Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Precise cut size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

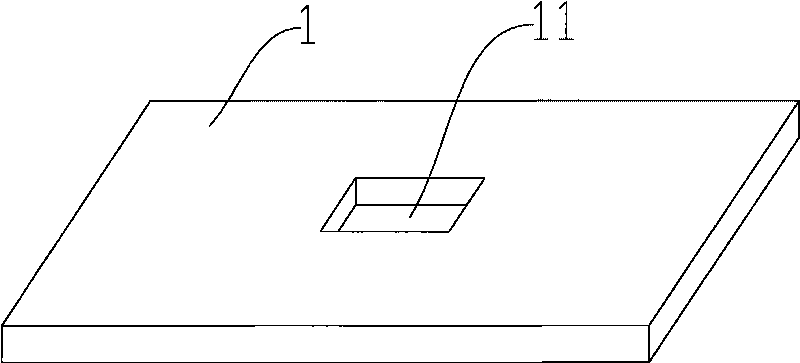

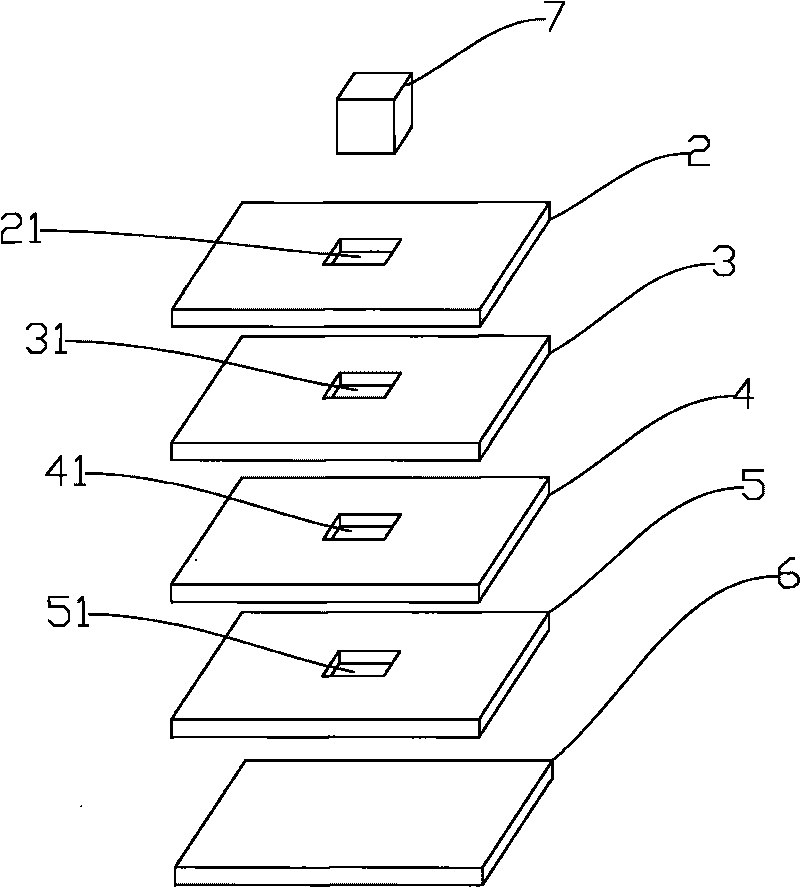

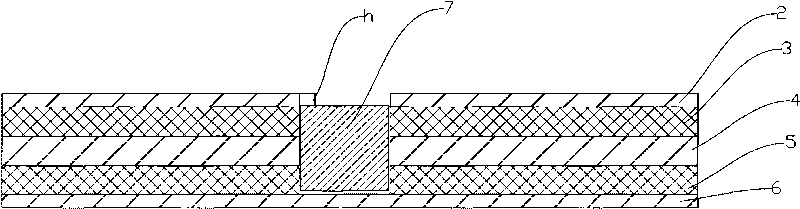

Method for producing stepped PCB board

ActiveCN101699937APrecise positioningControllable depth of cutMultilayer circuit manufactureEngineeringLaser cutting

The invention discloses a method for producing a stepped PCB board, which is characterized by comprising the following steps: a, windowing an inner core board; b, respectively pasting windowed prepregs on two surfaces of the inner core board, and making windows on the prepregs opposite to the window on the inner core board; c, putting silicon sheets into the windows on the inner core board and the prepregs; d, respectively arranging an outer core board on the surfaces of the two prepregs, and performing lamination; and e, cutting a stepped groove with laser, and taking the silicon sheets and the cut outer core boards out to form the stepped PCB board. In the method, the position of the stepped groove can be precisely positioned, the size and depth of the stepped groove are precisely ensured, and the groove wall of the stepped groove is neat and non-defective; the laminated panel and the silicon sheets after laser cutting can be easily taken out, and do not stick to the groove bottom; in addition, the inner core board and the prepregs are required to be windowed only, and other plates are not required to be windowed, so the working procedures are less. The method is simple, effective and convenient to implement, and is suitable for processing the stepped PCB board.

Owner:SHANGHAI MEADVILLE ELECTRONICS

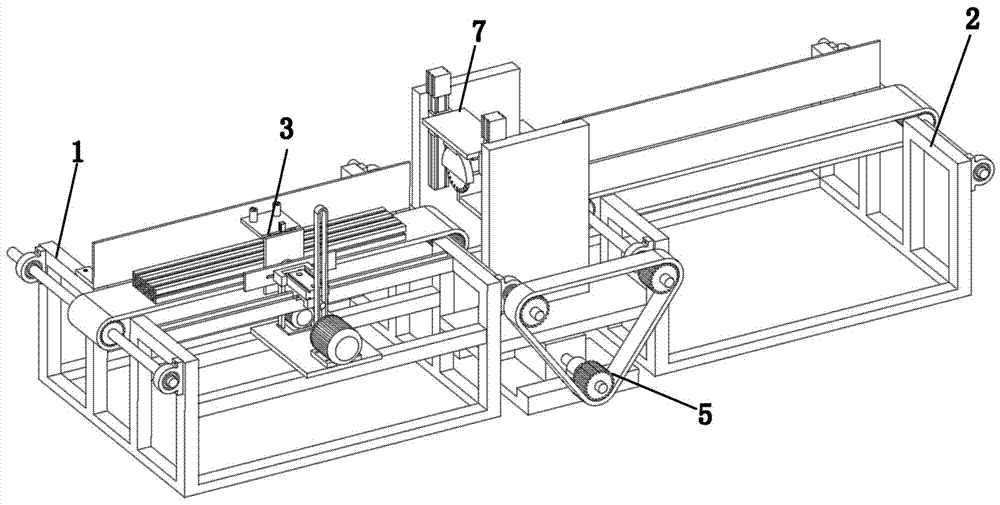

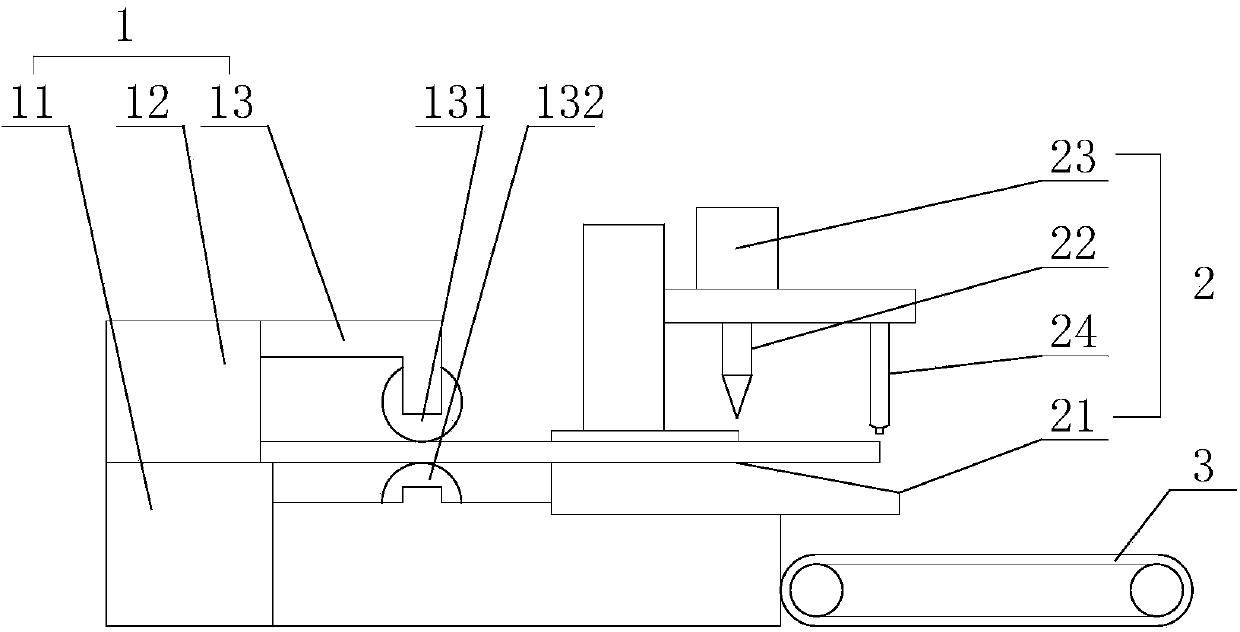

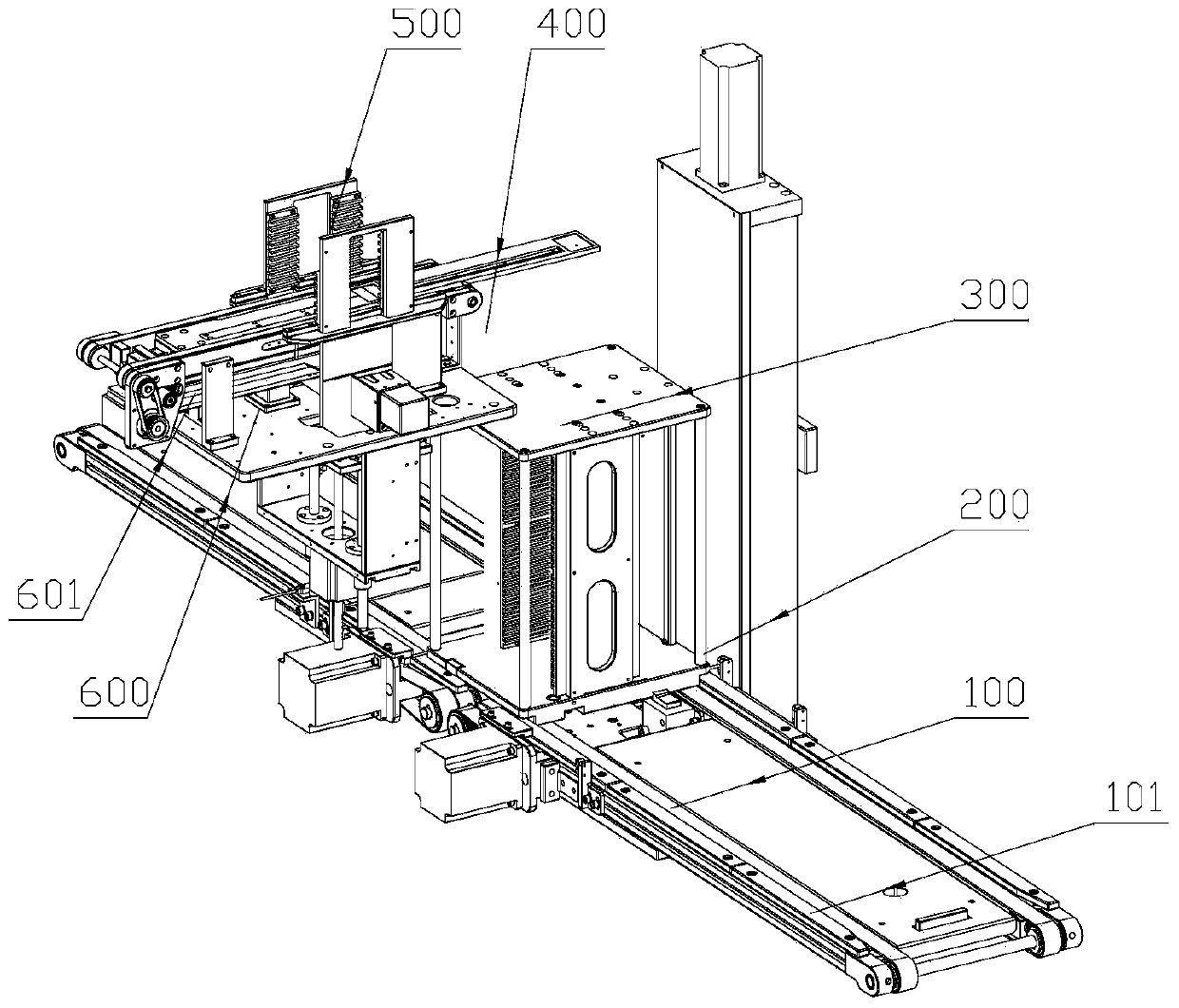

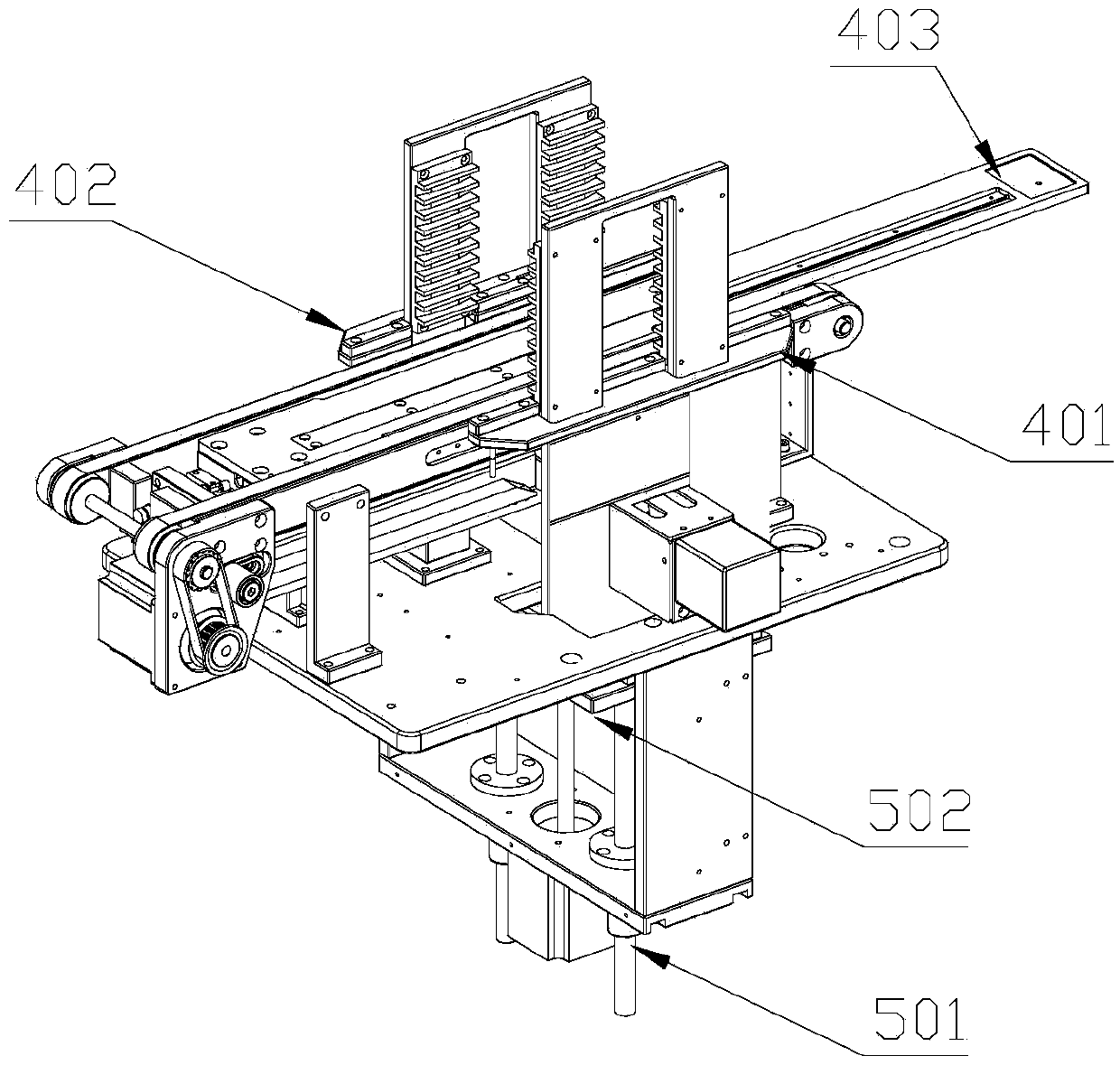

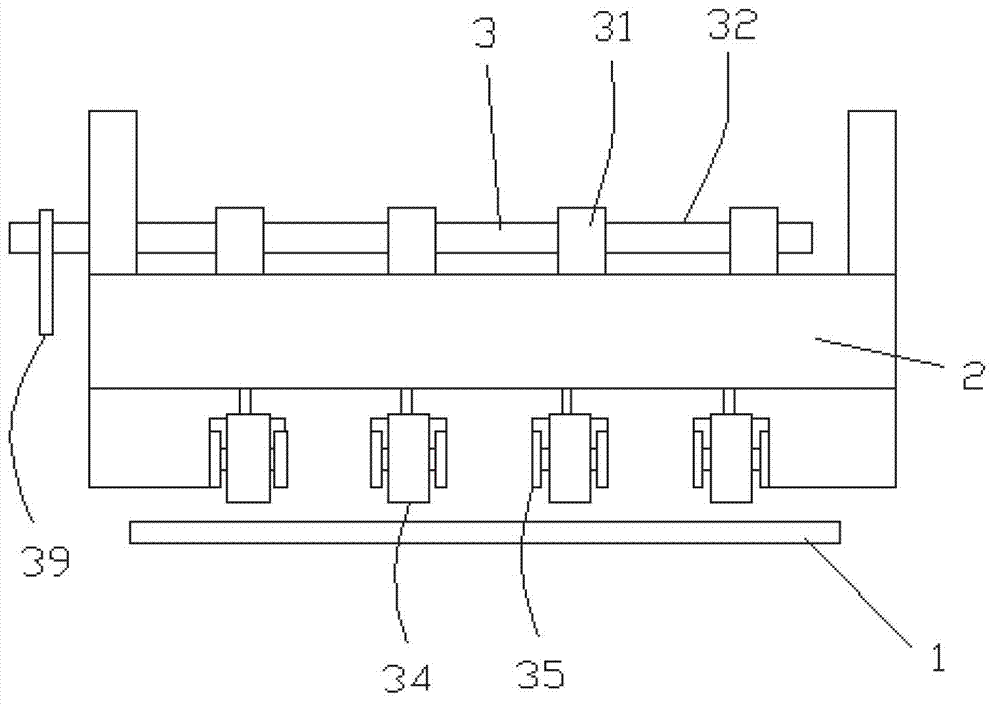

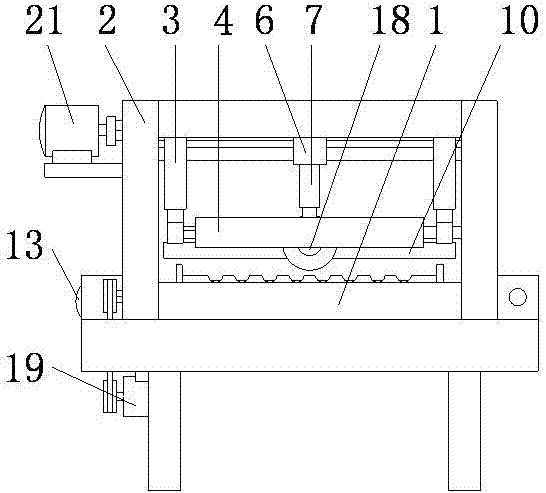

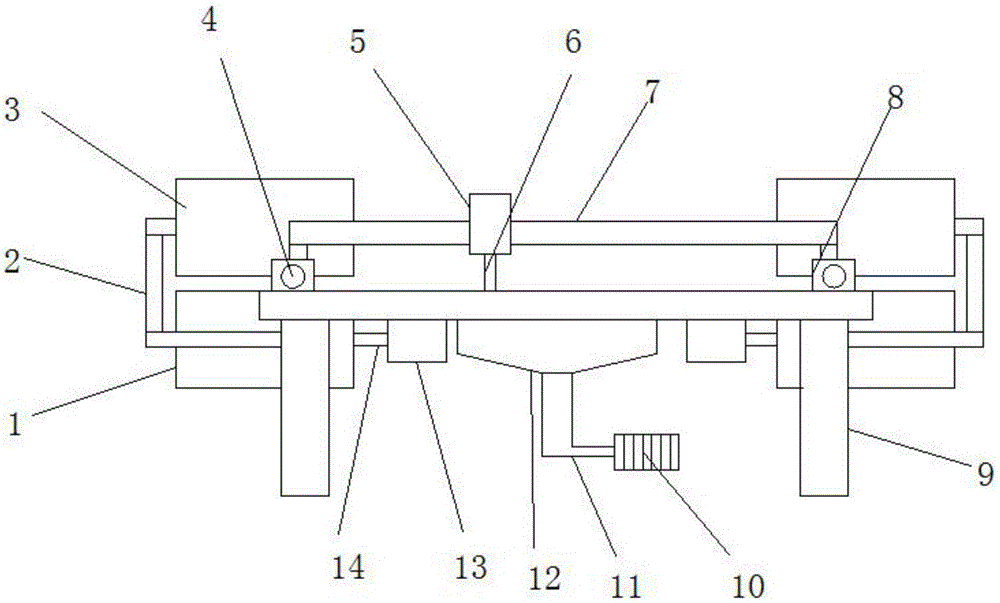

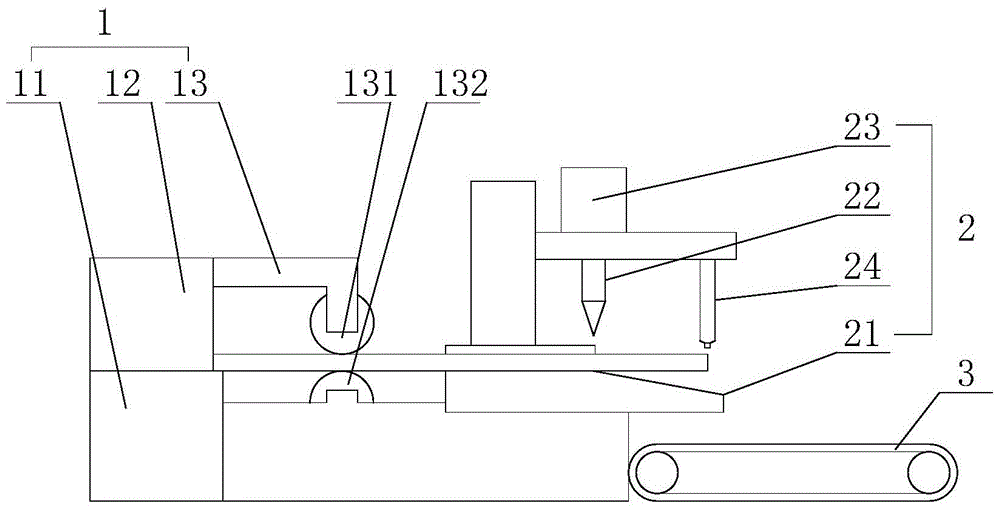

Automatic cutting machine of aluminum profile

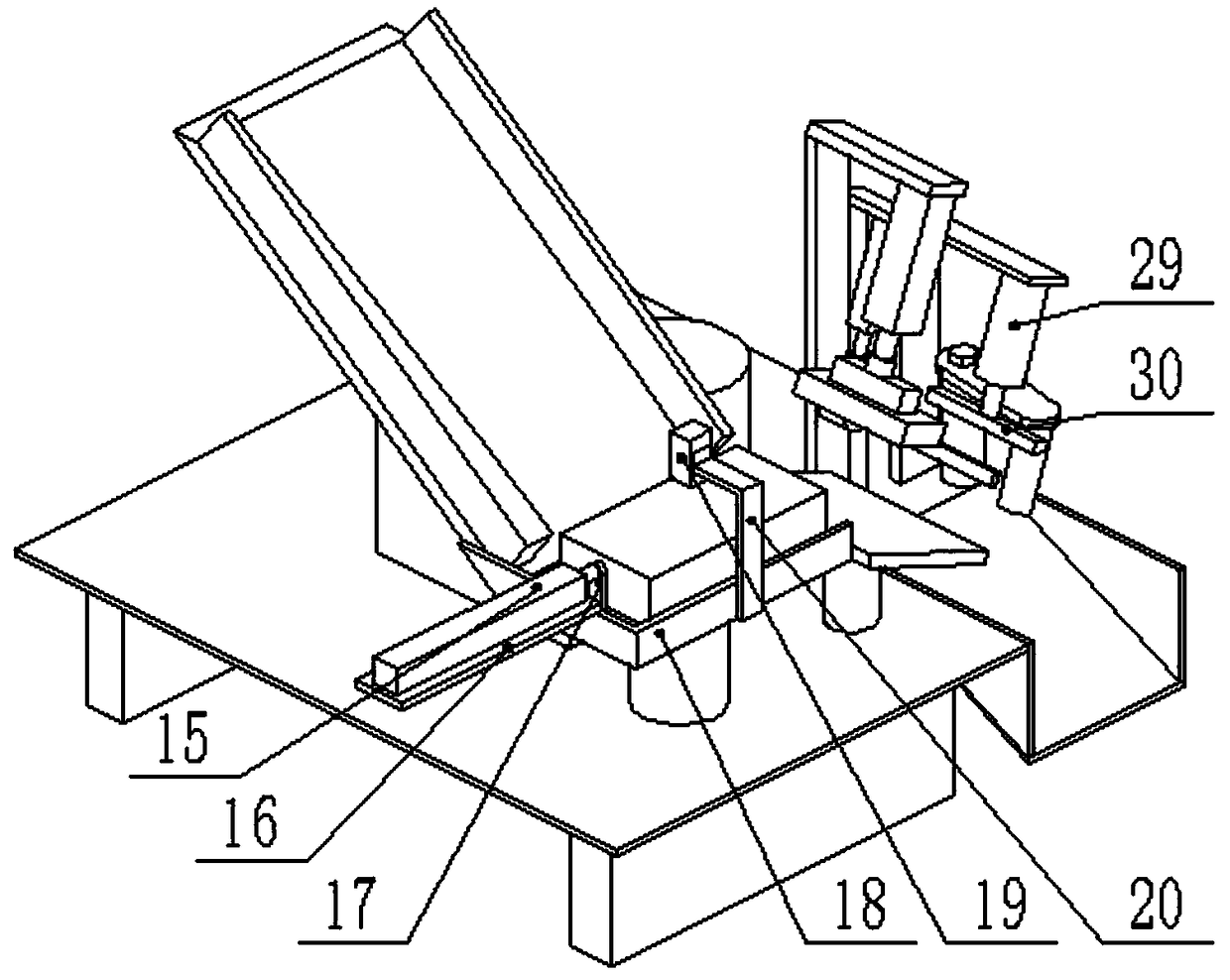

ActiveCN107486594AReduce outputImprove work efficiencyMetal sawing devicesMeasurement/indication equipmentsEngineeringMachining

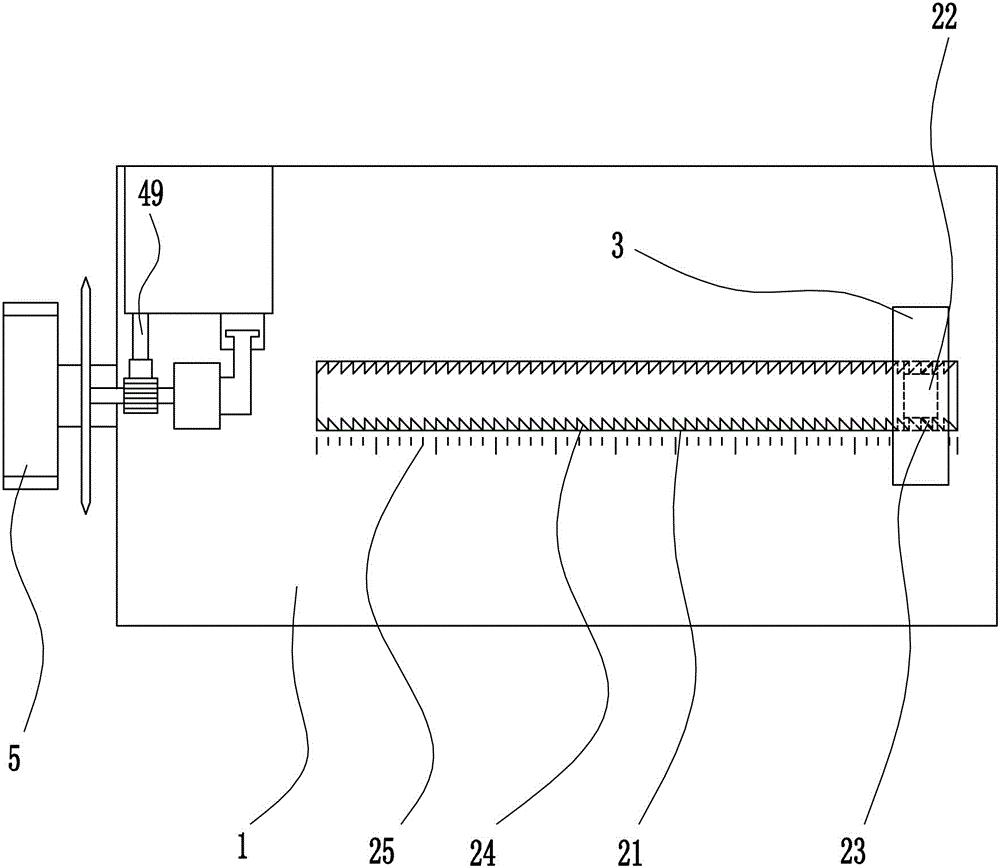

The invention relates to the field of aluminum profile machining equipment, in particular to an automatic cutting machine of an aluminum profile. The automatic cutting machine comprises a feeding conveying table, a discharging conveying table, a quantitative limiting device, an ejection device and a transmission device; the feeding conveying table comprises a feeding conveying belt, the discharging conveying table is provided with a discharging conveying belt, the quantitative limiting device comprises a positioning component and a cutting component, the positioning component is provided with a positioning assembly, and the cutting component is located between the feeding conveying belt and the discharging conveying belt and is provided with a cutting assembly; and the transmission device is provided with a conveying assembly, and the ejection device is arranged between the output end of the feeding conveying belt and the input end of the discharging conveying belt and is located below the cutting device. According to the automatic cutting machine, the automatic feeding, cutting, ejection and discharging manner is adopted, manpower output is reduced, and the working efficiency of cutting operation is improved; and accurate grasping on the to-be-cut aluminum profile position is achieved through a sensing component, and the method is high in working efficiency, accurate in cutting size and high in uniformity of products.

Owner:华铝铝业有限公司

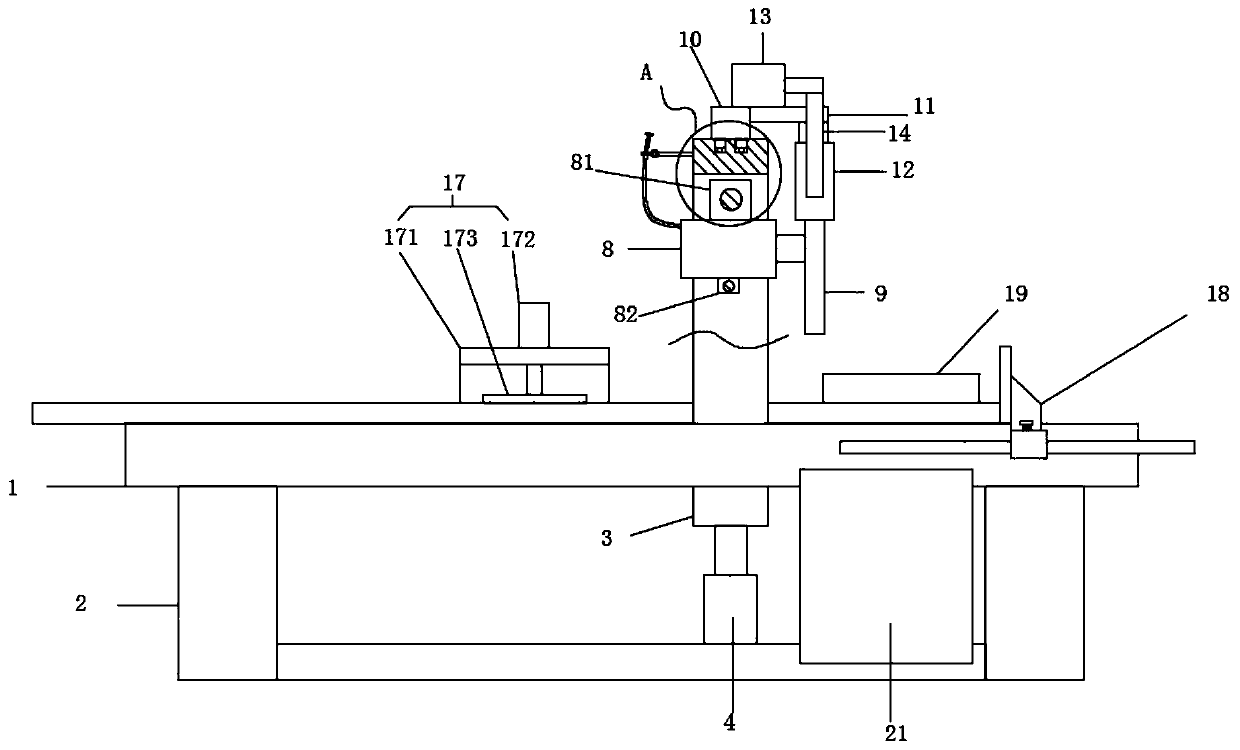

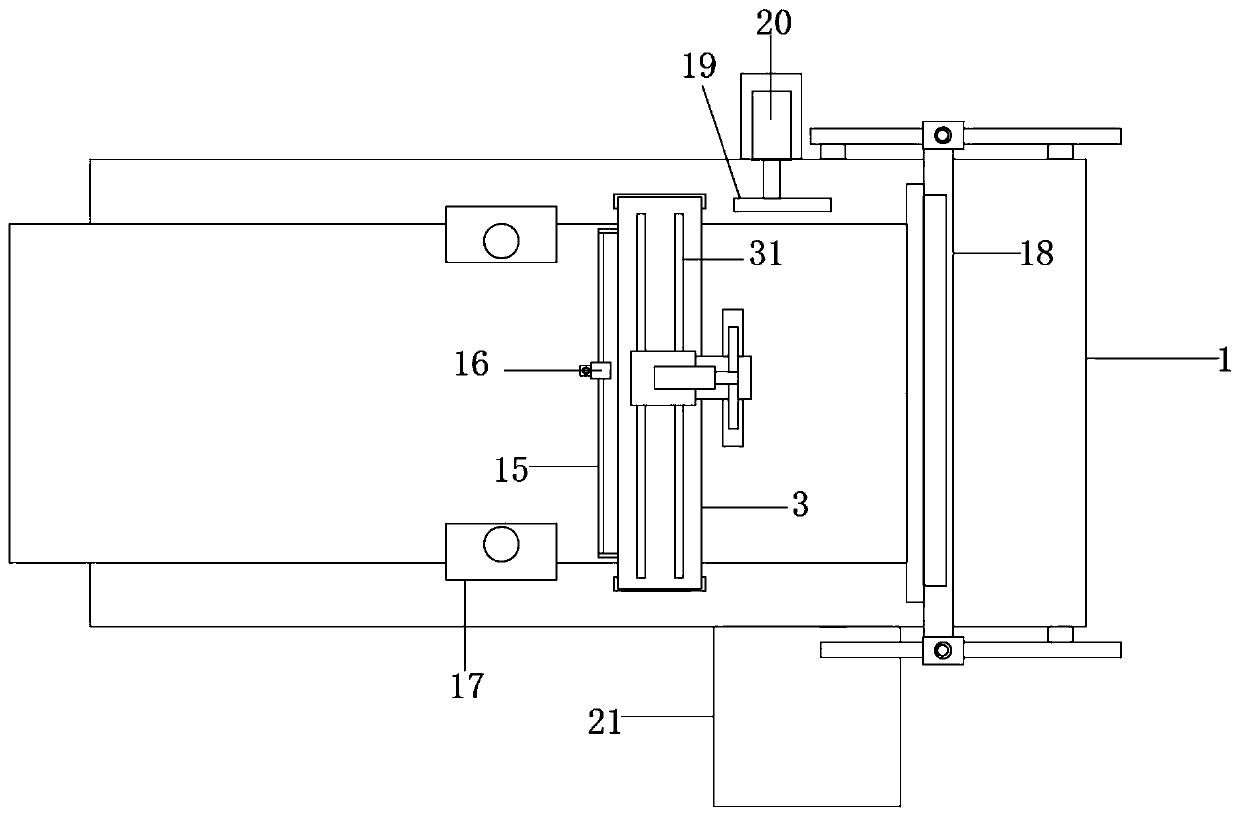

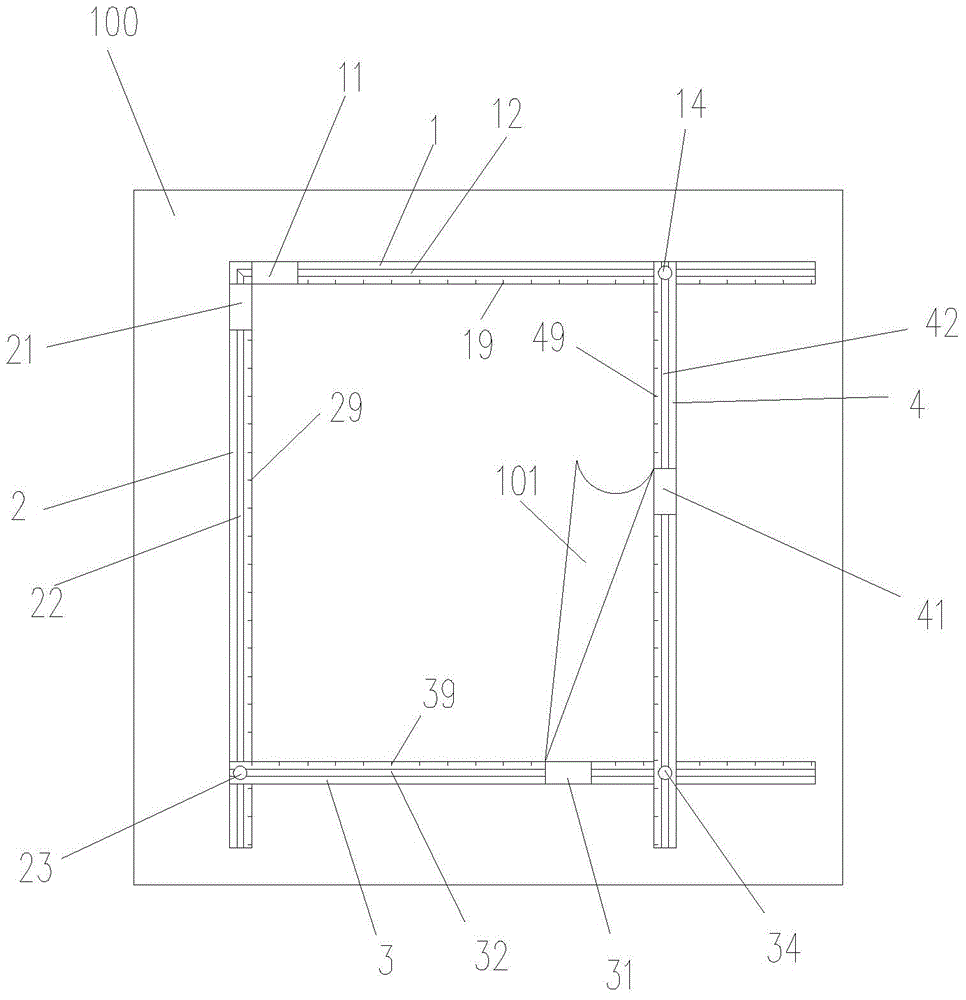

Full-automatic plate shearing machine

ActiveCN104174920AFeed process smoothSmall size errorShearing machinesEngineeringMechanical engineering

The invention discloses a full-automatic plate shearing machine. The machine comprises a feeding device, a shearing device and a discharging conveying belt, wherein a limiting mechanism is arranged in the feeding device, a proximity switch for controlling a shearing mechanism to work is arranged in the shearing device, and the discharging conveying belt is arranged below a discharging end of the shearing device. According to the full-automatic plate shearing machine, automatic feeding of steel strips, automatic shearing according to preset dimensions and automatic discharging of steel plates can be realized, dimension errors of steel plate products are small, and the percent of pass is high.

Owner:ANHUI NINGGUO DONGBO FASTENER

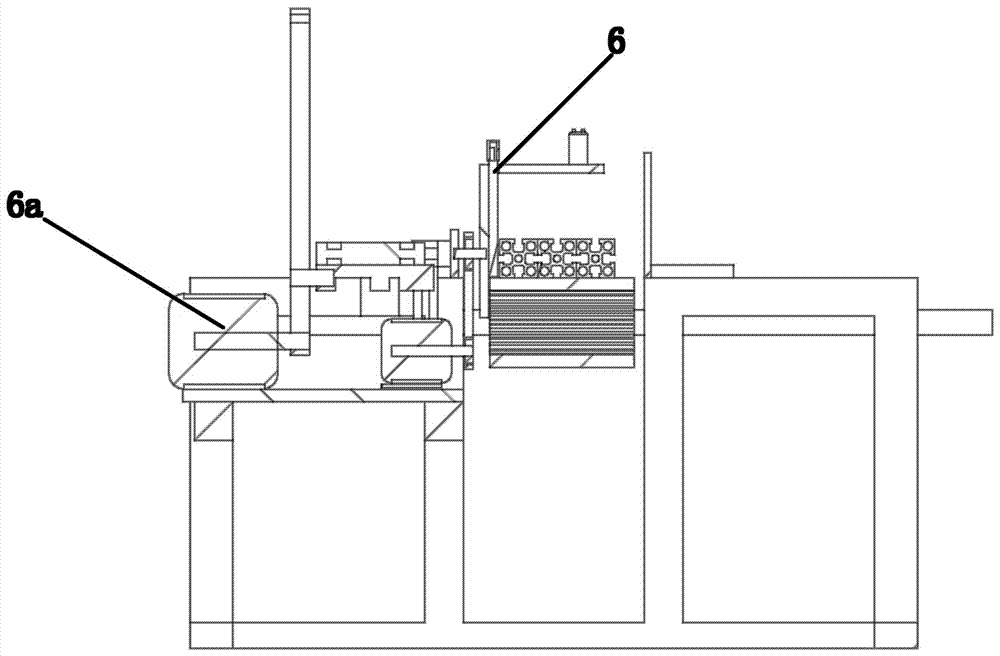

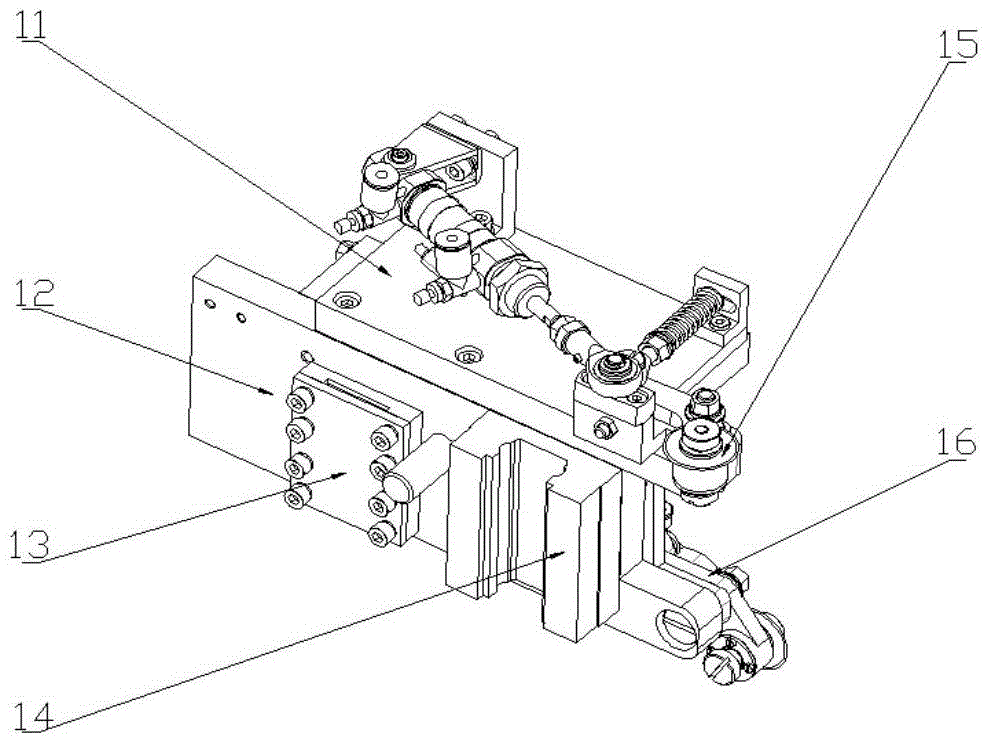

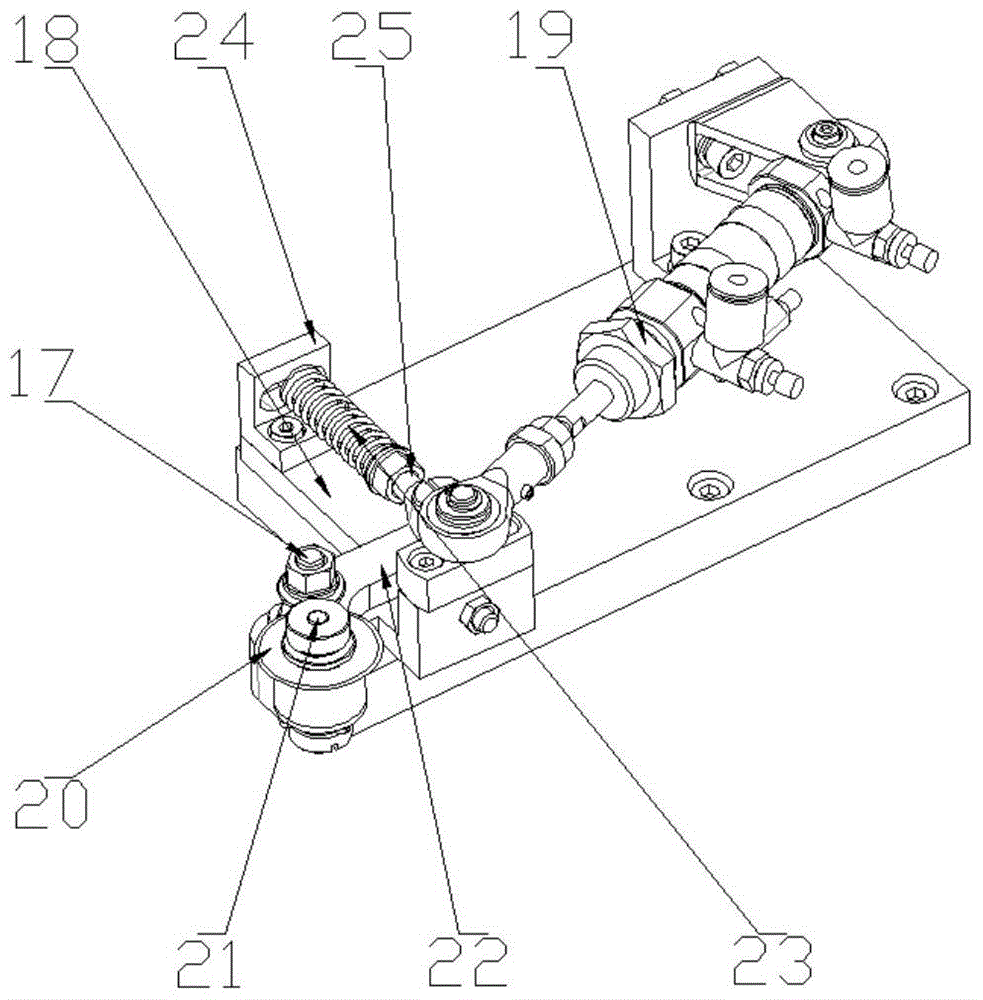

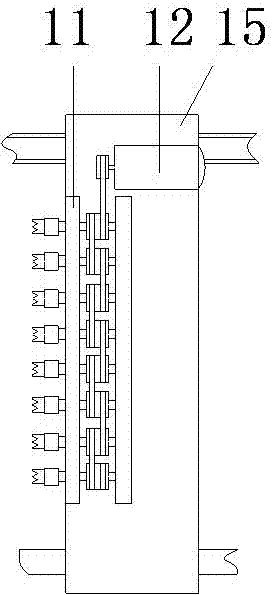

Automatic fusing cutting machine for stainless steel woven polytetrafluoroethylene tubes

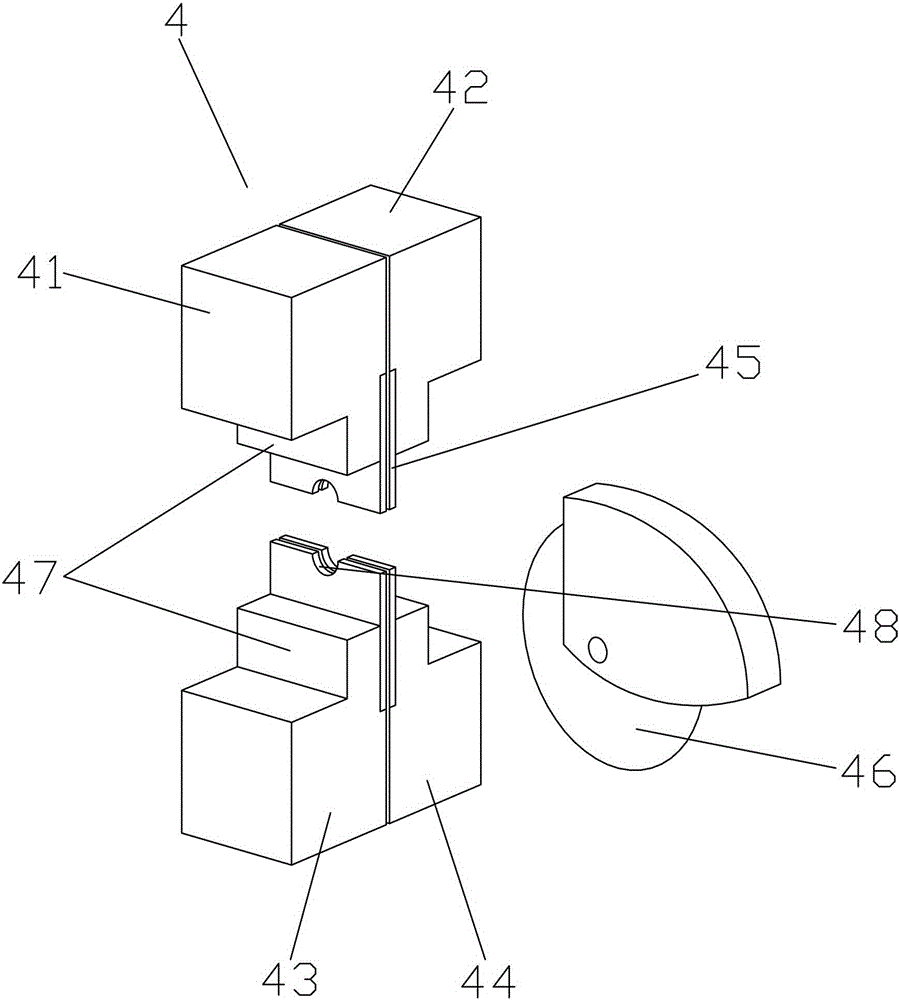

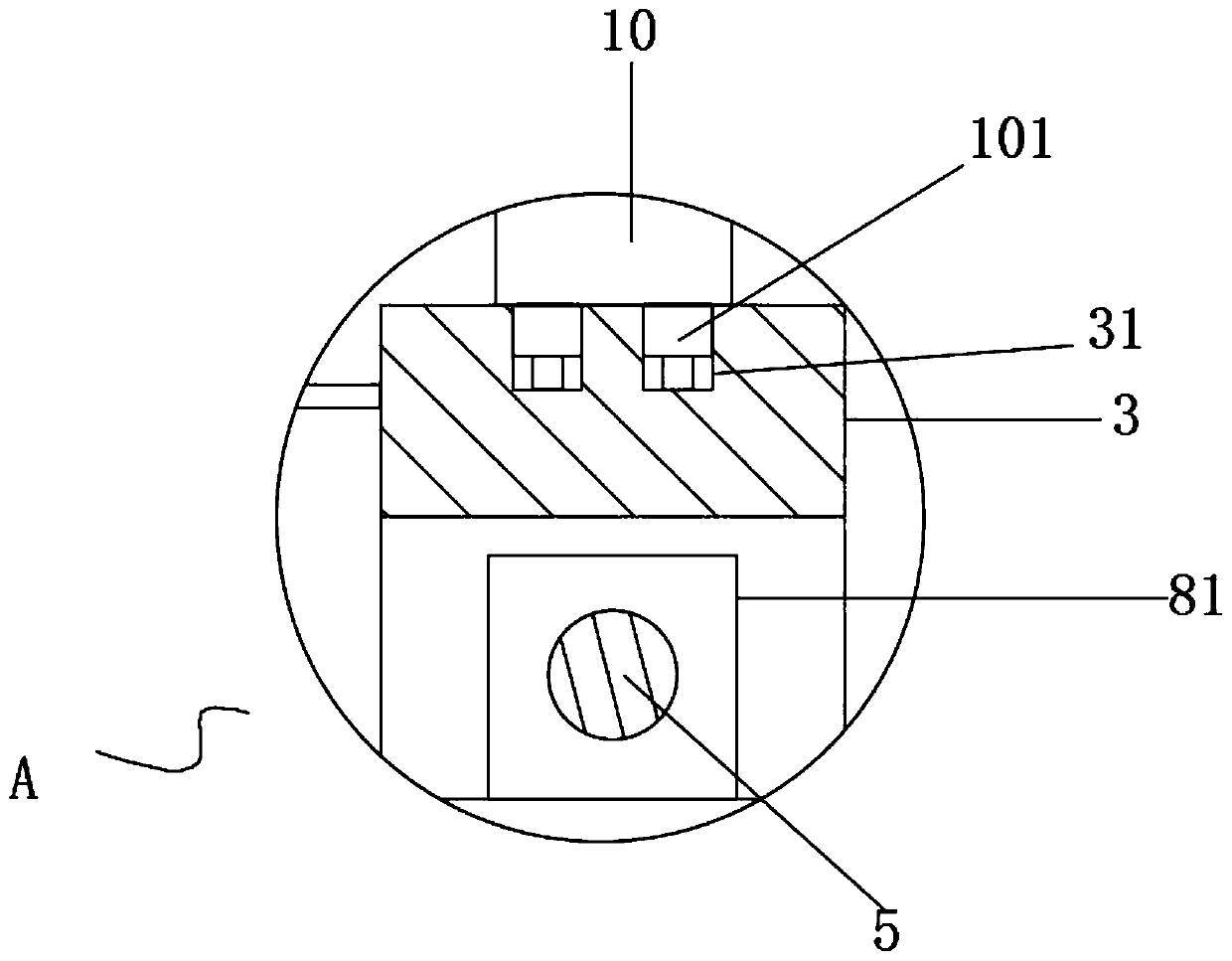

The invention discloses an automatic fusing cutting machine for stainless steel woven polytetrafluoroethylene tubes. The machine comprises a wire feeding and pressing module, a belt wheel wire pressing module, a guiding wire pressing module and a fusing module in sequence from right to left. The fusing module comprises a left upper pressing block, a right upper pressing block, a left lower pressing block and a right lower pressing block, wherein the left upper pressing block and the right upper pressing block can slide vertically and move horizontally; the left lower pressing block and the right lower pressing block can move horizontally; the pipeline passing workstation positions among the left upper pressing block, the right upper pressing block, the left lower pressing block and the right lower pressing block are each provided with a dismountable fusing conductive copper knife installed vertically; a vertically installed saw blade is installed in front of the pipeline passing workstation position of the fusing module. For the characteristics of woven hoses, through the reasonable structural improvement, especially the design of combination of the pressing blocks and the saw blade, steel wire layers of the woven hoses are fused through the combination of the pressing blocks, then the saw blade cuts off tubes on the inner layers, the woven hoses are pulled broken when the combination of the pressing blocks is in a heating state, and therefore the steel wires do not explode without external force when fused, and it is ensured that the fracture surfaces after fusing are tidier and smoother.

Owner:FOSHAN HAOBANG MACHINERY CO LTD

Ceramic tile making method

InactiveCN1891420AReduce the type of specificationReduce processing costsCeramic shaping apparatusStone-like material working toolsBrickEngineering

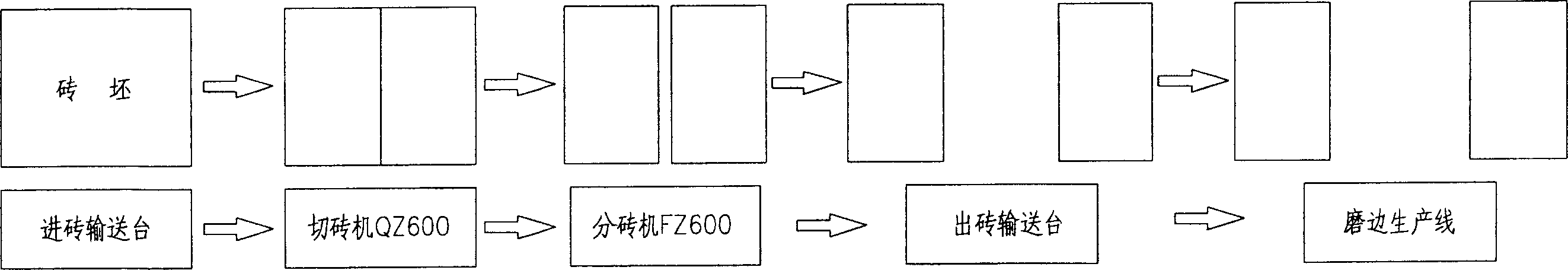

This invention provides a method for manufacturing tiles including: sending adobes into a feeding platform then to a brick cutter and utilizing a knife flywheel to cut cut-lines on the surfaces of the adobes, sending the adobes with cut-lines into a brick separating machine then to knock on them with a knocking device, the adobes are cut off along the cut-lines, the separated adobes are sent to an edge-grind production line from the platform to grind the edges, in which, the method reduces the specifications of dies to reduce the process cost of tiles in small scale.

Owner:KEDA INDUSTRIAL GROUP CO LTD

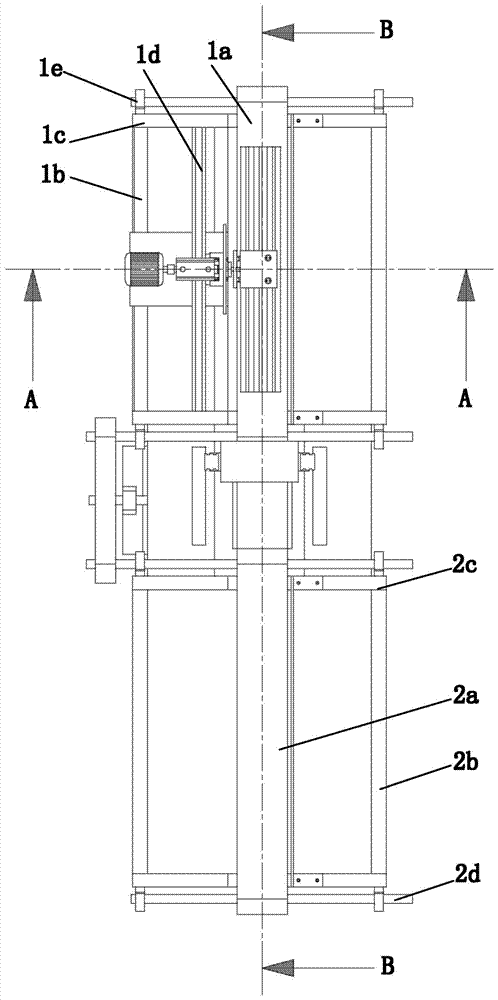

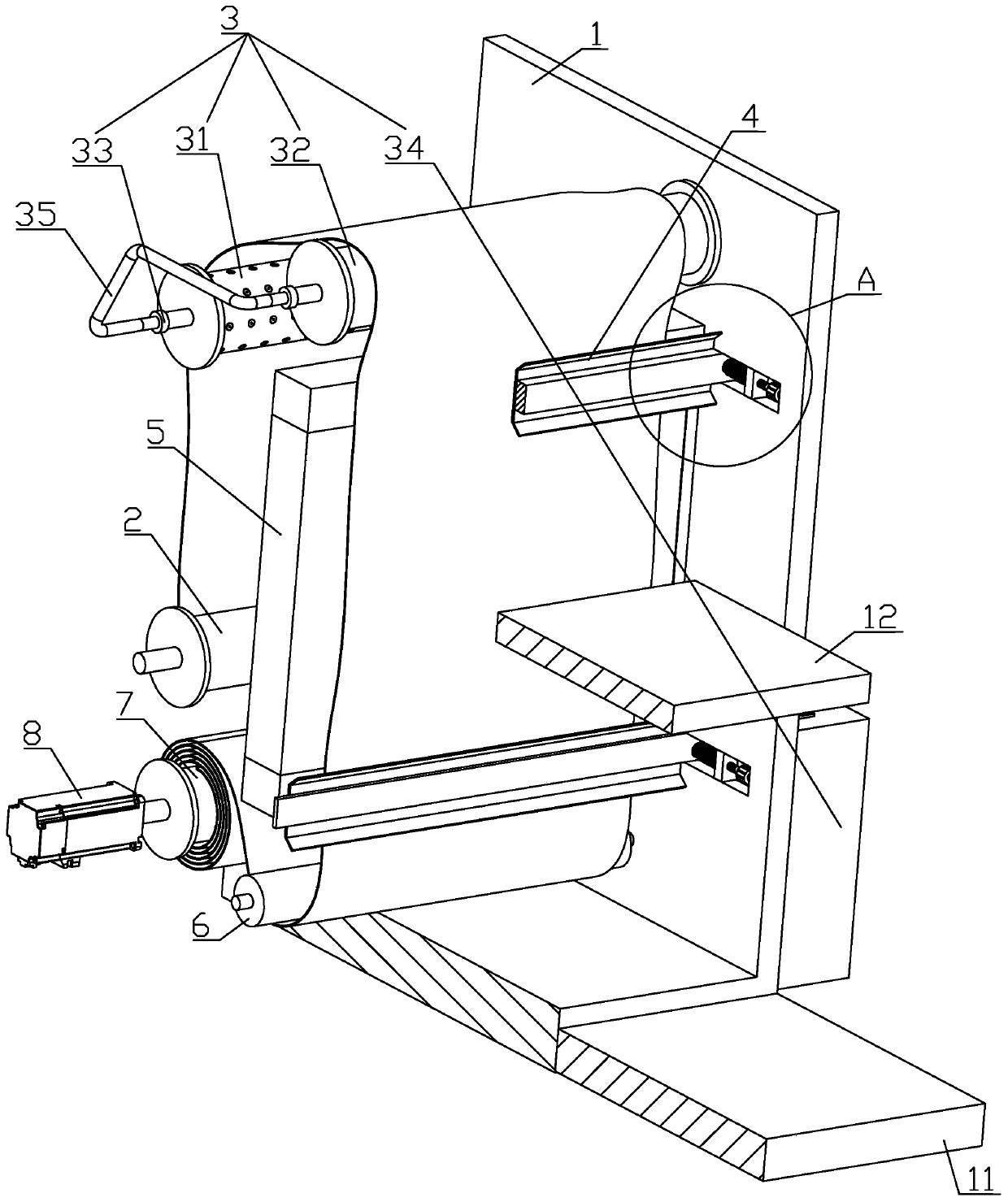

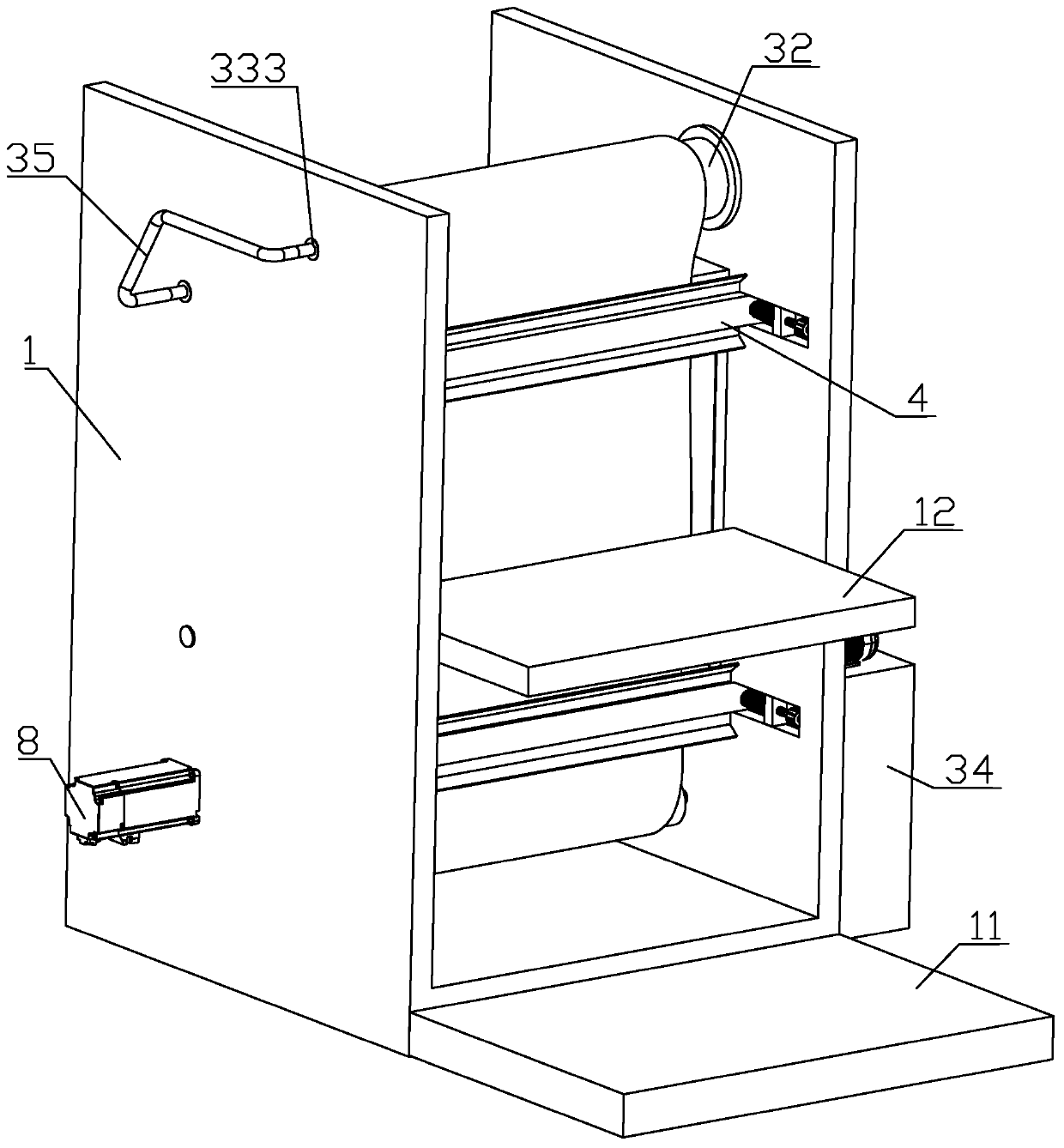

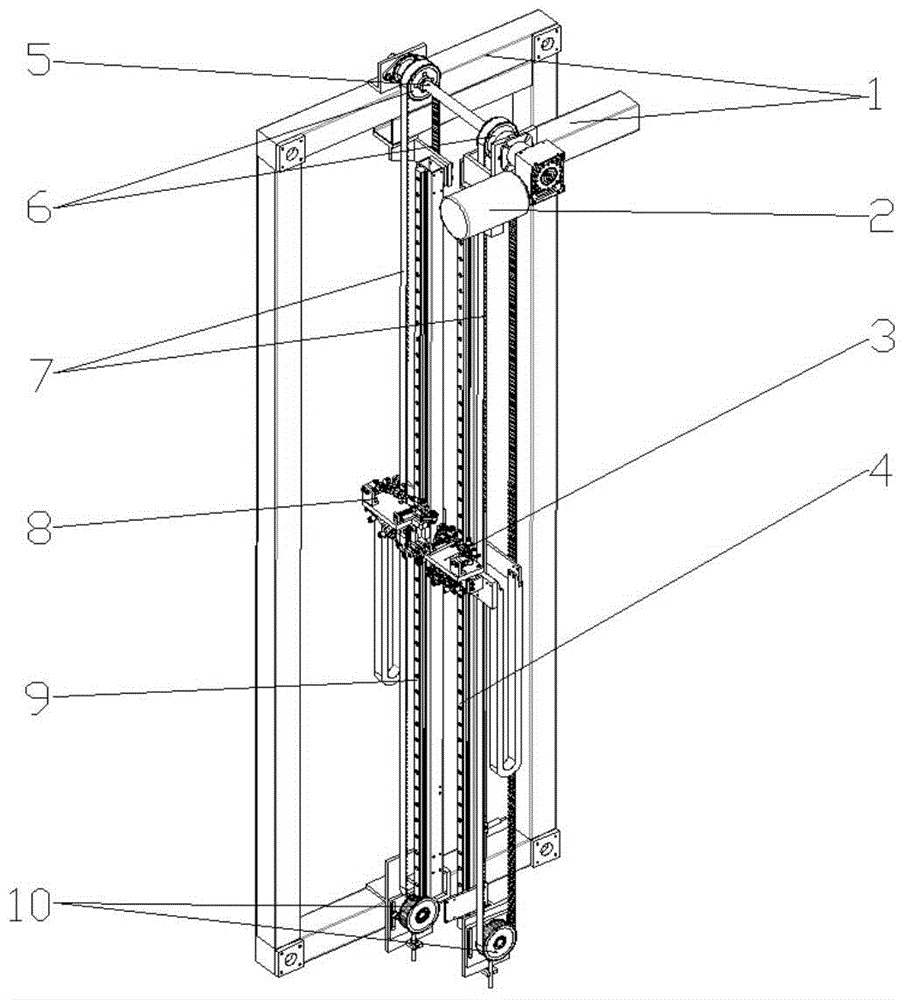

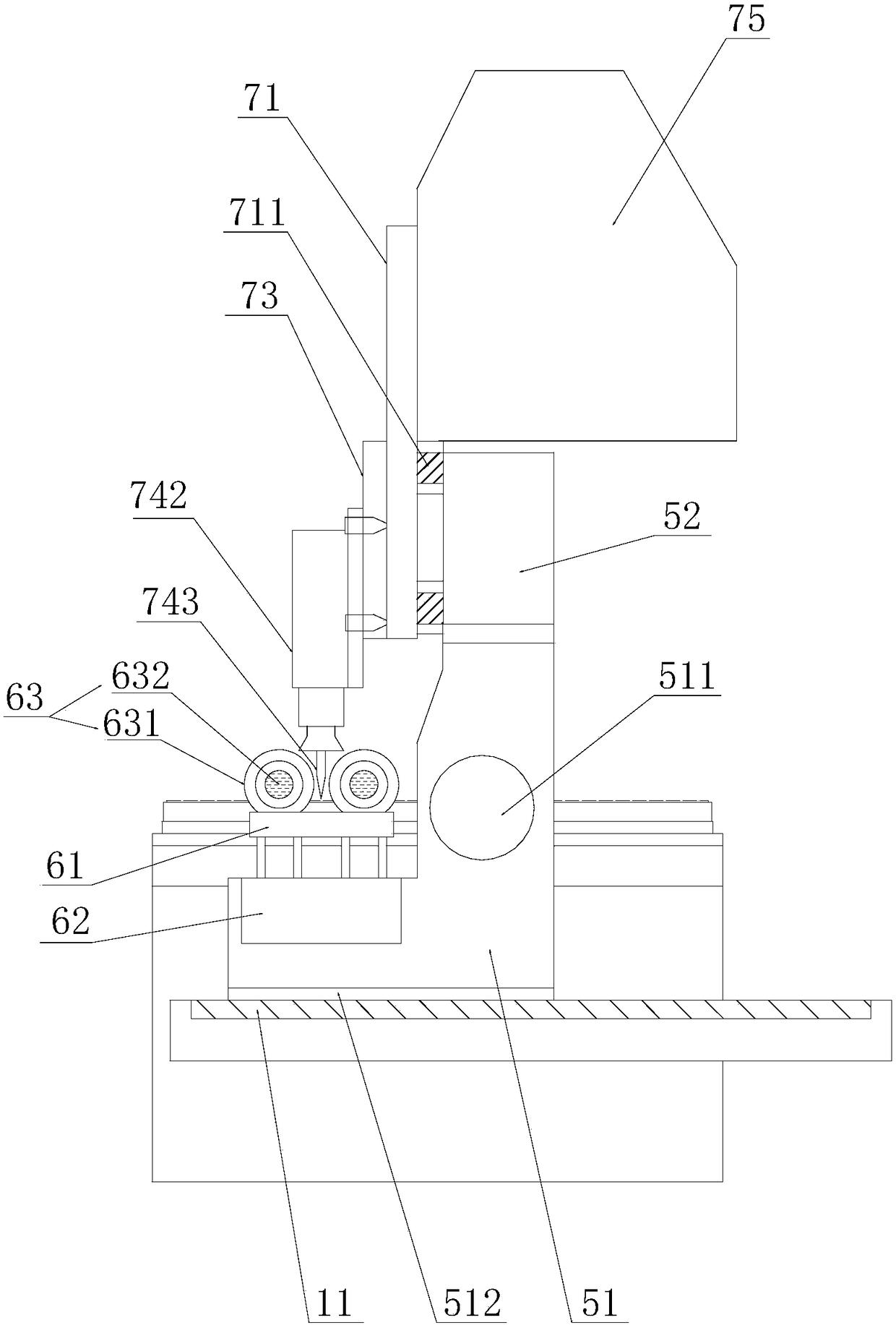

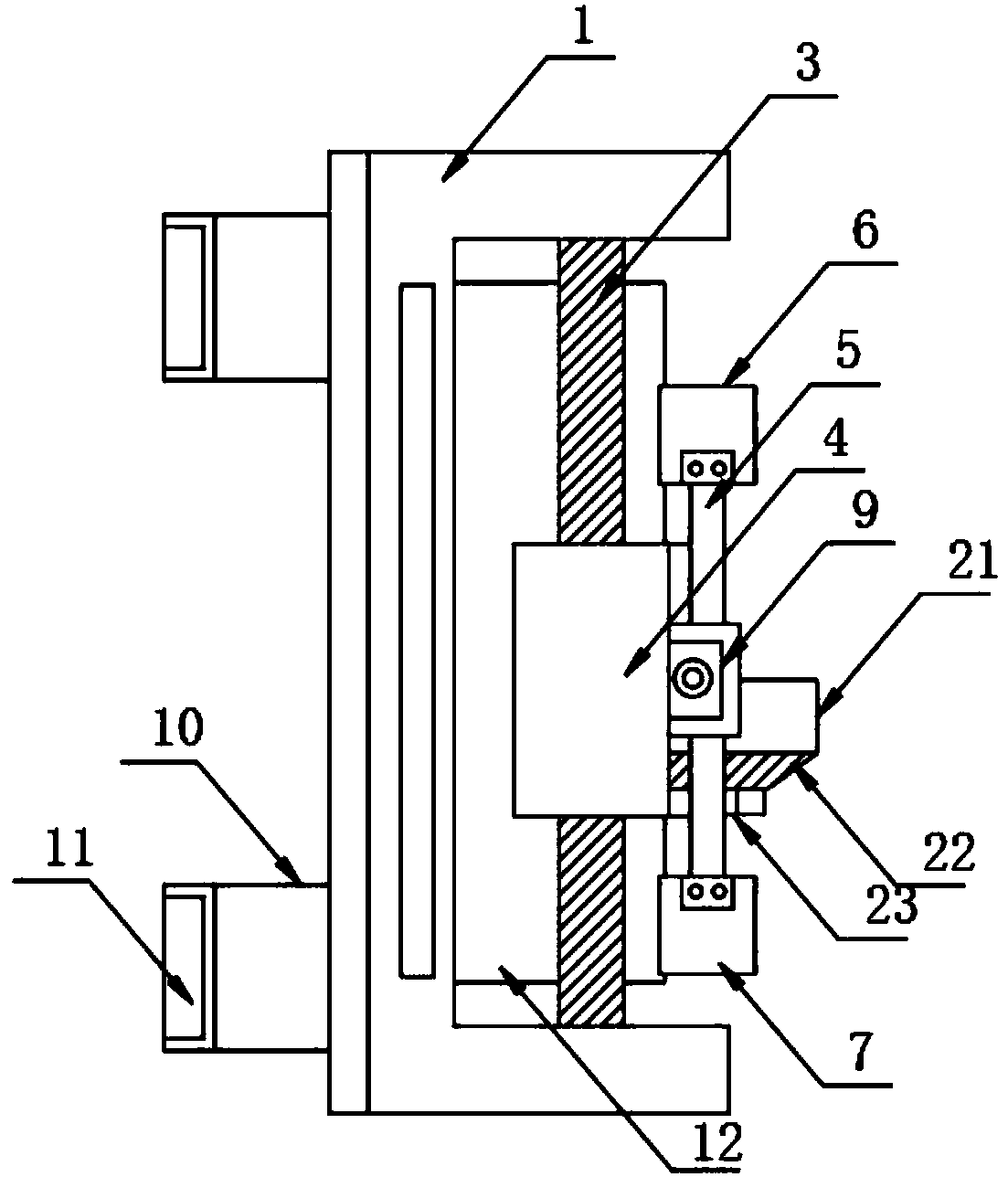

Thin film cutting mechanism of vertical type glass film laminating machine

ActiveCN104526736APrecise cut sizeReduce changeover timeMetal working apparatusEngineeringMechanical engineering

The invention provides a thin film cutting mechanism of a vertical type glass film laminating machine. The thin film cutting mechanism comprises a vertical type machine frame, a synchronous belt transmission mechanism, a thin film cutting knife wheel set and a knife wheel movement guide rail mechanism, wherein the synchronous belt transmission mechanism and the knife wheel movement guide rail mechanism are installed on the vertical type machine frame; the synchronous belt transmission mechanism is used for moving the knife wheel set and comprises a servo motor, a driving synchronous pulley, a driven synchronous pulley, synchronous belts and a synchronous belt driving shaft; the thin film cutting knife wheel set comprises a front face cutting knife wheel set body and a back face cutting knife wheel set body which are fixed to the two synchronous belts respectively; knife wheel movement guide rails are used for movement supporting and guiding of the knife wheel set and comprise the front face cutting knife wheel movement guide rail and back face cutting knife wheel movement guide rail. By means of the thin film cutting mechanism, the thin film cutting knife wheel set is controlled through servo control, the cutting size is accurate, manual operation of an operator is not needed, the remodeling time is saved, and the working efficiency is greatly improved.

Owner:江西仁义新能源有限公司

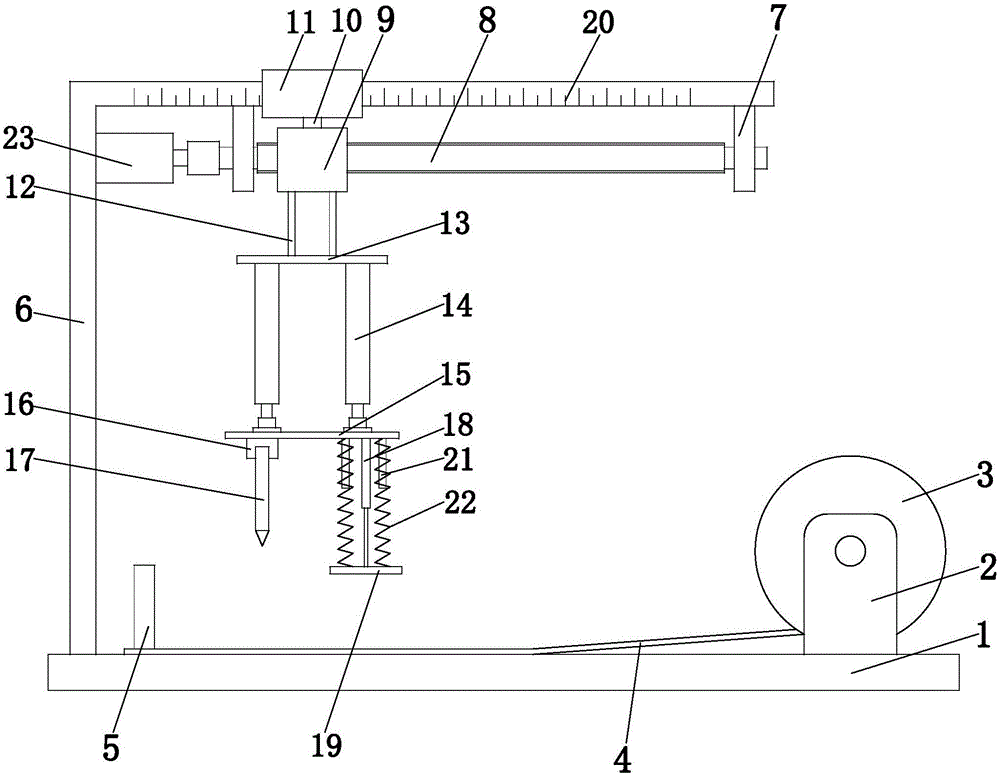

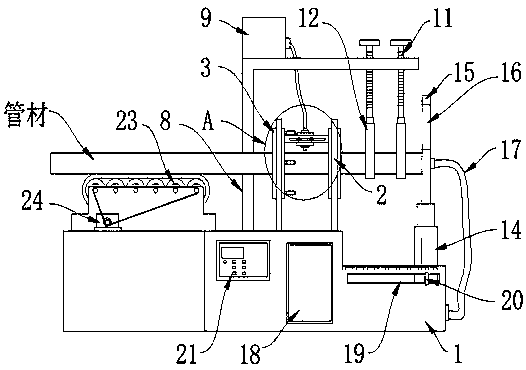

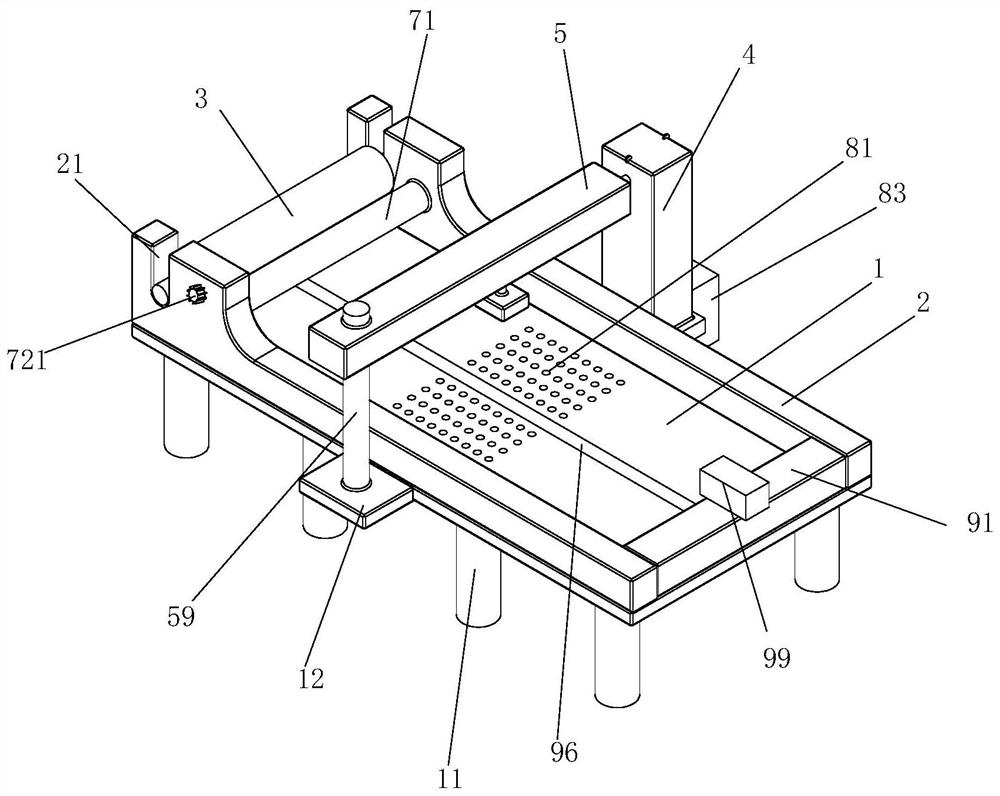

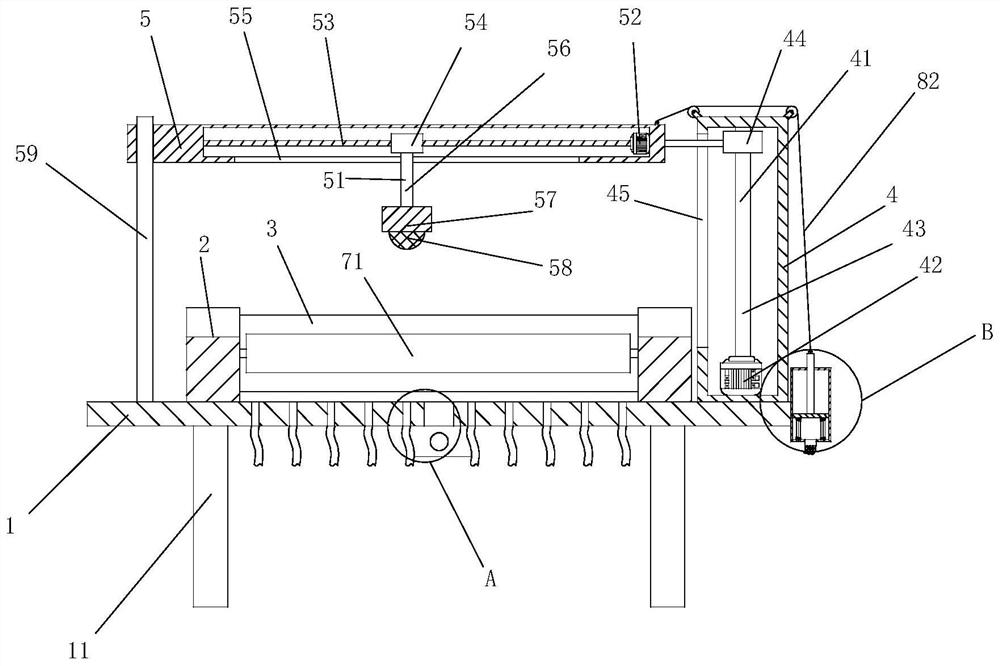

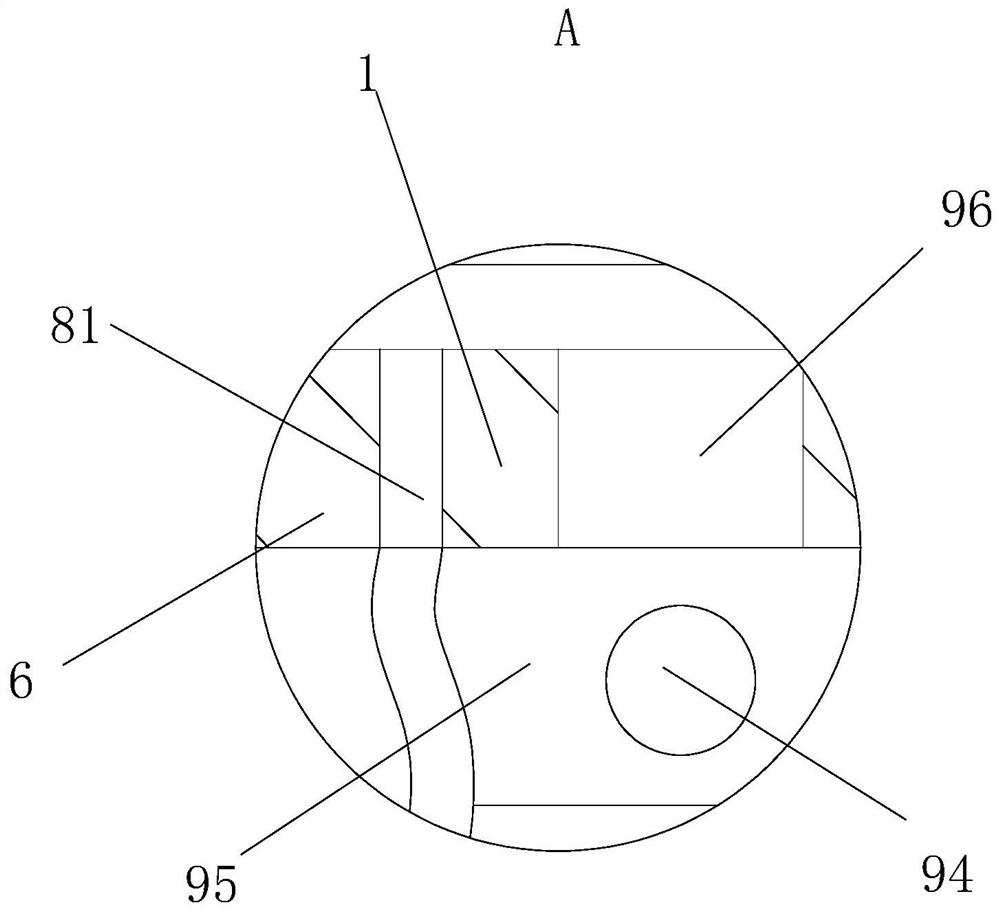

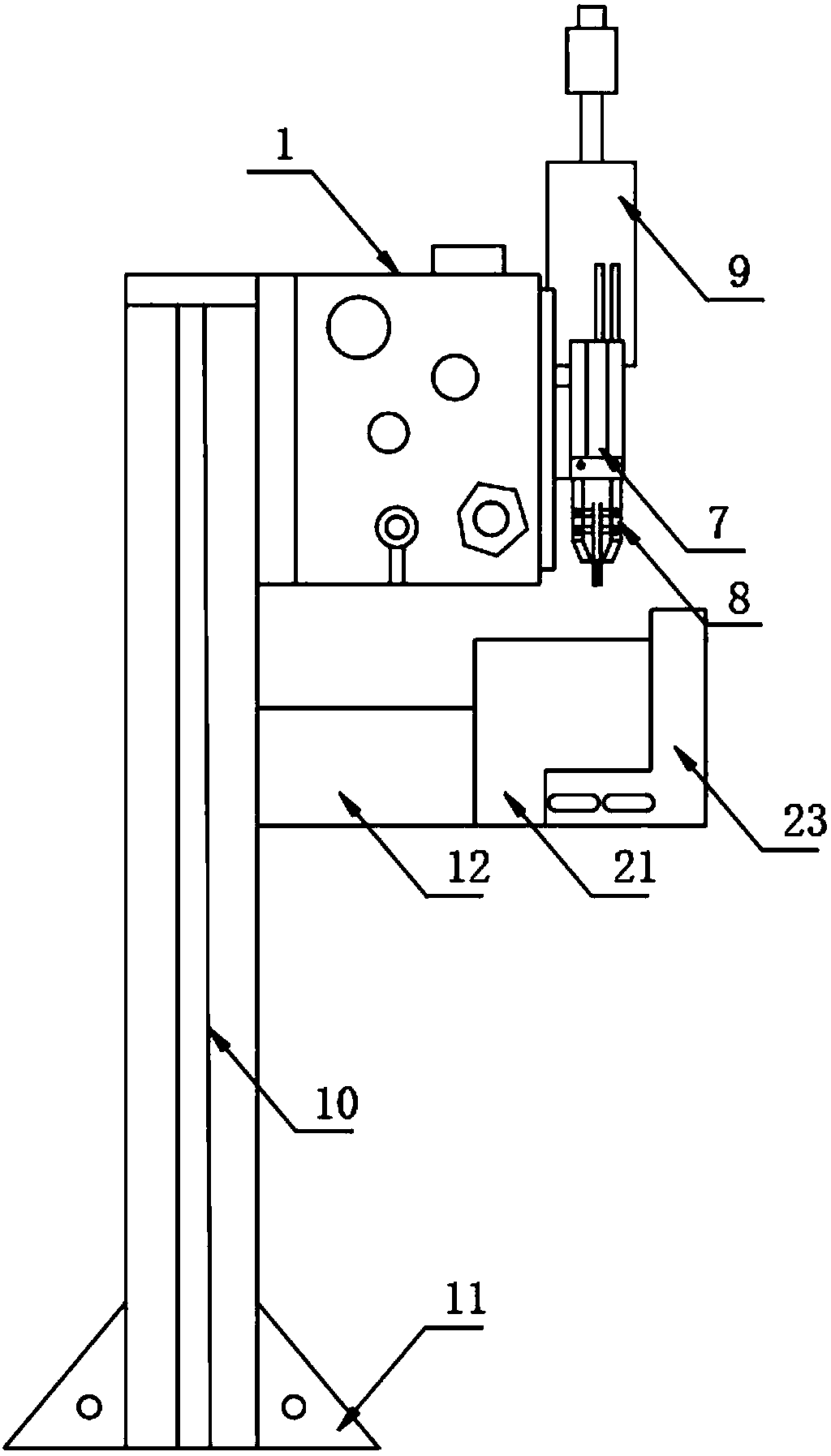

Cutting equipment of pipeline for water conservancy project

ActiveCN106825733AAvoid damageExtended service lifeTube shearing machinesMaintainance and safety accessoriesEngineeringHydraulic engineering

The invention relates to cutting equipment and in particular relates to cutting equipment of a pipeline for a water conservancy project. Aiming at solving the technical problems, the invention provides the cutting equipment of the pipeline for the water conservancy project, which is simple and safe in cutting operation, and has an accurate cutting size. In order to solve the technical problems, the cutting equipment of the pipeline for the water conservancy project, provided by the invention, comprises a cutting platform and the like; a measuring mechanism is mounted at the right side of the middle of the cutting platform; a clamping mechanism is mounted on the measuring mechanism; a cutting mechanism is mounted above the left side of the middle of the cutting platform; a cooling mechanism is mounted at the left side of the bottom of the cutting platform. The cutting equipment provided by the invention is used for the pipeline for the water conservancy project, which needs to be cut; one end of the pipeline is arranged on the clamping mechanism and the pipeline is arranged on a supporting seat; meanwhile, the measuring mechanism is moved and a size needing to be cut is selected.

Owner:涌纬集团股份有限公司

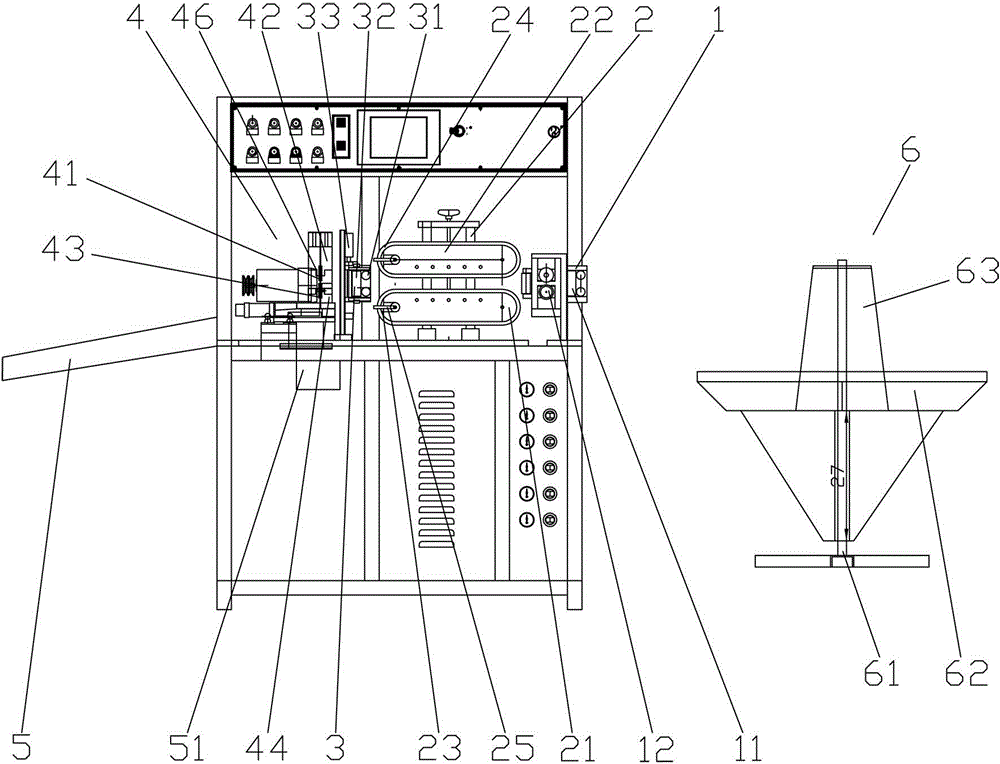

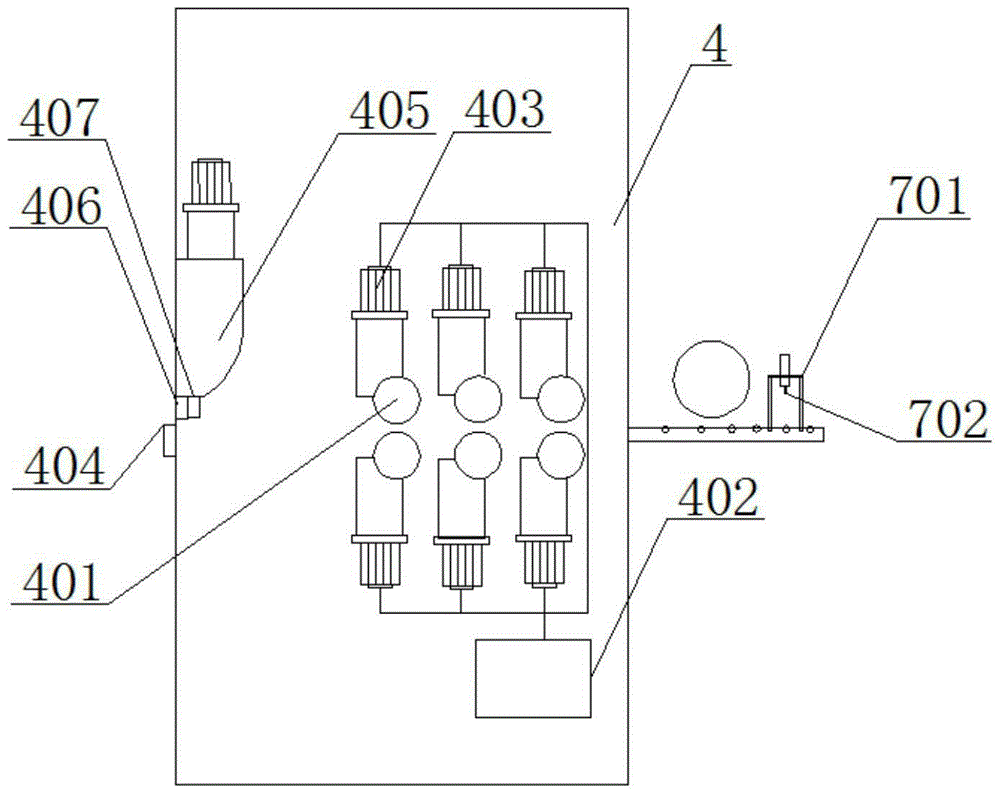

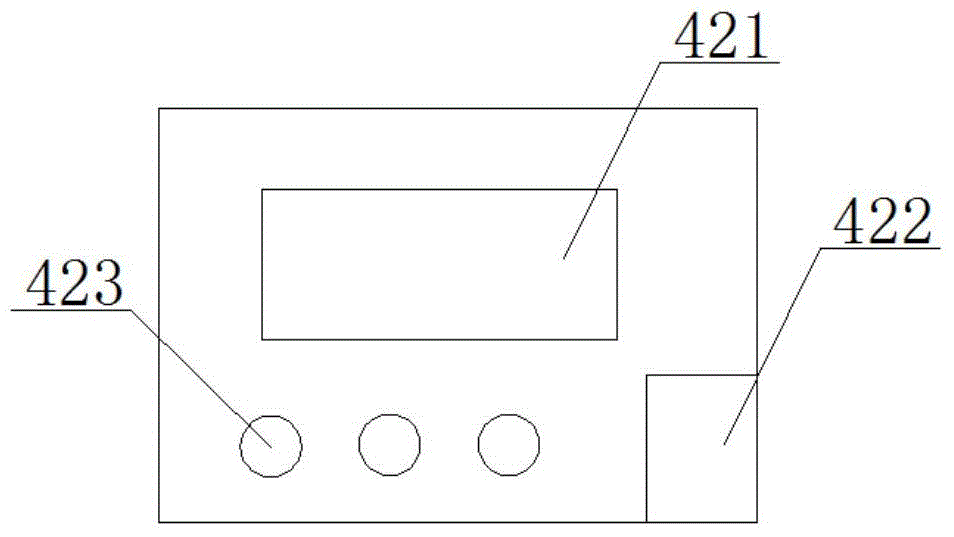

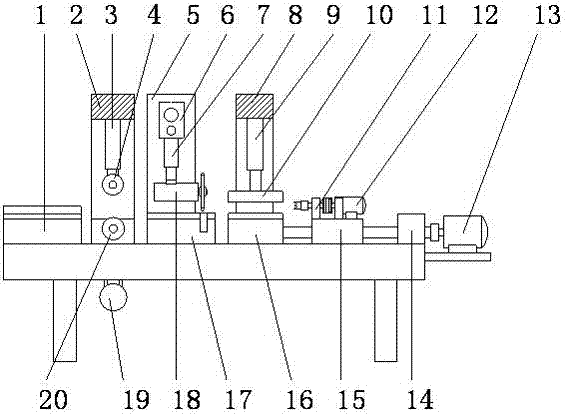

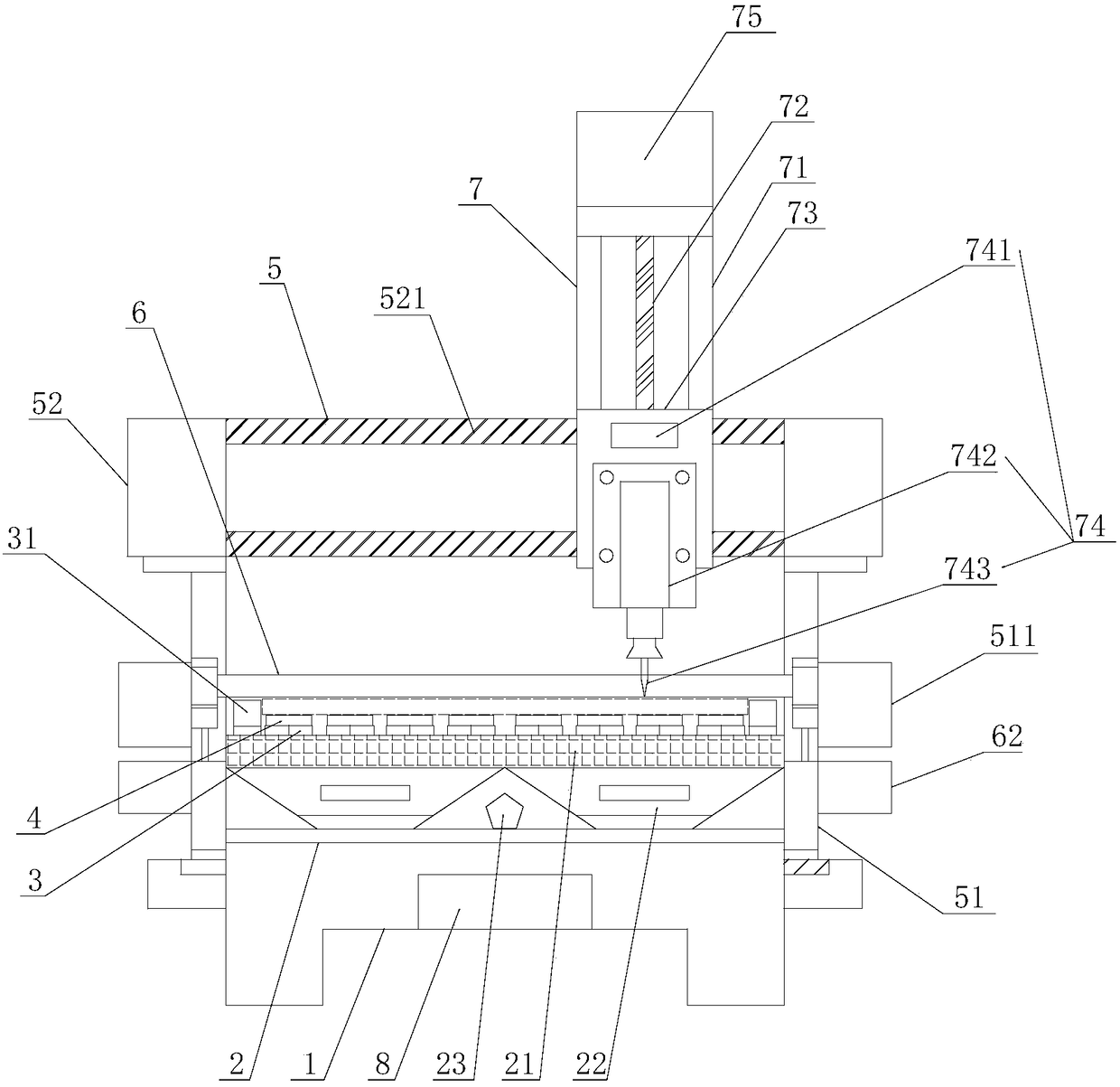

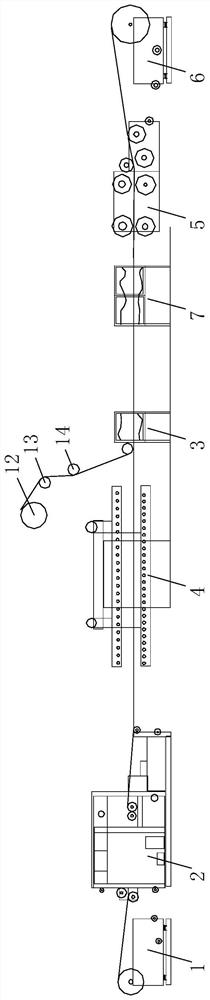

Automatic distance-measuring, leveling and shearing production line

ActiveCN105171432AReduce the process of interconnect matching debuggingImprove stabilityOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses an automatic distance-measuring, leveling and shearing production line and belongs to the field of processing of shearing plates. The automatic distance-measuring, leveling and shearing production line comprises an unreeling machine (1), a primary leveling machine (2), a distance measuring roller (3), a conveying belt (5), a material receiving machine (6) and a transition conveying belt (8) and is characterized by also comprising a secondary leveling and shearing module (4) and a probe module(7) wherein the unreeling machine (1), the primary leveling machine (2), the transition conveying belt (8), the secondary leveling machine (4), the conveying belt (5) and the material receiving machine (6) are connected in sequence; the probe module (7) and the distance measuring roller (3) are arranged above the transition conveying belt (8) in sequence. The automatic distance-measuring, leveling and shearing production line is capable of implementing full automation of secondary leveling and has the advantages of high leveling and plate-shearing accuracy, high consistency and high efficiency.

Owner:MAANSHAN JINGSHUN METAL PROCESSING

Accurate heat preservation cotton cutting mechanism

ActiveCN106498692ASolve the speed problemSolve the flatnessIroning machinesSevering textilesCouplingEngineering

The invention relates to an accurate heat preservation cotton cutting mechanism which comprises a base plate. Two lifting lugs are symmetrically arranged on the upper end face of the base plate, a winding wheel is installed between the two lifting lugs through a hinge pin and is wound with cotton, the starting end of the cotton always extends to the left side of the upper end face of the base plate, and a magnet is attracted to the starting end of the cotton. An L-shaped support is arranged on the left side of the upper end face of the base plate, two installing lugs are arranged on the lower side of the upper end face of the L-shaped support, a lead screw is installed between the two installing lugs through a bearing, a driving motor is installed at the left end of the lead screw through a coupler, and the bottom end of the driving motor is installed on the L-shaped support through a motor seat. The problems of low cutting speed, uneven cutting, inaccurate cutting size, low working efficiency and the like existing in a manual heat preservation cotton cutting mode can be solved, a rapid and accurate heat preservation cotton cutting function can be achieved, and the accurate heat preservation cotton cutting mechanism has the advantages of being high in cutting speed, flat in cutting, accurate in cutting size, high in working efficiency and the like.

Owner:广东加美堡保温材料有限公司

Low-heating laser cutting machine

InactiveCN111390405AEasy to cut size positioningPrecise cut sizeWelding/soldering/cutting articlesMetal working apparatusCold airElectric machinery

The invention discloses a low-heating laser cutting machine. The low-heating laser cutting machine comprises a machine table, a conveying mechanism is arranged on the left side of the machine table, two circular frames are fixedly connected to the upper surface of the machine table, and large-diameter bearings are mounted on the circular inner arc surfaces of the two circular frames. According tothe low-heating laser cutting machine, a servo drive motor is utilized to drive a conveyor belt and drives a pipe to horizontally move, the large-diameter bearings and a mounting frame are utilized todrive a laser cutting head to rotate around the pipe, a handle is held by hand during cutting, rotated by 180 degrees clockwise and then rotated by 370 degrees anticlockwise to achieve rotary cuttingof the pipe, and winding of a reflecting hose is avoided. Meanwhile, the laser cutting machine is provided with an electric telescopic rod to drive a lifting positioning plate, so that cutting sizingof the pipe and pipe discharging are facilitated. Meanwhile, cold air generated by a refrigerating device is conveyed into a pipe body through a cold conveying hose, so that the phenomenon that a cutof the pipe body made of plastic is melted during cutting is avoided, and the cutting size is more accurate.

Owner:安徽汉超智能装备科技有限公司

Rapid cutting equipment for crease-resistant clothing accessories

ActiveCN112323467APrecise cut sizeLabor savingSevering textilesStructural engineeringMechanical engineering

The invention belongs to the technical field of clothing processing, and particularly relates to rapid cutting equipment for crease-resistant clothing accessories. The equipment comprises a cutting table; wherein a set of supporting columns are fixedly connected with the bottom end of the cutting table; flange plates are fixedly connected with two sides of the top end of the cutting table; a containing groove is formed in the position, close to the end of the cutting table, of the flange plate; a cloth roll is placed in the containing groove; extending plates are fixedly connected to two sidesof the cutting table; a first fixing box is fixedly connected to the extending plate on the right side of the cutting table; a moving mechanism is arranged in the fixing box; the moving mechanism isfixedly connected with a moving box through a supporting rod. a cutting mechanism is arranged in the moving box; and an anti-wrinkling mechanism is arranged on the cutting table. The invention provides rapid cutting equipment for crease-resistant clothing accessories, and aims to solve the problems that after clothing is cut, wrinkles are often left on cloth after cutting, and the attractive effect and the cutting quality of the cloth are greatly reduced due to the appearance of the wrinkles.

Owner:胜利油田德利实业有限责任公司

Automatic tubular product packaging equipment

PendingCN107416250APrecise cut sizeThe pasting position is accuratePackagingMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic tubular product packaging equipment which comprises a rack, a film band mechanism, a tube discharging mechanism, a tube feeding mechanism, a cutter mechanism, a tube adsorption mechanism, a tube pasting mechanism and a rolling mechanism, wherein the rack is provided with a horizontal fixed plate; the film band mechanism, the tube pasting mechanism and the rolling mechanism are sequentially fixed on the fixed plate in the first horizontal direction; and the tube feeding mechanism, the cutter mechanism, the tube adsorption mechanism and the tube pasting mechanism are sequentially fixed on the fixed plate in the second horizontal direction perpendicular to the first horizontal direction. When the automatic tubular product packaging equipment works, continuous tubular products stored in the tube discharging mechanism are cut into tubular product sections with specific length by the cutter mechanism, the tubular product sections are adsorbed by the tube adsorption mechanism and transmitted to the tube pasting mechanism to be pasted with film bands, and the film bands pasted with the tubular product sections are rolled by the rolling mechanism and transmitted to a disc to finish the automatic packaging process of tubular products.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Automatic cutting device for red bricks for architectural engineering

InactiveCN108247855AReduce wastePrecise cut sizeWorking accessoriesStone-like material working toolsHydraulic cylinderUltrasonic sensor

The invention discloses an automatic cutting device for red bricks for architectural engineering, and belongs to the field of architectural engineering equipment. A feeding slide plate is fixedly arranged at the top end of a sixth bracket; a nut is fixedly arranged at the top end of a fourth bracket; a limiting bracket is fixed with the fourth bracket through a nut; a first hydraulic cylinder is fixedly arranged on a first hydraulic cylinder pedestal; a slide slot is connected with the feeding slide plate; an ultrasonic sensor is fixedly arranged on the ultrasonic sensor pedestal; a controlleris mounted on the center of a workbench; a first pressure sensor is mounted between a second hydraulic cylinder and a first pressure block; a second pressure sensor is fixedly arranged between a third hydraulic cylinder and a cutting saw; and the cutting saw is fixedly arranged on a main shaft of the third hydraulic cylinder. Red bricks are fixedly arranged on a cutting table through a first pressure block, cuts are cut out for the red bricks by the cutting saw, and a cut-off block quickly acts for cutting off the red bricks along the cuts, so that manual cut-off is replaced, cut-off efficiency and precision is improved, and materials are saved.

Owner:荆门宁杰机电技术服务有限公司

Cutting device with dust removal effect and used for PVC board machining

The invention discloses a cutting device with the dust removal effect and used for PVC board machining, and belongs to the technical field of PVC board machining. The device comprises a worktable, a support is arranged on the bottom end of the worktable, a lifting frame is movably arranged on the top of the worktable in a penetrating manner, when the cutting device is used, the cutting size of a board is adjusted through a limiting baffle mechanism, the board cutting size is accurate, the cut board is in order and unified, through a pressing mechanism, the machining board can be fixed, board deflection during machining is avoided, a cutting machine can transversely move front and back in the direction of the screw, the board wire cutting can be automatically finished, manual operation is not needed, time and labor are saved, a board cutting line cannot deflect, through structures of dust sucking devices, an arc cover and the like, dust removal can be carried out along with the positionof a cutting disc, the dust removal effect is more efficient, and through a following sliding cable guide ring, knotting and winding of cutting machine cables can be avoided.

Owner:安徽可尔海思新材料科技有限公司

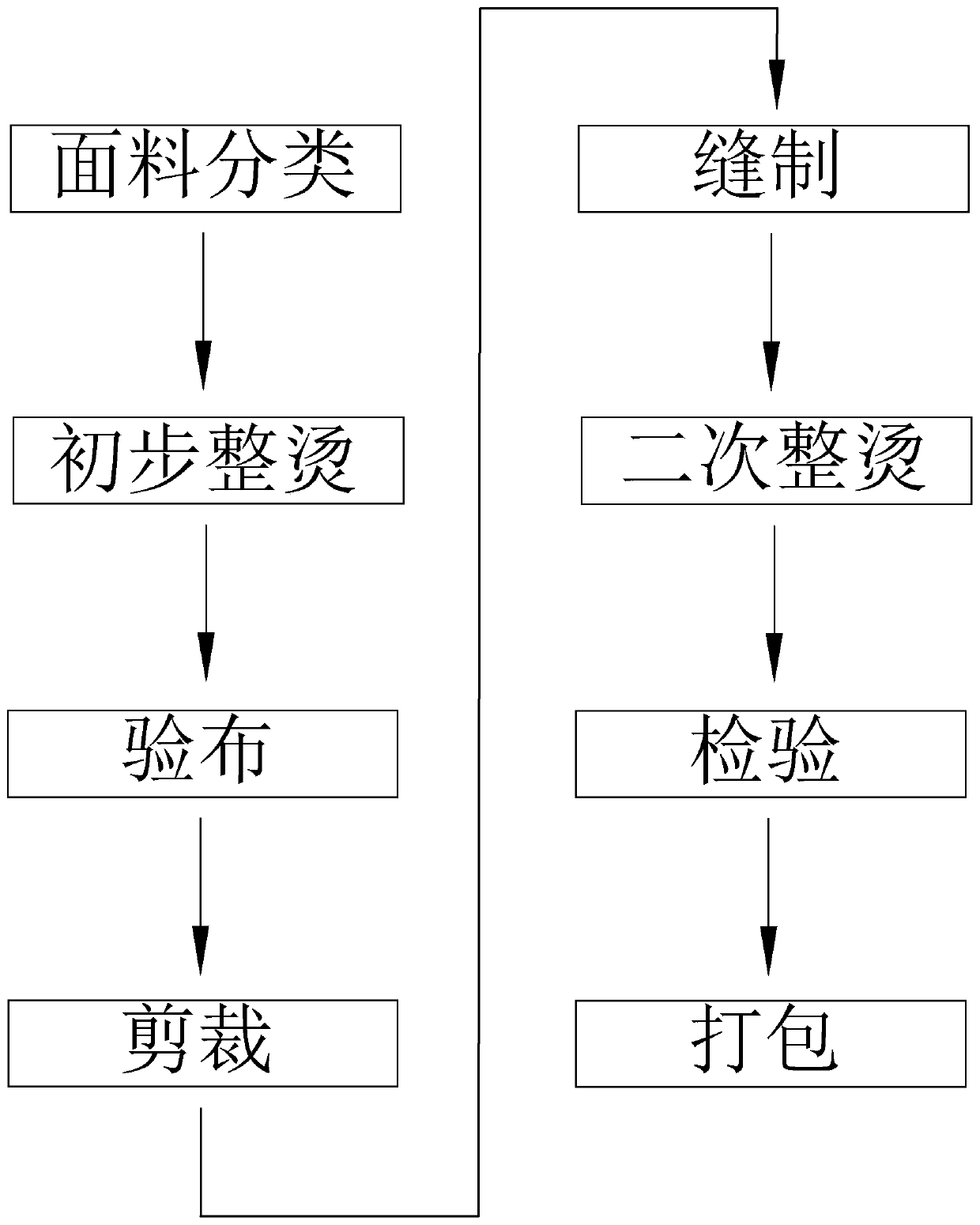

Clothing production process

ActiveCN110409095AAvoid situations where blemishes are hidden in raised creasesAvoid hiding in crease bumpsLiquid/gas/vapor removalFabric steaming/decatisingPulp and paper industryAnti wrinkle

The invention discloses a clothing production process. The clothing production process comprises the following steps of a, fabric classification, wherein fabrics are classified into an easy-to-wrinklefabric and an anti-wrinkle fabric; b, preliminary ironing, wherein the surface of the easy-to-wrinkle fabric is leveled; c, fabric inspection, wherein the leveled cloth is inspected through a fabricinspection machine; d, cutting, wherein the inspected fabric is cut according to a marker; e, sewing, wherein the cut fabric is put into an operation line of machine sewing; f, secondary ironing, wherein the finished product of sewn clothing is ironed to make the surface of the finished product of the clothing leveled; g, inspection; h, packaging. The process has the advantages that the fabric cankeep flat before fabric inspection, thus the success rate of the fabric inspection machine in inspecting defective fabrics is thus improved, the defective fabrics are prevented from involving in theproduction process of the clothing, the size accuracy of the cut fabric is improved, and thus the quality of the finished product of the clothing is improved.

Owner:晋江市霖园塑胶雨具有限公司

A gate cutting device for injection molding products

The invention relates to a gate cutting device for injection molding products. The device includes a fixed base plate, an adjustable high-speed electric motor, a cutting saw blade, a product positioning slide plate, a slide base, a travel switch, a pneumatic vacuum cleaner, a dust collection bag, and the cutting saw blade is fixed. On the rotating shaft of the high-speed motor, the high-speed motor is fixed on the fixed base, the product positioning slide is fixed on the base of the slide, the travel switch is fixed on the product positioning slide, and the pneumatic vacuum cleaner is located directly below the saw blade and fixed on the fixed base. Compared with the prior art, the invention has the advantages of accurate cutting size, good control of gate residual height, high work efficiency during mass production, and effective prevention of defective products caused by human beings, and has a wide range of applications.

Owner:SHANGHAI FUJITECH PLASTIC

Automatic charge and discharge system for laser cutting of glass

InactiveCN103466928AReduce dependenceEasy to operateGlass severing apparatusGlass productionLaser cuttingManipulator

The embodiment of the invention discloses an automatic charge and discharge system for laser cutting of glass. The system comprises a discharge box conveying unit, a Z-axis movement unit, a material box unit, a telescopic manipulator, a feeding buffer unit and a charge box conveying unit. A 50- or 100-glass box-type automatic cycle system can be realized. Sensors prompt an operator to charge or discharge; the system is simple and reliable to operate; the dependence of equipment on people is reduced; and the production efficiency is improved. Compared with the traditional simply manual charge and discharge cutting method, the system can realize high phase location and displacement precision, lower labor cost, simplified technical process, precise cutting size and higher processing efficiency.

Owner:WUHAN DR LASER TECH CORP LTD

A film cutting mechanism of a vertical glass laminating machine

The invention provides a thin film cutting mechanism of a vertical type glass film laminating machine. The thin film cutting mechanism comprises a vertical type machine frame, a synchronous belt transmission mechanism, a thin film cutting knife wheel set and a knife wheel movement guide rail mechanism, wherein the synchronous belt transmission mechanism and the knife wheel movement guide rail mechanism are installed on the vertical type machine frame; the synchronous belt transmission mechanism is used for moving the knife wheel set and comprises a servo motor, a driving synchronous pulley, a driven synchronous pulley, synchronous belts and a synchronous belt driving shaft; the thin film cutting knife wheel set comprises a front face cutting knife wheel set body and a back face cutting knife wheel set body which are fixed to the two synchronous belts respectively; knife wheel movement guide rails are used for movement supporting and guiding of the knife wheel set and comprise the front face cutting knife wheel movement guide rail and back face cutting knife wheel movement guide rail. By means of the thin film cutting mechanism, the thin film cutting knife wheel set is controlled through servo control, the cutting size is accurate, manual operation of an operator is not needed, the remodeling time is saved, and the working efficiency is greatly improved.

Owner:江西仁义新能源有限公司

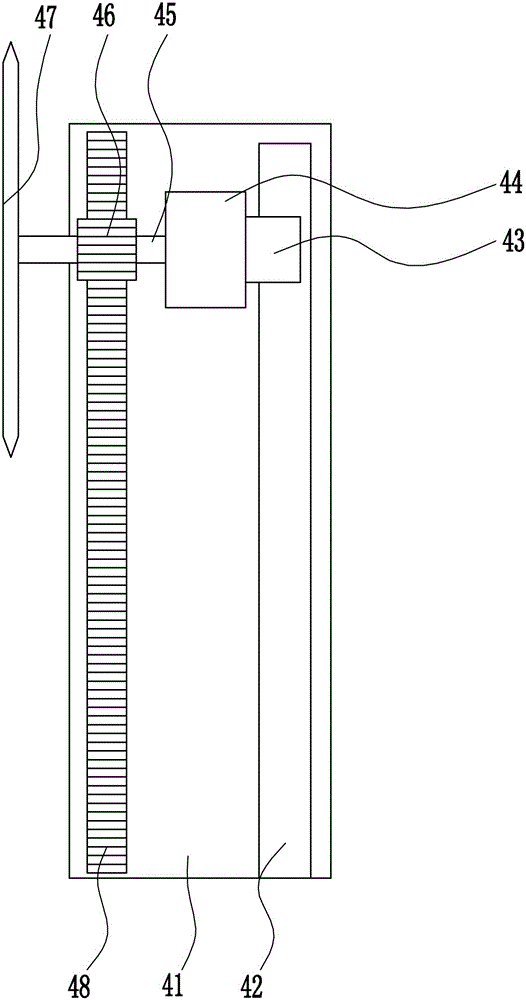

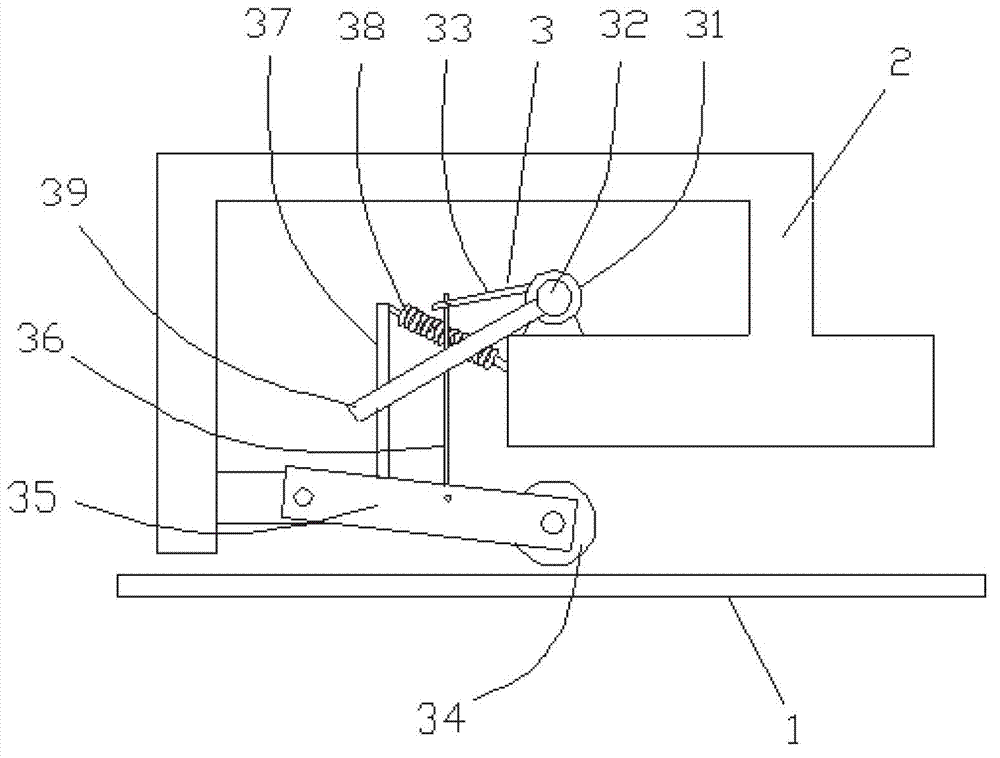

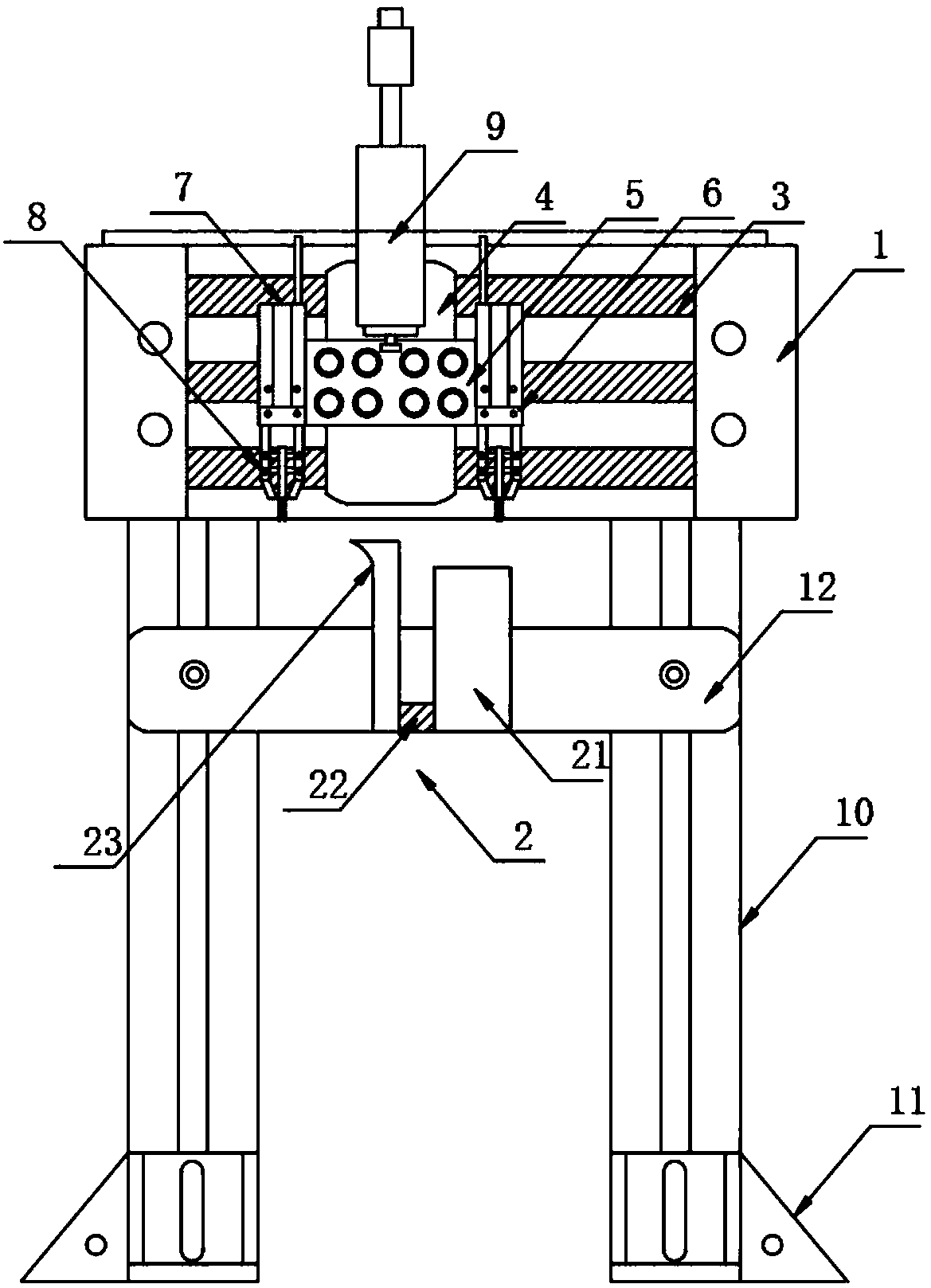

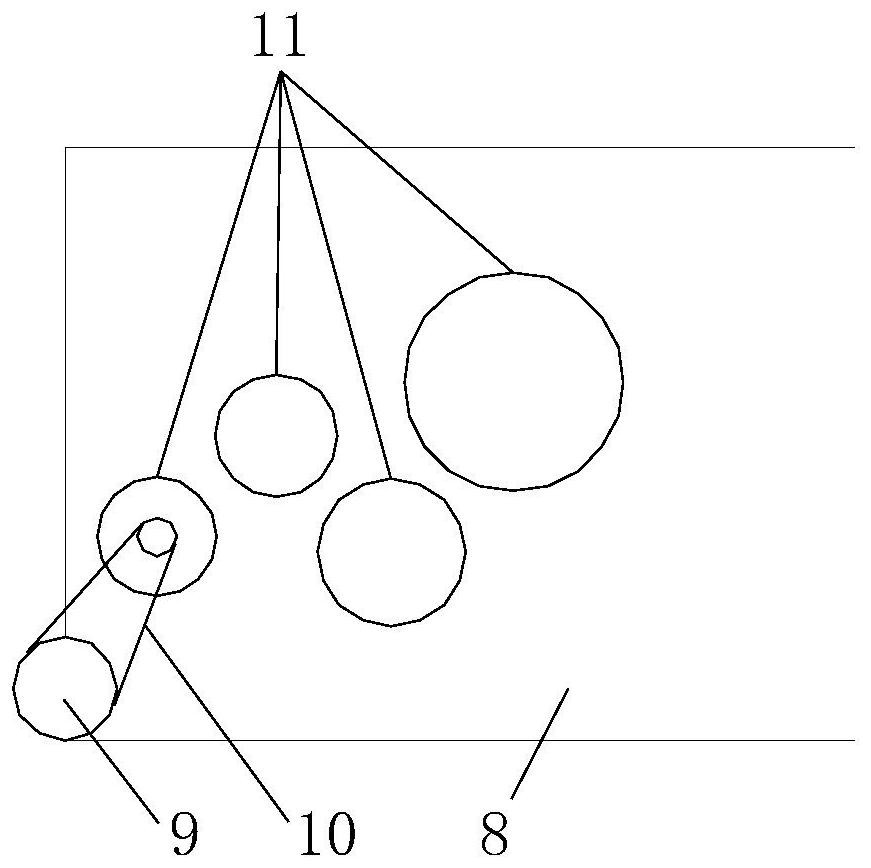

Pressing device for wood chip automatic cutting machine

InactiveCN102962875AEasy to processUniform cutting sizeVeneer manufactureEngineeringMechanical engineering

The invention discloses a pressing device for a wood chip automatic cutting machine, and relates to the technical field of wood chip automatic cutting machines. The pressing device comprises a conveying belt, a bracket and a pressing mechanism; the pressing mechanism is arranged on the bracket and is positioned above the conveying belt. The pressing device is characterized in that the pressing mechanism comprises a rotating shaft which is connected to the right side of the bracket by a shaft seat, a crank fixed on the rotating shaft, a pressure wheel arranged above the conveying belt and a wheel frame for fixing the pressure wheel; the end side of the wheel frame is movably connected with the left side of the bracket; a connecting rod is movably connected between the wheel frame and the crank; a fixed rod is also fixedly arranged above the wheel frame; and the upper end of the fixed rod is connected with the right side of the bracket by a spring. The pressing device can be used for pressing and flattening a wood blade, enables the cutting size to be uniform and accurate, is convenient for subsequent wood board processing and is convenient to use.

Owner:安徽大岭峡谷饮料有限公司

Wheelchair frame assembly line type processing equipment

InactiveCN106881593AEfficient removalPrecise cut sizeOther manufacturing equipments/toolsMetal working apparatusHydraulic cylinderWheelchair

The invention discloses wheelchair frame assembly line type processing equipment. The wheelchair frame assembly line type processing equipment comprises a supporting table and a control assembly, wherein a placing base station, a feeding assembly, a cutting assembly, a fixed assembly and a chamfering assembly are separately arranged at the upper end of the supporting table; the feeding assembly comprises a feeding frame arranged at the upper end of the supporting table; a first hydraulic cylinder is arranged on the upper part of the feeding frame; the first hydraulic cylinder is connected with an upper feeding roller; the lower part of the feeding frame is equipped with a lower feeding roller; the cutting assembly comprises a cutting frame arranged at the upper end of the supporting table; the fixed assembly comprises a fixed frame which is arranged at the upper end of the supporting table; a third hydraulic cylinder is arranged on the upper part of the fixed frame; and the lower end of the third hydraulic cylinder is connected with a pressure plate. According to the wheelchair frame assembly line type processing equipment disclosed by the invention, the automatic control assembly can be adopted to continuously cut wheelchair processing pipes, is precise in cutting dimension, is high in cutting efficiency, and can realize batch assembly line type production. The chamfering angle is additionally arranged, so that burrs of a rear mouth can be effectively removed and cut, processing of a next process is convenient, processing quality is improved and time is saved.

Owner:CHANGSHU PINGFANG WHEELCHAIR CO LTD

Solid plate cutting device

PendingCN108372539AGuaranteed stabilitySmall cutting seamDirt cleaningMetal working apparatusNeedle ShapeUtilization rate

The invention discloses a solid plate cutting device. The device includes a base, a dust suction mechanism, a cutting padding block, a cutting padding plate, a first positioning mechanism, a second positioning mechanism, a cutting mechanism and a control mechanism; the dust suction mechanism is arranged above the base, the first positioning mechanism includes a sliding base and a cutting mechanismmounting plate, and the cutting mechanism is mounted on the cutting mechanism mounting plate and consists of a base plate, a retractable rod, a fixing plate and a cutting head. The first positioningmechanism and the second positioning mechanism cooperate with each other under driving of a servo motor, positioning is precise, and a cutter of the cutting mechanism cuts a solid plate between two parallel roller shafts; the needle-shaped cutter is driven by the two roller shafts to conduct circular motion for cutting, cutting seams of the cutter are small, the cutting dimension is accurate, thecutting speed is increased, the cutting quality is improved, and the utilization rate of materials is high. Waste shreds generated during cutting are sucked into a dust storage box below through a dust suction port and are prevented from scattering all around, and therefore the solid plate cutting device is environmentally friendly.

Owner:黄 志力

Waterproof material test specimen cutting tool

The invention provides a waterproof material test specimen cutting tool, which is characterized by comprising four strip-shaped edges, and graduations are marked on the upper surface of each edge; a cutter sheath movably sleeves each edge, and a cutter is arranged on the lower surface of the cutter sheath; a rectangular frame is defined by the four edges, and at least three intersection points of the four intersection points of the rectangular frame are provided with regulating screws; the regulating screws penetrate through the two edges stacked at the intersection points. The four edges can be regulated and fixed by the regulating screws, so that the precise cutting size can be obtained, and the cutter can move along the edges to precisely cut off test specimens.

Owner:福建融诚检测技术股份有限公司

PVC floor cutting and dust sucking device

The invention relates to a PVC floor cutting and dust sucking device. The PVC floor cutting and dust sucking device comprises an installing base, a feeding device and a cutting device. The cutting device is composed of sliding rods, sliding blocks, a ruler frame and a blade. The two sliding rods are arranged on the installing base and connected with the ruler frame through the sliding blocks. The ruler frame is provided with a limiting block capable of sliding along the ruler frame. The blade is arranged at the bottom of the limiting block. The feeding device is composed of drive wheels, driven wheels, supports and drive devices. One end of each drive wheel is connected with the corresponding drive device through a rotating shaft, and the other end of each drive wheel is connected with the corresponding driven wheel through the corresponding support. The supports are fixed to the installing base. The installing base is provided with a cutting groove, and a fan cover is arranged below the cutting groove. The top of the fan cover is connected with a draught fan through a suction pipe. The PVC floor cutting and dust sucking device can solve the problems that in the floor cutting process, waste scraps and dust are generated, and the cutting size cannot be adjusted.

Owner:ANHUI YOUSHENGMEI NEW MATERIAL TECH CO LTD

Gate cutting device

InactiveCN102009455APrecise cut sizeImprove work efficiencyMetal working apparatusPunch pressHeat conducting

The invention relates to a gate cutting device, which comprises a heater, a heat conducting part, a cutting blade, a product fixing seat and a punch. The heater is connected to the heat conducting part, the cutting blade is arranged at one end of the heat conducting part, the product fixing seat is arranged below the heat conducting part and the punch is connected to the upper part of the heat conducting part. Compared with the prior art, the invention has the advantages of accurate positioning, capability of controlling cutting size, greater batch cutting speed, nearly no scratching risk in use, high work efficiency, reduced defective products and wide scope of application.

Owner:SHANGHAI FUJITECH PLASTIC

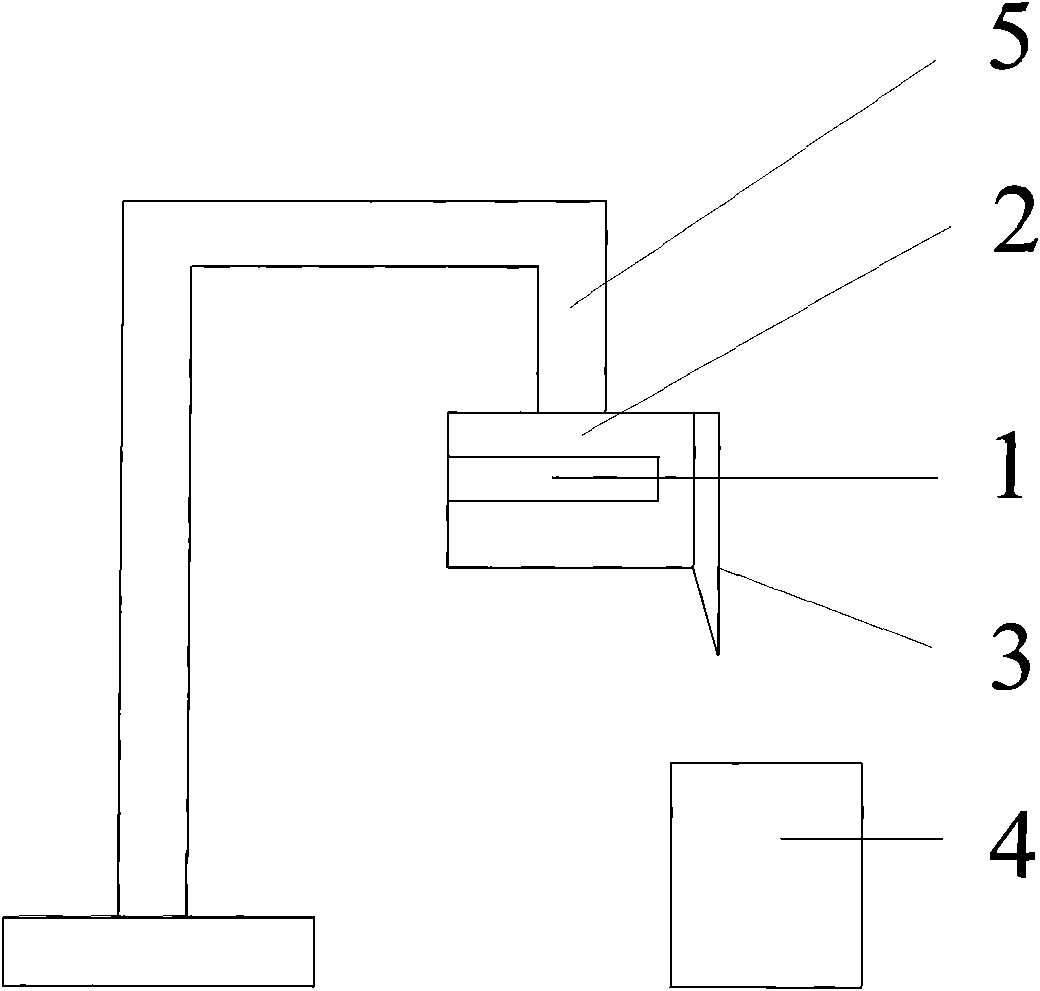

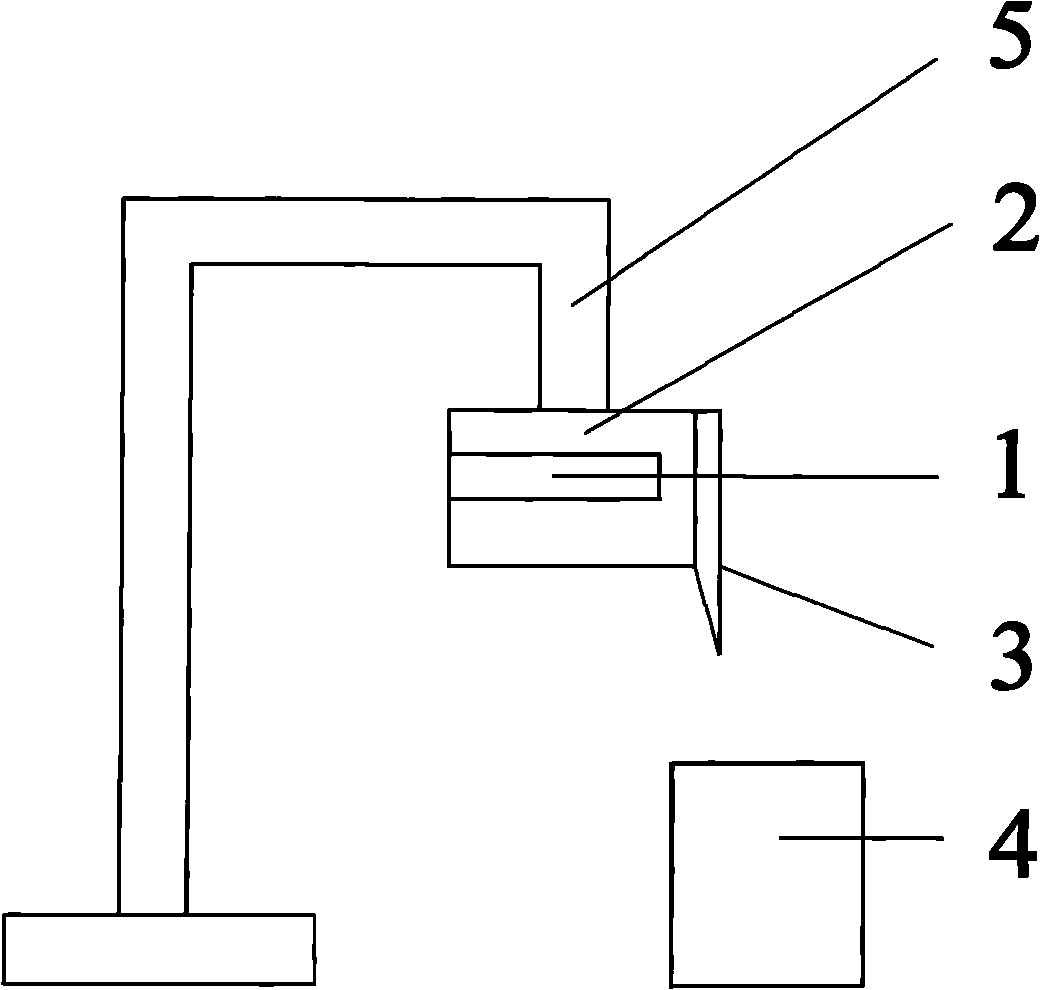

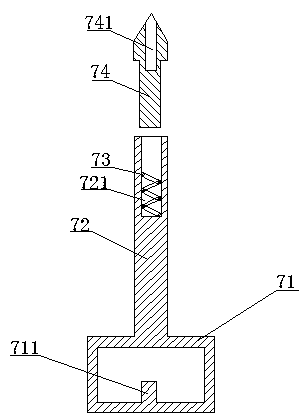

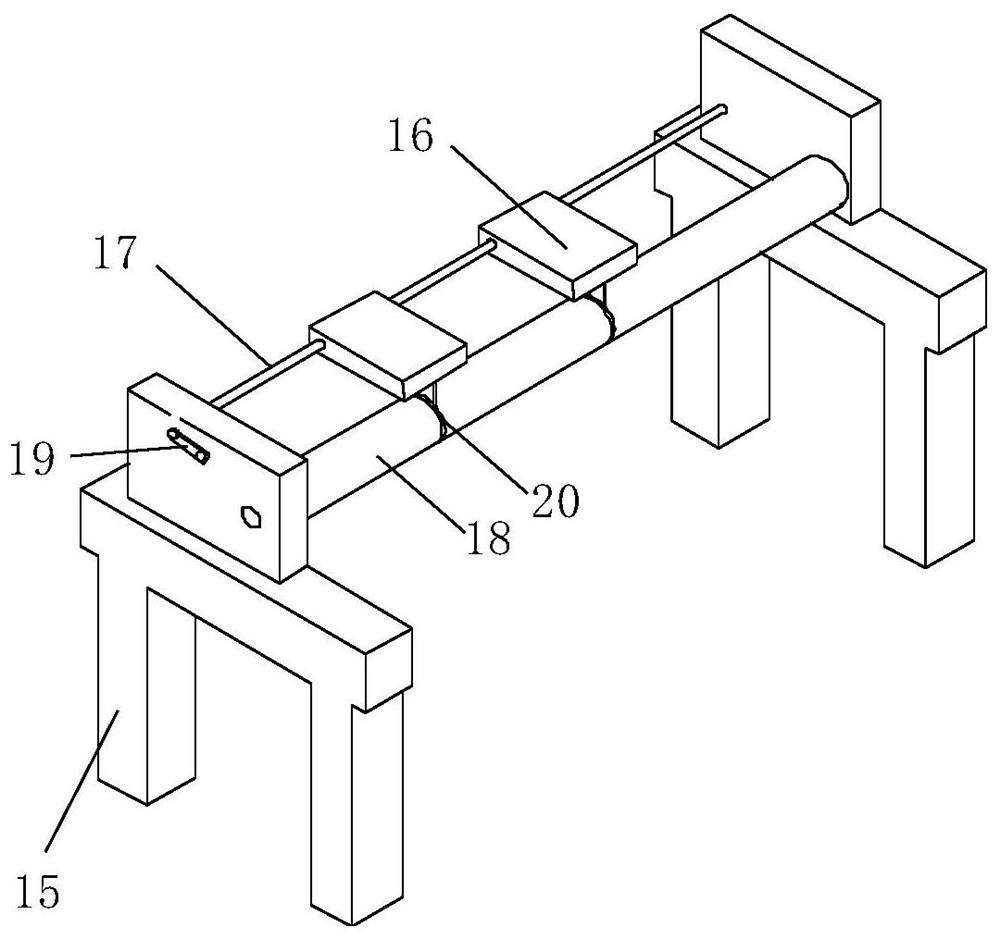

Labeling device used for machining petroleum pipeline

InactiveCN103817680APrecise cut sizeHigh precisionOther workshop equipmentCircular discStructural engineering

The invention discloses a labeling device used for machining a petroleum pipeline. The labeling device comprises a left support and a right support, wherein the left support and the right support respectively comprise an arc-shaped mounting base (1) at the upper end, a supporting column (4) at the middle end, and a fixing disk (6) at the lower end, the left support and the right support are connected through a scaleplate rod (8), the two ends of the scaleplate rod (8) are horizontally connected with the supporting column (4) of the left support and the supporting column (4) of the right support respectively, the scaleplate rod (8) is sleeved with two vertically arranged labeling rulers (7), and the two labeling rulers (7) can slide in the axial direction of the scaleplate rod (8). With the device, the cutting size and the hole size of the petroleum pipeline can be accurately labeled, and therefore the subsequent machining accuracy of the pipeline is improved, machining errors are reduced, and machining accuracy is improved; meanwhile, the device can be used for labeling the size of two holes having the interval requirement, practicality is high, the acting force between a labeling pen and the petroleum pipeline is small, the surface of the petroleum pipeline and the labeling pen can be protected well, and the protecting performance is good.

Owner:SICHUAN XILIN OIL SUPPLIES EQUIP

A fully automatic shearing machine

The invention discloses a fully automatic plate shearing machine, which comprises a feeding device, a shearing device, and a discharge conveyor belt. The feeding device is provided with a limit mechanism, and the shearing device is provided with a proximity switch for controlling the operation of the shearing mechanism. A discharge conveyor belt is arranged below the discharge end of the shearing device. The automatic shearing machine proposed by the present invention can realize automatic feeding of steel strips, automatic cutting according to a predetermined size, automatic output of steel plates, small dimensional error of finished steel plates, and high pass rate.

Owner:ANHUI NINGGUO DONGBO FASTENER

Grabbing, correcting, positioning and shearing mechanism of automatic foot cutter

The invention discloses a grabbing, correcting, positioning and shearing mechanism of an automatic foot cutter. The mechanism comprises a rodless air cylinder and a shearing mechanism, wherein the shearing mechanism is arranged at the bottom end of the rodless air cylinder, an air cylinder rod is arranged in the shearing mechanism, a movable connecting plate is movably locked to the air cylinder rod, one end of the movable connecting plate penetrates through a side wall of the rodless air cylinder and extends to one side of the outer wall of the rodless air cylinder, the movable connecting plate is movably connected to the rodless air cylinder, a fixed rack is arranged on one side of the outer wall of the movable connecting plate, and a first finger air cylinder and a second finger air cylinder are fixedly arranged at two ends of the fixed rack, separately. By arranging the shearing mechanism, an article on the shearing mechanism is sheared favorably through a slicer under a slicer aircylinder, and the article put on the shearing mechanism is corrected and limited through a connecting block in the shearing mechanism and is prevented from sliding on the shearing mechanism o affectthe shearing dimension of the article when the article is sheared by the slicer.

Owner:ZHUHAI FUYUAN ELECTRONICS TECH CO LTD

High-speed cutting all-in-one machine for producing steel

InactiveCN105773373AQuick cutShorten production timeGrinding carriagesGrinding machinesMechanical engineeringHigh velocity

The invention discloses a high-speed cutting all-in-one machine for producing steel. The high-speed cutting all-in-one machine comprises a base, wherein a cutting mechanism is arranged on the base; a controller is arranged on one side of the base and is electrically connected with the cutting mechanism. The high-speed cutting all-in-one machine has the advantages of simple structure and high practicability.

Owner:广东粤韶钢铁有限公司

Hot paste composite slitting machine and hot paste composite slitting method thereof

PendingCN111716744APrecise cut sizeAvoid wrinklesMetal working apparatusProcess engineeringManufacturing engineering

The invention relates to a hot paste composite slitting method of a hot paste composite slitting machine. The hot paste composite slitting machine comprises an uncoiling mechanism, a leveling mechanism, a composite mechanism, a pasted film feeding mechanism, a drying mechanism, a slitting mechanism and a coiling mechanism which are sequentially arranged. According to the hot paste composite slitting machine and the hot paste composite slitting method thereof, only one-time winding is needed in the whole process, the production process is greatly simplified, the production efficiency is improved, and the equipment investment and the plant occupied space are reduced.

Owner:江苏常舜光电科技有限公司

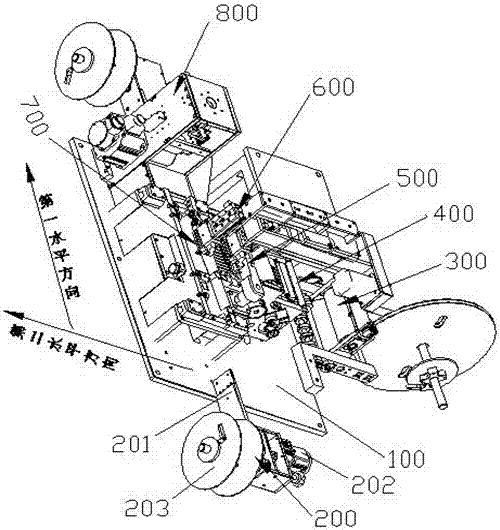

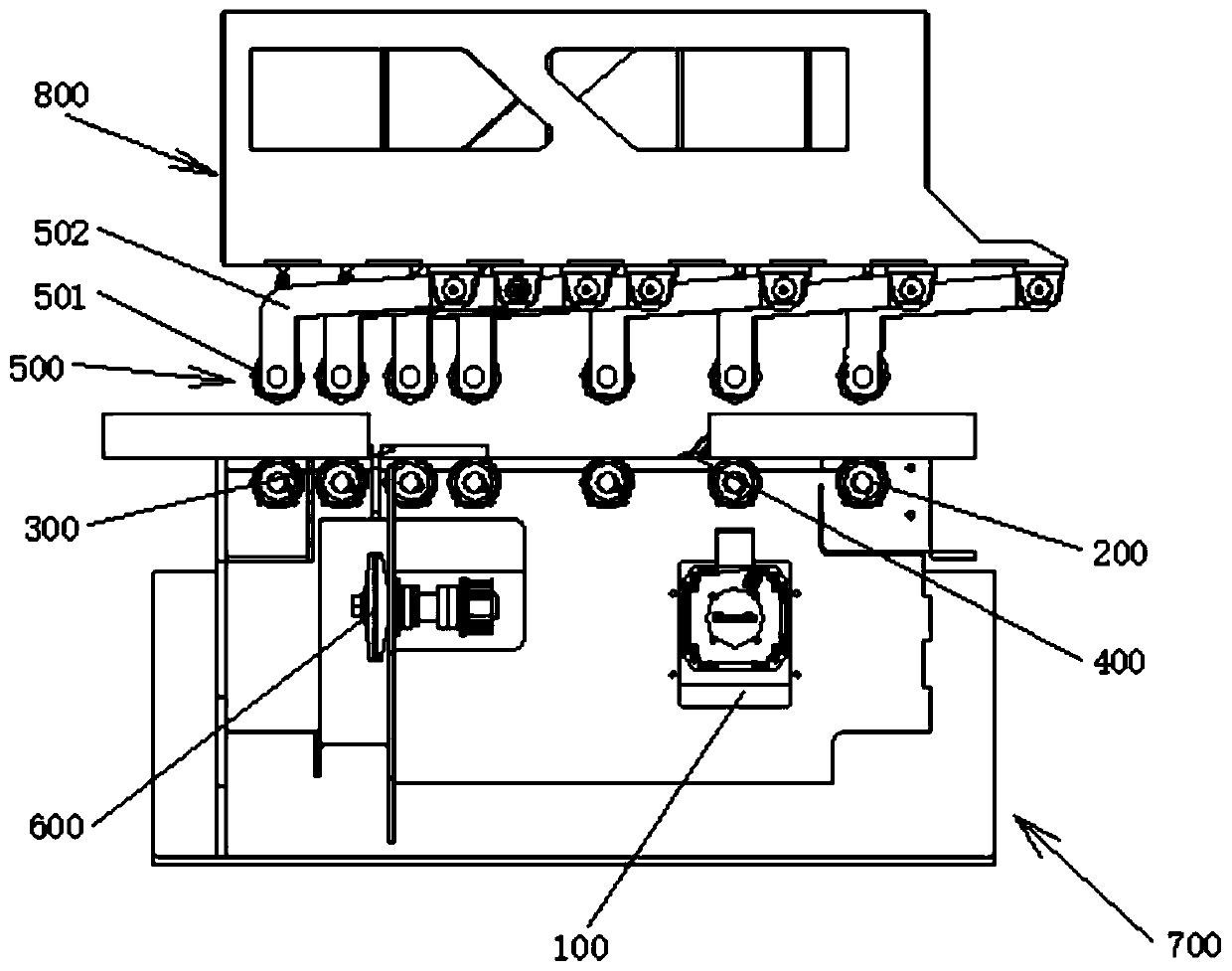

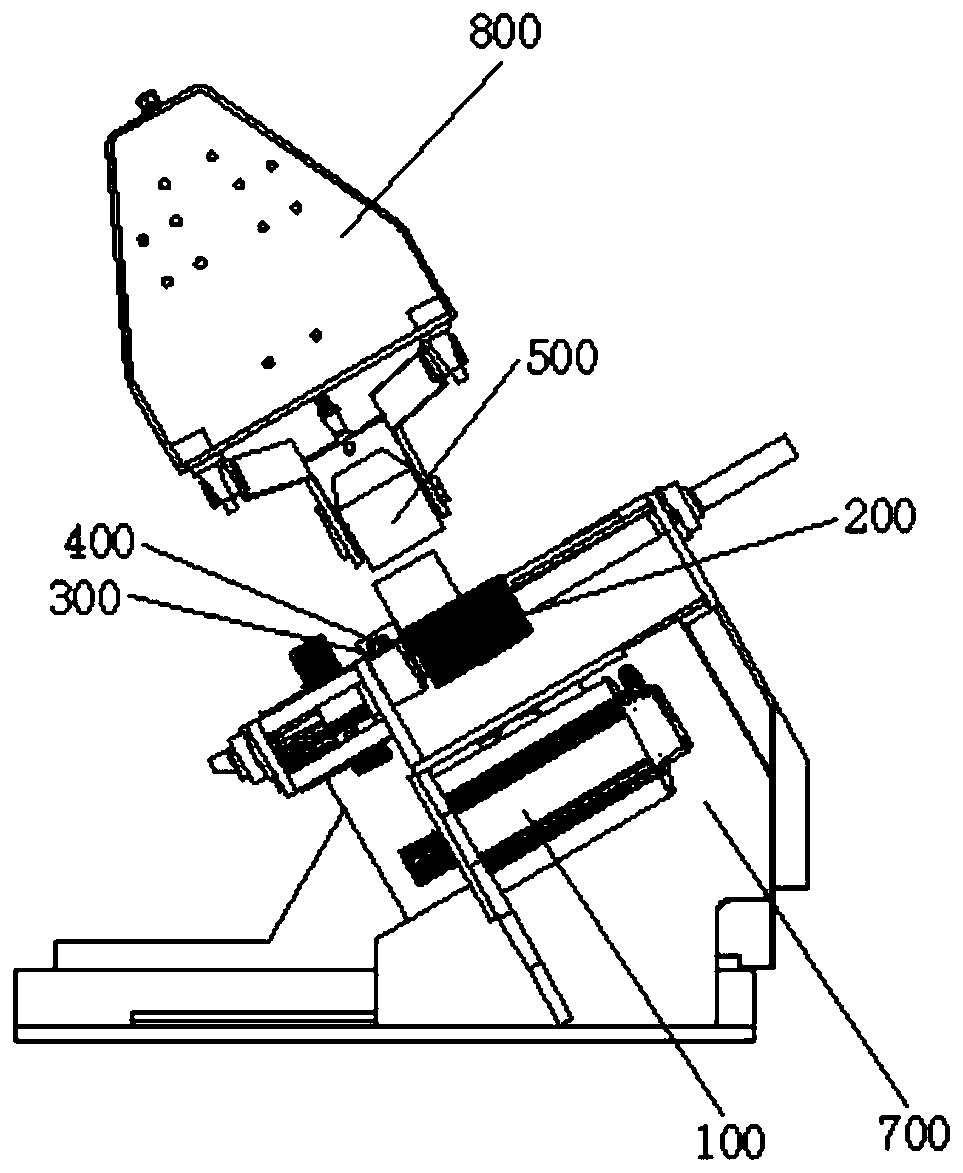

Plate sawing equipment

The invention relates to plate sawing equipment. The plate sawing equipment is characterized by comprising an upper body (800) and a lower body (700), wherein the upper body (800) is used for pressingand positioning a first surface of a to-be-sawn plate, and the lower body (700) is used for detecting and conveying the to-be-sawn plate and conduct cutting treatment on the to-be-sawn board; the upper body (800) comprises an upper compression roller (500) and a supporting upper machine body, wherein the upper compression roller (500) is positioned at the bottom of the supporting upper machine body, and is connected with the supporting upper machine body into a whole; and the upper compression roller (500) of the upper body (800) can move to get close to or get away from the lower body (700).

Owner:南通思威机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com