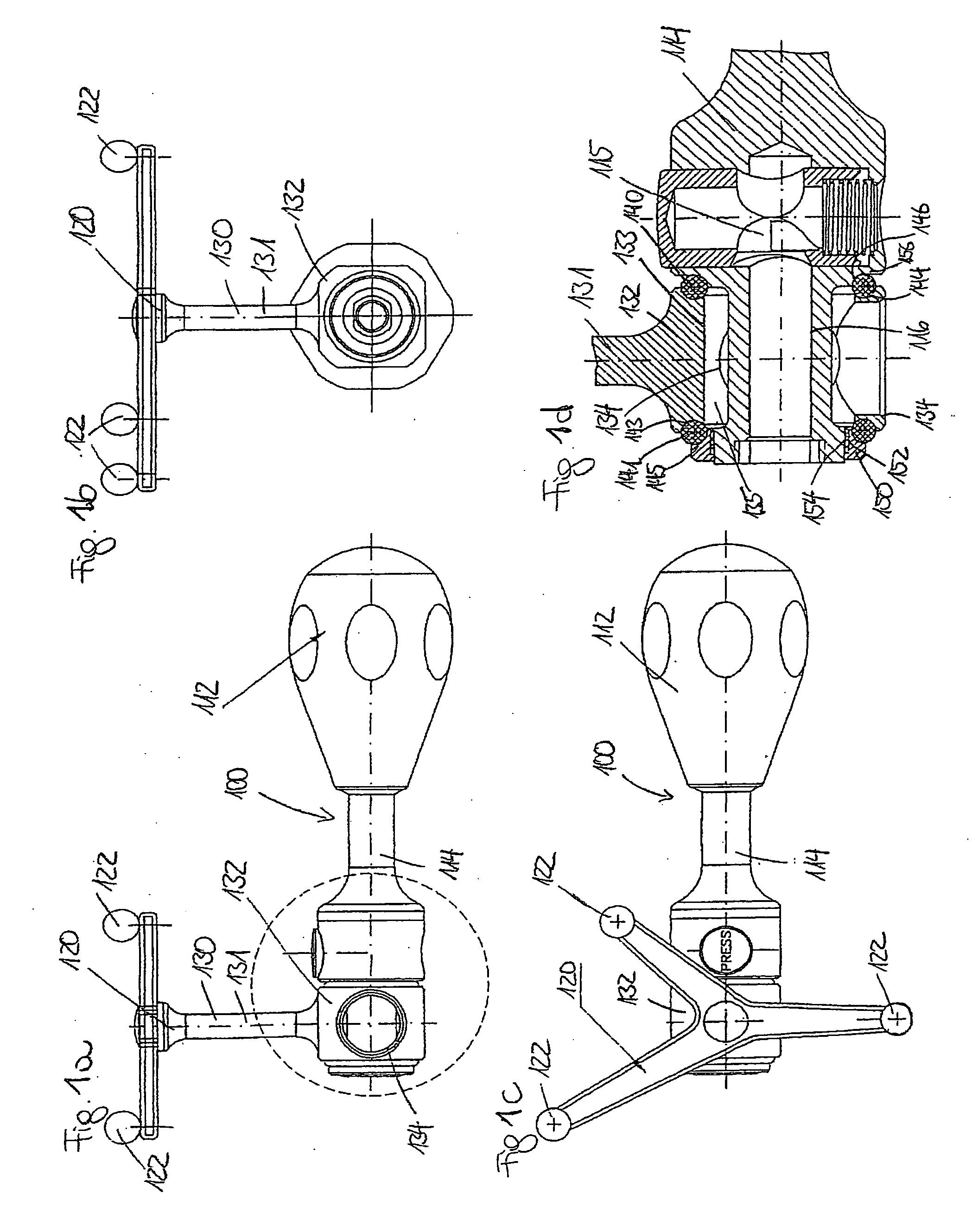

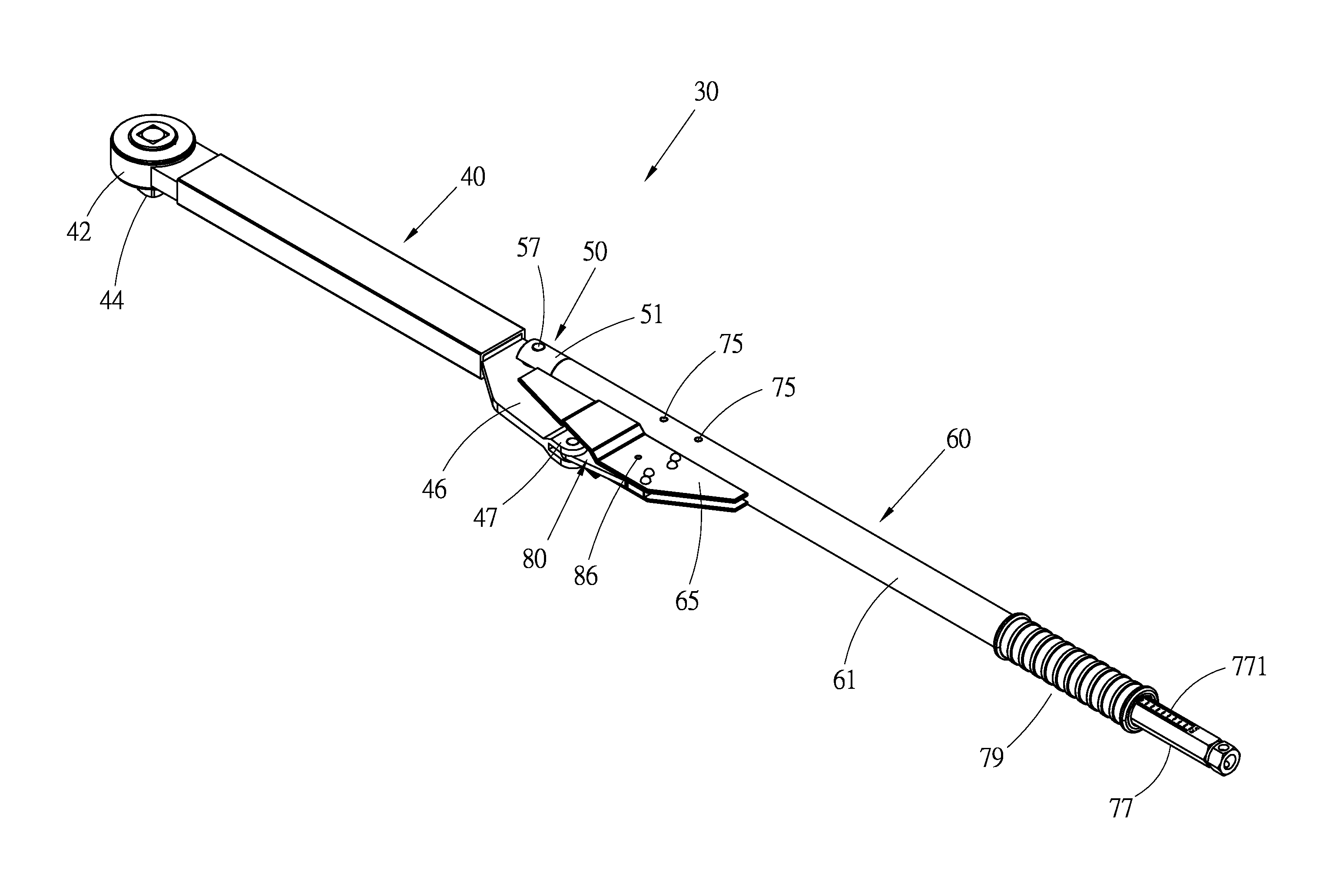

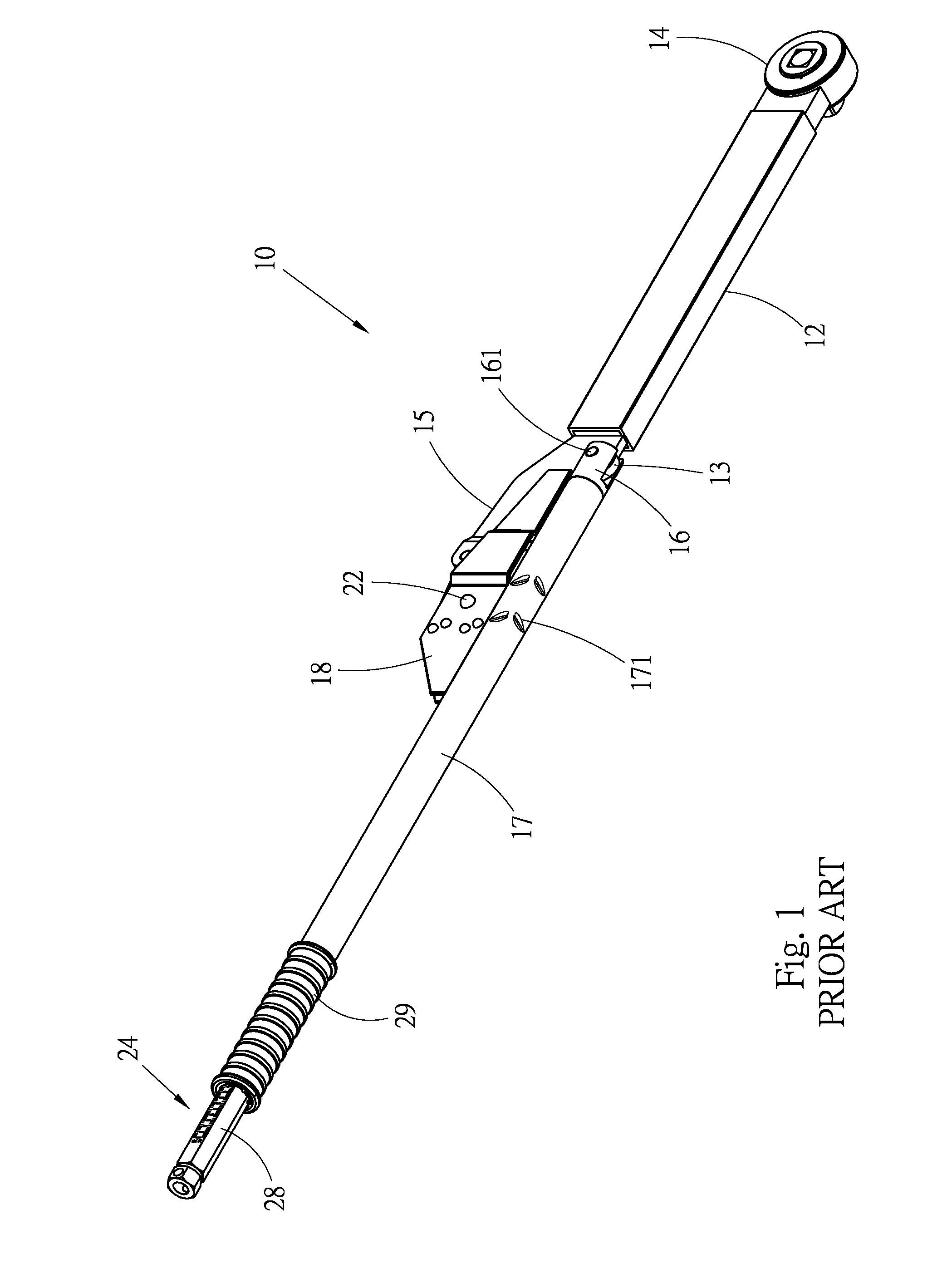

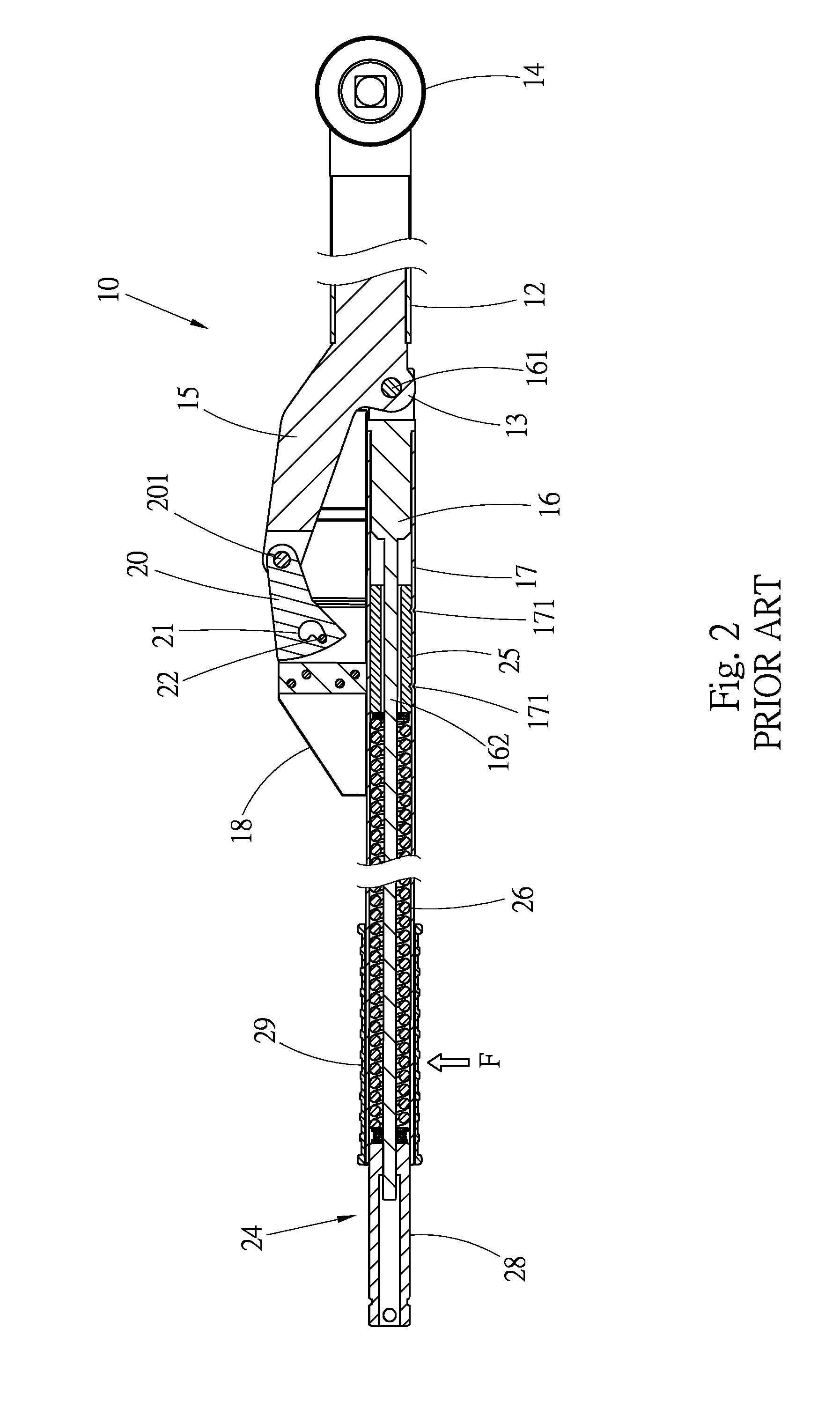

Collapsible torque wrench

A collapsible torque wrench includes: a shank having a drive head at a front end and two pivoted ends at a rear end; a connection rod, a front end of which being pivotally connected with the first pivoted end; a housing having a tubular body and a casing fixedly disposed on one side of the tubular body, the connection rod being relatively slidably fitted in the tubular body; a torque adjustment mechanism being mounted in the tubular body and including a fixing block, the fixing block being mounted in the tubular body by at least two pins; and a stop member received in the casing. A front end of the stop member is pivotally connected with the second pivoted end. The fixing block is easily demounted from the tubular body for replacement.

Owner:KABO TOOL COMPANY

Apparatus for detecting the position of a rotor of an electric motor and related method

InactiveUS8970150B2Precision can be ensuredOvercomes drawbackMotor/generator/converter stoppersSynchronous motors startersThree-phaseEngineering

An apparatus detects the position of a rotor of an electric motor having three phases and a plurality of windings. The apparatus includes circuitry configured to connect at least two of said windings between first and second reference voltages according to a first current path disconnect said at least two windings, and allow the current stored in said two windings to be discharged through a second current path. The apparatus comprises a measuring circuit configured to measure the time period between the starting instant of storing the current in the two windings and the final instant of discharging the two windings and a rotor detector configured to detect the rotor position based at least in part on the measured time period.

Owner:STMICROELECTRONICS SRL

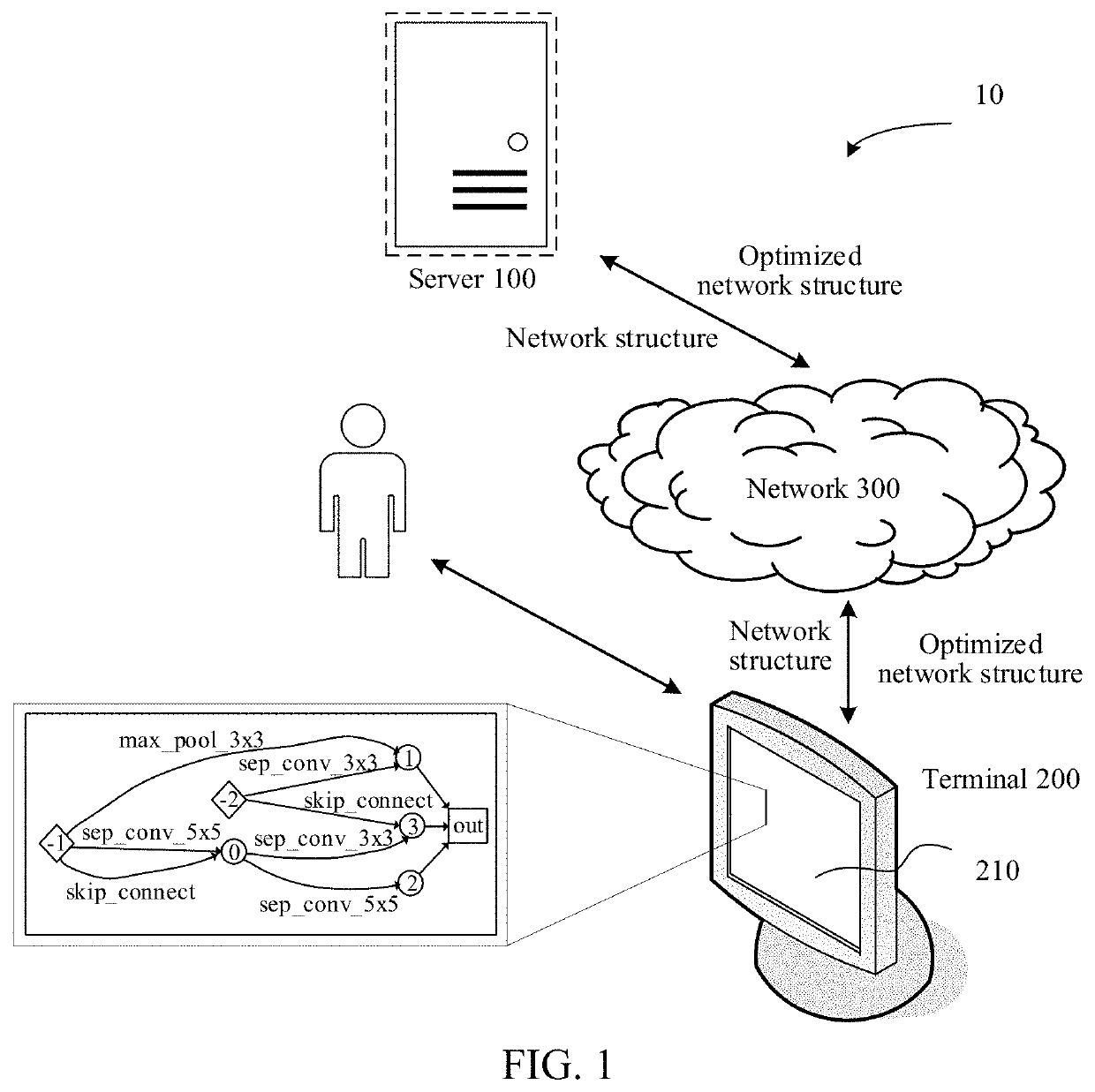

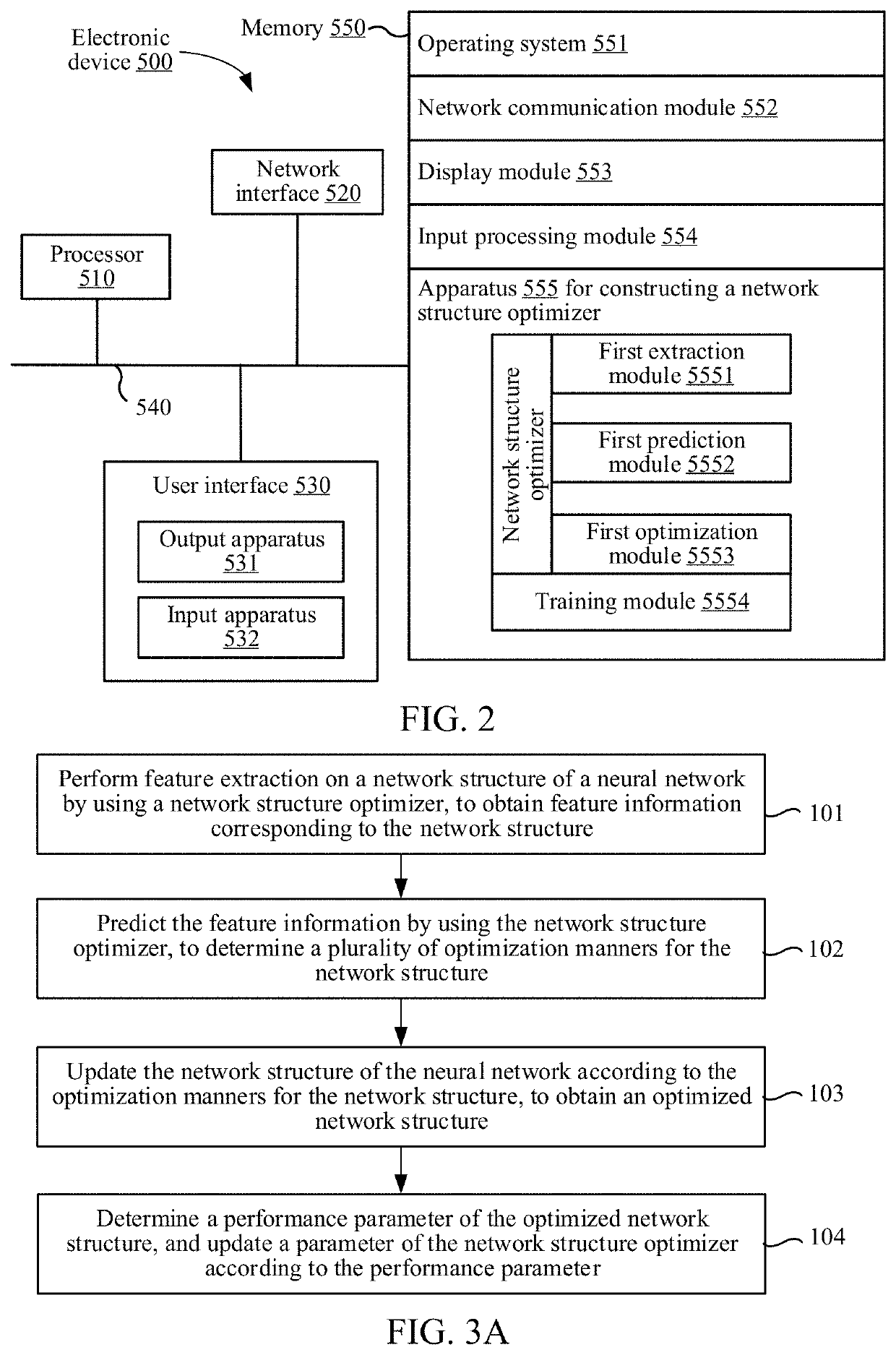

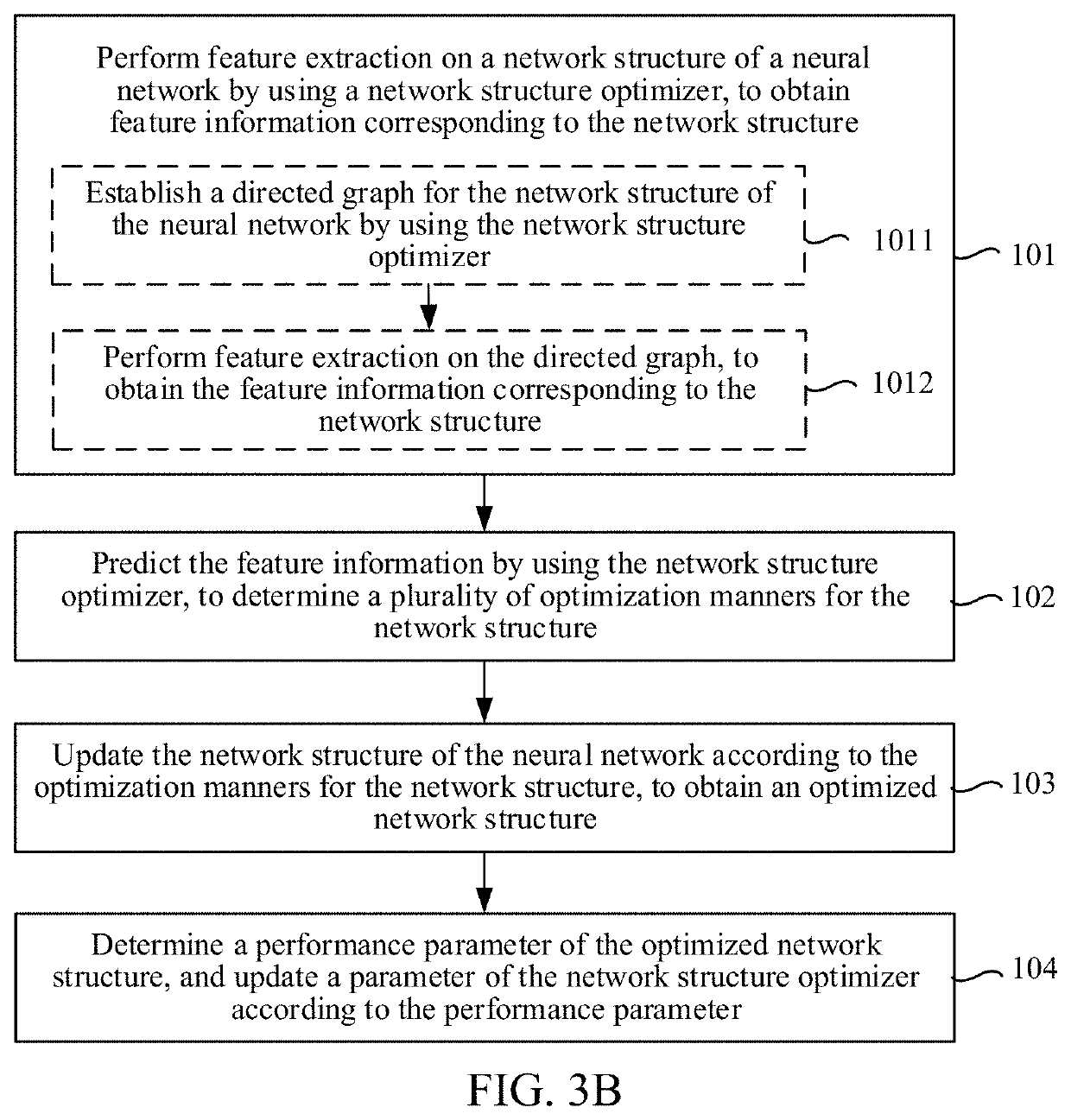

Method and apparatus for constructing network structure optimizer, and computer-readable storage medium

PendingUS20220044094A1Improve image recognitionImage recognition is accurateNeural architecturesNeural learning methodsFeature extractionNetwork structure

This application provides a method for constructing a network structure optimizer performed by an electronic device. The method includes: performing feature extraction on a network structure of an image recognition neural network by using a network structure optimizer, to obtain feature information corresponding to the network structure; predicting the feature information by using the network structure optimizer, to determine a plurality of optimization manners for the network structure; updating the network structure of the image recognition neural network according to the optimization manners for the network structure, to obtain an optimized network structure of the image recognition neural network; and determining an image recognition performance parameter of the optimized network structure of the image recognition neural network, and updating a parameter of the network structure optimizer according to the image recognition performance parameter, the network structure optimizer being configured to optimize the network structure of the image recognition neural network.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Device for detecting spatial position

InactiveUS20080262343A1Easy to operateEasy to fixMeasurement devicesSurgical navigation systemsBall bearingEngineering

The invention relates to a device for detecting spatial position, which can be attached via a mounting device to a surgical instrument, which has a longitudinal axis, wherein the mounting device has a through opening, which is penetrated by the instrument, wherein the mounting device is mounted so as to be rotatable around the longitudinal axis of the instrument, and wherein the mounting device can be immobilized in an axial and a radial direction via two angular ball bearings.

Owner:WEBER INSTR

Electrical distribution center with terminal stabilizing terminal position assurance member

ActiveUS20180358724A1Prevent occurrence of damagePrevents reduction in mounting accuracyVehicle connectorsSubstation/switching arrangement detailsEngineeringPrinted circuit board

An electrical distribution center includes a housing, an electronic device, an upper fixing member, a printed circuit board (PCB), a lower fixing member and a connector. The upper fixing member has a first inserting hole. Pin terminals of the electronic device pass through the first inserting hole and are connected to the PCB. A connector mounting slot for fixing the connector is arranged on the lower fixing member. A second inserting hole and a guide rod member are arranged in the connector mounting slot. A TPA member is sheathed on the guide rod member. The TPA member has a third inserting hole. Pin terminals of the connector pass through the third inserting hole and the second inserting hole and are fixed in the connector mounting slot with the TPA member. The pin terminals of the connector are connected to the PCB after passing through the first inserting hole.

Owner:DELPHI ELECTRICAL CENTS SHANGHAI CO LTD

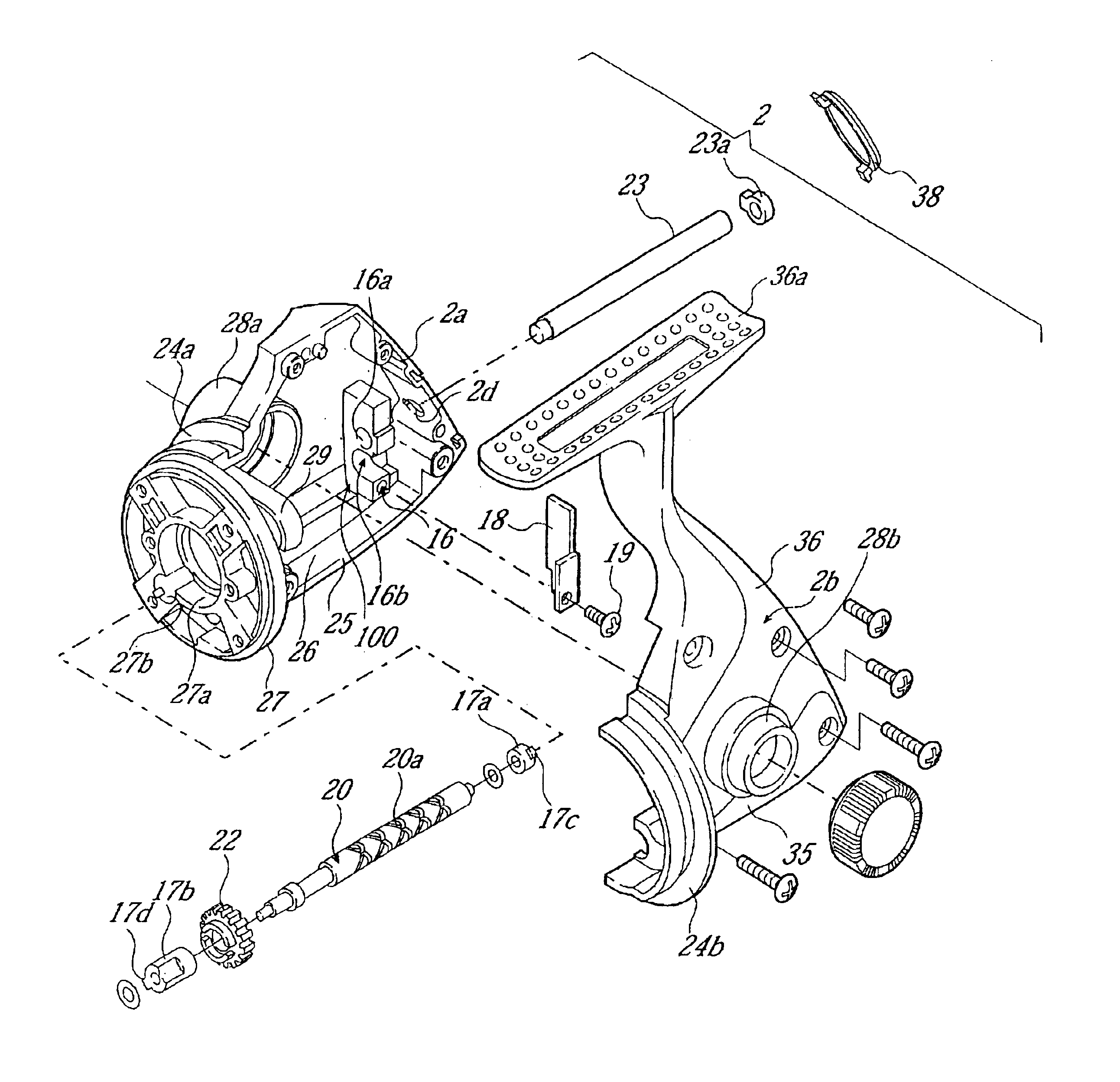

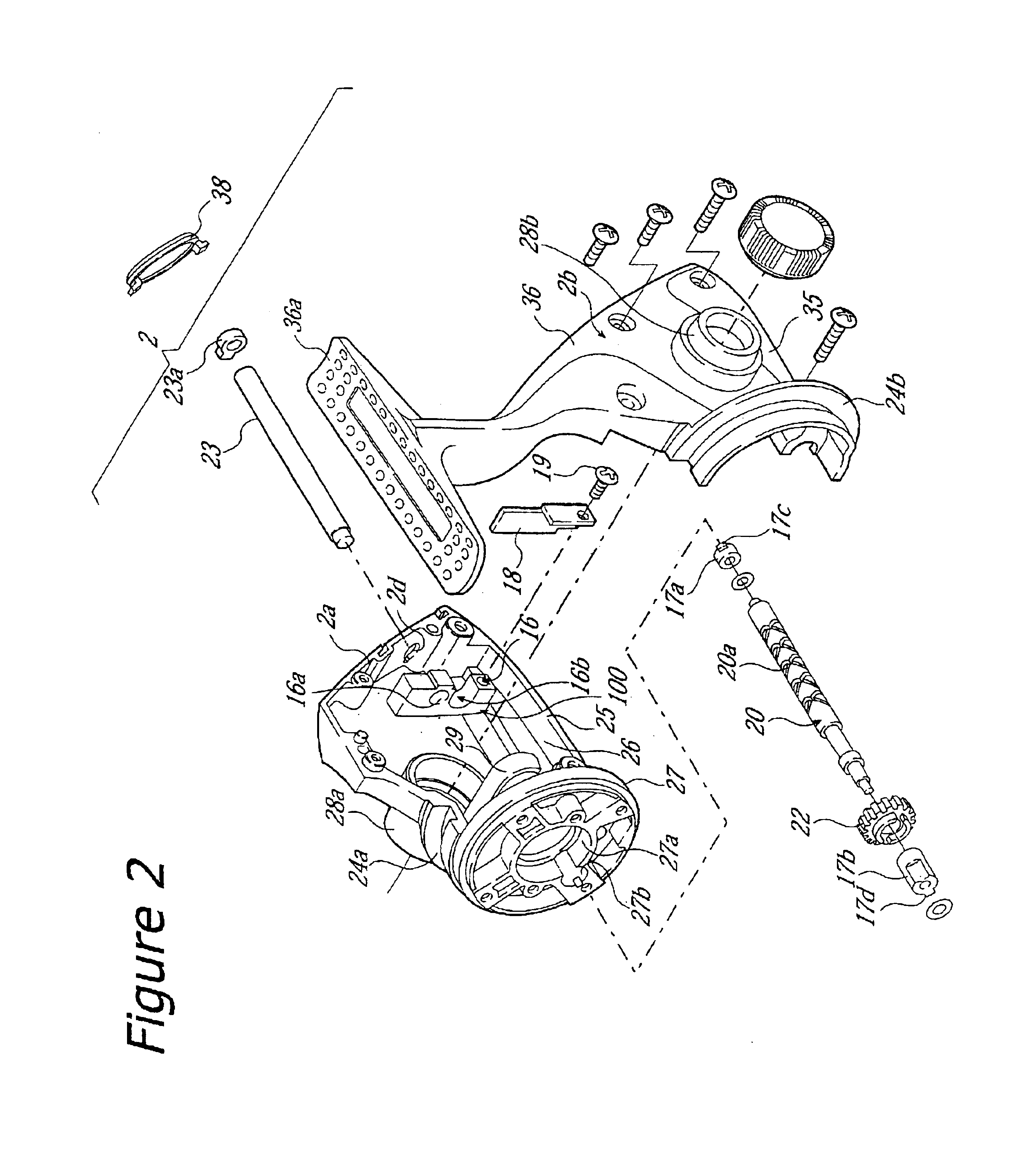

Worm shaft attachment structure for spinning reel

A worm shaft attachment structure for a spinning reel includes a mechanism attachment portion having a first attachment portion, and a locking member. The rear end of a worm shaft is attached to the first attachment portion, which includes an aperture portion and a bearing mounting portion that is depressed from the aperture portion in a first direction. The bearing mounting portion can come into contact with an outer circumferential surface of the first bearing, which is mounted to the rear end of the worm shaft. The locking member is mounted detachably to the first attachment portion so as to close the aperture portion, and restricts shifting of the first bearing in the first direction by abutting against the outer circumferential surface of the first bearing. This way, the precision with which a worm shaft is attached is ensured, and the restrictions on the design options are reduced.

Owner:SHIMANO INC

Collapsible torque wrench

A collapsible torque wrench includes: a shank having a drive head at a front end and two pivoted ends at a rear end; a connection rod, a front end of which being pivotally connected with the first pivoted end; a housing having a tubular body and a casing fixedly disposed on one side of the tubular body, the connection rod being relatively slidably fitted in the tubular body; a torque adjustment mechanism being mounted in the tubular body and including a fixing block, the fixing block being mounted in the tubular body by at least two pins; and a stop member received in the casing. A front end of the stop member is pivotally connected with the second pivoted end. The fixing block is easily demounted from the tubular body for replacement.

Owner:KABO TOOL COMPANY

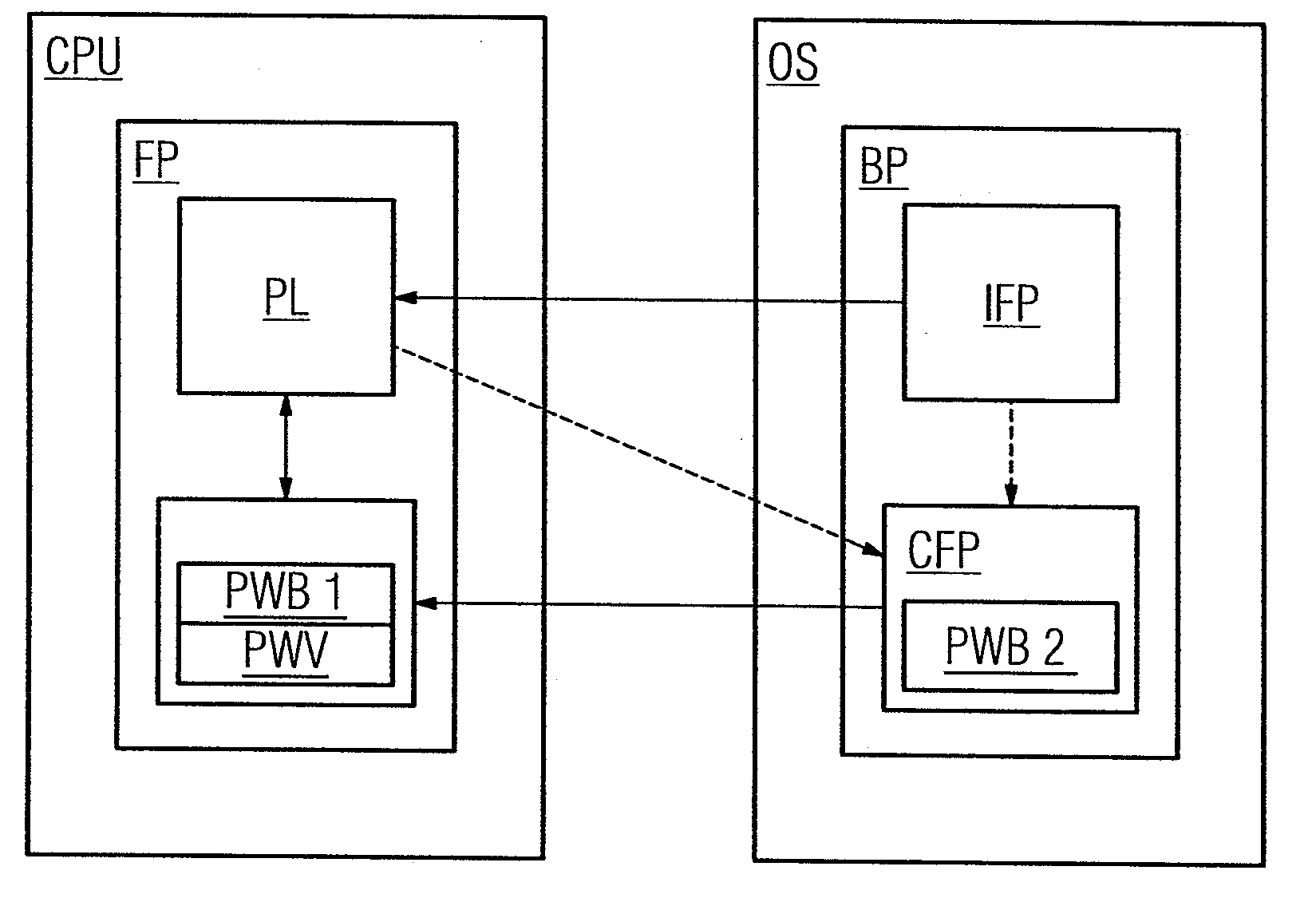

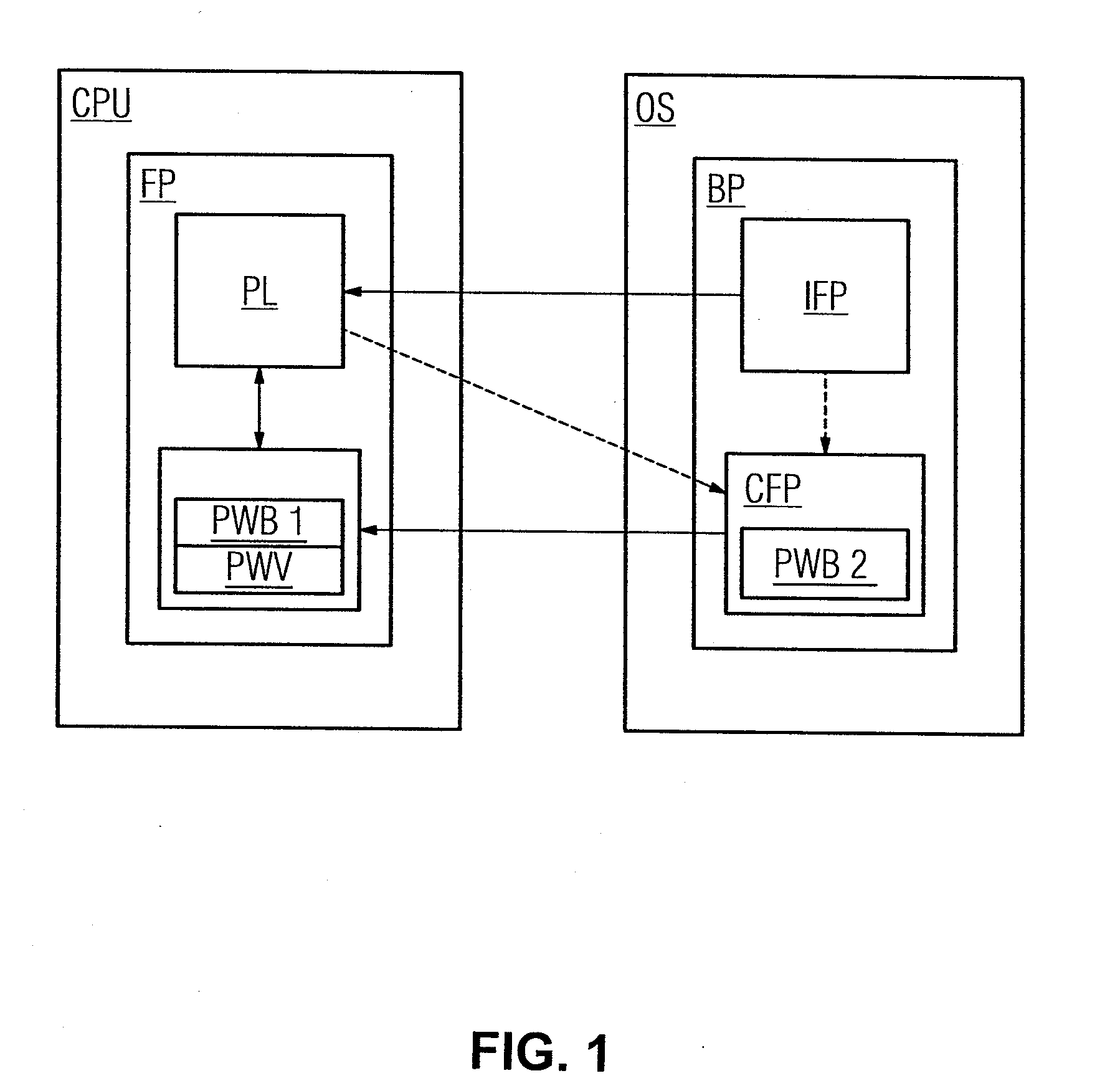

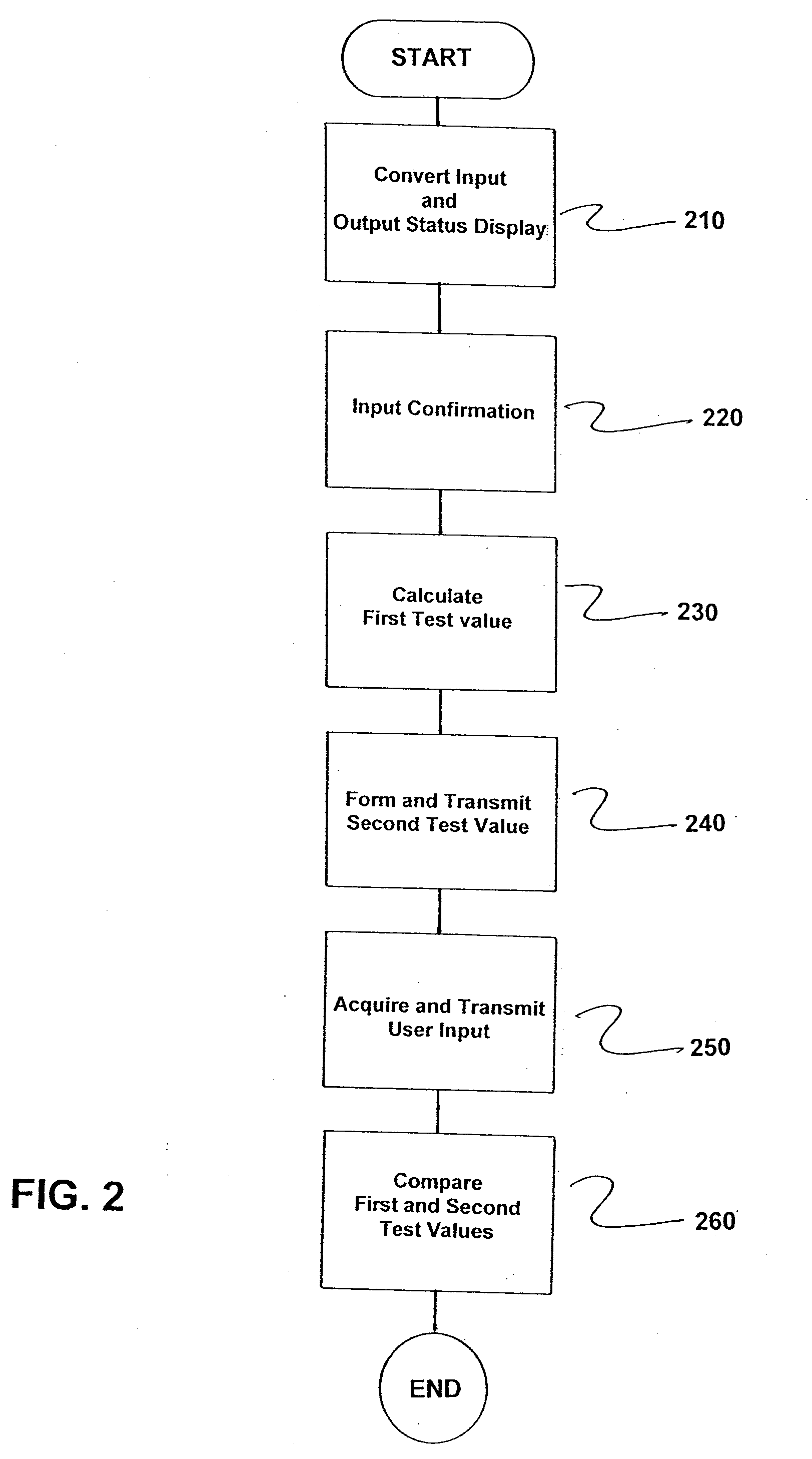

Method and Controller for Controlling a Safety-Oriented Industrial Automation Component

ActiveUS20100280633A1Safely transmit valueFlexible planningProgramme controlSafety arrangmentsAutomationUser interface

A method for a safety-oriented industrial automation component, wherein the controller is connected to the automation component by a data link includes providing, by a user, an input to the controller at a first user interface. The controller transmits a result of the input to the automation component. The result of the input is used in the automation component to calculate a first test value. The input is converted into a status display in the controller and is output at a second user interface. Here, the user or another user acknowledges the status display by inputting a confirmation, after which a second test value is formed from the status display and the confirmation in the controller, and the second test value is transmitted to the automation component. Finally, the first and second test values are compared in the automation component and the result of the input is used if the comparison is positive.

Owner:SIEMENS AG

Wired circuit board and connection structure between wired circuit boards

InactiveUS8314338B2Improve reliabilityPrecision can be ensuredPrinted circuit aspectsPrinted circuit manufactureEngineeringPrinted circuit board

Owner:NITTO DENKO CORP

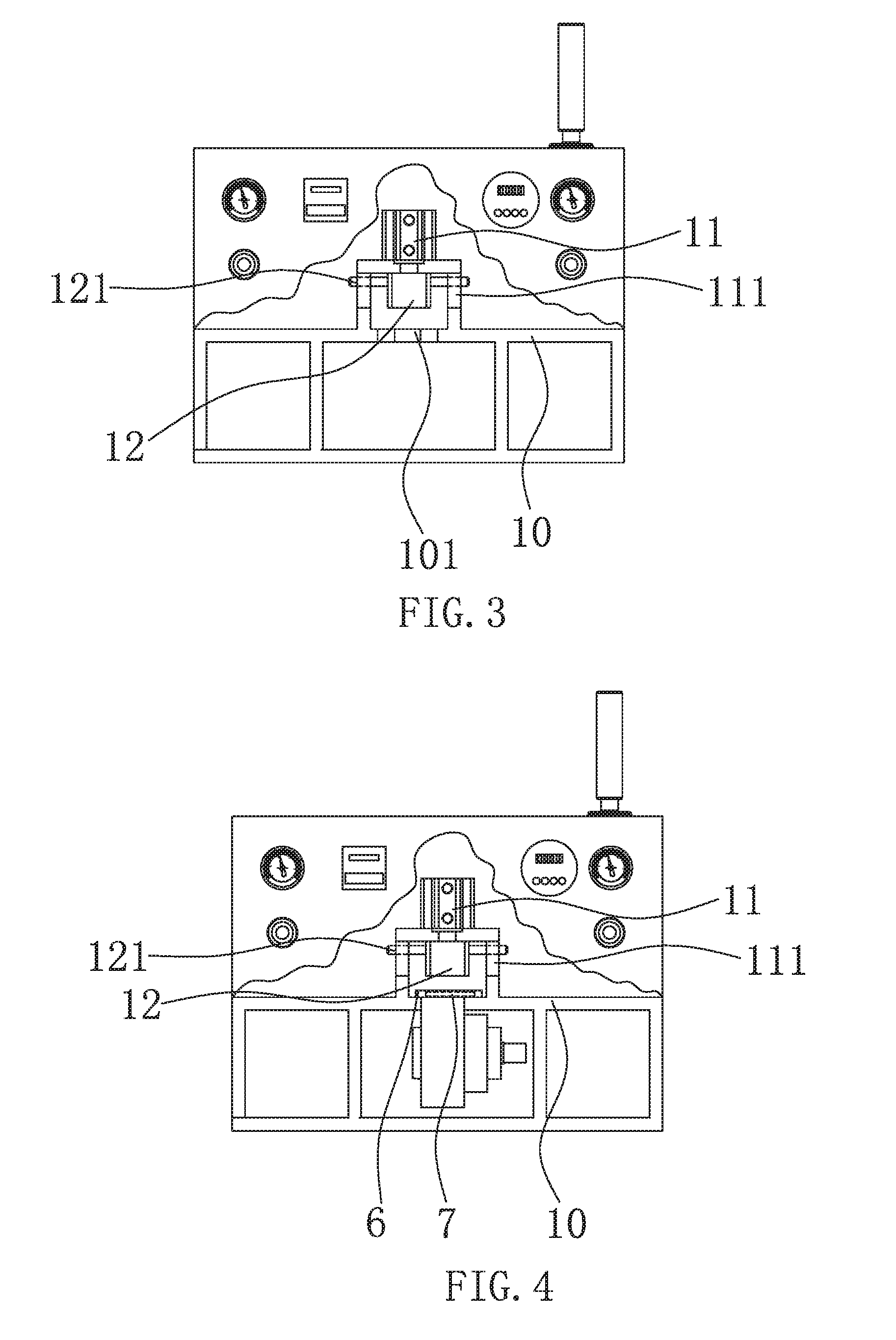

Air-tightness test equipment for turbine reduction gearbox

ActiveUS20170059443A1Easy and convenient testEasy to compressFluid pressure measurement using piezo-electric devicesPump testingFiltrationTurbine

The present invention discloses air-tightness test equipment for a turbine reduction gearbox, comprising a base, characterized in that a product mounting plate is arranged and fixed on the base by a support frame, the product mounting plate is provided with a product positioning slot having an opening on its one side; a compression cylinder is arranged over the product mounting plate by a cylinder support plate, the compression cylinder is vertically arranged, and a piston rod of the compression cylinder faces downward and a sealed connector corresponding to the upper part of the product positioning slot is fixed at the lower end of the piston rod; the sealed connector has a cavity in which an inflator is arranged, and the inflator is connected with an inflator bump by a pipeline; the inflator pump is provided with a gas filtration device, the pipeline is provided with a gas valve, and a gas pressure sensor is arranged on the pipeline between the gas valve and the inflator; the compression cylinder, the inflator bump, the gas valve and the gas pressure sensor are connected to a controller, respectively.

Owner:ZHEJIANG LINIX MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com