Automatic cutting device for red bricks for architectural engineering

An automatic cutting device, a technology for construction engineering, applied in the direction of work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of labor and time consumption, cutting deviation, red brick can not meet the needs and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

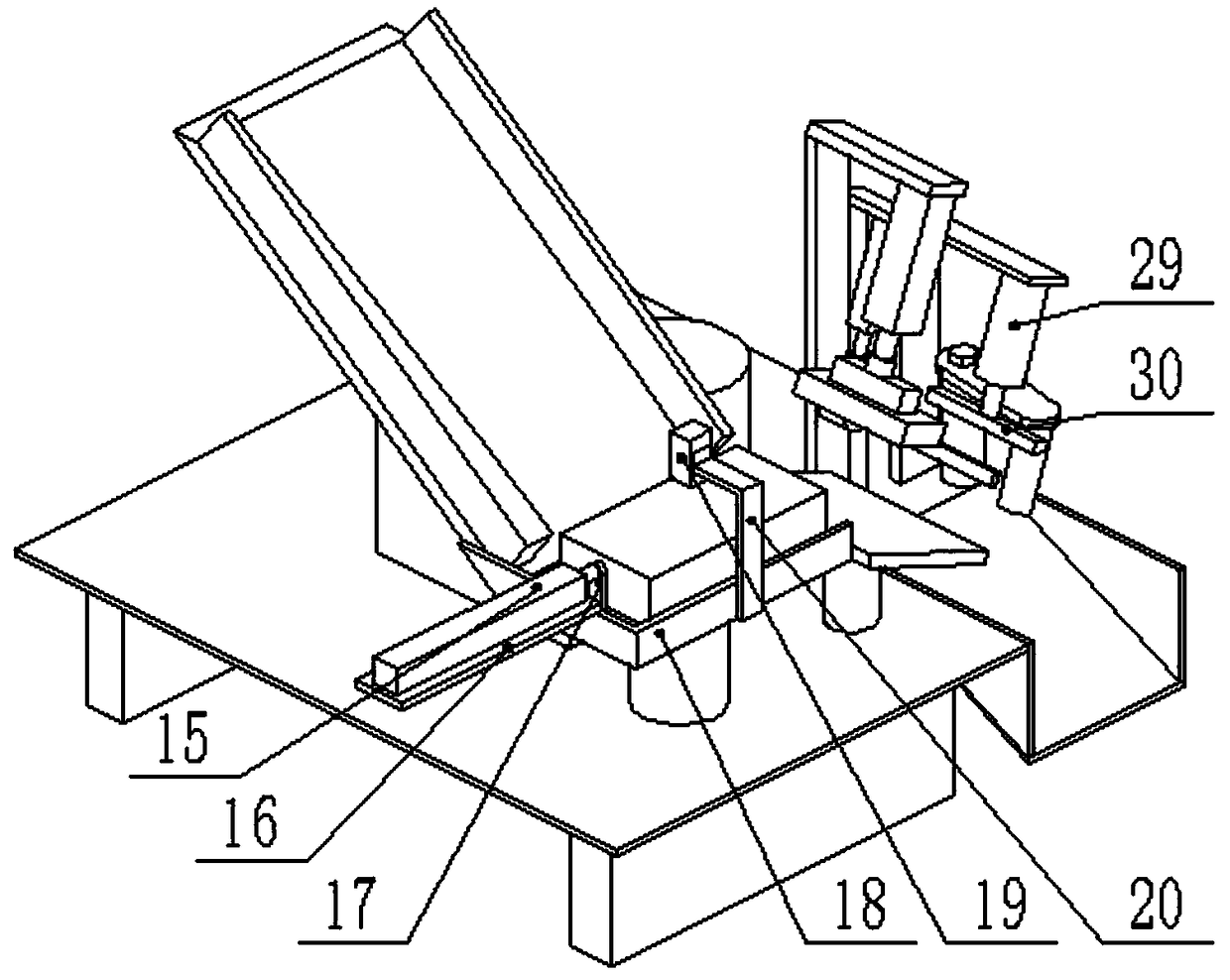

[0018] The present invention is achieved through the following technical solutions: an automatic red brick cutting device for construction engineering, comprising a feeding slide 1, a left baffle 2, a first bracket 3, a second bracket 4, a third bracket 5, a workbench 6, Nut 7, fourth bracket 8, limit bracket 9, discharge slide plate 10, leg 11, fifth bracket 12, cutting table 13, right baffle plate 14, first hydraulic cylinder 15, first hydraulic cylinder base 16, Push block 17, chute 18, ultrasonic sensor 19 ultrasonic sensor base 20, controller 21, second hydraulic cylinder 22, first pressure sensor 23, first pressure block 24, rubber block 25, third hydraulic cylinder 26, the first Two pressure sensors 27, a cutting saw 28, a fourth hydraulic cylinder 29, a cutting block 30 and a sixth support 31, the feeding slide 1 is fixed on the top of the sixth support 31, and the left baffle 2 is vertically installed on the feeding The left side of the feed slide 1 has the same lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com